Efficient Operation Method of Aquifer Thermal Energy Storage System Using Demand Response

Abstract

:1. Introduction

2. Method

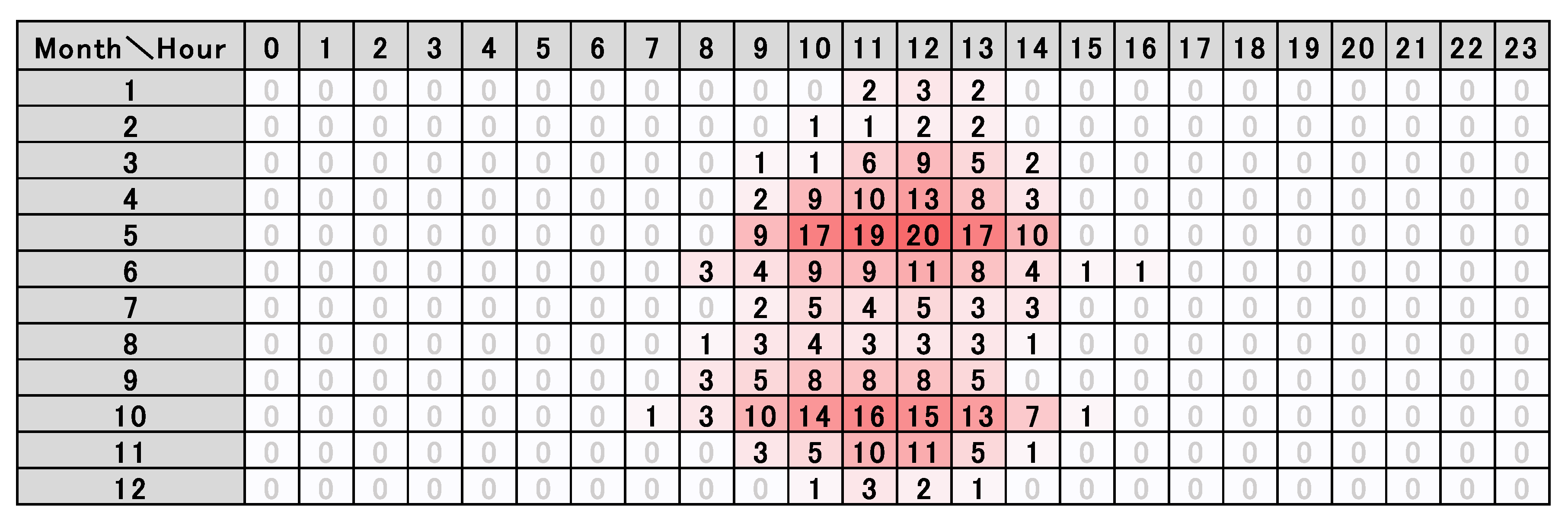

2.1. DR Schedule

2.2. ATES System

3. Components Modeling

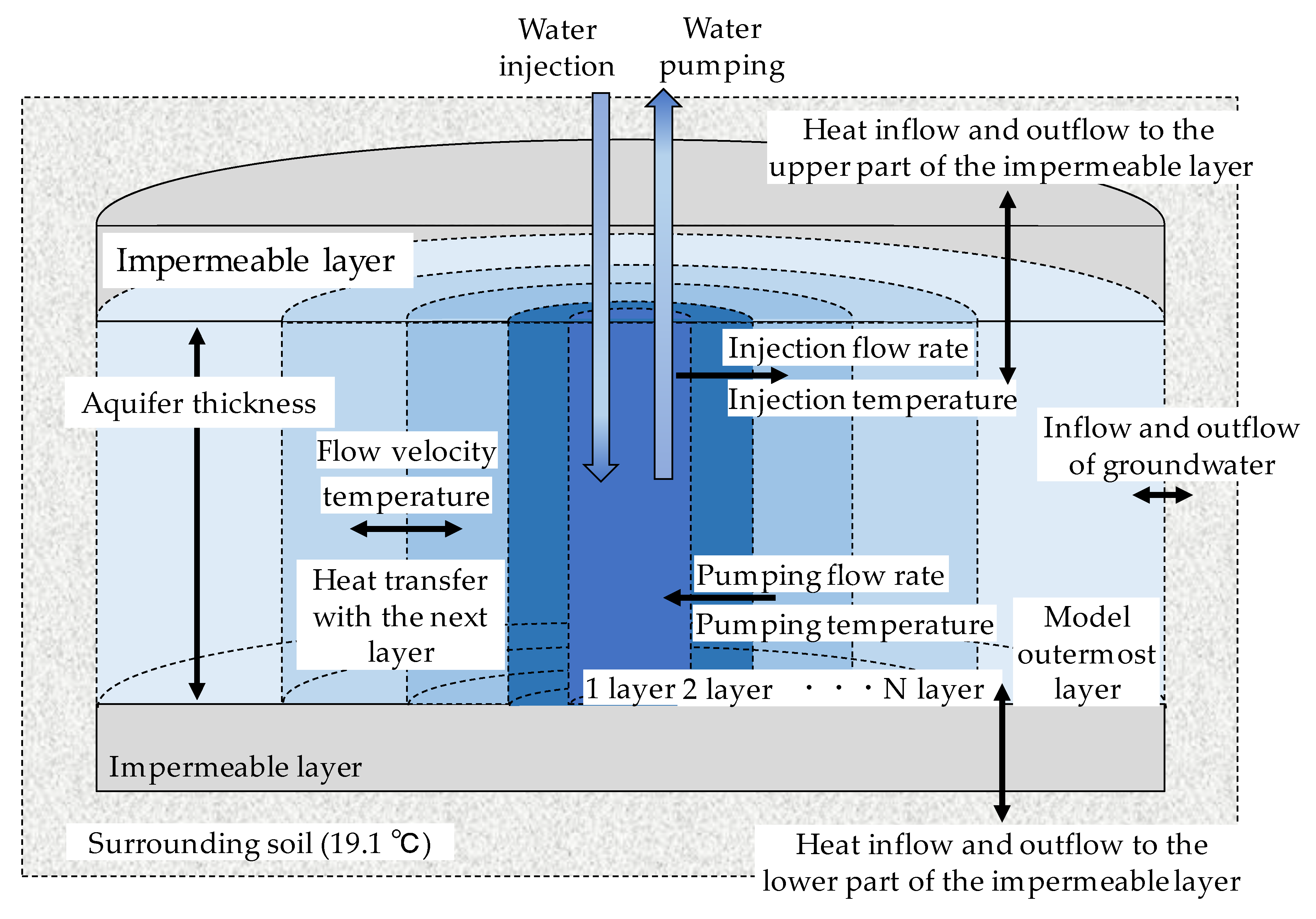

3.1. ATES Model

3.2. Heat Source Model

4. Calculation Methods

4.1. Air Conditioning System Operating Method

4.2. Operation Case of ATES System Using DR

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

Appendix C

Appendix D

- Heat dissipation

- Heat storage

- Stop

References

- Lund, H.; Mathiesen, B.V. Energy system analysis of 100% renewable energy system—The case of Denmark in years 2030 and 2050. Energy 2009, 34, 524–531. [Google Scholar] [CrossRef]

- Gyanwali, K.; Komiyama, R.; Fujii, Y. Representing hydropower in the dynamic power sector model and assessing clean energy deployment in the power generation mix of Nepal. Energy 2020, 202, 117795. [Google Scholar] [CrossRef]

- Lund, H. Large-scale integration of optimal combinations of PV, wind and wave power into the electricity supply. Renew. Energy 2006, 31, 503–515. [Google Scholar] [CrossRef]

- Albadi, M.H.; El-Saadany, E.F. A summary of demand response in electricity markets. Electr. Power Syst. Res. 2008, 78, 1989–1996. [Google Scholar] [CrossRef]

- Palensky, P.; Dietrich, D. Demand Side Management: Demand Response, Intelligent Energy Systems, and Smart Loads. IEEE Trans. Ind. Inform. 2011, 7, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Janota, L.; Králík, T.; Knápek, J. Second Life Batteries Used in Energy Storage for Frequency Containment Reserve Service. Energies 2020, 13, 6396. [Google Scholar] [CrossRef]

