A Technology of Hydrocarbon Fluid Production Intensification by Productive Stratum Drainage Zone Reaming

Abstract

1. Introduction

- specification of ideas and hypotheses of the study;

- development of formation stages of the expanded drainage zone of a productive stratum;

- specification of admissible dimensions of circular recesses and interval of their drilling from conditions of safety operation;

- testing the possibility of the proposed technology application based on the condition of strength of the formed reservoir rock mass; and

- development of the technical mean design to implement the technology of well diameter local reaming.

2. Materials and Methods

3. Results

3.1. Specification of Circular Recess Allowable Dimensions and Interval of Its Drilling

3.2. Specification of Circular Recess Allowable Dimensions and Interval of Its Drilling

3.3. Technical Means for Local Reaming of the Well Diameter

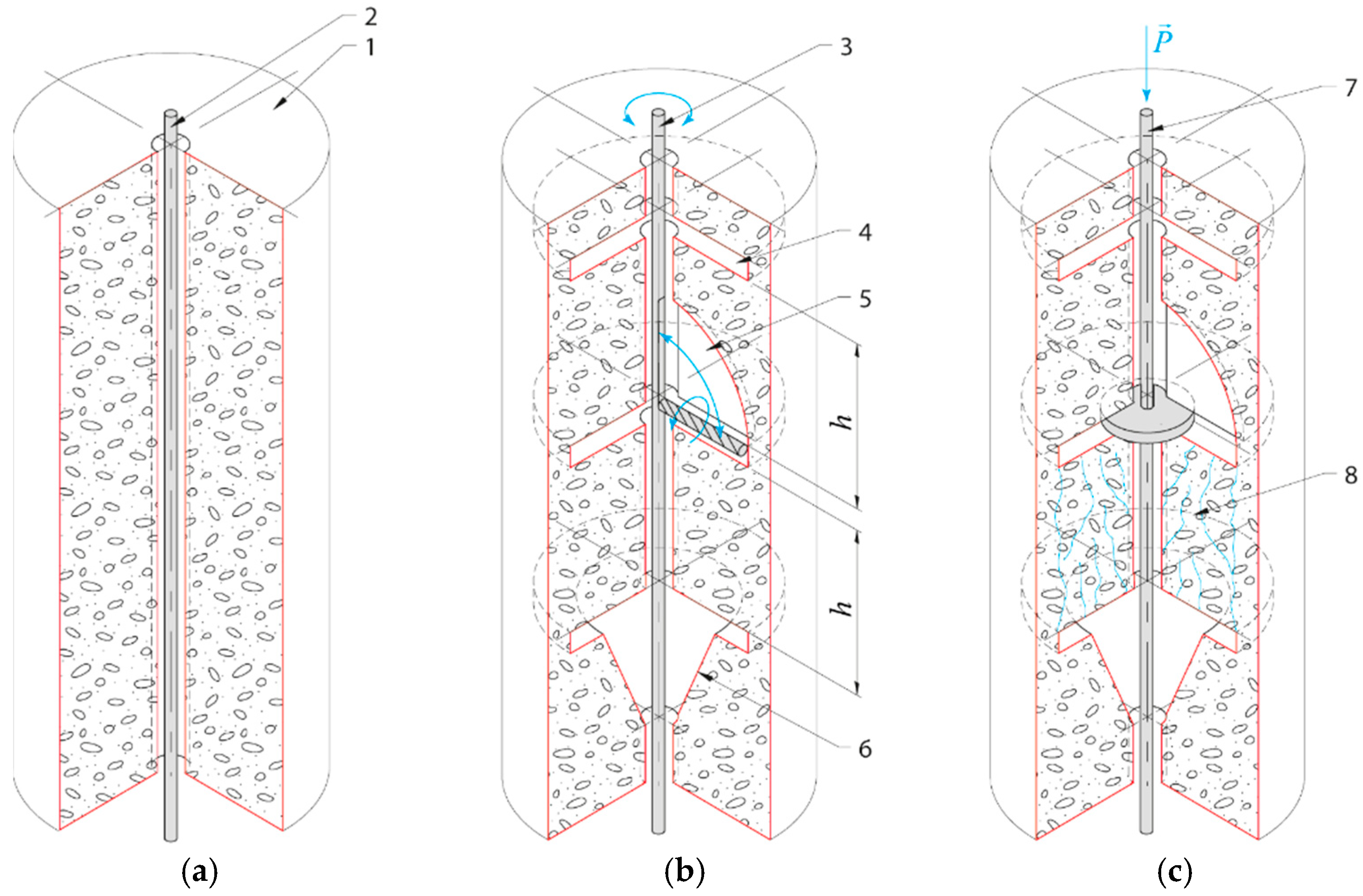

- drilling of the well of nominal radius r;

