A Mathematical Model for the Analysis of Jet Engine Fuel Consumption during Aircraft Cruise

Abstract

:1. Introduction

- Calculation of pollutant emissions (carbon dioxide (CO), hydrocarbons (HC), nitrogen oxides (NO) and similar) by means of the aircraft’s fuel flow rate closed-form formula and validated emissions indices.

- Knowing the fuel fraction that has been invested during the cruising flight phase and the aircraft’s weight at any moment in time.

- Knowing the closed-form formula of the relationship between the aircraft’s weight and the engine’s fuel consumption.

- Performance analysis with different types of jet fuel.

- Optimal aircraft selection for a certain route in terms of fuel consumption.

- Optimal engine selection for a certain aircraft type and route in terms of fuel consumption.

2. Problem Statement

- (a)

- Constant altitude and Mach number.

- (b)

- Constant altitude and lift coefficient.

- (c)

- Constant Mach number and lift coefficient.

- (1)

- The aircraft is considered a variable-mass system: fuel is being consumed along time and weight varies consequently.

- (2)

- Fuel consumption is only considered for the aircraft’s engines and under ideal conditions, i.e., engines consume equal fuel quantity and their degradation effects are not taken into account.

- (3)

- Static atmosphere and ideal gas conditions enable thermodynamic parameters such as pressure, temperature and air density to be expressed only as a function of altitude.

- (4)

- Regarding aircraft flight mechanics:

- The aircraft is considered as a physical system that follows a rectilinear trajectory contained in a horizontal plane, meaning that its velocity vector remains constant both in magnitude and direction.

- A vertical mass symmetry plane exists along the longitudinal axis and all the interacting forces are contained in the same plane, including the aircraft’s velocity vector.

- Wind effects are not taken into account.

- (5)

- Regarding the aircraft performance parameters:

- The thrust specific fuel consumption (TSFC) is considered a constant parameter [22], since the flight configuration studied implies constant altitude and Mach number, and the parabolic drag polar approach is employed.

