Comparison of Efficient Ways of Mud Cake Removal from Casing Surface with Traditional and New Agents

Abstract

:1. Introduction

- Injection yield and the associated flow rate of spacer fluid in annular space;

- Chemical composition of agents used for making spacer fluids;

- Concentration of surface-active agents, surfactants or other additives applied to the spacer;

- Type of surface from which a mud cake is removed;

- Borehole conditions (temperature and pressure).

2. Materials and Methods

- PN-85/G-02320 Cements and cement slurries used for cementing wellbores;

- PN-EN 10426-2 Oil and gas industry. Cements and materials for cementing wellbores. Part 2: Analysis of drilling cements;

- API SPEC 10 Specification for materials and testing for well cements.

- MDC—anionic surface-active agent used for cleaning the annular space;

- RL8—ethoxylated alcohol C9-C11 non-ionic surface-active compound;

- CD—fatty alcohol alkyl polyglucoside C8-C10.

- SL225—ethoxylated alcohol C12-C14 (anionic surfactant from alkyl ether sulfate group);

- SL327—ethoxylated alcohol C12-C15 (anionic surfactant from alkyl ether sulfate group);

- RB2—ethoxylated alcohol C16-C18 (non-ionic surface-active compound used as a component of cleaning and washing products);

- RB7—ethoxylated alcohol C12-C15 (used as an intermediate product for cleansing, cleaning and washing preparations);

- RL80—ethoxylated alcohol C12-C14 (surface active agent used for wetting and as a non-ionic component of emulsifiers);

- RL22—ethoxylated alcohol C12-C14 (non-ionic surface-active compound used as emulsifier).

3. Results

4. Discussion

5. Conclusions

- (1)