- the special bottomhole assembly is lowered into the well to a given depth and fixed;

- washing liquid starts circulation, causes the rock-destroying tool rotation, and serves as a trigger for the remote control system on the circular recess drilling to start;

- the remote control system provides a control signal to the linear drive which through the rod (1), via the lever mechanism (2), deflects the rock-destroying tool at an angle of 90 degrees (Figure 6);

- the rotary device (3) rotates the device with the rotary bit around its axis by 360 degrees, and as a result, the circular recess is formed;

- the rock-destroying tool returns to its original position on the signal of the control system, and the BHA is fixed; and

- the BHA rises to a given height h, after which the whole process is repeated.

- the BHA is lowered into the well, which is positioned in one of the known ways so that the device to retract the legs is in front of the drilled circular recesses;

- the legs retract to the circular recess after the command;

- intensive circulation of the washing liquid begins with simultaneous rotation of the drill string;

- the axial load is applied to the rock mass, the static component of which is created by the weight of the of heavy weighted drill pipes—due to the operation of the vibrator. As a result, the main cracks appear in the rock and its destruction occurs; and

- to prevent trapping of the drill string and high-quality cleaning of the well, pieces of rock that fall into the space between the drill string and the walls of the well are further crushed using the section of eccentric expanders 8 (Figure 3) and are carried to the surface with flushing fluid.

4. Discussion

- layout for drilling disk and conical recesses;

- layout for destruction and crushing of rock mass.

- a special tool with a rotating bit for drilling disk recesses has been developed, its design is presented and the principle of operation is described. The designs of bottomhole assembly for the proposed technology implementation have been presented:

- BHA for circular and conical recess drilling; and

- BHA for rock mass destruction.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| h | thickness of the rock mass between two adjacent circular recesses; |

| R | radius of the circular recess; |

| r | radius of the through hole in the rock mass; |

| γ | specific weight of the rock; |

| P | axial force, which loads the rock mass; |

| [R] | the maximum allowable radius of the circular recess; |

| ρ | polar coordinate; |

| s | area of the side surface of the rock mass with the radius of ρ; |

| V | volume of rock mass; |

| τ | tangential stresses in the rock mass; |

| τmax | maximum tangential stresses in the rock mass; |

| τu | ultimate resistance to rock displacement; |

| ζ | coefficient of operational conditions (depends on water saturation of the rock, the porosity coefficient, thermal impact); |

| k | safety factor; |

| λ | the coefficient of axial force application dynamics. |

References

- Al-Rbeawi, S.; Artun, E. Fishbone type horizontal wellbore completion: A study for pressure behavior, flow regimes, and productivity index. J. Pet. Sci. Eng. 2019, 176, 172–202. [Google Scholar] [CrossRef]

- Abolhasanzadeh, A.; Reza Khaz’ali, A.; Hashemi, R.; Jazini, M. Experimental study of microbial enhanced oil recovery in oil-wet fractured porous media. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2020, 75, 73. [Google Scholar] [CrossRef]

- Falshtynskyi, V.; Saik, P.; Lozynskyi, V.; Dychkovskyi, R.; Petlovanyi, M. Innovative aspects of underground coal gasification technology in mine conditions. Min. Miner. Depos. 2018, 12, 68–75. [Google Scholar] [CrossRef]

- Lozynskyi, V.; Medianyk, V.; Saik, P.; Rysbekov, K.; Demydov, M. Multivariance solutions for designing new levels of coal mines. Rud. Geol. Naft. Zb. 2020, 35, 23–32. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J.; Szurgacz, D.; Sobik, L.; Zhironkin, S. The Impact of the Ventilation System on the Methane Release Hazard and Spontaneous Combustion of Coal in the Area of Exploitation—A Case Study. Energies 2020, 13, 4891. [Google Scholar] [CrossRef]

- Sekerin, V.; Dudin, M.; Gorokhova, A.; Bank, S.; Bank, O. Mineral resources and national economic security: Current features. Min. Miner. Depos. 2019, 13, 72–79. [Google Scholar] [CrossRef]

