Availability and LCOE Analysis Considering Failure Rate and Downtime for Onshore Wind Turbines in Japan

Abstract

:1. Introduction

2. Analysis of Failure Rate and Downtime for Onshore Wind Turbines in Japan and Europe

2.1. Failure Databases in Japan and Europe

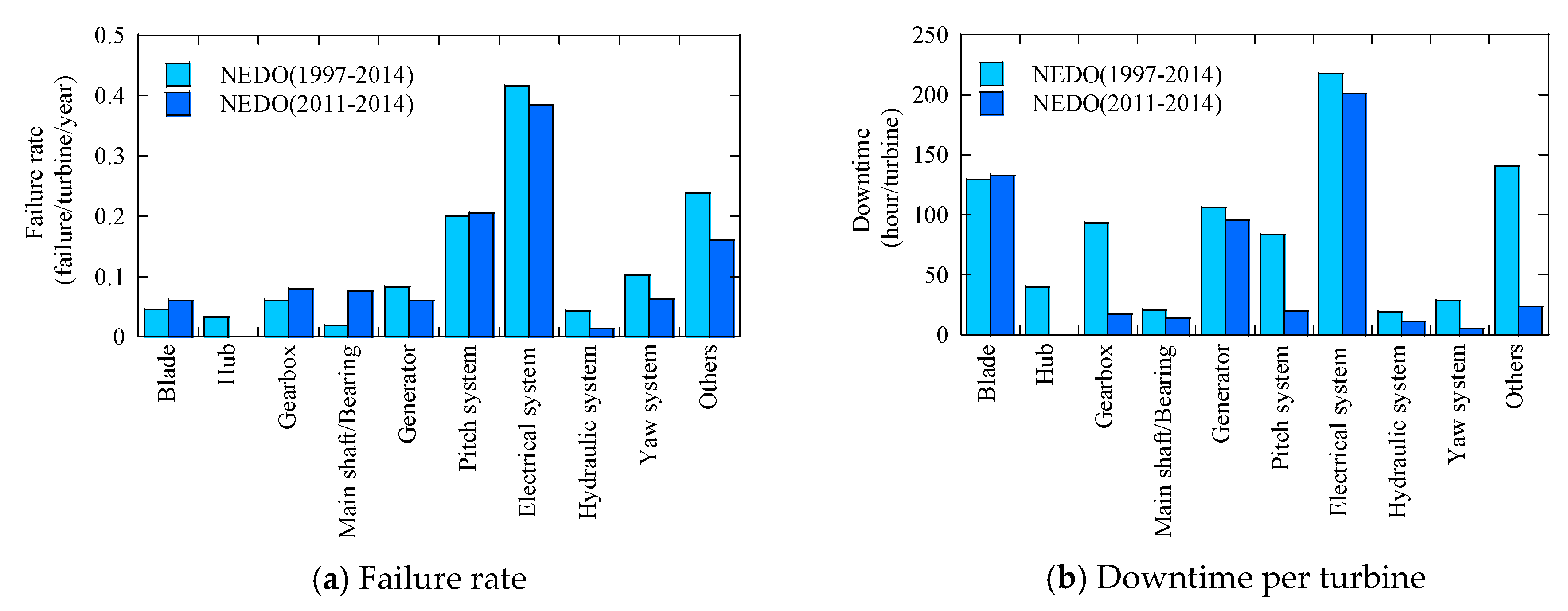

2.2. Analysis of Failure Rate and Downtime at Assembly Level

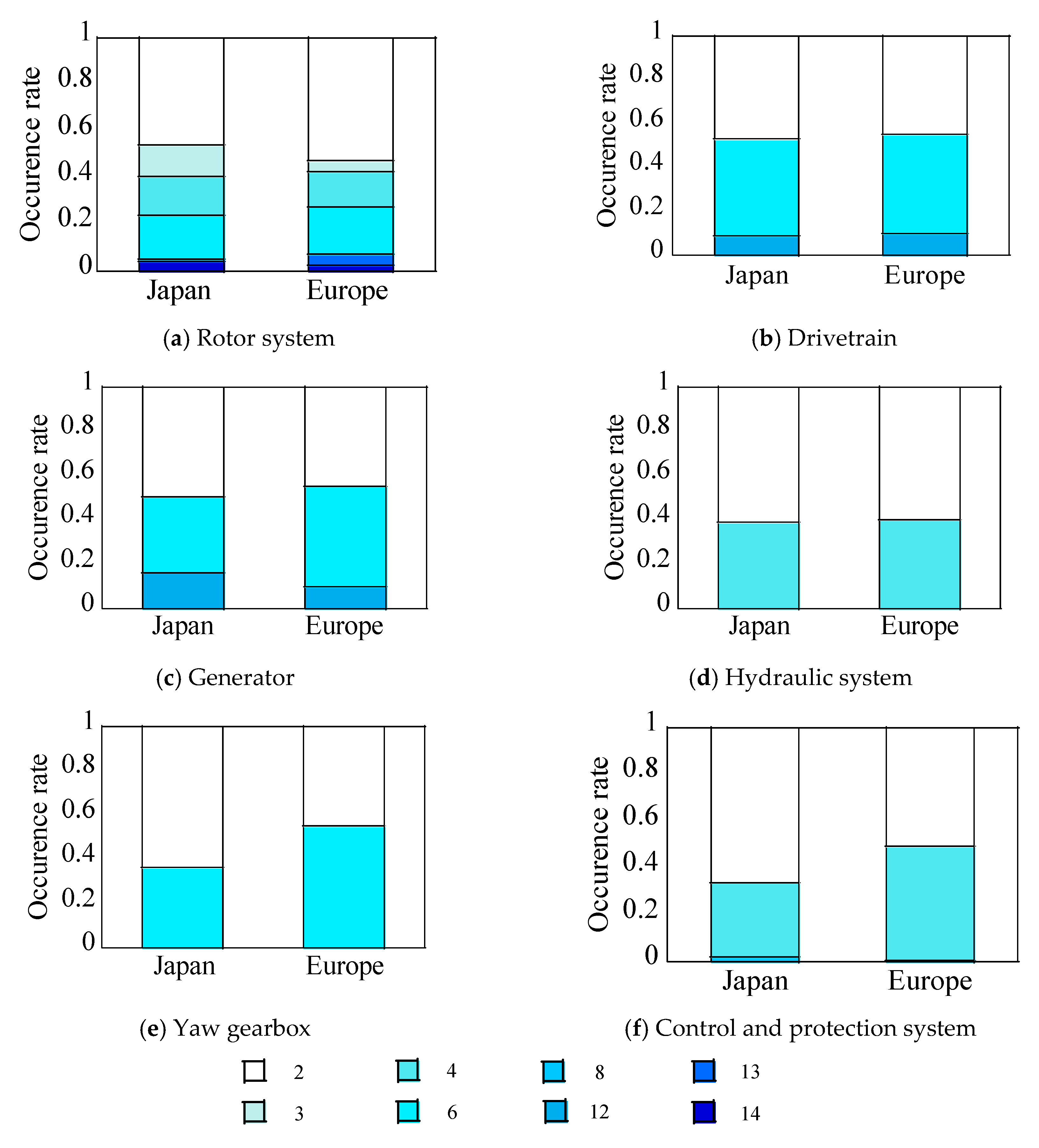

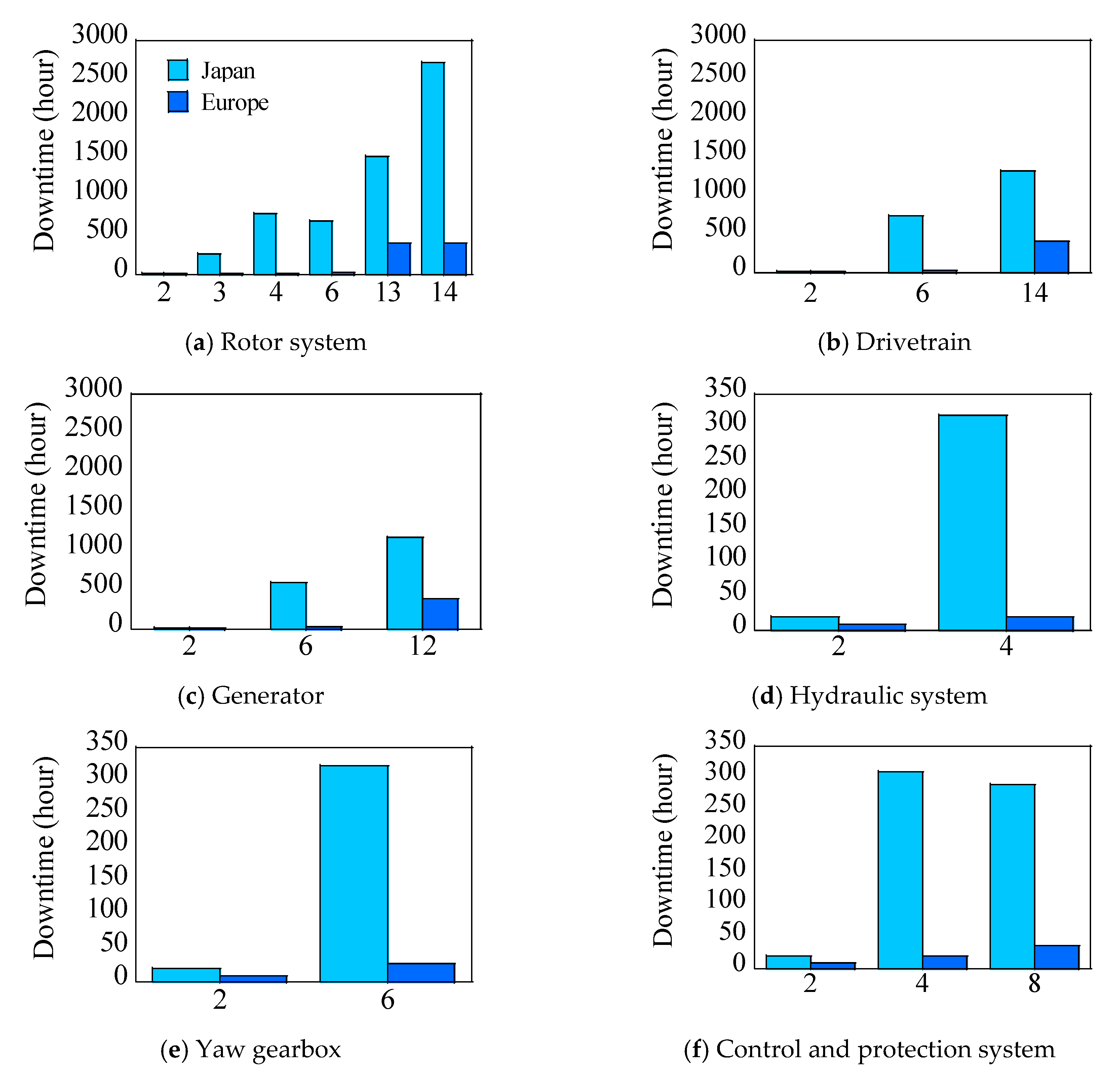

2.3. Analysis of Failure Rate and Downtime at Failure Mode Level

3. Availability Improvement and LCOE Reduction

