3.1.1. Two-Well Synergistic Mode

For this mode, the following conditions are applied: stratum dip of 6°, thickness of the oil layer of 6.6 m, a large body of water with sufficient energy, positive rhythm, Lorentz coefficient of 0.5, length of the horizontal section of 70 m parallel to the oil layer, entire section discharged, viscosity of the crude oil of 90 mPa·s, no interlayers, and horizontal section located in the middle-upper part of the oil layer. The two horizontal wells are facing each other: P1 is in the lower position, and P2 is in the higher position. After the water cut of P1 reaches 98%, P1 and P2 simultaneously perform CO2 huff and puff. The daily gas injection volume of the well is 100 t, a total of 400 t is injected, and the wells are closed for 30 days. After well stuffy, P1 and P2 are opened for simultaneous production. During the simulation process, the model parameter settings are modified according to the parameter value.

(1) Stratum dip

The stratum dip has a non-negligible effect on the water flooding development. When the local dip exists, the performance of the production wells in different structural positions is different [

42]. In low structural positions, the water cut of the production wells rises faster, whereas water breakthrough occurs later for production wells in high structural positions. To analyze the influence of the stratum dip on the synergistic CO

2 huff-and-puff development performance, we set the stratum dip to 3, 6, and 15° in the typical model.

Figure 5 shows the oil increment and water-cut reduction of P1, P2, and well groups during the validity period. From

Figure 5, it is observed that as the stratum dip increases, the oil increment of low-position production wells decreases, whereas it increases for high-position production wells. After the stratum dip angle exceeds 6°, the oil increment and water cut of the well group change slightly. They show a tendency of first increasing and then stabilizing with the increase in the stratum dip.

Figure 6 shows the oil viscosity distribution after well stuffy. The figure indicates that when the stratum dip is 3°, the viscosity of the crude oil near the production well decreases, but there is no significant change in the density of the crude oil between P1 and P2. When the stratum dip increases to 15°, the range of oil viscosity reduction between wells continues to increase, indicating that under the action of gravity, the higher the stratum dip, the more evident the effect of gravity differentiation, which expands the action range of CO

2. Hence, the stratum dip is a favorable factor for synergistic CO

2 huff and puff.