- Kalantari, H.; Ghoreishi-Madiseh, S.A.; Sasmito, A.P. Hybrid Renewable Hydrogen Energy Solution for Application in Remote Mines. Energies 2020, 13, 6365. [Google Scholar] [CrossRef]

- Misaki, C.; Hara, D.; Katayama, N.; Dowaki, K. Improvement of Power Capacity of Electric-Assisted Bicycles Using Fuel Cells with Metal Hydride. Energies 2020, 13, 6272. [Google Scholar] [CrossRef]

- Bloemendal, M.; Olsthoorn, T.; Boons, F. How to achieve optimal and sustainable use of the subsurface for Aquifer Thermal Energy Storage. Energy Policy 2014, 66, 104–114. [Google Scholar] [CrossRef]

- Lee, K.S. A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems. Energies 2010, 3, 1320–1334. [Google Scholar] [CrossRef]

- Pinamonti, M.; Prada, A.; Baggio, P. Rule-Based Control Strategy to Increase Photovoltaic Self-Consumption of a Modulating Heat Pump Using Water Storages and Building Mass Activation. Energies 2020, 13, 6282. [Google Scholar] [CrossRef]

- Vanhoudt, D.; Desmedt, J.; Van Bael, J.; Robeyn, N.; Hoes, H. An aquifer thermal storage system in a Belgian hospital: Long-term experimental evaluation of energy and cost savings. Energy Build. 2011, 43, 3657–3665. [Google Scholar] [CrossRef]

- Paksoy, H.; Gürbüz, Z.; Turgut, B.; Dikici, D.; Evliya, H. Aquifer thermal storage (ATES) for air-conditioning of a supermarket in Turkey. Renew. Energy 2004, 29, 1991–1996. [Google Scholar] [CrossRef]

- Xu, J.; Wang, R.; Li, Y. A review of available technologies for seasonal thermal energy storage. Sol. Energy 2014, 103, 610–638. [Google Scholar] [CrossRef]

- Bloemendal, M.; Jaxa-Rozen, M.; Olsthoorn, T. Methods for planning of ATES systems. Appl. Energy 2018, 216, 534–557. [Google Scholar] [CrossRef]

- Bloemendal, M.; Hartog, N. Analysis of the impact of storage conditions on the thermal recovery efficiency of low-temperature ATES systems. Geothermics 2018, 71, 306–319. [Google Scholar] [CrossRef]

- Kranz, S.; Frick, S. Efficient cooling energy supply with aquifer thermal energy storages. Appl. Energy 2013, 109, 321–327. [Google Scholar] [CrossRef]

- Sommer, W.; Valstar, J.; Leusbrock, I.; Grotenhuis, T.; Rijnaarts, H. Optimization and spatial pattern of large-scale aquifer thermal energy storage. Appl. Energy 2015, 137, 322–337. [Google Scholar] [CrossRef]

- Bloemendal, M.; Olsthoorn, T.; van de Ven, F. Combining climatic and geo-hydrological preconditions as a method to determine world potential for aquifer thermal energy storage. Sci. Total Environ. 2015, 538, 621–633. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Qi, C.; Wang, E.; Zhao, J. A case study of underground thermal storage in a solar-ground coupled heat pump system for residential buildings. Renew. Energy 2009, 34, 307–314. [Google Scholar] [CrossRef]

- Zhai, X.; Qu, M.; Yu, X.; Yang, Y.; Wang, R. A review for the applications and integrated approaches of ground-coupled heat pump systems. Renew. Sustain. Energy Rev. 2011, 15, 3133–3140. [Google Scholar] [CrossRef]

- Bozkaya, B.; Zeiler, W. The effectiveness of night ventilation for the thermal balance of an aquifer thermal energy storage. Appl. Therm. Eng. 2019, 146, 190–202. [Google Scholar] [CrossRef]

- Gao, L.; Zhao, J.; An, Q.; Wang, J.; Liu, X. A review on system performance studies of aquifer thermal energy storage. Energy Procedia 2017, 142, 3537–3545. [Google Scholar] [CrossRef]

