Economic, Environmental and Energetic Analysis of a Distributed Generation System Composed by Waste Gasification and Photovoltaic Panels

Abstract

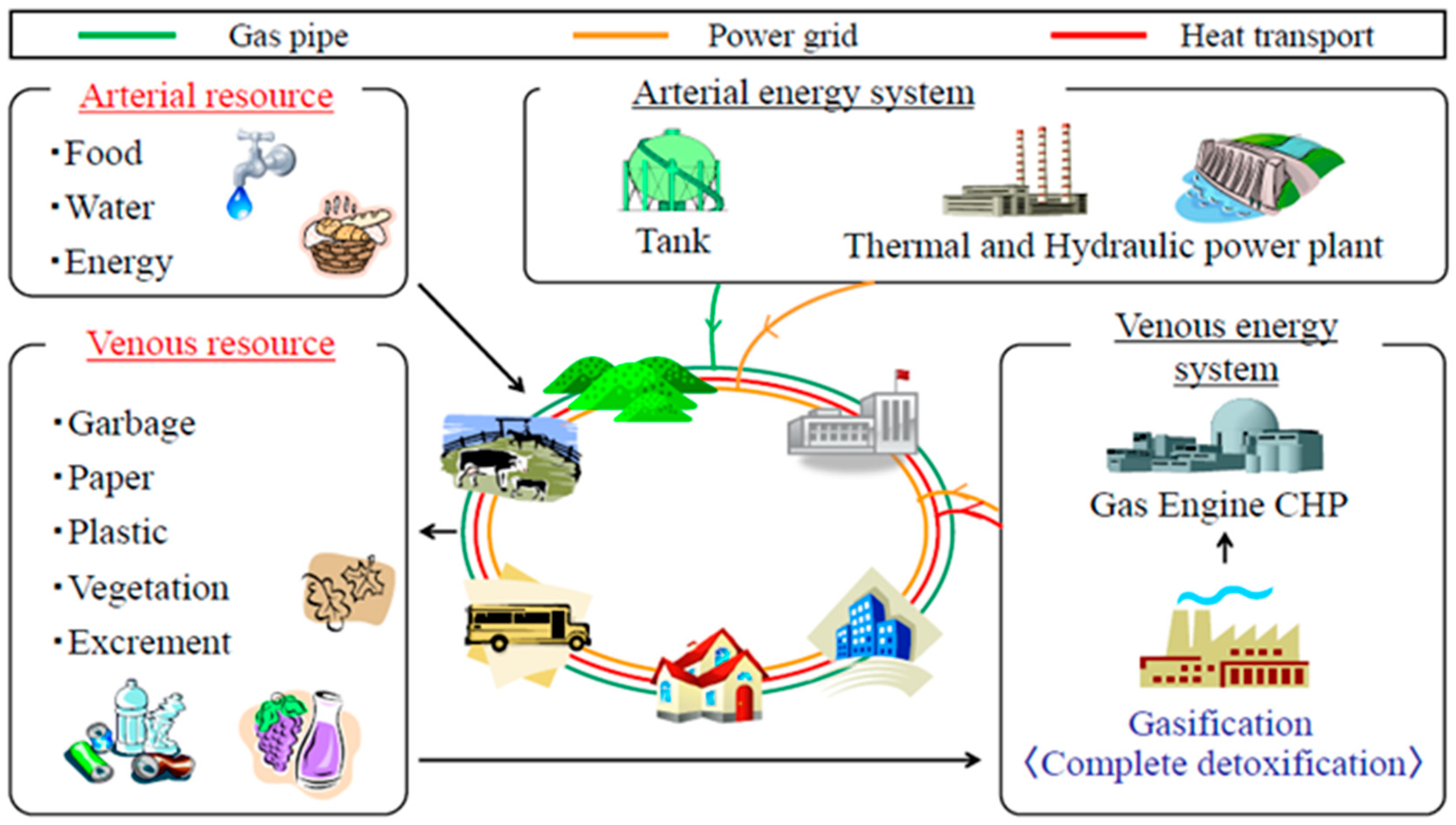

:1. Introduction

1.1. Energy Generation Background

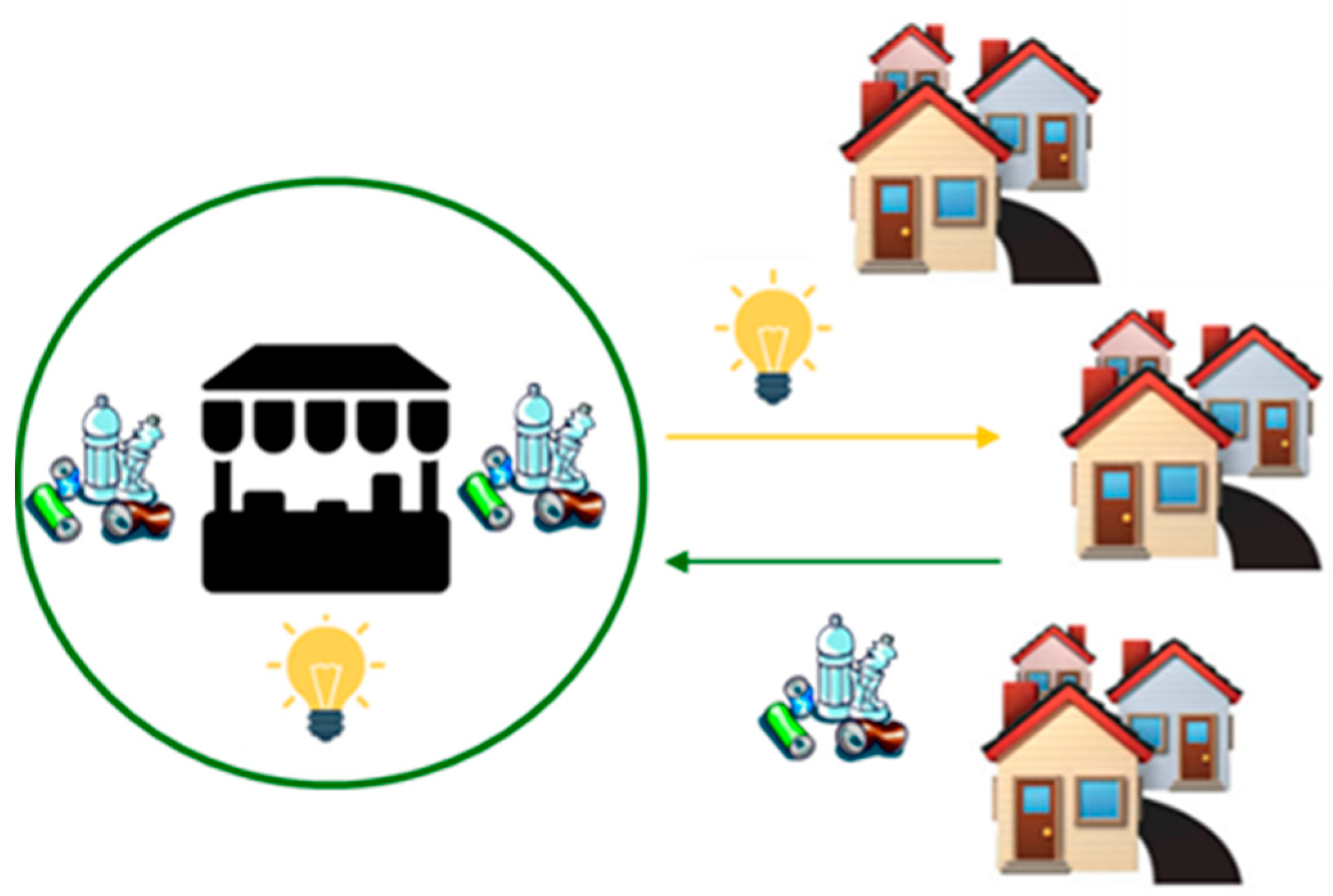

1.2. Local Energy Generation

1.3. Purpose of the Research

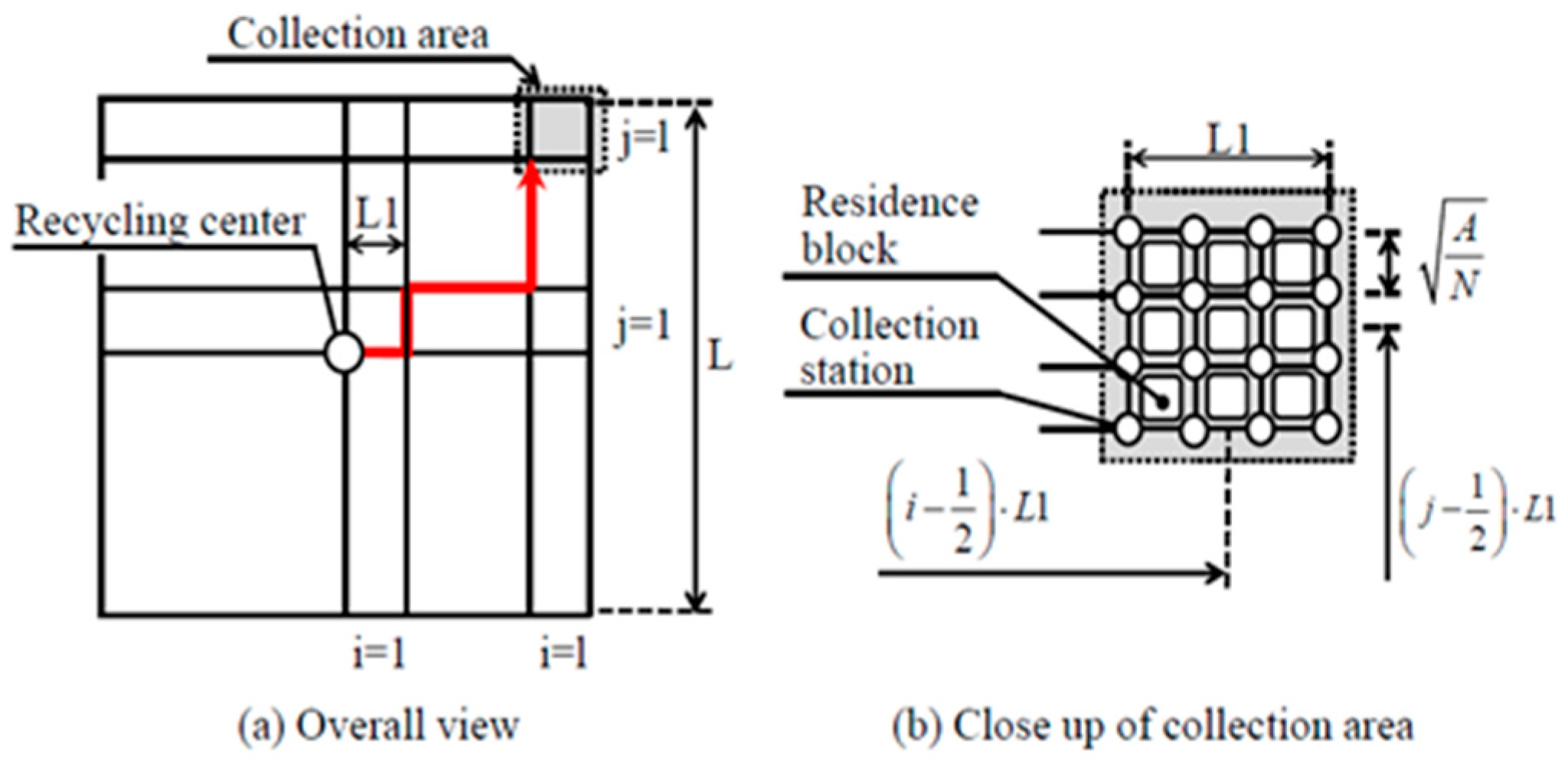

2. Analysis Conditions