- Haiko, H.; Saik, P.; Lozynskyi, V. The Philosophy of Mining: Historical Aspect and Future Prospect. Philos. Cosmol. 2019, 22, 76–90. [Google Scholar] [CrossRef]

- Ursul, A.; Ursul, T. Environmental Education for Sustainable Development. Future Human Image 2018, 9, 115–125. [Google Scholar] [CrossRef]

- Xiang, H.; Valery Kadet, V. Modern methods of underground hydromechanics with applications to reservoir engineering. J. Hydrodynam. B 2016, 28, 937–946. [Google Scholar] [CrossRef]

- Mufazalov, R.S. Tim’s Theorem: A New Paradigm for Underground Hydrodynamics Part 2. ROGTEC Oil Gas Mag. 2019, 58, 64–80. [Google Scholar]

- Poltavskaya, M.D.; Verzhbickij, V.V.; Gun’kina, T.A. The influence of increased well bore diameter on an increase in wells productivity. Perm J. Pet. Min. Eng. 2013, 6, 74–85. [Google Scholar]

- Yanukyan, A.P.; Lushpeev, V.A.; Nagaeva, S.N.; Sorokin, P.M. Optimization of the Gas Wells Performance Indicators. Int. J. Ocean. Oceanogr. 2016, 10, 1–11. [Google Scholar]

- Zhu, X.H. Analysis of reamer failure based on vibration analysis of the rock breaking in horizontal directional drilling. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Butterworth-Heinemann: Oxford, UK, 2016; pp. 199–214. [Google Scholar] [CrossRef]

- Jing, J.; Lu, Y.; Zhu, X. Weight Distribution Characteristics During the Process of Hole Enlargement When Drilling. Arab. J. Sci. Eng. 2018, 43, 6445–6459. [Google Scholar] [CrossRef]

- Vlasiy, O.; Mazurenko, V.; Ropyak, L.; Rogal, O. Improving the aluminum drill pipes stability by optimizing the shape of protector thickening. EEJET 2017, 85, 25–31. [Google Scholar] [CrossRef]

- Shats’kyi, I.P.; Lyskanych, O.M.; Kornuta, V.A. Combined Deformation Conditions for Fatigue Damage Indicator and Well-Drilling Tool Joint. Strength Mater. 2016, 48, 469–472. [Google Scholar] [CrossRef]

- Onysko, O.; Kopei, V.; Medvid, I.; Pituley, L.; Lukan, T. Influence of the Thread Profile Accuracy on Contact Pressure in Oil and Gas Pipes Connectors. Lect. Notes Mech. Eng. 2020, 432–441. [Google Scholar] [CrossRef]

- Pryhorovska, T.; Ropyak, L. Machining Error Influnce on Stress State of Conical Thread Joint Details. In Proceedings of the International Conference on Advanced Optoelectronics and Lasers, (CAOL), Sozopol, Bulgaria, 6–8 September 2019; pp. 493–497. [Google Scholar] [CrossRef]

- Onysko, O.R.; Kopey, V.B.; Panchuk, V.G. Theoretical investigation of the tapered thread joint surface contact pressure in the dependence on the profile and the geometric parameters of the threading turning tool. IOP Conf. Ser. Mater. Sci. Eng. 2020, 749, 012007. [Google Scholar] [CrossRef]

- Shatskyi, I.; Ropyak, L.; Velychkovych, A. Model of contact interaction in threaded joint equipped with spring-loaded collet. Eng. Solid Mech. 2020, 8, 301–312. [Google Scholar] [CrossRef]

- Ropyak, L.Y.; Pryhorovska, T.O.; Levchuk, K.H. Analysis of Materials and Modern Technologies for PDC Drill Bit Manufacturing. Prog. Phys. Met. 2020, 21, 274–301. [Google Scholar] [CrossRef]

- Pryhorovska, T.A.; Chaplinskiy, S.S. Finite element modeling of rock mass cutting by cutters for PDC drill bits. Neftyanoe Khozyaystvo Oil Ind. 2018, 1, 38–41. [Google Scholar] [CrossRef]

- Ropyak, L.; Schuliar, I.; Bohachenko, O. Influence of technological parameters of centrifugal reinforcement upon quality indicators of parts. East. Eur. J. Enterp. Technol. 2016, 1, 53–62. [Google Scholar] [CrossRef]

- Ropyak, L.Y.; Vytvytskyi, V.S.; Velychkovych, A.S.; Pryhorovska, T.O.; Shovkoplias, M.V. Study on grinding mode effect on external conical thread quality. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1018, 012014. [Google Scholar] [CrossRef]

