Effect of Floating Metallic Particles in Pre-Breakdown and Breakdown Characteristics of Oil Transformer under DC Voltage

Abstract

:1. Introduction

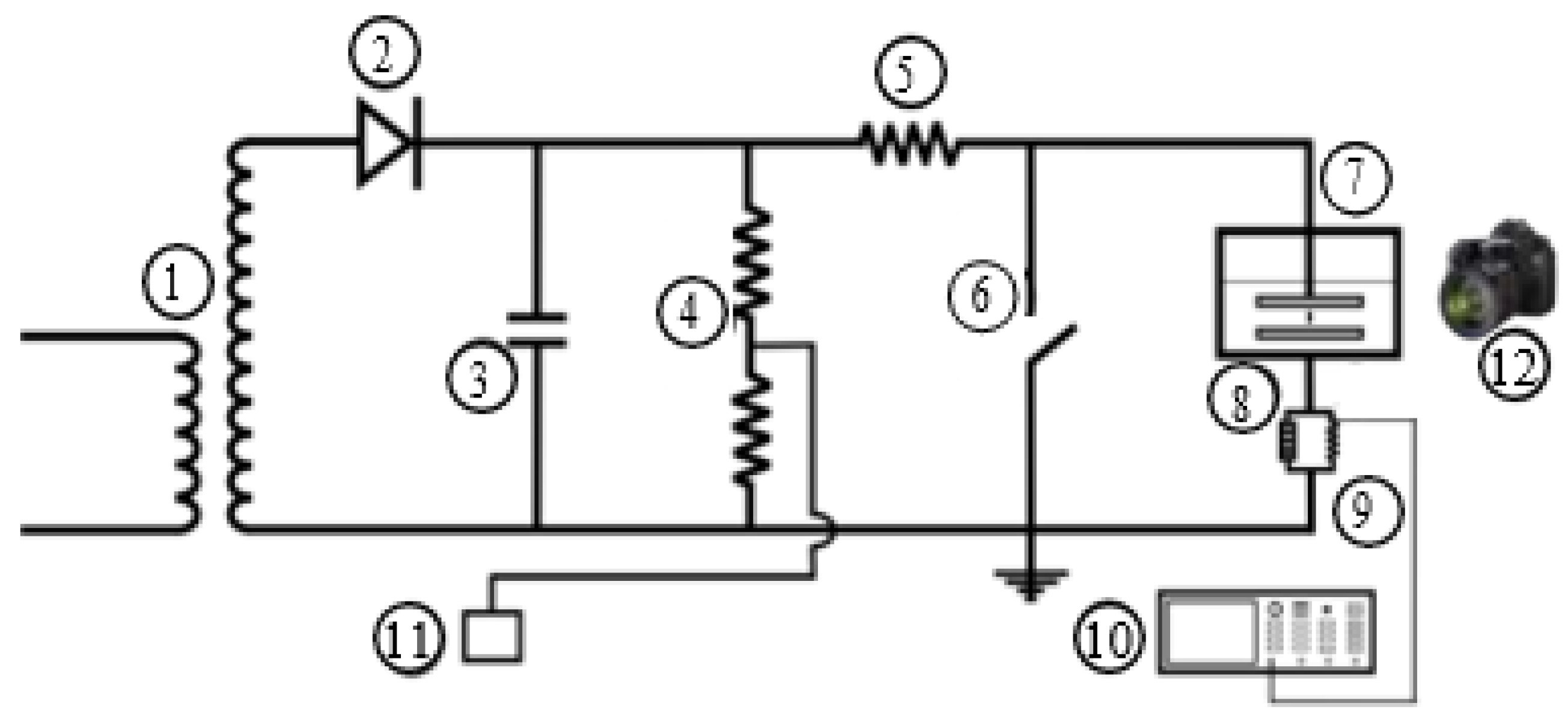

2. Breakdown Mechanism and Corona as Pre-Breakdown Phenomenon

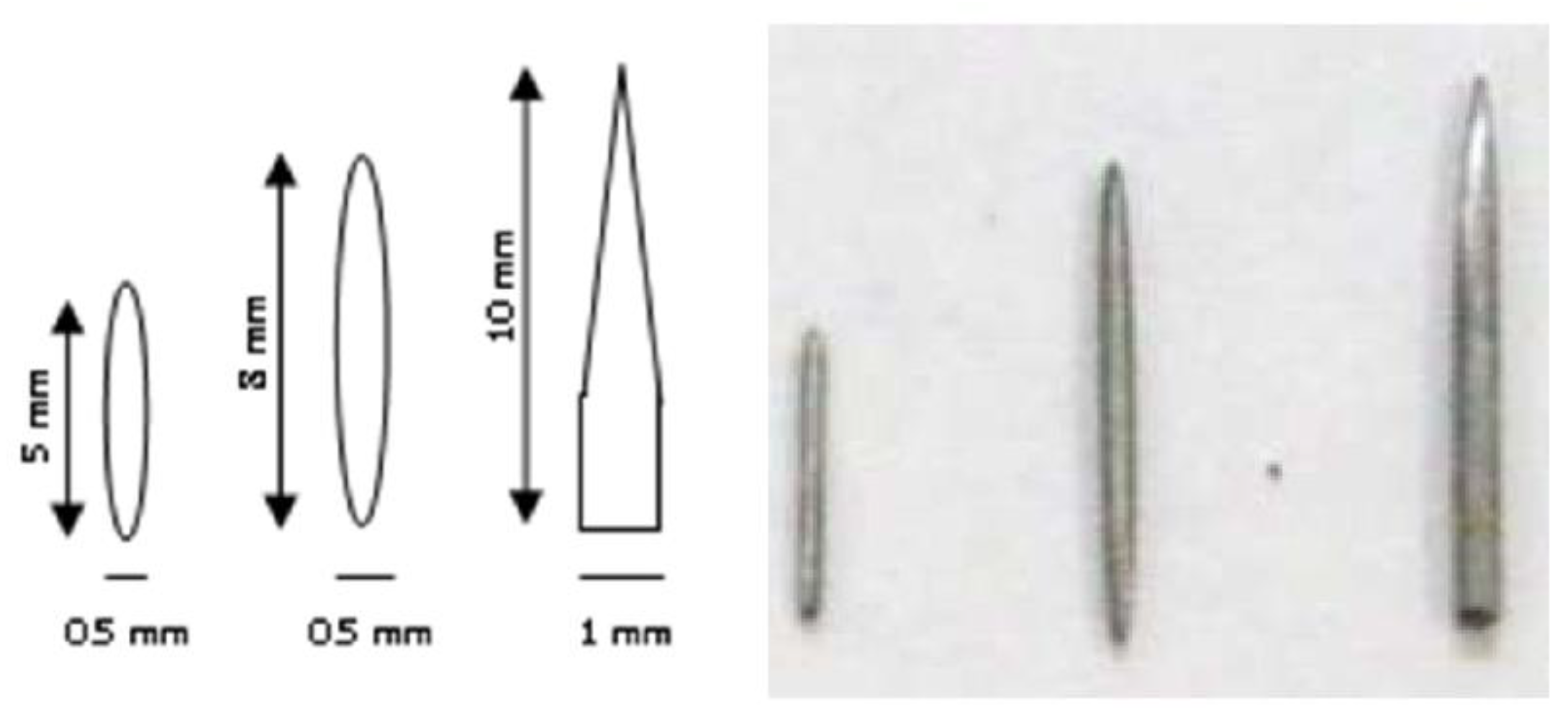

3. Experimental Setup of Oil Insulation Testing with Floating Metallic Particles

- -

- Top and bottom electrode were set as terminal V0 = Vapp and ground V = 0, respectively;

- -

- The floating particle was assumed to have zero voltage and zero charge so total normal electric displacement field equals to zero;

- -

- The exterior boundaries were defined as zero charge n·(εoεrE) = 0.

