Effect of Two Different Heat Transfer Fluids on the Performance of Solar Tower CSP by Comparing Recompression Supercritical CO2 and Rankine Power Cycles, China

Abstract

:1. Introduction

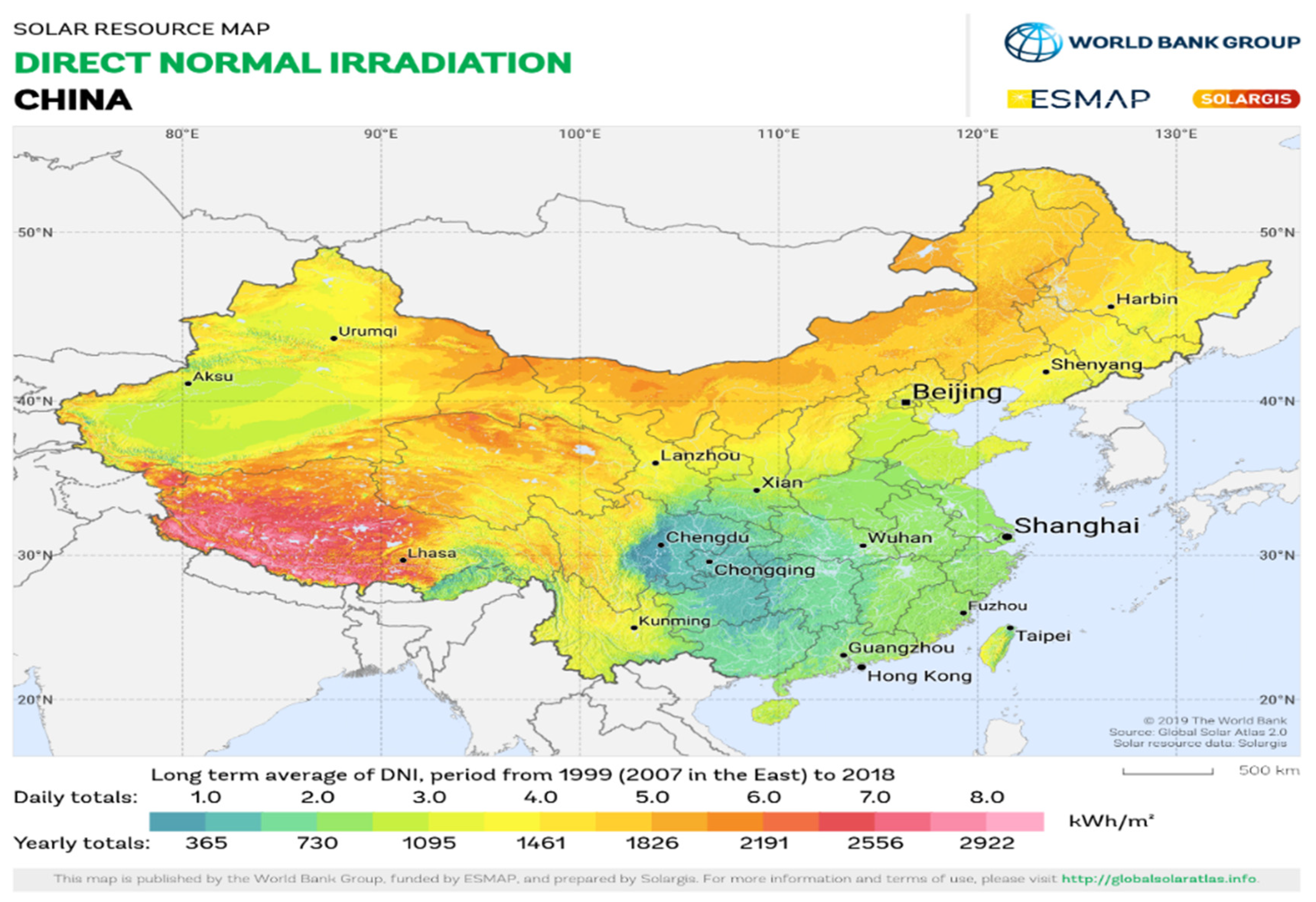

2. Description of the Study Area

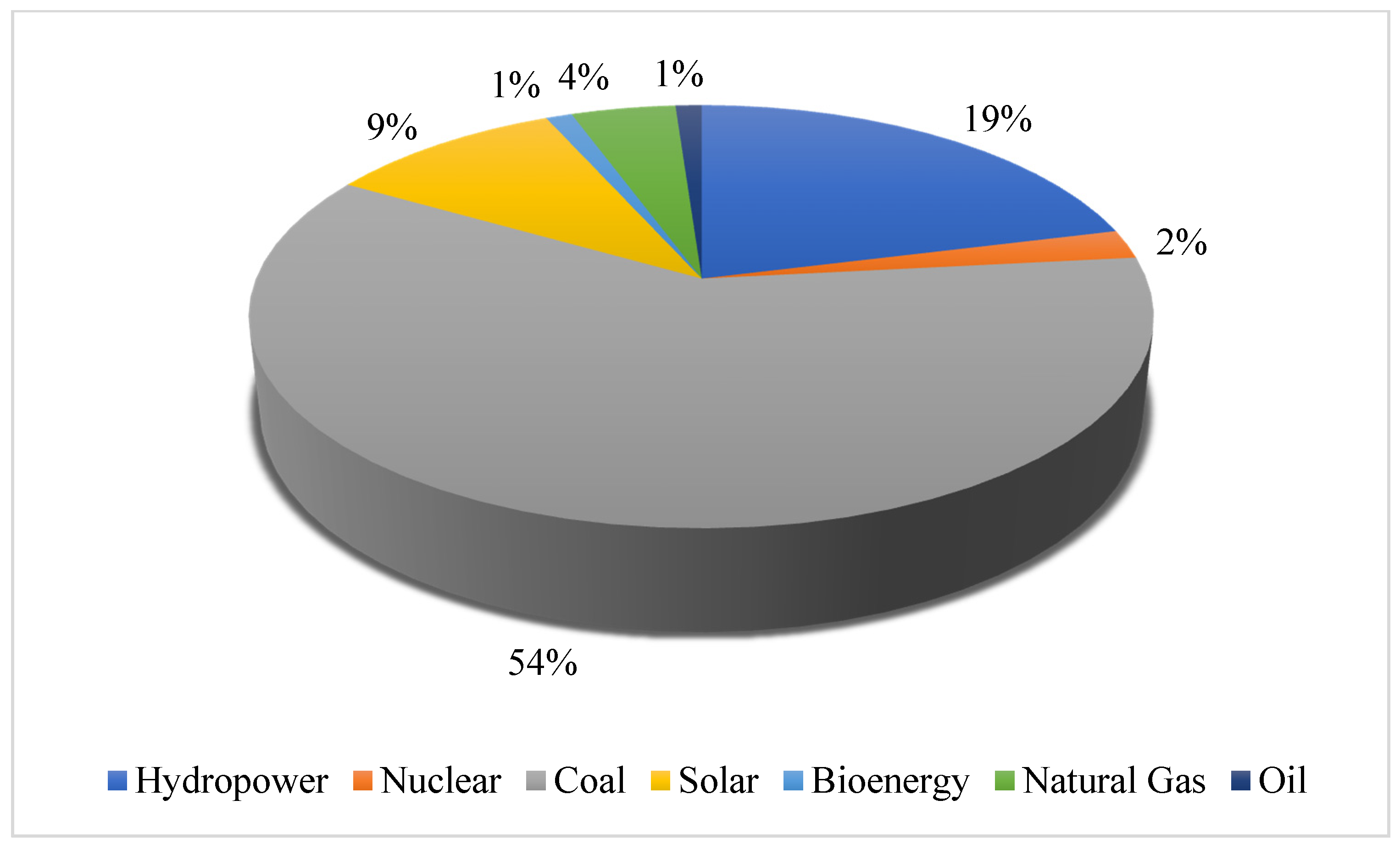

China’s Energy Generation Mix and the Need for CSP Development

3. Methodology

3.1. Power Cycle

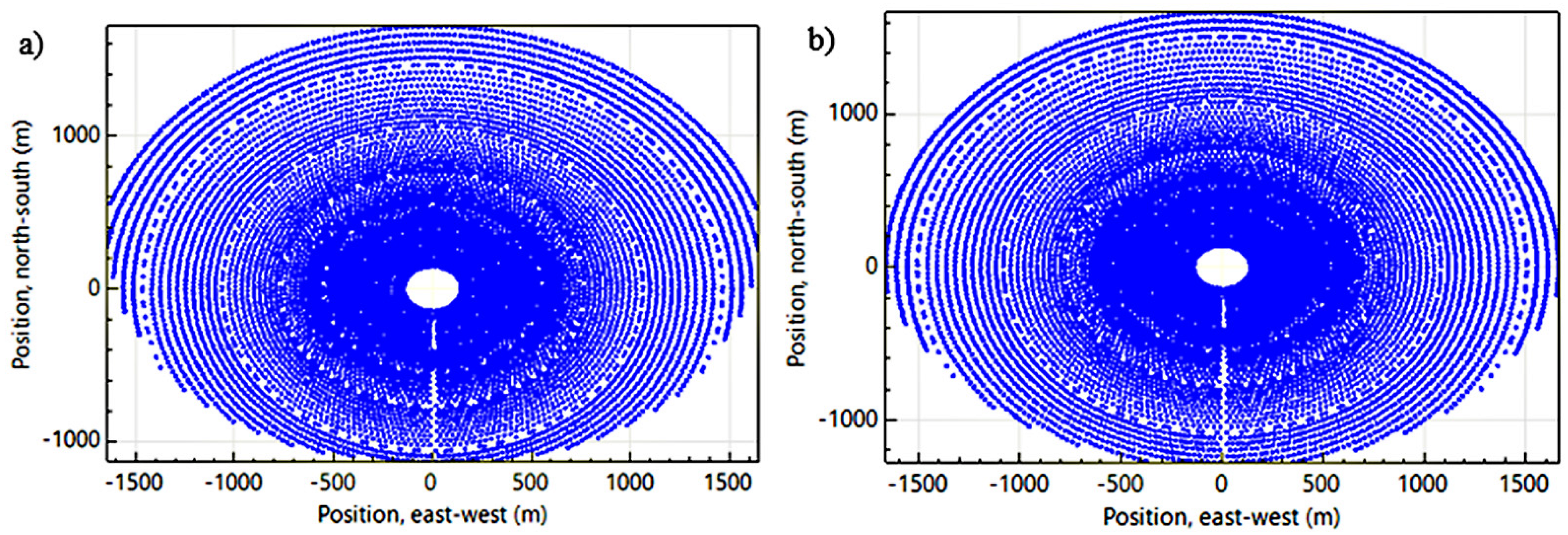

3.2. Modeling of the Power Plant

- Gathering of data on the location of the plant, weather characteristics, parameters of the heliostat, receiver parameters, and parameters for the tower.

- Generation of a set of potential positions for the heliostat by means of the “radial stagger” layout approach. This methodology positions the heliostat in rows with a constant radius. In this case, the center of the base of the tower becomes the center point and along the lines of constant azimuth angle.

- Assessing the accessible heliostat positions by estimating the yearly performance for every heliostat, throughout the year, a set of about 25 time-steps are simulated and for each simulation, average weather profiles are used.

- Collection of results of the simulation for each heliostat and then ranking of every heliostat relative to its annual output from the simulation.

- Determination of the energy sent from the solar field to the receiver by running a reference point simulation at a reference condition.

- Removal of the worst performing heliostats from the layout.