- Shats’kyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Influence of a Flexible Coating on the Strength of a Shallow Cylindrical Shell with Longitudinal Crack. J. Math. Sci. 2019, 238, 165–173. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Makoviichuk, M.V.; Shcherbii, A.B. Influence of Flexible Coating on the Limit Equilibrium of a Spherical Shell with Meridional Crack. Mater. Sci. 2020, 55, 484–491. [Google Scholar] [CrossRef]

- Tarel’nik, V.B.; Konoplyanchenko, E.V.; Kosenko, P.V.; Martsinkovskii, V.S. Problems and Solutions in Renovation of the Rotors of Screw Compressors by Combined Technologies. Chem. Petrol. Eng. 2017, 53, 540–546. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Ropyak, L.Y.; Makoviichuk, M.V. Strength optimization of a two-layer coating for the particular local loading conditions. Strength Mater. 2016, 48, 726–730. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V.; Martsynkovskyy, V.S.; Tarelnyk, N.V.; Vasylenko, O.O. Improvement of Quality of the Surface Electroerosive Alloyed Layers by the Combined Coatings and the Surface Plastic Deformation. I. Features of Formation of the Combined Electroerosive Coatings on Special Steels and Alloys. Metallofiz. Noveishie Tekhnol. 2019, 41, 47–69. [Google Scholar] [CrossRef]

- Shatskyi, I.P.; Perepichka, V.V.; Ropyak, L.Y. On the influence of facing on strength of solids with surface defects. Metallofiz. Noveishie Tekhnol. 2020, 42, 69–76. [Google Scholar] [CrossRef]

- Grydzhuk, J.; Chudyk, I.; Velychkovych, A.; Andrusyak, A. Analytical estimation of inertial properties of the curved rotating section in a drill string. East. Eur. J. Enterp. Technol. 2019, 7, 6–14. [Google Scholar] [CrossRef]

- Pryhorovska, T. Rock heterogeneity numerical simulation as a factor of drill bit instability. Eng. Solid Mech. 2018, 6, 315–330. [Google Scholar] [CrossRef]

- Tatsiy, R.M.; Pazen, O.Y.; Vovk, S.Y.; Ropyak, L.Y.; Pryhorovska, T.O. Numerical study on heat transfer in multilayered structures of main geometric forms made of different materials. J. Serb. Soc. Comput. Mech. 2019, 13, 36–55. [Google Scholar] [CrossRef]

- Panevnik, D.A.; Velichkovich, A.S. Assessment of the stressed state of the casing of the above-bit hydroelevator. Neftyanoe Khozyaystvo Oil Ind. 2017, 1, 70–73. [Google Scholar]

- Dutkiewicz, M.; Gołębiowska, I.; Shatskyi, I.; Shopa, V.; Velychkovych, A. Some aspects of design and application of inertial dampers. MATEC Web Conf. 2018, 178, 06010. [Google Scholar] [CrossRef][Green Version]

- Velichkovich, A.S.; Velichkovich, S.V. Vibration-impact damper for controlling the dynamic drillstring conditions. Chem. Pet. Eng. 2001, 37, 213–215. [Google Scholar] [CrossRef]

- Vytvytskyi, I.I.; Seniushkovych, M.V.; Shatskyi, I.P. Calculation of distance between elastic-rigid centralizers of casing. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2017, 5, 28–35. [Google Scholar]

- Shatskyi, I.; Velychkovych, A.; Vytvytskyi, I.; Seniushkovych, M. Analytical models of contact interaction of casing centralizers with well wall. Eng. Solid Mech. 2019, 7, 355–366. [Google Scholar] [CrossRef]

- Velychkovych, A.S.; Andrusyak, A.V.; Pryhorovska, T.O.; Ropyak, L.Y. Analytical model of oil pipeline overground transitions, laid in mountain areas. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2019, 74, 65. [Google Scholar] [CrossRef]

- Shatskyi, I.; Perepichka, V. Problem of Dynamics of an Elastic Rod with Decreasing Function of Elastic-Plastic External Resistance. Springer Proc. Math. Stat. 2018, 249, 335–342. [Google Scholar] [CrossRef]

- Velichkovich, A.; Dalyak, T.; Petryk, I. Slotted shell resilient elements for drilling shock absorbers. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2018, 73, 34. [Google Scholar] [CrossRef]

