Failure Mechanism Analysis and Support Technology for Roadway Tunnel in Fault Fracture Zone: A Case Study

Abstract

:1. Introduction

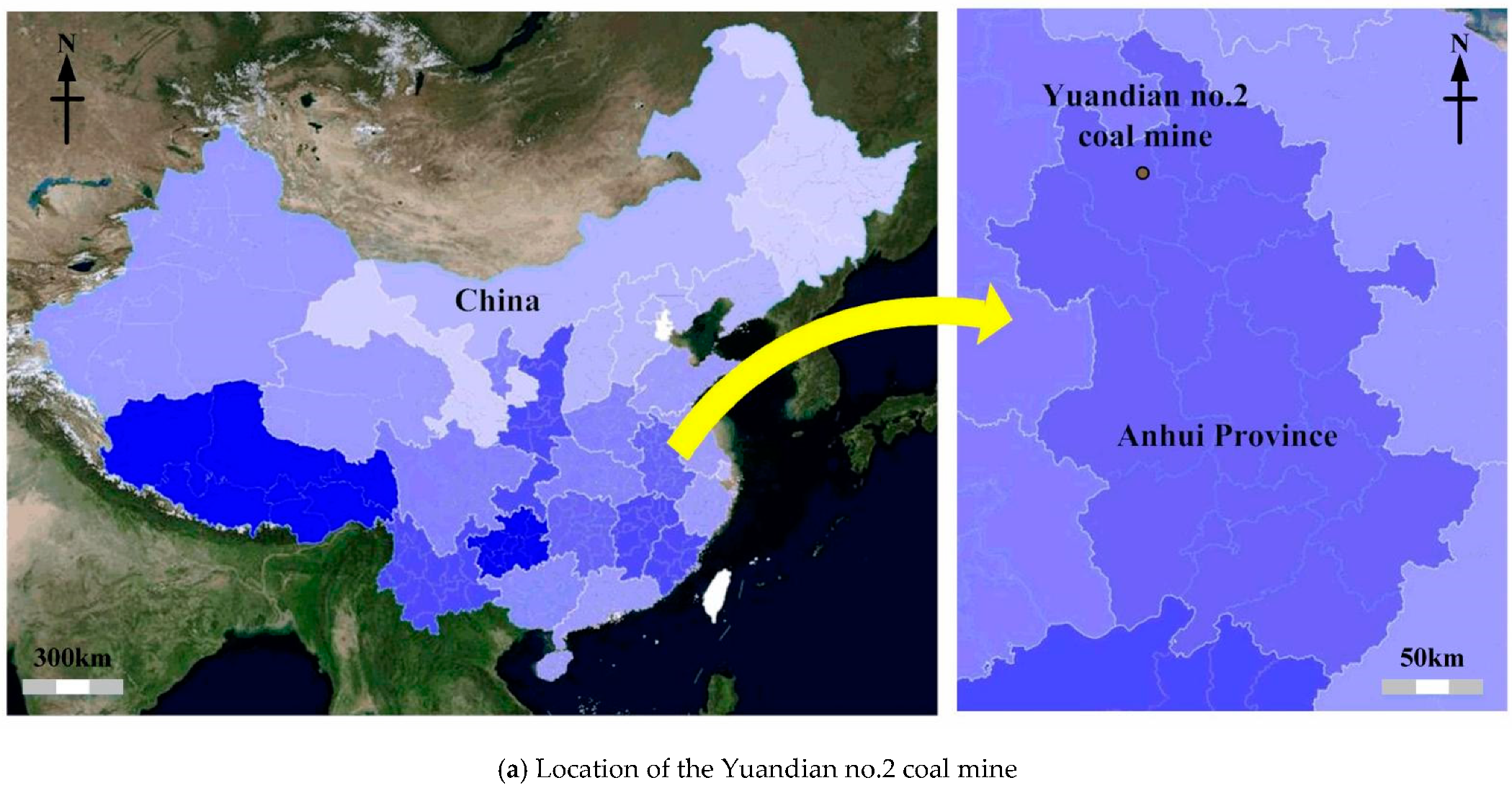

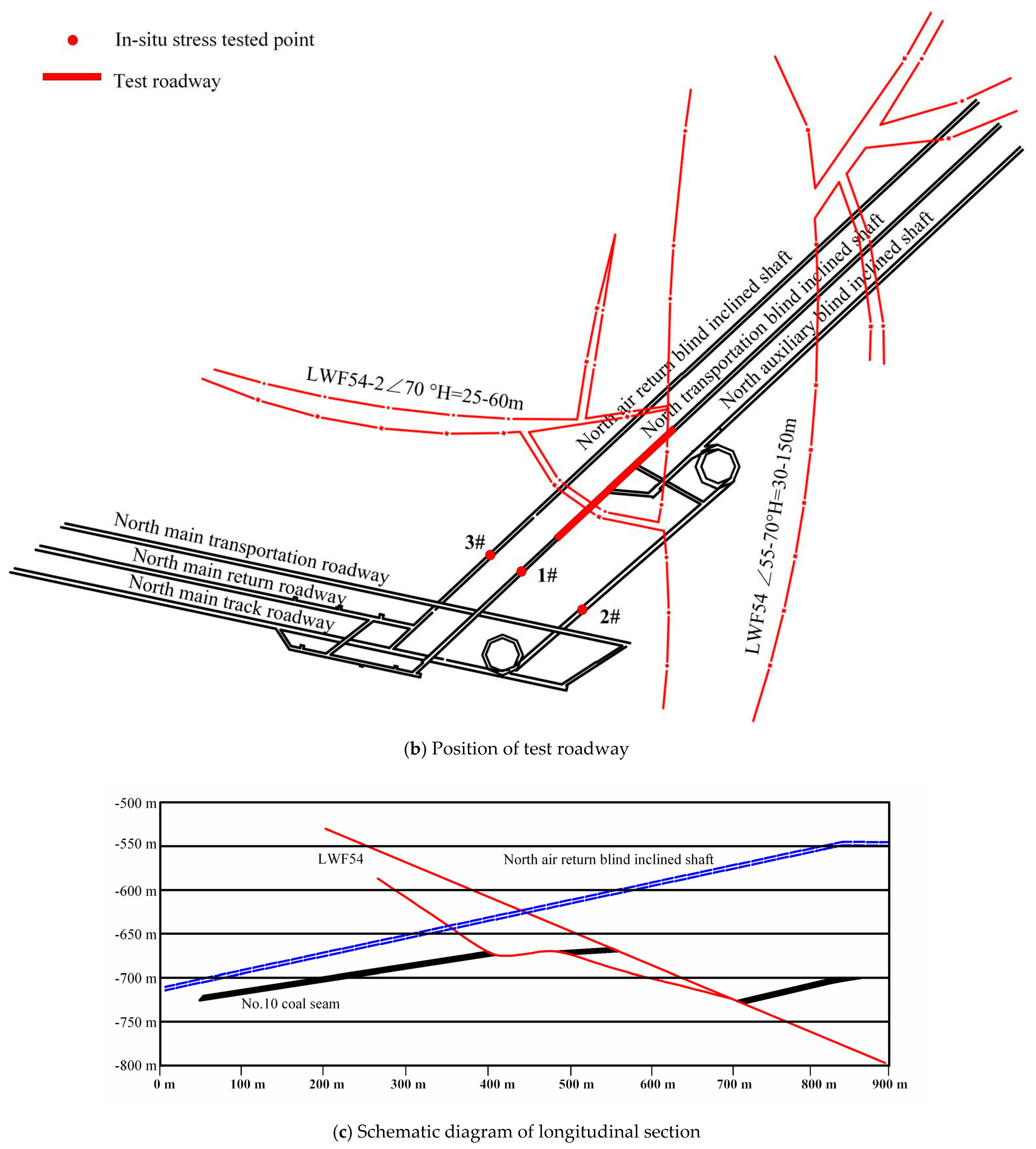

2. Geologic and Engineering Backgrounds

