Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT

Abstract

1. Introduction

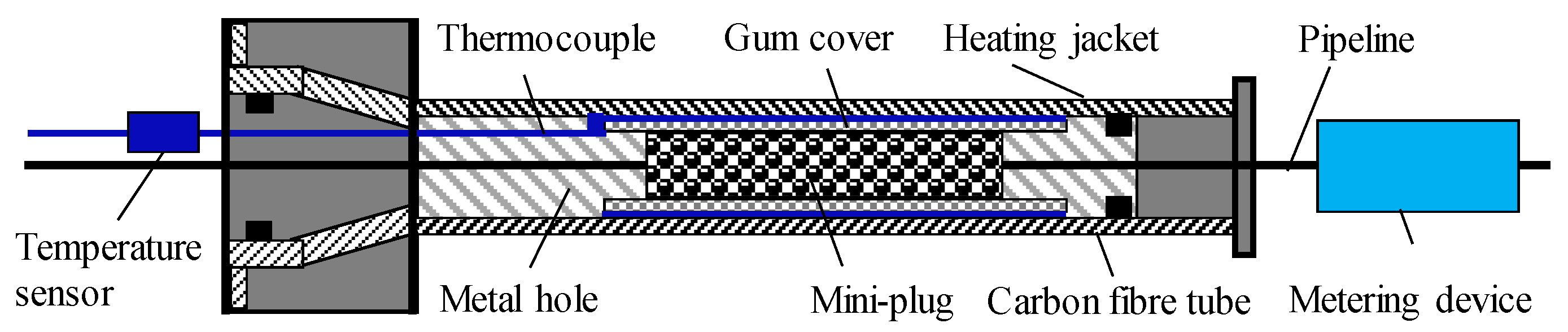

2. Experimental Methodology

2.1. Rock Samples and Fluid Properties

2.2. Experimental Procedure

- (1)

- Core was placed in the core holder and subjected to a confining pressure of 12 MPa for 5 h, and then the first scanning was performed to obtain a reference dry scan. The confining pressure of 8 MPa was applied during all experiments.

- (2)

- The core was vacuumed and completely saturated with water phase and left for 12 h until the water phase and the core reached a chemical equilibrium, and the second scanning was performed.

- (3)

