Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study

Abstract

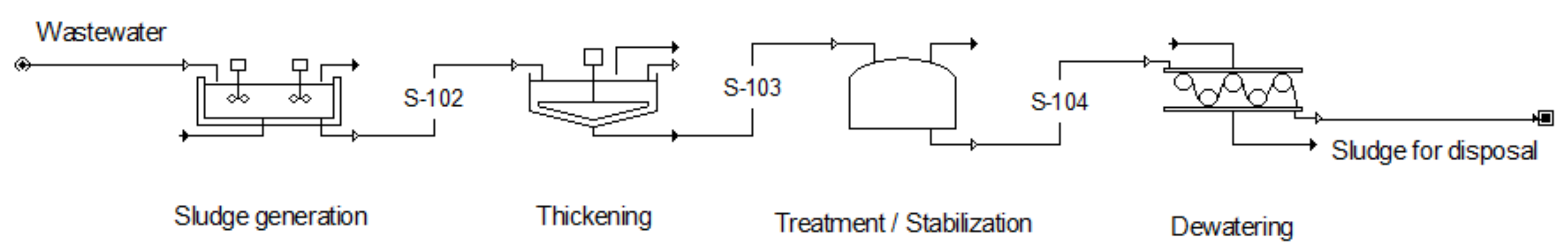

:1. Introduction

2. Sewage Sludge Management in Scandinavia

2.1. Denmark

2.2. Norway

2.3. Sweden

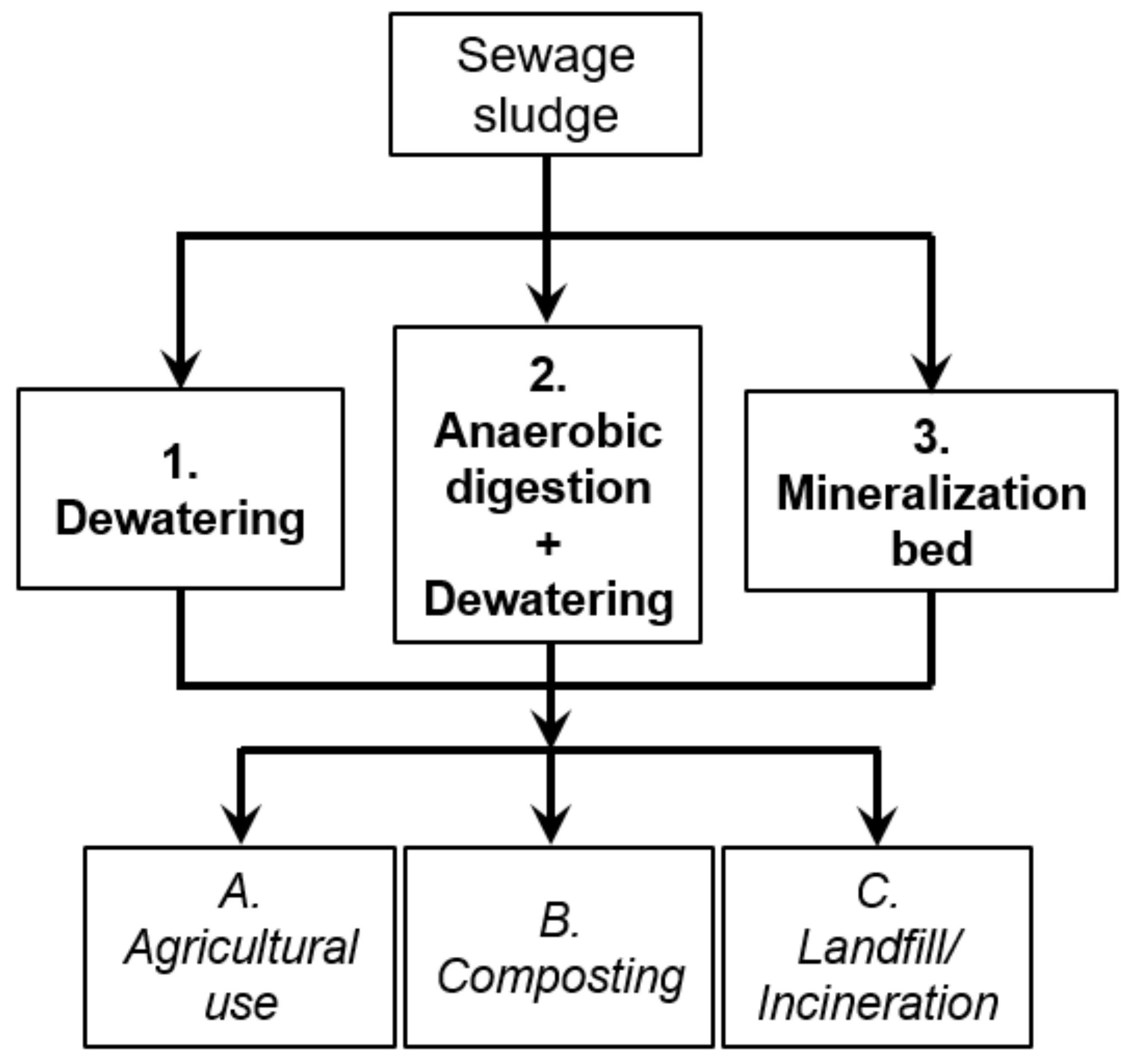

2.4. Comparison of Sludge Management and Quality

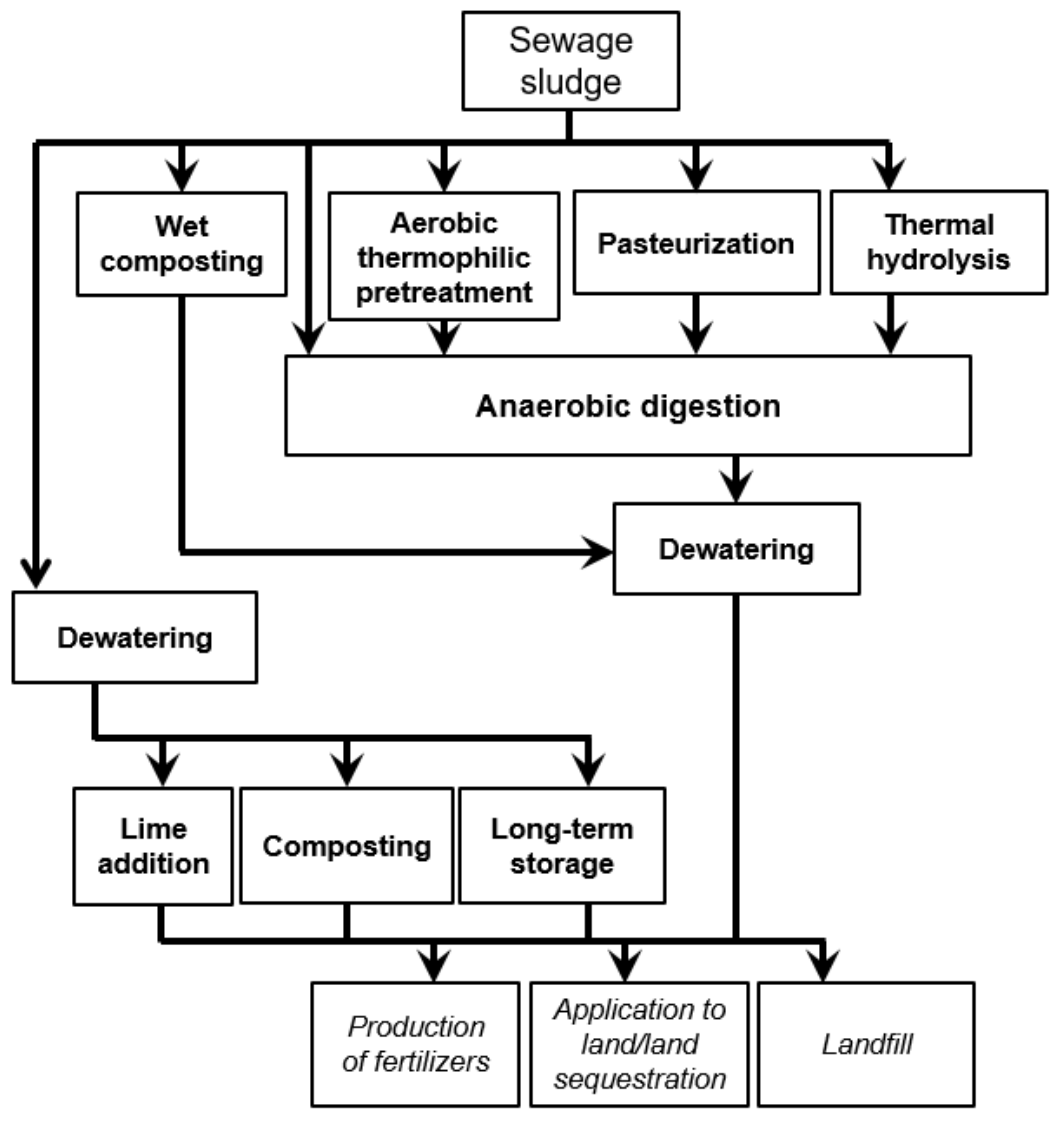

2.5. Environmental and Economic Aspects of Sludge Management in a Circular Bioeconomy

3. Other Representative Organic Wastes in Scandinavia

3.1. Denmark

3.2. Norway

3.3. Sweden

4. Co-Digestion Concepts of Organic Wastes for Higher Energy Yields and Production of Green Chemicals

4.1. Billund Vand, Denmark. Co-Digestion of Sewage Sludge with OFMSW and Organic Industrial Waste

4.2. IVAR, Norway. Co-Digestion of Sewage Sludge with Fish Sludge

4.3. Gryaab, Sweden. Co-Digestion of Sewage Sludge with Grease and Food Waste

4.4. Advanced Biorefinery Scenarios for Wastewater Treatment and Resource Recovery

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| DM | Dry matter |

| EBPR | Enhanced biological phosphorus removal |

| EC | European Commission |

| EU | European Union |

| LCA | Life cycle assessment |

| MBBR | Moving bed biofilm reactor |

| OFMSW | Organic fraction of municipal solid waste |

| OIW | Organic industrial waste |

| STBR | Sludge treatment reed beds |

| VS | Volatile solids |

| WAS | Waste activated sludge |

| WRRF | Wastewater resource recovery facility |

| WWBR | Wastewater biorefinery |

| WWTP | Wastewater treatment plant |

References

- Holmgren, K.E.; Li, H.; Verstraete, W.; Cornel, P. State of the Art Compendium Report on Resource Recovery from Water; International Water Association (IWA): London, UK, 2016. [Google Scholar]

