Experimental Study of Fuel Consumption and Exhaust Gas Composition of a Diesel Engine Powered by Biodiesel from Waste of Animal Origin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Fuel

2.2. Purpose and Scope of Experimental Testing

2.3. Engine Selected for Testing

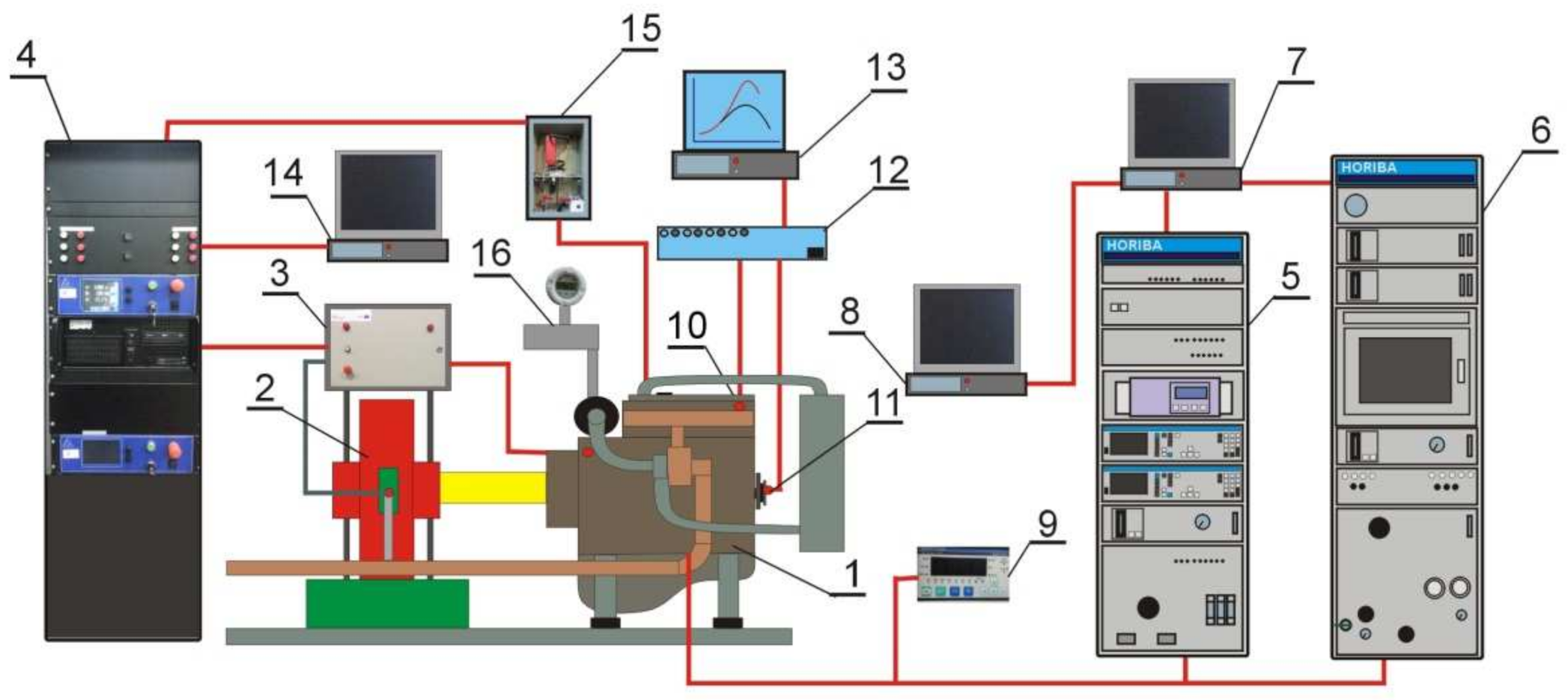

2.4. Experimental Setup

2.5. Measurement Instrumentation

2.6. Development Methodology of the Experimental Test Results

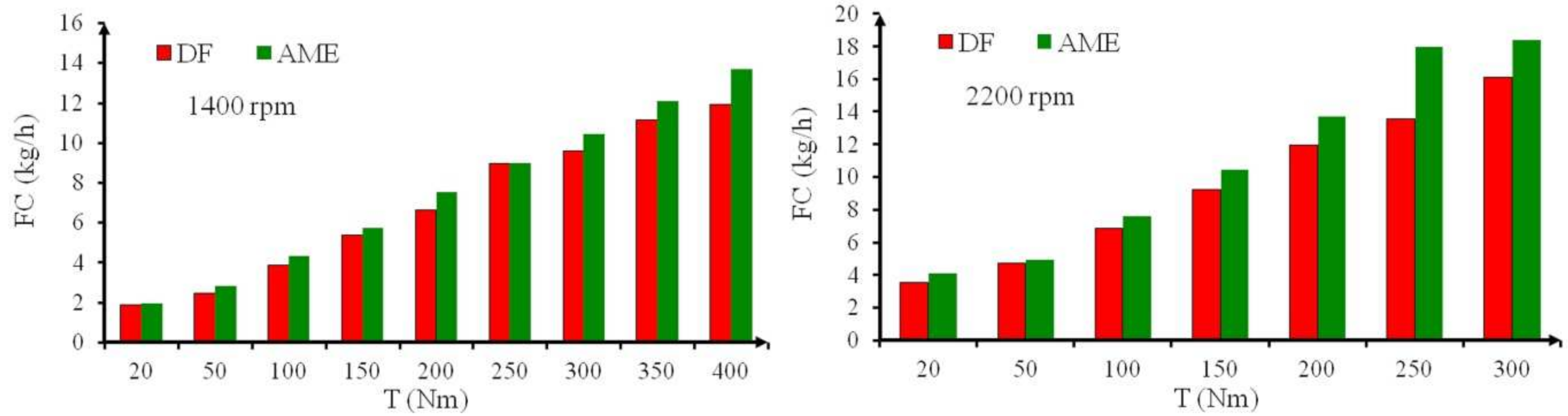