3. Failure Mechanism Analyses

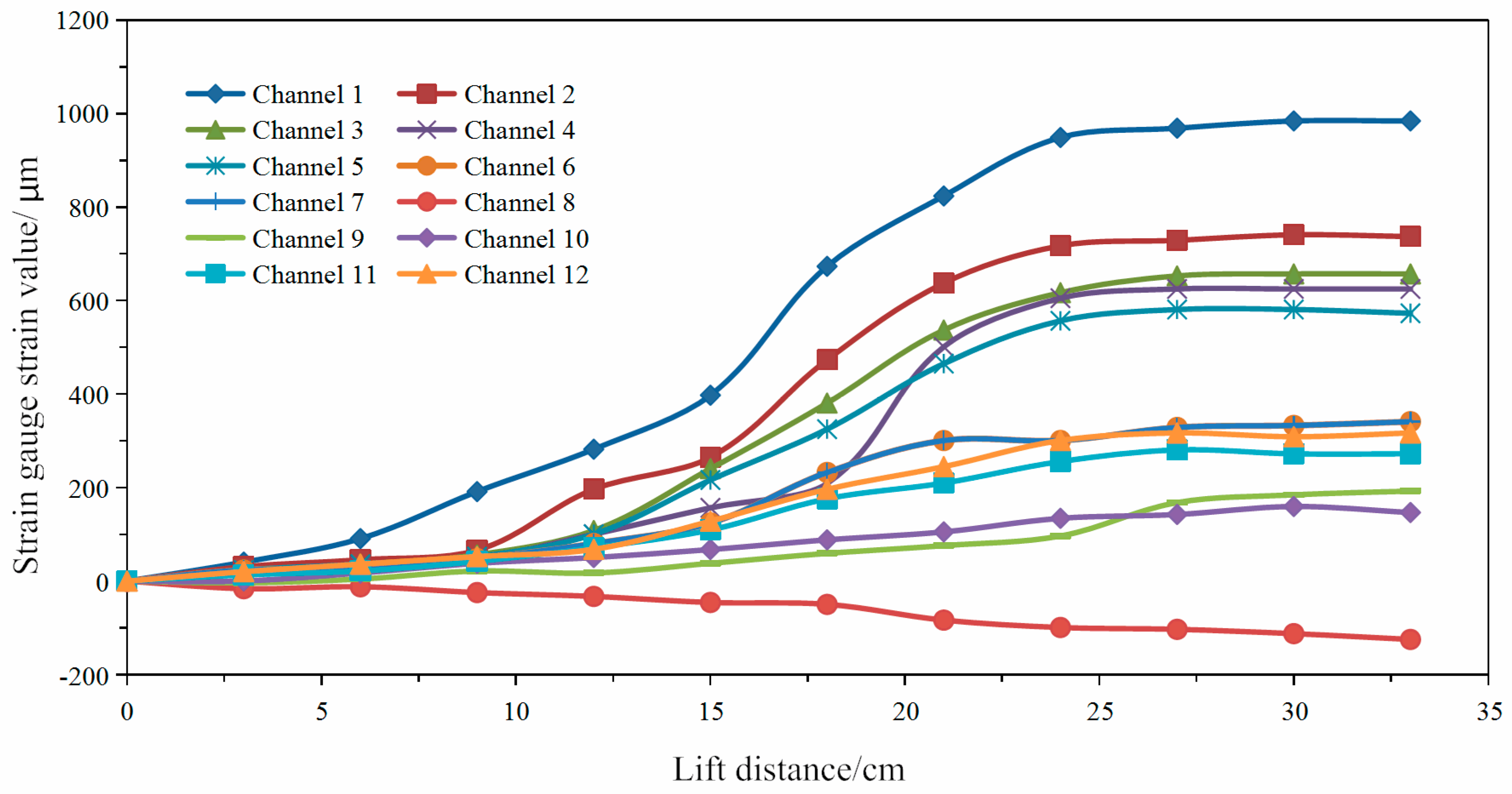

3.1. In-Situ Stress Test

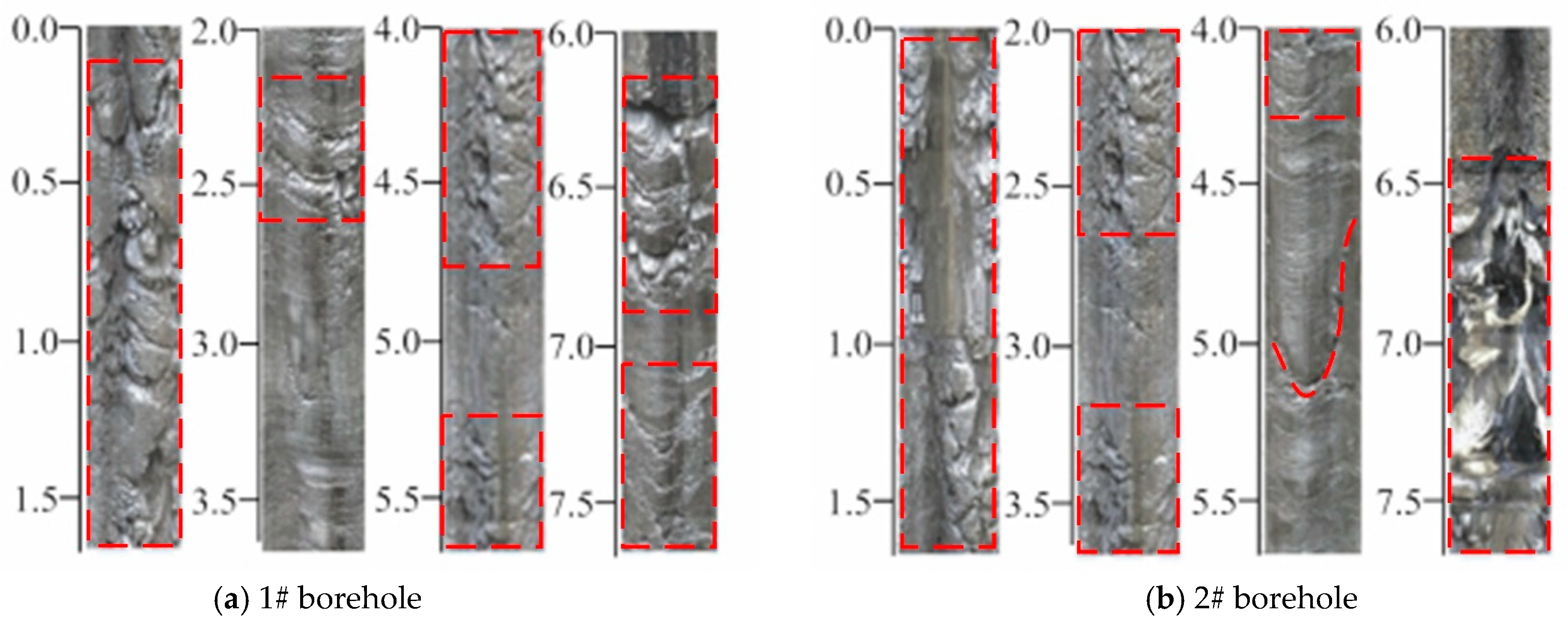

3.2. Borehole Television Imaging

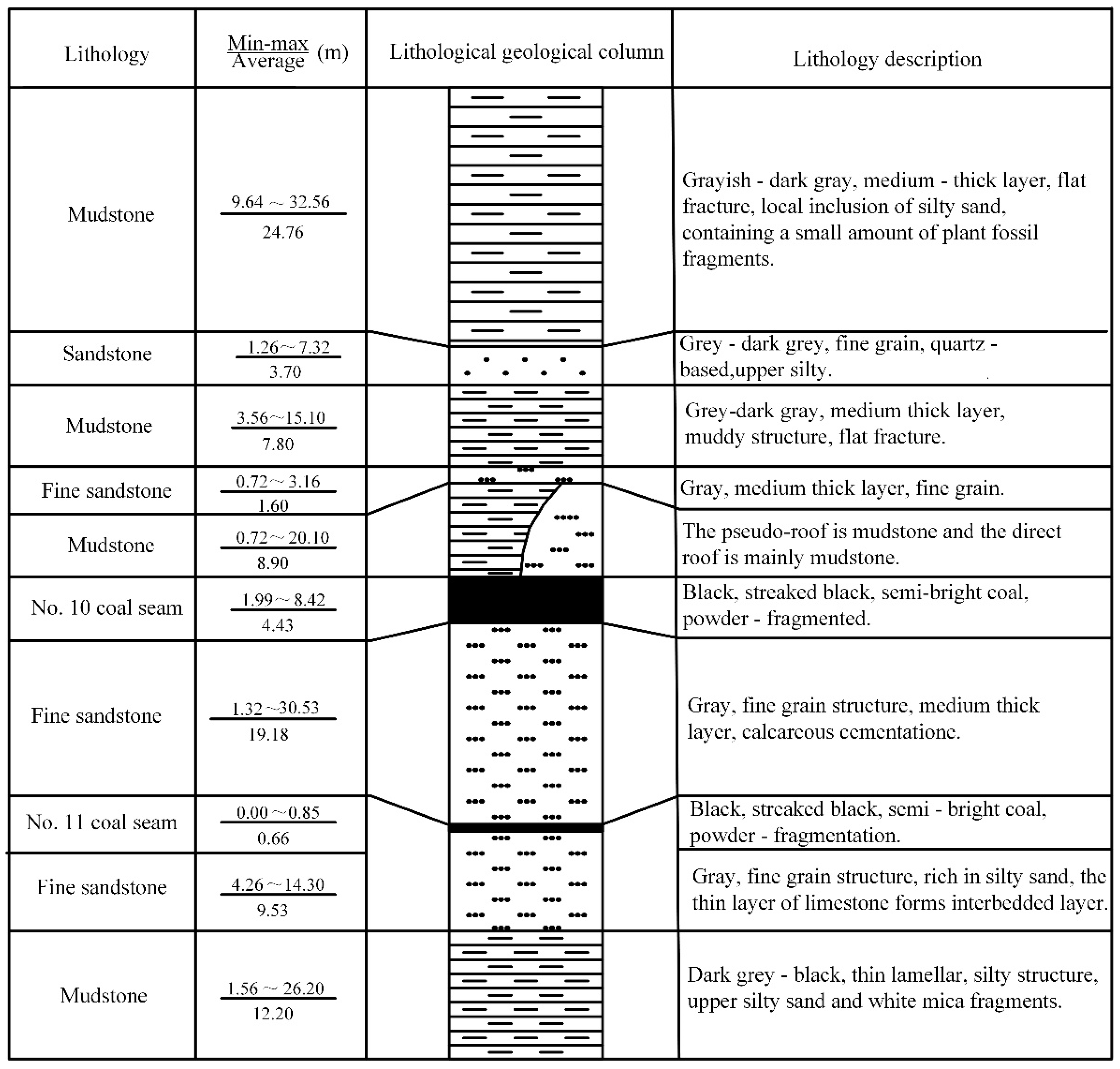