- Pott, R.; Johnstone-Robertson, M.; Verster, B.; Rumjeet, S.; Nkadimeng, L.; Raper, T.; Rademeyer, S.; Harrison, S.T.L. Wastewater biorefineries: Integrating water treatment and value recovery. In The Nexus: Energy, Environment and Climate Change; Leal Filho, W., Surroop, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 289–302. ISBN 9783319636122. [Google Scholar]

- Peccia, J.; Westerhoff, P. We should expect more out of our sewage sludge. Environ. Sci. Technol. 2015, 49, 8271–8276. [Google Scholar] [CrossRef] [PubMed]

- Healy, M.G.; Clarke, R.; Peyton, D.; Cummins, E.; Moynihan, E.L.; Martins, A.; Béraud, P.; Fenton, O. Resource recovery from sewage sludge. In Sewage Treatment Plants: Economic Evaluation of Innovative Technologies for Energy Efficiency; Stamatelatou, K., Tsagarakis, K.P., Eds.; IWA Publishing: London, UK, 2015; pp. 139–162. ISBN 9781780405025. [Google Scholar]

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage sludge management in Europe: A critical analysis of data quality. Int. J. Environ. Waste Manag. 2016, 18, 226–238. [Google Scholar] [CrossRef]

- European Commission. Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land—Final Report—Part I: Overview Report. Available online: https://ec.europa.eu/environment/archives/waste/sludge/pdf/part_i_report.pdf (accessed on 21 September 2019).

- European Commission. Council Directive of 21 May 1991 concerning urban waste water treatment (91/271/EEC). Off. J. Eur. Commun. 1991, L135, 40–52. [Google Scholar]

- European Commission. Council Directive of 12 June 1986 on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture (86/278/EEC). Off. J. Eur. Commun. 1986, L181, 6–12. [Google Scholar]

- EurEau. Europe’s Water in Figures: An Overview of the European Drinking Water and Waste Water Sectors, 2017 ed.; The European Federation of National Associations of Water Services: Brussels, Belgium, 2017. [Google Scholar]

- European Commission. Urban Waste Water Treatment Directive: Dissemination Platform. Available online: https://uwwtd.eu/ (accessed on 7 July 2020).

- Olkiewicz, M.; Torres, C.M.; Jiménez, L.; Font, J.; Bengoa, C. Scale-up and economic analysis of biodiesel production from municipal primary sewage sludge. Bioresour. Technol. 2016, 214, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Brar, S.K.; Verma, M.; Tyagi, R.D.; Valéro, J.R.; Surampalli, R.Y. Entomotoxicity, protease and chitinase activity of Bacillus thuringiensis fermented wastewater sludge with a high solids content. Bioresour. Technol. 2009, 100, 4317–4325. [Google Scholar] [CrossRef] [PubMed]

- Crutchik, D.; Franchi, O.; Caminos, L.; Jeison, D.; Belmonte, M.; Pedrouso, A.; Val del Rio, A.; Mosquera-Corral, A.; Campos, J. Polyhydroxyalkanoates (PHAs) production: A feasible economic option for the treatment of sewage sludge in municipal wastewater treatment plants? Water 2020, 12, 1118. [Google Scholar] [CrossRef]

- Luo, K.; Pang, Y.; Yang, Q.; Wang, D.; Li, X.; Lei, M.; Huang, Q. A critical review of volatile fatty acids produced from waste activated sludge: Enhanced strategies and its applications. Environ. Sci. Pollut. Res. 2019, 26, 13984–13998. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.; Wickham, R.; Nghiem, L.D. Synergistic effect from anaerobic co-digestion of sewage sludge and organic wastes. Int. Biodeterior. Biodegrad. 2017, 116, 191–197. [Google Scholar] [CrossRef]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W.C. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef] [PubMed]

- Coma, M.; Martinez-Hernandez, E.; Abeln, F.; Raikova, S.; Donnelly, J.; Arnot, T.C.; Allen, M.J.; Hong, D.D.; Chuck, C.J. Organic waste as a sustainable feedstock for platform chemicals. Faraday Discuss. 2017, 202, 175–195. [Google Scholar] [CrossRef] [Green Version]

- Sovacool, B.K. Contestation, contingency, and justice in the Nordic low-carbon energy transition. Energy Policy 2017, 102, 569–582. [Google Scholar] [CrossRef]

- Kofoed-Wiuff, A.; Dyhr-Mikkelsen, K.; Rueskov, I.S.; Pasquali, A.; Brunak, K.; Bröckl, M.; Hagström, M. Progress towards Nordic Carbon Neutrality: Tracking Nordic Clean Energy Progress 2020; Nordic Energy Research: Oslo, Norway, 2020. [Google Scholar]

- Banerjee, A.; Bhaskar, T.; Ghosh, D. A biorefinery approach for sewage sludge. In Waste Biorefinery: Integrating Biorefineries for Waste Valorization; Bhaskar, T., Pandey, A., Rene, E.R., Tsang, D.C.W., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 393–421. ISBN 9780128182284. [Google Scholar]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Spinosa, L.; Leschber, R.; Wichmann, K. Sewage sludge co-management: Developments in EU regulations and characterization procedures. Water Pract. Technol. 2007, 2. [Google Scholar] [CrossRef]