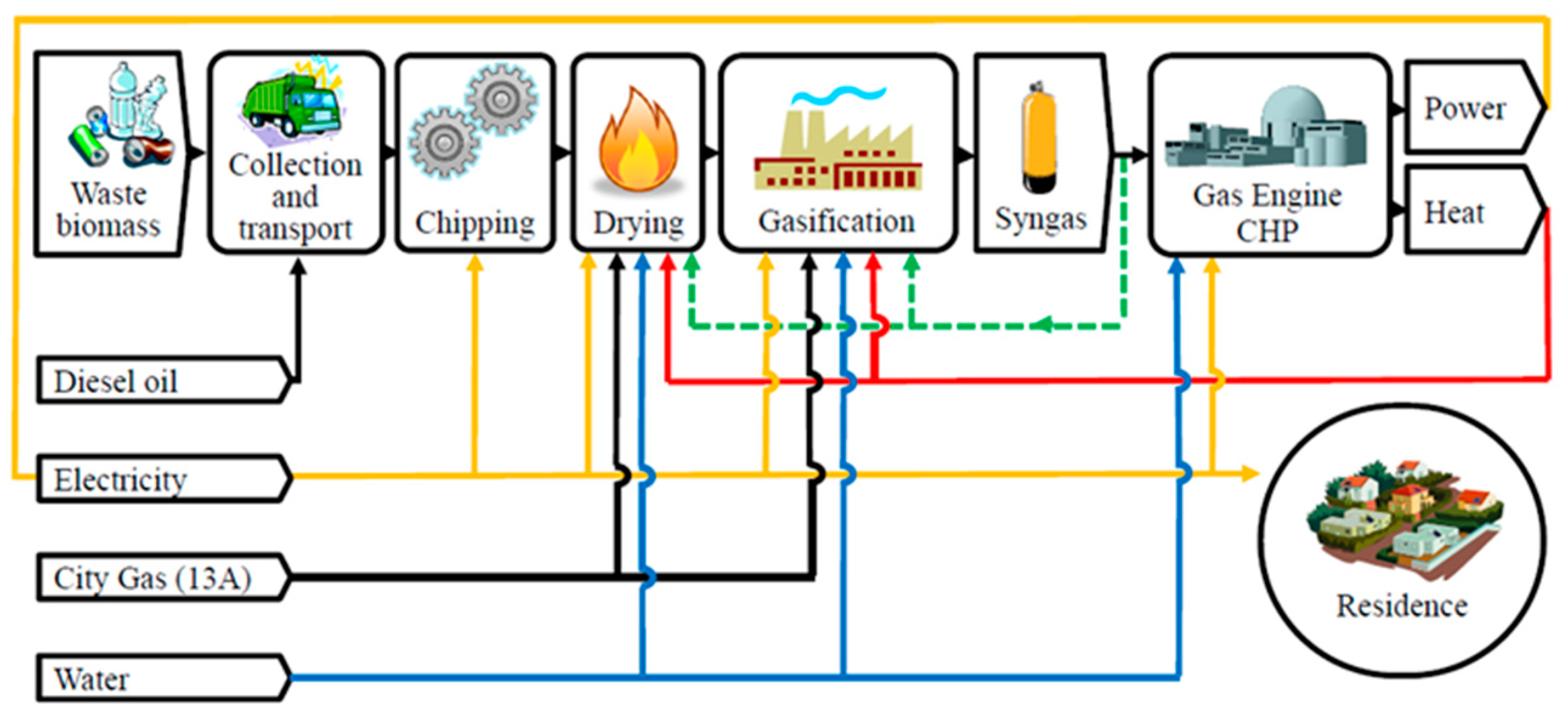

3. Energy Generation Process

3.1. Energy Generation Background

3.2. Collection and Transportation

3.3. Pretreatment Stages: Chipping and Drying

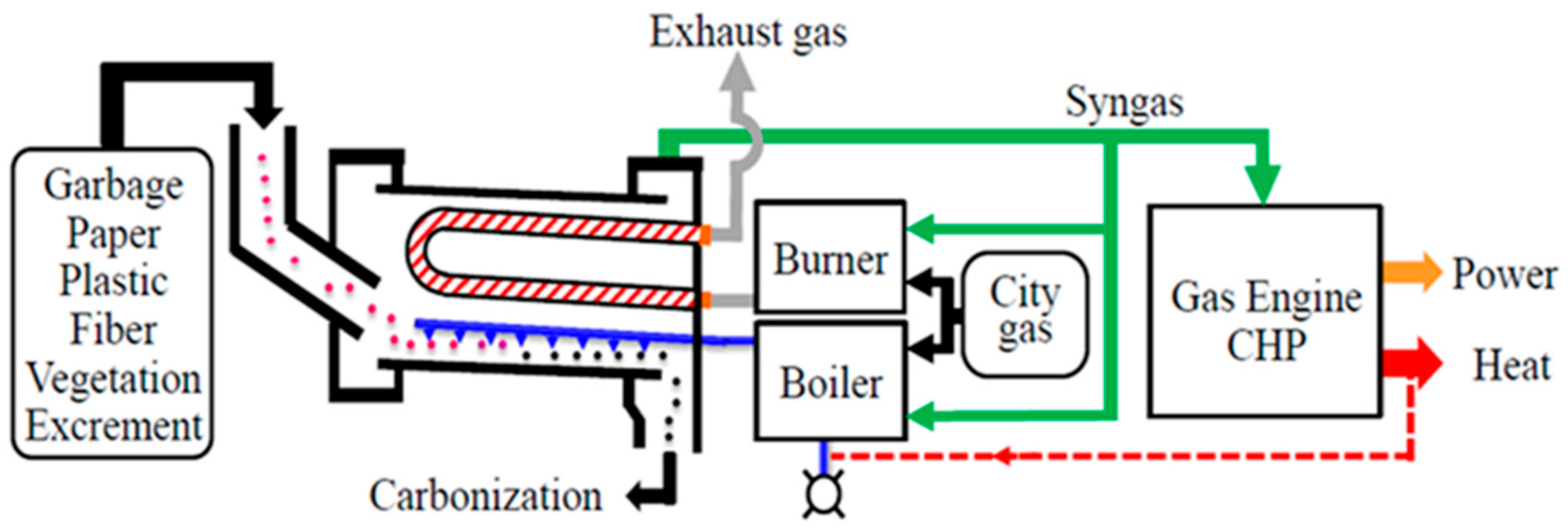

3.4. Gasification

3.5. Power Generation Process

3.6. Solar Energy Generation

4. Evaluation Methodology

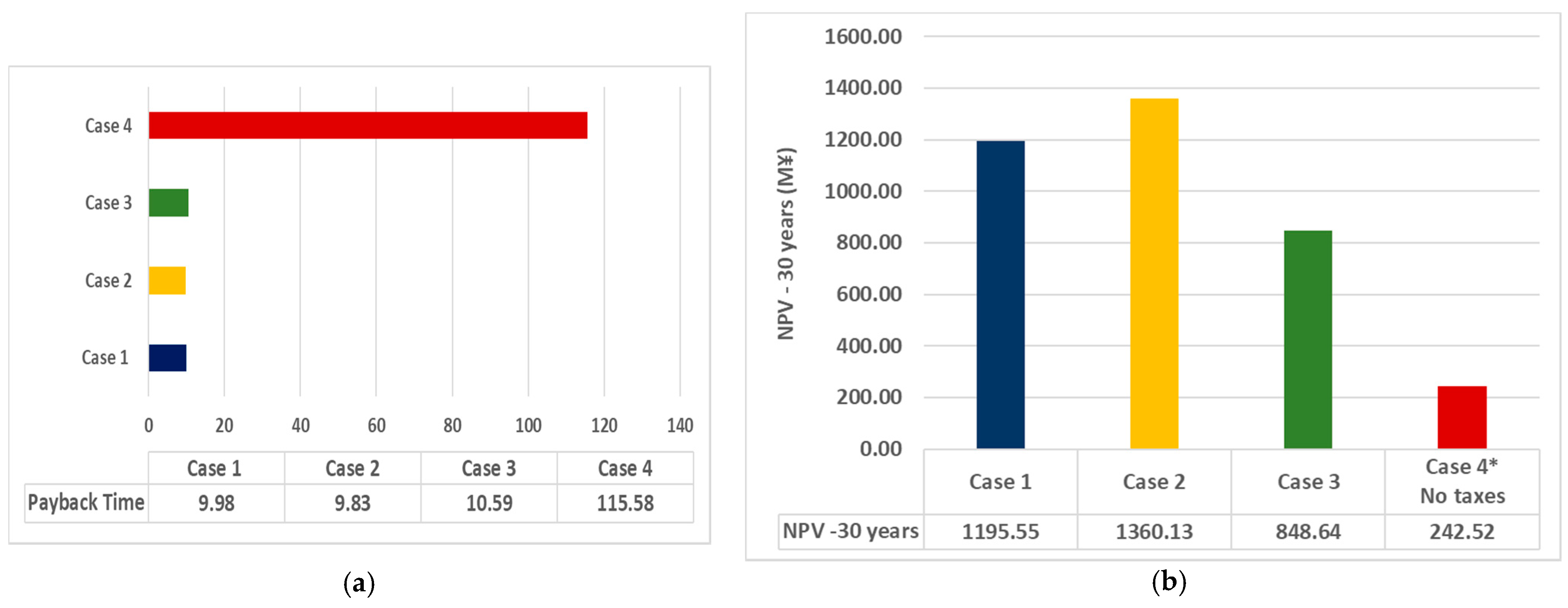

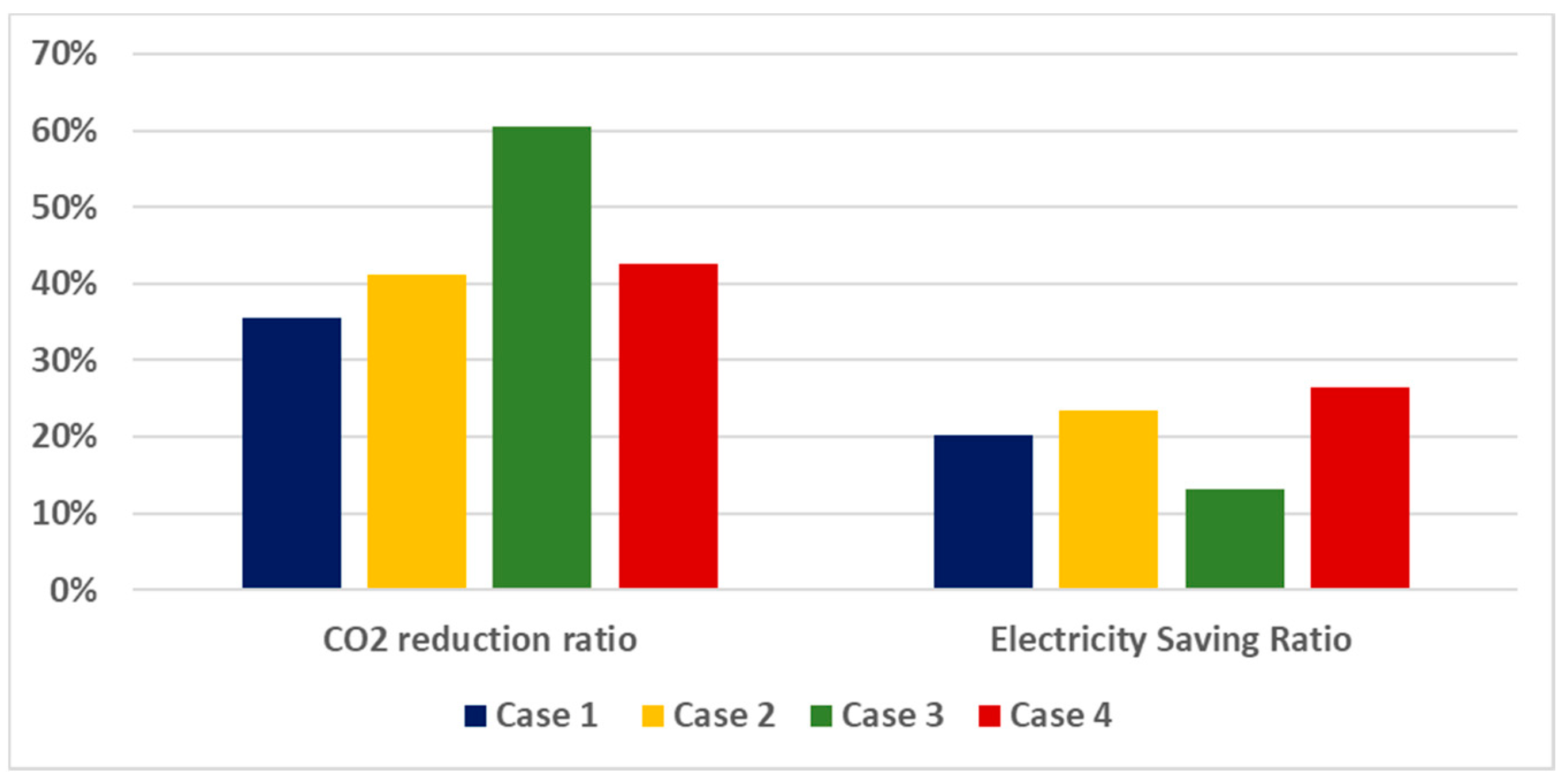

- Case 1: municipal solid waste (MSW) is collected from the mall and the surrounding neighborhood; the energy generation system is composed of only waste gasification;

- Case 2: MSW is collected from the mall and the surrounding neighborhood; the energy generation system is composed of waste gasification and photovoltaic panels. This case analyzes the addition of solar energy to the system;

- Case 3: MSW is collected from the mall and the surrounding neighborhood with the peculiarity that plastics are not collected. The energy generation system is composed of only waste gasification. This case analyzes the absence of plastics in the system;

- Case 4: MSW is collected only from the mall; the energy generation system is composed of waste gasification and photovoltaic panels. This case analyzes the influence of the processing collection fee.

