Application of Technological Processes to Create a Unitary Model for Energy Recovery from Municipal Waste

Abstract

:1. Introduction

2. Potential of Municipal Waste to Energy Production—Review

3. Materials and Methods

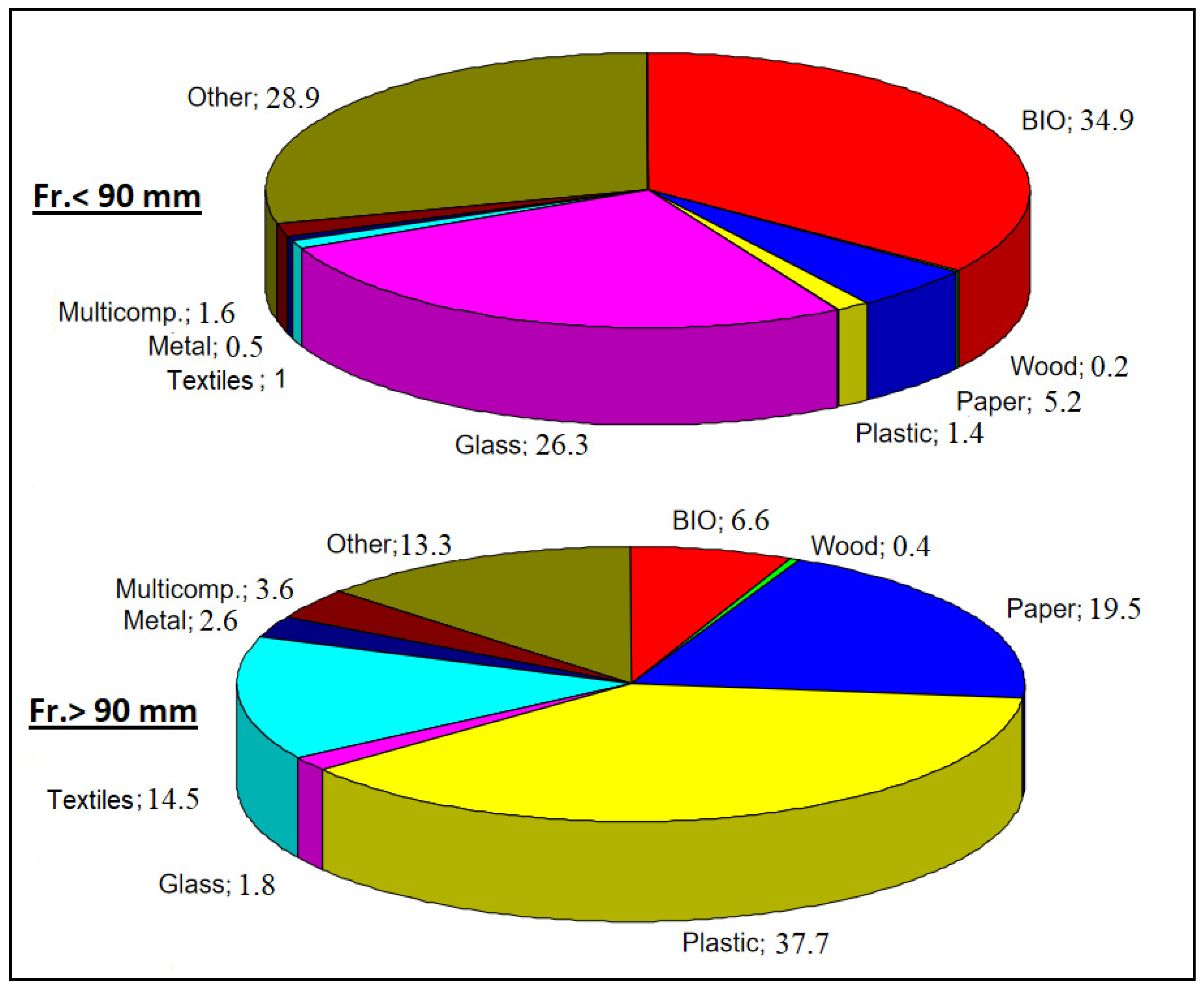

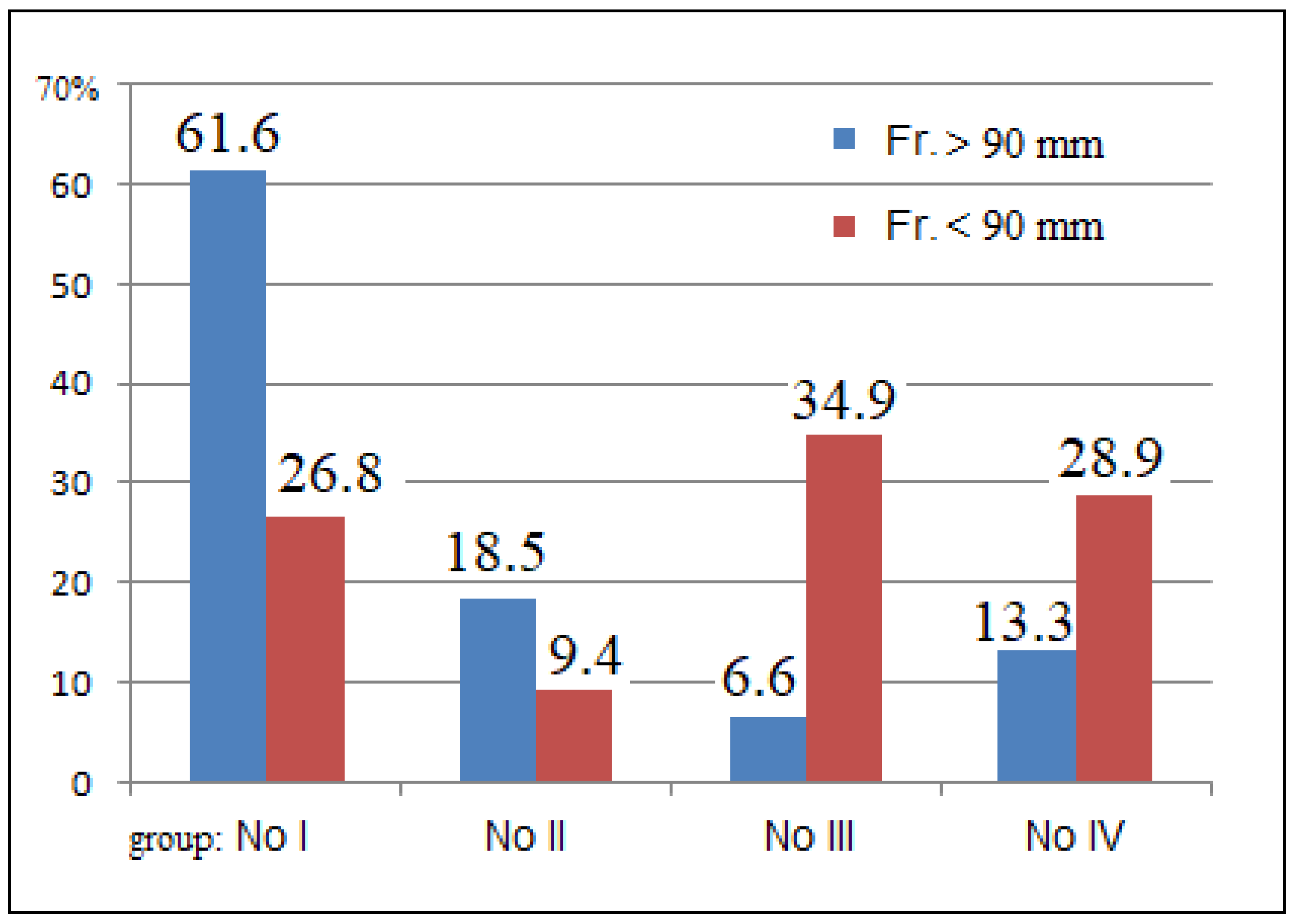

3.1. Composition of Municipal Waste

3.2. Physicochemical Analyses

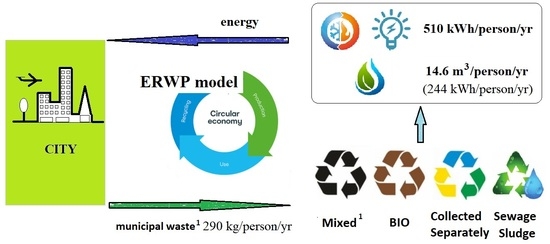

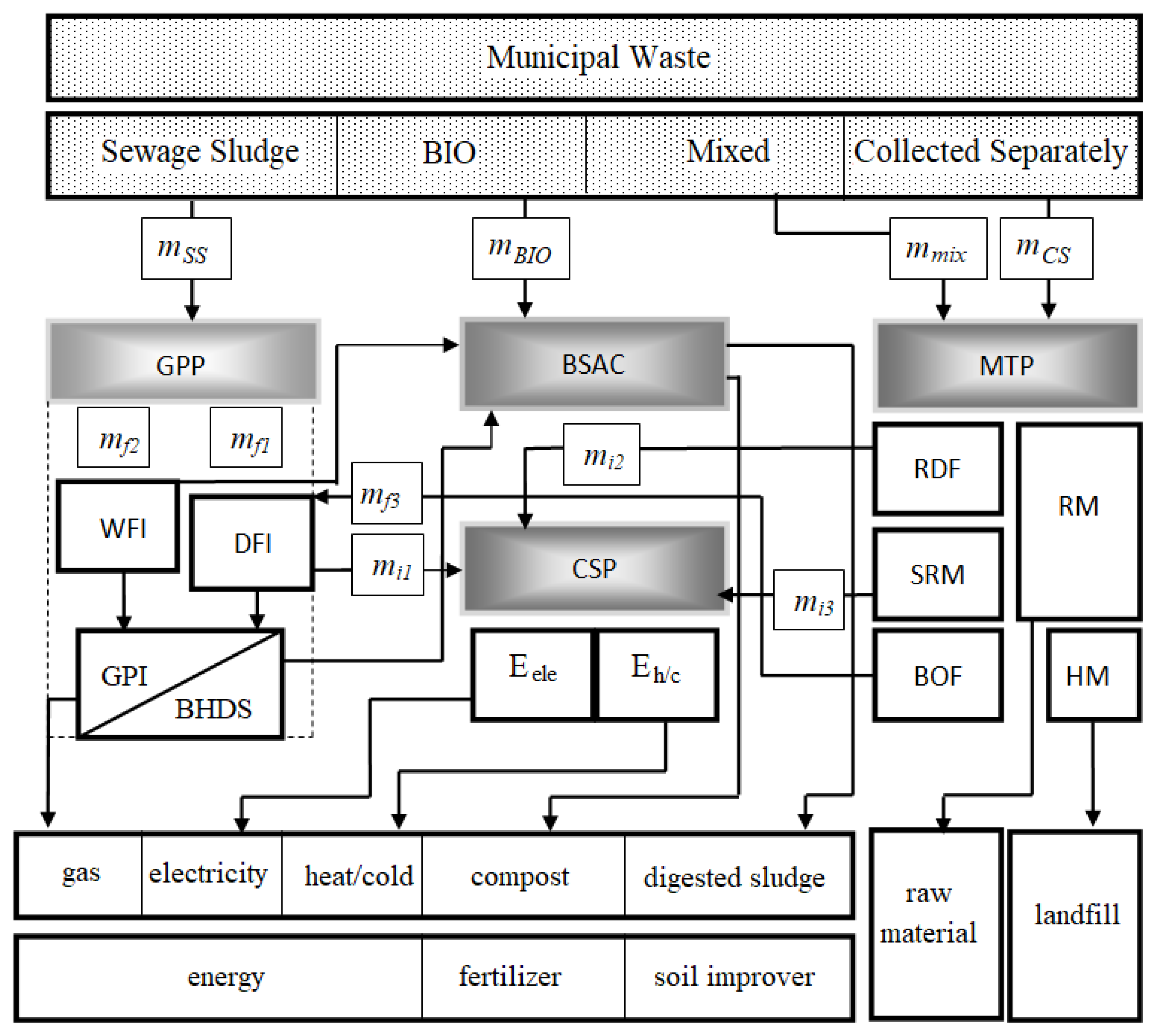

3.3. Model for Energy Waste Management

3.4. Mass Balance and Energy Balance

4. Results

5. Discussion

6. Conclusions and Recommendation