- Kirchmann, H.; Börjesson, G.; Kätterer, T.; Cohen, Y. From agricultural use of sewage sludge to nutrient extraction: A soil science outlook. Ambio 2017, 46, 143–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shaddel, S.; Bakhtiary-Davijany, H.; Kabbe, C.; Dadgar, F.; Østerhus, S. Sustainable sewage sludge management: From current practices to emerging nutrient recovery technologies. Sustainability 2019, 11, 3435. [Google Scholar] [CrossRef] [Green Version]

- Lam, K.L.; Zlatanović, L.; van der Hoek, J.P. Life cycle assessment of nutrient recycling from wastewater: A critical review. Water Res. 2020, 173, 115519. [Google Scholar] [CrossRef] [PubMed]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Sund Energy AS. Mapping Biogas in the Nordic Countries; Sund Energy AS: Oslo, Norway, 2010. [Google Scholar]

- Nybruket, S.; Paulsrud, B.; Nedland, K.T. Erfaringer Med Hygienisering av Slam i Norge; VA-FORSK RAPPORT Nr 32; VA-Forsk: Stockholm, Sweden, 2003. [Google Scholar]

- Mackenzie, L.D. Water and Wastewater Engineering. Design Principles and Practice; McGraw-Hill Companies, Inc.: New York, NY, USA, 2010; ISBN 978-0-07-171385-6. [Google Scholar]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

- Baresel, C.; Lüdtke, M.; Levlin, E.; Fortkamp, U.; Ekengren, Ö. Slamavvattning i Kommunala Reningsverk—Nuläget, Begråansningar och Perspektiv (IVL Rapport B2188); IVL: Stockholm, Sweden, 2014. [Google Scholar]

- Svenskt Vatten. Slamanvändning och Strategier för Slamanvändning (Meddelande M137); Svensk Vatten AB: Stockholm, Sweden, 2013. [Google Scholar]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Chen, P.; Xie, Q.; Addy, M.; Zhou, W.; Liu, Y.; Wang, Y.; Cheng, Y.; Li, K.; Ruan, R. Utilization of municipal solid and liquid wastes for bioenergy and bioproducts production. Bioresour. Technol. 2016, 215, 163–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kehrein, P.; van Loosdrecht, M.; Osseweijer, P.; Garfí, M.; Dewulf, J.; Posada, J. A critical review of resource recovery from municipal wastewater treatment plants—Market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 2020, 6, 877–910. [Google Scholar] [CrossRef] [Green Version]

- Callegari, A.; Capodaglio, A.G. Properties and beneficial uses of (bio)chars, with special attention to products from sewage sludge pyrolysis. Resources 2018, 7, 20. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.M.; Nesse, A.S.; Eich-Greatorex, S.; Sogn, T.A.; Aanrud, S.G.; Aasen Bunæs, J.A.; Lyche, J.L.; Kallenborn, R. Organic contaminants of emerging concern in Norwegian digestates from biogas production. Environ. Sci. Process. Impacts 2019, 21, 1498–1508. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Keller, A.S.; Jimenez-Martinez, J.; Mitrano, D.M. Transport of nano- and microplastic through unsaturated porous media from sewage sludge application. Environ. Sci. Technol. 2020, 54, 911–920. [Google Scholar] [CrossRef] [PubMed]

- Eggen, T.; Heimstad, E.S.; Nikiforov, V.; Vogelsang, C. Maximum Limit Values for Selected Hazardous Organic Contaminants (HOCs) in Secondary Raw Materials Used in Fertilisers and Soil Products (NIBIO Rapport 5/110/2019); Norsk Institut for Bioøkonomi (NIBIO): Ås, Norway, 2019. [Google Scholar]

- Díaz-Cruz, M.S.; García-Galán, M.J.; Guerra, P.; Jelic, A.; Postigo, C.; Eljarrat, E.; Farré, M.; López de Alda, M.J.; Petrovic, M.; Barceló, D. Analysis of selected emerging contaminants in sewage sludge. Trends Anal. Chem. 2009, 28, 1263–1275. [Google Scholar] [CrossRef]

- Papineschi, J.; Hoog, D.; Chowdhury, T.; Durrant, C.; Thomson, A. Analysis of Nordic Regulatory Framework and Its Effect on Waste Prevention and Recycling in the Region (2019:522); Nordic Council of Ministers, Ed.; Nordic Council of Ministers/Publication Unit: Copenhagen, Denmark, 2019; ISBN 9789289361033.

- Dansk Vand- og Spildevandsforening (DANVA). Water in Figures 2019, DANVA Statistics & Benchmarking. Available online: https://www.danva.dk/media/6355/2019_water-in-figures_web.pdf (accessed on 28 July 2020).

- Dansk Vand- og Spildevandsforening (DANVA). Water in Figures 2020, DANVA Statistics & Benchmarking. Available online: https://www.danva.dk/media/7251/2020_water-in-figures_web.pdf (accessed on 21 April 2021).