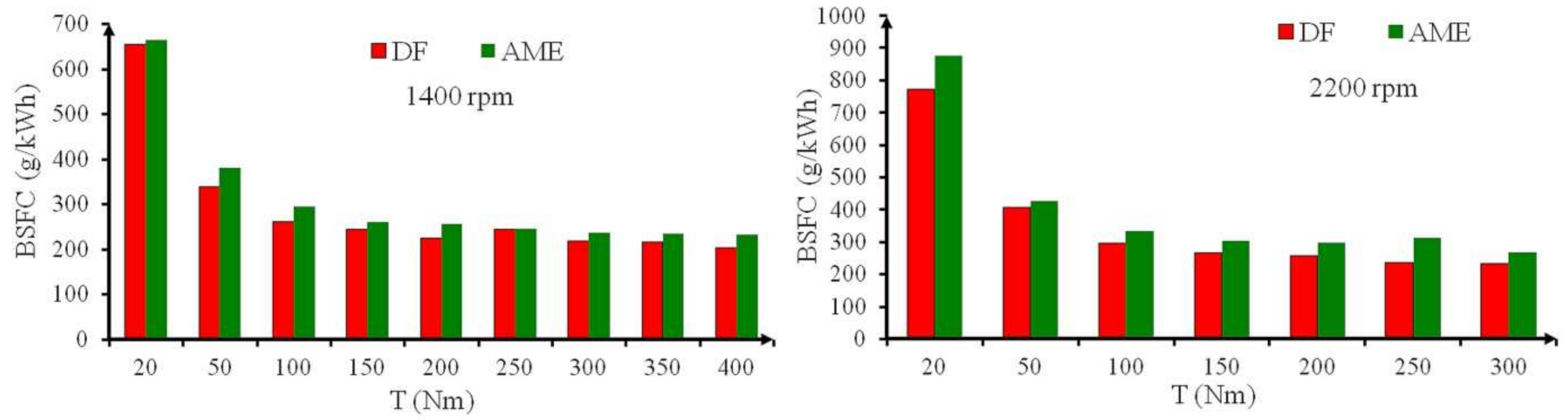

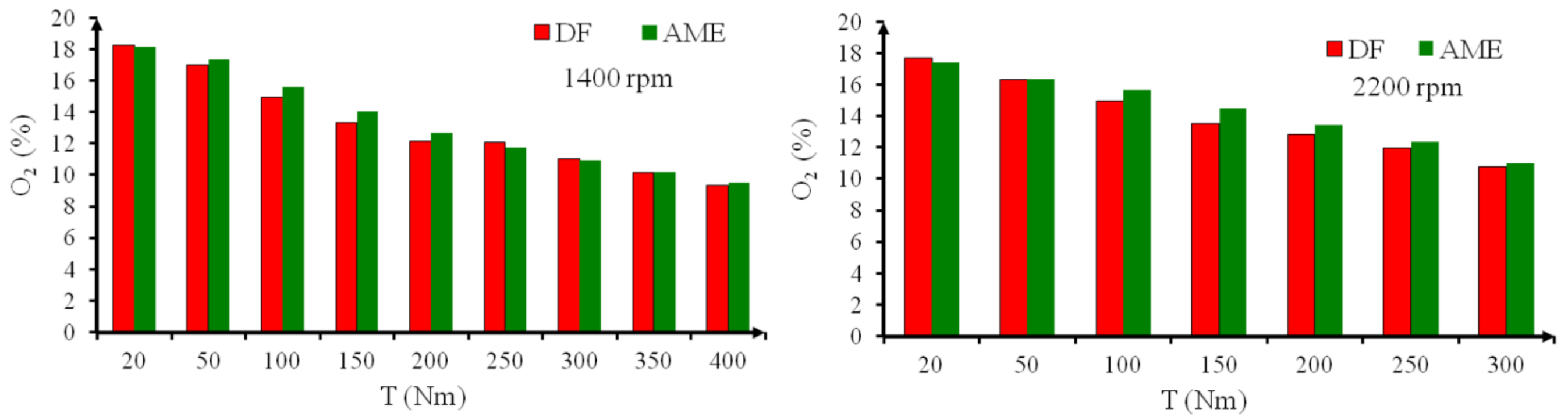

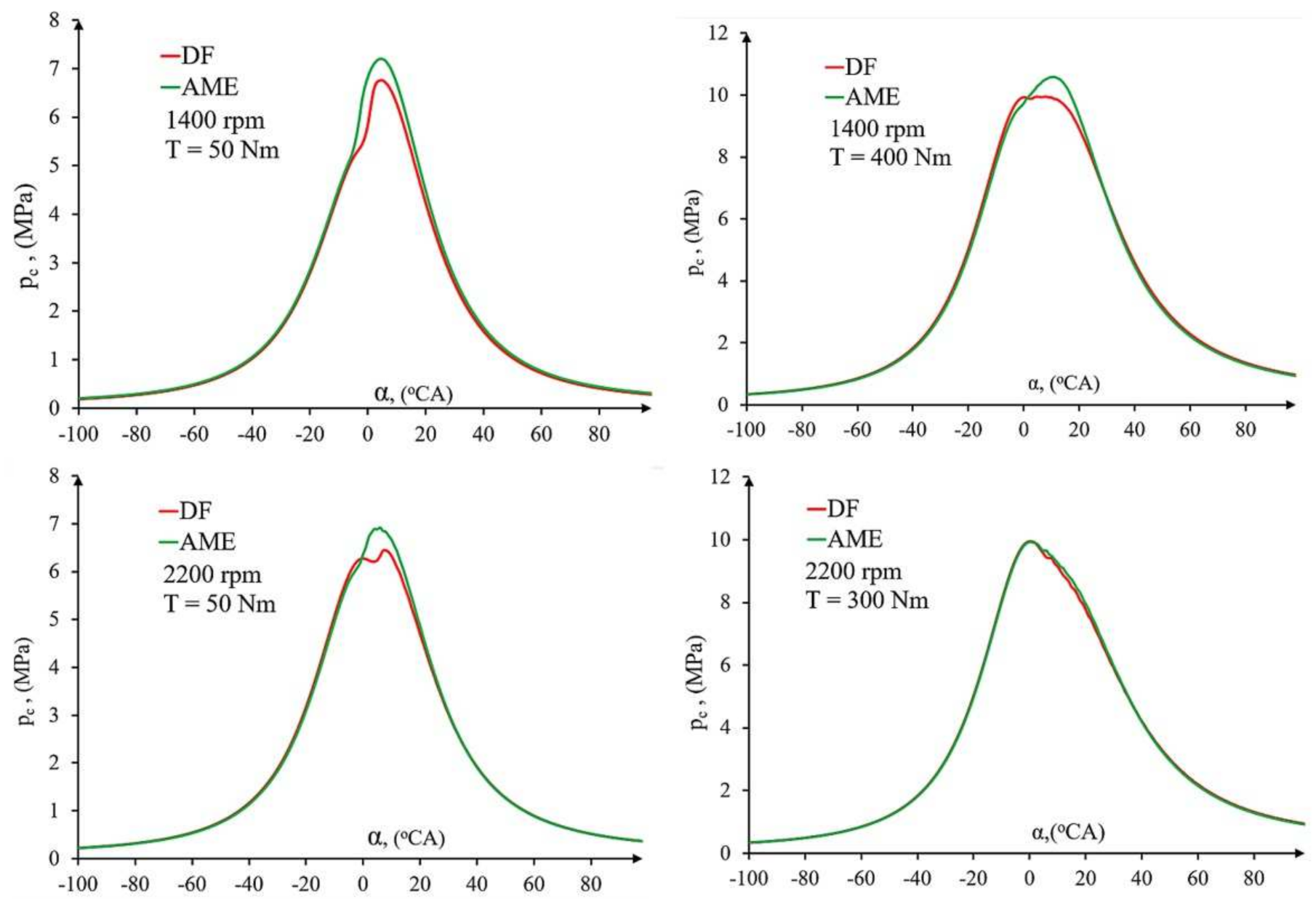

3. Test Results and Analysis

4. Conclusions

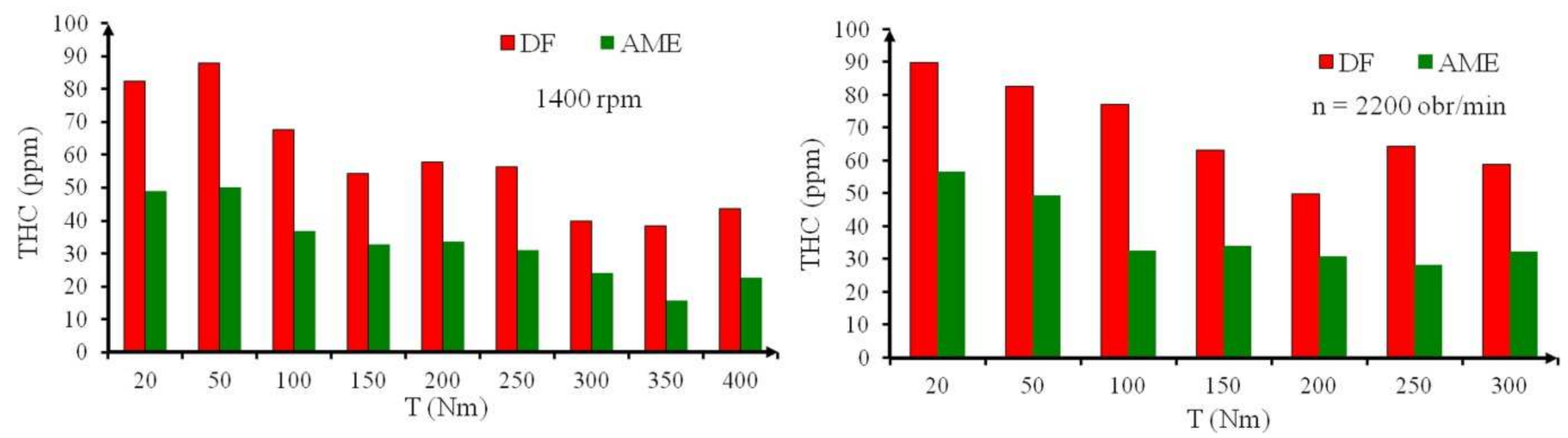

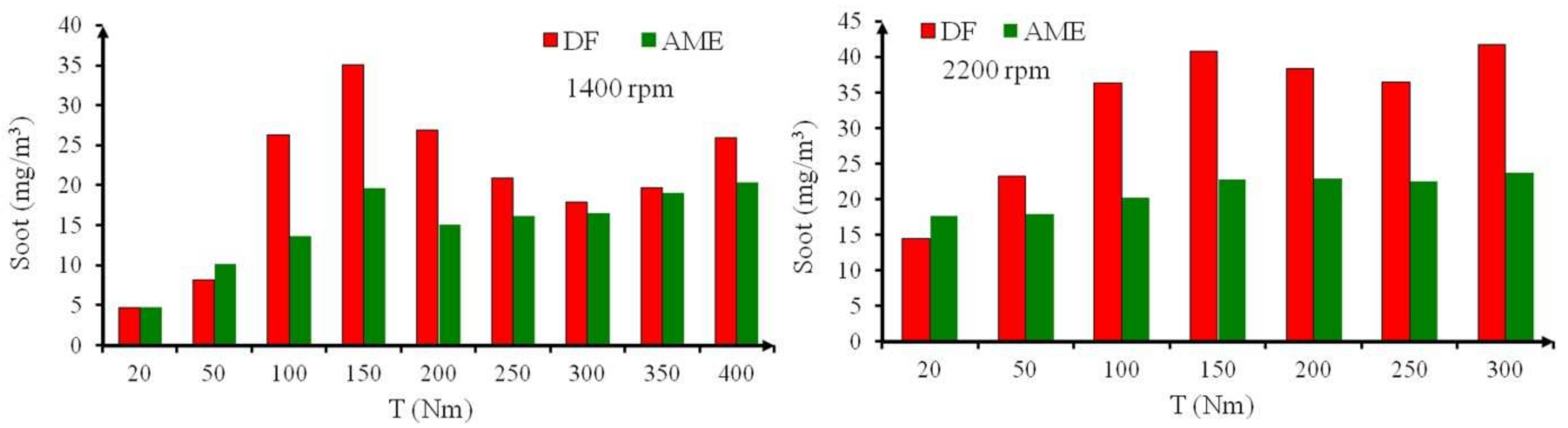

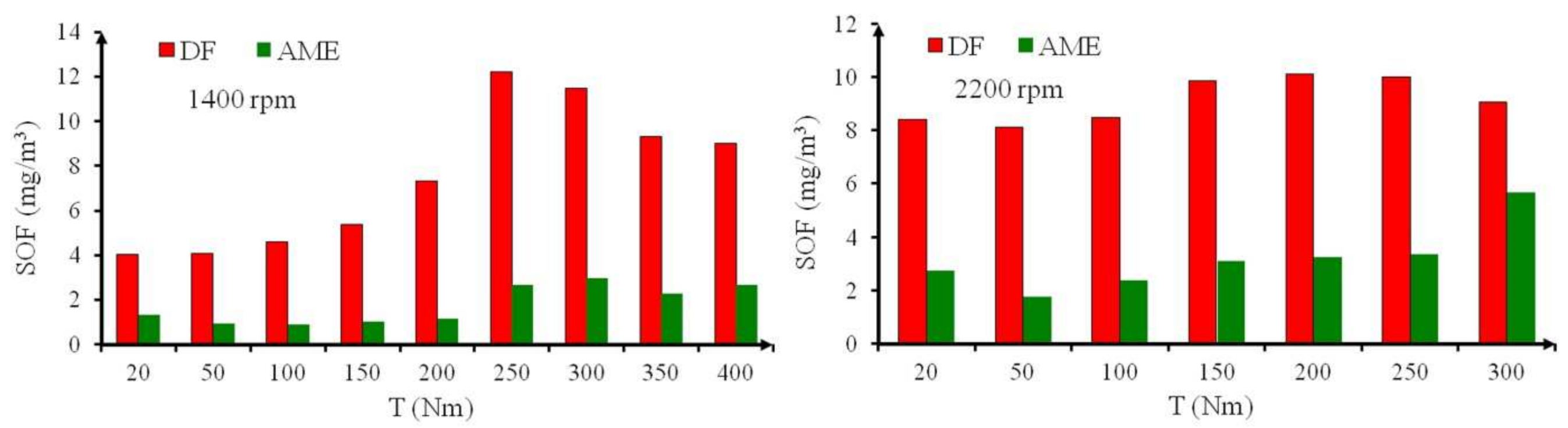

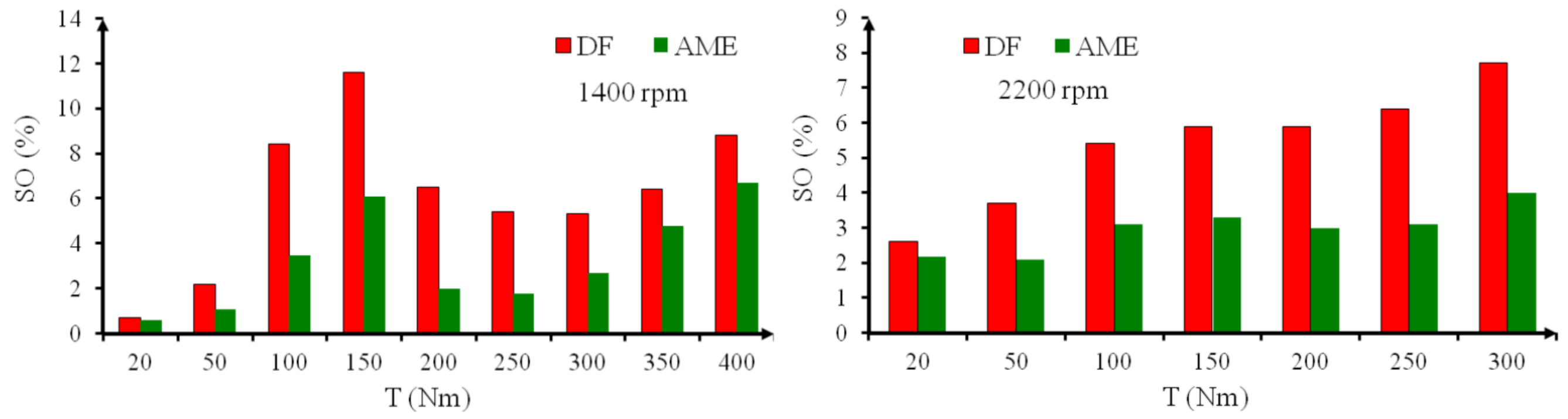

- The use of pure AMEs to fuel the engine allowed for a substantial reduction in the hydrocarbon and PM concentrations of the exhaust gas when compared to DF. The average reduction in THC concentration of the exhaust gas over the entire load range investigated was approximately 45% lower, whereas the average reduction in PM concentration was approximately 36.5% lower at 1400 rpm and 39.7% lower at 2200 rpm.

- Fuelling the engine with AMEs also led to the average reduction in smoke opacity that was over 40% lower over the entire load range investigated both for 1400 rpm and 2200 rpm.