3.3. Economic Assessment Strategy

3.3.1. Levelized Cost of Energy

3.3.2. Payback Period

3.3.3. Net Present Value

4. Results and Discussion

4.1. Technical Analysis

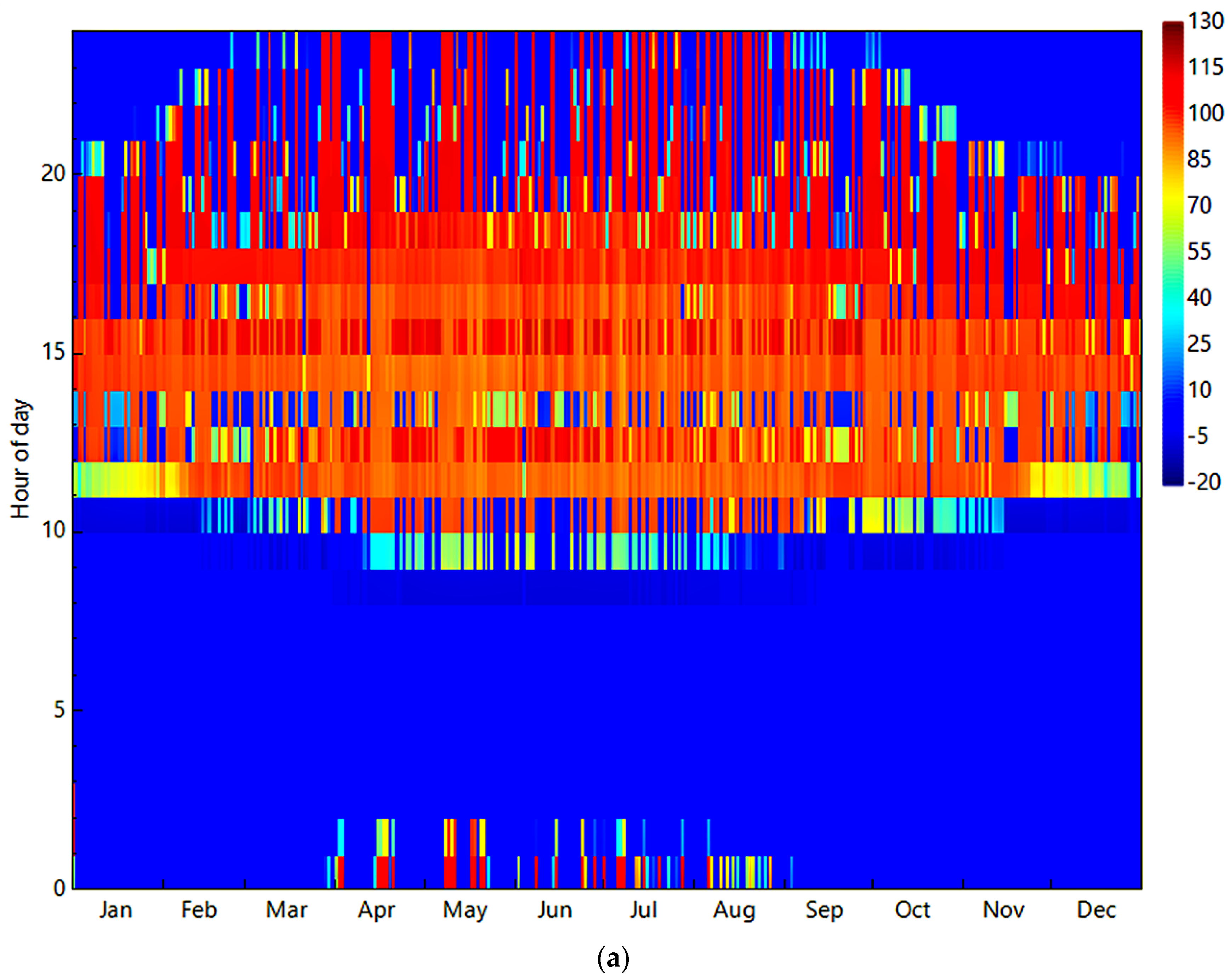

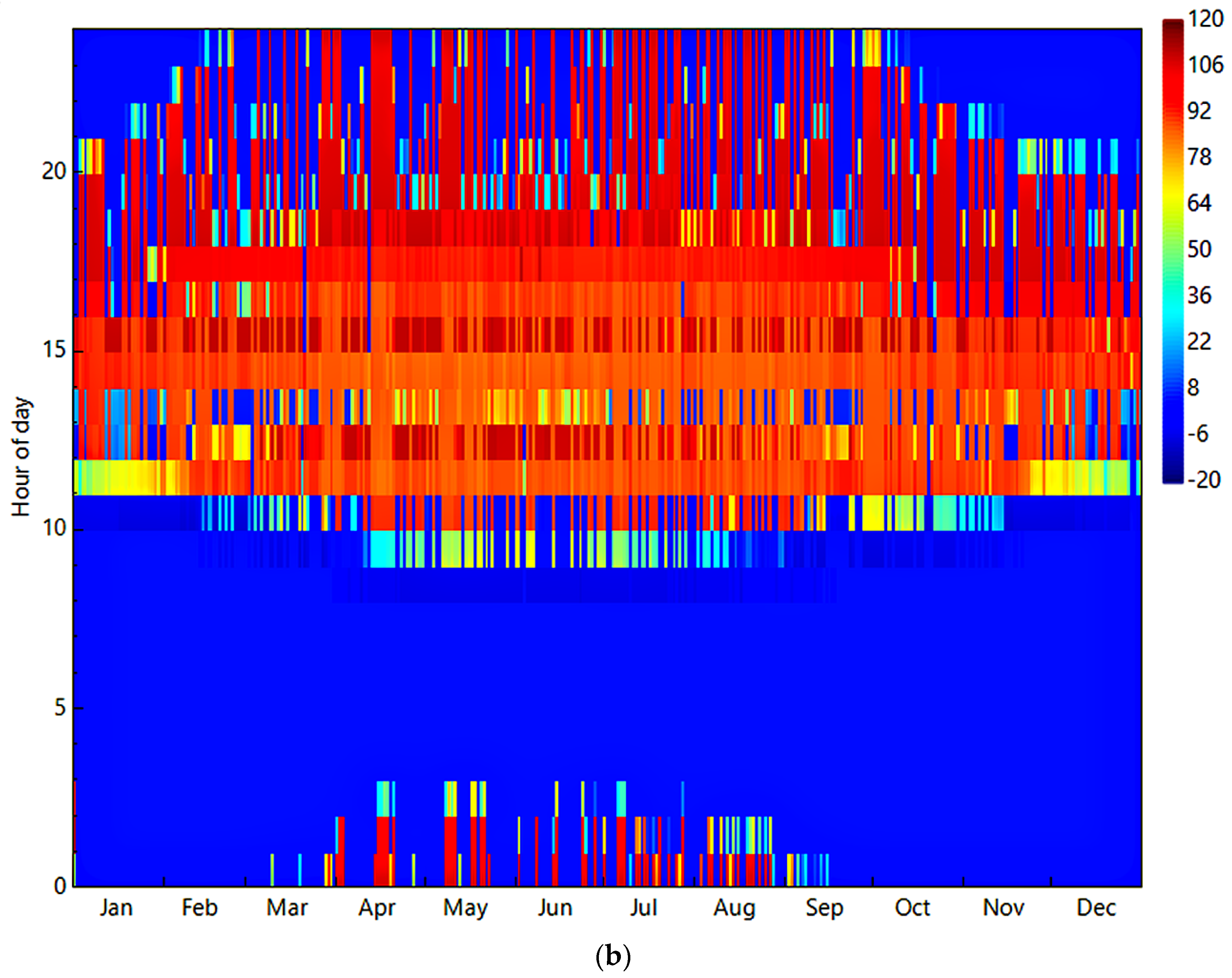

4.1.1. Weather Characteristics

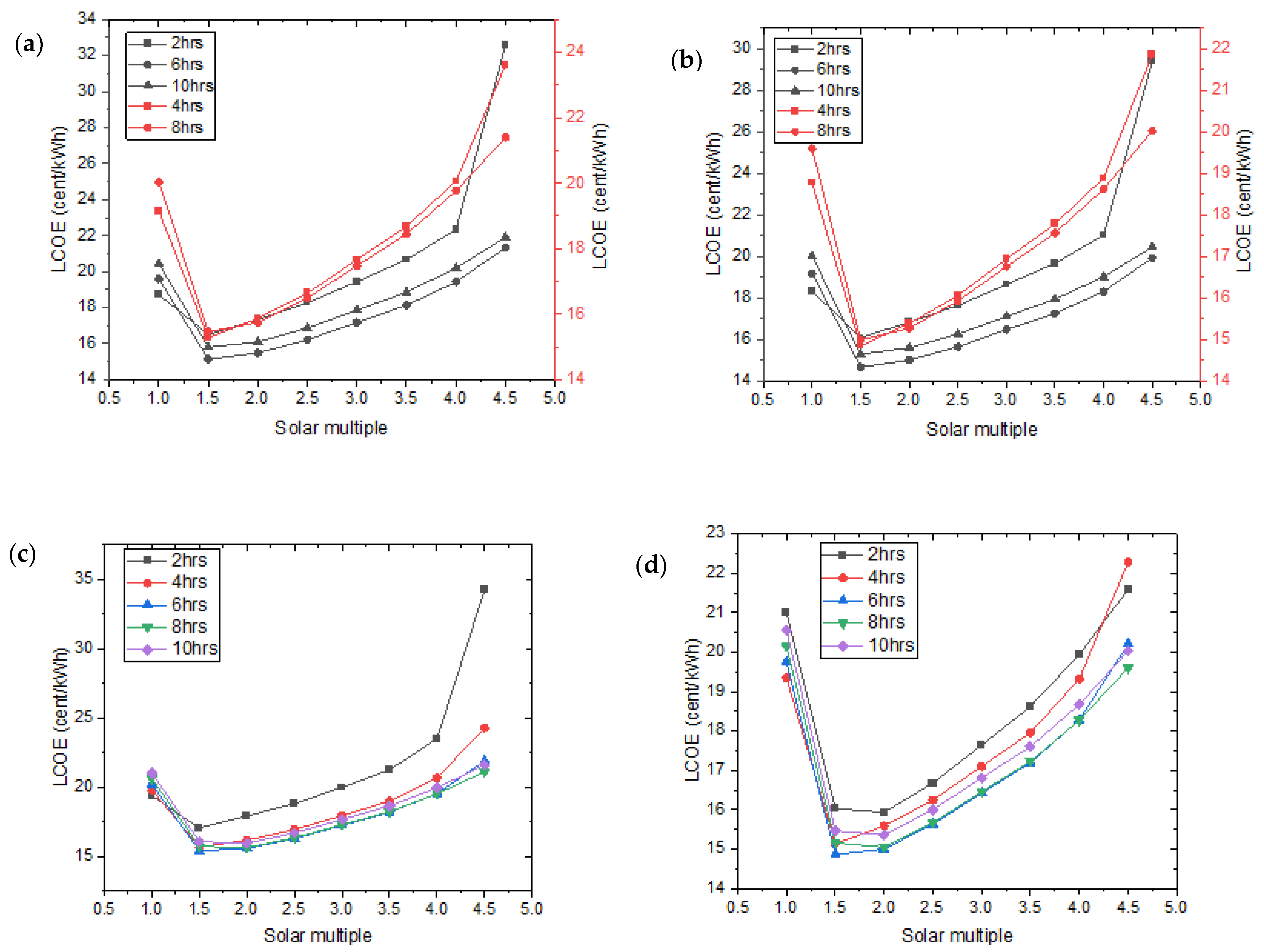

4.1.2. Effects of Solar Multiple and Full Load Hours of Storage

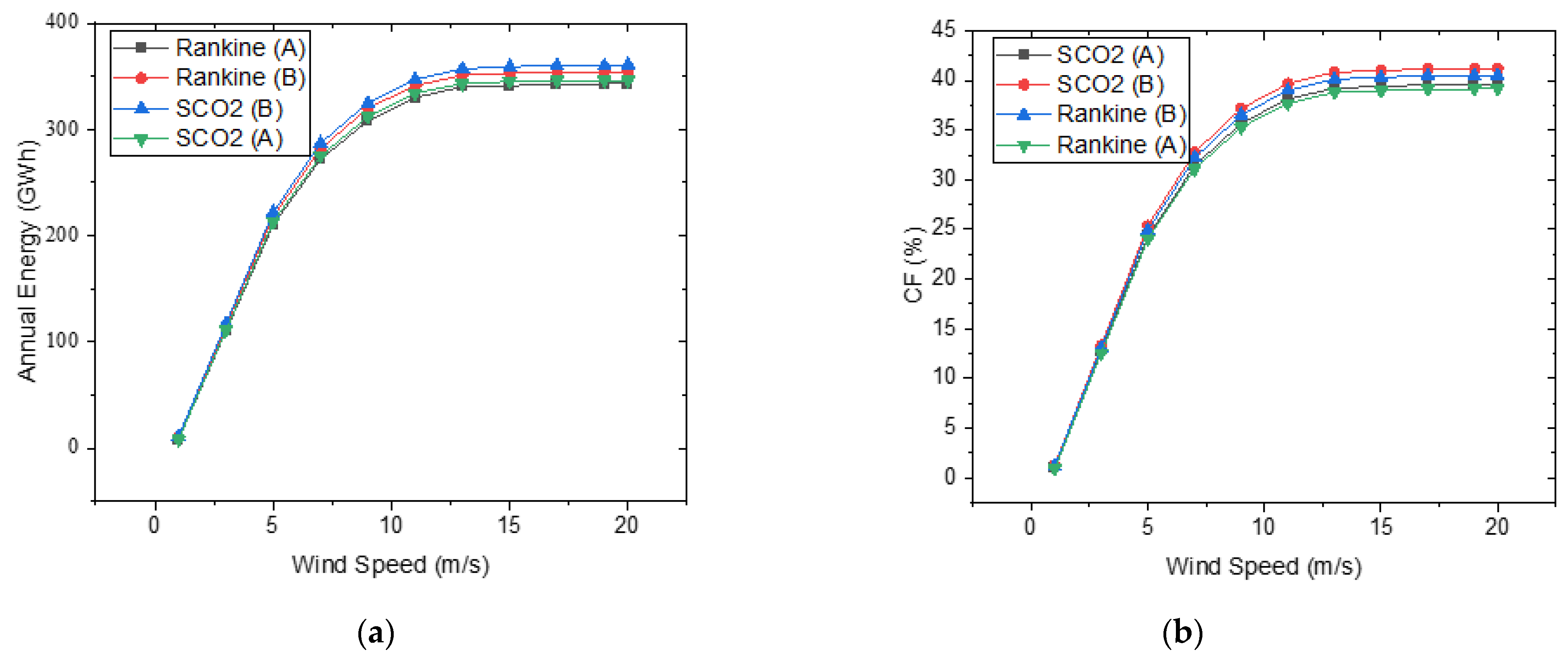

4.1.3. Electricity Generated, Capacity Factors and Water Consumption

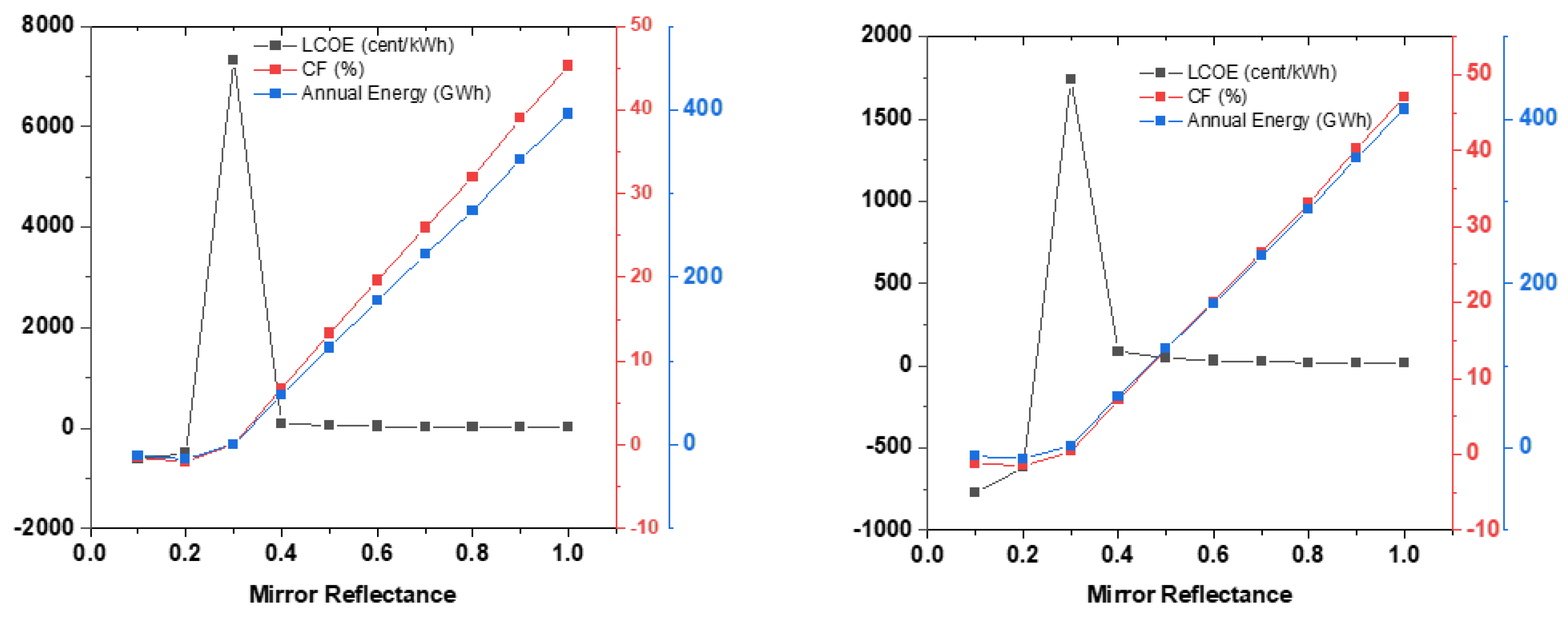

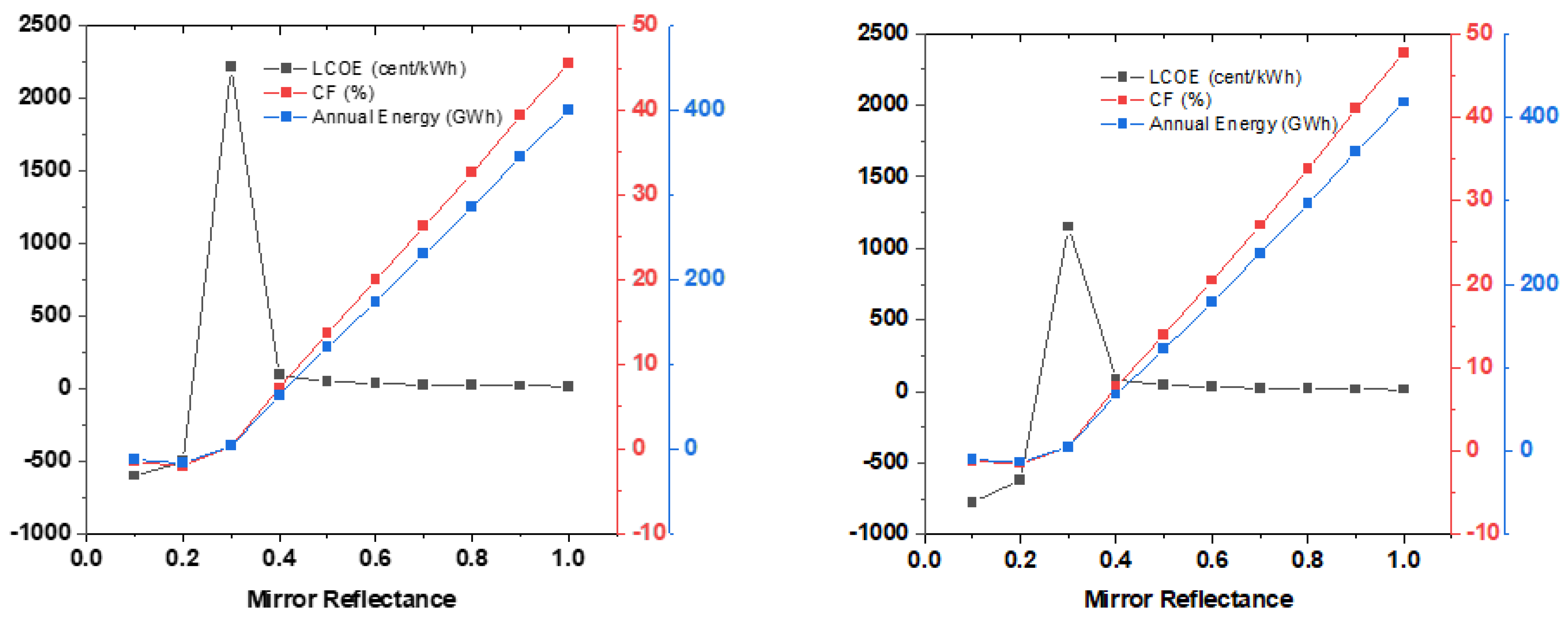

4.1.4. Parametric Analysis of Some Technical Parameters

4.2. Economic Analysis

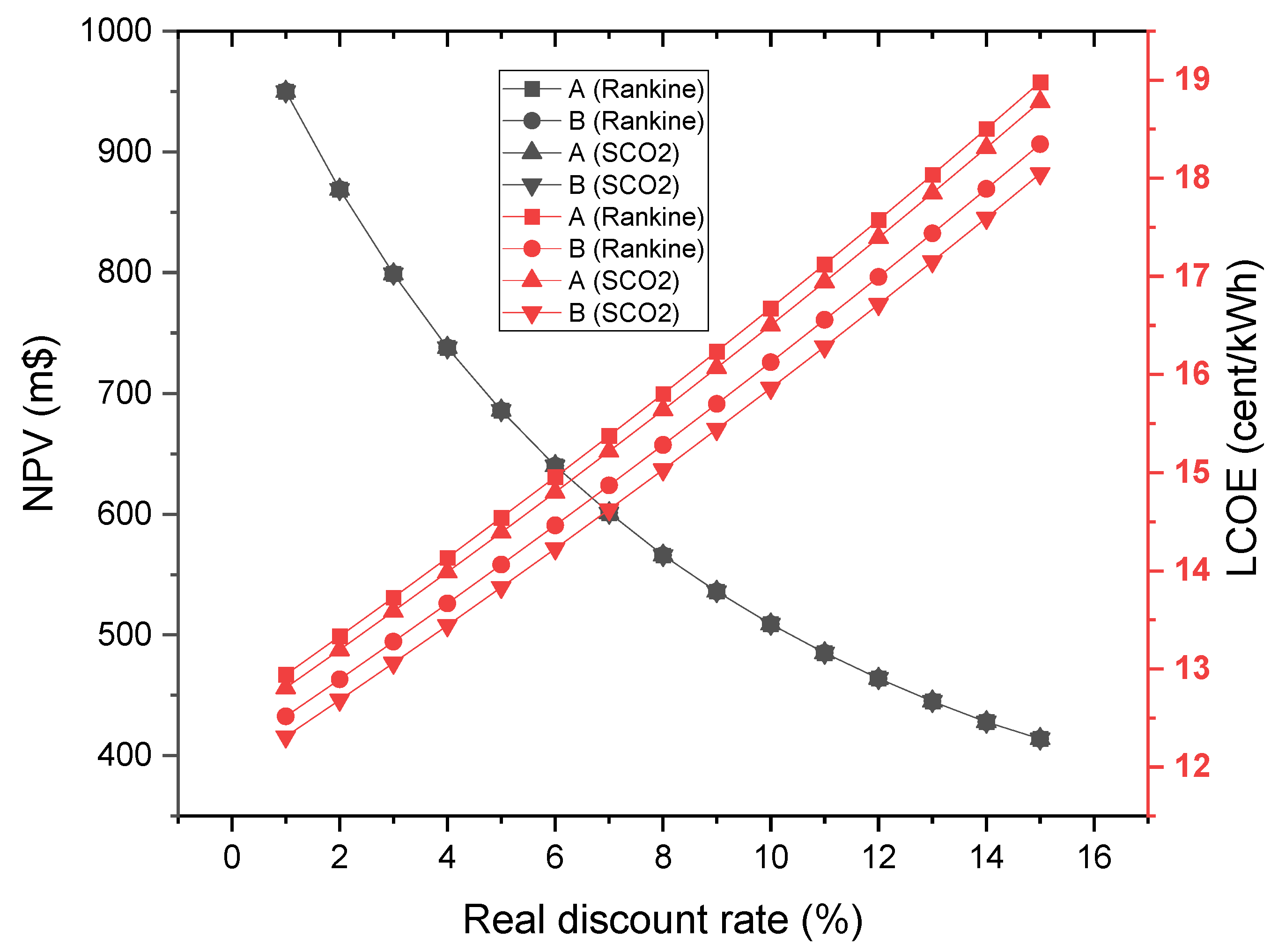

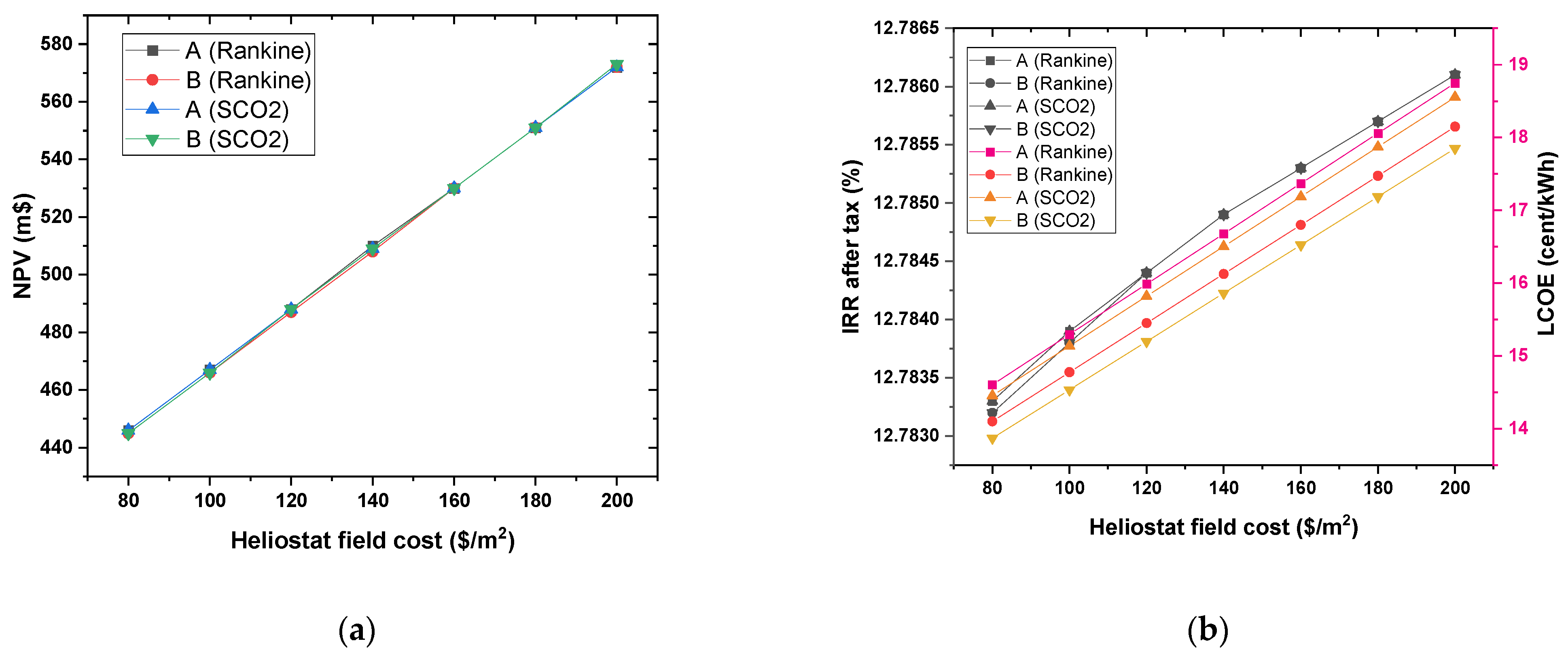

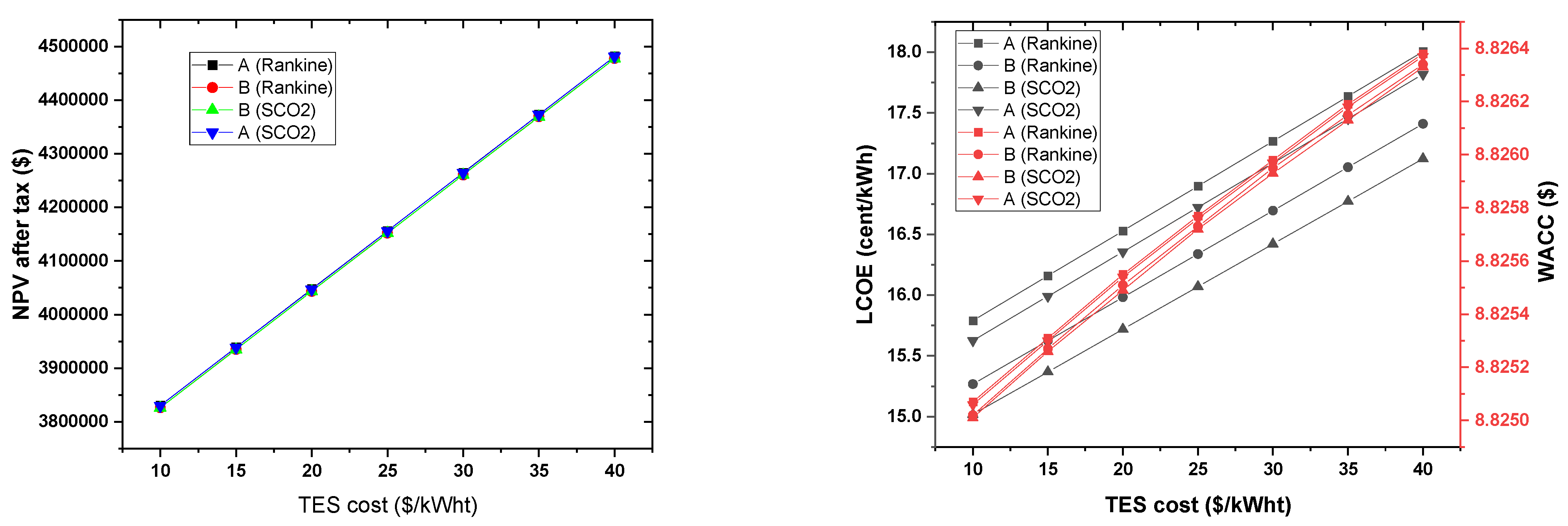

Sensitivity Analysis on Economic Parameters

4.3. Comparative Studies

5. Conclusions and Future Research Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CF | Capacity factor |

| CSP | Concentrated solar plant |

| DNI | Direct normal irradiation |

| GHG | Greenhouse gases |

| HTF | Heat transfer fluid |

