Optimal Scheduling Strategy of AC/DC Hybrid Distribution Network Based on Power Electronic Transformer

Abstract

:1. Introduction

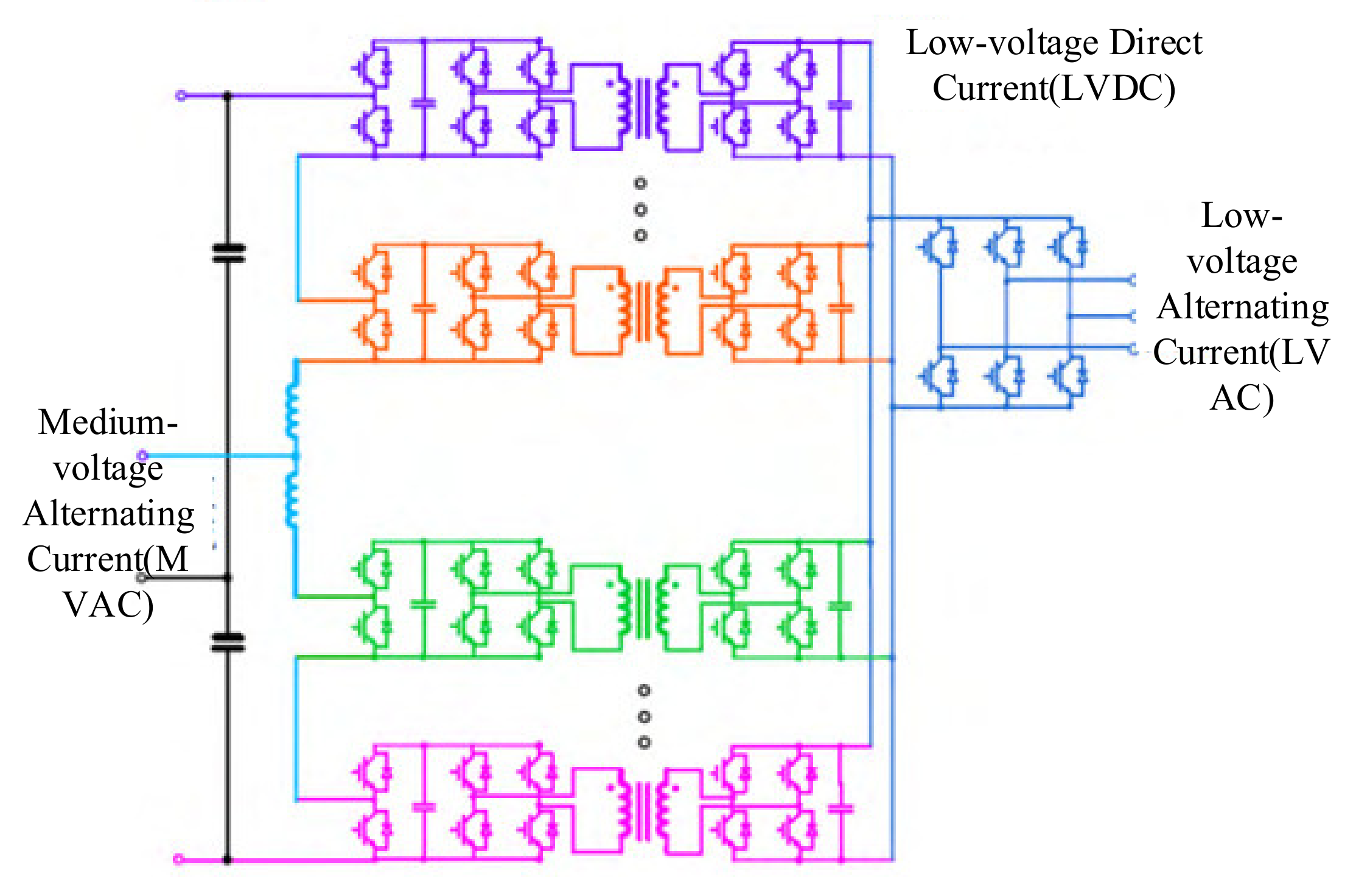

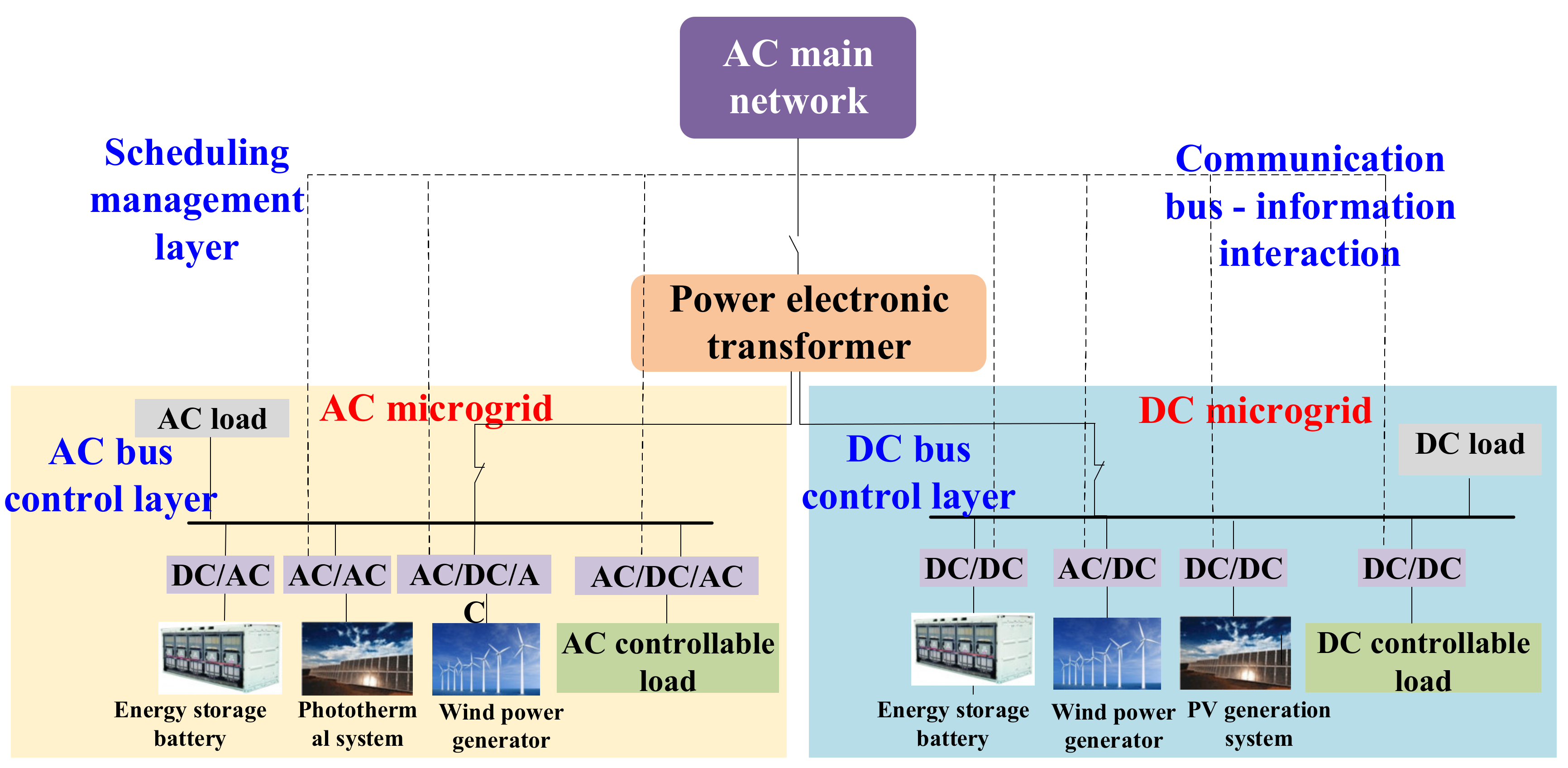

2. AC/DC Hybrid Distribution Network

2.1. Topology

2.2. Control Structure

3. Scheduling Management

3.1. The Objective Function

3.1.1. Distributed Generation Operating Cost

3.1.2. Photothermal System Operating Cost

3.1.3. Power Purchase Cost

3.1.4. Compensation Cost of Controllable Load

3.2. Constraints

3.2.1. Power Balance Constraints

3.2.2. Exchange Power Constraints

3.2.3. Photovoltaic Power Constraints

3.2.4. Wind Power Constraints

3.2.5. Storage System Constraints