4. Result and Analysis

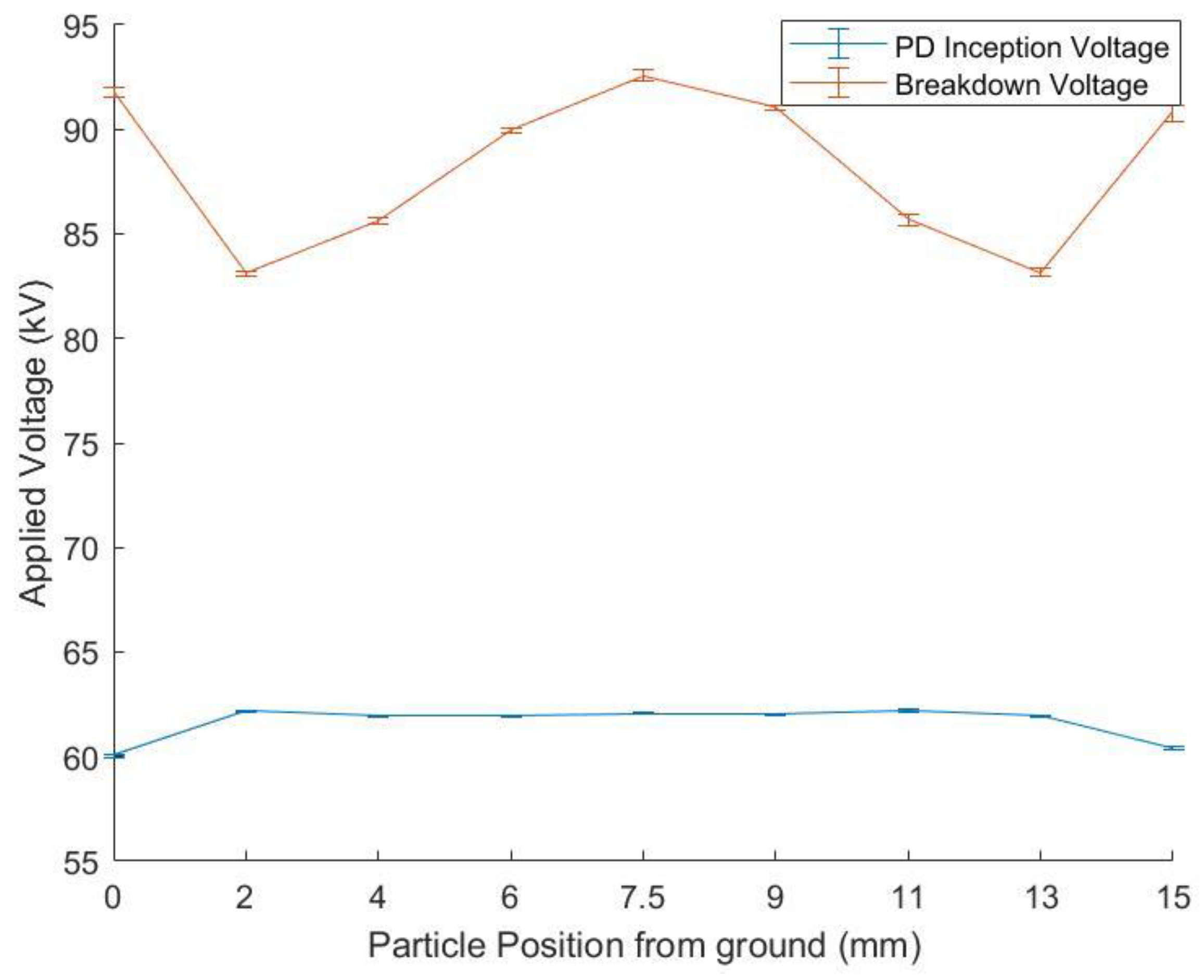

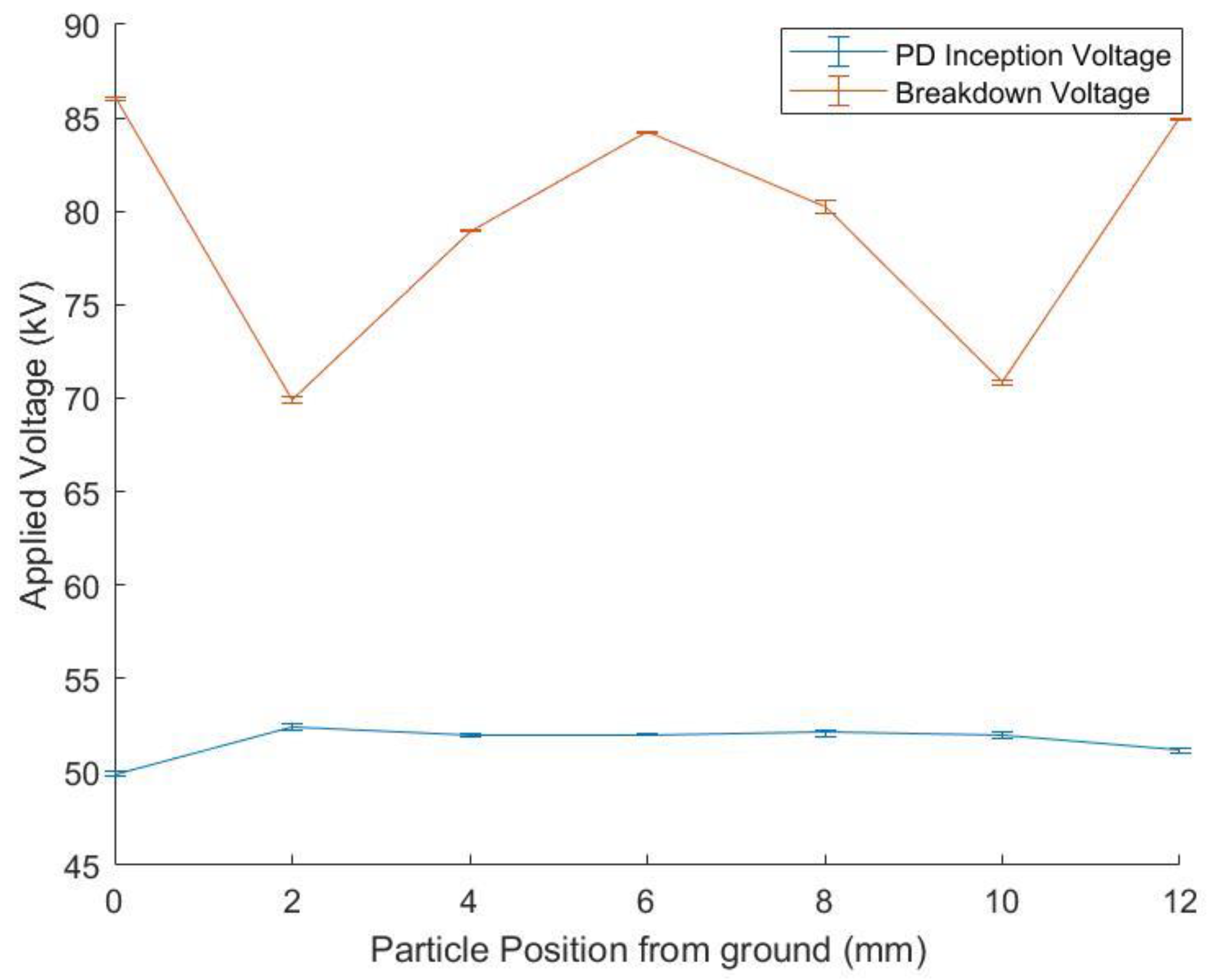

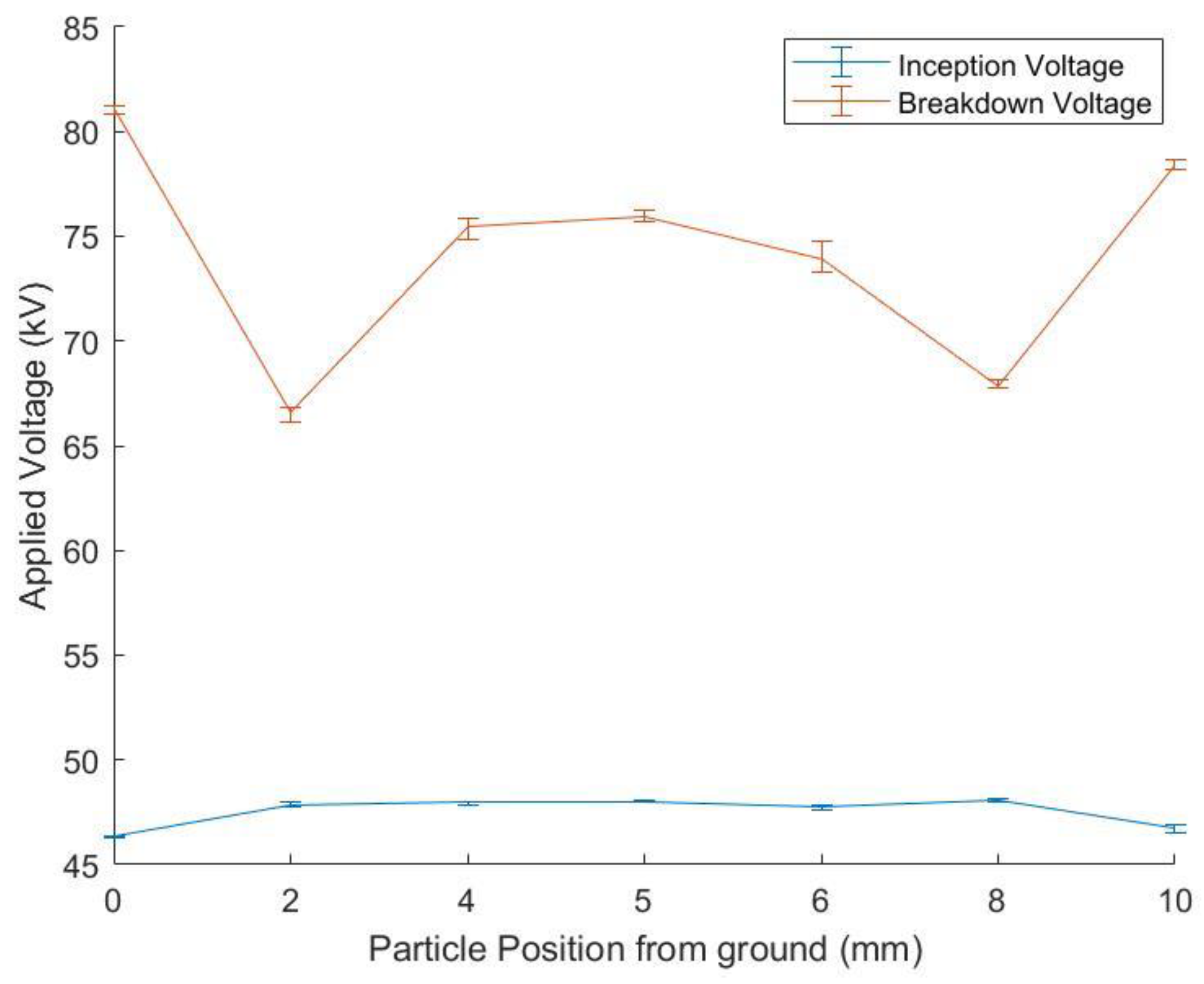

4.1. Corona Inception and Breakdown Voltage

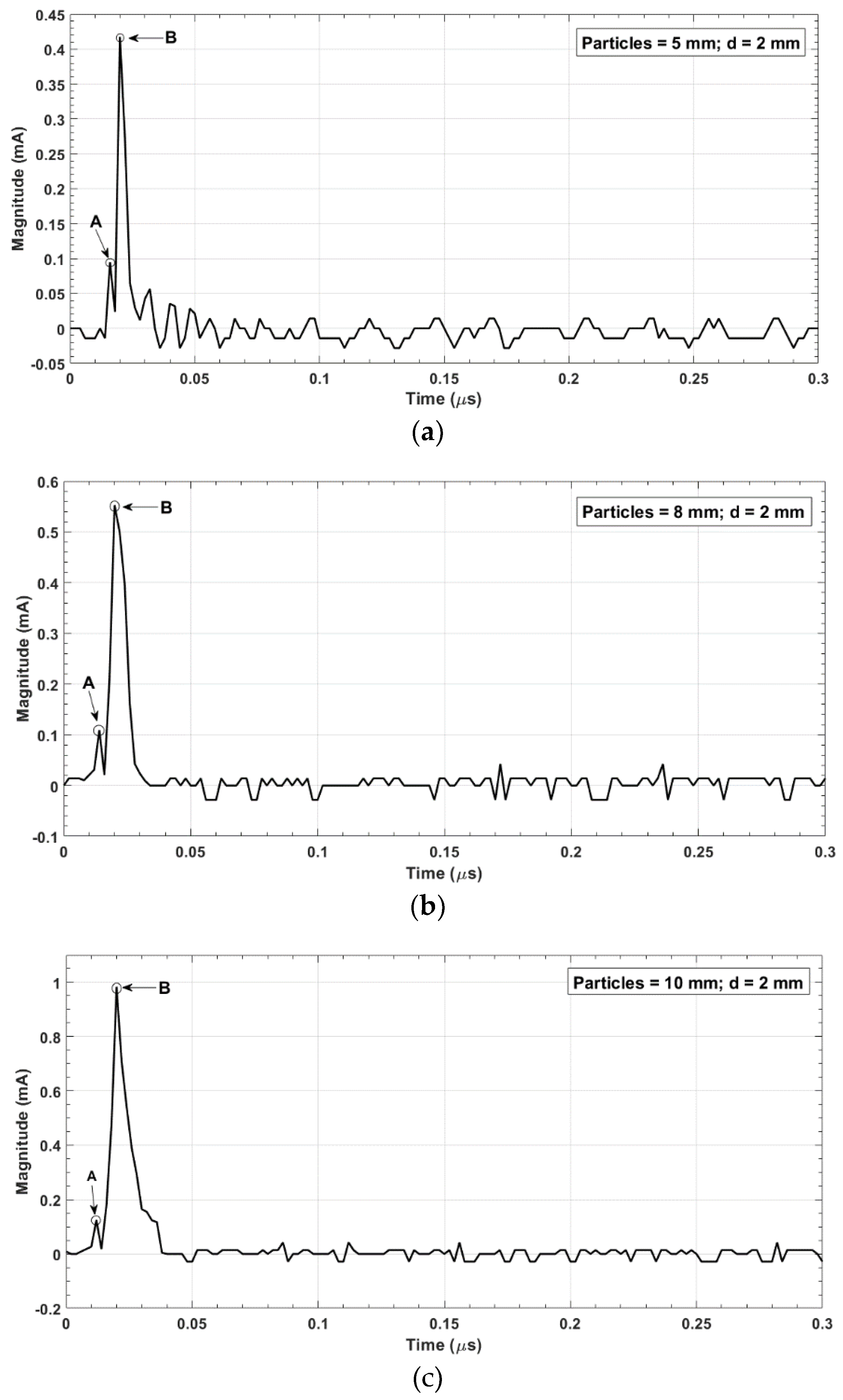

4.2. Corona Current

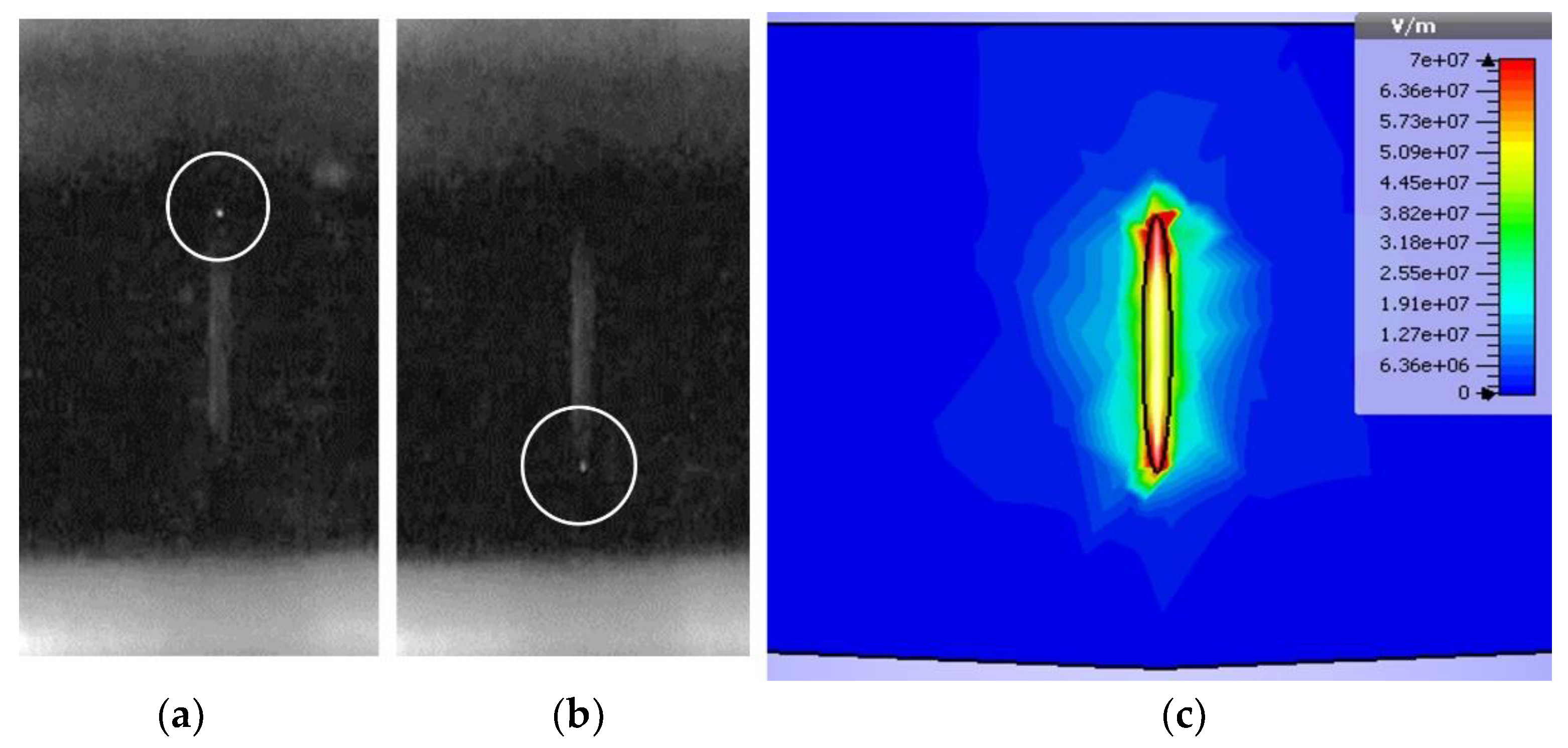

4.3. Corona Phenomenon

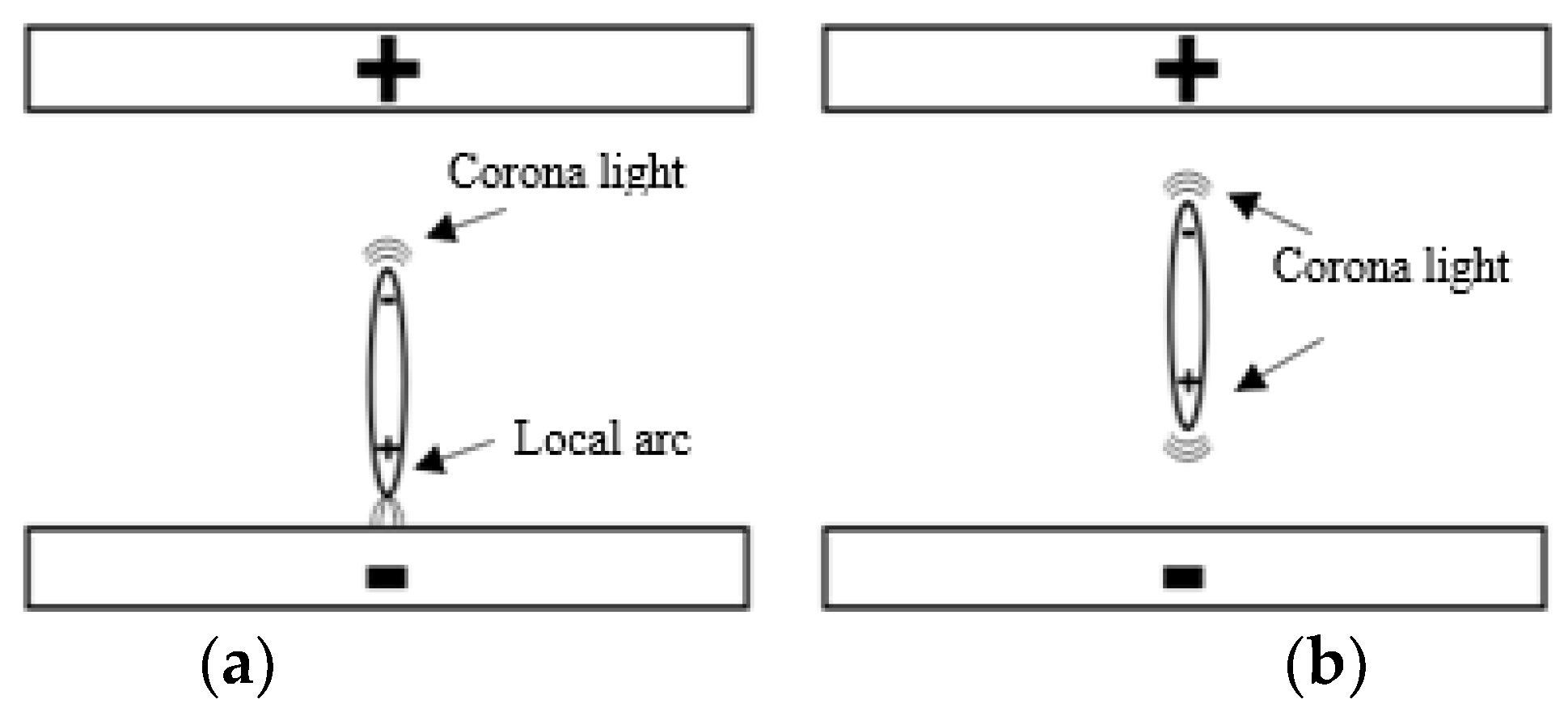

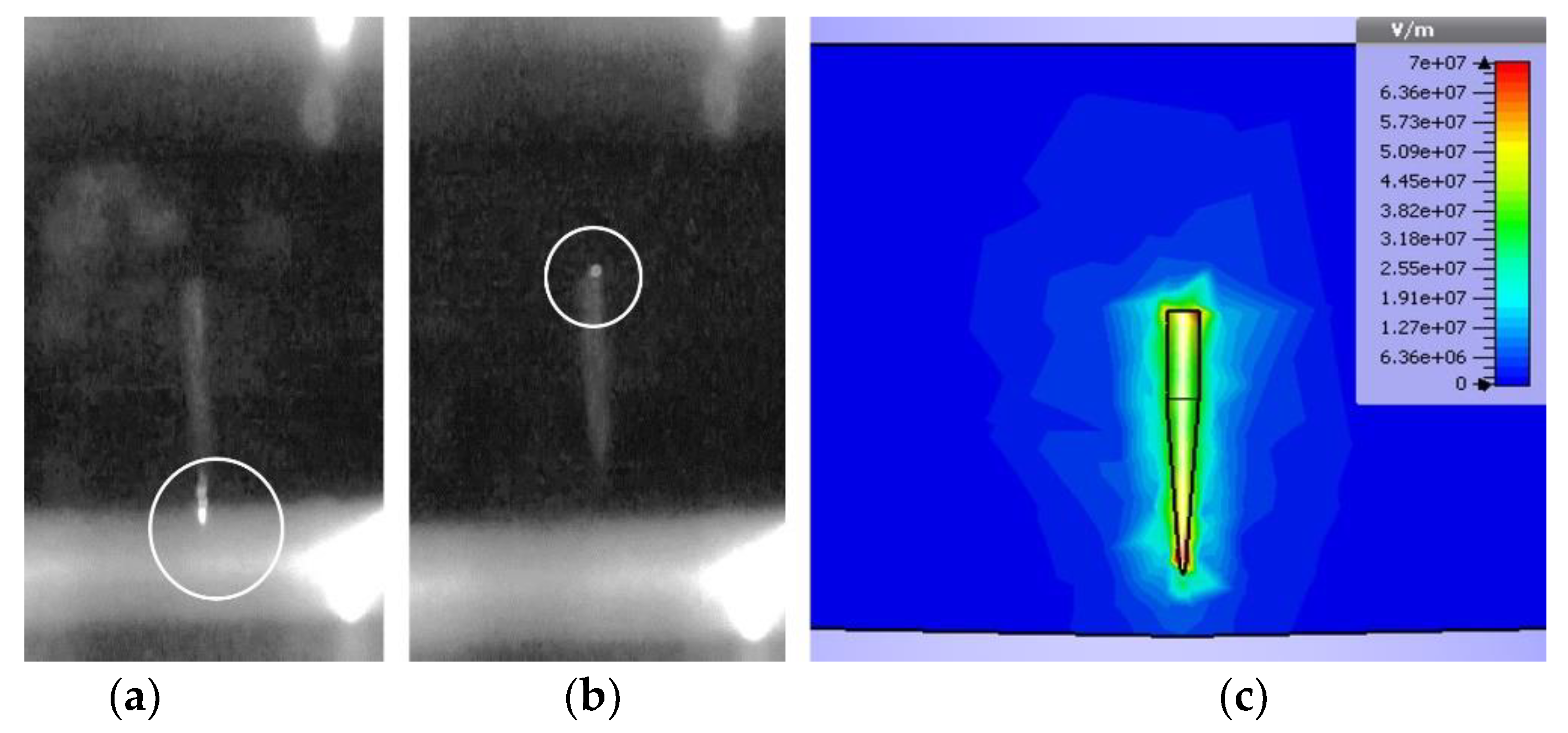

4.3.1. Symmetrical Particle

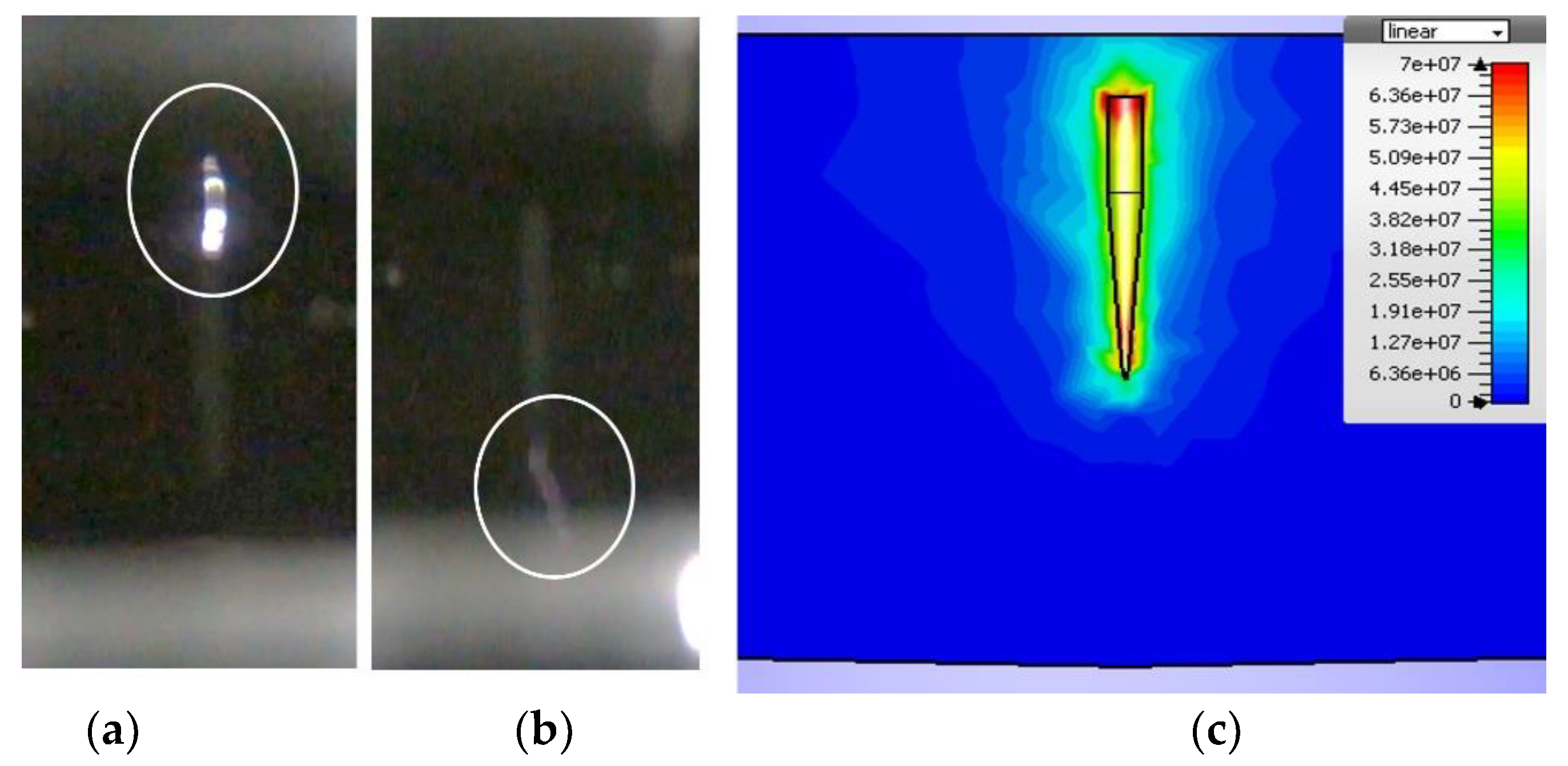

4.3.2. Unsymmetrical Particle

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Missas, S.; Danikas, M.G.; Liapis, I. Factors Affecting the Ageing of Transformer Oil in 150 / 20 kV Transformers. In