- Nielsen, S.; Larsen, J.D. Operational strategy, economic and environmental performance of sludge treatment reed bed systems—Based on 28 years of experience. Water Sci. Technol. 2016, 74, 1793–1799. [Google Scholar] [CrossRef] [PubMed]

- Brix, H. Sludge dewatering and mineralization in sludge treatment reed beds. Water 2017, 9, 160. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, S.; Bruun, E.W. Sludge quality after 10–20 years of treatment in reed bed systems. Environ. Sci. Pollut. Res. 2015, 22, 12885–12891. [Google Scholar] [CrossRef] [PubMed]

- Statistisk Sentralbyrå Norway (SSB). Land Use and Land Cover. Available online: https://www.ssb.no/en/natur-og-miljo/statistikker/arealstat (accessed on 10 May 2021).

- Berge, G.; Chaudhary, M. Kommunale Avløp 2017. Ressursinnsats, Utslipp, Rensing og Slamdisponering 2017. Gebyrer 2018 (Rapporter 2018/40); Statistisk Sentralbyrå: Oslo, Norway, 2018; ISBN 9788253798523. [Google Scholar]

- Paruch, A.M.; Mæhlum, T.; Obarska-Pempkowiak, H.; Gajewska, M.; Wojciechowska, E.; Ostojski, A. Rural domestic wastewater treatment in Norway and Poland: Experiences, cooperation and concepts on the improvement of constructed wetland technology. Water Sci. Technol. 2011, 63, 776–781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ødegaard, H.; Rusten, B.; Storhaug, R.; Paulsrud, B. Veiledning for Dimensjonering av Avløpsrenseanlegg (Rapportnr: 168/2009); Norsk Vann: Hamar, Norway, 2009. [Google Scholar]

- Norsk Institutt for Bioøkonomi (NIBIO). Available online: https://www.nibio.no/ (accessed on 30 July 2020).

- Landbruks- og matdepartementet. Forskrift om Gjødselvarer mv. av Organisk Opphav. 2003. Available online: https://lovdata.no/dokument/SF/forskrift/2003-07-04-951 (accessed on 30 July 2020).

- Landbruks- og matdepartementet. Forskrift om Endring i Forskrift om Gjødselvarer mv. av Organisk Opphav (Avløpsslambasert Gjødsel Med Særskilte Bruksvilkår). 2019. Available online: https://lovdata.no/dokument/LTI/forskrift/2019-01-30-58 (accessed on 30 July 2020).

- Statistics Sweden (SCB). Production and Use of Sewage Sludge from Municipal Waste Water Treatment Plants by County and Use Category. Every Other Year 2014–2018. Available online: http://www.statistikdatabasen.scb.se/pxweb/en/ssd/START__MI__MI0106/MI0106T03/ (accessed on 16 September 2020).

- Åkerblom, A.; Lüdtke, M.; Lans, N.; Linderholm, L.; Johansson, E.; Unger, M.L.; Gunnarsson, Å.; Dimberg, A.; Åkerblom, S. Wastewater Treatment in Sweden 2018; Swedish Environmental Protection Agency: Stockholm, Sweden, 2020; ISBN 978-91-620-8867-5. [Google Scholar]

- Jarvis, A. Biogas ur Gödsel, Avfall och Restprodukter—Goda Svenska Exempel; Swedish Environmental Protection Agency: Stockholm, Sweden, 2012; ISBN 9789162065188. [Google Scholar]

- Valderrama, C.; Granados, R.; Cortina, J.L. Stabilisation of dewatered domestic sewage sludge by lime addition as raw material for the cement industry: Understanding process and reactor performance. Chem. Eng. J. 2013, 232, 458–467. [Google Scholar] [CrossRef]

- Ekane, N.; Barquet, K.; Rosemarin, A. Resources and risks: Perceptions on the application of sewage sludge on agricultural land in Sweden, a case study. Front. Sustain. Food Syst. 2021, 5, 647780. [Google Scholar] [CrossRef]

- Miljö- och energidepartementet. Kommittédirektiv. Giftfri och Cirkulär Återföring av Fosfor Från Avloppsslam (Dir. 2018:67; Stockholm, 2018. Available online: https://www.regeringen.se/rattsliga-dokument/kommittedirektiv/2018/07/dir.-201867/ (accessed on 19 August 2020).

- European Commission. European Commission Urban Waste Water Website: Denmark. Graphs for National Stats. Available online: https://uwwtd.eu/Denmark/stats/graphs (accessed on 7 July 2020).

- Statistisk Sentralbyrå Norway (SSB). Discharges and treatment of municipal waste water 05279: Disposal of sewage slugde (C) 2002–2018. Available online: https://www.ssb.no/en/statbank/table/05279 (accessed on 16 September 2020).

- Statistics Denmark. Waste Generation by Industry, Kind of Treatment and Waste Category. Available online: https://www.statbank.dk/statbank5a/SelectVarVal/Define.asp?MainTable=AFFALD&PLanguage=1&PXSId=0&wsid=cftree (accessed on 10 May 2021).

- DAKOFA. Waste and Resources Network Denmark Incineration in Denmark. Available online: https://dakofa.com/element/incineration-in-denmark/ (accessed on 10 May 2021).