- The CO2 concentrations of the exhaust gas were comparable for the two fuels.

- Fuelling the engine with AMEs resulted in the average reduction in CO concentration that was approximately 7.2% at 1400 rpm and 13.4% at 2200 rpm over the entire load range investigated.

- Fuel consumption increased with the use of the AME fuel. The average increased BSFC over the entire load range investigated amounted to approximately 8.4% at 1400 rpm and 15.2% at 2200 rpm. This is obviously a result of the biodiesel’s lower heating value.

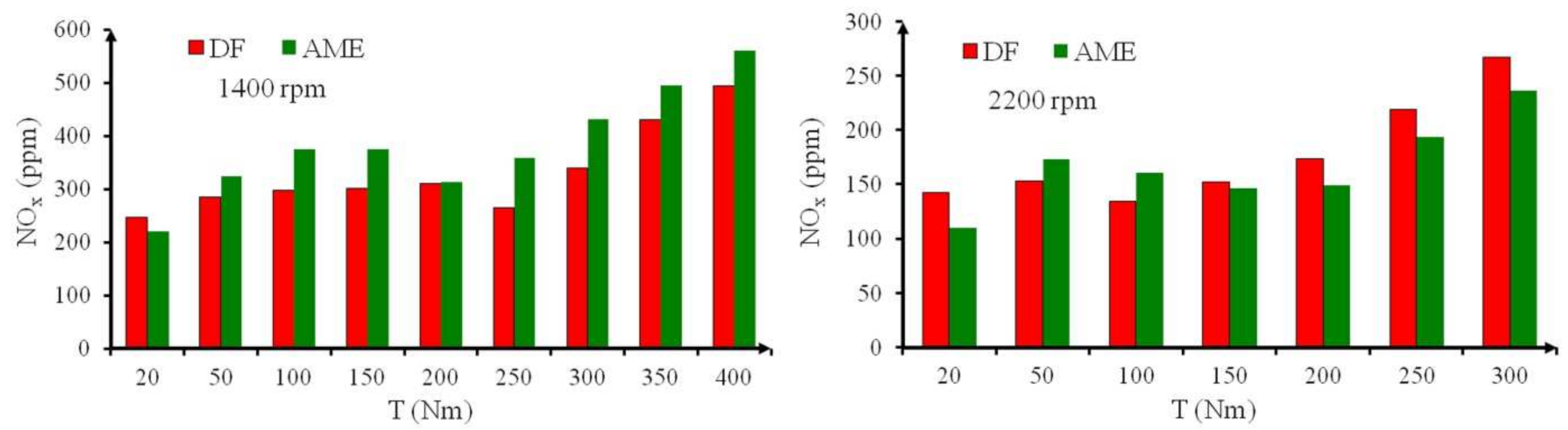

- The average increased in NOx concentrations of the exhaust gas amounted to approximately 15.9% over the entire load range investigated for 1400 rpm when the engine was fuelled with AMEs. On the other hand, at 2200 rpm, the average reduction in NOx concentration amounted to approximately 4.4% when the engine was fuelled with AMEs. It can be assumed that with suitable fuel injection control, it is possible to reduce NOx emissions at lower crankshaft rotation speeds. This aspect requires further research.

- Similar BTE quantities were obtained when the engine was fuelled with AMEs and with DF. AME fuel is characterised by high self-ignition capabilities. A correction in the injection process may improve the effectiveness of the combustion process. Further detailed testing would be required for this purpose.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AME | animal methyl esters |

| BSFC | brake specific fuel consumption, g/kWh |

| BTE | brake thermal efficiency, % |

| CA | crank angle, deg |

| CFPP | cold filter plugging point |

| CLD | chemiluminescent detector |

| CO | carbon monoxide, ppm |

| CO2 | carbon dioxide, % |

| DC | diffusion charging |

| DF | diesel fuel |

| FAME | fatty acid methyl ester |

| FC | hourly fuel consumption, kg/h |

| FID | flame ionisation detector |

| HPLC | high performance liquid chromatography |

| LHV | lower heating value, kJ/kg |

| MPD | paramagnetic detector |

| NOx | nitrogen oxides, ppm |

| NDIR | non-dispersive infrared |

| O2 | oxygen, % |

| pc | cylinder pressure, MPa |

| P | engine power, kW |

| PM | particulate matter, mg/m3 |

| PNA | polynuclear aromatic hydrocarbons |

| SO | smoke opacity of the exhaust gas, % |

| SOF | soluble organic fraction, mg/m3 |

| T | torque, Nm |

| THC | total hydrocarbons, ppm |

| WSD | wear scar diameter |

| ΔCO | standard uncertainty of the arithmetic mean of CO measurements, ppm |

| ΔCO2 | standard uncertainty of the arithmetic mean of CO2 measurements, % |

| ΔNOx | standard uncertainty of the arithmetic mean of NOx measurements, ppm |

| ΔO2 | standard uncertainty of the arithmetic mean of O2 measurements, % |

| ΔTHC | standard uncertainty of the arithmetic mean of THC measurements, ppm |

| ΔSoot | standard uncertainty of the arithmetic mean of Soot measurements, mg/m3 |

| ΔSOF | standard uncertainty of the arithmetic mean of SOF measurements, mg/m3 |

| ΔPM | standard uncertainty of the arithmetic mean of PM measurements, mg/m3 |

| ΔT | standard uncertainty of the arithmetic mean of T measurements, Nm |

| ΔP | standard uncertainty of the arithmetic mean of P measurements, kW |

| ΔFC | standard uncertainty of the arithmetic mean of FC measurements, kg/h |

| Δ(BSFC)c | complex uncertainty of BSFC calculations, g/kWh |

| Δ(BTE)c | complex uncertainty of BTE calculations, % |

References

- Klimiuk, E.; Pawłowska, M.; Pokój, T. Biofuels. Technologies for Sustainable Development; Polish Scientific Publishers PWN: Warsaw, Poland, 2012. [Google Scholar]

- Tayari, S.; Abedi, R.; Rahi, A. Comparative assessment of engine performance and emissions fueled with three different biodiesel generations. Renew. Energy 2020, 147, 1058–1069. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K. Prospects of 2nd generation biodiesel as a sustainable fuel—Part: 1 selection of feedstocks, oil extraction techniques and conversion technologies. Renew. Sustain. Energy Rev. 2016, 55, 1109–1128. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Yaşar, F. Comparison of fuel properties of biodiesel fuels produced from different oils T to determine the most suitable feedstock type. Fuel 2020, 264, 116817. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The examination of a compression-ignition engine powered by peanut oil biodiesel and diesel fuel in terms of energetic and exegetic performance parameters. Fuel 2020, 278, 118319. [Google Scholar] [CrossRef]

- Saravanan, A.; Murugan, M.; Sreenivasa, R.M.; Parida, S. Performance and emission characteristics of variable compression ratio CI engine fueled with dual biodiesel blends of Rapeseed and Mahua. Fuel 2020, 263, 116751. [Google Scholar] [CrossRef]

- Zhong, W.; Xuan, T.; He, Z.; Wang, Q.; Li, D.; Zhang, X.; Yin, H.Y. Experimental study of combustion and emission characteristics of diesel engine with diesel/second-generation biodiesel blending fuels. Energy Convers. Manag. 2016, 121, 241–250. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumari, D. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel 2019, 253, 60–71. [Google Scholar] [CrossRef]

- Saladini, F.; Patrizi, N.; Pulselli, F.M.; Marchettini, N.; Bastianoni, S. Guidelines for energy evaluation of first, second and third generation biofuels. Renew. Sustain. Energy Rev. 2016, 66, 221–227. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Shameer, P.M. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Biernat, K. Perspectives for global development of biofuel technologies to 2050. Chemik 2012, 66, 1178–1189. [Google Scholar]