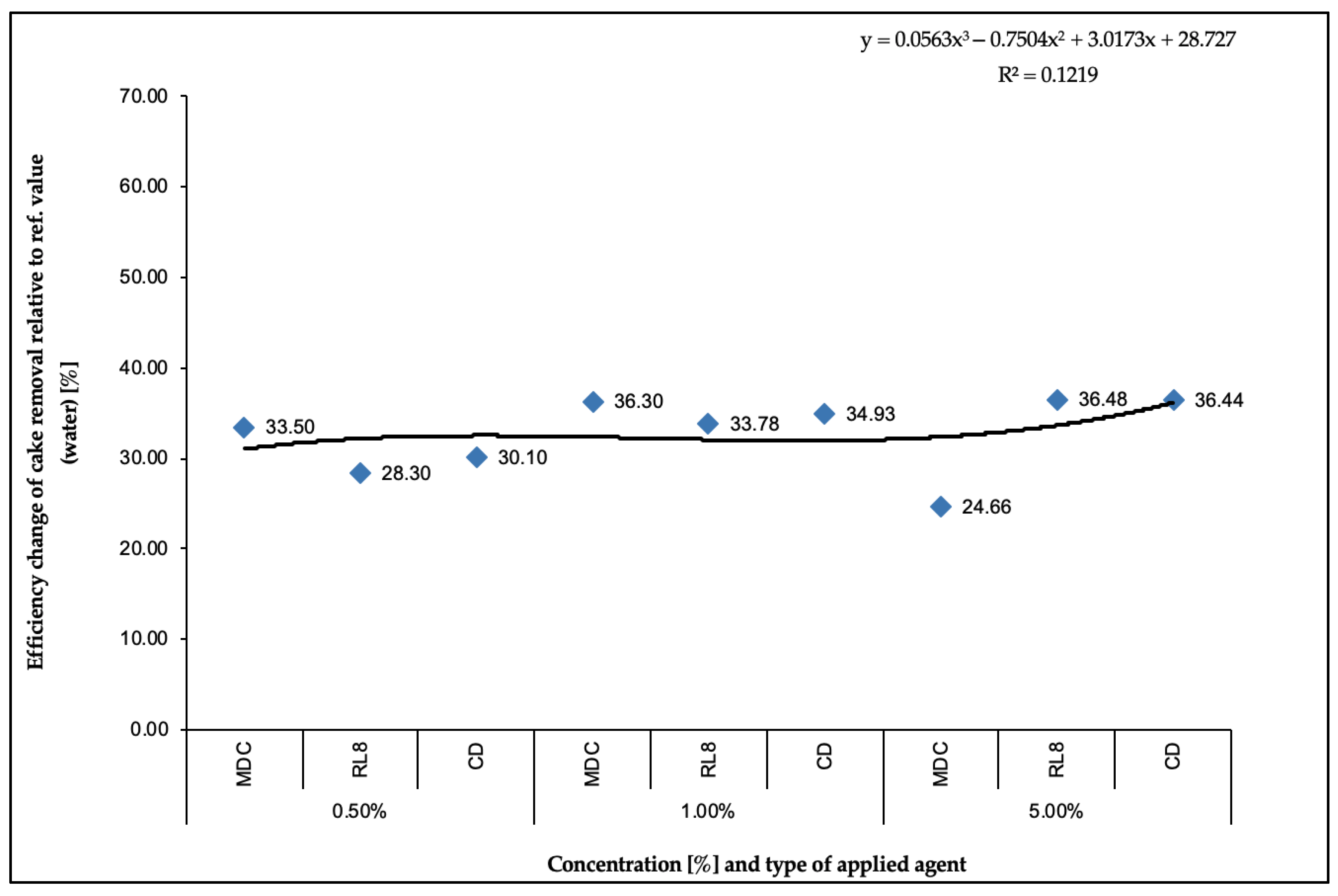

- The traditional agents had a comparable efficiency of operation.

- (2)

- The efficiency of mud cake removal from the rotor surface (casing) for the traditional agents ranged from 69.08% to 75.63%.

- (3)

- For the traditional agents, the percentage efficiency change of mud cake removal as compared with the water reference value ranged from 24.66% to 36.48%. With one exception (5% MDC), it increased with the increase of concentration.

- (4)

- The efficient applicability range of traditional agents was 0.5% to 5%.

- (5)

