Thermal Insulation of Excavations and Its Effect on Climate Conditions

Abstract

:1. Introduction

- emission of radiation and its absorption by the air as a gas containing water vapor and carbon dioxide

- heat transfer to the air by convection from heated surfaces affected by thermal radiation from warmer surfaces.

- verification of theoretical predictions and calculations of the reduction in heat flow due to thermal insulation,

- assessment of the possibility and effectiveness of using various types of insulation materials in mining conditions,

- assessment of the effectiveness of thermal insulation in the event of leaving an uninsulated floor,

- gaining experience and knowledge about the practical problems of isolating workpieces.

2. Installing Thermal Insulation in the Heading under Analysis

2.1. Research Objectives

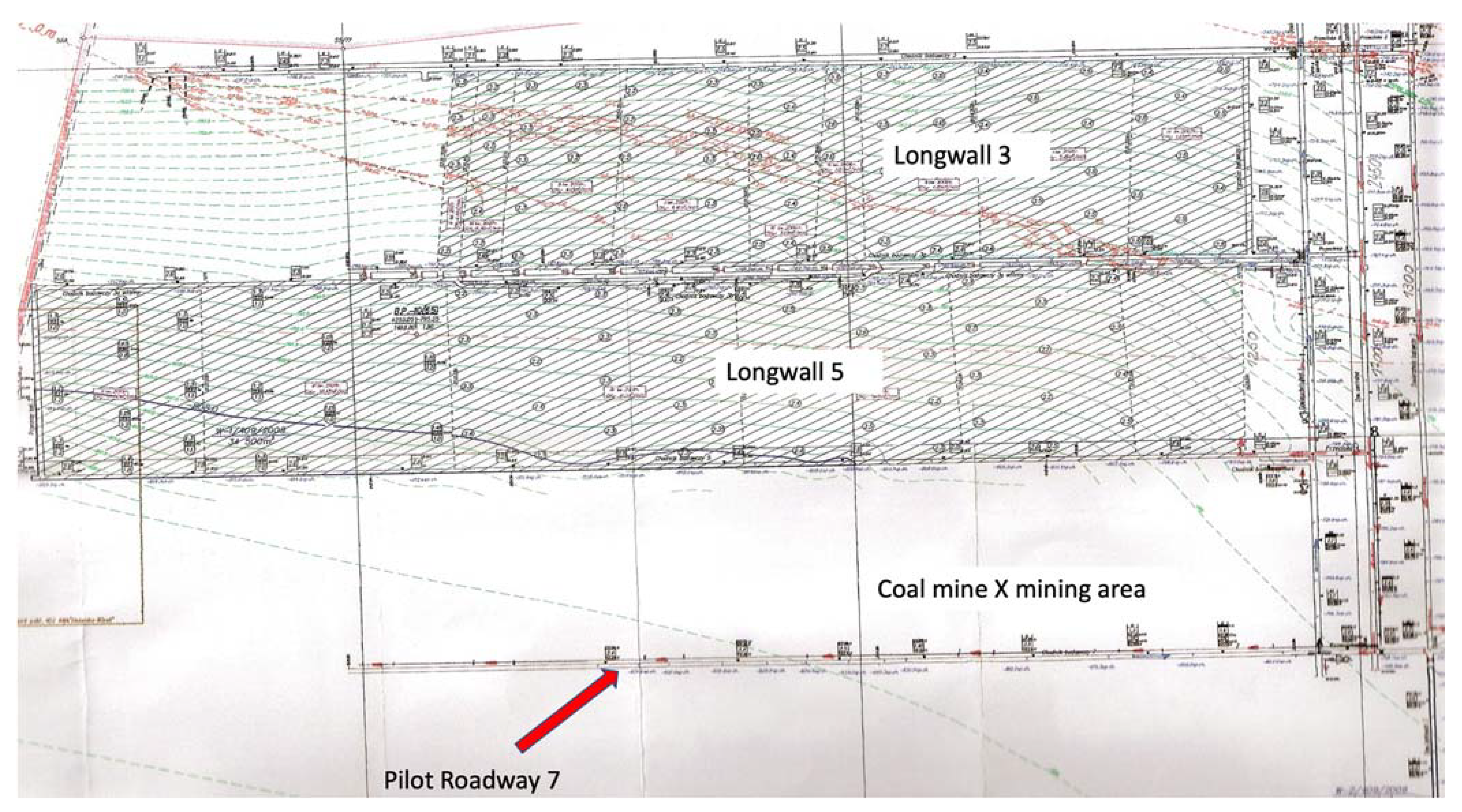

2.2. Geological and Mining Conditions around Seam 409

- fault IV, which constitutes the natural eastern border of the area. This fault, along the NNE-SSW course, drops layers from 60 to 70 m to the west. Fault IV reaches the Kłodnica fault and is continued in the “Śląsk” coal mine field as fault VII (Kalina);

- fault VIa, which runs parallel to fault IV and drops the layers to the east by about 50 m. In the northern part, this fault crosses the Kłodnica fault and runs meridians in the home field of the “Śląsk” coal mine.

- along the Research Roadway 5 (main gate), the seam deposition was regular. Its thickness ranged from 2.5 to 2.7 m. The roadway was made with a slope of about 4 degrees to the east, i.e., towards the longwall.

- along the secondary Research Roadway 3a (tail gate), the deposition of the seam was less regular due to faults. Its thickness ranged from 2.4 to 2.7 m, and the roadway was also made with a rise of about 4 degrees to the east, i.e., in the direction of longwalls. At approximately 45 m behind the longwall face, there was a normal fault dropping by approximately 1.3 m to the east. Additionally, at 105 to 120 m behind the longwall face, three normal faults were dropping 0.2 ÷ 0.3 m to the east.

- the retention of the seam 409 in the longwall 5 was also regular except for the upper section, where there were two reverse faults (11 and 26 m from the secondary research heading 3a) with discharges of 0.3 and 1.2 m, respectively. Below the larger fault, the floor was trimmed up to 1.2 m in clay shale. The thickness of coal seam 409 in longwall face 5 ranged from 2.1 to 2.6 m. There was clay slate along the entire length of the longwall in the ceiling and floor. The mean slope of the longwall towards the south was about 4 degrees.