3.2.6. Solar Thermal System Power Constraints

3.2.7. Reducible Load Constraints

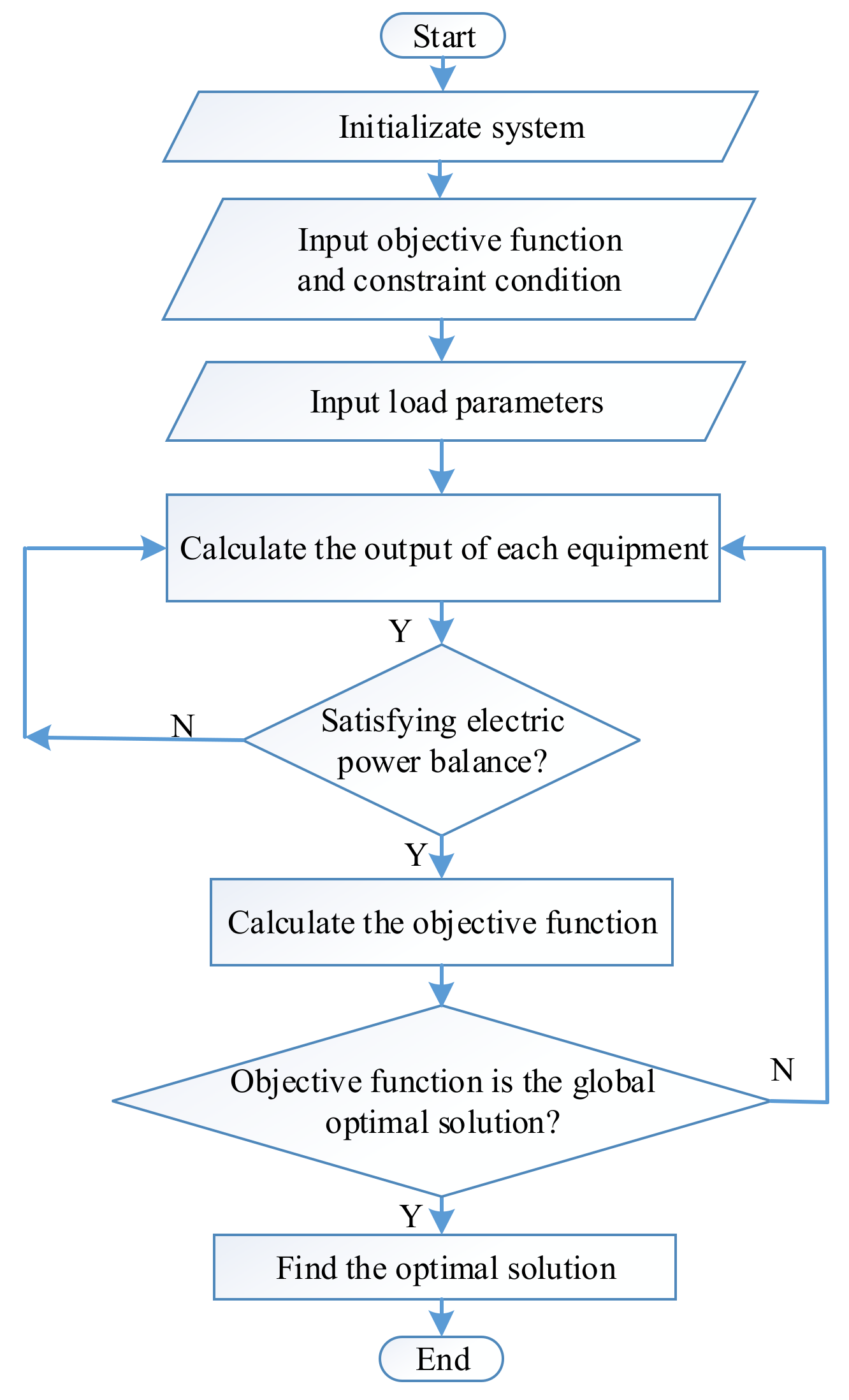

3.3. Control Structure

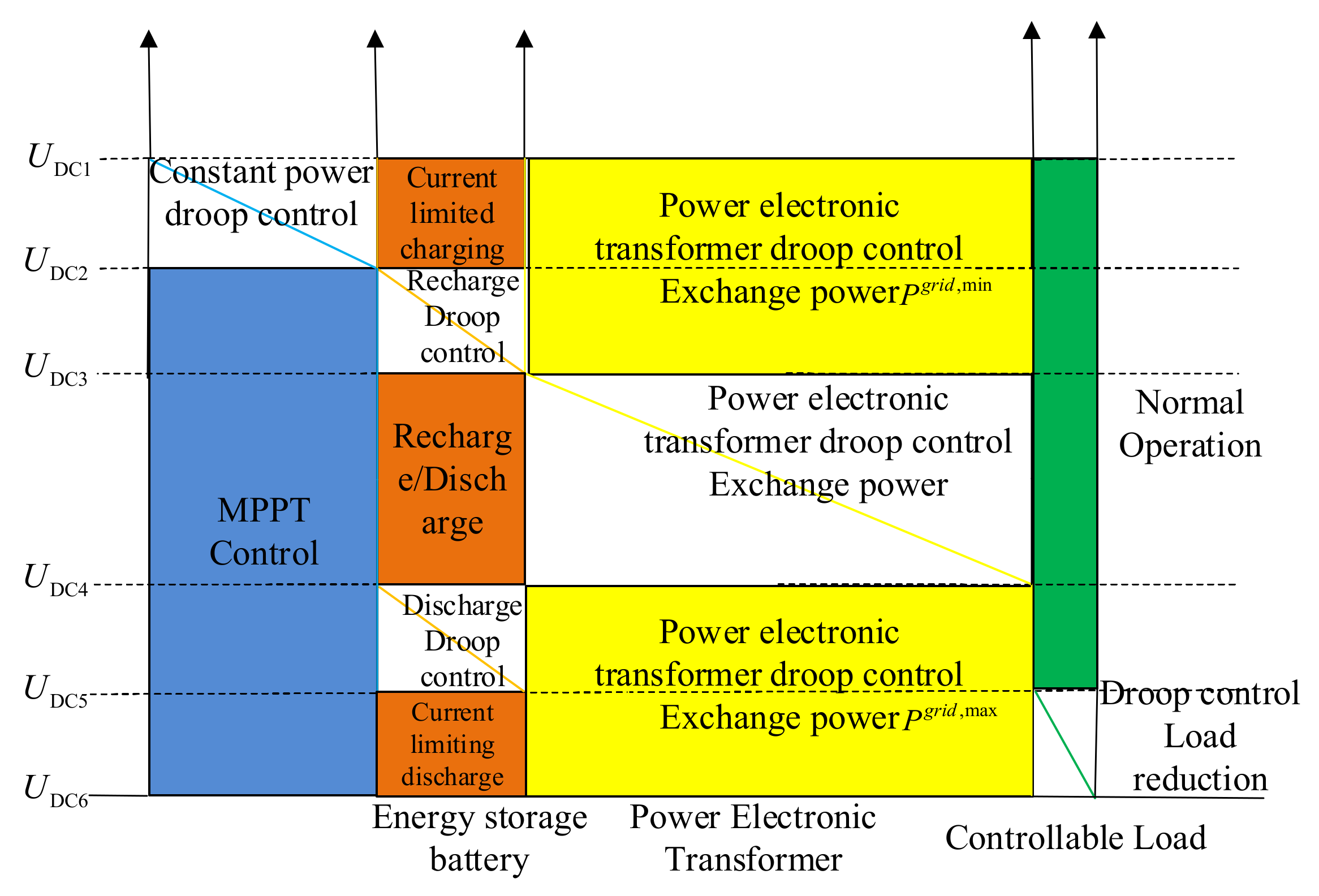

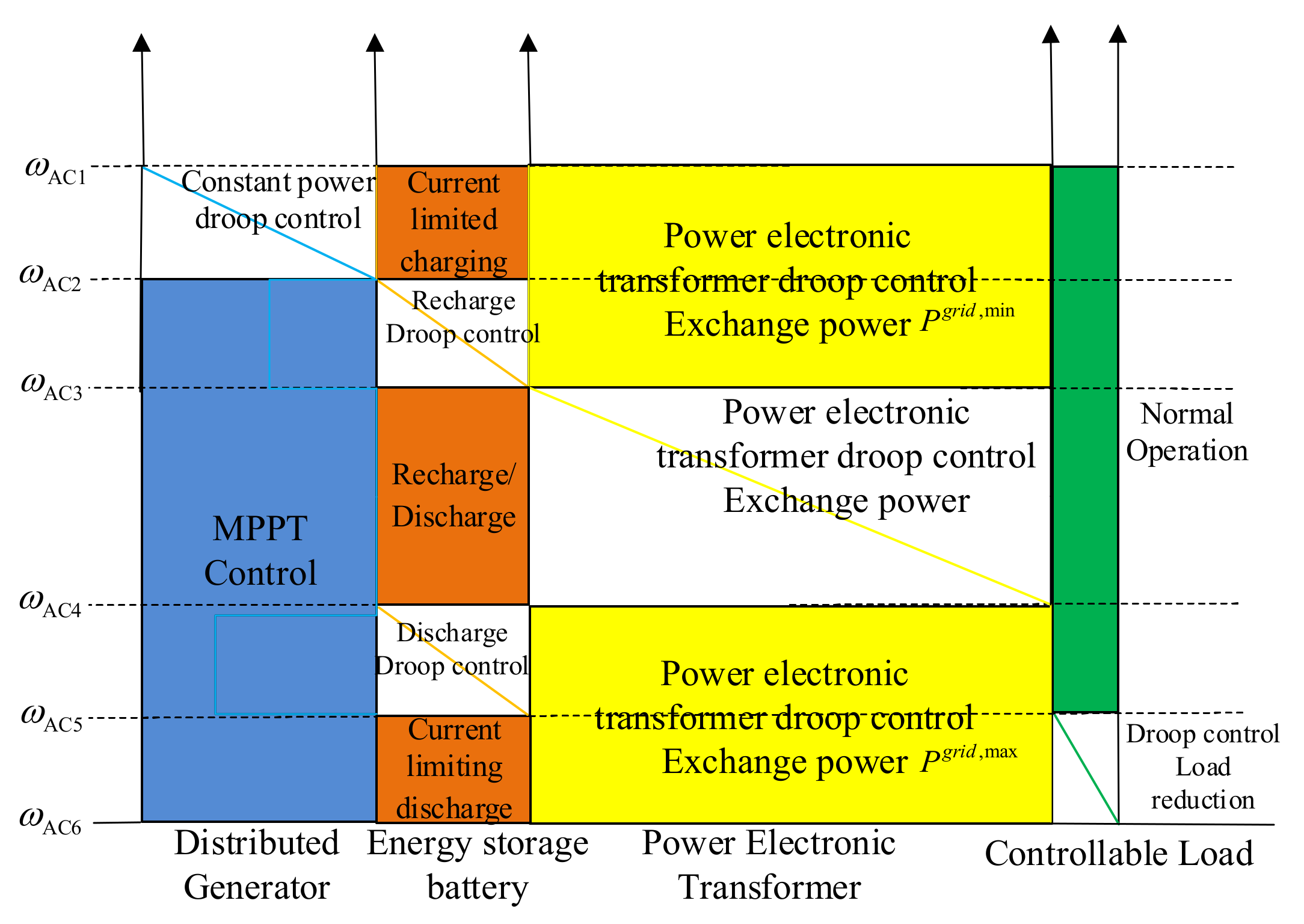

4. Bus Control

4.1. DC Microgrid

4.2. AC Microgrid

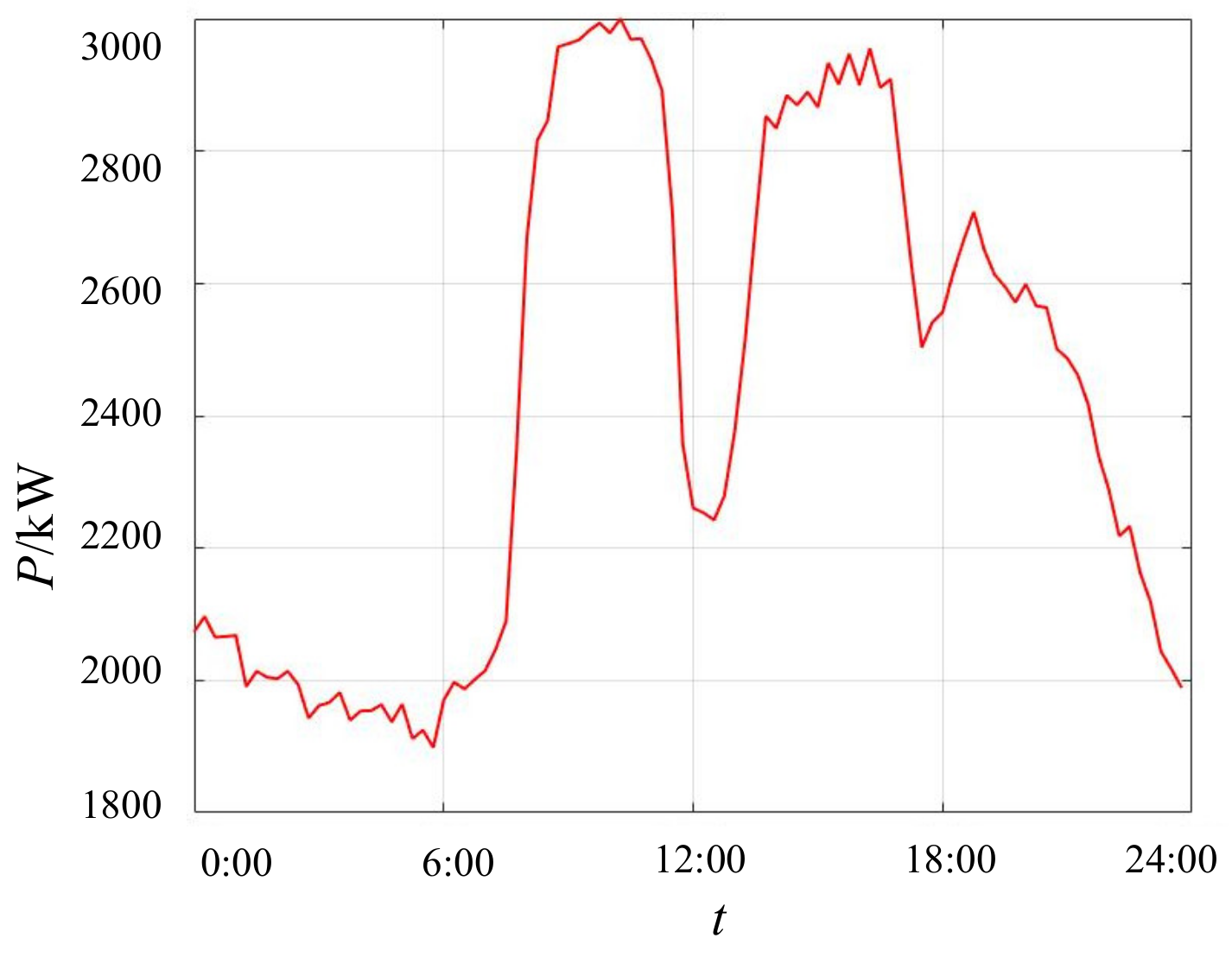

5. Case Analysis

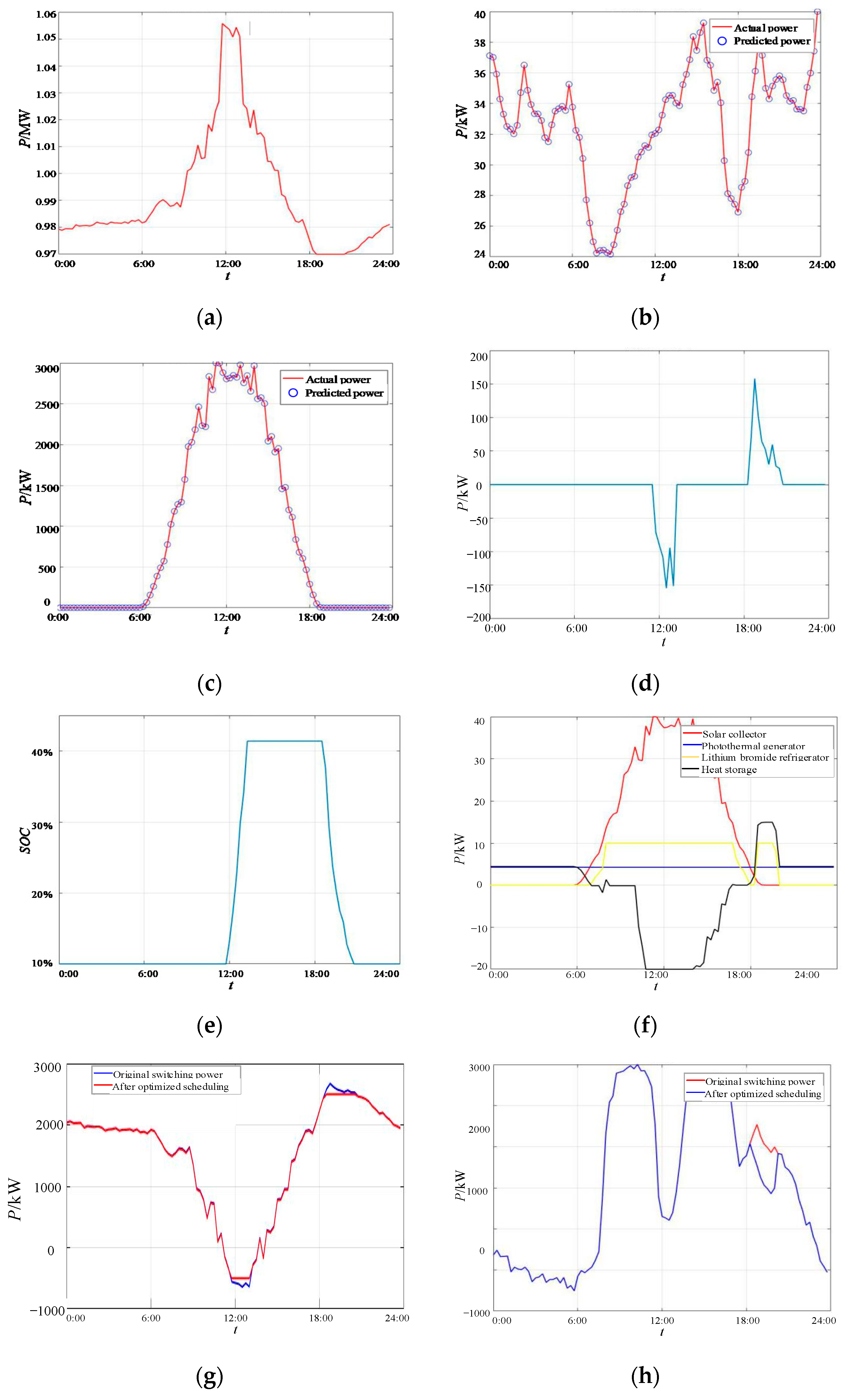

5.1. System Configuration

5.2. Case Solving

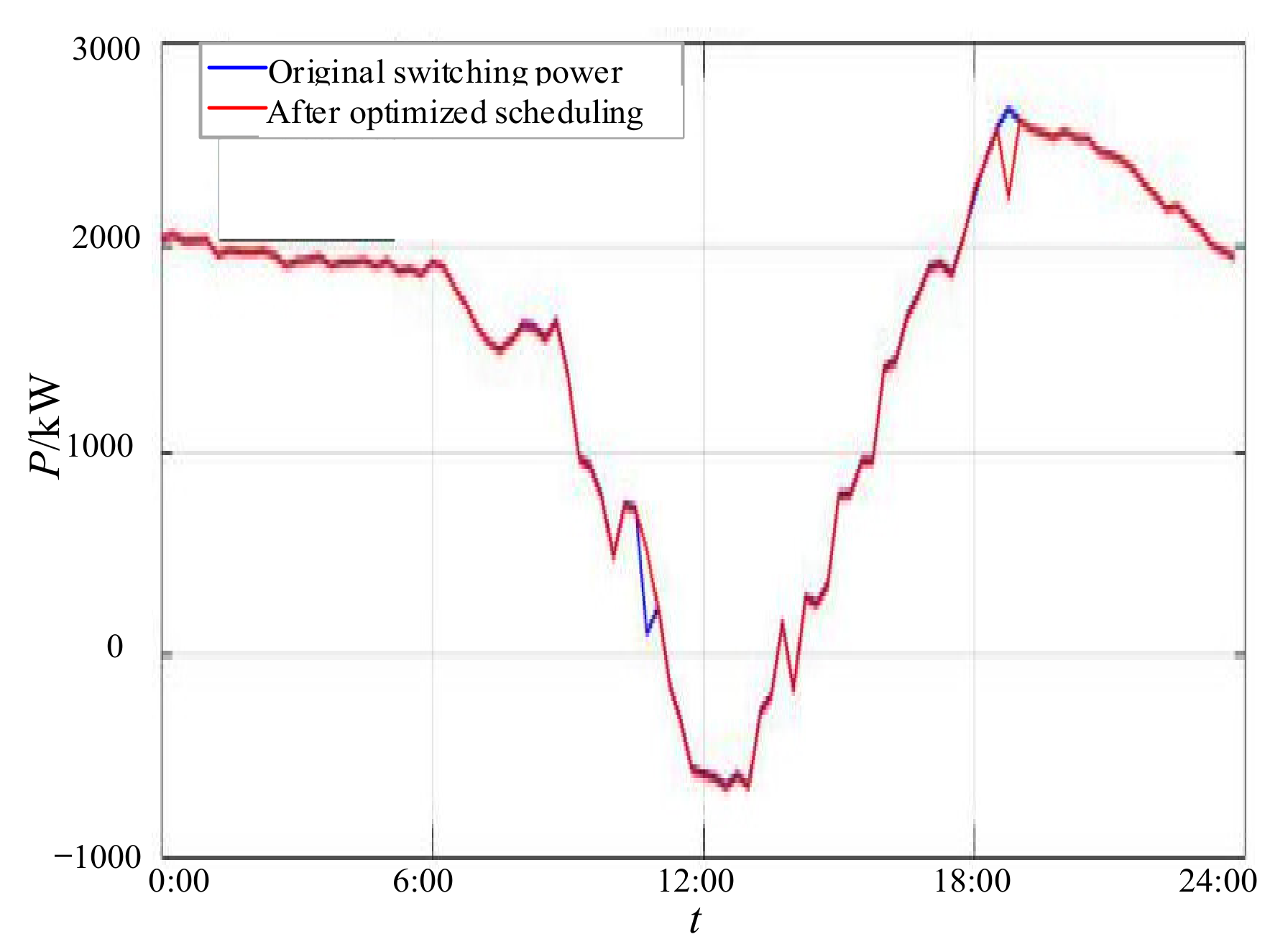

5.3. Result Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Baran, M.E.; Mahajan, N.R. DC distribution for industrial systems: Opportunities and challenges. IEEE Trans. Ind. Appl. 2003, 39, 1596–1601. [Google Scholar] [CrossRef]