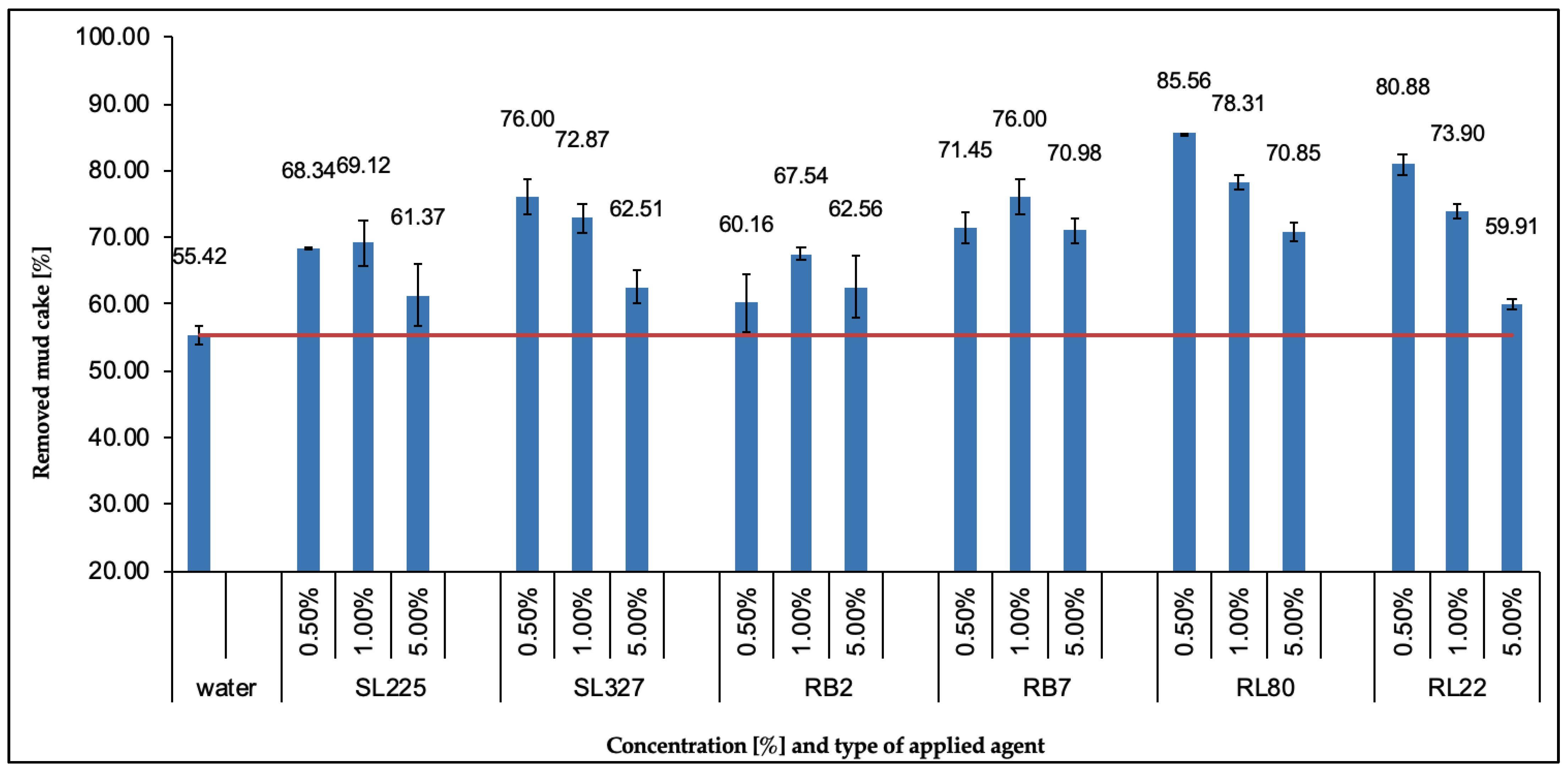

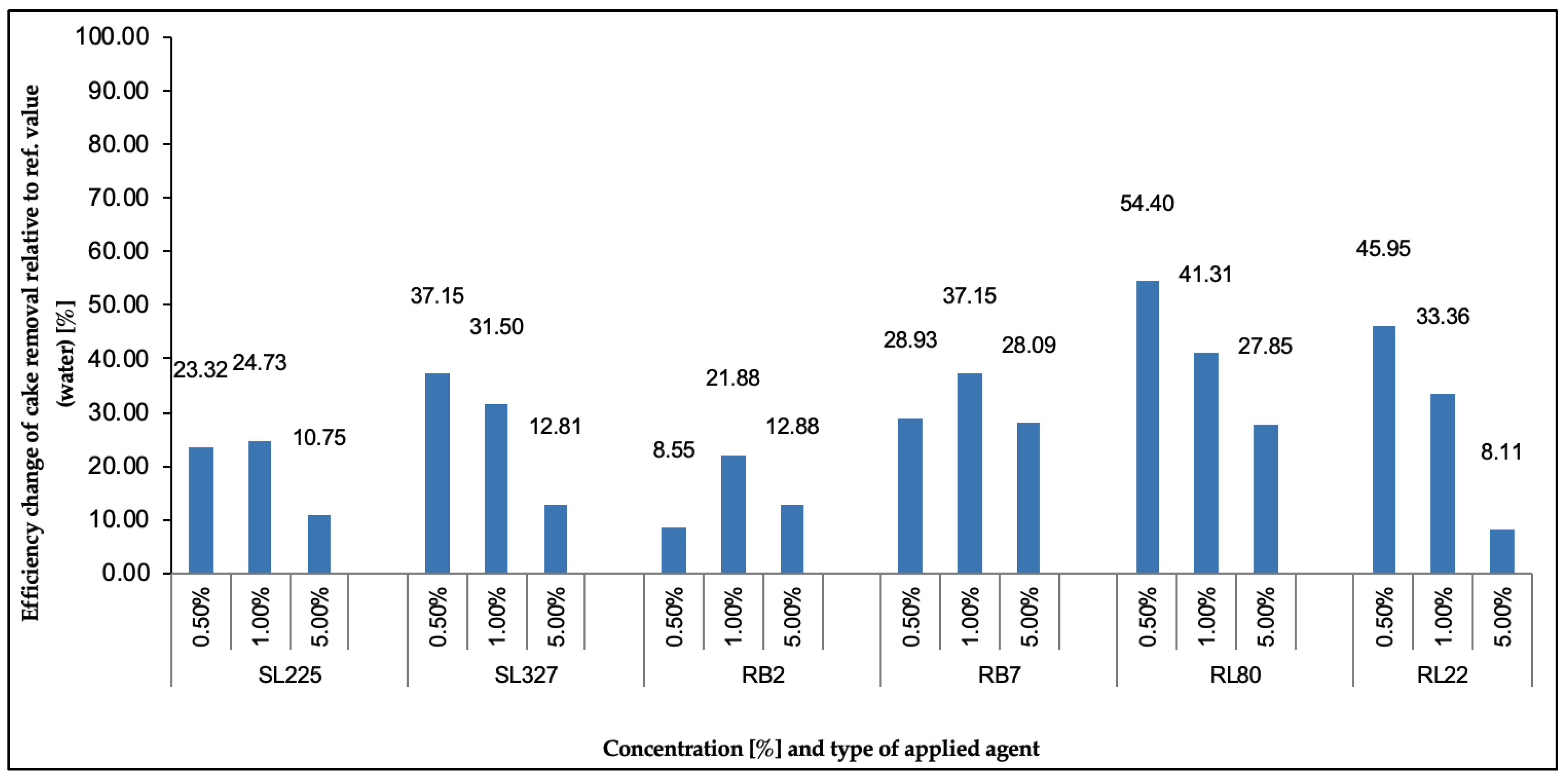

- New agents used for preparing spacer fluids were diversified in their efficiency, depending on the applied concentrations.

- (6)

- The efficiency of mud cake removal with fluids based on new agents ranged from 59.91% to 85.56%.

- (7)

- The percentage efficiency change of mud cake removal as compared with the reference value ranged from 8.11% to 54.40%.

- (8)

- The most efficient applicability range for new agents was observed for the 0.5% and 1% solutions. The worst efficiency was observed for the 5% solutions, except RB2, for which the worst result was observed for the 0.5% solution.

- (9)

- An increase over 1% of the concentration of new agents resulted in exceeding the critical micelle concentration, and thus, considerable deterioration of the efficiency of the spacer fluids.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kremieniewski, M. Recipe of Lightweight Slurry with High Early Strength of the Resultant Cement Sheath. Energies 2020, 13, 1583. [Google Scholar] [CrossRef] [Green Version]

- Kremieniewski, M.; Rzepka, M.; Stryczek, S.; Wiśniowski, R. Comparison of Gas Migration Test and Building Structural Strength of Slurry in the Aspect of Limiting Gas Invasion. AGH Drill. Oil Gas 2016, 33, 595–608. [Google Scholar] [CrossRef] [Green Version]

- Kremieniewski, M.; Rzepka, M.; Kędzierski, M. Influence of the Contact Time of the Preflush Fluid with the Filter Cake on the Effectiveness of the Purification of the Annular Space. Nafta-Gaz 2018, 74. [Google Scholar] [CrossRef]

- Mitchell, R.F.; Miska, S. Fundamentals of Drilling Engineering; Spe Textbook Series; Society of Petroleum Engineers: Houston, TX, USA, 2011; Volume 12, ISBN 978-1-55563-207-6. [Google Scholar]