- Damartzis, T.; Zabaniotou, A. Thermochemical conversion of biomass to second generation biofuels through integrated process design—A review. Renew. Sustain. Energy Rev. 2011, 15, 366–378. [Google Scholar] [CrossRef]

- Ghasemi, A.; Moosavi-Nasab, M. Production of second-generation biodiesel using low-quality date fruits. Biotechnol. Rep. 2020, 27, e00480. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Commission of the European Communities. White Paper, European Transport Policy for 2010: Time to Decide; Commission of the European Communities: Brussels, Belgium, 2001. [Google Scholar]

- Commission of the European Communities. Communication from the Commission, an EU Strategy for Biofuels; Commission of the European Communities: Brussels, Belgium, 2006. [Google Scholar]

- Communication from the Commission to the Council and the European Parliament. Renewable Energy Road Map Renewable Energies in the 21st Century: Building a More Sustainable Future; Commission of the European Communities: Brussels, Belgium, 2007. [Google Scholar]

- Commission of the European Communities. Communication from the Commission to the Council and the European Parliament. Final Report on the Green Paper “Towards a European Strategy for the Security of Energy Supply”; Commission of the European Communities: Brussels, Belgium, 2002. [Google Scholar]

- European Parliament, Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; European Parliament: Strasbourg, France, 2009. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. In Clean Power for Transport: A European Alternative Fuels Strategy; European Commission: Brussels, Belgium.

- Kurczyński, D.; Łagowski, P. Performance indices of a common rail-system CI engine powered by diesel oil and biofuel blends. J. Energy Inst. 2019, 92, 1897–1913. [Google Scholar] [CrossRef]

- Özener, O.; Yuksek, L.; Ergenc, A.T.; Ozkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Shehata, M.S.; Razak, S.M.A. Experimental investigation of diesel engine performance and emission characteristics using jojoba/diesel blend and sunflower oil. Fuel 2011, 90, 886–897. [Google Scholar] [CrossRef]

- Aldhaidhawi, M.; Chiriac, R.; Badescu, V. Ignition delay, combustion and emission characteristics of Diesel engine fueled with rapeseed biodiesel—A literature review. Renew. Sustain. Energy Rev. 2017, 73, 178–186. [Google Scholar] [CrossRef]

- Merkisz, J.; Kozak, M.; Pielecha, J.; Andrzejewski, M. The influence of application of different diesel fuel-RME blends on PM emissions from a diesel engine. Combust. Engines 2012, 1, 35–39. [Google Scholar]

- Millo, F.; Debnath, B.K.; Vlachos, T.; Ciaravino, C.; Postrioti, L.; Buitoni, G. Effects of different biofuels blends on performance and emissions of an automotive diesel engine. Fuel 2015, 159, 614–627. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Araby, R.; Abed, K.A.; El-Ibiari, N.N.; El Morsi, A.K.; El-Diwani, G.I. Performance and emissions characteristics of C.I. engine fueled with palm oil/palm oil methyl ester blended with diesel fuel. Egypt. J. Petroleum 2018, 27, 215–219. [Google Scholar] [CrossRef]

- Ilkiliç, C. The Effect of Sunflower Oil Methyl Ester and Diesel Fuel Blend on the Performance of a Diesel Engine. Energy Sources, Part A Recover. Util. Environ. Eff. 2008, 30, 1761–1770. [Google Scholar] [CrossRef]

- Demirbas, A. Potential resources of non-edible oils for biodiesel. Energy Source Part B 2009, 4, 310–314. [Google Scholar] [CrossRef]

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- Deepanraj, B.; Srinivas, M.; Arun, N.; Sankaranarayanan, G.; Abdul, S.P. Comparison of jatropha and karanja biofuels on their combustion characteristics. Int. J. Green Energy 2017, 14, 231–1237. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Experimental investigations of the effect of pilot injection on performance, emissions and combustion characteristics of Karanja biodiesel fuelled CRDI engine. Energy Convers. Manag. 2015, 93, 357–366. [Google Scholar] [CrossRef]

- Yadav, A.K.; Khan, M.E.; Dubey, A.M.; Pal, A. Performance and emission characteristics of a transportation diesel engine operated with non-edible vegetable oils biodiesel. Case Stud. Therm. Eng. 2016, 8, 236–244. [Google Scholar] [CrossRef] [Green Version]

- Raheman, H.; Ghadge, S.V. Performance of compression ignition engine with mahua (Madhuca Indica) biodiesel. Fuel 2007, 86, 2568–2573. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Biodiesel production from high FFA rubber seed oil. Fuel 2005, 84, 335–340. [Google Scholar] [CrossRef]

- Ghadge, S.V.; Raheman, H. Biodiesel production from mahua (Madhuca Indica) oil having high free fatty acids. Biomass Bioenergy 2005, 28, 601–605. [Google Scholar] [CrossRef]

- Veljković, V.B.; Lakicević, S.H.; Stamenković, O.S.; Todorović, Z.B.; Lazić, M.L. Biodiesel production from tobacco (Nicotianatabacum L.) seed oil with a high content of free fatty acids. Fuel 2006, 85, 2671–2675. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Rajamanoharan, K. Experimental investigations of performance and emissions of Karanja oil and its blends in a single cylinder agricultural diesel engine. Appl. Energy 2009, 86, 106–112. [Google Scholar] [CrossRef]

- Ganapathy, T.; Murugesan, K.; Gakkhar, R.P. Performance optimization of Jatropha biodiesel engine model using Taguchi approach. Appl. Energy 2009, 86, 2476–2486. [Google Scholar] [CrossRef]

- Huang, G.; Chen, F.; Wei, D.; Zhang, X.; Chen, G. Biodiesel production by microalgal biotechnology. Appl. Energy 2010, 87, 38–46. [Google Scholar] [CrossRef]

- Akubude, V.C.; Nwaigwe, K.N.; Dintwa, E. Production of biodiesel from microalgae via nanocatalyzed transesterification process: A review. Mater. Sci. Energy Technol. 2019, 2, 216–225. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Assessment of diesel engine performance using spirulina microalgae biodiesel. Energy 2019, 166, 1025–1036. [Google Scholar] [CrossRef]

- Sun, J.; Xiong, X.; Wang, M.; Du, H.; Li, J.; Zhou, D.; Zuo, J. Microalgae biodiesel production in China: A preliminary economic analysis. Renew. Sustain. Energy Rev. 2019, 104, 296–306. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Dong, W.; Zhang, X.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. The potential of microalgae in biodiesel production. Renew. Sustain. Energy Rev. 2018, 90, 336–346. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Christi, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Faried, M.; Samer, M.; Abdelsalam, E.; Yousef, R.S.; Attia, Y.A.; Ali, A.S. Biodiesel production from microalgae: Processes, technologies and recent advancements. Renew. Sustain. Energy Rev. 2017, 79, 893–913. [Google Scholar] [CrossRef]

- Brémond, U.; Bertrandias, A.; Steyer, J.-P.; Bernet, N.; Carrere, H. A vision of European biogas sector development towards 2030: Trends and challenges. J. Clean. Prod. 2021, 287, 125065. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Black, A.; Tormey, D.; Bartlett, J. Biogas production from small-scale anaerobic digestion plants on European farms. Renew. Sustain. Energy Rev. 2021, 139, 110580. [Google Scholar] [CrossRef]

- Mainardis, M.; Goi, D. Pilot-UASB reactor tests for anaerobic valorisation of high-loaded liquid substrates in Friulian mountain area. J. Environ. Chem. Eng. 2019, 7, 103348. [Google Scholar] [CrossRef]

- Stürmer, B.; Leiers, D.; Anspach, V.; Brügging, E.; Scharfy, D.; Wissel, T. Agricultural biogas production: A regional comparison of technical parameters. Renew. Energy 2021, 164, 171–182. [Google Scholar] [CrossRef]