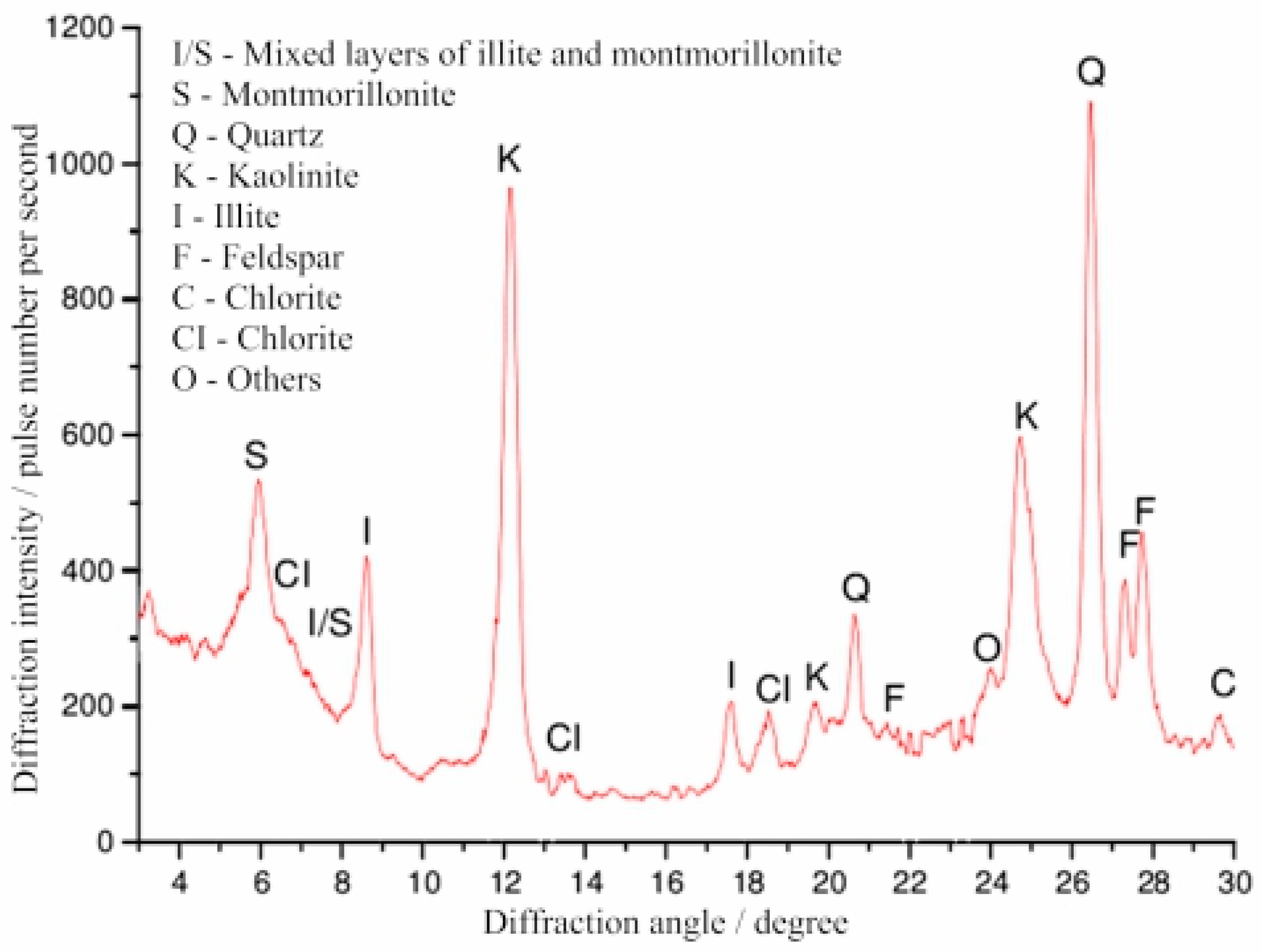

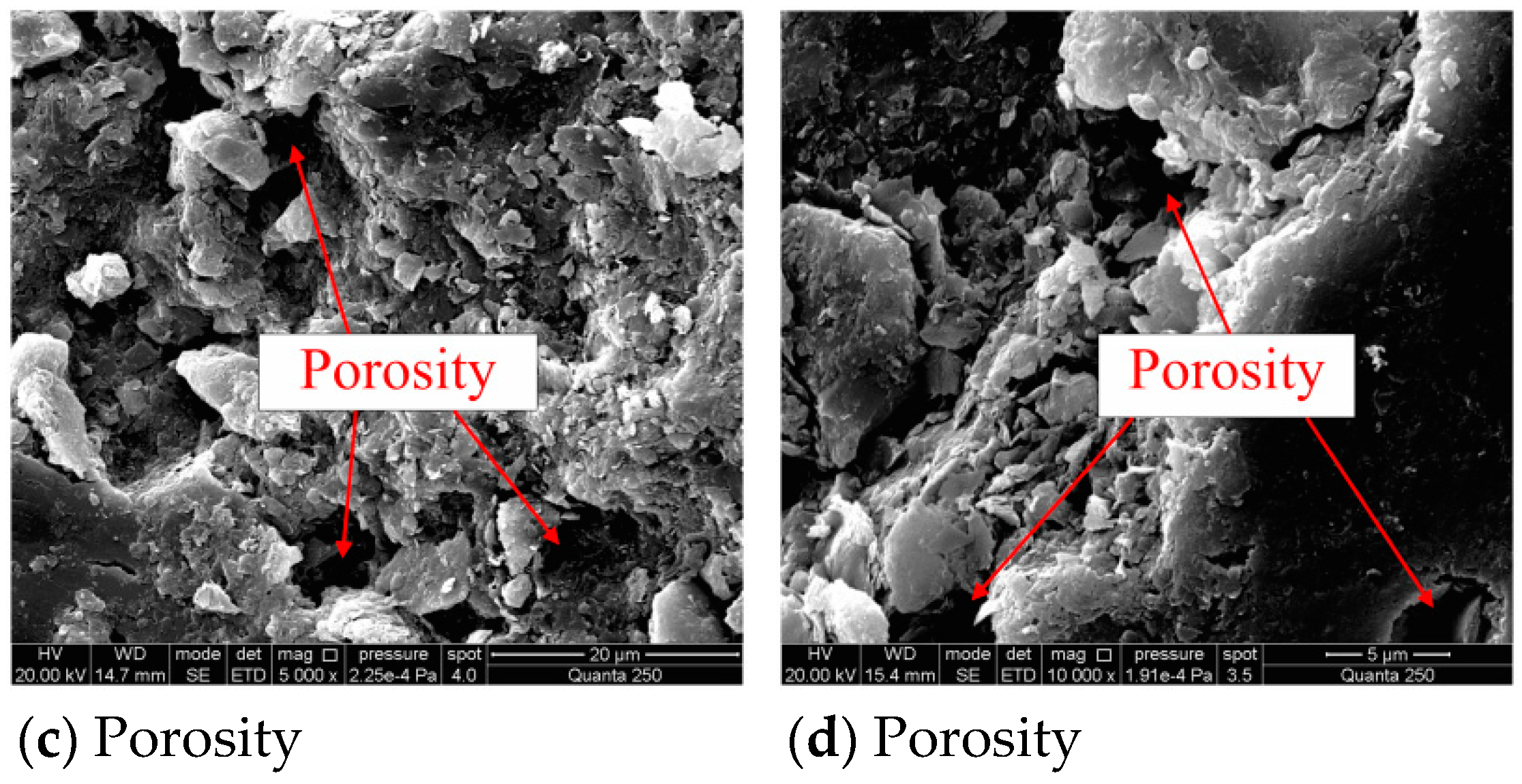

3.3. Lithological Analysis

3.4. Failure Mechanism of Roadway in the Fault Fracture Zone

- The horizontal stress in the fault fracture zone is the main stress of the in-situ stress field, which is almost perpendicular to the axial direction of the roadway. The high tectonic stress caused a stress concentration in the surrounding rock of the roadway, which caused the roof and floor of the roadway to fail first.