4.1. Economic Parameters

4.2. Environmental Parameters

4.3. Energetic Parameters

5. Results and Discussion

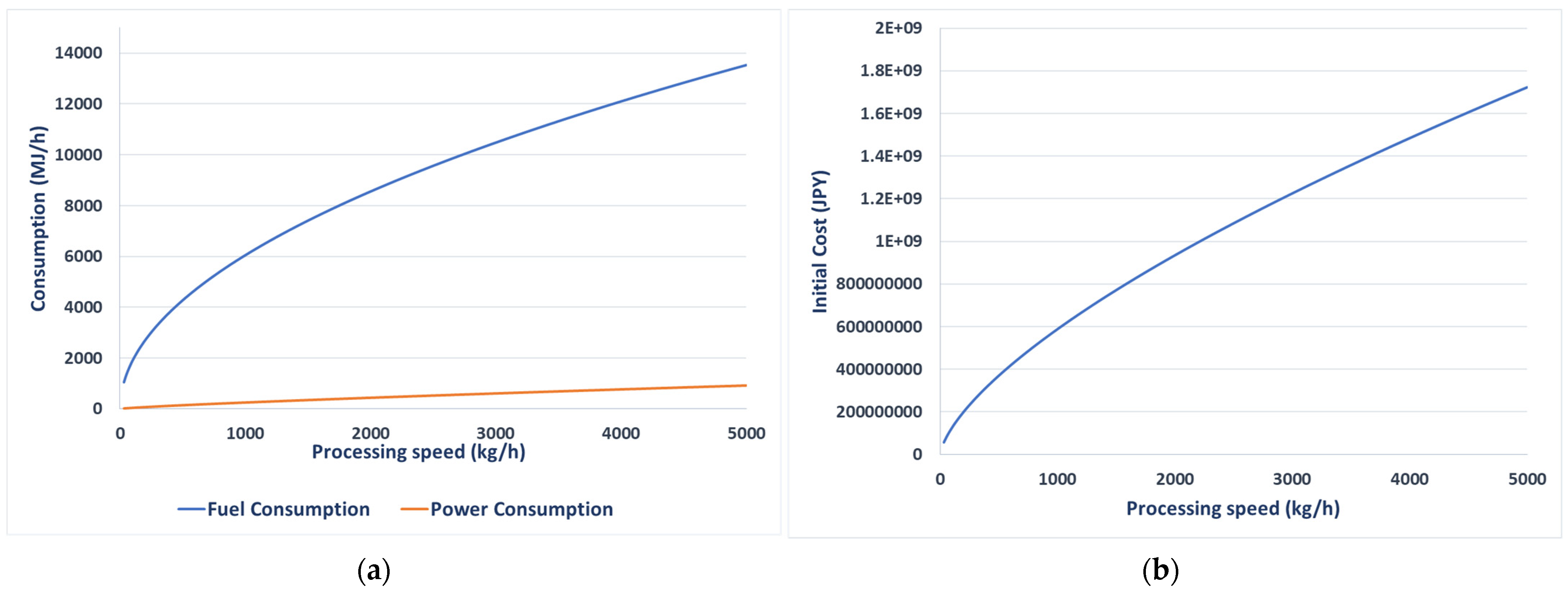

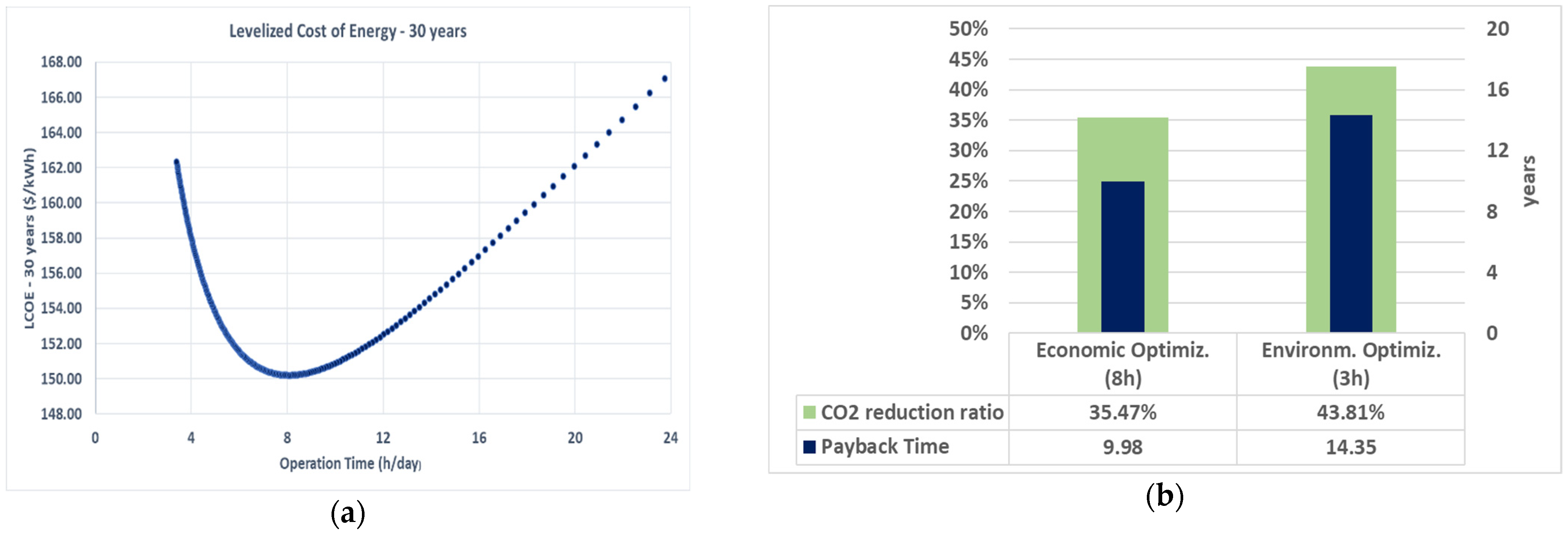

5.1. Optimization of Superheated Steam Gasification Process: Case 1

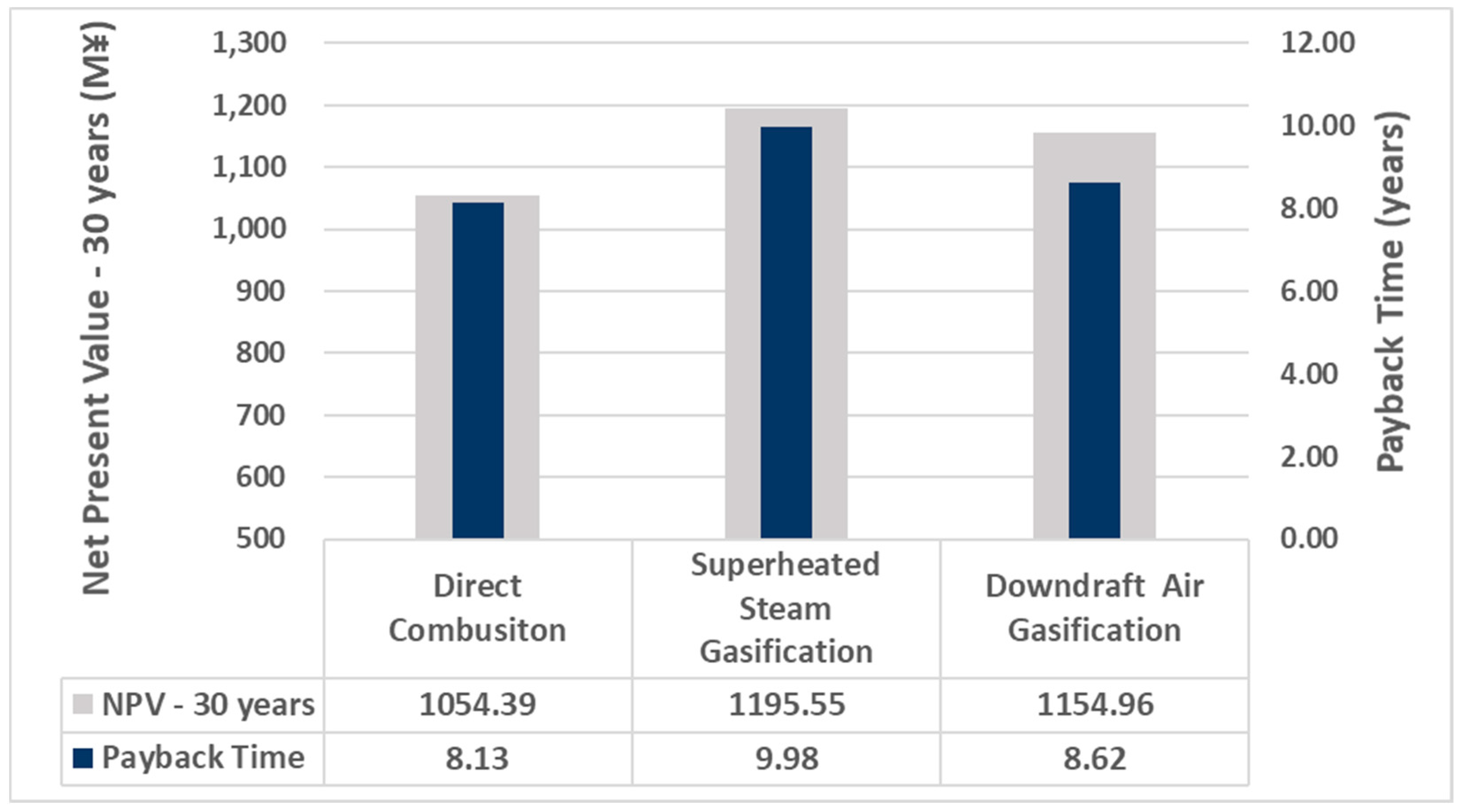

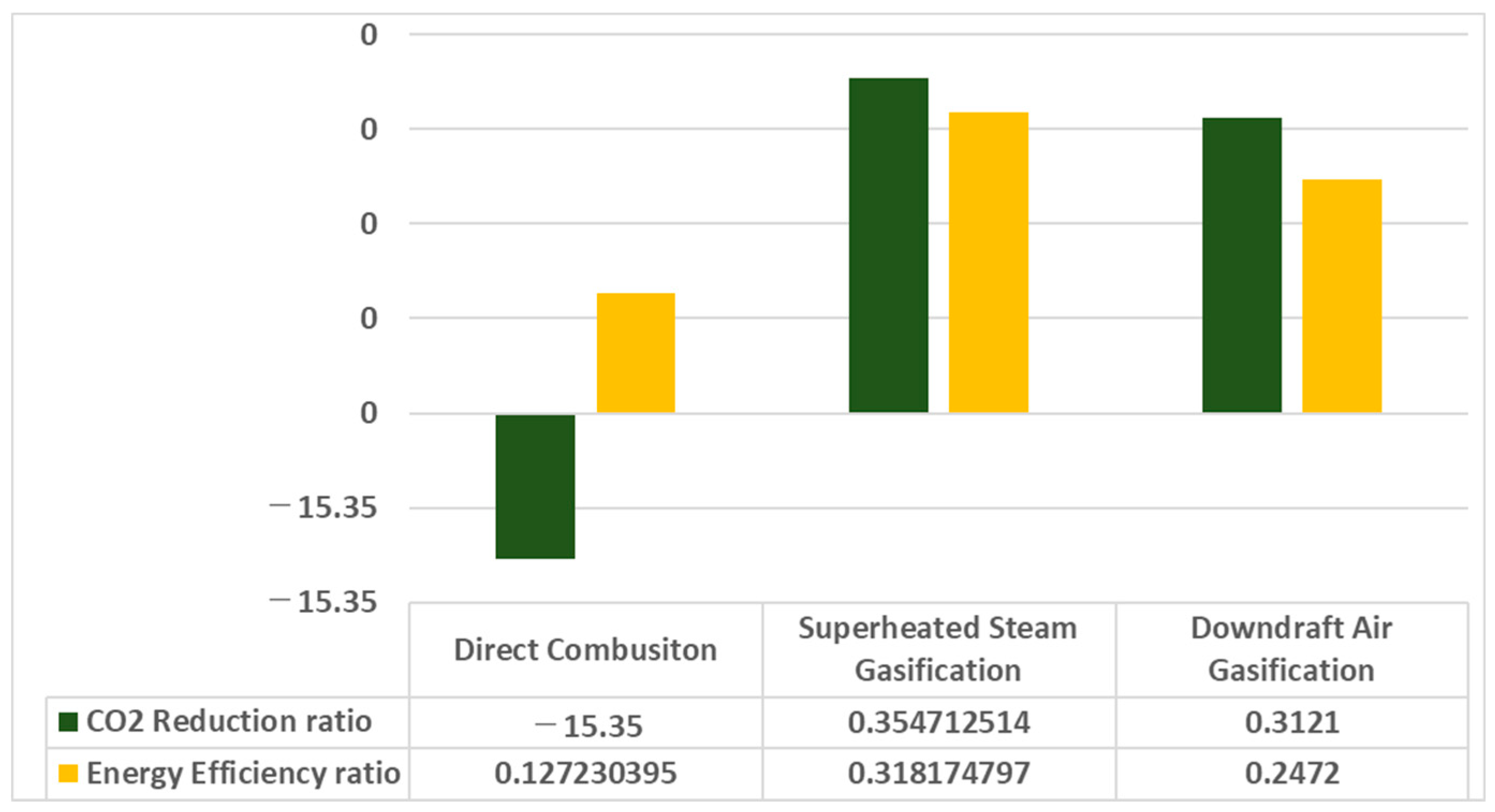

5.2. Comparison with Other Waste to Energy Techniques

5.3. Influence of Solar Energy and Plastic Usage

6. Conclusions

7. Future Steps

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Akai, M. Long Term Energy Scenario: A Challenge to the Climate Change. J. Gas Turbine Soc. Jpn. 2012, 30, 6–12. [Google Scholar]

- Akhtar, A.; Krepl, V.; Ivanova, T. A Combined Overview of Combustion, Pyrolysis, and Gasification of Biomass. Energy Fuels 2018, 32, 7294–7318. [Google Scholar] [CrossRef]

- Porteus, A. Why energy from waste incineration is an essential component of enviromentally responsibe waste management. Waste Manag. 2005, 25, 451–459. [Google Scholar] [CrossRef] [PubMed]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef] [PubMed]