- Allah, W.A.; Tawfik, M.; Sagade, A.A.; Gorjian, S.; Metwally, K.; El-Shal, H. Methane production enhancement of a family-scale biogas digester using cattle manure and corn stover under cold climates. Sustain. Energy Technol. Assess. 2021, 45, 101163. [Google Scholar] [CrossRef]

- Prabhu, A.V.; Avinash, A.; Brindhadevi, K.; Pugazhendhi, A. Performance and emission evaluation of dual fuel CI engine using preheated biogas-air mixture. Sci. Total. Environ. 2021, 754, 142389. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Investigation of the impacts of gasoline, biogas and LPG fuels on engine performance and exhaust emissions in different throttle positions on SI engine. Fuel 2020, 279, 118528. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K. Comparative assessment of a spark ignition engine fueled with gasoline and raw biogas. Renew. Energy 2019, 134, 1307–1319. [Google Scholar] [CrossRef]

- Feroskhan, M.; Thangavel, V.; Subramanian, B.; Sankaralingam, R.K.; Ismail, S.; Chaudhary, A. Effects of operating parameters on the performance, emission and combustion indices of a biogas fuelled HCCI engine. Fuel 2021, 298, 120799. [Google Scholar] [CrossRef]

- Legrottaglie, F.; Mattarelli, E.; Rinaldini, C.A.; Scrignoli, F. Application to micro-cogeneration of an innovative dual fuel compression ignition engine running on biogas. Int. J. Thermofluids 2021, 10, 100093. [Google Scholar] [CrossRef]

- Abed, K.; El Morsi, A.; Sayed, M.; El Shaib, A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Petroleum 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.; Hassan, N.; Uddin, M. Investigation of exhaust emissions from a stationary diesel engine fuelled with biodiesel. Energy Procedia 2019, 160, 791–797. [Google Scholar] [CrossRef]

- Borah, M.J.; Das, A.; Das, V.; Bhuyan, N.; Deka, D. Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste egg shell derived CaO nanocatalyst. Fuel 2019, 242, 345–354. [Google Scholar] [CrossRef]

- Fonseca, J.; Teleken, J.G.; Almeida, V.D.C.; da Silva, C. Biodiesel from waste frying oils: Methods of production and purification. Energy Convers. Manag. 2019, 184, 205–218. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Rehman, H.-U.; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hsu, K.-H.; Chen, C.-B. Experimental investigation of the performance and emissions of a heavy-duty diesel engine fueled with waste cooking oil biodiesel/ultra-low sulfur diesel blends. Energy 2011, 36, 241–248. [Google Scholar] [CrossRef]

- Kassem, Y.; Çamur, H. Effects of storage under different conditions on the fuel properties of biodiesel admixtures derived from waste frying and canola oils. Biomass Convers. Biorefin. 2018, 8, 825–845. [Google Scholar] [CrossRef]

- Uddin, M.; Techato, K.; Rasul, M.; Hassan, N.; Mofijur, M. Waste coffee oil: A promising source for biodiesel production. Energy Procedia 2019, 160, 677–682. [Google Scholar] [CrossRef]

- Mikulski, M.; Duda, K.; Wierzbicki, S. Performance and emissions of a CRDI diesel engine fuelled with swine lard methyl esters–diesel mixture. Fuel 2016, 164, 206–219. [Google Scholar] [CrossRef]

- Sakthivel, G. Prediction of CI engine performance, emission and combustion characteristics using fish oil as a biodiesel at different injection timing using fuzzy logic. Fuel 2016, 183, 214–229. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.-J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljković, V.B.; Hung, Y.-T. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef] [Green Version]

- Sakthivel, G.; Sivaraja, C.; Ikua, B.W. Prediction OF CI engine performance, emission and combustion parameters using fish oil as a biodiesel by fuzzy-GA. Energy 2019, 166, 287–306. [Google Scholar] [CrossRef]

- Cunha, A.; Feddern, V.; De Prá, M.C.; Higarashi, M.M.; de Abreu, P.G.; Coldebella, A. Synthesis and characterization of ethylic biodiesel from animal fat wastes. Fuel 2013, 105, 228–234. [Google Scholar] [CrossRef] [Green Version]

- Alptekin, E.; Canakci, M.; Sanli, H. Biodiesel production from vegetable oil and waste animal fats in a pilot plant. Waste Manag. 2014, 34, 2146–2154. [Google Scholar] [CrossRef] [PubMed]

- Encinar, J.; Sánchez, N.; Martínez, G.; García, L. Study of biodiesel production from animal fats with high free fatty acid content. Bioresour. Technol. 2011, 102, 10907–10914. [Google Scholar] [CrossRef] [PubMed]

- Kirubakaran, M.; Selvan, V.A.M. A comprehensive review of low cost biodiesel production from waste chicken fat. Renew. Sustain. Energy Rev. 2018, 82, 390–401. [Google Scholar] [CrossRef]

- Wcisło, G. Analysis of the Impact of Rapeseed Varieties on the Properties of RME Biofuels and Diesel Engine Operation Parameters; FALL Publishing House: Krakow, Poland, 2013. [Google Scholar]

- Kurczyński, D.; Łagowski, P.; Wcisło, G. Experimental study into the effect of the second-generation BBuE biofuel use on the diesel engine parameters and exhaust composition. Fuel 2021, 284, 118982. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

- Balamurugan, T.; Arun, A.; Sathishkumar, G. Biodiesel derived from corn oil—A fuel substitute for diesel. Renew. Sustain. Energy Rev. 2018, 94, 772–778. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Rao, Y.V.H.; Voleti, R.S.; Raju, A.V.S.; Reddy, P.N. The effect of cottonseed oil methyl ester on the performance and exhaust emissions of a diesel engine. Int. J. Ambient. Energy 2010, 31, 203–210. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.; Kalam, A.; Fattah, I.M.R.; Ashraful, A.; Mobarak, H. Biodiesel production and performance evaluation of coconut, palm and their combined blend with diesel in a single-cylinder diesel engine. Energy Convers. Manag. 2014, 87, 250–257. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. Experimental analysis of engine performance, combustion and emission using pongamia biodiesel as fuel in CI engine. Energy 2017, 129, 228–236. [Google Scholar] [CrossRef]

- Rakopoulos, C.; Rakopoulos, D.; Hountalas, D.; Giakoumis, E.; Andritsakis, E. Performance and emissions of bus engine using blends of diesel fuel with bio-diesel of sunflower or cottonseed oils derived from Greek feedstock. Fuel 2008, 87, 147–157. [Google Scholar] [CrossRef]

- Karabektas, M. The effects of turbocharger on the performance and exhaust emissions of a diesel engine fuelled with biodiesel. Renew. Energy 2009, 34, 989–993. [Google Scholar] [CrossRef]

- Puhan, S.; Jegan, R.; Balasubbramanian, K.; Nagarajan, G. Effect of injection pressure on performance, emission and combustion characteristics of high linolenic linseed oil methyl ester in a DI diesel engine. Renew. Energy 2009, 34, 1227–1233. [Google Scholar] [CrossRef]

- Özcanli, M.; Serin, H.; Saribiyik, O.Y.; Aydin, K.; Serin, S. Performance and Emission Studies of Castor Bean (Ricinus Communis) Oil Biodiesel and Its Blends with Diesel Fuel. Energy Sources Part A Recover. Util. Environ. Eff. 2012, 34, 1808–1814. [Google Scholar] [CrossRef]

- Swaminathan, C.; Sarangan, J. A Comparative Study of Performance and Emission Characteristics of Biodiesel Blends with Diethylene Glycol Dimethyl Ether as Additive. Energy Sources Part A: Recover. Util. Environ. Eff. 2013, 35, 778–788. [Google Scholar] [CrossRef]