- After the surrounding rock of the roadway was damaged, the fractures propagated and communicated with each other, and eventually formed a broken surrounding rock zone. The fractures caused by the crack propagation make the surrounding rock more broken. The broken surrounding rock loses its self-supporting ability, which caused the crack to expand to the deep surrounding rock, which further increases the damage range.

- Mudstone is the main component of the surrounding rock, which contains a large number of kaolinite, montmorillonite, and mixed layers of illite and montmorillonite. The mudstone expands rapidly after water is absorbed, which promotes the phenomenon of softening and disintegration, further reducing the rock strength.

- The borehole television imaging results showed that the surrounding rock is severely broken within 2.5 m, which affected the anchoring effect of the bolt. Large areas of delaminated and broken surrounding rocks can still be found beyond the 6.5 m depth of the surrounding rocks, exceeding the support range of the anchor cable. The support failure of the bolt and anchor cable caused large deformation of the roadway, which is also the main cause of the roof collapse.

4. Support Design

4.1. Roadway Support Design Principles

- Grouting reinforcement: Field test results showed that broken surrounding rocks and poor lithology are the main causes of roadway damage. The best way to solve this problem is to use grouting reinforcement technology. Grouting reinforcement is mainly used to inject grout into the fractures through the grouting pressure, fill the fractures through the solidification of the grout, and cement the broken rock masses together to improve the bearing capacity of the rock mass itself, thereby achieving the purpose of surrounding rock reinforcement.

- Pre-reinforced support: Field test results showed that the roof collapses with the roadway excavation due to the poor self-stabilizing capacity. Therefore, advanced grouting is used to support the uncovered roof. Advanced grouting is carried out on the broken surrounding rock in front of the excavation face so that the broken roof in the grouting section is cemented, preventing the surrounding rock from collapsing after excavation. Grouting also ensures the integrity of the roof after excavation, providing the supporting points for the subsequent grouting bolts and grouting cable anchors.

- Rational support range: Field test results showed that the damage depth of the surrounding rock is large, and large-scale delamination and broken rock masses can still be observed at 6.5 m. The length of the anchor cable of the initial support design is only 6.2 m, which is less than the damage depth of the surrounding rock, making the support useless. Therefore, the new support range should be greater than the damage depth of the roadway.

4.2. Roadway Support Design

- Advanced grouting support parameters: Advanced grouting support design is shown in Figure 10 and Figure 11. There are five grouting holes in the cross-section, including three grouting holes in the roof and two grouting holes in the ribs. The grouting hole is 0.3 m away from the roadway contour. The spacing between the grouting holes along the roadway axis is 1.5 m. The grouting holes have a diameter of 94 mm and a length of 12 m. The grouting holes are lifted upward by 10° in the vertical direction and inclined by 15° in the horizontal direction. The grouting pipes have a diameter of 73 mm and a length of 12 m. Multiple rows of 8 mm diameter grouting holes are drilled vertically along the wall of the grouting pipes. The anchorage length of each grouting pipe must be larger than 2 m.