- Frijns, J.; Hofman, J.; Nederlof, M. The potential of (waste)water as energy carrier. Energy Convers. Manag. 2013, 65, 357–363. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives (Text with EEA relevance). Off. J. Eur. Union 2008, L312, 3–30. [Google Scholar]

- European Commission. Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste. Off. J. Eur. Communities 1999, L182. [Google Scholar] [CrossRef]

- Thomsen, M. Wastewater Treatment and Discharge; Scientific Report from DCE—Danish Centre for Environment and Energy (no. 193); Aarhus University, DCE—Danish Centre for Environment and Energy: Aarhus, Denmark, 2016. [Google Scholar]

- BIOFOS. Miljøberetning 2019. 2019. Available online: https://biofos.dk/wwwroot/media/1430/publiceret-miljoeberetning_2019-d20-354027-10.pdf (accessed on 19 August 2020).

- Danish Ministry of Environment and Food. Bekendtgørelse om anvendelse af affald til jordbrugsformål. In Miljø- og Fødevaremin., j. nr. 2018-6950; Danish Ministry of Environment and Food: Copenhagen, Denmark, 2018. [Google Scholar]

- Statistisk Sentralbyrå Norway (SSB). Discharges and Treatment of Municipal Waste Water 05314: Heavy Metals in Sewage Sludge (mg/kg Dry Weight) 1993–2019. Available online: https://www.ssb.no/en/statbank/table/05314/ (accessed on 16 September 2020).

- Werther, I.L.; Petersen, P.H. Nabotjek af Reglerne om Spildevandsslam: Sverige, Norge, Finland, Tyskland og England (Miljøprojekt nr. 1989); Miljøstyrelsen: København, Denmark, 2018; ISBN 9788793614833. [Google Scholar]

- Statistics Sweden (SCB). Concentrations of Nutrients, Metals and Organic Indicator Substances in Sludge from Municipal Wastewater Treatment Plants. Every Other Year 2014–2018. Available online: http://www.statistikdatabasen.scb.se/pxweb/en/ssd/START__MI__MI0106/MI0106T05/ (accessed on 7 July 2020).

- European Commission. Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulation (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003 (Text with EEA relevance). Off. J. Eur. Union 2019, L170, 1–114. [Google Scholar]

- EasyMining Ash2Phos. Available online: https://www.easymining.se/technologies/ash2phos (accessed on 11 May 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Towards a Circular Economy: A zero waste programme for Europe 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52014DC0398 (accessed on 17 December 2020).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Closing the loop—An EU action plan for the Circular Economy 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 18 December 2020).

- Yoshida, H.; Christensen, T.H.; Scheutz, C. Life cycle assessment of sewage sludge management: A review. Waste Manag. Res. J. A Sustain. Circ. Econ. 2013, 31, 1083–1101. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Pawłowski, A. Life cycle assessment of two emerging sewage sludge-to-energy systems: Evaluating energy and greenhouse gas emissions implications. Bioresour. Technol. 2013, 127, 81–91. [Google Scholar] [CrossRef]

- Samolada, M.C.; Zabaniotou, A.A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste Manag. 2014, 34, 411–420. [Google Scholar] [CrossRef]

- Gentil, E.C.; Damgaard, A.; Hauschild, M.; Finnveden, G.; Eriksson, O.; Thorneloe, S.; Kaplan, P.O.; Barlaz, M.; Muller, O.; Matsui, Y.; et al. Models for waste life cycle assessment: Review of technical assumptions. Waste Manag. 2010, 30, 2636–2648. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 amending Directive 2008/98/EC on waste (Text with EEA relevance). Off. J. Eur. Union 2018, L150, 109–140. [Google Scholar]

- European Commission. Communication from the Commission to the Council and the European Parliament on Future Steps in Bio-Waste Management in the European Union (COM(2010)235 Final). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52010DC0235 (accessed on 21 September 2019).

- European Environment Agency. Bio-Waste in Europe—Turning Challenges into Opportunities (EEA Report No 04/2020); Publications Office of the European Union: Luxembourg, 2020; ISBN 9789294802231. [Google Scholar]

- European Commission. Proposal for a Directive of the European Parliament and of the Council Amending Directives 2008/98/EC on Waste, 94/62/EC on Packaging and Packaging Waste, 1999/31/EC on the Landfill of Waste, 2000/53/EC on End-of-Life Vehicles, 2006/66/EC on Batteries and Accumulators and Waste Batteries and Accumulators, and 2012/19/EU on Waste Electrical and Electronic Equipment (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/DA/ALL/?uri=CELEX:52014SC0209 (accessed on 27 July 2020).

- European Commission. Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018 amending Directive 1999/31/EC on the landfill of waste (Text with EEA relevance). Off. J. Eur. Union 2018, L150, 100–108. [Google Scholar]

- Madsen, M.L.; Kiilerich, O.; Nissen, A.L.; Nissen, E.L. Affaldsstatistik 2018 (Miljøprojekt nr. 2133); Miljøstyrelsen: København, Denmark, 2020; ISBN 9788770381833. [Google Scholar]

- Miljøstyrelsen. Denmark without Waste: Recycle More—Incinerate Less; Miljøstyrelsen: København, Denmark, 2013. [Google Scholar]

- Damgaard, C.K.; Christensen, C.; Werther, I.; Christensen, L.H.; Nyegaard, R. Organisk Affald fra Servicesektoren: Samfundsøkonomisk Vurdering af Øget Genanvendelse (Miljøprojekt nr. 2070); Miljøstyrelsen: København, Denmark, 2019; ISBN 9788770380454. [Google Scholar]

- Foged, H.L. Livestock Manure to Energy: Status, Technologies and Innovation in Denmark; Agro Business Park: Tjele, Denmark, 2012. [Google Scholar]

- Statistisk Sentralbyrå Norway (SSB). Waste from Households—Household Waste by Material. Available online: https://www.ssb.no/en/natur-og-miljo/statistikker/avfkomm (accessed on 16 September 2020).