Equations for the Mathematical Model

3. Closed-Form Solution of the Fuel Consumption for the Cruising Flight Phase

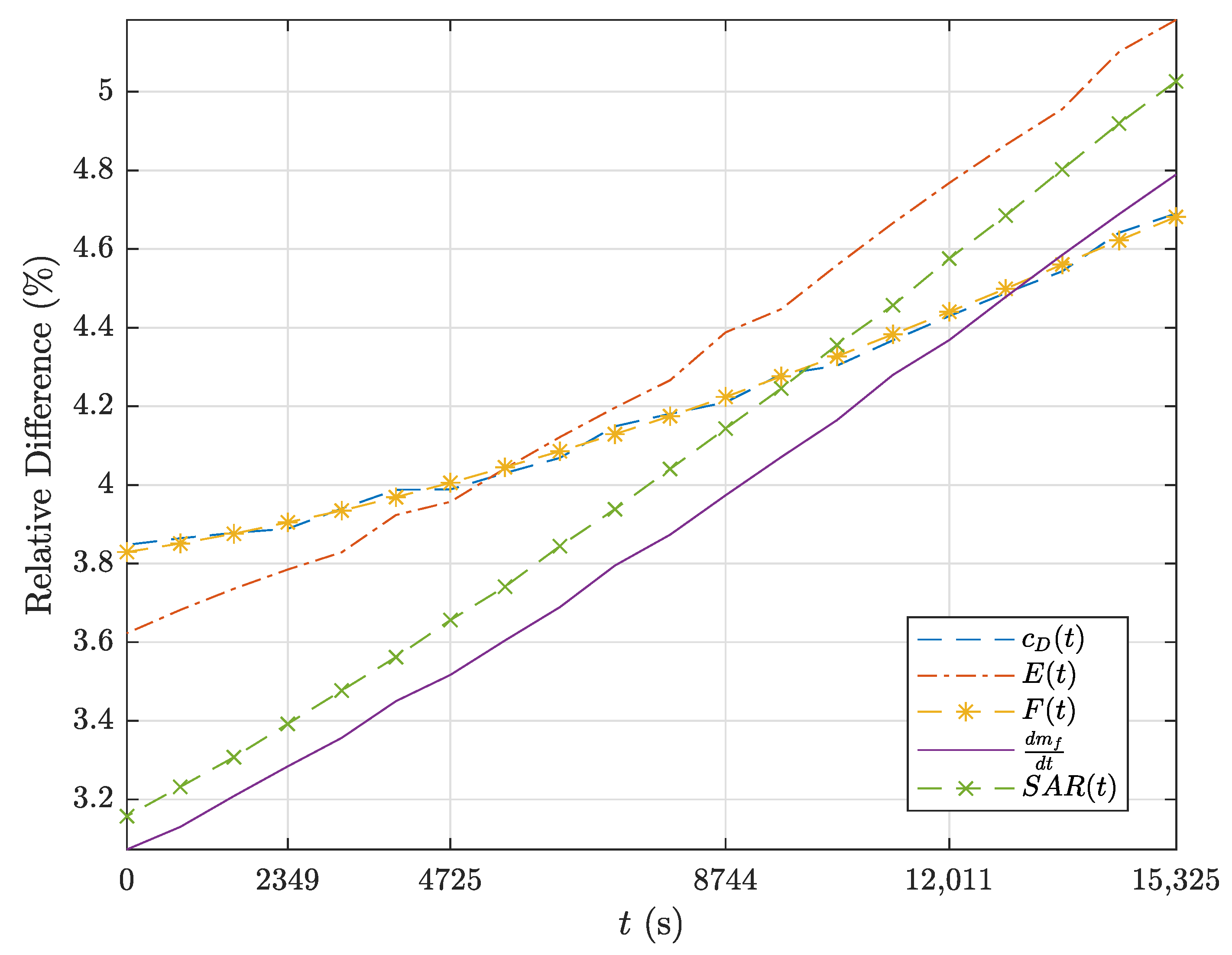

4. Example Case: Validation and Discussion

- (a)

- We have assumed the thrust specific fuel consumption to be constant, but it actually varies simultaneously with the aircraft’s thrust.

- (b)

- For the drag polar presented in Equation (8), we only included the zero-lift drag coefficient and the induced drag coefficient. Other phenomena such as the compressibility and trim effects need to be considered.

5. Application: Pollutant Emissions Calculation

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EASA | European Union Aviation Safety Agency |

| FAA | Federal Aviation Administration |

| ICAO | International Civil Aviation Organization |

| ATC | Air Traffic Control |

| ACSYNT | Aircraft Synthesis |

| FLOPS | Flight Optimization System |

| DATCOM | Stability and Control Data Compendium of the United States Air Force (USAF) |

| BADA | Base of Aircraft Data |

| ESDU | Engineering Sciences Data Unit |

| PIANO | Project Interactive Analysis and Optimization |

| TSFC | Thrust Specific Fuel Consumption |

| GDOC | Green Direct Operating Cost |

| t | time, s |

| W | aircraft’s weight, N |

| fuel mass, kg | |

| g | gravity’s acceleration, m/s |

| fuel flow rate, kg/s | |

| thrust specific fuel consumption, (kg/s)/N | |

| F | thrust, N |

| L | lift, N |

| D | drag, N |

| q | dynamic pressure , Pa |

| A | wing area, m |

| air density, kg/m | |

| v | true airspeed, m/s |

| drag coefficient, dimensionless | |

| lift coefficient, dimensionless | |

| zero-lift drag coefficient, dimensionless | |

| b | aircraft wingspan, m |

| aspect ratio, | |

| e | Oswald efficiency factor, dimensionless |

| k | induced drag factor, |

| constant, N/s | |

| constant, 1/(N · s) | |

| constant, dimensionless | |

| h | altitude, m |

| a | speed of sound, m/s |

| M | Mach number, |

| E | lift-to-drag ratio, |

| specific air range, nmi/kg | |

| p | total emitted pollutant mass, kg |

| emission index, dimensionless | |

| operating empty mass, kg | |

| payload mass, kg | |

| Subscripts | |

| cruise |

Appendix A. Piano-X Configuration

References

- Young, T.M. Performance of the Jet Transport Airplane; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- The Boeing Company. Boeing 767 Performance Summary. 2006. Available online: https://web.archive.org/web/20150415224410/http://www.boeing.com/assets/pdf/commercial/startup/pdf/767_perf.pdf (accessed on 15 September 2020).