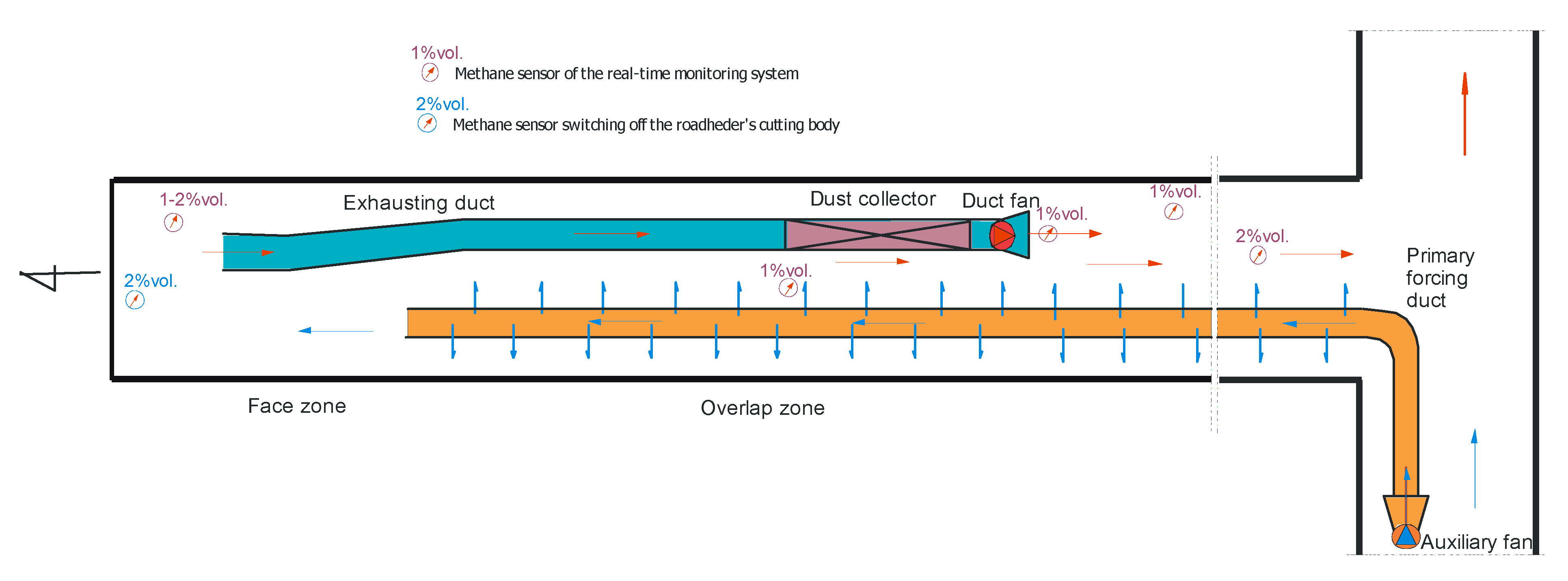

2.3. Auxiliary Ventilation System and Thermal Insulation Execution

3. Research Methodology

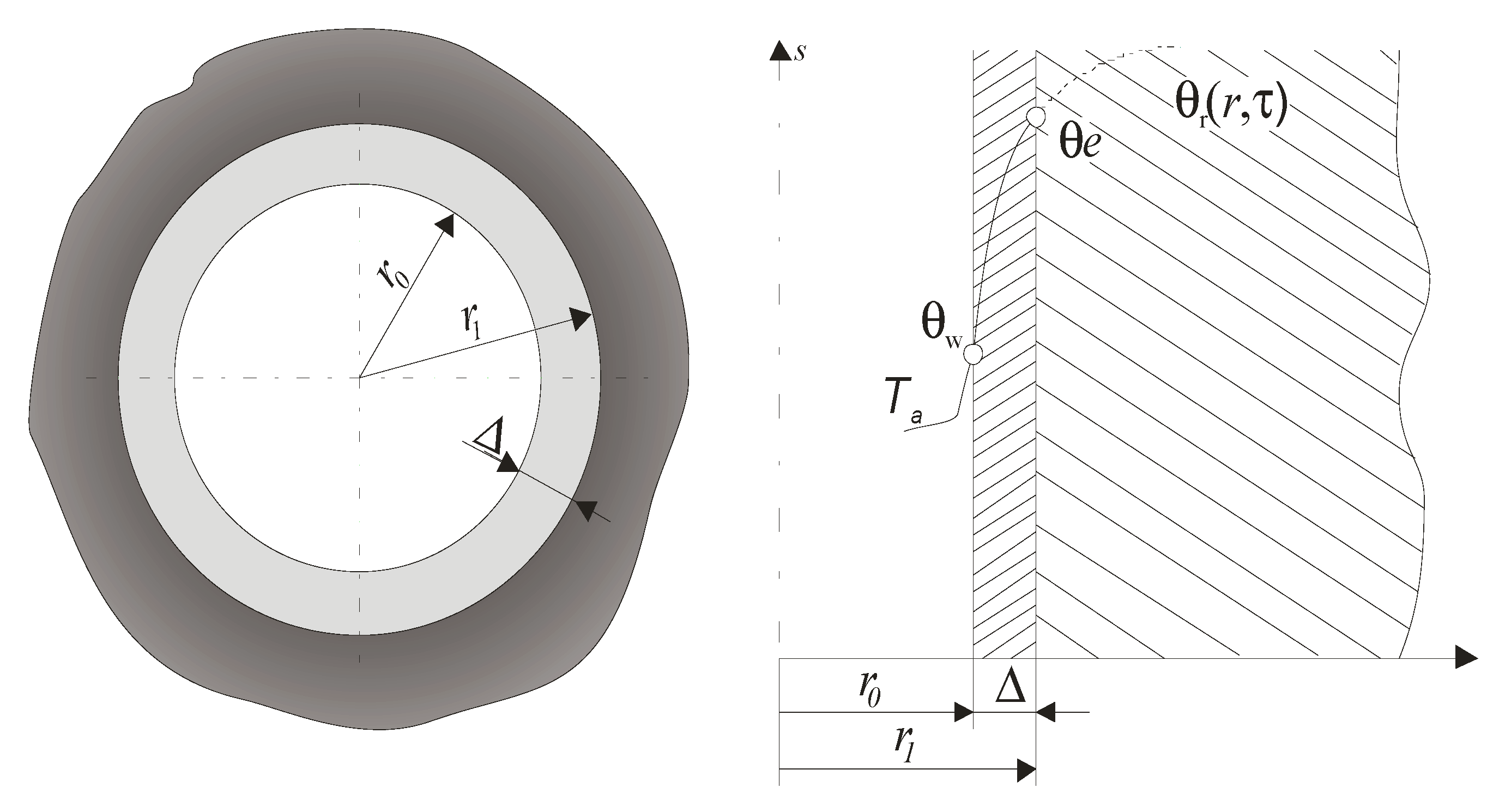

Calculating the Heat Flow Rate Permeating through the Insulating Layer

- cross-section—14.8 m2,

- time of drilling a section of 1256 m—16 months,

- average thermal conductivity of rock, λ = 1.6 W/(m·K),

- average thermal diffusivity of rock a = 0.6 × 10−6 m2/s,

- virgin rock temperature, θvr = 39 − 42 °C.