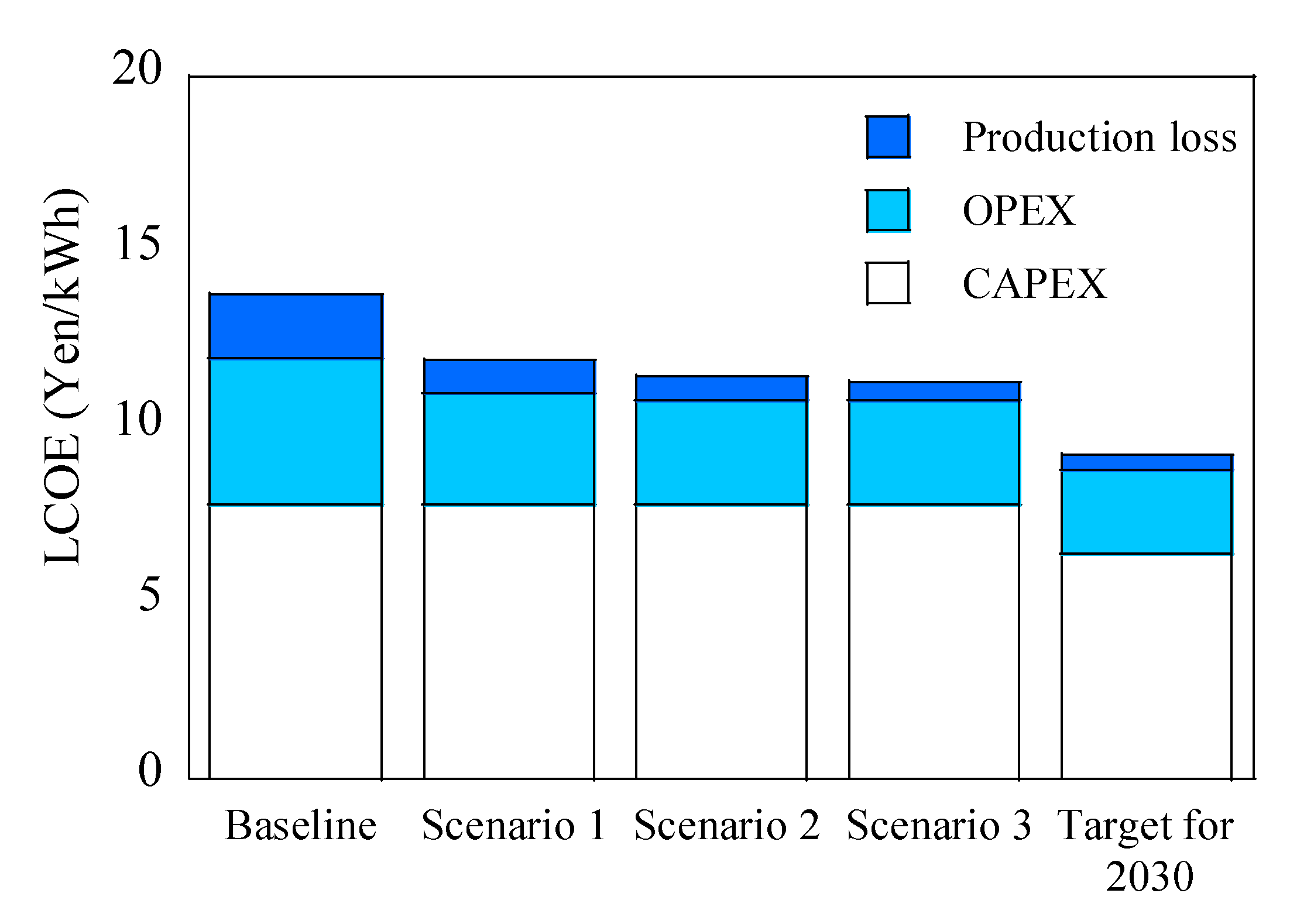

3.1. LCOE and Industry Practices of Onshore Wind Turbines in Japan

3.2. Scenarios for Availability Improvement and LCOE Reduction

3.3. Effect of Uncertainty on Levelized Cost of Energy

4. Conclusions

- The normalized failure rate and downtime are comparable between Japan and Europe for each fault type class at the assembly and failure mode levels. The occurrence rate is similar between Japan and Europe, but the downtime in Japan is much longer than that in Europe. It is clarified that the difference in downtime in each database comes from the operating years of turbines by analyzing old and new turbines in the NEDO database.

- Availability improvement and cost reduction scenarios are investigated using the failure rate and downtime for each fault type class based on the industry interview and best practices in Japan. The availability can be improved from 87.4% to 92.7, 95.5 and 96.4%, and the levelized cost of energy reduces from 13.7 Yen/kWh to 11.9, 11.0, 10.7 Yen/kWh considering spare parts, condition monitoring and industry maturity.