- Velychkovych, A.; Petryk, I.; Ropyak, L. Analytical study of operational properties of a plate shock absorber of a sucker-rod string. Shock Vib. 2020, 3292713. [Google Scholar] [CrossRef]

- Warren, T.M.; Sinor, L.A.; Dykstra, M.W. Simultaneous Drilling and Reaming with Fixed Blade Reamers. In Proceedings of the the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995. [Google Scholar] [CrossRef]

- Lunkad, S.F.; Grindhaug, G.; Hussain, S.; Walker, D.; Dhaher, K.S. Innovative Drilling Technologies Contribute in Implementing New Gas Lift Well Design on Statfjord Field, North Sea. In Proceedings of the SPE Artificial Lift Conference—Latin America and Caribbean, Salvador, Brazil, 27–28 May 2015. [Google Scholar] [CrossRef]

- Murillo, R.; Santarini, F.; Hurtado, P.; Costa, R.; Diaz, M.A. New-Generation Underreamers Reduce Trips, Decrease Operating Time, and Eliminate Nonproductive Time. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 20–23 March 2018. [Google Scholar] [CrossRef]

- Moisyshyn, V.; Voyevidko, I.; Tokaruk, V. Design of bottom hole assemblies with two rock cutting tools for drilling wells of large diameter. Min. Miner. Depos. 2020, 14, 128–133. [Google Scholar] [CrossRef]

- Lyons, W.C.; Plisga, G.J.; Lorenz, M.D. Drilling and Well Completions, Standard Handbook of Petroleum and Natural Gas Engineering; Gulf Professional Publishing: Houston, TX, USA, 2016; pp. 414–584. [Google Scholar] [CrossRef]

- Dreus, A.Y.; Sudakov, A.K.; Kozhevnikov, A.A.; Vakhalin, Y.N. Study on thermal strength reduction of rock formation in the diamond core drilling process using pulse flushing mode. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2016, 5–10. Available online: http://nvngu.in.ua/index.php/en/component/jdownloads/viewdownload/61/8504 (accessed on 25 May 2021).

- Sarraf Shirazi, A.; Frigaard, I.A. Gravel packing: How does it work? Phys. Fluids 2020, 32, 053308. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Shavarskyi, I.; Saik, P.; Lozynskyi, V.; Falshtynskyi, V.; Cabana, E. Research into stress-strain state of the rock mass condition in the process of the operation of double-unit longwalls. Min. Miner. Depos. 2020, 14, 85–94. [Google Scholar] [CrossRef]

- Abdiev, A.R.; Mambetova, R.S.; Mambetov, S.A. Geomechanical assessment of Tyan-Shan’s mountains structures for efficient mining and mine construction. Gorn. Zhurnal 2017, 4, 23–28. [Google Scholar] [CrossRef]

- Bazaluk, O.; Sai, K.; Lozynskyi, V.; Petlovanyi, M.; Saik, P. Research into Dissociation Zones of Gas Hydrate Deposits with a Heterogeneous Structure in the Black Sea. Energies 2021, 14, 1345. [Google Scholar] [CrossRef]

- Voloshyn, O.; Potapchuk, I.; Zhevzhyk, O.; Yemelianenko, V.; Zhovtonoha, M.; Sekar, M.; Dhunnoo, N. Experimental study of the thermal reaming of the borehole by axial plasmatron. Min. Miner. Depos. 2019, 13, 103–110. [Google Scholar] [CrossRef]

- Voloshyn, O.; Potapchuk, I.; Zhevzhyk, O.; Yemelianenko, V.; Horiachkin, V.; Zhovtonoha, M.; Semenenko, Y.; Tatarko, L. Study of the plasma flow interaction with the borehole surface in the process of its thermal reaming. Min. Miner. Depos. 2018, 12, 28–35. [Google Scholar] [CrossRef]

- Levchuk, K.G. Investigation of the vibration transfer process to a stuck drill string. SOCAR Proc. 2017, 2, 23–33. [Google Scholar] [CrossRef]

- Levchuk, K.G. Diagnosing of a Freeze-In of Metal Drill Pipes by Their Stressedly-Deformed State in the Controlled Directional Bore Hole. Metallofiz. Noveishie Tekhnol. 2018, 40, 701–712. [Google Scholar] [CrossRef]

- Moisyshyn, V.; Levchuk, K. Investigation on Releasing of a Stuck Drill String by Means of a Mechanical Jar. Oil Gas Sci. Technol. 2017, 72, 27. [Google Scholar] [CrossRef]

