Comprehensive Model for Real Battery Simulation Responsive to Variable Load

Abstract

:1. Introduction

- Fast and accurate representation of battery behavior for simulation purposes considering electrical impact, and variability in the cycling process.

- An improvement of the KiBaM model currently applied in commercial software as Homer, by considering voltage impact in battery degradation and cycling process.

- An algorithm for error reduction of the parametrization of battery variables related to cycling behavior, based on an iterative process.

- A novel combination of KiBaM and VM is proposed and called 4-Ki-VM. It uses four KiBaM cores and allows describing battery behavior more accurately than KiBaM with low computational cost compared to ECM models.

2. Battery Behavior

- Time of charging and power.

- Availability of energy during discharge.

- Battery charge process during CV.

- Maximum allowed power output.

- Impact of degradation in power injection.

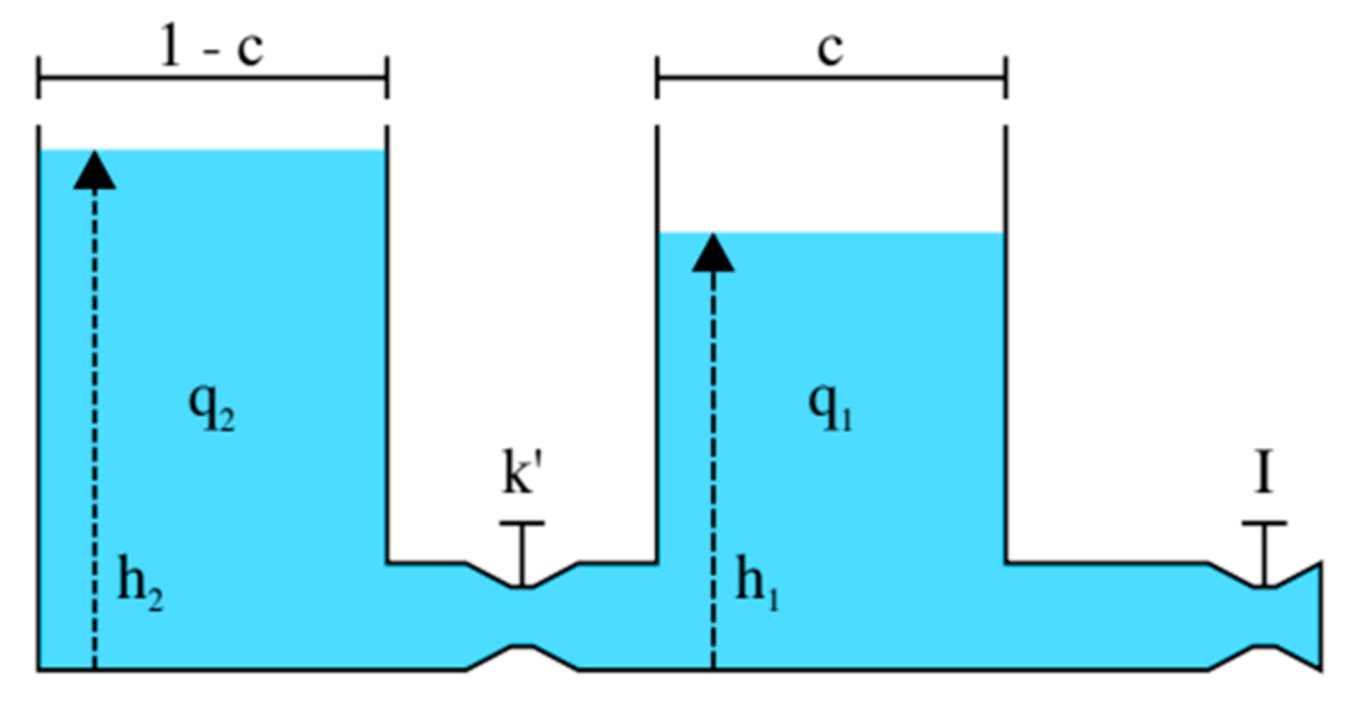

3. Kinetic Battery Model (KiBaM)

3.1. Voltage Model (VM)

3.2. SOC Forecast

4. Electric Battery Model (ECM)

5. Proposed Model

6. Parameter Estimation

Model Extraction

7. Results

8. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sarrafan, K.; Muttaqi, K.M.; Sutanto, D. Real-Time Estimation of Model Parameters and State-of-Charge of Li-Ion Batteries in Electric Vehicles Using a New Mixed Estimation Model. IEEE Trans. Ind. Appl. 2020, 56, 5417–5428. [Google Scholar] [CrossRef]

- Global EV Outlook 2019—Analysis-IEA. Available online: https://www.iea.org/reports/global-ev-outlook-2019 (accessed on 29 March 2021).