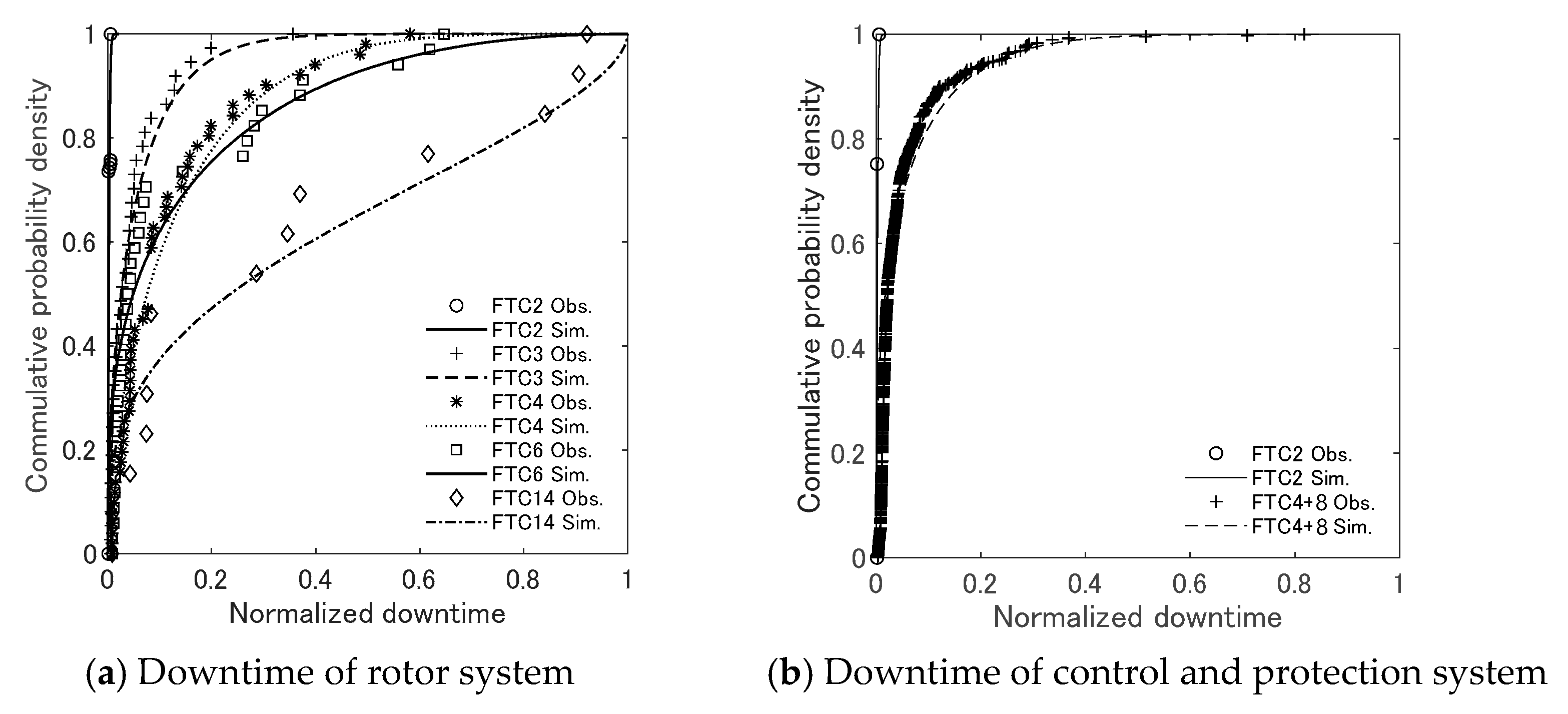

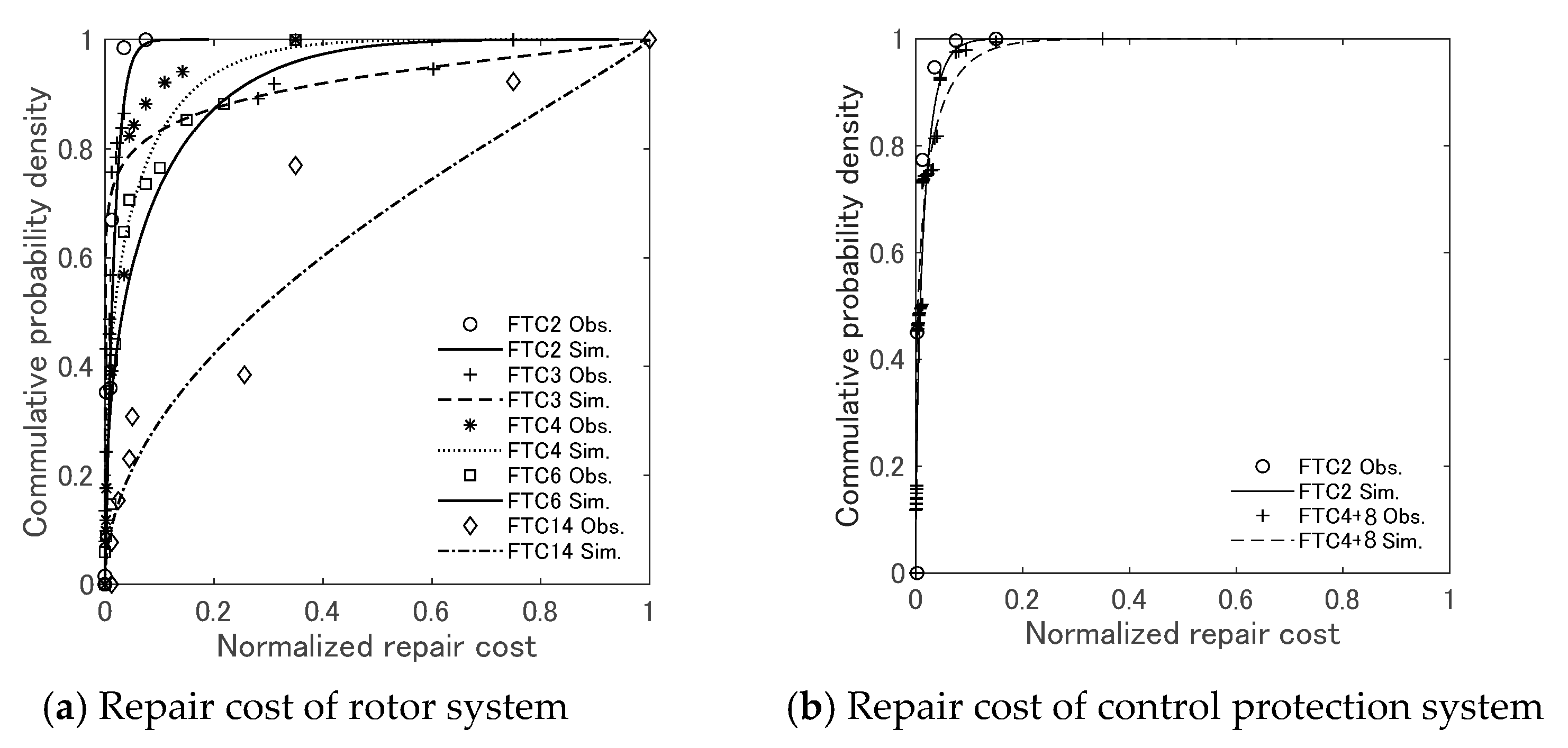

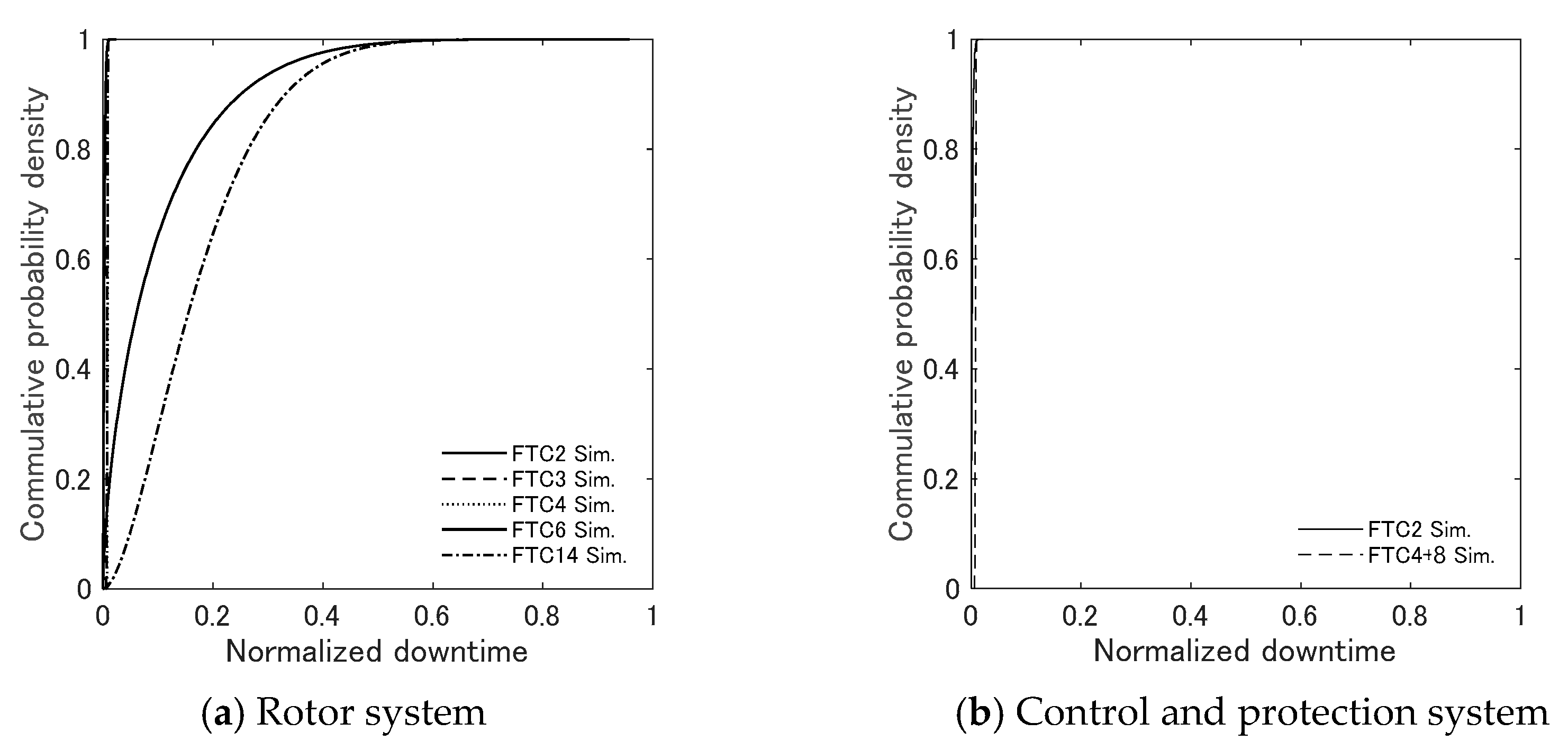

- The cumulative probability function of downtime and repair cost for each mode is analyzed. It is found that the cumulative probability functions of the failure modes with the shortest downtime show similar probability distributions regardless of the size of assembly. The uncertainty of LCOE in the three scenarios significantly reduces from the baseline case by about 30% due to a reduction in the downtime of small failure modes, which is an important aspect to consider OPEX cost reduction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Japan Wind Power Association, JWPA Report Detail 2021/02/12. Available online: http://jwpa.jp/page_304_englishsite/jwpa/detail_e.html (accessed on 28 May 2021).

- Wind Power Competitiveness Strengthening Committee, Final Report. 2016. Available online: https://www.meti.go.jp/committee/kenkyukai/energy_environment/furyoku/pdf/report_01_01.pdf (accessed on 28 May 2021). (In Japanese).

- Hand, M.M. IEA Wind TCP Task 26‒Wind Technology, Cost, and Performance Trends in Denmark, Germany, Ireland, Norway, Sweden, the European Union, and the United States: 2008‒2016. NREL/TP-6A20-71844. National Renewable Energy Laboratory, Golden, CO (US). 2018. Available online: https://www.nrel.gov/docs/fy19osti/71844.pdf (accessed on 28 May 2021).

- Herman, K.; Walker, R.; Wilkinson, M. Availability trends observed at operational wind farms. In Proceedings of the Science & Research Abstract for EWEA 2008 Annual Event, European Wind Energy Conference 2008, Brussels, Belgium, 31 March–3 April 2008. [Google Scholar]