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Guar, V.K.; Sharma, P.; Awasthi, M.K.; Dussap, C.G.; Pandey, A. Assessing the impact of industrial waste on environment and mitigation strategies: A comprehensive review. J. Hazard. Mater. 2020, 398, 123019. [Google Scholar] [CrossRef]

- Janowska, B.; Szymański, K.; Sidełko, R.; Walendzik, B.; Siebielska, I. Assessment of mobility and bioavailability of mercury compounds in sewage sludge and composts. Environ. Res. 2017, 156, 394–403. [Google Scholar] [CrossRef]

- Golwala, H.; Zhang, X.; Mdlskander, S.; Smith, A.L. Solid waste: An overlooked source of microplastics to the environment. Sci. Total Environ. 2021, 769, 144581. [Google Scholar] [CrossRef]

- Qugaard, M. Political Globalization: State, Power, and Social Forces; Palgrave Macmillan: New York, NY, USA, 2004. [Google Scholar]

- Vogli, R.; Kouvonen, A.; Elovainio, M.; Marmot, M.G. Economic globalization, inequality and body mass index: A cross-national analysis of 127 countries. Crit. Public Health 2014, 24, 7–21. [Google Scholar] [CrossRef]

- Schmukler, S.L.; Abraham, F. Financial Globalization; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Sánchez-López, C.; Aceytuno, M.T.; De Paz-Bañez, M.A. Inequality and globalisation: Analysis of European countries. Econ. Sociol. 2019, 12, 84–100. [Google Scholar] [CrossRef]