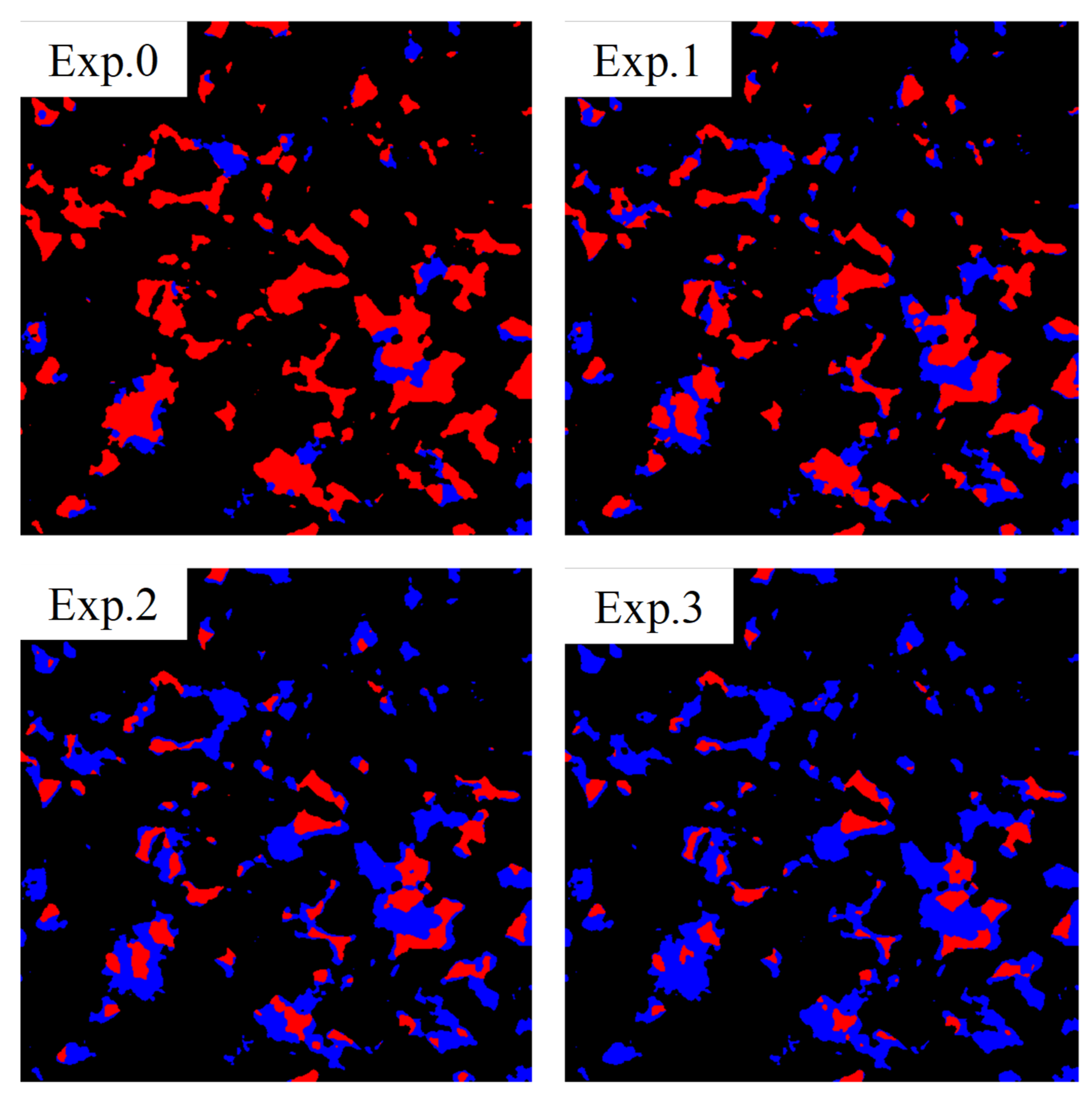

- Fifty PVs(Pore Volume) of oil was flushed through the plug at an injection rate of 0.03 mL/min to establish irreducible water condition. The third CT scanning was performed at the end of the saturation state called Exp. 0.

- (4)

- Fifty PVs of water displacement at an injection rate of 0.003 mL/min were conducted to establish residual oil state. Then the fourth CT scanning of the sandstone was conducted called Exp. 1.

- (5)

- Step 4 was repeated at an injection rate of 0.03 and 0.3 mL/min. Then the fifth and sixth CT scanning were performed called Exp. 2 and 3.