Proceedings of the 2011 IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- Homaei, M.; Moosavian, S.M.; Illias, H.A. Partial Discharge Localization in Power Transformers Using Neuro-Fuzzy Technique. IEEE Trans. Power Deliv. 2014, 29, 2066–2076. [Google Scholar] [CrossRef]

- Rahman, M.F.; Nirgude, P.; Burjupati, N.R. Effect of irregular-shaped Cu particles on transformer oil PD characteristics under varying electrode configurations. IET Sci. Meas. Technol. 2019, 13, 201–211. [Google Scholar] [CrossRef]

- Yan, W.; Yang, L.; Cui, H.; Ge, Z.; Li, S.; Li, S. Comparison of Degradation Mechanisms and Aging Behaviors of Palm Oil and Mineral Oil during Thermal Aging. In Proceedings of the 2018 Condition Monitoring and Diagnosis (CMD), Perth, WA, Australia, 23–26 September 2018; pp. 1–6. [Google Scholar]

- Omran, Y. Propagation Behavior of Partial Discharge Acoustic Signals by Using Finite Element Technique. In Proceedings of the 2018 1st International Conference on Computer Applications & Information Security (ICCAIS), Riyadh, Saudi Arabia, 4–5 April 2018; pp. 1–5. [Google Scholar]

- Shanker, T.B.; Nagamani, H.N.; Antony, D.; Punekar, G.S. Effects of Transformer-Oil Temperature on Amplitude and Peak Frequency of Partial Discharge Acoustic Signals. IEEE Trans. Power Deliv. 2018, 33, 3227–3229. [Google Scholar] [CrossRef]