- Shkolnyk, I.; Kozmenko, S.; Kozmenko, O.; Mershchii, B. The impact of economy financialization on the level of economic development of the associate EU member states. Econ. Sociol. 2019, 12, 43–58. [Google Scholar] [CrossRef] [PubMed]

- Balcerzak, A.P. Quality of institutions in the European Union countries. Application of TOPSIS based on entropy measure for objective weighting. Acta Polytech. Hung. 2020, 17, 101–122. [Google Scholar] [CrossRef]

- Halaskova, M.; Gavurova, B.; Korony, S. Change of EU28 countries research and development indicators between 2010 and 2015. Econ. Sociol. 2020, 13, 230–248. [Google Scholar] [CrossRef] [PubMed]

- Škare, M.; Franc-Dąbrowska, J.; Cvek, D. Cointegration analysis and VECM of FDI, employment, export and GDP in Croatia (2002/2017) with particular reference to the global crisis and poor macroeconomic governance. Equilib. Q. J. Econ. Econ. Policy 2020, 15, 761–783. [Google Scholar] [CrossRef]

- Gavurova, B.; Soltes, M.; Kovac, V. Application of cluster analysis in process of competitiveness modelling of Slovak Republic regions. Transform. Bus. Econ. 2017, 16, 129–147. [Google Scholar]

- Simionescu, M.; Balcerzak, A.P.; Bilan, Y.; Kotásková, A. The impact of money on output in Czech Republic and Romania. J. Bus. Econ. Manag. 2018, 19, 20–41. [Google Scholar] [CrossRef] [Green Version]

- Szopik-Depczyńska, K.; Kędzierska-Szczepaniak, A.; Szczepaniak, K.; Cheba, K.; Gajda, W.; Ioppolo, G. Innovation in sustainable development: An investigation of the EU context using 2030 agenda indicators. Land Use Policy 2018, 79, 251–262. [Google Scholar] [CrossRef]

- Kiseľáková, D.; Šofranková, B.; Onuferová, E.; Čabinová, V. The evaluation of competitive position of EU-28 economies with using global multi-criteria indices. Equilibrium. Q. J. Econ. Econ. Policy 2019, 14, 441–462. [Google Scholar] [CrossRef]

- Androniceanu, A.M.; Kinnunen, J.; Georgescu, I.; Androniceanu, A.A. Multidimensional Approach to Competitiveness, Innovation and Well-Being in the EU Using Canonical Correlation Analysis. J. Compet. 2020, 12, 5–21. [Google Scholar] [CrossRef]

- Kuc, M. Is the regional divergence a price for the international convergence? The case of Visegrad group. J. Compet. 2017, 9, 50–65. [Google Scholar] [CrossRef] [Green Version]

- Kijek, A.; Matras-Bolibok, A. Technological convergence across European regions. Equilibrium. Q. J. Econ. Econ. Policy 2020, 15, 295–313. [Google Scholar] [CrossRef]

- Kónya, I.; Ohashi, H. International Consumption Patterns among High income Countries: Evidence from the OECD Data. Rev. Int. Econ. 2007, 15, 744–757. [Google Scholar] [CrossRef]

- Horáková, M. Consumer behavior of college students in the Czech Republic. J. Compet. 2015, 7, 68–85. [Google Scholar]

- Grybaitė, V.; Stankevičienė, J. An empirical analysis of factors affecting sharing economy growth. Oeconomia Copernic. 2018, 9, 635–654. [Google Scholar] [CrossRef]

- Jankiewicz, M.; Pietrzak, M.B. Assessment of trends in the share of expenditure on services and food in the visegrad group member states. Intern. J. Bus. Soc. 2020, 21, 977–996. [Google Scholar] [CrossRef]

- Walczak, D.; Dziawgo, L.; Dziawgo, D.; Buszko, M.; Pawłowski, J.; Żołądkiewicz-Kuzioła, A.; Krupa, D. Attitudes and Behaviors Regarding Environmental Protection in the Financial Decisions of Individual Consumers. Energies 2021, 14, 1934. [Google Scholar] [CrossRef]

- Pietrzak, M.B.; Walczak, D. The Analysis of the Agrarian Structure in Poland with the Special Consideration of the Years 1921 and 2002. Bulg. J. Agric. Sci. 2014, 20, 1018–1039. [Google Scholar]

- Rokicki, T.; Perkowska, A.; Klepacki, B.; Bórawski, P.; Bełdycka-Bórawska, A.; Michalski, K. Changes in Energy Consumption in Agriculture in the EU Countries. Energies 2021, 14, 1570. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, B.; Hwang, H. Which Institutional Conditions Lead to a Successful Local Energy Transition? Applying Fuzzy-Set Qualitative Comparative Analysis to Solar PV Cases in South Korea. Energies 2020, 13, 3696. [Google Scholar] [CrossRef]