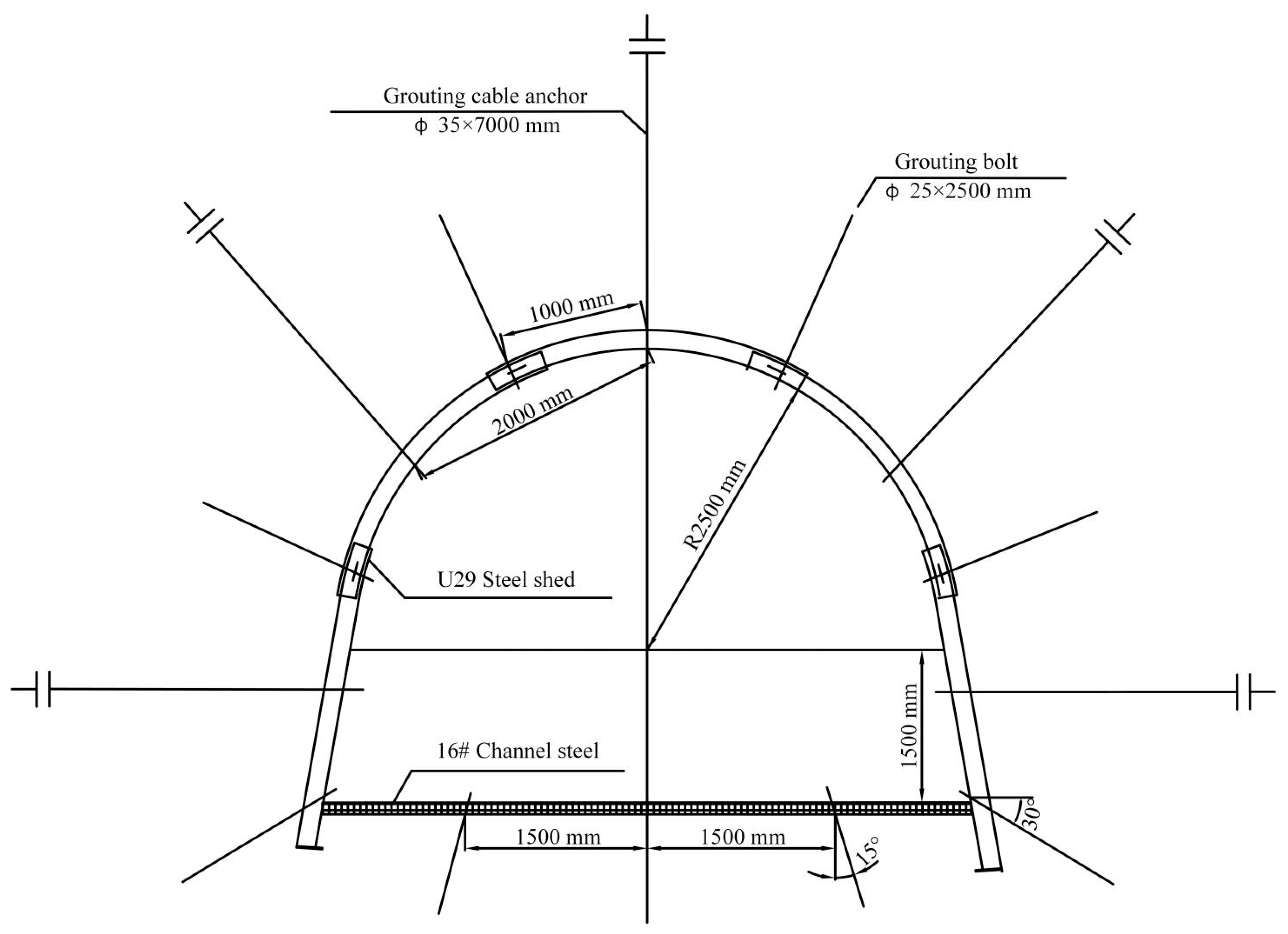

- U-shaped steel sheds support parameters: The U-shaped steel model used in this study is U29. As shown in Figure 10, the distance between U-shaped steel sheds along the roadway is 0.8 m. The overlap length of any two U-shaped steels is 0.5 m. The size of the steel back plate is 800 × 1200 × 80 mm.

- Grouting bolts’ parameters: Grouting bolts’ support is shown in Figure 12. There are fourteen grouting bolts in the roadway cross-section, including seven grouting bolts in the roof, four grouting bolts in the ribs, and three grouting bolts in the floor. The grouting bolts have a diameter of 25 mm and a length of 2.5 m. The distance between the grouting bolts in the roof and ribs along the roadway axis and the radial direction is 1.0 and 1.6 m, respectively. The distance between the grouting bolts in the floor along the roadway axis and the radial direction is 1.5 and 1.6 m, respectively. The anchorage length of each grouting bolt must be larger than 1.0 m. The primary concrete support is applied as soon as the grouting bolts pavement is finished.

- Grouting cable anchors’ parameters: Grouting cable anchors’ support is shown in Figure 12. As shown in Figure 12, there are five grouting cable anchors in the roadway cross-section, including three grouting cable anchors in the roof and two grouting bolts in the ribs. The grouting cable anchors have a diameter of 35 mm and a length of 7.0 m. The distance between the grouting cable anchors in the roof and ribs along the roadway axis and the radial direction is 2.0 and 1.6 m, respectively. The anchorage length of each grouting cable anchor must be larger than 1.0 m. The secondary concrete support is applied as soon as the grouting cable anchors pavement is finished.

- Grouting parameters: The grout material is composed of PO. 42.5 ordinary silicate cement and cement additive. The ratio of water/cement is 1:1.5. The cement additive is used with a dosage of 5% cement weight. The grouting pressure of advanced grouting, grouting bolt, and anchor cable is 8~10, 2~3, and 4~6 MPa, respectively.

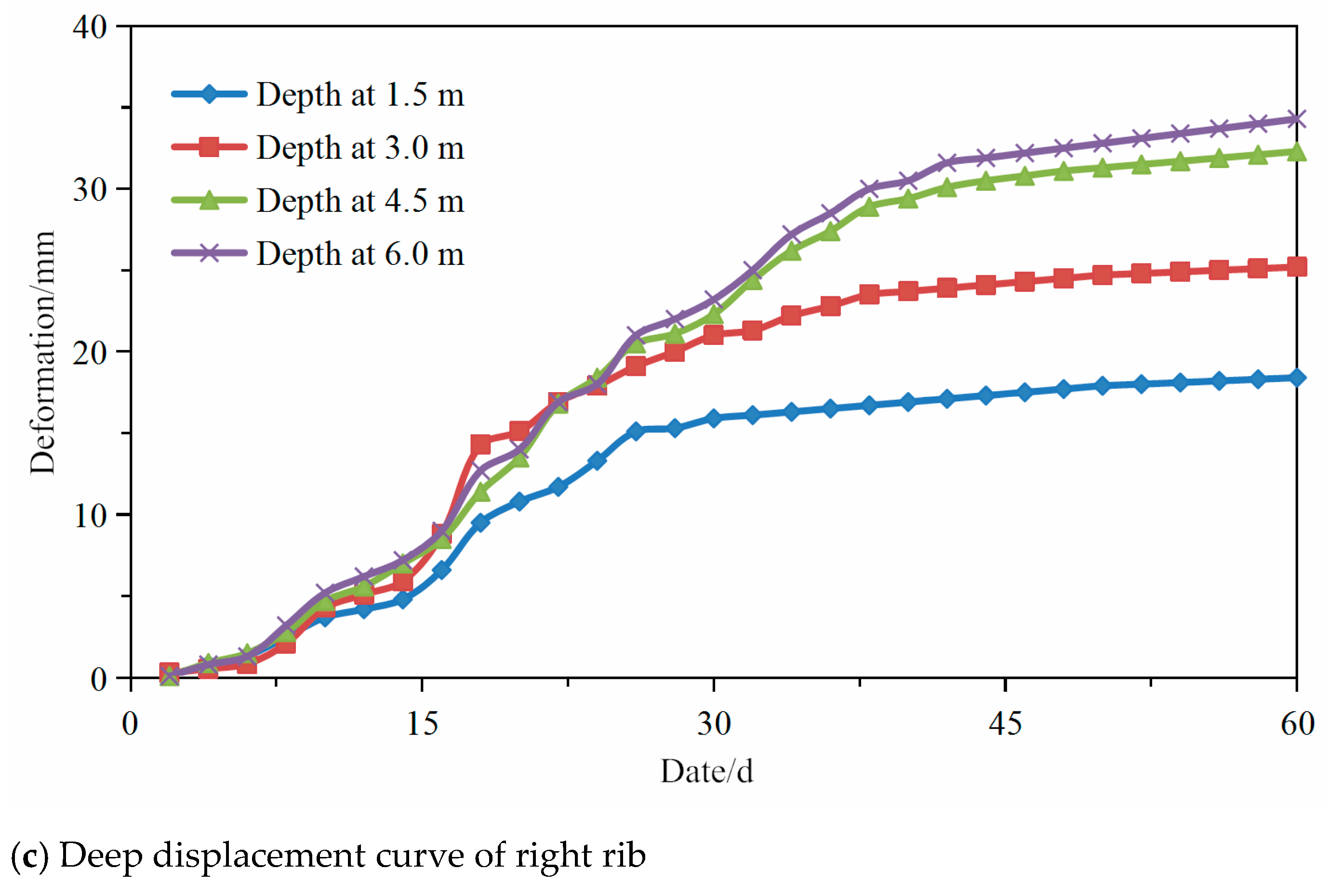

5. On-Site Monitoring

6. Conclusions

- Field investigations and tests showed that the tectonic stress state in the fault fracture zone was complex. The horizontal stress was about 1.55 times the vertical stress, and the angle between the main roadway axis and the main horizontal stress was 84.4°. The surrounding rock was severely broken within 2.5 m, and large-scale delamination can still be found beyond the 6.5 m depth of the surrounding rocks. Mudstone is the main component of the surrounding rock, which contained a large number of kaolinite, montmorillonite, and mixed layers of illite and montmorillonite. The internal causes for the failure of the roadway in the fault fracture zone were the high tectonic stress, broken surrounding rock, and poor lithology, and the external cause was the unreasonable support design.