- Ganat, T.A.A.O. Fundamentals of Reservoir Rock Properties; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Shats’kyi, I.P.; Struk, A.B. Stressed state of pipeline in zones of soil local fracture. Strength Mater. 2009, 41, 548–553. [Google Scholar] [CrossRef]

- Shatskyi, I.; Popadyuk, I.; Velychkovych, A. Hysteretic Properties of Shell Dampers. In Dynamical Systems in Applications, Proceedings of the DSTA 2017, Łódź, Poland, 11–14 December 2017; Awrejcewicz, J., Ed.; Springer: Cham, Switzerland, 2018; pp. 343–350. [Google Scholar] [CrossRef]

- Velichkovich, A.S.; Popadyuk, I.I.; Shopa, V.M. Experimental study of shell flexible component for drilling vibration damping devices. Chem. Pet. Eng. 2011, 46, 518–524. [Google Scholar] [CrossRef]

- Moisyshyn, V.M.; Slabyi, O.O. Creation of the Vibroprotective Device for Adjustment of Dynamics of a Column of Steel Drill Pipes and a Bit. Metallofiz. Noveishie Tekhnol. 2018, 40, 541–550. [Google Scholar] [CrossRef][Green Version]

- Slabyi, O. Studying the coupled axial and lateral oscillations of the drilling riser under conditions of irregular seaways. East-Eur. J. Enterp. Technol. 2018, 3, 27–33. [Google Scholar] [CrossRef]

- Liew, M.S.; Danyaro, K.U.; Zawawi, N.A.W.A. A Comprehensive Guide to Different Fracturing Technologies: A Review. Energies 2020, 13, 3326. [Google Scholar] [CrossRef]

- Basirat, R.; Goshtasbi, K.; Ahmadi, M. Geomechanical key parameters of the process of hydraulic fracturing propagation in fractured medium. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2019, 74, 58. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, Z. Review of Radial Jet Drilling and the key issues to be applied in new geo-energy exploitation. Energy Procedia 2019, 158, 5969–5974. [Google Scholar] [CrossRef]

- Luo, X.; Gong, H.; Ziling, H.; Zhang, P.; He, L. Recent advances in applications of power ultrasound for petroleum industry. Ultrason. Sonochem. 2021, 70, 105337. [Google Scholar] [CrossRef]

- Li, K.; Wang, D.; Jiang, S. Review on enhanced oil recovery by nanofluids. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2018, 73, 37. [Google Scholar] [CrossRef]

| Reservoir Rock | Siltstone | Sandstone | Limestone Fine-Grained | Dolomite |

|---|---|---|---|---|

| Index | 1 | 2 | 3 | 4 |

| Specific weight of the rock, N/m3 | 1.95 × 104 | 2.4 × 104 | 2.71 × 104 | 2.94 × 104 |

| Maximum shear resistance, KPa | 82 | 110 | 140 | 95 |

| Allowable stresses, , KPa | 54.7 | 73.3 | 93.3 | 63.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazaluk, O.; Slabyi, O.; Vekeryk, V.; Velychkovych, A.; Ropyak, L.; Lozynskyi, V. A Technology of Hydrocarbon Fluid Production Intensification by Productive Stratum Drainage Zone Reaming. Energies 2021, 14, 3514. https://doi.org/10.3390/en14123514

Bazaluk O, Slabyi O, Vekeryk V, Velychkovych A, Ropyak L, Lozynskyi V. A Technology of Hydrocarbon Fluid Production Intensification by Productive Stratum Drainage Zone Reaming. Energies. 2021; 14(12):3514. https://doi.org/10.3390/en14123514

Chicago/Turabian StyleBazaluk, Oleg, Orest Slabyi, Vasyl Vekeryk, Andrii Velychkovych, Liubomyr Ropyak, and Vasyl Lozynskyi. 2021. "A Technology of Hydrocarbon Fluid Production Intensification by Productive Stratum Drainage Zone Reaming" Energies 14, no. 12: 3514. https://doi.org/10.3390/en14123514

APA StyleBazaluk, O., Slabyi, O., Vekeryk, V., Velychkovych, A., Ropyak, L., & Lozynskyi, V. (2021). A Technology of Hydrocarbon Fluid Production Intensification by Productive Stratum Drainage Zone Reaming. Energies, 14(12), 3514. https://doi.org/10.3390/en14123514