- Caliskan, H.; Dincer, I.; Hepbasli, A. Energy and exergy analyses of combined thermochemical and sensible thermal energy storage systems for building heating applications. Energy Build. 2012, 48, 103–111. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, J.; Xu, W.; Zhang, G. Current status of ground-source heat pumps in China. Energy Policy 2010, 38, 323–332. [Google Scholar] [CrossRef]

- Bozkaya, B.; Li, R.; Zeiler, W. A dynamic building and aquifer co-simulation method for thermal imbalance investigation. Appl. Therm. Eng. 2018, 144, 681–694. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Q.; Chen, X.; Yan, Y.; Spitler, J.D. Developmental status and challenges of GWHP and ATES in China. Renew. Sustain. Energy Rev. 2015, 42, 973–985. [Google Scholar] [CrossRef]

- Shikoku Electric Power Co., Inc. Electricity Forecast (Electricity Usage in Shikoku Area). Available online: https://www.yonden.co.jp/nw/denkiyoho/index.html (accessed on 4 December 2020).

- Nakaso, Y.; Sasaki, K.; Fujii, R.; Nakao, M.; Nishioka, M.; Nnabeshima, M. Study on Daily Thermal Storage System ufflizing High Closure Aquifer Part2—Experiment and Verification with ATES Model. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2013, 38, 11–18. [Google Scholar] [CrossRef]

- FEFLOW Manual. Available online: http://www.feflow.infouploadsmediauser_manual.pdf (accessed on 4 December 2020).

| Radius [m] | 20 | |

| Initial division width [m] | 0.03 | |

| common ratio [–] | 1.10 | |

| Aquifer | Volumetric specific heat [MJ/(m3·K)] | 3.18 |

| Effective thermal conductivity [W/(mK)] | 1.6 | |

| Clearance rate [–] | 0.3 | |

| clay | Volumetric specific heat [MJ/(m3·K)] | 3.06 |

| Effective thermal conductivity [W/(m·K)] | 1.2 | |

| Clearance rate [–] | 0.3 | |

| Water | Volumetric specific heat [MJ/(m3·K)] | 4.18 |

| Thermal conductivity [W/(m·K)] | 0.59 | |

| Aquifer thickness [m] | 8 | |

| Dispersion length [m] | Change | |

| Impermeable layer thickness [m] | Change | |

| Initial underground temperature [°C] | 19.1 | |

| Thickness of Impervious Layer | Dispersion Length 0.05 m | Dispersion Length 0.1 m | Dispersion Length 0.2 m | Dispersion Length 0.3 m | Dispersion Length 0.4 m |

|---|---|---|---|---|---|

| 0.002 m | 0.78 | 1.03 | 1.07 | 1.49 | 1.83 |

| 0.005 m | 0.87 | 1.16 | 1.06 | 1.45 | 1.75 |

| 0.1 m | 0.95 | 1.26 | 1.06 | 1.43 | 1.76 |

| 4 m | 0.95 | 1.27 | 1.06 | 1.43 | 1.76 |

| Input Data | Output Data |

|---|---|

|

|

| Case | Case Contents |

|---|---|

| Case 0 | Water-cooled HP operation No heat storage operation |

| Case 1-1 | Night heat storage 10 h, DR operation |

| Case 1-2 | Night heat storage 6 h, DR operation |

| Case 1-3 | Night heat storage 3 h, DR operation |

| Case 2 | DR operation |

| |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, J.; Sumiyoshi, D.; Nishioka, M.; Kim, H. Efficient Operation Method of Aquifer Thermal Energy Storage System Using Demand Response. Energies 2021, 14, 3129. https://doi.org/10.3390/en14113129

Oh J, Sumiyoshi D, Nishioka M, Kim H. Efficient Operation Method of Aquifer Thermal Energy Storage System Using Demand Response. Energies. 2021; 14(11):3129. https://doi.org/10.3390/en14113129

Chicago/Turabian StyleOh, Jewon, Daisuke Sumiyoshi, Masatoshi Nishioka, and Hyunbae Kim. 2021. "Efficient Operation Method of Aquifer Thermal Energy Storage System Using Demand Response" Energies 14, no. 11: 3129. https://doi.org/10.3390/en14113129