- Çelikten, I.; Mutlu, E.; Solmaz, H. Variation of performance and emission characteristics of a diesel engine fueled with diesel, rapeseed oil and hazelnut oil methyl ester blends. Renew. Energy 2012, 48, 122–126. [Google Scholar] [CrossRef]

- Nwafor, O. Emission characteristics of diesel engine operating on rapeseed methyl ester. Renew. Energy 2004, 29, 119–129. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx emission of biodiesel compared to diesel: Higher or lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.; Kalam, A.; Atabani, A. Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Godiganur, S.; Murthy, C.S.; Reddy, R. 6BTA 5.9 G2-1 Cummins engine performance and emission tests using methyl ester mahua (Madhuca Indica) oil/diesel blends. Renew. Energy 2009, 34, 2172–2177. [Google Scholar] [CrossRef]

- Nayak, S.K.; Pattanaik, B.P. Experimental Investigation on Performance and Emission Characteristics of a Diesel Engine Fuelled with Mahua Biodiesel Using Additive. Energy Procedia 2014, 54, 569–579. [Google Scholar] [CrossRef] [Green Version]

- Qi, D.; Geng, L.; Chen, H.; Bian, Y.; Liu, J.; Ren, X. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Sureshkumar, K.; Velraj, R.; Ganesan, R. Performance and exhaust emission characteristics of a CI engine fueled with Pongamia pinnata methyl ester (PPME) and its blends with diesel. Renew. Energy 2008, 33, 2294–2302. [Google Scholar] [CrossRef]

- Lemaire, R.; Béjaoui, S.; Therssen, E. Study of soot formation during the combustion of Diesel, rapeseed methyl ester and their surrogates in turbulent spray flames. Fuel 2013, 107, 147–161. [Google Scholar] [CrossRef]

- Kousoulidou, M.; Fontaras, G.; Ntziachristos, L.; Samaras, Z. Biodiesel blend effects on common-rail diesel combustion and emissions. Fuel 2010, 89, 3442–3449. [Google Scholar] [CrossRef]

- Randazzo, M.L.; Sodré, J.R. Exhaust emissions from a diesel powered vehicle fuelled by soybean biodiesel blends (B3–B20) with ethanol as an additive (B20E2–B20E5). Fuel 2011, 90, 98–103. [Google Scholar] [CrossRef]

| Property | Method | Value | |

|---|---|---|---|

| Diesel Fuel | AME | ||

| Cetane number (CN) | EN ISO 5165 | 51.7 | 55.4 |

| Higher heating value, MJ/kg | PN-C-04375-3 | 46.32 | 42.23 |

| Lower heating value, MJ/kg | PN-C-04375-3 | 43.34 | 38.67 |

| Viscosity at 40 °C, mm2/s | PN-EN ISO 3104 | 2.11 | 4.32 |

| Density at 15 °C, g/cm3 | PN-EN ISO 12185 | 0.828 | 0.883 |

| Flash point, °C | EN ISO 2719 A | 58.5 | 116.2 |

| Water content, mg/kg | EN ISO 12937 | 24 | 84 |

| Cold filter plugging point, °C | EN 116 | –27 | 13 |

| Lubricity (WSD), μm | PN-EN ISO 12,156 (1) | 408 | 614 |

| HPLC total aromatics, % (m/m) | Infrared analysis (instrument TD PPA-PetroSpec by PAC) | 16.3 | – |

| HPLC PNA aromatics, % (m/m) | Infrared analysis (instrument TD PPA-PetroSpec by PAC) | 1.4 | – |

| FAME content, % (v/v) | (DF-Irox Diesel apparatus, AME-PN-EN 14103) | 0.1 | 100 |

| Parameter | Unit | Value |

|---|---|---|

| Efficiency per cycle | dm3 | 50 |

| Production time per cycle | h | 1.5 |

| Supply voltage | V | 230 |

| Process temperature | °C | 60/120 |

| Rated power per cycle | kWh | 5.24/5.15 |

| Type of catalyst | - | basic/acidic |

| Process | - | periodic or semi-continuous |

| Type of process | - | single-stage or two-stage |

| Parameter | Value |

|---|---|

| Cylinder layout | Inline |

| Cylinder count | 4 |

| Injection type | Direct |

| Power supply type | Delphi DP310 rotary pump |

| Maximum engine power | 75 kW |

| Maximum power rotational speed | 2200 rpm |

| Maximum engine torque | 416.0 Nm |

| Maximum torque rotational speed | 1400 rpm |

| Engine displacement | 4.4·10−3 m3 |

| Cylinder diameter | 105 mm |

| Piston stroke | 127 mm |

| Compression ratio | 18.2 |

| Air supply system | Turbocharger, intercooler |

| Measured Parameter | Measurement Range | Measurement Accuracy | Measurement Resolution |

|---|---|---|---|

| Rotation speed | 0–6000 rpm | ≤1 rpm | 1 rpm |

| Torque | 0–700 Nm | 1% of full scale | 0.001 Nm |

| Fuel consumption | 0–180 kg/h | 0.1% of measured value | 0.001 g/s |

| Air consumption | 0–750 kg/h | 0.2% of measured value | 0.001 kg/h |

| Component Measured | Method | Measurement Ranges Min/Max | Repeatability | Measurement Resolution | Response Time |

|---|---|---|---|---|---|

| CO | NDIR | 0–100/3000 ppm | ±1% of full scale | 0.1 ppm | 3.0 s |

| CO2 | NDIR | 0–1/16% | ±1% of full scale | 0.01% | 2.0 s |

| THC | Hot-FID | 0–100/20,000 ppm | ±1% of full scale | 0.1 ppm | 2.0 s |

| NOx | CLD | 0–100/5000 ppm | ±1% of full scale | 0.1 ppm | 3.0 s |

| O2 | MPD | 0–10/25%% | ±1% of full scale | 0.01% | 2.5 s |

| PM | Soot: DCSOF: dual-FID | 0–300 mg/m3 | ±1% of full scale | 0.01 mg/m3 | 3.0 s |

| T (Nm) | Quantities Measured Directly | Calculated Quantities | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΔCO (ppm) | ΔCO2 (%) | ΔNOx (ppm) | ΔO2 (%) | ΔTHC (ppm) | ΔSoot (mg/m3) | ΔSOF (mg/m3) | ΔPM (mg/m3) | ΔT (Nm) | ΔP (kW) | ΔFC (kg/h) | Δ(BSFC)c (g/kWh) | Δ(BTE)c (%) | |

| 20 | 0.094 | 0.012 | 1.241 | 0.041 | 1.603 | 0.327 | 0.059 | 0.344 | 0.102 | 0.015 | 0.049 | 16.950 | 0.358 |

| 50 | 0.071 | 0.013 | 1.448 | 0.023 | 0.486 | 0.212 | 0.015 | 0.212 | 0.101 | 0.015 | 0.009 | 1.449 | 0.093 |

| 100 | 0.067 | 0.008 | 3.314 | 0.018 | 0.564 | 0.276 | 0.012 | 0.280 | 0.129 | 0.021 | 0.057 | 3.895 | 0.421 |

| 150 | 0.112 | 0.011 | 2.582 | 0.020 | 0.307 | 0.741 | 0.088 | 0.716 | 0.129 | 0.021 | 0.028 | 1.297 | 0.178 |

| 200 | 0.059 | 0.005 | 30.005 | 0.016 | 1.437 | 0.817 | 0.038 | 0.832 | 0.158 | 0.039 | 0.020 | 0.759 | 0.108 |

| 250 | 0.075 | 0.000 | 1.410 | 0.020 | 0.414 | 0.375 | 0.207 | 0.461 | 0.202 | 0.047 | 0.039 | 1.109 | 0.173 |