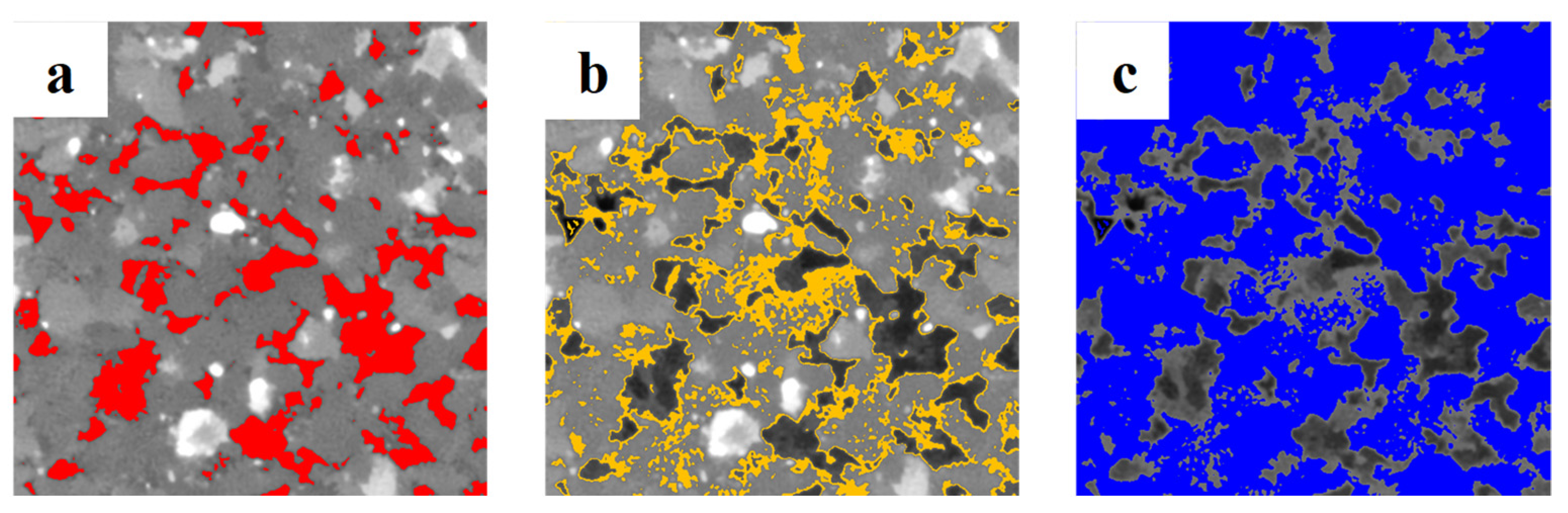

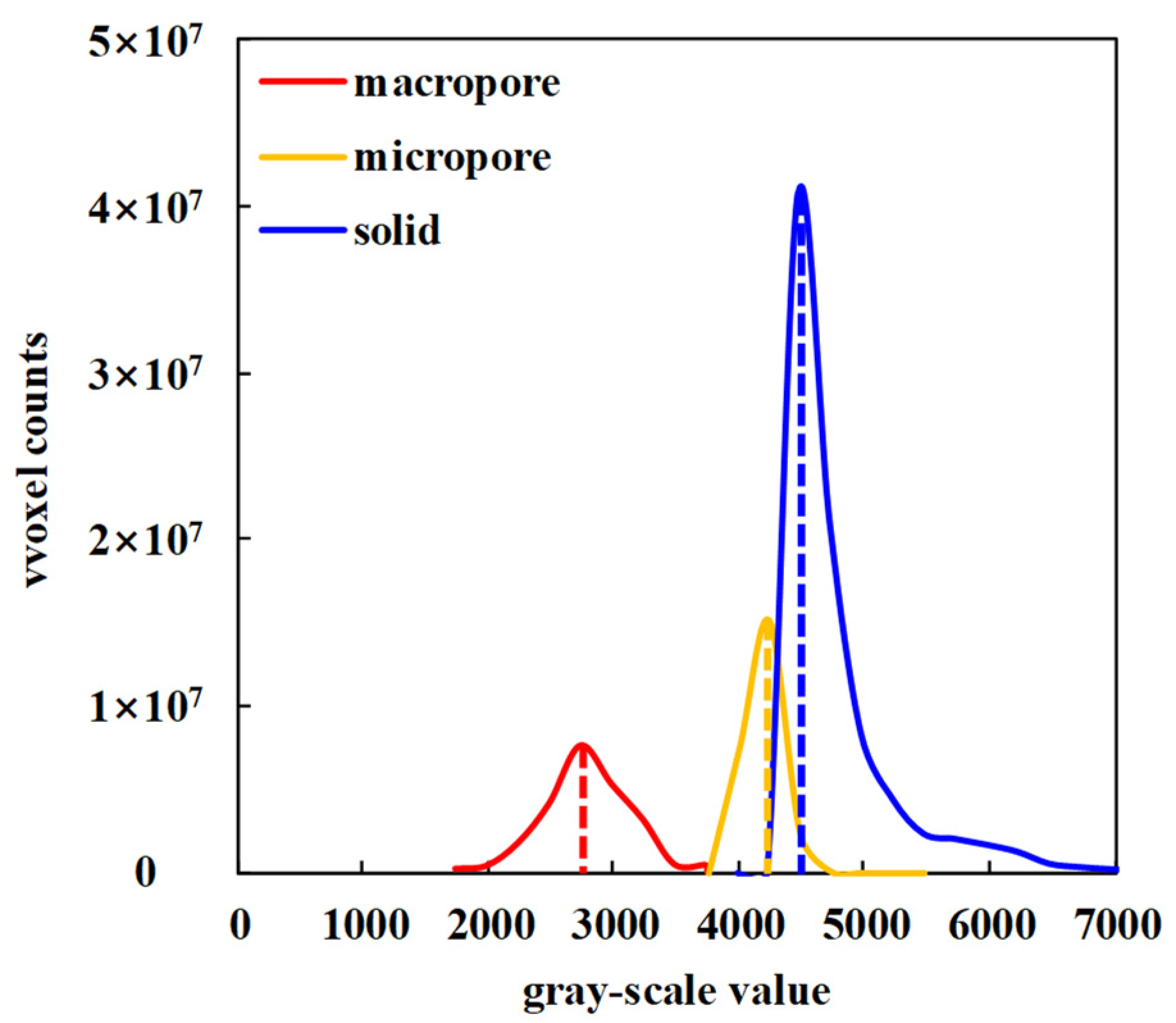

2.3. Data Process

3. Results and Discussion

3.1. Representative Elementary Volume

3.2. Cluster Morphologies and Classification

- (1)

- Clustered Flow (Continuous phase) occupied multiple pores, causing its Euler Number to be less than or equal to −1. Different from the Membranous Flow, the Oil Thickness of the Clustered Flow was larger, which was determined to be greater than or equal to 5 μm through analysis and comparison.

- (2)

- Membranous Flow (Continuous phase) occupied multiple pores, and its Euler Number was the same as Clustered Flow. The Oil Thickness of Membranous Flow was less than that of Clustered Flow, which was determined to be less than 5 μm.

- (3)

- Discontinuous phase only occupied single or a few pores, which was the remaining oil with discrete distribution after water flooding. The Euler Number of the Discontinuous phase was greater than −1.