- Norwegian Directorate of Fisheries Aquaculture Statistics: Total Sale 1998–2019. Available online: https://www.fiskeridir.no/English/Aquaculture/Statistics/Total (accessed on 3 August 2020).

- Torrissen, O.; Hansen, P.K.; Aure, J.; Husa, V.; Andersen, S.; Strohmeier, T.; Olsen, R.E. Næringsutslipp fra Havbruk—Nasjonale og Regionale Perspektiv. (Rapport fra Havforskningen nr 21-2016); Havforskningsinstituttet: Bergen, Norway, 2016. [Google Scholar]

- Bjørndal, T.; Holte, E.A.; Hilmarsen, Ø.; Tusvik, A. Analyse av Lukka Oppdrett av Laks—Landbaseret og i sjø: Produksjon, Økonomi og Risiko (Sluttrapport FHF Prosjekt 901442); The Norwegian Seafood Research Fund (FHF): Oslo, Norway, 2018. [Google Scholar]

- Estevez, M.M.; Sapci, Z.; Linjordet, R.; Morken, J. Incorporation of fish by-product into the semi-continuous anaerobic co-digestion of pre-treated lignocellulose and cow manure, with recovery of digestate’s nutrients. Renew. Energy 2014, 66, 550–558. [Google Scholar] [CrossRef]

- Avfall Sverige. Svensk Avfallshantering 2019; Avfall Sverige: Malmö, Sweden, 2020. [Google Scholar]

- BIOGÖDSEL. Certifierad Återvinning av Biogödsel. Available online: https://www.biogodsel.se/certifiering/ (accessed on 8 July 2020).

- Mata-Alvarez, J.; Dosta, J.; Macé, S.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011, 31, 99–111. [Google Scholar] [CrossRef] [PubMed]

- Avfall Norge. Status Biologisk Behandling 2019; Avfall Norge: Oslo, Norway, 2019. [Google Scholar]

- Wittrup, S. Billund Vand har lavet biogas af madaffald i 15 år. Ingeniøren. 2012. Available online: https://ing.dk/artikel/billund-vand-har-lavet-biogas-af-madaffald-i-15-ar-127927 (accessed on 8 September 2019).

- IVAR. Kort om IVAR. Available online: https://www.ivar.no/Omivar/ (accessed on 28 November 2019).

- Estevez, M.M.; Tomczak-wandzel, R.; Akervold, K.; Tornes, O. Co-digestion of waste from the salmon aquaculture sector with regional sewage sludge: Effects on methane yield and digestate nutrient content. Eco-Energetics Technol. Environ. Law Econ. 2019, 2, 29–34. [Google Scholar] [CrossRef]

- IVAR. Minorga Gjødselfabrikk. Available online: https://www.ivar.no/minorga/ (accessed on 28 November 2019).

- Nunes, J.; Lindqvist, P.; Tumlin, S.; Neth, M.; Lumley, D. Teknisk Beskrivning: Tillståndsansökan för Ryaverket; Gryaab AB: Göteborg, Sweden, 2017. [Google Scholar]

- Gryaab. Kort om Gryaab. Available online: https://www.gryaab.se/vad-vi-gor/kort-om-gryaab/ (accessed on 8 September 2019).

- SVENSKT VATTEN. Aktivt Uppströmsarbete Med Revaq-Certifiering. Available online: https://www.svensktvatten.se/vattentjanster/avlopp-och-miljo/kretslopp-och-uppstromsarbete/revaq-certifiering/ (accessed on 8 September 2019).

- VEOLIA. Exelys™ Continuous Thermal Hydrolysis. Available online: https://www.veoliawatertechnologies.com/en/products/exelys (accessed on 8 September 2019).

- Billund Vand & Energi. Et Fyrtårnsprojekt for Miljø og Eksport. Available online: https://www.billundvand.dk/bæredygtighed/billund-biorefinery/ (accessed on 11 May 2021).

- VEOLIA. ANITA™ Mox: The MBBR Solution for High Ammonia Waste. Available online: https://www.veoliawatertechnologies.com/en/technologies/anita-mox (accessed on 11 May 2021).

- Aarhus Vand. Aarhus ReWater—På Vej Mod Verdens Mest Effektive Ressourceanlæg. Available online: https://www.aarhusvand.dk/projekter/vores-losninger/aarhus-rewater/ (accessed on 11 May 2021).

- EnviDan. The Wastewater Treatment Plant of the Future Is Located in Egå. Available online: https://www.envidan.com/cases/expansion-of-egaa-wwtp (accessed on 11 May 2021).

- Salsnes Filter. Municipal Wastewater Treatment Applications. Available online: https://www.salsnes-filter.com/applications/municipal/ (accessed on 11 May 2021).