- New Energy and Industrial Technology Development Organization. The Report of Wind Turbine Failure and Accident 2013–2017; New Energy and Industrial Technology Development Organization: Kawasaki, Japan, 2013–2017. (In Japanese) [Google Scholar]

- Pfaffel, S.; Faulstich, S.; Rohrig, K. Performance and reliability of wind turbines: A review. Energies 2017, 10, 1904. [Google Scholar] [CrossRef] [Green Version]

- Dao, C.; Kazemtabrizi, B.; Crabtree, C. Wind turbine reliability data review and impacts on levelised cost of energy. Wind Energy 2019, 22, 1848–1871. [Google Scholar] [CrossRef] [Green Version]

- Faulstich, S.; Pfaffel, S.; Hahn, B. Performance and reliability benchmarking using the cross-company initiative WInD-Pool. In Proceedings of the RAVE Offshore Wind R&D Conference, Bremerhaven, Germany, 14 October 2015. [Google Scholar]

- Portfolio Review 2016; System Performance, Availability and Reliability Trend Analysis (SPARTA): Northumberland, UK, 2016.

- Faulstich, S.; Hahn, B.; Tavner, P.J. Wind turbine downtime and its importance for offshore deployment. Wind Energy 2011, 14, 327–337. [Google Scholar] [CrossRef]

- Wilkinson, M. Measuring wind turbine reliability—Results of the reliawind project. In Proceedings of the Science & Research Abstract for EWEA 2011 Annual Event, European Wind Energy Conference 2011, Brussels, Belgium, 14–17 March 2011. [Google Scholar]

- VGB Standards, RDS-PP—Application Guideline; Part 32: Wind Power Plants. 2014. Available online: https://www.vgb.org/shop/technicalrules/vgb-standards/s-823-0.html?___store=en&___from_store=default (accessed on 28 May 2021).

- Shafiee, M.; Dinmohammadi, F. An FMEA-based risk assessment approach for wind turbine systems: A comparative study of onshore and offshore. Energies 2014, 7, 619–642. [Google Scholar] [CrossRef] [Green Version]