- Air Transport Action Group (ATAG). Facts & Figures. 2019. Available online: https://www.atag.org/facts-figures.html (accessed on 15 September 2020).

- Filippone, A. Advanced Aircraft Flight Performance; Cambridge University Press: New York, NY, USA, 2012. [Google Scholar]

- Saarlas, M. Aircraft Performance; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Collins, B.P. Estimation of Aircraft Fuel Consumption. J. Aircr. 1982, 19, 969–975. [Google Scholar] [CrossRef]

- Baumann, S.; Klingauf, U. Modeling of aircraft fuel consumption using machine learning algorithms. CEAS Aeronaut. J. 2019, 11, 277–287. [Google Scholar] [CrossRef]

- Baklacioglu, T. Fuel flow-rate modelling of transport aircraft for the climb flight using genetic algorithms. Aeronaut. J. 2015, 119, 173–183. [Google Scholar] [CrossRef]

- Baklacioglu, T. Predicting the fuel flow rate of commercial aircraft via multilayer perceptron, radial basis function and ANFIS artificial neural networks. Aeronaut. J. 2021, 125, 453–471. [Google Scholar] [CrossRef]

- Chati, Y.S.; Balakrishnan, H. Statistical modeling of aircraft engine fuel flow rate. In Proceedings of the 30th Congress of the International Council of the Aeronautical Science, Daejeon, Korea, 25–30 September 2016; Available online: http://www.icas.org/ICAS_ARCHIVE/ICAS2016/data/papers/2016_0619_paper.pdf (accessed on 30 September 2020).

- Zhang, M.; Huang, Q.; Liu, S.; Zhang, Y. Fuel Consumption Model of the Climbing Phase of Departure Aircraft Based on Flight Data Analysis. Sustainability 2019, 11, 4362. [Google Scholar] [CrossRef] [Green Version]

- Turgut, E.T.; Cavcar, M.; Usanmaz, O.; Canarslanlar, A.O.; Dogeroglu, T.; Armutlu, K.; Yay, O.D. Fuel flow analysis for the cruise phase of commercial aircraft on domestic routes. Aerosp. Sci. Technol. 2014, 37, 1–9. [Google Scholar] [CrossRef]

- Trani, A.; Wing-Ho, F.; Schilling, G.; Baik, H.; Seshadri, A. A neural network model to estimate aircraft fuel consumption. In Proceedings of the AIAA 4th Aviation Technology, Integration and Operations (ATIO) Forum, Chicago, IL, USA, 20–22 September 2004; p. 6401. [Google Scholar] [CrossRef] [Green Version]

- Wasiuk, D.K.; Lowenberg, M.H.; Shallcross, D.E. An aircraft performance model implementation for the estimation of global and regional commercial aviation fuel burn and emissions. Transp. Res. D Transp. Environ. 2015, 35, 142–159. [Google Scholar] [CrossRef] [Green Version]

- Yanto, J.; Liem, R.P. Aircraft fuel burn performance study: A data-enhanced modeling approach. Transp. Res. D Transp. Environ. 2018, 65, 574–595. [Google Scholar] [CrossRef]

- Seymour, K.; Held, M.; Georges, G.; Boulouchos, K. Fuel Estimation in Air Transportation: Modeling global fuel consumption for commercial aviation. Transp. Res. D Transp. Environ. 2020, 88, 102528. [Google Scholar] [CrossRef]

- Baughcum, S.L.; Henderson, S.C.; Tritz, T.G. Scheduled Civil Aircraft Emission Inventories for 1976 and 1984: Database Development and Analysis. 1996. Available online: https://ntrs.nasa.gov/api/citations/19960035824/downloads/19960035824.pdf (accessed on 17 March 2021).

- Baughcum, S.L.; Tritz, T.G.; Henderson, S.C.; Pickett, D.C. Scheduled Civil Aircraft Emission Inventories for 1992: Database Development and Analysis. 1996. Available online: https://ntrs.nasa.gov/api/citations/19960038445/downloads/19960038445.pdf (accessed on 17 March 2021).