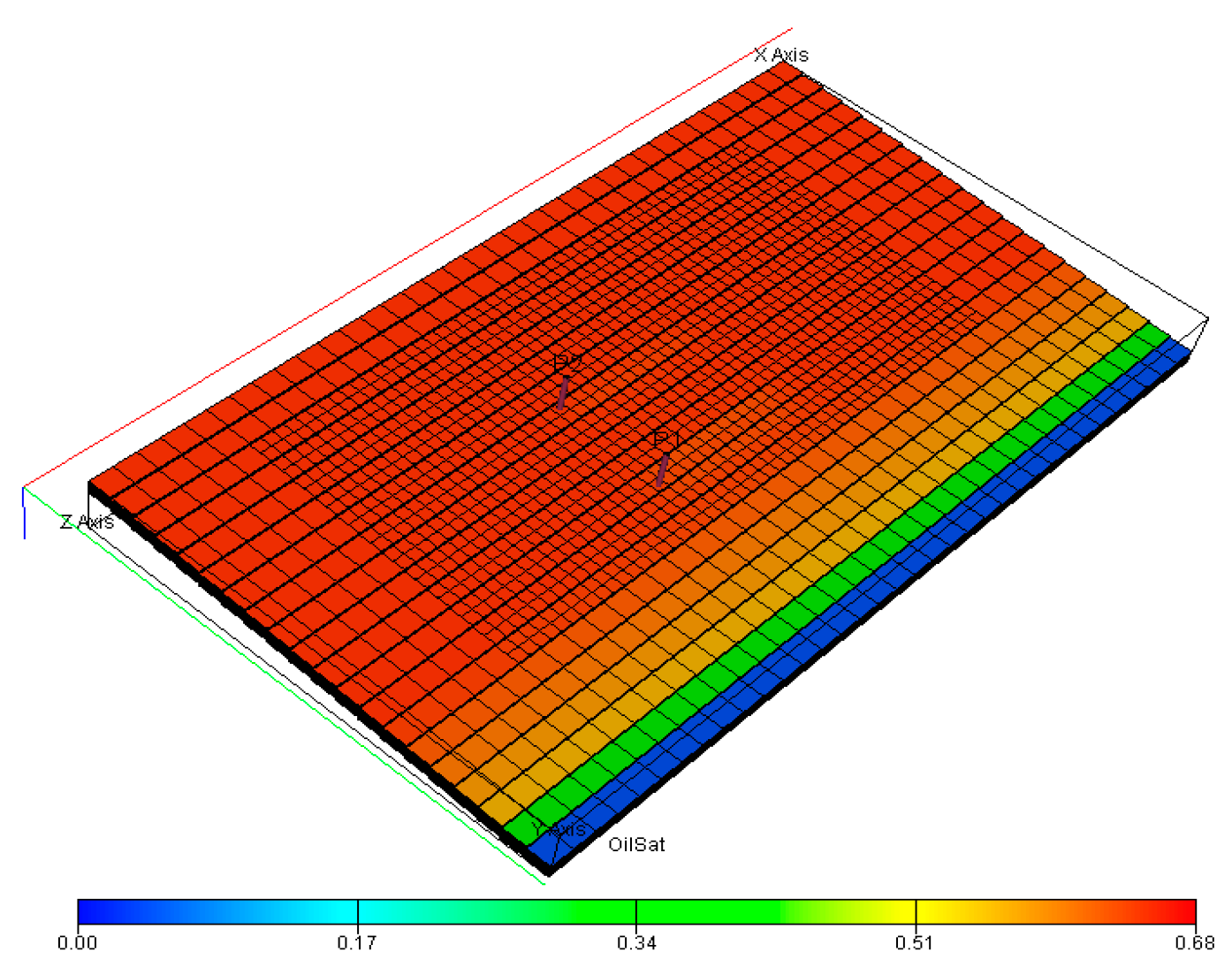

Figure 6 shows the distribution of oil saturation after the validity period. In

Figure 7, we can see that as the stratum dip increases, the production range of P1 decreases because the injected gas moves upward under the action of gravity. As a result, the CO

2 that acts on the low structural part decreases, and the performance of well P1 becomes worse. For the high structural and inter-well parts, as the stratum dip increases, the production range becomes larger, and the performance of P2 gradually improves.

(2) Sedimentary rhythm and well type

The water flooding field application indicates that the sedimentary rhythm mode of the reservoir is closely related to reservoir development performance [

43]. The physical properties and oil saturation of the lower part of positive rhythm oil layer are better than those of the upper part, and the utilization degree of the lower part is also higher. The main productive zone of reverse rhythm oil layer is located in the upper part. This means that the lower part does not produce oil; thus, the performance of water flooding development is poor. The longitudinal oil–water distribution of homogeneous oil layers is relatively uniform, and the development performance is the relation between positive- and negative-rhythm reservoirs. For fault-block oil reservoirs, edge and bottom water are common. The positive rhythm, homogeneous, and reverse rhythm models are established to study the influence of well types and different formation sedimentary rhythms on the performance of synergistic CO

2 huff and puff when the production well is close to the edge and bottom water. In addition, horizontal and vertical wells are used for CO

2 synergistic huff and puff.

The oil increment of horizontal well P1, vertical well P2, and well groups are shown in

Figure 8. It can be seen from

Figure 8 that the oil increment of P1 and P2 decreases with the changing of sedimentary rhythm. For the P1 well, the oil increment decreases from 586 t of positive rhythm and 566 t of homogeneous reservoir to 506 t of reverse rhythm. For the P2 well, the oil increment decreases from 675 t of positive rhythm and 549 t of homogeneous reservoir to 480 t of reverse rhythm. Comparing the oil increment of horizontal well P1 and vertical well P2, it was observed that the oil increasing performance of vertical wells in positive rhythm reservoirs is slightly better than that of horizontal wells. For homogeneous and reverse rhythm reservoirs, the development performance of horizontal wells is slightly better than that of vertical wells. The total oil increment of the well group is 1260 t for positive rhythm, 1115 t for the homogeneous oil reservoir, and 986 t for the reverse rhythm reservoir, and the total oil increment of the well group gradually decreases. Therefore, when the mixed well pattern of vertical and horizontal wells is implemented for synergistic CO

2 huff and puff, positive rhythm is the optimal choice, followed by the homogeneous reservoir, and the reverse rhythm is the worst option.

Figure 9 shows the oil viscosity distribution after well stuffy. Comparing the viscosity reduction range, we can conclude that crude oil viscosity reduction is the largest for the positive rhythm reservoir, followed by homogeneous and reverse rhythm reservoirs. In addition, the viscosity reduction range of the reverse rhythm reservoir is concentrated in the upper part of the reservoir, and the longitudinal sweep effect is poor.

Figure 10 shows the oil saturation distribution after validity period. Comparing the oil saturation distribution of the three different sedimentary rhythms, it was found that the decreasing range of oil saturation in the positive rhythm reservoir is evidently large, that is, the range of reservoir utilization during the validity period is larger. The porosity and permeability of the lower part of the positive rhythm reservoir are relatively high. Under the action of CO

2 injection, the crude oil expands, and the gravity differentiation is more effective. The positive rhythm reservoir shows better performance of synergistic CO

2 huff and puff. The oil saturation of the lower part of positive rhythm reservoir is lower after validity period, indicating that bottom water cresting occurs. The closer to the edge and bottom water, the more evident the edge and bottom water intrusion. Comprehensive analysis results of well performance of these two types of wells in different sedimentary rhythms indicate that the performance of synergistic CO

2 huff and puff is considerably affected by the sedimentary rhythm.