- Lin, M.-X.; Liou, H.M.; Chou, K.T. National Energy Transition Framework toward SDG7 with Legal Reforms and Policy Bundles: The Case of Taiwan and Its Comparison with Japan. Energies 2020, 13, 1387. [Google Scholar] [CrossRef] [Green Version]

- Pietrzak, M.B.; Igliński, B.; Kujawski, W.; Iwański, P. Energy Transition in Poland–Assessment of the Renewable Energy Sector. Energies 2021, 14, 2046. [Google Scholar] [CrossRef]

- Singh, J.; Laurenti, R.; Sinha, R.; Frostell, B. Progress and challenges to the global waste management system. Waste Manag. Res. 2014, 32, 800–812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jouhara, H.; Czajczyńska, D.; Ghazal, H.; Krzyżyńska, R.; Anguilano, L.; Reynolds, A.J.; Spencer, A. Municipal waste management systems for domestic use. Energy 2017, 139, 485–506. [Google Scholar] [CrossRef]

- Eurostat Statistics. 2020. Available online: https://ec.europa.eu/eurostat/statisticsexplained (accessed on 1 April 2021).

- Szymański, K.; Sidełko, R.; Janowska, B.; Siebielska, I. Monitoring of waste landfills. Zesz. Nauk. Wbiiś Politech. Koszalińskiej 2007, 23, 75–136. [Google Scholar]

- Zaman, A.U. A comprehensive study of the environmental and economic benefits of resource recovery from global waste management systems. J Clean. Prod. 2016, 124, 41–50. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Woerden, F. What a Waste 2.0. A Global Snapshot of Solid Waste Management to 2050; Urban Development Series; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Alzamora, B.R.; Baros, R.T. Review of municipal waste management charging methods in different countries. Waste Manag. 2020, 115, 47–55. [Google Scholar] [CrossRef]

- Statistical Yearbook of the Republic of Poland. 2018. Available online: https://stat.gov.pl (accessed on 1 April 2021).

- Sadeleer, I.; Brattebø, H.; Callewaert, P. Waste prevention, energy recovery or recycling—Directions for household food waste management in light of circular economy policy. Resour. Conserv. Recycl. 2020, 160, 104908. [Google Scholar] [CrossRef]

- Szymanski, K.; Sidelko, R.; Janowska, B.; Siebielska, I. Monitoring of waste landfills. Book Ser. Sci. Noteb. Wbiis 2007, 23, 75–133. [Google Scholar]

- Senetra, A.; Krzywnicka, I.; Tuyet, M.D.T. The Analysis and the Evaluation of Municipal Waste Management in Voivodship Cities in Poland. Rocz. Ochr. Środowiska 2019, 21, 1076–1098. [Google Scholar]

- Nanda, S.; Berruti, F. A technical review of bioenergy and resource recovery from municipal solid waste. J. Hazard. Mater. 2021, 403, 123970. [Google Scholar] [CrossRef]

- Leckner, B. Process aspects in combustion and gasification Waste-to-Energy (WtE) units. Waste Manag. 2015, 37, 13–25. [Google Scholar] [CrossRef] [PubMed]

- Hossein, R.; Izadbakhsh, H.; Shakouri, H. A planning model for using municipal solid waste management technologies- considering Energy, Economic, and Environmental Impacts in Tehran-Iran. Sustain. Cities Soc. 2021, 65, 102566. [Google Scholar]

- CPH 2025 Climate Plan. Available online: http://kk.sites.itera.dk/apps/kk_pub2/pdf/983_jkP0ekKMyD.pdf (accessed on 1 April 2021).

- Jędrczak, A.; den Boer, E. Final Report of the Third Stage of Expertise Aimed at Conducting Waste Tests in 20 Mechanical-Biological Installations Waste Processing. Zielona Góra 2015. Available online: https://sdr.gdos.gov.pl/Documents/GO/Ekspertyzy/Ekspertyza%20MBP_III%20etap_%2022-06-2015%20+%20za%C5%82aczniki.pdf (accessed on 26 May 2021).

- Azam, M.; Jahromy, S.S.; Raza, W.; Raza, N.; Lee, S.S.; Kim, K.H.; Winter, F. Status, characterization, and potential utilization of municipal solid waste as renewable energy source: Lahore case study in Pakistan. Environ. Int. 2020, 134, 105291. [Google Scholar] [CrossRef] [PubMed]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008. Off. J. EU. 2008. no. l 312/3. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2008:312:0003:0030:EN:PDF (accessed on 26 May 2021).