- Sutkus, D.J., Jr.; Baughcum, S.L.; DuBois, D.P. Scheduled Civil Aircraft Emission Inventories for 1999: Database Development and Analysis. 2001. Available online: https://ntrs.nasa.gov/api/citations/20020012699/downloads/20020012699.pdf (accessed on 17 March 2021).

- Wasiuk, D.K.; Khan, M.A.H.; Shallcross, D.E.; Lowenberg, M.H. A Commercial Aircraft Fuel Burn and Emissions Inventory for 2005–2011. Atmosphere 2016, 7, 78. [Google Scholar] [CrossRef] [Green Version]

- Turgut, E.T.; Usanmaz, O. An assessment of cruise NOx emissions of short-haul commercial flights. Atmos. Environ. 2017, 171, 191–204. [Google Scholar] [CrossRef]

- Bensel, A. Characteristics of the Specific Fuel Consumption for Jet Engines. 2018. Available online: https://www.fzt.haw-hamburg.de/pers/Scholz/arbeiten/TextBensel.pdf (accessed on 15 September 2020). [CrossRef]

- Sforza, P.M. Commercial Airplane Design Principles; Butterworth-Heinemann (Elsevier): Waltham, MA, USA, 2014. [Google Scholar]

- Lee, T.-W. Aerospace Propulsion; John Wiley & Sons: Chichester, UK, 2014. [Google Scholar]

- Sadraey, M.H. Aircraft Performance: An Engineering Approach; CRC Press Taylor & Francis: Boca Raton, FL, USA, 2017. [Google Scholar]

- Gradshteyn, I.S.; Ryzhik, I.M. Table of Integrals, Series, and Products; Jeffrey, A., Zwillinger, D., Eds.; Academic Press Elsevier: Burlington, MA, USA, 2007. [Google Scholar]

- Piano-X. Lissys Ltd. Available online: https://www.lissys.uk/ (accessed on 15 September 2020).

- Flightradar24. Available online: https://www.flightradar24.com/ (accessed on 8 February 2021).

- The Boeing Company. Boeing 767 Airplane Characteristics for Airport Planning. 2005, p. 12. Available online: http://www.boeing.com/assets/pdf/commercial/airports/acaps/767.pdf (accessed on 7 October 2020).

- Jenkinson, L.; Simpkin, P.; Rhodes, D. Civil Jet Aircraft Design; Butterworth-Heinemann (Elsevier): Waltham, MA, USA, 1999; Available online: https://booksite.elsevier.com/9780340741528/appendices/default.htm (accessed on 17 June 2021).

- Tian, Y.; Wan, L.; Ye, B.; Xing, D. Cruise Flight Performance Optimization for Minimizing Green Direct Operating Cost. Sustainability 2019, 11, 3899. [Google Scholar] [CrossRef] [Green Version]

- DuBois, D.; Paynter, G. Fuel Flow Method2 for Estimating Aircraft Emissions. SAE Trans. J. Aerosp. 2006, 115, 1–14. [Google Scholar] [CrossRef]

- Howe, D. Aircraft Conceptual Design Synthesis; Professional Engineering Publishing: London, UK, 2000. [Google Scholar]

| Aircraft Model | Range (nmi) | (-) | (FL) | (N) | (s) | (kg) |

|---|---|---|---|---|---|---|

| B767-300ER | 2145 | 0.8 | 350 | 1,045,232 | 15,325 | 22,227 |

| t (s) | Performance Parameter | Mathematical Model | Piano-X | Relative Difference |