- Azmi, K.; Ishak, D.; Kamarol, M.; Zuhairi, A. Comparison of Partial Discharge Behavior in Mineral Oil and PFAE under Influence of Spherical Metal Particle. In Proceedings of the 2017 International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Sanur, Indonesia, 2–5 October 2017; pp. 519–523. [Google Scholar]

- Lundgaard, L.E.; Linhjell, D.; Berg, G. Streamer/leaders from a metallic particle between parallel plane electrodes in transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 1054–1063. [Google Scholar] [CrossRef]

- Sarathi, R.; Koperundevi, G. Investigation of partial discharge activity of single conducting particle in transformer oil under DC voltages using UHF technique. IET Sci. Meas. Technol. 2009, 3, 325–333. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, C.; Zhang, M.; Tang, J. Discharge characteristics and mechanism of conductive metal particles in function of the oil flow under AC voltages. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 268–278. [Google Scholar] [CrossRef]

- Luo, X.; Tang, J.; Pan, C.; Zhang, Y. Contribution of free iron particles to PD characteristics in flowing transformer oil at DC voltages. IET Gener. Transm. Distrib. 2020, 14, 294–300. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, J.; Pan, C.; Luo, X. Comparison of PD and Breakdown Characteristics Induced by Metal Particles and Bubbles in Flowing Transformer Oil. IEEE Access 2019, 7, 48098–48108. [Google Scholar] [CrossRef]

- Pan, C.; Tang, J.; Tao, X.; Zhang, Y.; Ma, S. Partial discharge and breakdown characteristics of moving transformer oil contaminated by metallic particles. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1774–1784. [Google Scholar] [CrossRef]

- Tang, J.; Ma, S.; Zhang, X.; Zhang, M.; Liu, Z.; Li, X.; Zeng, F. Investigation of partial discharge between moving charged metal particles and electrodes in insulating oil under flow state and AC condition. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1099–1105. [Google Scholar] [CrossRef]