- Ozturk, S.; Fthenakis, V.; Faulstich, S. Failure modes, effects and criticality analysis for wind turbines considering climatic regions and comparing geared and direct drive wind turbines. Energies 2018, 11, 2317. [Google Scholar] [CrossRef]

- Carroll, J.; McDonald, A.; McMillan, D. Failure rate, repair time and unscheduled O&M cost analysis of offshore wind turbines. Wind Energy 2016, 19, 1107–1119. [Google Scholar] [CrossRef] [Green Version]

- Asgarpour, M.; van de Pieterman, R.; Netherlands, E.R.C. O&M Cost Reduction of Offshore Wind Farms—A Novel Case Study; ECN, 2014; Available online: https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-E--14-028 (accessed on 28 May 2021).

- Maples, B.; Saur, G.; Hand, M.; van de Pietermen, R.; Obdam, T. Installation, Operation, and Maintenance Strategies to Reduce the Cost of Offshore Wind Energy; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013. [Google Scholar]

- Seyr, H.; Muskulus, M. Value of information of repair times for offshore wind farm maintenance planning. J. Phys. Conf. Ser. 2016, 754, 92009. [Google Scholar] [CrossRef]

- Mortstock, K.; Wilkinson, M. Data mining to reduce risk and better predict P90 performance. In Proceedings of the Wind Europe 2017, Wind Europe Conference 2017, Amsterdam, The Netherlands, 28–30 November 2017. [Google Scholar]

- Okumoto, H.; Kato, H.; Niijima, K. Failure rate and downtime analysis for wind turbine by using failure and accident survey. In Proceedings of the 15th World Wind Energy Conference and Exhibition, Tokyo, Japan, 31 October–1 November 2016; pp. 1–4. [Google Scholar]

- Ministry of Economy, Trade and Industry. Feed-In Tariff Scheme in Japan. 2010. Available online: https://www.meti.go.jp/english/policy/energy_environment/renewable/pdf/summary201207.pdf (accessed on 28 May 2021). (In Japanese).