- Song, Z.; Wang, H.; Hou, J.; Hofmann, H.F.; Sun, J. Combined State and Parameter Estimation of Lithium-Ion Battery With Active Current Injection. IEEE Trans. Power Electron. 2020, 35, 4439–4447. [Google Scholar] [CrossRef]

- Lawder, M.; Suthar, B.; Northrop, P.; De, S.; Hoff, C.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Diouf, B.; Pode, R. Potential of lithium-ion batteries in renewable energy. Renew. Energy 2015, 76, 375–380. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z. Lithium-ion Battery SOC Estimation Based on Weighted Adaptive Recursive Extended Kalman Filter Joint Algorithm. In Proceedings of the 2020 IEEE 8th International Conference on Computer Science and Network Technology (ICCSNT), Dalian, China, 20–22 November 2020; pp. 11–15. [Google Scholar]

- Zhang, Z.; Xue, B.; Fan, J. Noise Adaptive Moving Horizon Estimation for State-of-Charge Estimation of Li-Ion Battery. IEEE Access 2021, 9, 5250–5259. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Manwell, J.F.; McGowan, J.G. Lead acid battery storage model for hybrid energy systems. Sol. Energy 1993, 50, 399–405. [Google Scholar] [CrossRef]

- HOMER—Hybrid Renewable and Distributed Generation System Design Software. Available online: https://www.homerenergy.com/ (accessed on 31 March 2021).

- Kim, T.; Qiao, W.; Qu, L. An Enhanced Hybrid Battery Model. IEEE Trans. Energy Convers. 2019, 34, 1848–1858. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Shang, Y.; Duan, B.; Cui, N.; Zhang, C. A Fractional-Order Kinetic Battery Model of Lithium-Ion Batteries Considering a Nonlinear Capacity. Electronics 2019, 8, 394. [Google Scholar] [CrossRef] [Green Version]

- Jongerden, M.; Haverkort, B. Battery Aging, Battery Charging and the Kinetic Battery Model: A First Exploration. In Proceedings of the International Conference on Quantitative Evaluation of Systems, Berlin, Germany, 5–7 September 2017; Springer: Cham, Switzerland, 2017; pp. 88–103. [Google Scholar]

- Fenner, G.P.; Ramos, L.F.; Canha, L.N. Battery Analysis using Kinetic Battery Model with Voltage Response. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Turin, Italy, 1–4 September 2020; pp. 1–5. [Google Scholar]

- Li, B.; Chen, T.; Wang, X.; Giannakis, G.B. Real-Time Energy Management in Microgrids With Reduced Battery Capacity Requirements. IEEE Trans. Smart Grid 2019, 10, 1928–1938. [Google Scholar] [CrossRef]

- Hossain, M.; Saha, S.; Arif, M.T.; Oo, A.M.T.; Mendis, N.; Haque, M.E. A Parameter Extraction Method for the Li-Ion Batteries With Wide-Range Temperature Compensation. IEEE Trans. Ind. Appl. 2020, 56, 5625–5636. [Google Scholar] [CrossRef]

- Bian, X.; Wei, Z.; He, J.; Yan, F.; Liu, L. A two-step parameter optimization method for low-order model-based state of charge estimation. IEEE Trans. Transp. Electrif. 2020, 7, 399–409. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.-S.; McPhee, J. A survey of mathematics-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef] [Green Version]

- Kwak, M.; Lkhagvasuren, B.; Park, J.; You, J.-H. Parameter Identification and SOC Estimation of a Battery Under the Hysteresis Effect. IEEE Trans. Ind. Electron. 2020, 67, 9758–9767. [Google Scholar] [CrossRef]

- Daniil, N.; Drury, D.; Mellor, P.H. Performance Comparison of Diffusion, Circuit-Based and Kinetic Battery Models. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015. [Google Scholar]

- Rodrigues, L.; Montez, C.; Moraes, R.; Portugal, P.; Vasques, F. A Temperature-Dependent Battery Model for Wireless Sensor Networks. Sensors 2017, 17, 422. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Y.; Li, Y.; Zhou, F.; Zhou, Z.; Chen, Y. An iterative learning approach to identify fractional order KiBaM model. IEEE/CAA J. Autom. Sin. 2017, 4, 322–331. [Google Scholar] [CrossRef]

- Rodrigues, L.M.; Bitencourt, N.L.; Rech, L.; Montez, C.; Moraes, R. An analytical model to estimate the state of charge and lifetime for batteries with energy harvesting capabilities. Int. J. Energy Res. 2020, 44, 5243–5258. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.-A. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Tremblay, O.; Dessaint, L.-A.; Dekkiche, A.-I. A Generic Battery Model for the Dynamic Simulation of Hybrid Electric Vehicles. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 284–289. [Google Scholar]

- Remaining Energy Estimation for Lithium-Ion Batteries via Gaussian Mixture and Markov Models for Future Load Prediction—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2352152X19312502 (accessed on 27 April 2021).