- Riccobono, A.; Santi, E. Comprehensive review of stability criteria for DC power distribution systems. IEEE Trans. Ind. Appl. 2014, 50, 3525–3535. [Google Scholar] [CrossRef]

- Suryanarayana, H.; Sudhoff, S.D. Design paradigm for power electronics-based DC distribution systems. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 5, 51–63. [Google Scholar] [CrossRef]

- Qu, L.; Yu, Z.; Song, Q.; Yuan, Z.; Zhao, B.; Yao, D.; Chen, J.; Liu, Y.; Zeng, R. Planning and analysis of the demonstration project of the MVDC distribution network in Zhuhai. Front. Energy 2019, 13, 120–130. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Qu, L.; Yu, Z.; Nie, Z.; Zeng, R. Research on Access Mode of the Flexible DC Power Distribution System into AC System. Energies 2019, 12, 20. [Google Scholar]

- Kanchev, H.; Lu, D.; Colas, F.; Lazarov, V.; Francois, B. Energy Management and Operational Planning of a Microgrid with a PV-Based Active Generator for Smart Grid Applications. IEEE Trans. Ind. Electron. 2011, 58, 4583–4592. [Google Scholar] [CrossRef] [Green Version]

- Sechilariu, M.; Wang, B.; Locment, F. Building Integrated Photovoltaic System with Energy Storage and Smart Grid Communication. IEEE Trans. Ind. Electron. 2013, 60, 1607–1618. [Google Scholar] [CrossRef]