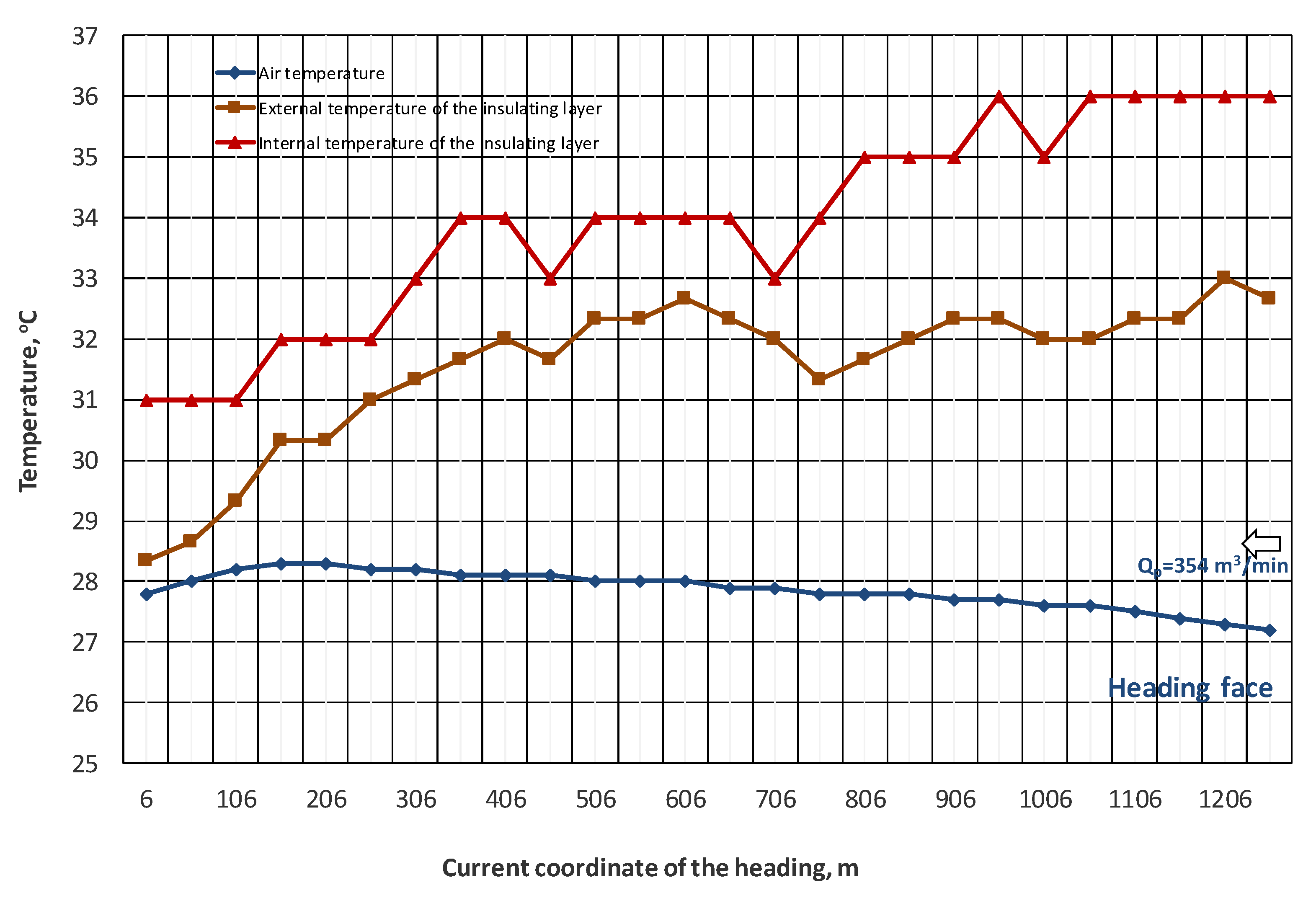

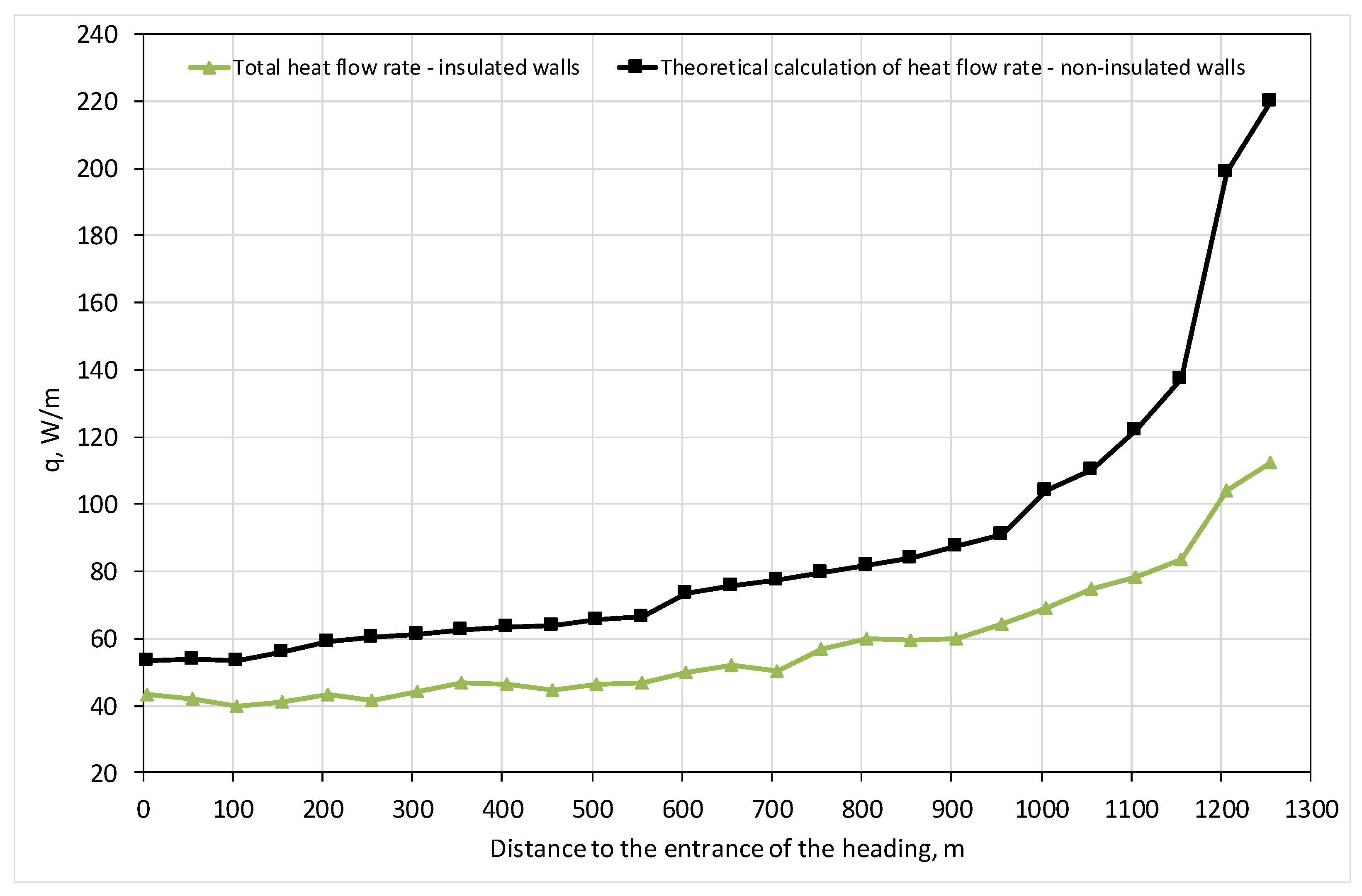

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Szlązak, N.; Obracaj, D.; Borowski, M. Methods for controlling temperature hazard in Polish coal mines. Arch. Min. Sci. 2008, 53, 497–510. [Google Scholar]

- Szlązak, N.; Obracaj, D.; Borowski, M. Prognozowanie temperatury i wilgotności powietrza w wyrobiskach z wentylacją odrębną i urządzeniami chłodniczymi bezpośredniego działania za pomocą programu komputerowego. Wiadomości Górnicze 2008, 59, 86–96. (In Polish) [Google Scholar]

- Szlązak, N.; Obracaj, D.; Swolkień, J. Ocena i Możliwości Poprawy Stanu Zagrożenia Klimatycznego w Polskich Kopalniach Podziemnych; Agencja Wydawniczo-Poligraficzna ART-TEKST: Kraków, Poland, 2018. (In Polish) [Google Scholar]

- Chmura, K.; Chudek, M. Geotermomechanika Górnicza; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 1992. (In Polish) [Google Scholar]