- Committee for Procurement Price. Annual Report from Calculation Committee for Procurement Price. 2012–2021. Available online: https://www.meti.go.jp/shingikai/santeii/ (accessed on 28 May 2021). (In Japanese).

- Kikuchi, Y.; Saito, R.; Ishihara, T. Assessment of levelized cost of energy for wind energy based on reliability analysis. J. Wind Energy 2019, 43, 1–12. (In Japanese) [Google Scholar] [CrossRef]

- Wind Power Equipment and Installation Results in Japan, NEDO. Available online: https://www.nedo.go.jp/library/fuuryoku/pdf/05_kaigai_kokusan_dounyuu_suii.pdf (accessed on 28 May 2021). (In Japanese).

- Takagi, K. Towards the availability improvement of wind farm. In Proceedings of the 38th Wind Energy Symposium 2018, Tokyo, Japan, 30 November–1 December 2018. (In Japanese). [Google Scholar]

- Department of Hokkaido Industrial Safety and Inspection of Ministry of Economy, Trade and Industry. Current Status and Challenges of Wind Power in Hokkaido 2013–2015; Available online: https://www.safety-hokkaido.meti.go.jp/denki_hoan/h30fy_wp_enq/index.htm (accessed on 28 May 2021). (In Japanese)

- New Energy and Industrial Technology Development Organization, NeoWins. Available online: https://appwdc1.infoc.nedo.go.jp/Nedo_Webgis/top.html (accessed on 28 May 2021).

- Wiser, R.; Jenni, K.; Seel, J.; Baker, E.; Hand, M.; Lantz, E.; Smith, A. Forecasting Wind Energy Costs & Cost Drivers. IEA Wind 2016, LBNL-1005717. Available online: https://eta-publications.lbl.gov/sites/default/files/lbnl-1005717.pdf (accessed on 28 May 2021).

| Item | Sub-Item |

|---|---|

| Wind farm | Location, Turbine type, Operating start day |

| Failure data | Assembly, Event, Occurrence data, Root cause, Countermeasure |

| Downtime | Written question (1 h resolution) |

| Repair cost | Multiple choice questions in 8 Categories |

| 1: 0~500,000 Yen (0–3846 Euro) | |

| 2: 500,000–2,000,000 Yen (3846–15,385 Euro) | |

| 3: 2,000,000–5,000,000 Yen (15,385–38,462 Euro) | |

| 4: 5,000,000–10,000,000 Yen (38,462–76,923 Euro) | |

| 5: 10,000,000–20,000,000 Yen (76,932–153,846 Euro) | |

| 6: 20,000,000–50,000,000 Yen (153,846–384,615 Euro) | |

| 7: 50,000,000–100,000,000 Yen (384,615–769,231 Euro) | |

| 8: 100,000,000 Yen–(769,231 Euro–) |

| NEDO | Reliawind | WMEP | |

|---|---|---|---|

| Collection period | 2014–2018 | 2008–2011 | 1999–2006 |

| Years of operation | <20 years | 2–4 years | <17 years |

| Number of turbines | 780 | 350 | 1593 |

| Rotational speed | Fixed/Variable | Variable | Fixed/Variable |

| Control | Stall/Pitch | Pitch | Stall/Pitch |

| Drivetrain | Geared/Direct | Geared | Geared/Direct |

| Collection method | Questionnaire | SCADA, O&M reports Automated fault-log | SCADA, Questionnaire |

| RDS-PP Taxonomy | Reliawind Assembly | NEDO Assembly |

|---|---|---|

| Rotor system | Blade, Hub, Hub cover | Blade, Hub |

| Drivetrain | Drivetrain module | Gearbox, Main shaft/main bearing |

| Generator | Generator assembly | Generator |

| Hydraulic system | Hydraulic system | Hydraulic system, Pitch system |

| Yaw gearbox | Yaw system | Yaw system |

| Control and protection system | Control & communication system, Nacelle sensors, CMS, Auxiliary, Wind farm | Electrical system |