(3) Permeability contrast of inter-well channel

The dominant flow channels between wells are considerably important in distributing the remaining oil during water flooding development [

44]. For gas flooding development, existing studies have shown that the existence of dominant flow channels causes gas channeling along the flow channel and worsens the development performance of gas flooding. To clarify the influence of the advantageous flow channels between wells on the performance of synergistic CO

2 huff and puff, we set advantages flow channel in 3–11 simulation layers. The channel permeability contrasts are 1, 20, 50, and 100, and the permeability profiles diagrams of permeability contrast 1 and 100 are shown in

Figure 11.

The oil increment of P1, P2, and well group under different channel permeability contrasts is shown in

Figure 12. The oil increment of well P1 increases with the increase in permeability contrast, whereas it decreases for well P2 as the channel permeability level difference increases. When the channel permeability contrast is 1, the oil increment of P1 well is 445 t, which is less than 628 t of P2. As the channel permeability contrast increases to 20, the oil increment of P1 increases to 657 t, but the oil increment of P2 decreases to 254 t. Subsequently, with the further increase in permeability contrast, the oil increment of both production wells decreases slightly. When there is no main flow channel, the high-position well presents a higher oil increment.

Figure 13 shows the production gas–oil ratio (GOR) curve of P2. As the channel permeability contrast increases from 1 to 100, the GOR rises from 1600 to 15,000 m

3/m

3. The larger the channel permeability contrast, the more CO

2 is consumed in the strong water washing layer, and the worse the well group oil increases.

Comparing the oil saturation before and after gas injection, shown in

Figure 14 and

Figure 15, respectively, it was found that without channel, the oil saturation between production wells and near P1 increases. When the channel permeability contrast exceeds 1, the oil saturation between production wells decreases, and crude oil migrates down the channel. Therefore, in the presence of channels, CO

2 is transported to the upper part of the oil layer under the influence of gravity differentiation, and crude oil migrates and accumulates to the lower part, resulting in a high oil increment of low-structural-position wells.

(4) Allocation scheme of injection volume

The total gas injection volume of the two wells is 800 t, which remains unchanged, and the injection volume allocation schemes are shown in

Table 8.

Figure 16 shows the oil increment in each injection volume allocation scheme. As the injection volume of the low-structural-position well P1 increases from 100 to 700 t, the oil increment increases from 247 to 581 t, and the oil increment of the well group increases from 838 to 917 t. As the injection volume of P2 decreases, the oil increment decreases from 591 to 386 t. Although the oil increment of P2 gradually decreases, the synergistic CO

2 huff and puff still shows a good performance because the oil increment of P1 is higher than the decrease in P2.

The viscosity distributions after well stuff of different injection volume allocation schemes are shown in

Figure 17. According to

Figure 17, as the injection volume of P1 increases, the viscosity reduction range near the well P1 becomes larger, and the oil viscosity between P1 and P2 also decreases. Thus, the action range of CO

2 increases. Comparing the oil saturation of different injection schemes, shown in

Figure 18, it was found that as the injection volume of the lower-structural-position well P1 increases, the average oil saturation decreases after validity period and the production degree and production action range increases. Under the influence of gravity differentiation and edge–bottom water propulsion, the effect of CO

2 to drive crude oil to a higher position is more evident; thus, the larger the injection amount at the lower-structural-position well, the better the development performance of CO

2 synergistic huff and puff.

(5) Well spacing

Figure 19 shows the oil increment of P1, P2, and well group with different well spacing. It can be seen from the figure that as the well spacing increases, the oil increment of P1 increases, whereas it decreases for P2. The oil increment in the well group decreases and then increases, forming a V shape. When the well spacing is higher than 60 m, it has little influence on the performance of higher-structural-position wells.

The production water cut of P1 and P2 after well stuffy is shown in

Figure 20. It can be seen from

Figure 20 that as the well spacing increases, the lower-structural-position well P1 gradually decreases, whereas the water cut of P2 remains unchanged.

Figure 21 shows the oil distribution after the production validity period, and the well spacing mainly affects the lower-structural-position well. The larger the well spacing, the higher the CO

2 sweep volume, the lower the production water cut after well stuffy, and the higher the oil increment of the lower-structural-position well. If the well spacing exceeds 60 m, it has little effect on the performance of synergistic CO

2 huff and puff of high-position wells.

(6) Relationship with structural isobaths

For horizontal wells, the relative direction of the horizontal section and the structural contours affect the performance of huff and puff [

45]. To determine the influence of the relative direction of the horizontal section and structural isobaths on the development performance of synergistic CO

2 huff and puff, a comparative study was made on the oil increment when the horizontal well line and the structural isobaths line are perpendicular and parallel.