- Arkle, K.; Collins, L.; Blackwood-Murray, T.J. Use of thermal insulation materials in mines. J. Mine Vent. Soc. South Afr. 1985, 38, 43–45. [Google Scholar]

- Wacławik, J. Wpływ Izolacji Termicznej Skał na Intensywność Wymiany Ciepła w Wyrobiskach. Cuprum 2005, 2, 71–85. [Google Scholar]

- Szlązak, N.; Obracaj, D. Możliwości Wykorzystywania Termoizolacji Wyrobisk Udostępniających do Poprawy Warunków Klimatycznych; Nowe Spojrzenie na Wybrane Zagrożenia Naturalne w Kopalniach, Główny Instytut Górnictwa: Katowice, Poland, 2012; pp. 164–174. ISBN 978-83-61126-50-8. (In Polish) [Google Scholar]

- Szlązak, N.; Obracaj, D. Wpływ termoizolacji wyrobisk chodnikowych na warunki klimatyczne. In Proceedings of the Materiały Szkoły Eksploatacji Podziemnej, Kraków, Poland, 20–24 February 2012; Instytut Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk: Kraków, Poland, 2012. (In Polish). [Google Scholar]

- Bottomley, P. The Reduction in Heat Flow due to the Insulation of Rock Surfaces in Mine Air Ways, 2nd ed.; US Mine Ventilation Symposium: Reno, NV, USA, 1985. [Google Scholar]

- Bottomley, P.; van Rensburg, B. The insulation of rock surfaces—An empirical study. J. Mine Vent. Soc. South Afr. 1987, 40, 41–45. [Google Scholar]

- Hughes, R.O. A few thoughts on heat loads in intake haulages. J. Mine Vent. Soc. South Afr. 1978, 31, 50–53. [Google Scholar]

- Kollu SRao Sastry, B.S.; Misra, B. The insulation of Mine Roadway Rock Surfaces—An Altemative for Reduction of Strata Heat Flow. In Proceedings of the 16 World Mining Congress, Sofia, Bulgaria, 12–16 September 1994. [Google Scholar]

- Strumiński, A.; Nędza, Z.; Turkiewicz, W. Wykorzystanie Termoizolacji Wyrobisk Górniczych do Poprawy Warunków Klimatycznych w Kopalniach LGOM; Politechnika Śląska: Gliwice, Poland, 1994. (In Polish) [Google Scholar]

- Liu, W.V.; Apel, D.B.; Bindiganavile, V. Thermal characterisation of a lightweight mortar containing expanded perlite for underground insulation. Int. J. Min. Miner. Eng. 2011, 3, 55–71. [Google Scholar] [CrossRef]