- According to the support principles of grouting reinforcement, pre-reinforced support, and reasonable support range, a new type of combined support technology was proposed, which included advanced grouting, grouting bolts, and grouting anchor cables. The unexposed broken roof is supported by advanced grouting to strengthen the self-supporting capacity of the surrounding rock. U-shaped steel support is used to support the roadway immediately after excavation to limit the deformation and collapse of surrounding rock. Grouting bolts and grouting cable anchors are used to maintain the long-term stability of the roadway. By using the new combined support technology, the broken surrounding rock in the fault fracture area is cemented into a complete rock mass, and the support capacity of the whole support system is improved.

- On-site industrial tests were carried out on a 100 m tested roadway. Test results show that the new support scheme is more effective than the initial support scheme, and the deformation of the roadway surrounding rock is significantly reduced under the new support scheme. With the new support technology, the safety hazard of roof collapse after roadway excavation can be effectively solved, and the long-term stability of the roadway was ensured. The results provide a reference for the support design of roadway engineering in similar geologic conditions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, B.; Gu, S.; Wang, L.; Zhang, G.; Li, W. Strainburst process of marble in tunnel-excavation-induced stress path considering intermediate principal stress. J. Cent. South Univ. 2019, 26, 984–999. [Google Scholar] [CrossRef]

- Kang, Y.; Liu, Q.; Gong, G.; Wang, H. Application of a combined support system to the weak floor reinforcement in deep underground coal mine. Int. J. Rock Mech. Min. Sci. 2014, 71, 143–150. [Google Scholar] [CrossRef]

- Song, R.; Zhang, D.; Wen, M. The cusp catastrophe theory analysis for instability of deep-buried tunnels surrounding rock through fault fracture zone. China Civ. Eng. J. 2015, 48, 289. [Google Scholar]

- Zhang, C.; Tu, S. Control technology of direct passing karstic collapse pillar in longwall top-coal caving mining. Nat. Hazards 2016, 84, 17–34. [Google Scholar] [CrossRef]

- Zhang, W.; He, Z.; Zhang, D.; Qi, D.; Zhang, W. Surrounding rock deformation control of asymmetrical roadway in deep three-soft coal seam: A case study. J. Geophys. Eng. 2018, 15, 1917–1928. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Lu, C.; Lu, H. Application and analysis of ground surface pre-grouting strengthening deep fault fracture zone. Chin. J. Rock Mech. Eng. 2013, 32, 3688–3695. [Google Scholar]

- Liu, Q.; Zhang, W.; Lu, X.; Fu, J. Safety monitoring and stability analysis of large-scale roadway in fault fracture zone. Chin. J. Rock Mech. Eng. 2010, 29, 1954–1962. [Google Scholar]

- Roy, C.K.; Uddin, M.G.; Roy, B.; Dean, T.R. Evaluating Aspect Mining Techniques: A Case Study. In Proceedings of the IEEE International Conference on Program Comprehension, Buenos Aires, Argentina, 22–23 May 2017. [Google Scholar]

- Seon-Bok, L.; Hae-Chan, J. Case Study of the Longest Roadway Tunnel in Korea, Baehuryeong Tunnel. Tunn. Undergr. Space 2005, 15, 432–440. [Google Scholar]

- Wang, Q.; Qu, L.; Guo, H.; Wang, Q. Grouting reinforcement technique of Qingdao Jiaozhou bay subsea tunnel. Chin. J. Rock Mech. Eng. 2011, 30, 790–802. [Google Scholar]

- Xue, Y.; Li, S.; Su, M.; Zhang, X.; Zhao, Y.; Xu, Z.; Li, Z.; Zhang, G. Stduy of comprehensive test method for grouting effect of water filling fault in Qingdao Kiaochow Bay subsea tunnel. Chin. J. Rock Mech. Eng. 2011, 30, 1382–1388. [Google Scholar]

- Zhou, R.; Cheng, B.; Ye, G.; Wu, Q. Time effect of water bursting in fault rupture zone. J. Eng. Geol. 2000, 8, 411–415. [Google Scholar]

- Wang, F.; Zhang, C.; Wei, S.; Zhang, X.; Guo, S. Whole section anchor–grouting reinforcement technology and its application in underground roadways with loose and fractured surrounding rock. Tunn. Undergr. Space Technol. 2016, 51, 133–143. [Google Scholar]

- Yao, Q.; Li, X.; Pan, F.; Wang, T.; Wang, G. Deformation and failure mechanism of roadway sensitive to stress disturbance and its zonal support technology. Shock Vib. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Zhang, D.; Wang, H.; Liang, S. Discrete element simulation of the control technology of large section roadway along a fault to drivage under strong mining. J. Geophys. Eng. 2018, 15, 2642–2657. [Google Scholar] [CrossRef] [Green Version]

- Piotr, M.; Łukasz, O.; Piotr, B. Modelling the small throw fault effect on the stability of a mining roadway and its verification by in situ investigation. Energies 2017, 10, 2082. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Jing, H.; Su, H.; Xie, J. Effect of a fault fracture zone on the stability of tunnel-surrounding rock. Int. J. Geomech. 2016, 17, 04016135. [Google Scholar] [CrossRef]

- Qian, D.; Zhang, N.; Shimada, H.; Wang, C.; Sasaoka, T.; Zhang, N. Stability of goaf-side entry driving in 800-m-deep island longwall coal face in underground coal mine. Arab. J. Geosci. 2016, 9, 82. [Google Scholar] [CrossRef]

- Qian, D.; Zhang, N.; Pan, D.; Xie, Z.; Shimada, H.; Wang, Y.; Zhang, C.; Zhang, N. Stability of deep underground openings through large fault zones in argillaceous rock. Sustainability 2017, 9, 2153. [Google Scholar] [CrossRef] [Green Version]