| IRR | Internal rate of return |

| NPV | Net present value |

| PPA | Power purchase agreement |

| PV | Photovoltaic |

| STPP | Solar thermal power plants |

| WACC | Weight average cost of capital |

| kWh | Kilowatt hour |

References

- Agyekum, E.B. Energy poverty in energy rich Ghana: A SWOT analytical approach for the development of Ghana’s renewable energy. Sustain. Energy Technol. Assess. 2020, 40, 100760. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Nutakor, C. Feasibility study and economic analysis of stand-alone hybrid energy system for southern Ghana. Sustain. Energy Technol. Assess. 2020, 39, 100695. [Google Scholar] [CrossRef]

- Segura, E.; Morales-Herrera, R.; Somolinos, J. A strategic analysis of tidal current energy conversion systems in the European Union. Appl. Energy 2018, 212, 527–551. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Amjad, F.; Mohsin, M.; Ansah, M.N.S. A bird’s eye view of Ghana’s renewable energy sector environment: A Multi-Criteria Decision-Making approach. Util. Policy 2021, 70, 101219. [Google Scholar] [CrossRef]

- Adebayo, T.S.; Awosusi, A.A.; Kirikkaleli, D.; Akinsola, G.D.; Mwamba, M.N. Can CO2 emissiovns and energy consumption determine the economic performance of South Korea? A time series analysis. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Adebayo, T.S.; Kalmaz, D.B. Determinants of CO2 emissions: Empirical evidence from Egypt. Environ. Ecol. Stat. 2021, 28, 1–24. [Google Scholar] [CrossRef]

- Agyekum, E.; PraveenKumar, S.; Eliseev, A.; Velkin, V. Design and Construction of a Novel Simple and Low-Cost Test Bench Point-Absorber Wave Energy Converter Emulator System. Inventions 2021, 6, 20. [Google Scholar] [CrossRef]

- Qaisrani, M.A.; Fang, J.; Jin, Y.; Wan, Z.; Tu, N.; Khalid, M.; Rahman, M.U.; Wei, J. Thermal losses evaluation of an external rectangular receiver in a windy environment. Sol. Energy 2019, 184, 281–291. [Google Scholar] [CrossRef]

- Petrollese, M.; Cocco, D.; Cau, G.; Cogliani, E. Comparison of three different approaches for the optimization of the CSP plant scheduling. Sol. Energy 2017, 150, 463–476. [Google Scholar] [CrossRef]