| 300 | 0.071 | 0.000 | 2.731 | 0.021 | 0.238 | 0.272 | 0.224 | 0.397 | 0.153 | 0.053 | 0.137 | 3.116 | 0.522 |

| 350 | 0.086 | 0.000 | 2.053 | 0.015 | 1.511 | 0.605 | 0.055 | 0.588 | 0.175 | 0.049 | 0.197 | 3.843 | 0.649 |

| 400 | 0.122 | 0.000 | 3.453 | 0.023 | 0.315 | 0.688 | 0.050 | 0.659 | 0.263 | 0.091 | 0.053 | 0.972 | 0.167 |

| T (Nm) | Quantities Measured Directly | Calculated Quantities | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΔCO (ppm) | ΔCO2 (%) | ΔNOx (ppm) | ΔO2 (%) | ΔTHC (ppm) | ΔSoot (mg/m3) | ΔSOF (mg/m3) | ΔPM (mg/m3) | ΔT (Nm) | ΔP (kW) | ΔFC (kg/h) | Δ(BSFC)c (g/kWh) | Δ(BTE)c (%) | |

| 20 | 0.043 | 0.011 | 0.621 | 0.058 | 1.215 | 0.335 | 0.227 | 0.499 | 0.108 | 0.025 | 0.018 | 6.079 | 0.073 |

| 50 | 0.108 | 0.028 | 0.597 | 0.069 | 0.901 | 0.235 | 0.037 | 0.244 | 0.106 | 0.024 | 0.016 | 1.640 | 0.085 |

| 100 | 0.047 | 0.026 | 1.526 | 0.024 | 0.614 | 0.316 | 0.141 | 0.421 | 0.123 | 0.028 | 0.023 | 1.091 | 0.091 |

| 150 | 0.048 | 0.017 | 2.997 | 0.038 | 0.393 | 0.334 | 0.132 | 0.447 | 0.177 | 0.040 | 0.034 | 1.045 | 0.106 |

| 200 | 0.050 | 0.007 | 1.809 | 0.012 | 0.275 | 0.229 | 0.064 | 0.223 | 0.119 | 0.030 | 0.034 | 0.762 | 0.081 |

| 250 | 0.000 | 0.005 | 2.527 | 0.012 | 0.407 | 0.834 | 0.108 | 0.863 | 0.145 | 0.033 | 0.197 | 3.422 | 0.328 |

| 300 | 0.048 | 0.000 | 1.588 | 0.018 | 1.067 | 1.053 | 1.408 | 1.179 | 0.153 | 0.062 | 0.057 | 0.860 | 0.113 |

| T (Nm) | Quantities Measured Directly | Calculated Quantities | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΔCO (ppm) | ΔCO2 (%) | ΔNOx (ppm) | ΔO2 (%) | ΔTHC (ppm) | ΔSoot (mg/m3) | ΔSOF (mg/m3) | ΔPM (mg/m3) | ΔT (Nm) | ΔP (kW) | ΔFC (kg/h) | Δ(BSFC)c (g/kWh) | Δ(BTE)c (%) | |

| 20 | 0.037 | 0.011 | 1.149 | 0.033 | 1.735 | 0.102 | 0.437 | 0.477 | 0.079 | 0.012 | 0.014 | 5.537 | 0.107 |

| 50 | 0.055 | 0.007 | 2.121 | 0.165 | 1.387 | 0.371 | 0.363 | 0.649 | 0.173 | 0.025 | 0.075 | 10.311 | 0.744 |

| 100 | 0.057 | 0.008 | 2.069 | 0.469 | 1.644 | 1.132 | 0.341 | 1.304 | 0.118 | 0.018 | 0.110 | 7.490 | 0.901 |

| 150 | 0.071 | 0.011 | 2.052 | 0.329 | 1.961 | 1.320 | 0.301 | 1.416 | 0.180 | 0.024 | 0.367 | 16.669 | 2.327 |

| 200 | 0.083 | 0.005 | 1.604 | 0.227 | 2.046 | 1.580 | 0.313 | 1.689 | 0.122 | 0.020 | 0.070 | 2.395 | 0.388 |

| 250 | 0.078 | 0.005 | 1.748 | 0.216 | 2.592 | 1.518 | 1.307 | 1.627 | 0.137 | 0.025 | 0.315 | 8.589 | 1.197 |

| 300 | 0.030 | 0.011 | 1.412 | 0.021 | 0.801 | 1.106 | 0.396 | 1.166 | 0.130 | 0.031 | 0.076 | 1.737 | 0.301 |

| 350 | 0.058 | 0.008 | 2.356 | 0.353 | 0.493 | 0.894 | 0.261 | 0.941 | 0.177 | 0.059 | 0.253 | 4.932 | 0.869 |

| 400 | 0.065 | 0.004 | 1.933 | 0.245 | 0.908 | 1.084 | 0.177 | 1.085 | 0.180 | 0.058 | 0.143 | 2.444 | 0.492 |

| T (Nm) | Quantities Measured Directly | Calculated Quantities | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΔCO (ppm) | ΔCO2 (%) | ΔNOx (ppm) | ΔO2 (%) | ΔTHC (ppm) | ΔSoot (mg/m3) | ΔSOF (mg/m3) | ΔPM (mg/m3) | ΔT (Nm) | ΔP (kW) | ΔFC (kg/h) | Δ(BSFC)c (g/kWh) | Δ(BTE)c (%) | |

| 20 | 0.107 | 0.024 | 0.575 | 0.043 | 3.627 | 0.419 | 1.061 | 1.308 | 0.130 | 0.030 | 0.023 | 7.031 | 0.071 |

| 50 | 0.040 | 0.007 | 1.212 | 0.597 | 1.674 | 0.486 | 0.473 | 0.638 | 0.113 | 0.027 | 0.025 | 2.352 | 0.109 |

| 100 | 0.076 | 0.018 | 0.751 | 0.083 | 1.461 | 0.685 | 1.073 | 0.971 | 0.128 | 0.031 | 0.028 | 1.272 | 0.116 |

| 150 | 0.057 | 0.024 | 0.620 | 0.377 | 1.607 | 1.100 | 0.640 | 1.266 | 0.093 | 0.024 | 0.105 | 3.036 | 0.358 |

| 200 | 0.041 | 0.018 | 0.780 | 0.117 | 1.227 | 0.705 | 0.391 | 0.841 | 0.118 | 0.027 | 0.114 | 2.473 | 0.307 |

| 250 | 0.021 | 0.005 | 0.819 | 0.016 | 0.786 | 1.355 | 1.044 | 2.039 | 0.124 | 0.031 | 0.049 | 0.859 | 0.128 |

| 300 | 0.050 | 0.001 | 0.743 | 0.018 | 1.177 | 1.192 | 0.606 | 1.360 | 0.137 | 0.044 | 0.330 | 4.789 | 0.729 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurczyński, D.; Wcisło, G.; Łagowski, P. Experimental Study of Fuel Consumption and Exhaust Gas Composition of a Diesel Engine Powered by Biodiesel from Waste of Animal Origin. Energies 2021, 14, 3472. https://doi.org/10.3390/en14123472

Kurczyński D, Wcisło G, Łagowski P. Experimental Study of Fuel Consumption and Exhaust Gas Composition of a Diesel Engine Powered by Biodiesel from Waste of Animal Origin. Energies. 2021; 14(12):3472. https://doi.org/10.3390/en14123472

Chicago/Turabian StyleKurczyński, Dariusz, Grzegorz Wcisło, and Piotr Łagowski. 2021. "Experimental Study of Fuel Consumption and Exhaust Gas Composition of a Diesel Engine Powered by Biodiesel from Waste of Animal Origin" Energies 14, no. 12: 3472. https://doi.org/10.3390/en14123472