- Das, A.J.; Mandal, P.K.; Sahu, S.P.; Kushwaha, A.; Bhattacharjee, R.; Tewari, S. Evaluation of the Effect of Fault on the Stability of Underground Workings of Coal Mine through DEM and Statistical Analysis. J. Geol. Soc. India 2018, 92, 732–742. [Google Scholar] [CrossRef]

- Emamjome, F.; Andrews, R.; Hofstede, A.H.M.T. A Case Study Lens on Process Mining in Practice. In Proceedings of the OTM Confederated International Conferences “On the Move to Meaningful Internet Systems”, Rhodes, Greece, 21–25 October 2019. [Google Scholar]

- Heenan, D.M.; Xu, M. Grouting to Minimize Settlements Prior to Tunnel Excavation—A Case Study. In Proceedings of the International Conference on Grouting & Ground Treatment, New Orleans, LA, USA, 10–12 February 2003. [Google Scholar]

- Islam, M.R.; Shinjo, R. Numerical simulation of stress distributions and displacements around an entry roadway with igneous intrusion and potential sources of seam gas emission of the Barapukuria coal mine, NW Bangladesh. Int. J. Coal Geol. 2009, 78, 249–262. [Google Scholar] [CrossRef]

- Qian, D.; Zhang, N.; Zhang, M.; Shimada, H.; Cao, P.; Chen, Y.; Wen, K.; Yang, S.; Zhang, N. Application and evaluation of ground surface pre-grouting reinforcement for 800-m-deep underground opening through large fault zones. Arab. J. Geosci. 2017, 10, 285. [Google Scholar] [CrossRef]

- Liu, J.; Jing, J.; Feng, Y.; Wu, L.; Zhang, P. Study on grouting anchor cable supporting technology of roadway through extra large fault fracture zone. In Proceedings of the Aishan Academic Forum–Project on Mine Disaster Prevention and Control, Qingdao, China, 17–20 October 2014. [Google Scholar]

- Ma, Z.; Jiang, Y.; Du, W.; Zuo, Y.; Kong, D. Fracture evolution law and control technology of roadways with extra thick soft roof. Eng. Fail. Anal. 2018, 84, 331–345. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, R.; Jiang, B.; Li, S.; He, M.; Sun, H.; Wang, L.; Qin, Q.; Yu, H.; Luan, Y. Study on failure mechanism of roadway with soft rock in deep coal mine and confined concrete support system. Eng. Fail. Anal. 2017, 81, 155–177. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, P.-q.; Zhao, W.-j.; Tian, H.-m. Application of a combined supporting technology with U-shaped steel support and anchor-grouting to surrounding soft rock reinforcement in roadway. J. Cent. South Univ. 2018, 25, 1240–1250. [Google Scholar] [CrossRef]

- Behera, P.K.; Sarkar, K.; Singh, A.K.; Verma, A.K.; Singh, T.N. Dump slope stability analysis—A case study. J. Geol. Soc. India 2016, 88, 725–735. [Google Scholar] [CrossRef]

- Sears, M.M.; Rusnak, J.; Dyke, M.V.; Rashed, G.; Mohamed, K.; Sloan, M. Coal rib response during bench mining: A case study. Int. J. Min. Sci. Technol. 2018, 28, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Li, S.; Zeng, X.; Lin, D. Corrosion Inestigation and Mechanical Behavior Test on Support of Bolts in Underground Drift. Chin. J. Rock Mech. Eng. 2008, 27, 3. [Google Scholar]

- Shen, B. Coal mine roadway stability in soft rock: A case study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Yang, J. Analysis on Excavation and Support Technique of the Fault and Crushing Zone in Cimushan Tunnel. Chin. J. Undergr. Space Eng. 2011, 7, 361–365. [Google Scholar]

- Zhang, C.Y.; Wu, M.L.; Liao, C.T. In-situ stress measurement and study of stress state characteristics of Jin⁃ chuan No. 3 mine. Rock Soil Mech. 2013, 34, 3254–3260. [Google Scholar]

- Wang, Y.; Liu, B.G.; Qi, Y. A Risk Evaluation Method with an Improved Scale for Tunnel Engineering. Arab. J. Sci. Eng. 2018, 43, 2053–2067. [Google Scholar] [CrossRef]

| Tested Point Number | Point Depth (m) | Tested Point Position | Drilling | ||

|---|---|---|---|---|---|

| Hole Depth (m) | Azimuth (°) | Inclination (°) | |||

| 1# | 511 | The north transportation blind inclined shaft | 8.0 | 128 | 5 |

| 2# | 553 | The north auxiliary blind inclined shaft | 8.3 | 145 | 5 |

| 3# | 559 | The north air return blind inclined shaft | 8.3 | 133 | 5 |

| Core Group | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|

| 1# | 27.90 | 0.25 |

| 2# | 28.53 | 0.23 |

| 3# | 28.64 | 0.23 |

| Tested Point Number | Tested Point Position | Point Depth (m) | Principal Stress | Vertical Stress (MPa) | |||

|---|---|---|---|---|---|---|---|

| Principal Stress | Size (MPa) | Azimuth (°) | Inclination (°) | ||||

| 1# | The north transportation blind inclined shaft | 511 | σ1 | 20.04 | 81.36 | 9.36 | 12.77 |

| σ2 | 11.22 | 88.71 | 83.29 | ||||

| σ3 | 10.31 | 278.32 | 8.93 | ||||

| 2# | The north auxiliary blind inclined shaft | 553 | σ1 | 20.25 | 88.25 | 6.73 | 13.82 |

| σ2 | 13.36 | 8.71 | 83.29 | ||||

| σ3 | 11.00 | 276.66 | 7.34 | ||||

| 3# | The north air return blind inclined shaft | 559 | σ1 | 21.76 | 85.13 | 8.25 | 13.97 |

| σ2 | 13.48 | 29.63 | 77.01 | ||||

| σ3 | 11.48 | 274.85 | 7.55 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Wang, L.; Ren, B. Failure Mechanism Analysis and Support Technology for Roadway Tunnel in Fault Fracture Zone: A Case Study. Energies 2021, 14, 3767. https://doi.org/10.3390/en14133767

Wang K, Wang L, Ren B. Failure Mechanism Analysis and Support Technology for Roadway Tunnel in Fault Fracture Zone: A Case Study. Energies. 2021; 14(13):3767. https://doi.org/10.3390/en14133767

Chicago/Turabian StyleWang, Kai, Lianguo Wang, and Bo Ren. 2021. "Failure Mechanism Analysis and Support Technology for Roadway Tunnel in Fault Fracture Zone: A Case Study" Energies 14, no. 13: 3767. https://doi.org/10.3390/en14133767