- Schonberger, J.; Duke, R.; Round, S.D. DC-Bus Signaling: A Distributed Control Strategy for a Hybrid Renewable Nano grid. IEEE Trans. Ind. Electron. 2006, 53, 1453–1460. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, L.; Xing, Y.; Guerrero, J.M. A Distributed Control Strategy Based on DC Bus Signaling for Modular Photovoltaic Generation Systems with Battery Energy Storage. IEEE Trans. Power Electron. 2011, 26, 3032–3045. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.F.; Setyawan, L.; Wang, P.; Jin, C. Power-Capacity-Based Bus-Voltage Region Partition and Online Droop7, Coefficient Tuning for Real-Time Operation of DC Microgrids. IEEE Trans. Energy Convers. 2015, 30, 1338–1347. [Google Scholar] [CrossRef]

- Zhen, L.I.; Wanxing, S.; Qing, D. Coordinated control strategy of AC/DC hybrid power router based on voltage stabilization by energy storage. Autom. Electr. Power Syst. 2019, 43, 121–134. [Google Scholar]

- Li, Y.; Wang, L.; Huang, H.; Zhang, H. Coordinated Control Strategy for DC Bus of Energy Storage System without Communication Interconnection Line. Autom. Electr. Power Syst. 2018, 42, 118–124. [Google Scholar]

- Jin, C.; Wang, P.; Xiao, J.; Tang, Y.; Choo, F.H. Implementation of Hierarchical Control in DC Microgrids. IEEE Trans. Ind. Electron. 2014, 61, 4032–4042. [Google Scholar] [CrossRef]

- Xia, Y.; Yu, M.; Yang, P.; Peng, Y.; Wei, W. Generation-storage coordination for islanded DC microgrids dominated by PV generators. IEEE Trans. Energy Convers. 2018, 34, 130–138. [Google Scholar] [CrossRef]

- Gao, F.; Kang, R.; Cao, J.; Yang, T. Primary and Secondary Control in DC Microgrids: A Review. J. Mod. Power Syst. Clean Energy 2019, 7, 227–242. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Fan, C.; Huang, N.; Zhu, Y.; He, M. A Fault Location Method for DC Lines Connected With DAB Terminal in Power Electronic Transformer. IEEE Trans. Power Del. 2018, 34, 301–311. [Google Scholar] [CrossRef]

- Hooshmand, R.A.; Ataei, M.; Rezaei, M.H. Improving the Dynamic Performance of Distribution Electronic Power Transformers Using Sliding Mode Contro. J. Power Electron. 2012, 12, 145–156. [Google Scholar] [CrossRef] [Green Version]