- Aadnoy, B.S.; Cooper, I.; Miska, S.; Mitchell, R.F.; Payne, M.L. Advanced Drilling and Well Technology; Society of Petroleum Engineers: Houston, TX, USA, 2009; ISBN 978-1-55563-145-1. [Google Scholar]

- Knez, D.; Gonet, A.; Macuda, J.; Stryczek, S. Selected Issues of Wellbore Hydraulics and Cementing; AGH University of Science and Technology Press: Krakow, Poland, 2017; ISBN 978-83-7464-885-1. [Google Scholar]

- Kremieniewski, M.; Rzepka, M. Przyczyny i skutki przepływu gazu w zacementowanej przestrzeni pierścieniowej otworu wiertniczego oraz metody zapobiegania temu zjawisku (ang. The causes and effects of gas flow in the cemented annular space of borehole and methods to prevent this phenomenon). Nafta-Gaz 2016, 72, 722–728. [Google Scholar] [CrossRef]

- Wiśniowski, R.; Skrzypaszek, K.; Małachowski, T. Selection of a Suitable Rheological Model for Drilling Fluid Using Applied Numerical Methods. Energies 2020, 13, 3192. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Kędzierski, M. Badania nad opracowaniem hybrydowej cieczy buforowej (ang.Research into the development of a hybrid spacer). Nafta-Gaz 2020, 76, 517–526. [Google Scholar] [CrossRef]

- Kremieniewski, M. Korelacja skuteczności usuwania osadu za pomocą cieczy na osnowie jonowych (anionowych) i niejonowych SPCz (ang. Correlation of the effectiveness of mud sludge removal with liquids on the ionic (anionic) and nonionic surfactants). Nafta-Gaz 2019, 75, 167–177. [Google Scholar] [CrossRef]

- McLean, R.H.; Manry, C.W.; Whitaker, W.W. Displacement Mechanics in Primary Cementing. J. Pet. Technol. 1967, 19, 251–260. [Google Scholar] [CrossRef]

- Nelson, E.B. Well Cementing; Schlumberger Educational Services: Elsevier Science, 1990. [Google Scholar]

- Błaż, S. Nowe rodzaje cieczy przemywających osady z płuczki inwersyjnej przed zabiegiem cementowania otworów wiertniczych (ang. New types of preflush fluids removing invert emulsion drilling mud filter cake prior to casing cementing). Nafta-Gaz 2017, 73, 302–311. [Google Scholar] [CrossRef]

- Kremieniewski, M. Ocena skuteczności oczyszczania kolumny rur okładzinowych przed cementowaniem na podstawie badań przy użyciu wiskozymetru obrotowego (ang. Cleaning of the casing string before cementation, based on research using a rotational viscometer). Nafta-Gaz 2018, 74, 676–683. [Google Scholar] [CrossRef]

- Xu, D.; Guo, J.; Yuan, B.; Wen, D.; Fang, X.; Li, H.; Ling, B. A Minimum Volume Prediction of Spacer Based on Turbulent Dispersion Theory: Model and Example. Petroleum 2019, 5, 397–401. [Google Scholar] [CrossRef]

- Li, L.; Alegria, A.; Doan, A.A.; Kellum, M.G.; Hughes, B. A Novel Spacer System to Prevent Lost Circulation in Cementing Applications. In Proceedings of the 2016 AADE Fluids Technical Conference and Exhibition, Hilton Houston North Hotel, Houston, TX, USA, 12 April 2016; p. 5. [Google Scholar]

- Li, L.; Padilla, F.; Doan, A.A.; Kellum, M.G.; Hughes, B. Evaluation of a New Spacer System Mixed On-The-Fly. In Proceedings of the 2016 AADE Fluids Technical Conference and Exhibition; Hilton Houston North Hotel, Houston, TX, USA, 12 April 2016; p. 5. [Google Scholar]