|---|---|---|---|---|

| (N) | 1.26049 | 1.26049 | 0% | |

| (-) | 0.4164 | 0.418 | 0.3659% | |

| (-) | 0.02135 | 0.02221 | 3.84% | |

| (-) | 19.5 | 18.82 | 3.62% | |

| (N) | 64,634 | 67,208 | 3.83% | |

| (kg/s) | 1.12 | 1.15 | 3.07% | |

| (nmi/kg) | 0.1143 | 0.1108 | 3.15% | |

| (N) | 1.23495 | 1.23410 | 0.07% | |

| (-) | 0.408 | 0.409 | 0.23% | |

| (-) | 0.02105 | 0.02191 | 3.88% | |

| (-) | 19.37 | 18.67 | 3.78% | |

| (N) | 63,734 | 66,324 | 3.9% | |

| (kg/s) | 1.10 | 1.14 | 3.28% | |

| (nmi/kg) | 0.1159 | 0.1121 | 3.4% | |

| (N) | 1.20947 | 1.20771 | 0.14% | |

| (-) | 0.3996 | 0.4 | 0.0965% | |

| (-) | 0.02076 | 0.02163 | 3.98% | |

| (-) | 19.24 | 18.51 | 3.95% | |

| (N) | 62,854 | 65,477 | 4% | |

| (kg/s) | 1.09 | 1.13 | 3.51% | |

| (nmi/kg) | 0.1175 | 0.1134 | 3.65% | |

| (N) | 1.16715 | 1.16372 | 0.3% | |

| (-) | 0.3856 | 0.3860 | 0.0953% | |

| (-) | 0.0203 | 0.02119 | 4.2% | |

| (-) | 18.9 | 18.2 | 4.38% | |

| (N) | 61,433 | 64,143 | 4.2% | |

| (kg/s) | 1.06 | 1.10 | 3.97% | |

| (nmi/kg) | 0.1202 | 0.1154 | 4.14% | |

| t = 12,011 | (N) | 1.13345 | 1.12854 | 0.43% |

| (-) | 0.3745 | 0.3740 | 0.13% | |

| (-) | 0.01993 | 0.02086 | 4.43% | |

| (-) | 18.78 | 17.93 | 4.76% | |

| (N) | 60,338 | 63,142 | 4.4% | |

| (kg/s) | 1.04 | 1.09 | 4.36% | |

| (nmi/kg) | 0.1224 | 0.1170 | 4.57% | |

| t = 15,325 | (N) | 1.09988 | 1.09335 | 0.6% |

| (-) | 0.3634 | 0.362 | 0.38% | |

| (-) | 0.01958 | 0.02055 | 4.7% | |

| (-) | 18.55 | 17.64 | 5.18% | |

| (N) | 59,279 | 62,191 | 4.68% | |

| (kg/s) | 1.02 | 1.08 | 4.79% | |

| (nmi/kg) | 0.1246 | 0.11867 | 5.02% |

| Route | (s) | (kg) | (kg) | ||

|---|---|---|---|---|---|

| A | 1 | FL350 | 11,280 | 12,566 | 39,696 |

| B | 2 | FL310 | 3000 | 3632 | 11,473 |

| FL370 | 9600 | 10,220 | 32,285 | ||

| C | 3 | FL360 | 2040 | 2435 | 7692 |

| FL370 | 9180 | 10,444 | 32,992 | ||

| FL390 | 8160 | 8620 | 27,230 | ||

| D | 4 | FL340 | 3240 | 4063 | 12,835 |

| FL360 | 3540 | 4272 | 13,495 | ||

| FL370 | 9540 | 10,914 | 34,477 | ||

| FL390 | 6660 | 7073 | 22,343 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velásquez-SanMartín, F.; Insausti, X.; Zárraga-Rodríguez, M.; Gutiérrez-Gutiérrez, J. A Mathematical Model for the Analysis of Jet Engine Fuel Consumption during Aircraft Cruise. Energies 2021, 14, 3649. https://doi.org/10.3390/en14123649

Velásquez-SanMartín F, Insausti X, Zárraga-Rodríguez M, Gutiérrez-Gutiérrez J. A Mathematical Model for the Analysis of Jet Engine Fuel Consumption during Aircraft Cruise. Energies. 2021; 14(12):3649. https://doi.org/10.3390/en14123649

Chicago/Turabian StyleVelásquez-SanMartín, Francisco, Xabier Insausti, Marta Zárraga-Rodríguez, and Jesús Gutiérrez-Gutiérrez. 2021. "A Mathematical Model for the Analysis of Jet Engine Fuel Consumption during Aircraft Cruise" Energies 14, no. 12: 3649. https://doi.org/10.3390/en14123649

APA StyleVelásquez-SanMartín, F., Insausti, X., Zárraga-Rodríguez, M., & Gutiérrez-Gutiérrez, J. (2021). A Mathematical Model for the Analysis of Jet Engine Fuel Consumption during Aircraft Cruise. Energies, 14(12), 3649. https://doi.org/10.3390/en14123649