- Melikoglu, M. Vision 2023: Assessing the feasibility of electricity and biogas production from municipal solid waste in Turkey. Renew. Sustain. Energy Rev. 2013, 19, 52–63. [Google Scholar] [CrossRef]

- Shumal, M.; Reza, A.; Jahromi, T.; Ferdowsi, A.; Mohammad, S.; Dehkordi, M.N.; Moloudian, A.; Dehnavi, A. Comprehensive analysis of municipal solid waste rejected fractions as a source of Refused Derived Fuel in developing countries (case study of Isfahan-Iran): Environmental impact and sustainable development. Renew. Energy 2020, 146, 404–413. [Google Scholar] [CrossRef]

- Jedelhauser, M. The Future of Waste Incineration in a Modern Circular Economy; Info: Waste Incineration; Naturschutzbund Deutschland (NABU): Berlin, Germany, 2020. [Google Scholar]

- Agar, D.A.; Kwapinska, M.; Leahy, J.J. Pyrolysis of waste water sludge and composed organic fines from municipal solid waste: Laboratory reactor characterisation and product distribution. Environ. Sci. Pollut. Res. 2018, 25, 35874–35882. [Google Scholar] [CrossRef]

- Werle, S. Influence of the Gasification Agent Type on Syngas Parameters. Rocz. Ochr. Środowiska 2014, 16, 440–452. [Google Scholar]

- Thome-Kozmiensky, K.J. Thermische Abfall Behandlung; EF-Verlag für Energie und Umwelt technik: Berlin, Germany, 1994. [Google Scholar]

- Juniper Consultancy Services. Advanced Conversion Technologies; Juniper Consultancy Services: London, UK, 2007. [Google Scholar]

- Kalinichenko, A.; Havrysh, V. Feasibility study of biogas project development: Technology maturity, feedstock, and utilization pathway. Arch. Environ. Prot. 2019, 45, 68–83. [Google Scholar]

- Nguyen, V.K.; Chaudhary, D.K.; Ram, R.H.; Dahal, H.; Trinth, N.H.; Kim, J.; Chang, W.; Hong, Y.; La, D.D.; Nguyen, X.C.; et al. Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 2021, 285, 119105. [Google Scholar] [CrossRef]

- Sosnowski, P.; Wieczorek, A.; Ledakowicz, S. Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv. Environ. Res. 2003, 7, 609–616. [Google Scholar] [CrossRef]

- Campuzano, R.; Gonzalez-Martinez, S. Start-up of dry semi-continuous OFMSW fermentation for methane production. Biomass Bioenergy 2020, 136, 105544. [Google Scholar] [CrossRef]

- Bachmann, N. Sustainable Biogas Production in Municipal Waste Water Treatment Plants; Technical Report; IEA Bioenergy: Paris, France, 2015. [Google Scholar]

- Sarra, A.; Mazzocchitti, M.; Nissi, E. A methodological proposal to determine the optimal levels of inter-municipal cooperation in the organization of solid waste management systems. Waste Manag. 2020, 115, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Jaworski, T.J.; Grochowska, G. Circular Economy-the criteria for achieving and the prospect of implementation in Poland. Arch. Waste Manag. Environ. Prot. 2017, 19, 13–22. [Google Scholar]

- Foggia, G.; Beccarello, M. Designing waste management systems to meet circular economy goals: The Italian case. Sustain. Prod. Consum. 2021, 26, 1074–1083. [Google Scholar] [CrossRef]

- Matthews, K. 6 Waste-To-Energy Trends in 2020 That Are Worth Watching. Available online: https://blueandgreentomorrow.com/environment/ (accessed on 1 April 2021).

- Leckner, B.; Lind, F. Combustion of municipal solid waste in fluidized bed or on grate—A comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef] [PubMed]

- Ibikunle, R.A.; Titiladunayo, I.F.; Lukman, A.F.; Dahunsi, S.O.; Akeju, E.A. Municipal solid waste sampling, quantification and seasonal characterization for power evaluation: Energy potential and statistical modeling. Fuel 2020, 277, 118122. [Google Scholar] [CrossRef]

- Kuo, W.C.; Lasek, J.; Słowik, J.; Głód, K.; Jagustyn, B.; Li, Y.H.; Cygan, A. Low-temperature pre-treatment of municipal solid waste for efficient application in combustion systems. Energy Convers. Manag. 2019, 196, 525–535. [Google Scholar] [CrossRef]

- Niessen, W.R. Combustion and Incineration Process—Aplication in Environmental Engineering; Marcel Dekker: New York, NY, USA, 1995. [Google Scholar]