Figure 22 shows the oil increment of P1, P2, and well group of different relationships with structural isobaths. It was found that when the line of the huff-and-puff well is parallel to the isobaths, the oil increment is lower than that when the line is perpendicular to the isobaths. Thus, a better performance is obtained for the perpendicular case. This is because when the horizontal well is parallel to isobaths, it is affected by strong edge water, and water cut rapidly rises, which leads to a lower oil increment.

3.1.2. Single-Well Synergistic Mode

The model parameters are consistent with the two-well synergistic mode. However, under the single-well synergistic mode, the high-position well P2 maintains production during the entire program of CO2 huff and puff of low-position well P1. Single-well synergistic CO2 huff and puff does not involve the allocation of injection volume and the relationship with isobaths. In addition, the influence of permeability contrast of inter-well channel, stratum dip, and sedimentary rhythm on the development performance is generally applicable. Therefore, the main controlling factors in this mode are well spacing and daily liquid production rate of higher-structural-position wells.

(1) Permeability contrast of inter-well channel

The dominant flow channels between wells are important in distributing the remaining oil during water flooding development. For gas flooding development, existing studies have shown that the existence of dominant flow channels causes gas channeling along the flow channel and worsen the development performance of gas flooding. The oil increment of P1, P2, and well group under different channel permeability contrasts is shown in

Figure 23. The oil increment of well P1 increases with the increase in permeability contrast, and the oil increment of well P2 decreases as the channel permeability level difference increases. When the channel permeability contrast is 1, the oil increment of P1 well is 130 t, which is less than 1343 t of P2. As the channel permeability contrast increases to 20, the oil increment of P1 decreases to 85 t, and the oil increment of P2 decreases to 329 t. Subsequently, with further increase in permeability contrast, the oil increment of both production wells decreases slightly. When there is no main flow channel, the high-position well present a higher oil increment.

Figure 24 shows the comparison of P1 water cut before and after CO

2 huff and puff. It can be seen that with the increase in permeability contrast of inter-well channel, the water cut after CO

2 huff and puff increases. This indicates that the higher the permeability contrast, the worse the water cur reduction ability.

(2) Well Spacing

For the single-well synergistic mode, five levels of 40, 60, 70, 80, and 120 m are designed to investigate the impact of well spacing on the performance of synergistic CO

2 huff and puff. The influence of well spacing on the oil increase and water cut is shown in

Figure 25 and

Figure 26. The results indicate that for the lower-structural-position well P1, as the well spacing increases, the CO

2 swept volume increases. The lower the water cut after well stuffy, the higher the oil increase. When the well spacing exceeds 70 m, the higher-structural-position well P2 is less affected by the huff and puff of lower-structural-position well P1. With the increase in well spacing, the total oil increment continues to increase. When the well spacing exceeds 70 m, the total oil increment decreases. These results indicate that CO

2 has a certain sweep radius after injection into the formation.

(3) Liquid production rate of high-position well

The liquid production rate of high-position wells mainly affects the gas migration speed in the formation [

46]. To clarify the influence of the high-position well liquid production rate on the performance of CO

2 huff and puff, three levels of 20, 100, and 200 m

3/d are designed. Statistical results of the oil increase and water cut after well opening at different liquid production rates are shown in

Figure 27 and

Figure 28. It can be seen from

Figure 27 that with the increase in liquid production rate of P2, the oil increment of P1 well decreases, whereas that of P2 well increases, and the oil increment of the well group first increases and then basically remains unchanged. From

Figure 28, it is observed that the production water cut of well P1 after well stuffy decreases. With the increase in well spacing, the production water cut increases, and the water cut reduction capacity of synergistic CO

2 huff and puff decreases.

The production GOR of P1 is shown in

Figure 29. It can be seen that as production progresses, gas channeling occurs in the high-structural-position well. The higher the liquid production rate of the high-position well, the earlier the gas channeling but the smaller the maximum GOR. This is because the higher the liquid production rate, the higher the rate of CO

2 migration to high-position wells, and the earlier the gas channeling in high-position wells. When the liquid production rate is small, the CO

2 migration speed is slow. In the process of slow upward migration, a large amount of CO

2 is accumulated and stored between the wells. After the gas reaches the P1 well, the inter-well percolation resistance rapidly decreases, such that the CO

2 quickly migrates to the bottom of the well and the GOR rises sharply. When the liquid production rate is high, the CO

2 migration is relatively fast. During the upward migration process, there is less accumulated CO

2; thus, the maximum gas oil is relatively small. The simulation results indicate that the higher the liquid production rate of higher-structural-position wells, the earlier the gas channeling, the smaller the decrease in water cut after well stuffy of low-position well, and the smaller the oil increase.