- Lavrov, A.; Torsæter, M. Physics and Mechanics of Primary Well Cementing. In SpringerBriefs in Petroleum Geoscience & Engineering; Springer: Cham, Switzerland, 2016; ISBN 978-3-319-43165-9. [Google Scholar]

- Boyou, N.V.; Ismail, I.; Wan Sulaiman, W.R.; Sharifi Haddad, A.; Husein, N.; Hui, H.T.; Nadaraja, K. Experimental Investigation of Hole Cleaning in Directional Drilling by Using Nano-Enhanced Water-Based Drilling Fluids. J. Pet. Sci. Eng. 2019, 176, 220–231. [Google Scholar] [CrossRef] [Green Version]

- Rafati, R.; Smith, S.R.; Sharifi Haddad, A.; Novara, R.; Hamidi, H. Effect of Nanoparticles on the Modifications of Drilling Fluids Properties: A Review of Recent Advances. J. Pet. Sci. Eng. 2018, 161, 61–76. [Google Scholar] [CrossRef] [Green Version]

- Critical Micelle Concentration—An Overview | ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/chemistry/critical-micelle-concentration (accessed on 16 May 2021).

| Agent | Concentration of Spacer Fluids [%] | Weight of Rotor before Test m0 [g] | Weight of Rotor after Mud m1 [g] | Weight of Rotor after Spacer Fluid m2 [g] | Flushing | % of Flushing (Cake Removal) Average Value | Efficiency Change of Cake Removal Relative to Ref. Value (Water) [%] | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| water | --- | 72.18 | 72.21 | 74.57 | 74.85 | 73.27 | 73.36 | 54.39 | 56.44 | 55.42 | 0.0 |

| MDC | 0.5% | 72.18 | 72.14 | 74.32 | 74.49 | 72.72 | 72.77 | 74.77 | 73.19 | 73.98 | 33.50 |

| 1.0% | 72.25 | 72.32 | 74.42 | 74.27 | 72.8 | 72.78 | 74.65 | 76.41 | 75.53 | 36.30 | |

| 5.0% | 72.2 | 72.22 | 74.31 | 74.22 | 72.84 | 72.85 | 69.67 | 68.50 | 69.08 | 24.66 | |

| RL8 | 0.5% | 72.29 | 72.28 | 73.93 | 74.22 | 72.68 | 72.94 | 76.22 | 65.98 | 71.1 | 28.30 |

| 1.0% | 72.11 | 72.13 | 74.09 | 74.13 | 72.57 | 72.7 | 76.77 | 71.50 | 74.13 | 33.78 | |

| 5.0% | 72.11 | 72.13 | 74.09 | 74.13 | 72.57 | 72.64 | 76.77 | 74.50 | 75.63 | 36.48 | |

| CD | 0.5% | 72.18 | 72.24 | 74.3 | 74.35 | 72.71 | 72.89 | 75.00 | 69.19 | 72.1 | 30.10 |

| 1.0% | 72.13 | 72.25 | 74.25 | 74.29 | 72.68 | 72.75 | 74.06 | 75.49 | 74.77 | 34.93 | |

| 5.0% | 72.35 | 72.43 | 74.4 | 74 | 72.88 | 72.79 | 74.15 | 77.07 | 75.61 | 36.44 | |

| Agent | Concentration of Spacer Fluids [%] | Weight of Rotor before Test mo [g] | Weight of Rotor after Mud m1 [g] | Weight of Rotor after Spacer Fluid m2 [g] | Flushing | % of Flushing (Cake Removal) Average Value | Efficiency Change of Cake Removal Relative to Ref. Value (Water) [%] | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| water | --- | 72.18 | 72.21 | 74.57 | 74.85 | 73.27 | 73.36 | 54.39 | 56.44 | 55.42 | 0.0 |