3.3. Research on Microscopic Remaining Oil

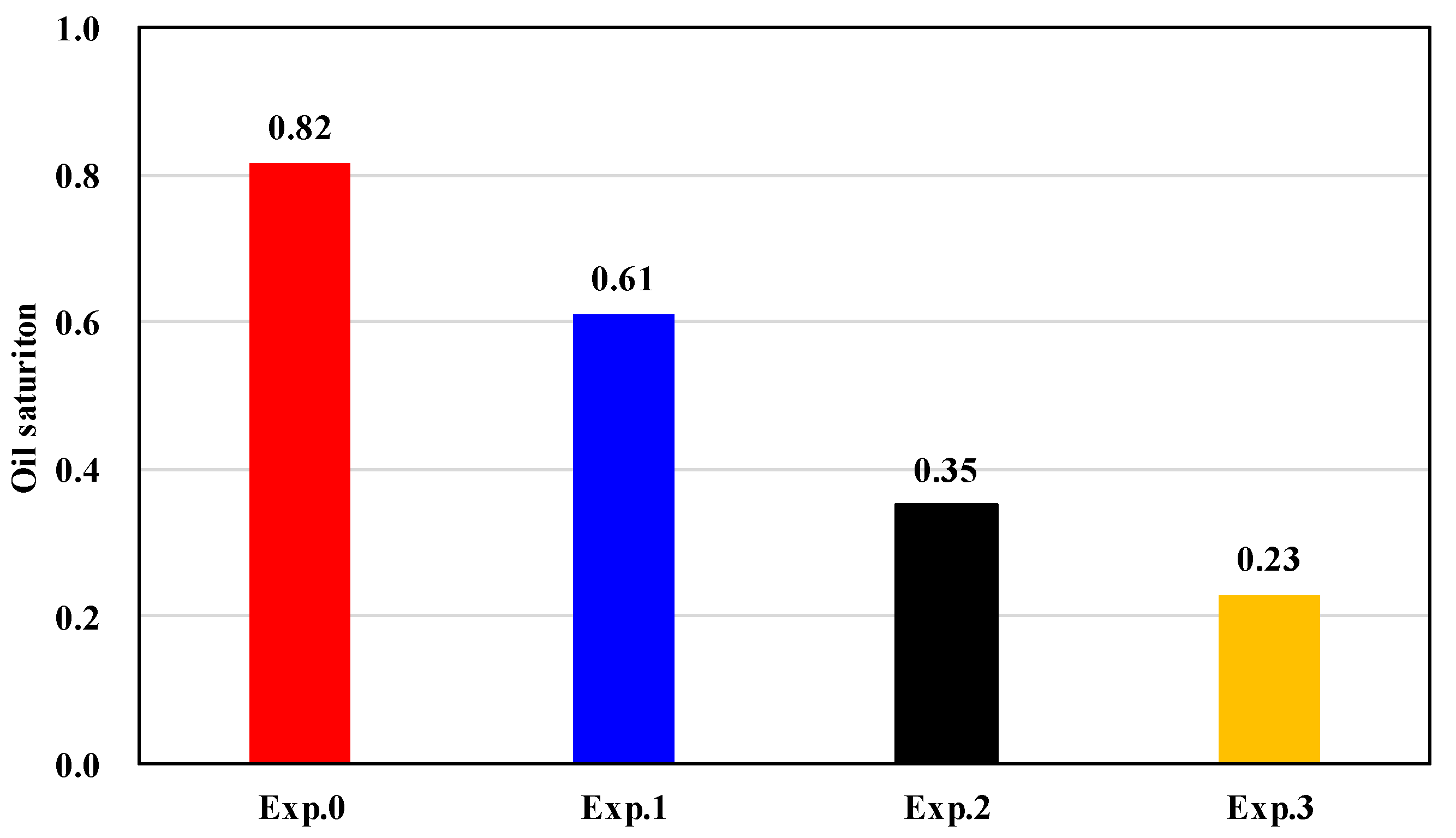

3.3.1. Oil Saturation

3.3.2. The Morphological Characteristics of Microscopic Remaining Oil

3.3.3. The Distribution Characteristics of Microscopic Remaining Oil

4. Conclusions

- (1)

- From the perspective of oil saturation, the remaining oil saturations corresponding to the displacement rates from low to high were 61%, 35% and 23% respectively. At the same time, the standard deviation of the oil saturation along the core slice gradually decreased, which are 4.92, 4.87 and 4.35, respectively. As the displacement rate increased, the remaining oil saturation decreased, but the remaining oil was more evenly distributed along the slice.

- (2)

- From the perspective of remaining oil occurrence states, the lower two displacement speeds reduced the volume of huge oil clusters under oil-saturated conditions, and the highest displacement speed could completely break up large oil clusters into small oil droplets. At the same time, with the increase of the displacement rate, the shape factor of the oil clusters also gradually increased. The result of remaining oil classification is that the proportion of continuous remaining oil volume decreased, and the proportion of discontinuous remaining oil increased.

- (3)

- From the perspective of remaining oil distribution characteristics, after water flooding at different displacing speeds, the microscopic remaining oil was more inclined to the middle and corner parts of the larger pores.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jing, W.; Fu, S.; Zhang, L.; Li, A.; Ren, X.; Xu, C.; Gao, Z. Pore Scale Experimental and Numerical Study of Surfactant Flooding for Enhanced Oil Recovery. J. Pet. Sci. Eng. 2021, 196, 107999. [Google Scholar] [CrossRef]

- Martyushev, D.A.; Mengaliev, A.G. Planning of cyclic watering based on anisotropic hydrodynamic model of the carbonate deposit of Gagarinskoe field, Bulletin of the Tomsk Polytechnic University. Geo Assets Eng. 2020, 331, 84–93. [Google Scholar] [CrossRef]

- Jamshidi, T.; Zeng, F.; Tontiwachwuthikul, P.; Torabi, F. Viability of Carbonated Water Injection (CWI) as a Means of Secondary Oil Recovery in Heavy Oil Systems in Presence and Absence of Wormholes: Microfluidic Experiments. Fuel 2019, 249, 286–293. [Google Scholar] [CrossRef]

- Martyushev, D.A. Rock stress state influence on permeability of carbonate reservoirs, Bulletin of the Tomsk Polytechnic University. Geo Assets Eng. 2020, 331, 24–33. [Google Scholar] [CrossRef]

- Xie, X.; Yin, B.; Xu, S.; Jia, H.; Dong, F.; Chen, X. Effects of Microstructure Shape Parameters on Water Removal in a PEMFC Lotus-like Flow Channel. Int. J. Hydrogen Energy 2020. [Google Scholar] [CrossRef]

- Machado, A.C.; Oliveira, T.J.L.; Cruz, F.B.; Lopes, R.T.; Lima, I. X-Ray Microtomography of Hydrochloric Acid Propagation in Carbonate Rocks. Appl. Radiat. Isot. 2015, 96, 129–134. [Google Scholar] [CrossRef]