| No. | Assembly | Description of Failure | DT | RC | FTC [17] |

|---|---|---|---|---|---|

| 1 | Blade | Minor repair | 21 | 140 | 2 |

| 2 | Surface repair | 780 | 340 | 4 | |

| 3 | Failure in blade bearing | 682 | 464 | 6 | |

| 4 | Failure in blade | 2724 | 3032 | 14 | |

| 5 | Hub | Minor repair | 21 | 42 | 2 |

| 6 | Misalignment of generator iron core | 266 | 76 | 3 | |

| 7 | Major failure inside of hub | 1517 | 5938 | 13 | |

| 8 | Gearbox | Minor repair | 21 | 145 | 2 |

| 9 | Failure in oil pump motor | 267 | 72 | 6 | |

| 10 | Failure in medium speed shaft gear | 943 | 419 | 6 | |

| 11 | Major failure in medium speed shaft | 1299 | 1388 | 14 | |

| 12 | Main shaft/main bearing | Minor repair | 21 | 95 | 2 |

| 13 | Failure in pump motor | 263 | 15 | 6 | |

| 14 | Misalignment of main shaft/Failure in clutch disk | 1810 | 1813 | 6 | |

| 15 | Failure in main bearing | 1410 | 4917 | 14 | |

| 16 | Generator | Minor repair | 21 | 257 | 2 |

| 17 | Minor failure in generator | 595 | 234 | 6 | |

| 18 | Major failure in generator | 1179 | 1982 | 12 | |

| 19 | Pitch system | Minor repair | 21 | 94 | 2 |

| 20 | Malfunction of pitch cylinder | 292 | 91 | 4 | |

| 21 | Electrical system | Minor repair | 21 | 155 | 2 |

| 22 | Defective converter panel controller | 310 | 119 | 4 | |

| 23 | Failure in IGBT | 289 | 609 | 8 | |

| 24 | Hydraulic system | Minor repair | 21 | 134 | 2 |

| 25 | Hydraulic cylinder | 319 | 83 | 4 | |

| 26 | Yaw system | Minor repair | 21 | 285 | 2 |

| 27 | Break in bolt on yaw gear | 323 | 146 | 6 |

| Scenario Number | Scenario Description | Evidence |

|---|---|---|

| Baseline | Current failure rates and downtime | Based on NEDO database in Section 2.1 |

| Scenario 1 | Prepare spare parts in the country Reduce the logistic downtime to 72 h for minor failure modes (FTC 2,3,4). | Based on the industry practice [23], which states that logistic downtimes of yaw control and hydraulic were 143 days and 130 days without spares, but 3 days and 1 day with spares. |

| Scenario 2 | Install a condition monitoring system Reduce the downtime to 10 days for major failure mode | Based on the industry report [25], which states that downtime of large assebly was reduced from 25 days to 10 days using condition monitoring system. |

| Scenario 3 | Reduce the repair time due to industry maturity | Use a learning rate of 18.6% [28] |

| Baseline | Scenario 1 | Scenario 2 | Scenario 3 | ||

|---|---|---|---|---|---|

| Downtime | (hours) | 970 | 501 | 261 | 181 |

| Scheduled downtime | (hours) | 135 | 135 | 135 | 135 |

| Total downtime | (hours) | 1,105 | 636 | 396 | 316 |

| Availability | (%) | 87.4 | 92.7 | 95.5 | 96.4 |

| Average | Reference | |

|---|---|---|

| CAPEX | 282,000 Yen/kW | [2] |

| FCR | 6.12% | Identified |

| OPEX | 9300 Yen/kW | [2] |

| 2300 Yen/kW | Identified | |

| 4500 Yen/kW | [2] | |

| 2500 Yen/kW | [2] | |

| Capacity Factor | 22% | [2] |

| 970 h/turbine | Identified | |

| 135 h/turbine | [26] | |

| Availability | 87% | [2] |

| Levelized Cost of Energy | 13.9 Yen/kWh | [2] |

| Baseline | Scenario 1 | Scenario 2 | Scenario 3 | Target for 2030 | ||

|---|---|---|---|---|---|---|

| CAPEX | (Yen/kW) | 282,000 | 230,180 | |||

| FCR | (%) | 6.12 | 6.12 | |||

| OPEX | (Yen/kW) | 9300 | 7124 | 6011 | 5640 | 4603 |

| (Hour) | 970 | 501 | 261 | 181 | 181 | |

| (Hour) | 135 | 135 | 135 | 135 | 135 | |

| Availability | (%) | 87.4 | 92.7 | 95.5 | 96.4 | 96.4 |

| Capacity factor | (%) | 22.1 | 23.5 | 24.2 | 24.4 | 24.4 |

| Average of LCOE | (Yen/kWh) | 13.7 | 11.9 | 11.0 | 10.7 | 8.7 |

| Reduction | (Yen/kWh) | ― | −1.9 | −0.9 | −0.3 | −2.0 |

| P50 Yen/kWh | P90 Yen/kWh | P90/P50 | |

|---|---|---|---|

| Baseline | 12.52 | 23.86 | 1.91 |

| Scenario 1 | 11.14 | 15.29 | 1.37 |

| Scenario 2 | 10.53 | 14.10 | 1.34 |

| Scenario 3 | 10.36 | 13.91 | 1.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kikuchi, Y.; Ishihara, T. Availability and LCOE Analysis Considering Failure Rate and Downtime for Onshore Wind Turbines in Japan. Energies 2021, 14, 3528. https://doi.org/10.3390/en14123528

Kikuchi Y, Ishihara T. Availability and LCOE Analysis Considering Failure Rate and Downtime for Onshore Wind Turbines in Japan. Energies. 2021; 14(12):3528. https://doi.org/10.3390/en14123528

Chicago/Turabian StyleKikuchi, Yuka, and Takeshi Ishihara. 2021. "Availability and LCOE Analysis Considering Failure Rate and Downtime for Onshore Wind Turbines in Japan" Energies 14, no. 12: 3528. https://doi.org/10.3390/en14123528

APA StyleKikuchi, Y., & Ishihara, T. (2021). Availability and LCOE Analysis Considering Failure Rate and Downtime for Onshore Wind Turbines in Japan. Energies, 14(12), 3528. https://doi.org/10.3390/en14123528