| SL225 | 0.50% | 72.11 | 72.13 | 74.09 | 74.13 | 72.74 | 72.76 | 68.18 | 68.50 | 68.34 | 23.32 |

| 1.00% | 72.09 | 72.19 | 74.35 | 74.43 | 72.84 | 72.83 | 66.81 | 71.43 | 69.12 | 24.73 | |

| 5.00% | 72.12 | 72.21 | 74.53 | 74.36 | 73.13 | 72.97 | 58.09 | 64.65 | 61.37 | 10.75 | |

| SL327 | 0.50% | 72.15 | 72.16 | 74.12 | 74.06 | 72.66 | 72.58 | 74.11 | 77.89 | 76.00 | 37.15 |

| 1.00% | 72.15 | 72.16 | 74.18 | 74.22 | 72.67 | 72.75 | 74.38 | 71.36 | 72.87 | 31.50 | |

| 5.00% | 72.06 | 72.14 | 74.48 | 74.52 | 73.01 | 72.99 | 60.74 | 64.29 | 62.51 | 12.81 | |

| RB2 | 0.50% | 72.14 | 72.15 | 74.49 | 74.52 | 73.15 | 73.02 | 57.02 | 63.29 | 60.16 | 8.55 |

| 1.00% | 72.14 | 72.11 | 74.43 | 74.19 | 72.9 | 72.77 | 66.81 | 68.27 | 67.54 | 21.88 | |

| 5.00% | 72.06 | 72.18 | 74.42 | 74.08 | 73.02 | 72.83 | 59.32 | 65.79 | 62.56 | 12.88 | |

| RB7 | 0.50% | 72.15 | 72.13 | 74.63 | 74.81 | 72.9 | 72.85 | 69.76 | 73.13 | 71.45 | 28.93 |

| 1.00% | 72.15 | 72.16 | 74.12 | 74.06 | 72.66 | 72.58 | 74.11 | 77.89 | 76.00 | 37.15 | |

| 5.00% | 72.15 | 72.18 | 74.26 | 74.31 | 72.79 | 72.77 | 69.67 | 72.30 | 70.98 | 28.09 | |

| RL80 | 0.50% | 72.15 | 72.17 | 74.09 | 74.04 | 72.43 | 72.44 | 85.57 | 85.56 | 85.56 | 54.40 |

| 1.00% | 72.17 | 72.19 | 74.4 | 73.86 | 72.67 | 72.54 | 77.58 | 79.04 | 78.31 | 41.31 | |

| 5.00% | 72.1 | 72.16 | 73.87 | 74.09 | 72.6 | 72.74 | 71.75 | 69.95 | 70.85 | 27.85 | |

| RL22 | 0.50% | 72.22 | 72.19 | 74.6 | 74.57 | 72.65 | 72.67 | 81.93 | 79.83 | 80.88 | 45.95 |

| 1.00% | 72.19 | 72.17 | 74.02 | 73.98 | 72.68 | 72.63 | 73.22 | 74.59 | 73.90 | 33.36 | |

| 5.00% | 72.13 | 72.17 | 74.42 | 74.04 | 73.06 | 72.91 | 59.39 | 60.43 | 59.91 | 8.11 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kremieniewski, M.; Wiśniowski, R.; Stryczek, S.; Łopata, P. Comparison of Efficient Ways of Mud Cake Removal from Casing Surface with Traditional and New Agents. Energies 2021, 14, 3653. https://doi.org/10.3390/en14123653

Kremieniewski M, Wiśniowski R, Stryczek S, Łopata P. Comparison of Efficient Ways of Mud Cake Removal from Casing Surface with Traditional and New Agents. Energies. 2021; 14(12):3653. https://doi.org/10.3390/en14123653

Chicago/Turabian StyleKremieniewski, Marcin, Rafał Wiśniowski, Stanisław Stryczek, and Paweł Łopata. 2021. "Comparison of Efficient Ways of Mud Cake Removal from Casing Surface with Traditional and New Agents" Energies 14, no. 12: 3653. https://doi.org/10.3390/en14123653