- Rezaei, F.; Izadi, H.; Memarian, H.; Baniassadi, M. The Effectiveness of Different Thresholding Techniques in Segmenting Micro CT Images of Porous Carbonates to Estimate Porosity. J. Pet. Sci. Eng. 2019, 177, 518–527. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.; Wei, M.; Jiang, R. Experimental Study and Numerical Simulation of Hydraulic Fracturing Tight Sandstone Reservoirs. Fuel 2015, 159, 334–344. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Gao, Y.; Cheng, B.; Meng, F.; Xu, H. Effects of Microscopic Pore Structure Heterogeneity on the Distribution and Morphology of Remaining Oil. Pet. Explor. Dev. 2018, 45, 1112–1122. [Google Scholar] [CrossRef]

- She, Y.; Zhang, C.; Mahardika, M.A.; Patmonoaji, A.; Hu, Y.; Matsushita, S.; Suekane, T. Pore-Scale Study of in-Situ Surfactant Flooding with Strong Oil Emulsification in Sandstone Based on X-Ray Microtomography. J. Ind. Eng. Chem. 2021, 98, 247–261. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Ge, L.; Hu, F.; Li, C.; Li, X.; Yu, J.; Xu, H.; Lu, S.; Xue, Q. Pore-Scale Characterization of Tight Sandstone in Yanchang Formation Ordos Basin China Using Micro-CT and SEM Imaging from Nm- to Cm-Scale. Fuel 2017, 209, 254–264. [Google Scholar] [CrossRef]

- Iglauer, S.; Fernø, M.A.; Shearing, P.; Blunt, M.J. Comparison of Residual Oil Cluster Size Distribution, Morphology and Saturation in Oil-Wet and Water-Wet Sandstone. J. Colloid Interface Sci. 2012, 375, 187–192. [Google Scholar] [CrossRef]

- Liu, B.; Ma, R.; Fan, H. Evaluation of the Impact of Freeze-Thaw Cycles on Pore Structure Characteristics of Black Soil Using X-Ray Computed Tomography. Soil Tillage Res. 2021, 206, 104810. [Google Scholar] [CrossRef]

- Cao, Q.; Gong, Y.; Fan, T.; Wu, J. Pore-Scale Simulations of Gas Storage in Tight Sandstone Reservoirs for a Sequence of Increasing Injection Pressure Based on Micro-CT. J. Nat. Gas Sci. Eng. 2019, 64, 15–27. [Google Scholar] [CrossRef]

- Ali, H.; Soleimani, H.; Yahya, N.; Khodapanah, L.; Kozlowski, G.; Sabet, M.; Demiral, B.M.R.; Adebayo, L.L.; Hussain, T. Experimental Investigation and Two-Phase Flow Simulation of Oil and Nanofluids on Micro CT Images of Sandstone for Wettability Alteration of the System. J. Pet. Sci. Eng. 2021, 204, 108665. [Google Scholar] [CrossRef]

- Wu, B.; Jiang, L.; Liu, Y.; Lyu, P.; Wang, D.; Li, X.; Song, Y. An Experimental Study on the Influence of CO2 Containing N2 on CO2 Sequestration by X-Ray CT Scanning. Energy Procedia 2017, 114, 4119–4128. [Google Scholar] [CrossRef]

- Gao, Y.; Qaseminejad Raeini, A.; Blunt, M.J.; Bijeljic, B. Pore Occupancy, Relative Permeability and Flow Intermittency Measurements Using X-Ray Micro-Tomography in a Complex Carbonate. Adv. Water Resour. 2019, 129, 56–69. [Google Scholar] [CrossRef]

- Andrew, M.; Bijeljic, B.; Blunt, M.J. Pore-Scale Contact Angle Measurements at Reservoir Conditions Using X-Ray Microtomography. Adv. Water Resour. 2014, 68, 24–31. [Google Scholar] [CrossRef]

- Alhammadi, A.M.; Gao, Y.; Akai, T.; Blunt, M.J.; Bijeljic, B. Pore-Scale X-Ray Imaging with Measurement of Relative Permeability, Capillary Pressure and Oil Recovery in a Mixed-Wet Micro-Porous Carbonate Reservoir Rock. Fuel 2020, 268, 117018. [Google Scholar] [CrossRef]