- Briz, F.; Lopez, M.; Rodriguez, A.; Arias, M. Modular Power Electronic Transformers: Modular Multilevel Converter Versus Cascaded H-Bridge Solutions. IEEE Ind. Electron. Mag. 2016, 10, 6–19. [Google Scholar] [CrossRef]

- Xu, J.; Gao, C.; Ding, J.; Shi, X.; Feng, M.; Zhao, C.; Ding, H. High-speed Electromagnetic Transient (EMT) Equivalent Modelling of Power Electronic Transformer. IEEE Trans. Power Deliv. 2020, 36, 975–986. [Google Scholar] [CrossRef]

- Chen, X.; Wang, C.; Wu, Q.; Dong, X.; Yang, M.; He, S.; Liang, J. Optimal operation of integrated energy system considering dynamic heat-gas characteristics and uncertain wind power. Energy 2020, 198, 117270. [Google Scholar] [CrossRef]

- Chen, H.; Chen, S.; Li, M.; Chen, J. Optimal Operation of Integrated Energy System Based on Exergy Analysis and Adaptive Genetic Algorithm. IEEE Access 2020, 8, 158752–158764. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z.; Wang, N.; Yang, W.; Li, M.; Zhou, X.; Yin, Y.; Wang, J.; Guo, T. Stochastic robust optimal operation of community integrated energy system based on integrated demand response. Int. J. Electr. Power Energy Syst. 2021, 128, 106735. [Google Scholar] [CrossRef]

| Control Mode | Distributed Power Converter | Storage Power Converter | Power Electronic Transformer | Reducible Load Converter |

|---|---|---|---|---|

| 1 | Droop control | Charging | Limit exchange power | Normal operation |

| 2 | MPPT | Charging under droop | Limit exchange power | Normal operation |

| 3 | MPPT | Charging/discharging | Droop control exchange power | Normal operation |

| 4 | MPPT | Charging under droop | Limit exchange power | Normal operation |

| 5 | MPPT | Discharging | Limit exchange power | Droop control |

| Type of Distributed Power | Capacity (kW) | Rated Power (kW) | Service Life (year) | Investment Cost (RMB/kWh) | Operation Cost (RMB/kWh) | Annual Utilization Hours (h) | Depreciation Rate (%) |

|---|---|---|---|---|---|---|---|

| Photovoltaic | 2000 | 1500 | 25 | 6,000,000 | 0.015 | 2000 | 8 |

| Wind power | 40 | 30 | 20 | 144,000 | 0.005 | 1800 | 8 |

| Storage | 500 | 400 | 15 | 1,502,500 | 0.0013 | 8760 | 8 |

| Solar collector | 100 | 80 | 20 | 320,000 | 0.017 | 6000 | 8 |

| Solar collector | 5 | 4 | 15 | 20,000 | 0.003 | 6000 | 8 |

| Lithium absorption chiller | 10 | 8 | 20 | 60,000 | 0.001 | 6000 | 8 |

| Thermal storage | 20 | 16 | 20 | 100,000 | 0.001 | 8760 | 8 |

| Storage power | Total battery limit: 500 kWh Charging/discharging efficiency: 93.81% Power storage SOC: 5–95% Initial power storage: 50 kWh Maximum number of charging and discharging in the scheduling period: 1.5 times |

| Thermal storage | Total calories: 200 kWh Thermal storage SOC: 5–95% Thermal charging/discharging efficiency: 95% Thermal dissipation coefficient: 0.6% |

| Reducible Load | Unit compensation: 1.1 RMB/kWh Maximum power reduction: 200 kW Maximum sustainable time: 2 h Minimum duration: 0.5 h Reducible time: 18:00–23:00 Limit of reducible times: 2 times |

| Photothermal system | Ascent rate limit: 10 kW/h Downhill rate limit: −10 kW/h Maximum number of starts and stops: 4 times Minimum continuous running time: 3 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Q.; Qu, L.; Yuan, Z.; Wang, X.; Chen, Y.; Tian, B. Optimal Scheduling Strategy of AC/DC Hybrid Distribution Network Based on Power Electronic Transformer. Energies 2021, 14, 3219. https://doi.org/10.3390/en14113219

Peng Q, Qu L, Yuan Z, Wang X, Chen Y, Tian B. Optimal Scheduling Strategy of AC/DC Hybrid Distribution Network Based on Power Electronic Transformer. Energies. 2021; 14(11):3219. https://doi.org/10.3390/en14113219

Chicago/Turabian StylePeng, Qingwen, Lu Qu, Zhichang Yuan, Xiaorui Wang, Yukun Chen, and Baoye Tian. 2021. "Optimal Scheduling Strategy of AC/DC Hybrid Distribution Network Based on Power Electronic Transformer" Energies 14, no. 11: 3219. https://doi.org/10.3390/en14113219

APA StylePeng, Q., Qu, L., Yuan, Z., Wang, X., Chen, Y., & Tian, B. (2021). Optimal Scheduling Strategy of AC/DC Hybrid Distribution Network Based on Power Electronic Transformer. Energies, 14(11), 3219. https://doi.org/10.3390/en14113219