- Shivashankar, S.; Mekhilef, S.; Mokhlis, H.; Karimi, M. Mitigating methods of power fluctuation of photovoltaic (PV) sources—A review. Renew. Sustain. Energy Rev. 2016, 59, 1170–1184. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Velkin, V.I. Optimization and techno-economic assessment of concentrated solar power (CSP) in South-Western Africa: A case study on Ghana. Sustain. Energy Technol. Assess. 2020, 40, 100763. [Google Scholar] [CrossRef]

- Baba, Y.F.; Ajdad, H.; Al Mers, A.; Bouatem, A.; Idrissi, B.B.; El Alj, S. Preliminary cost-effectiveness assessment of a Linear Fresnel Concentrator: Case studies. Case Stud. Therm. Eng. 2020, 22, 100730. [Google Scholar] [CrossRef]

- Reuters. Heat Transfer Fluids: Key to CSP Success|Reuters Events|Renewables. 2013. Available online: https://www.reutersevents.com/renewables/csp-today/technology/heat-transfer-fluids-key-csp-success (accessed on 1 November 2020).

- Vignarooban, K.; Xu, X.; Arvay, A.; Hsu, K.; Kannan, A. Heat transfer fluids for concentrating solar power systems—A review. Appl. Energy 2015, 146, 383–396. [Google Scholar] [CrossRef]