- Consonni, S.; Vigano, F. Waste gasification vs. conventional Waste-To-Energy: A comparative evaluation of two commercial technologies. Waste Manag. 2012, 32, 653–666. [Google Scholar] [CrossRef] [PubMed]

- Famoso, F.; Prestipino, M.; Brusca, S.; Galvagno, A. Designing sustainable bioenergy from residual biomass: Site allocation criteria and energy/exergy performance indicators. Appl. Energy 2020, 274, 115315. [Google Scholar] [CrossRef]

- Chicco, G.; Pierluigi, M. Distributed multi-generation: A comprehensive review. Renew. Sustain. Energy Rev. 2009, 13, 535–551. [Google Scholar] [CrossRef]

- Ushida, Y.; Sakai, T.; Senda, J. 102 Modeling Analysis for Life Cycle Assessment of Waste Energy Recycling Society. Japan Society of Mechanical Engineers: Tokyo, Japan, 2012. Available online: https://www.jstage.jst.go.jp/article/jsmepes/2012.17/0/2012.17_169/_pdf/-char/ja (accessed on 1 December 2019).

- Tanaka, M.; Seguchi, D.; Sugawara, R.; Alvaro, Q.; Saito, A.; Matusumura, E.; Senda, J. Construction and Evaluation of Platform for Superheated Gasification Power Generation System using Waste Biomass; Japan Society of Mechanical Engineers: Tokyo, Japan, 2020; Available online: https://www.jstage.jst.go.jp/article/jsmekansai/2020.95/0/2020.95_09_910/_article/-char/ja/ (accessed on 16 May 2020).

- Ishikawa, M. A logistics Model for Post-Consumer Waste Recycling. J. Packag. Sci. Technol. Jpn. 1996, 5, 119–130. (In Japanese) [Google Scholar]

- Fujitex Co. (n.d.). Available online: https://www.fjtex.co.jp/kankyo/ (accessed on 1 December 2018).

- Kenki Dryer Co. (n.d.). Available online: https://kenkidryer.com/products/spesifications (accessed on 25 January 2019).

- Miura Kogyo Co. (n.d.). Miura Boiler. Available online: https://www.miuraboiler.com/steam-boilers (accessed on 25 January 2019).

- Keer, L.M.; Knapp, W.; Hocken, R. Resonance Effects for a Crack Near a Free Surface. Trans. ASME J. Appl. Mech. 1986, 51, 65–69. [Google Scholar] [CrossRef]

- Muthu Dinesh Kumar, R.; Arnand, R. Production of Biofuel from Biomass downdraft gasification and its applications. In Advanced Biofuels; Woodhead Publishing: Cambridgeshire, UK, 2019; Available online: https://www.sciencedirect.com/topics/engineering/downdraft-gasifiers (accessed on 3 January 2019).

- Yanmar Co. Yanmar CP35 Brochure Web. from Yanmar’s 35 kW Combined Heat and Power System. 2016. Available online: www.yanmar-es.com/wp-content/uploads/YANMAR-CP35-Brochure-Web.pdf (accessed on 3 January 2019).

- Colmenar-Santos, A.; Campíñez-Romero, S.; Pérez-Molina, C.; Mur-Pérez, F. An assessment of photovoltaic potential in shopping centres. Sol. Energy 2016, 135, 662–673. [Google Scholar] [CrossRef]

- Hills, C.D.; Tripathi, N.; Carey, P.J. Mineralization Technology for Carbon Capture, Utilization, and Storage. Front. Energy Res. 2020, 8. [Google Scholar] [CrossRef]

- Romanov, V.; Soong, Y.; Carney, C.; Rush, G.E.; Nielsen, B.; O’Connor, W. Mineralization of Carbon Dioxide: A Literature Review. ChemBioEng Rev. 2015, 2, 231–256. [Google Scholar] [CrossRef]

| Store area | 30,100 m2 |

| Electricity demand | 346.16 kWh/m2·y |

| Municipal solid waste generation | 76.65 kg/m2·y |

| Population | 20,000 inhabitants |

| Electricity demand | 904.18 kWh/population·y |

| Municipal solid waste generation | 226 kg/population·y |

| Type of Gasification | Superheated Steam Gasification | Downdraft Gasification |

|---|---|---|

| Cold gas efficiency | 85% | 60% |

| Power plant capacity | 0.66 MW | 0.50 MW |

| Fuel consumption | 6578 MJ/h | 4276 MJ/h |

| Machine cost | 624,301,410 JPY | 405,795,917 JPY |

| Service life | 15 y | 15 y |

| Type of Panel | Multicrystalline |

|---|---|

| Initial cost of PV system | 180 yen/W |

| Max. power (STC) | 300 W |

| Efficiency | 16% |

| Roof space/GLA ratio | 58% |

| Suitable ratio | 80% |

| Availability ratio | 65% |

| Covering ratio (Kyoto) | 49% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia, A.Q.; Nishiumi, N.; Saito, A.; Matsumura, E.; Senda, J. Economic, Environmental and Energetic Analysis of a Distributed Generation System Composed by Waste Gasification and Photovoltaic Panels. Energies 2021, 14, 3889. https://doi.org/10.3390/en14133889

Garcia AQ, Nishiumi N, Saito A, Matsumura E, Senda J. Economic, Environmental and Energetic Analysis of a Distributed Generation System Composed by Waste Gasification and Photovoltaic Panels. Energies. 2021; 14(13):3889. https://doi.org/10.3390/en14133889

Chicago/Turabian StyleGarcia, Alvaro Quiles, Naoya Nishiumi, Atsushi Saito, Eriko Matsumura, and Jiro Senda. 2021. "Economic, Environmental and Energetic Analysis of a Distributed Generation System Composed by Waste Gasification and Photovoltaic Panels" Energies 14, no. 13: 3889. https://doi.org/10.3390/en14133889