- Dicke, P.; Resch, S.; Steinbacher, F.; Luther, M.; German, R. Benefits and Challenges of the Kinetic Battery Model in System-Level Storage Unit Simulations. In Proceedings of the 12th International Conference on Computer Modeling and Simulation, Brisbane, Australia, 23–25 June 2020; Available online: https://dl.acm.org/doi/10.1145/3408066.3408072 (accessed on 26 April 2021).

- Wei, Z.; Meng, S.; Xiong, B.; Ji, D.; Tseng, K.J. Enhanced online model identification and state of charge estimation for lithium-ion battery with a FBCRLS based observer. Appl. Energy 2016, 181, 332–341. [Google Scholar] [CrossRef]

- A Noise-Tolerant Model Parameterization Method for Lithium-Ion Battery Management System—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S030626192030444X (accessed on 26 April 2021).

- Huang, C.; Wang, Z.; Zhao, Z.; Wang, L.; Lai, C.S.; Wang, D. Robustness Evaluation of Extended and Unscented Kalman Filter for Battery State of Charge Estimation. IEEE Access 2018, 6, 27617–27628. [Google Scholar] [CrossRef]

- Chen, Z.; Qiu, S.; Masrur, M.A.; Murphey, Y.L. Battery state of charge estimation based on a combined model of Extended Kalman Filter and neural networks. In Proceedings of the 2011 International Joint Conference on Neural Networks, San Jose, CA, USA, 31 July–5 August 2011; IEEE: San Jose, CA, USA, 2011; pp. 2156–2163. [Google Scholar]

- Tran, M.-K.; Mevawala, A.; Panchal, S.; Raahemifar, K.; Fowler, M.; Fraser, R. Effect of integrating the hysteresis component to the equivalent circuit model of Lithium-ion battery for dynamic and non-dynamic applications. J. Energy Storage 2020, 32, 101785. [Google Scholar] [CrossRef]

- Online State-of-Charge Estimation for Lithium-Ion Batteries Considering Model Inaccuracies Under Time-Varying Current Conditions. IEEE Access 2020, 8, 192419–192434. Available online: https://ieeexplore.ieee.org/document/9234395 (accessed on 27 April 2021). [CrossRef]

- Chen, M.; Rincon-Mora, G.A. Accurate electrical battery model capable of predicting runtime and I-V performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2018, 6, 1832–1843. [Google Scholar] [CrossRef]

- Schmidt, A.P.; Bitzer, M.; Imre, Á.W.; Guzzella, L. Experiment-driven electrochemical modeling and systematic parameterization for a lithium-ion battery cell. J. Power Sources 2010, 195, 5071–5080. [Google Scholar] [CrossRef]

- Smith, K.A.; Rahn, C.D.; Wang, C.Y. Model-based electrochemical estimation and constraint management for pulse operation of lithium ion batteries. IEEE Trans. Control Syst. Technol. 2010, 18, 654–663. [Google Scholar] [CrossRef]

- Li, G.; Peng, K.; Li, B. State-of-charge Estimation for Lithium-ion Battery using a Combined Method. J. Power Electron. 2018, 18, 129–136. [Google Scholar]

- Thele, M.; Bohlen, O.; Sauer, D.; Karden, E. Development of a voltage-behavior model for NiMH batteries using an impedance-based modeling concept. J. Power Sources 2008, 175, 635–643. [Google Scholar] [CrossRef]

- He, H.; Zhang, X.; Xiong, R.; Xu, Y.; Guo, H. Online model-based estimation of state-of-charge and open-circuit voltage of lithium-ion batteries in electric vehicles. Energy 2012, 39, 310–318. [Google Scholar] [CrossRef]

- Snihir, I.; Rey, W.; Verbitskiy, E.; Belfadhel-Ayeb, A.; Notten, P.H.L. Battery open-circuit voltage estimation by a method of statistical analysis. J. Power Sources 2006, 159, 1484–1487. [Google Scholar] [CrossRef] [Green Version]