- Setyawan, M.Y. Effect of Shape and Number of Particles on the Characteristics of Partial Discharge and Oil Insulation Breaking Voltage in Uniform Fields. Bachlelor’s Thesis, Institut Teknologi Sepuluh Nopember, Surabaya, Indonesia, 2014. [Google Scholar]

- Asano, K.; Hishinuma, R.; Yatsuzuka, Y. Bipolar DC Corona Discharge from a Floating Filamentary Metal Particle. IEEE Trans. Ind. Appl. 2002, 38, 57–63. [Google Scholar] [CrossRef]

- Upadhyay, P.; Amernath, J.; Singh, B.P.; Upadhyay, P. Movement of Metallic Particles in Gas Insulated Line Using SF6 and N2 Gas Mixture under the Influence of Power Frequency and Switching Transient Voltage. In Proceedings of the 2006 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006; pp. 280–283. [Google Scholar]

- Baek, M.K.; Kim, H.K.; Lee, K.H.; Seo, K.S.; Park, I.H. Numerical Analysis of Floating Conductive Particle Motion in High-Voltage System. In Proceedings of the 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 135–138. [Google Scholar]

- Hara, M.; Negara, Y.; Setoguchi, M.; Kurihara, T.; Suehiro, J.; Haashi, N. Particle-triggered Pre-breakdown Phenomena in Atmospheric Air Gaps under AC voltage. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 1071–1081. [Google Scholar] [CrossRef]

- Negara, Y.; Yaji, K.; Imasaka, K.; Suehiro, J.; Hayashi, N.; Hara, M. Corona Discharge Mechanism and Breakdown Voltage Characteristics from Metallic Floating Particles in SF6 Gas under DC Voltage. In Proceedings of the IEEE 8th International Conference on Properties & applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006; pp. 649–652. [Google Scholar]

- Zhang, J.; Wang, F.; Li, J.; Ran, H.; Huang, D. Influence of Copper Particle on Breakdown Voltage and Frequency-Dependent Dielectric Property of Vegetable Insulating Oil. Energies 2017, 10, 938. [Google Scholar] [CrossRef] [Green Version]

- Fahmi, D.; Negara, I.M.Y.; Asfani, D.A.; Hernanda, I.G.N.S.; Deliana, T.H.; Soebagio, J.C. Floating Metal Particle Motion Characteristics with Shape and Size Variation in the Oil Insulation Under DC Voltage. In Proceedings of the 2019 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 28–29 August 2019; pp. 259–264. [Google Scholar]

- Niasar, M.G.; Edin, H. Corona in Oil as a Function of Geometry, Temperature and Humidity. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena, West Lafayette, IN, USA, 17–20 October 2010. [Google Scholar]

- Xie, G.; Yang, Y.; Luo, J.; Guo, D.; Si, L. C Pulse Dielectric Barrier Corona Discharge over Oil Surfaces: Effect of Oil Temperature. IEEE Trans. Plasma Sci. 2013, 41, 481–484. [Google Scholar] [CrossRef]

| Component | Specification |

|---|---|

| High Voltage Transformer | 100 kV, 10 kVA |

| High Voltage Diode | 140 kV, 20 mA |

| Smoothing Capacitor | 140 kV, 25 μF |

| Measuring Resistor | 140 kV DC, 280 mΩ |

| Resistor Damping | 6 kΩ |

| Control Box | OT276 dan DMI551 |

| Secondary Part for RM (DC) | 75 Ω |

| d (mm) | Peak (mA) | d (mm) | Peak (mA) |

|---|---|---|---|

| 0 | 0.39 | 9 | 0.34 |

| 2 | 0.42 | 11 | 0.38 |

| 4 | 0.47 | 13 | 0.34 |

| 6 | 0.43 | 15 | 0.44 |

| 7.5 | 0.40 | Average | 0.40 |

| d (mm) | Peak (mA) | d (mm) | Peak (mA) |

|---|---|---|---|

| 0 | 0.63 | 8 | 0.61 |

| 2 | 0.55 | 10 | 0.61 |

| 4 | 0.60 | 12 | 0.54 |

| 6 | 0.62 | Average | 0.59 |

| d (mm) | Peak (mA) | d (mm) | Peak (mA) |

|---|---|---|---|

| 0 | 0.90 | 6 | 0.99 |

| 2 | 0.98 | 8 | 0.99 |

| 4 | 0.87 | 10 | 1.05 |

| 5 | 0.85 | Average | 0.95 |

| Particle Size (mm) | Average Current Inception (mA) |

|---|---|

| 5 | 0.4009 |

| 8 | 0.5945 |

| 10 | 0.9475 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yulistya Negara, I.M.; Fahmi, D.; Asfani, D.A.; Hernanda, I.G.N.S.; Wahyudi, M.; Ibrahim, M.N. Effect of Floating Metallic Particles in Pre-Breakdown and Breakdown Characteristics of Oil Transformer under DC Voltage. Energies 2021, 14, 3669. https://doi.org/10.3390/en14123669

Yulistya Negara IM, Fahmi D, Asfani DA, Hernanda IGNS, Wahyudi M, Ibrahim MN. Effect of Floating Metallic Particles in Pre-Breakdown and Breakdown Characteristics of Oil Transformer under DC Voltage. Energies. 2021; 14(12):3669. https://doi.org/10.3390/en14123669

Chicago/Turabian StyleYulistya Negara, I. Made, Daniar Fahmi, Dimas Anton Asfani, I. G. N. Satriyadi Hernanda, Mochammad Wahyudi, and Muhammad Novis Ibrahim. 2021. "Effect of Floating Metallic Particles in Pre-Breakdown and Breakdown Characteristics of Oil Transformer under DC Voltage" Energies 14, no. 12: 3669. https://doi.org/10.3390/en14123669

APA StyleYulistya Negara, I. M., Fahmi, D., Asfani, D. A., Hernanda, I. G. N. S., Wahyudi, M., & Ibrahim, M. N. (2021). Effect of Floating Metallic Particles in Pre-Breakdown and Breakdown Characteristics of Oil Transformer under DC Voltage. Energies, 14(12), 3669. https://doi.org/10.3390/en14123669