- Hernández, C.; Barraza, R.; Saez, A.; Ibarra, M.; Estay, D. Potential Map for the Installation of Concentrated Solar Power Towers in Chile. Energies 2020, 13, 2131. [Google Scholar] [CrossRef]

- Aly, A.; Bernardos, A.; Fernández-Peruchena, C.M.; Jensen, S.S.; Pedersen, A.B. Is Concentrated Solar Power (CSP) a feasible option for Sub-Saharan Africa?: Investigating the techno-economic feasibility of CSP in Tanzania. Renew. Energy 2019, 135, 1224–1240. [Google Scholar] [CrossRef]

- Hakimi, M.; Baniasadi, E.; Afshari, E. Thermo-economic analysis of photovoltaic, central tower receiver and parabolic trough power plants for Herat city in Afghanistan. Renew. Energy 2020, 150, 840–853. [Google Scholar] [CrossRef]

- Mihoub, S.; Chermiti, A.; Beltagy, H. Methodology of determining the optimum performances of future concentrating solar thermal power plants in Algeria. Energy 2017, 122, 801–810. [Google Scholar] [CrossRef]

- Sultan, A.J.; Hughes, K.J.; Ingham, D.B.; Ma, L.; Pourkashanian, M. Techno-economic competitiveness of 50 MW concentrating solar power plants for electricity generation under Kuwait climatic conditions. Renew. Sustain. Energy Rev. 2020, 134, 110342. [Google Scholar] [CrossRef]