- Kachitvichyanukul, V. Comparison of Three Evolutionary Algorithms: GA, PSO, and DE. Ind. Eng. Manag. Syst. 2012, 11, 215–223. [Google Scholar] [CrossRef] [Green Version]

- Santos, F.M.D.P. Algoritmo Enxame de Partículas Evolutivo Para o Problema de Coordenação de Relés de Sobrecorrente Direcionais em Sistemas Elétricos de Potência. Ph.D. Thesis, Universidade de São Paulo, São Carlos, Brazil, 2013. [Google Scholar]

- Glover, F. Tabu Search: A Tutorial. Inf. J. Appl. Anal. 1990, 20, 74–94. [Google Scholar] [CrossRef] [Green Version]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef] [Green Version]

- Prognostics Center of Excellence—Data Repository. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/#batteryrnddischarge (accessed on 29 January 2021).

- Bole, B.; Kulkarni, C.; Daigle, M. Adaptation of an Electrochemistry-Based Li-Ion Battery Model to Account for Deterioration Observed Under Randomized Use; SGT, Inc.: Santa Clara County, CA, USA, 2014. [Google Scholar]

| 4-Ki-VM | KiBaM-VM | |||||

|---|---|---|---|---|---|---|

| Parameter | Charge | Discharge | Rest Charge | Rest Discharge | All Scenarios | |

| KiBaM | c | 0.5394 | 0.3494 | 0.4350 | 0.3987 | 0.0155 |

| k’ | 0.0078 | 0.0062 | 0.0075 | 0.0071 | 0.0064 | |

| C | 7200 As | 7200 As | ||||

| Voltage Model | A | 0.3648 | 0.4671 | 0.3609 | 0.6761 | 0.6683 |

| B | 0.3732 | 1.9196 | 1.5027 | 1.6687 | 1.5118 | |

| K | 0.0384 | 0.0479 | 0.0128 | 0.0172 | 0.0338 | |

| 3.7434 | 3.7990 | 3.7893 | 3.7127 | 3.7428 | ||

| µ | 0.9752 | 0.9008 | 1.2344 | 0.8815 | 0.0762 | |

| Model | RMSE (mV) | ||||

|---|---|---|---|---|---|

| Discharge | Charge | Pulse Charge | Pulse Discharge | Alternating | |

| KiBaM | 1.06 | 1.05 | 0.62 | 0.93 | 0.9 |

| ECM | 0.93 | 0.54 | 0.83 | 0.65 | 0.62 |

| 4-Ki-VM | 0.73 | 0.36 | 0.47 | 0.55 | 0.62 |

| KiBaM * | 0.91 | 0.56 | 0.55 | 0.68 | 2.54 |

| ECM * | 0.81 | 0.52 | 0.7 | 0.46 | 1.26 |

| 4-Ki-VM * | 0.47 | 0.39 | 0.41 | 0.56 | 1.05 |

| Mode Used | Time per Iteration | Characteristics |

|---|---|---|

| ECM | 6.0 µs | -Fast to compute and simplicity in implementation -Can describe VxI characteristics and apparent capacity -Great accuracy, which can be improved with more RC circuits |

| 4-Ki-VM | 5.5 µs | -With four models can precisely describe charging characteristics -Best accuracy -Fast to compute -Can describe VxI characteristics and SOC fluctuations |

| KiBaM | 5.28 µs | -Simplicity in implementation -Requires few constants -Explains SOC fluctuation and apparent capacity -Lacks accuracy |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fenner, G.P.; Stringini, L.W.; Rangel, C.A.S.; Canha, L.N. Comprehensive Model for Real Battery Simulation Responsive to Variable Load. Energies 2021, 14, 3209. https://doi.org/10.3390/en14113209

Fenner GP, Stringini LW, Rangel CAS, Canha LN. Comprehensive Model for Real Battery Simulation Responsive to Variable Load. Energies. 2021; 14(11):3209. https://doi.org/10.3390/en14113209

Chicago/Turabian StyleFenner, Gustavo Piske, Leonardo Weber Stringini, Camilo Alberto Sepulveda Rangel, and Luciane Neves Canha. 2021. "Comprehensive Model for Real Battery Simulation Responsive to Variable Load" Energies 14, no. 11: 3209. https://doi.org/10.3390/en14113209

APA StyleFenner, G. P., Stringini, L. W., Rangel, C. A. S., & Canha, L. N. (2021). Comprehensive Model for Real Battery Simulation Responsive to Variable Load. Energies, 14(11), 3209. https://doi.org/10.3390/en14113209