- Channivala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuel. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Khan, M.Z.A.; Abu-Gharah, Z.H. New approach for estimating Energy content of municipal solid waste. J. Environ. Eng. 1991, 117, 376–380. [Google Scholar] [CrossRef]

- Szaflik, W.; Iżewska, A.; Dominowska, M. Chemical Energy Balance of Digested Sludge in Sewage Treatment Plant Pomorzany in Szczecin. Annu. Set Environ. Prot. 2014, 16, 16–33. [Google Scholar]

- Tillman, D.A. Wood as an Energy Resources; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Iżewska, A.; Szaflik, W. Energy processing of sludge come from the Pomorzany Water Treatment Plant in Szczecin. Ecol. Eng. 2016, 48, 88–95. [Google Scholar]

- Sailer, G.; Eichermüller, J.; Poetsch, J.; Paczkowski, S.; Pelz, S.; Oechsner, H.; Müller, J. Datasets on chemical composition and anaerobic digestion of organic fraction of municipal solid waste (OFMSW), digested sewage sludge (inoculum) and ashes from incineratio norgasification. Data Brief 2020, 31, 105797. [Google Scholar] [CrossRef]

- Duan, N.; Dong, B.; Wu, B.; Dai, X. High-solid anaerobic digestion of sewage sludge under mesophilic conditions: Feasibility study. Bioresour. Technol. 2012, 104, 150–156. [Google Scholar] [CrossRef]

- Li, H.; Si, D.; Liu, C.; Feng, K.; Liu, C. Performance of directan aerobic digestion of dewatered sludge in long-term operation. Bioresour Technol. 2018, 250, 335–364. [Google Scholar] [CrossRef] [PubMed]

- Pavi, S.; Kramer, L.E.; Gomes, L.P.; Miranda, L.A.S. Biogas production from co-digestion of organic fraction of municipal solid waste and fruit and vegetable waste. Bioresour. Technol. 2017, 228, 362–367. [Google Scholar] [CrossRef] [PubMed]

- Giordano, A.; Di Capua, F.; Esposito, G.; Pirozzi, F. Long-term biogas desulfurization under different microaerobic conditions in full-scale thermophilic digesters co-digesting high-solid sewage sludge. Int. Biodeterior. Biodegrad. 2019, 142, 131–136. [Google Scholar] [CrossRef]

- Zawieja, I.E. The course of the methane fermentation process of dry ice modifi ed excess sludge. Arch. Environ. Prot. 2019, 45, 50–58. [Google Scholar]

- Sidełko, R.; Janowska, B.; Walendzik, B.; Siebielska, I. Two composting phases running in different process conditions timing relationship. Bioresour. Technol. 2010, 101, 6692–6698. [Google Scholar] [CrossRef] [PubMed]

- Chiumenti, A.; da Borso, F.; Limina, S. Dry anaerobic digestion of cow manure and agricultural products in a full-scale plant: Efficiency and comparison with wet fermentation. Waste Manag. 2018, 71, 704–710. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degreve, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Waweru, M.; Herrygers, V.; Van Langenhove, H.; Verstraete, W. Process engineering of biological waste gas purification. In Biotechnology Set, 2nd ed.; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Zhang, Y.; Banks, C.J. Impact of different particle size distribution on anaerobic digestion of the organic fraction of municipal solid waste. Waste Manag. 2013, 33, 297–307. [Google Scholar] [CrossRef] [Green Version]

| No. | Components | Mixed (1) | >80–90 mm (1) | <80–90 mm (1) | ||

|---|---|---|---|---|---|---|

| %(w/w) | %(w/w) | Group, No | %(w/w) | Group, No | ||

| 1 | Kitchen (BIO1) | 25.1 | 0.9 | III | 12.7 | III |

| 2 | Park, garden (BIO2) | 0.3 | 0.6 | III | 0.3 | III |

| 3 | Organic (BIO3) | 0.6 | 5.9 | III | 34.7 | III |

| 4 | Wood | 0.6 | 1.3 | II | 0.6 | II |

| 5 | Paper | 14.6 | 22.4 | I | 9.8 | II |

| 6 | Plastic | 14.1 | 32.6 | I | 5.7 | II |

| 7 | Glass | 8.6 | 1.4 | I | 11.1 | I |

| 8 | Textiles | 39 | 12.7 | II | 0.6 | II |

| 9 | Metals | 2 | 1.4 | I | 1.3 | I |

| 10 | Multicomponent | 3.6 | 6.5 | II | 1.5 | II |

| 11 | Other | 9.5 | 14.2 | IV | 21.7 | IV |

| <20 mm | 17.7 | - | - | - | - | |

| BOF | Biodegradable Organic Fraction | BHDS | Biological Half-Digested Sludge |

| BSAC | Biological Stabilisation in Air Condition | CSP | Cogeneration System Plant |