- World Water Works. DEMON® Anammox Treatment Technology. Available online: https://www.worldwaterworks.com/technologies/demon (accessed on 11 May 2021).

- EssDe. EssDe® in the Mainstream Plant. Available online: https://www.essde.com/en/essde/self-sufficient-wastewater-treatment-plant (accessed on 11 May 2021).

- Møller, F.B. The Energy Positive WWTP. Wastewater as a Major Challenge and a Great Opportunity. 2020. Available online: https://marmara.gov.tr/wp-content/uploads/2020/12/Flemming-B.-Moller.pdf (accessed on 15 May 2021).

- Aarhus Vand International. From Wastewater to Valuable Fertiliser. Available online: https://www.aarhusvand.dk/en/international/solutions/from-wastewater-to-valuable-fertiliser2/ (accessed on 11 May 2021).

- Cusidó, J.A.; Soriano, C. Valorization of pellets from municipal WWTP sludge in lightweight clay ceramics. Waste Manag. 2011, 31, 1372–1380. [Google Scholar] [CrossRef] [PubMed]

- Hias. The Hias® Process. Available online: https://www.hias.as/ (accessed on 11 May 2021).

- Olsen, T. Utvinner Fosfor fra Avløpsvann. Available online: https://www.vanytt.no/2017/12/27/utvinner-fosfor-fra-avlopsvann/ (accessed on 11 May 2021).

| DK [43] | NO [51] | SE [33] | |

|---|---|---|---|

| Treatment method | |||

| Dewatering | X | ||

| AD + Dewatering | X | X | X |

| Mineralization bed | X | ||

| AD + Mineralization bed | X | ||

| Dewatering + Lime addition | X | X | |

| Thermal treatment + AD | X | ||

| Disposal method | |||

| Agricultural use | X | X | X |

| Composting | X | X | |

| Landfill | X | X | X |

| Incineration | X | X | |

| Other | X |

| Units | DK [43,61] | NO [62] | SE [55] | EU [6,9] | |

|---|---|---|---|---|---|

| Generated sludge | Tons DM/year | 140,000 | 112,000 | 212,000 | 13,000,000 |

| Final destination | % | ||||

| Soil application | 64.9 | 82.4 | 64.5 | 61.6 | |

| Incineration | 28.2 | 0.6 | 1.3 | 24.9 | |

| Landfill | 0.8 | 6.3 | 18.2 | 8.7 | |

| Other | 6.1 | 10.7 | 16.0 | 4.9 |

| Compound | DK | NO | SE | EU | |||

|---|---|---|---|---|---|---|---|

| mg/kg DM | Average [68,69] | Max. Allowed [70] | Average [71,72] | Max. Allowed [72] | Average [73] | Max. Allowed [72] | Max. Allowed [8] |

| N | 30,000 | 30,000 | 46,000 | ||||

| P | 20,000 | 15,000 | 26,500 | ||||

| Cd | 0.9 | 0.8 | 0.6 | 0.4 | 0.7 | 2 | 20–40 |

| Cu | 295.5 | 1000 | 164.8 | 50 | 353.3 | 600 | 1000–1750 |

| Ni | 23.9 | 30 | 12.9 | 20 | 16.8 | 50 | 300–400 |

| Pb | 52.8 | 120 | 13.8 | 40 | 16.2 | 100 | 750–1200 |

| Zn | 1046 | 4000 | 391.1 | 150 | 562 | 800 | 250–4000 |

| Hg | 1 | 0.8 | 0.3 | 0.2 | 0.5 | 2.5 | 16–25 |

| Cr | 24.5 | 100 | 16.9 | 50 | 22.1 | 100 | - |

| Technology | Environment | Economy |

|---|---|---|

| Anaerobic digestion and soil application | Recovery of organic matter | Biogas production for heat and electricity |

| Nutrients can be reused | Recalcitrance of sludge may reduce biogas yield | |

| Greenhouse gas emissions reduction | Replacement of chemical fertilizers | |

| Potential contaminants and low nutrient bio-availability | ||

| Low investment and energy consumption | ||

| Mineralization beds | Organic matter mineralization | Volume reduction |

| Sludge stabilization | Large land extension required | |

| Released water treated via percolation | Volume reduction (handling costs reduction) | |

| Incineration | Energy recovery | Ashes disposal |

| Thermal destruction of pathogens and odours | Energy intensive | |

| Potential gas emissions | ||

| Nutrients not recovered | ||

| Pyrolysis | Energy recovery | Volume reduction (handling costs reduction) |

| Thermal destruction of pathogens and odours | Energy intensinve | |

| Nutrients recovered in biochar | Complex equipment | |

| Less pollutant (O2 absence) | ||

| Landfill | Landfill gas emissions | Low investment |

| Low sludge stability (odours, pathogens, etc.) | Large land extension required | |

| Underground water pollution | Linear economy approach |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernando-Foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies 2021, 14, 3411. https://doi.org/10.3390/en14123411

Fernando-Foncillas C, Estevez MM, Uellendahl H, Varrone C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies. 2021; 14(12):3411. https://doi.org/10.3390/en14123411

Chicago/Turabian StyleFernando-Foncillas, Clara, Maria M. Estevez, Hinrich Uellendahl, and Cristiano Varrone. 2021. "Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study" Energies 14, no. 12: 3411. https://doi.org/10.3390/en14123411