- Li, Y.; Liao, S.; Rao, Z.; Liu, G. A dynamic assessment based feasibility study of concentrating solar power in China. Renew. Energy 2014, 69, 34–42. [Google Scholar] [CrossRef]

- Islam, T.; Huda, N.; Saidur, R. Current energy mix and techno-economic analysis of concentrating solar power (CSP) technologies in Malaysia. Renew. Energy 2019, 140, 789–806. [Google Scholar] [CrossRef]

- Hirbodi, K.; Enjavi-Arsanjani, M.; Yaghoubi, M. Techno-economic assessment and environmental impact of concentrating solar power plants in Iran. Renew. Sustain. Energy Rev. 2020, 120, 109642. [Google Scholar] [CrossRef]

- Ling-Zhi, R.; Xin-Gang, Z.; Xin-Xuan, Y.; Yu-Zhuo, Z. Cost-benefit evolution for concentrated solar power in China. J. Clean. Prod. 2018, 190, 471–482. [Google Scholar] [CrossRef]

- Zhao, Z.-Y.; Chen, Y.-L.; Thomson, J.D. Levelized cost of energy modeling for concentrated solar power projects: A China study. Energy 2017, 120, 117–127. [Google Scholar] [CrossRef]

- Ji, J.; Tang, H.; Jin, P. Economic potential to develop concentrating solar power in China: A provincial assessment. Renew. Sustain. Energy Rev. 2019, 114, 109279. [Google Scholar] [CrossRef]

- Neises, T.; Turchi, C. A Comparison of Supercritical Carbon Dioxide Power Cycle Configurations with an Emphasis on CSP Applications. Energy Procedia 2014, 49, 1187–1196. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; He, Y.-L. Thermodynamic analysis and optimization of a molten salt solar power tower integrated with a recompression supercritical CO2 Brayton cycle based on integrated modeling. Energy Convers. Manag. 2017, 135, 336–350. [Google Scholar] [CrossRef]

- Iverson, B.D.; Conboy, T.M.; Pasch, J.J.; Kruizenga, A.M. Supercritical CO2 Brayton Cycles for Solar. Therm. Energy 2013, 111, 957–970. [Google Scholar]

- Atif, M.; Al-Sulaiman, F.A. Energy and exergy analyses of solar tower power plant driven supercritical carbon dioxide recompression cycles for six different locations. Renew. Sustain. Energy Rev. 2017, 68, 153–167. [Google Scholar] [CrossRef]

- Xu, X.; Vignarooban, K.; Xu, B.; Hsu, K.; Kannan, A. Prospects and problems of concentrating solar power technologies for power generation in the desert regions. Renew. Sustain. Energy Rev. 2016, 53, 1106–1131. [Google Scholar] [CrossRef]

- Polimeni, S.; Binotti, M.; Moretti, L.; Manzolini, G. Comparison of sodium and KCl-MgCl2 as heat transfer fluids in CSP solar tower with sCO2 power cycles. Sol. Energy 2018, 162, 510–524. [Google Scholar] [CrossRef]

- Advantour. The Geographical Position of China. 2020. Available online: https://www.advantour.com/china/geography.htm (accessed on 1 November 2020).

- European Commission. JRC Photovoltaic Geographical Information System (PVGIS). European Commission, 2019. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#TMY (accessed on 1 November 2020).

- EnergyPlus. Weather Search|EnergyPlus n.d. Available online: https://energyplus.net/weather-search/tibet (accessed on 30 April 2021).

- Solargis. Global Solar Atlas n.d. Available online: https://globalsolaratlas.info/download/china (accessed on 1 November 2020).

- O’Meara, S. China’s plan to cut coal and boost green growth. Nat. Cell Biol. 2020, 584, S1–S3. [Google Scholar] [CrossRef]

- EIA. International—U.S. Energy Information Administration (EIA). 2020. Available online: https://www.eia.gov/international/analysis/country/CHN (accessed on 2 November 2020).

- Qaisrani, M.A.; Wei, J.; Khan, L.A. Potential and transition of concentrated solar power: A case study of China. Sustain. Energy Technol. Assess. 2021, 44, 101052. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019—Analysis. 2019. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 2 November 2020).

- Elbeh, M.B.; Sleiti, A.K. Analysis and optimization of concentrated solar power plant for application in arid climate. Energy Sci. Eng. 2021, 9, 784–797. [Google Scholar] [CrossRef]

- Les, I.; Mutuberria, A.; Schöttl, P.; Nitz, P.; Leonardi, E.; Pisani, L. Optical Performance Comparison between Heliostat Field Generation Algorithms; AIP Publishing LLC: Santiago, Chile, 2018; p. 040020. [Google Scholar] [CrossRef]

- Bhargav, K.; Gross, F.; Schramek, P. Life Cycle Cost Optimized Heliostat Size for Power Towers. Energy Procedia 2014, 49, 40–49. [Google Scholar] [CrossRef] [Green Version]

- Belaid, A.; Filali, A.; Gama, A.; Bezza, B.; Arrif, T.; Bouakba, M. Design optimization of a solar tower power plant heliostat field by considering different heliostat shapes. Int. J. Energy Res. 2020, 44, 11524–11541. [Google Scholar] [CrossRef]

- Freeman, J.M.; DiOrio, N.A.; Blair, N.J.; Neises, T.W.; Wagner, M.J.; Gilman, P.; Janzou, S. System Advisor Model (SAM) General Description (Version 2017.9.5); 2018. Available online: https://www.osti.gov/biblio/1440404/ (accessed on 9 June 2021). [CrossRef] [Green Version]

- NREL. sam-help-2020-11-29r1.pdf. 2020. Available online: https://sam.nrel.gov/images/web_page_files/sam-help-2020-11-29r1.pdf (accessed on 13 May 2021).

- Agyekum, E.B.; Velkin, V.I.; Hossain, I. Sustainable energy: Is it nuclear or solar for African Countries? Case study on Ghana. Sustain. Energy Technol. Assess. 2020, 37, 100630. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Afornu, B.K.; Ansah, M.N.S. Effect of Solar Tracking on the Economic Viability of a Large-Scale PV Power Plant. Environ. Clim. Technol. 2020, 24, 55–65. [Google Scholar] [CrossRef]

- Wang, Q.; Pei, G.; Yang, H. Techno-economic assessment of performance-enhanced parabolic trough receiver in concentrated solar power plants. Renew. Energy 2020, 167, 629–643. [Google Scholar] [CrossRef]

- Kumar, S.; Agarwal, A.; Kumar, A. Financial viability assessment of concentrated solar power technologies under Indian climatic conditions. Sustain. Energy Technol. Assess. 2021, 43, 100928. [Google Scholar] [CrossRef]

- Hernández-Moro, J.; Martínez-Duart, J. Analytical model for solar PV and CSP electricity costs: Present LCOE values and their future evolution. Renew. Sustain. Energy Rev. 2013, 20, 119–132. [Google Scholar] [CrossRef]

- Torras, S.; Perez-Segarra, C.-D.; Rodríguez, I.; Rigola, J.; Oliva, A. Parametric Study of Two-tank TES Systems for CSP Plants. Energy Procedia 2015, 69, 1049–1058. [Google Scholar] [CrossRef] [Green Version]

- IRENA. Renewable Power Generation Costs in 2017. 2018. Available online: https://www.irena.org/publications/2018/jan/renewable-power-generation-costs-in-2017 (accessed on 9 June 2021).