| DMF/WMF | Dry/Wet Methane Fermentation | GPP | Gas Production Plant |

| GPI | Gas Pretreatment Installation | HHV/LHV | Higher/Lower Heating Value |

| HM | Harmful Materials | MBTP | Mechanical Biological Treatment Plant |

| MTP | Mechanical Treatment Plant | RDF | Refuse-Derived Fuel |

| RM | Recyclable Materials | SRM | Separated Row Materials |

| SS | Sewage Sludge |

| Mass | Equation (1) | Eq. No. | Assumption (1) |

|---|---|---|---|

| mf1 | mf3(WBOF − WDF)/(WDF − WSS) | (1) | mDF ∙WDF = ∑(mi⋯Wi) |

| mf2 | mSS − mf1 | (2) | part of SS to WMF process |

| mf3 | mmix(%fr>90 mm ∙% No III +%fr<90 mm∙%No III)0.01 | (3) | Group No III of both fractions |

| mi1 | ∆m (mf3+ mf1) | (4) | ∆m, as a result of om reduction |

| mi2 | mmix(%fr>90 mm ∙%No II + %fr<90 mm∙%No II)0.01 | (5) | Group No II of both fractions |

| mi3 | mCS⋯0.4 + mBIO⋯0 | (6) | worn out furniture, doors, …: Cs, wood and branches: BIO |

| Materials | Equation | R2 | References |

|---|---|---|---|

| Over sieve fraction of MSW | HHV = 0.3491C + 1.1783H + 0.1005S − (0.1034O + 0.0151N + 0.0211A) | 0.85 | [65] |

| Sewage Sludge | HHV = 0.2322C + 0.7655H − 0.072O + 0.0419N+ 0.0698S + 0.0262Cl + 0.18814P | - | [66] |

| Biomass materials | HHV = 0.328C + 1.4306H + 0.0929S − 0.0237N − (1 − A/100)∙ (40.11H/C) + 0.3466 | - | [67] |

| CR- sifted ballast after composting of MSW and MTR- rejected after manual separation | LHVd = HHV − (212.2H + 0.8(O + N)) LHVw = HHVd − ((1 − 0.01M) − 24.43M) | - | [48] |

| Raw Materials | T °C | M % | GP dm3/kg dm | CH4 %(vol) | HRT d | References |

|---|---|---|---|---|---|---|

| SS | 36 | 95.5 | 56.5 | - | 28 | [72] |

| SS | 35 | 98.4 | 64.7 | 72.3 | 27 | [73] |

| SS | 35 | 90 | 171 | - | 4 ÷ 59 | [74] |

| SS | 55 | 82.5 | 164 ÷ 233 | - | 30 | [75] |

| OFMSW + SS | 35 | 97.7 | 76 | 64.6 | 27 | [73] |

| OFMSW + SS | 35 | 80 | 215 | 76.5 | - | [76] |

| OFMSW + SS | 35 | 89.3 | 265 ÷ 311 | - | 44 ÷ 71 | [77] |

| OFMSW + FVW + SS | 35 | 80 | 433.9 | 80.8 | - | [76] |

| Raw Materials | Dry Mass (dm), % | Org. Matter, % dm | Corg, % dm | N, % dm |

|---|---|---|---|---|

| Group No II | 78.0 | 25.0 | 51.22 | 0.48 |

| Group No II | 72.0 | 65.0 | 34.56 | 1.11 |

| Sewage Sludge (SS) | 5.1 | 74.0 | 55.0 | 4.11 |

| Dewatered SS | 21.0 | 72.0 | 51.12 | 4.04 |

| Process | Raw Materials | Daily | ||

|---|---|---|---|---|

| Mg | GJ | MWh | ||

| WFI | mf2 | 79 | 5.39 | 1.49 |

| DFI | mf1+ mf3 | 48.3 | 118.8 | 33 |

| CSP | mi1 | 43.5 | 555.89 | 154.37 |

| CSP | mi2 | 13.7 | 335.58 | 93.19 |

| CSP | mi3 | 0.1 | 11.78 | 3.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sidełko, R. Application of Technological Processes to Create a Unitary Model for Energy Recovery from Municipal Waste. Energies 2021, 14, 3118. https://doi.org/10.3390/en14113118

Sidełko R. Application of Technological Processes to Create a Unitary Model for Energy Recovery from Municipal Waste. Energies. 2021; 14(11):3118. https://doi.org/10.3390/en14113118

Chicago/Turabian StyleSidełko, Robert. 2021. "Application of Technological Processes to Create a Unitary Model for Energy Recovery from Municipal Waste" Energies 14, no. 11: 3118. https://doi.org/10.3390/en14113118