- Shabaninejad, M.; Middlelton, J.; Fogden, A. Systematic Pore-Scale Study of Low Salinity Recovery from Berea Sandstone Analyzed by Micro-CT. J. Pet. Sci. Eng. 2018, 163, 283–294. [Google Scholar] [CrossRef]

- Turner, M.L.; Knüfing, L.; Arns, C.H.; Sakellariou, A.; Senden, T.J.; Sheppard, A.P.; Sok, R.M.; Limaye, A.; Pinczewski, W.V.; Knackstedt, M.A. Three-Dimensional Imaging of Multiphase Flow in Porous Media. Phys. A Stat. Mech. Appl. 2004, 339, 166–172. [Google Scholar] [CrossRef]

- Guo, C.; Wang, X.; Wang, H.; He, S.; Liu, H.; Zhu, P. Effect of Pore Structure on Displacement Efficiency and Oil-Cluster Morphology by Using Micro Computed Tomography (ΜCT) Technique. Fuel 2018, 230, 430–439. [Google Scholar] [CrossRef]

- Li, J.; Gao, Y.; Jiang, H.; Liu, Y.; Dong, H. Pore-Scale Imaging of the Oil Cluster Dynamic during Drainage and Imbibition Using In Situ X-Ray Microtomography. Geofluids 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Li, J.; Jiang, H.; Wang, C.; Zhao, Y.; Gao, Y.; Pei, Y.; Wang, C.; Dong, H. Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristics in Water-Wet Sandstone Using CT Scanning. J. Nat. Gas. Sci. Eng. 2017, 48, 36–45. [Google Scholar] [CrossRef]

- Khishvand, M.; Akbarabadi, M.; Piri, M. Micro-Scale Experimental Investigation of the Effect of Flow Rate on Trapping in Sandstone and Carbonate Rock Samples. Adv. Water Resour. 2016, 94, 379–399. [Google Scholar] [CrossRef]

- Yu, F.; Jiang, H.; Xu, F.; Zhen, F.; Wang, J.; Cheng, B.; Su, H.; Li, J. A Multi-Scale Experimental Study of Hydrophobically-Modified Polyacrylamide Flood and Surfactant-Polymer Flood on Enhanced Heavy Oil Recovery. J. Pet. Sci. Eng. 2019, 182, 106258. [Google Scholar] [CrossRef]

- Lin, Q.; Al-Khulaifi, Y.; Blunt, M.J.; Bijeljic, B. Quantification of Sub-Resolution Porosity in Carbonate Rocks by Applying High-Salinity Contrast Brine Using X-Ray Microtomography Differential Imaging. Adv. Water Resour. 2016, 96, 306–322. [Google Scholar] [CrossRef]

| Permeability/mD | Helium Porosity/% | Macro Porosity/% | Micro Porosity/% | Wettability |

|---|---|---|---|---|

| 80.5 | 20.6 | 14.2 | 5.9 | Water-wet |

| Remaining Oil Type | Euler Number | Oil Thickness/Voexl |

|---|---|---|

| Clustered Flow (Continuous phase) | En ≤ −1 | T ≥ 5 |

| Membranous Flow ((Continuous phase) | En ≤ −1 | T < 5 |

| Discontinuous phase | En > −1 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, B.; Li, J.; Jiang, S.; Lu, C.; Su, H.; Yu, F.; Jiang, H. Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT. Energies 2021, 14, 3057. https://doi.org/10.3390/en14113057

Cheng B, Li J, Jiang S, Lu C, Su H, Yu F, Jiang H. Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT. Energies. 2021; 14(11):3057. https://doi.org/10.3390/en14113057

Chicago/Turabian StyleCheng, Baoyang, Junjian Li, Shuai Jiang, Chunhua Lu, Hang Su, Fuwei Yu, and Hanqiao Jiang. 2021. "Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT" Energies 14, no. 11: 3057. https://doi.org/10.3390/en14113057

APA StyleCheng, B., Li, J., Jiang, S., Lu, C., Su, H., Yu, F., & Jiang, H. (2021). Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT. Energies, 14(11), 3057. https://doi.org/10.3390/en14113057