- Emes, M.J.; Arjomandi, M.; Nathan, G.J. Effect of heliostat design wind speed on the levelised cost of electricity from concentrating solar thermal power tower plants. Sol. Energy 2015, 115, 441–451. [Google Scholar] [CrossRef]

- Hussaini, Z.A.; King, P.; Sansom, C. Numerical Simulation and Design of Multi-Tower Concentrated Solar Power Fields. Sustainability 2020, 12, 2402. [Google Scholar] [CrossRef] [Green Version]

- Jamali, H. Investigation and review of mirrors reflectance in parabolic trough solar collectors (PTSCs). Energy Rep. 2019, 5, 145–158. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, D.; Mischke, P.; Zhang, X. Electricity generation costs of concentrated solar power technologies in China based on operational plants. Energy 2015, 89, 65–74. [Google Scholar] [CrossRef] [Green Version]

- Trabelsi, S.E.; Chargui, R.; Qoaider, L.; Liqreina, A.; Guizani, A. Techno-economic performance of concentrating solar power plants under the climatic conditions of the southern region of Tunisia. Energy Convers. Manag. 2016, 119, 203–214. [Google Scholar] [CrossRef]

- Tahir, S.; Ahmad, M.; Abd-Ur-Rehman, H.M.; Shakir, S. Techno-economic assessment of concentrated solar thermal power generation and potential barriers in its deployment in Pakistan. J. Clean. Prod. 2021, 293, 126125. [Google Scholar] [CrossRef]

- Zayed, M.E.; Zhao, J.; Li, W.; Elsheikh, A.H.; Zhao, Z.; Khalil, A.; Li, H. Performance prediction and techno-economic analysis of solar dish/stirling system for electricity generation. Appl. Therm. Eng. 2020, 164, 114427. [Google Scholar] [CrossRef]

- de la Calle, A.; Bayon, A.; Pye, J. Techno-economic assessment of a high-efficiency, low-cost solar-thermal power system with sodium receiver, phase-change material storage, and supercritical CO2 recompression Brayton cycle. Sol. Energy 2020, 199, 885–900. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| sCO2 Power Cycle | Rankine Power Cycle | |

| Design point parameters | ||

| Solar multiple | 2.4 | 2.4 |

| Receiver thermal power | 647 MWt | 647 MWt |

| HTF hot temperature | 574 °C | 574 °C |

| HTF cold temperature | 406.04 °C | 406.04 °C |

| Full load hours of storage | 10 h | 10 h |

| Solar field hours of storage | 4.17 h | 4.17 h |

| Design turbine gross output | 111 MWe | 111 MWe |

| Estimated net output at design (nameplate) | 100 | 100 |

| Heliostat field | ||

| Heliostat height | 12.20 m | 12.20 m |

| Ratio of reflective area to profile | 0.97 | 0.97 |

| Initial optimization step size | 0.06 | 0.06 |

| Max. heliostat distance to tower height ratio | 9.50 | 9.50 |

| Min. heliostat distance to tower height ratio | 0.75 | 0.75 |

| Tower height | 192.03 m | 186.14 m |

| Mirror reflectance and soiling | 0.90 | 0.90 |

| Base land area | 1818 acres | 1892.72 acres |

| Total land area | 1864 acres | 1938 acres |

| Tower and Receiver | ||

| Receiver height | 19.75 m | 19.48 m |

| Receiver diameter | 17.49 m | 17.30 m |

| Tube outer diameter | 40 mm | 40 mm |

| Tube wall thickness | 1.25 mm | 1.25 mm |

| Power cycle | ||

| Estimated cycle gross output | 111 MWe | 111 MWe |

| Estimated gross to net conversion factor | 0.9 | 0.9 |

| Cycle thermal power | 269.42 MWt | 269.42 MWt |

| Cycle configuration | Recompression | - |

| Boiler operating pressure | - | 100 Bar |

| Condenser type | - | Air-cooled |

| Cycle thermal efficiency | 0.412 | - |

| Recompression fraction | 0.197 | - |

| Low pressure | 9.47 | - |

| Thermal storage | ||

| Storage type | Two-tank | Two-tank |

| TES thermal capacity | 2694.2 MWt-h | 2694.2 MWt-h |

| Available HTF volume | 21,536 m3 | 13,222 m3 |

| Tank diameter | 49.9 m | 39.1 m |

| Storage tank volume | 23,493 m3 | 14,424 m3 |

| Parameter | Value |

|---|---|

| Site improvements | 16 USD/m2 |

| Tower cost fixed | USD 3,000,000 |

| Tower cost scaling exponent | 0.0113 |

| Receiver reference cost | USD 103,000,000 |

| Thermal energy storage cost | 22.0 USD/kWht |

| Contingency cost | 7% of sub-total |

| Nominal discount rate | 12.42% |

| Insurance rate (annual) | 0.5% |

| Tenor | 18 years |

| Metric | Supercritical CO2 Cycle | Rankine Cycle | ||

|---|---|---|---|---|

| Salt (60% NaNO3 40% KNO3) | Salt (46.5% LiF 11.5% NaF 42% KF) | Salt (46.5% LiF 11.5% NaF 42% KF) | Salt (60% NaNO3 40% KNO3) | |

| PPA Price (year 1), cents/kWh | 16.02 | 15.34 | 15.44 | 16.02 |

| Levelized PPA price (nominal), cents/kWh | 19.78 | 19.01 | 19.33 | 19.99 |

| Levelized PPA price (real), cents/kWh | 16.64 | 15.99 | 16.25 | 16.81 |

| LCOE (nominal), cents/kWh | 19.63 | 18.86 | 19.18 | 19.83 |

| LCOE (real), cents/kWh | 16.50 | 15.86 | 16.13 | 16.68 |

| NPV, USD | 4,090,734 | 4,086,686 | 4,086,854 | 4,090,836 |

| Internal rate of return (IRR), % | 11.00 | 11.00 | 11.00 | 11.00 |

| Year IRR is achieved | 20.00 | 20.00 | 20.00 | 20.00 |

| IRR at end of project, % | 12.78 | 12.78 | 12.78 | 12.78 |

| Net capital cost, USD | 761,803,456 | 761,173,248 | 761,161,408 | 761,796,288 |

| Equity, USD | 342,008,512 | 341,722,752 | 341,718,496 | 342,005,920 |

| Size of debt, USD | 419,794,944 | 419,450,464 | 419,442,912 | 419,790,368 |

| Study | Location | Type of Cycle | Type of Technology | LCOE | Capacity of Plant |

|---|---|---|---|---|---|

| Aly et al. [16] | Tanzania | Rankine | Solar tower plant | 0.116 to 0.125 USD/kWh | 100 MW |

| Trabelsi et al. [57] | Tunisia | Rankine | Parabolic trough plants | 0.1828 EUR/kW he | 50 MW |

| Tahir et al. [58] | Pakistan | Parabolic trough plants | 0.147–0.153 USD/kWh | 100 MW | |

| Zayed et al. [59] | China | Solar Dish/Stirling | 0.2565 USD/kWh | 25 kW | |

| de la Calle et al. [60] | Australia | sCO2 | 0.1142 AUD/kWh | 100 MW | |

| Mihoub et al. [18] | Algeria | Rankine | Central tower receiver Solar plant | 0.2357 USD/kWh | 50 MW |

| Sultan et al. [19] | Kuwait | Parabolic trough | 0.150663 USD/kWh | 50 MW | |

| Zhu et al. [56] | China | Parabolic trough CSP, tower CSP, and dish CSP | 0.19–0.43 USD/kWh |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agyekum, E.B.; Adebayo, T.S.; Bekun, F.V.; Kumar, N.M.; Panjwani, M.K. Effect of Two Different Heat Transfer Fluids on the Performance of Solar Tower CSP by Comparing Recompression Supercritical CO2 and Rankine Power Cycles, China. Energies 2021, 14, 3426. https://doi.org/10.3390/en14123426

Agyekum EB, Adebayo TS, Bekun FV, Kumar NM, Panjwani MK. Effect of Two Different Heat Transfer Fluids on the Performance of Solar Tower CSP by Comparing Recompression Supercritical CO2 and Rankine Power Cycles, China. Energies. 2021; 14(12):3426. https://doi.org/10.3390/en14123426

Chicago/Turabian StyleAgyekum, Ephraim Bonah, Tomiwa Sunday Adebayo, Festus Victor Bekun, Nallapaneni Manoj Kumar, and Manoj Kumar Panjwani. 2021. "Effect of Two Different Heat Transfer Fluids on the Performance of Solar Tower CSP by Comparing Recompression Supercritical CO2 and Rankine Power Cycles, China" Energies 14, no. 12: 3426. https://doi.org/10.3390/en14123426