- Yao, W.; Pang, J.; Ma, Q.; Lyimo, H. Influence and sensitivity analysis of thermal parameters on temperature field distribution of active thermal insulated roadway in high temperature mine. Int. J. Coal Sci. Technol. 2021, 8, 47–63. [Google Scholar] [CrossRef]

- Knechtel, J. Wpływ rodzaju termoizolacji na poprawę trudnych warunków klimatycznych w gorących wyrobiskach górniczych. In Materiały III Konferencji Wybieranie Złóż na Dużych Głębokościach Oraz w Trudnych Warunkach Geotermicznych; Lądek Zdrój: Wrocław, Poland, 2000; pp. 26–29. (In Polish) [Google Scholar]

- Soroko, K.; Kowalik MGola SNieśpiałowski, T. Schładzanie powietrza zespolonym układem: Urządzenie chłodnicze–termoizolacja. Cuprum 2006, 1, 53–72. (In Polish) [Google Scholar]

- Piany – Isoschaum. Available online: https://www.dsi-schaumchemie.pl/produkty/piany/isoschaum (accessed on 1 July 2021).

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1959; reprint in 2000; Volume 310. [Google Scholar]

- Wang, J.; Wan, Z.; Zhang, H.; Wu, D.; Zhang, Y.; Wang, Y.; Xiong, L.; Wang, G. Application of Thermal Insulation Gunite Material to the High Geo-Temperature Roadway. Adv. Civ. Eng. 2020, 2020, 8853870. [Google Scholar] [CrossRef]

- Nottrot RSadée, C. Abkühlung homogenen isotropen Gesteins um eine zylindrische Strecke durch Wetter von konstanter Temperatur. Glückauf Forschungsh. 1966, 27, 193–200. [Google Scholar]

- Wang, Y.; Zhou, G.; Wu, L.; Yang, Z.; Lu, Y. An analytical study of unsteady heat transfer in the rock surrounding a deep airway. Int. J. Min. Sci. Technol. 2012, 22, 411–415. [Google Scholar] [CrossRef]

| Data and Results | Heat Flow Rate acc to (5) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| s | Ta | θw | θe | v | θvr | τ | α0 | kz | Fo | Bi | K | qc | qins | qa | qav |

| m | °C | °C | °C | m/s | °C | days | W/(m2·K) | W/(m2·K) | - | - | - | W/m | W/m | W/m | W/m |

| 6 | 27.8 | 28.3 | 31.0 | 0.9 | 39.0 | 372 | 5.084 | 0.550 | 11.835 | 0.439 | 0.214 | 24.1 | 13.4 | 11.8 | 16.4 |

| 56 | 28.0 | 28.7 | 31.0 | 0.9 | 390.0 | 347 | 5.084 | 0.550 | 11.040 | 0.439 | 0.216 | 23.9 | 11.8 | 10.3 | 15.3 |

| 106 | 28.2 | 29.3 | 31.0 | 0.9 | 39.0 | 332 | 5.084 | 0.550 | 10.562 | 0.439 | 0.218 | 23.7 | 8.4 | 7.4 | 13.2 |

| 156 | 28.3 | 30.3 | 32.0 | 0.9 | 39.5 | 317 | 5.084 | 0.550 | 10.085 | 0.439 | 0.219 | 23.6 | 8.4 | 7.4 | 13.1 |

| 206 | 28.3 | 30.3 | 32.0 | 0.9 | 40.0 | 300 | 5.084 | 0.550 | 9.544 | 0.439 | 0.221 | 26.0 | 8.4 | 7.4 | 13.9 |

| 256 | 28.2 | 31.0 | 32.0 | 0.9 | 40.0 | 290 | 5.084 | 0.550 | 9.226 | 0.439 | 0.222 | 26.4 | 5.0 | 4.4 | 12.0 |

| 306 | 28.2 | 31.3 | 33.0 | 0.8 | 40.0 | 273 | 4.627 | 0.543 | 8.685 | 0.433 | 0.223 | 26.4 | 8.4 | 7.3 | 14.0 |

| 356 | 28.1 | 31.7 | 34.0 | 0.8 | 40.0 | 258 | 4.627 | 0.543 | 8.208 | 0.433 | 0.225 | 26.9 | 11.8 | 10.2 | 16.3 |

| 406 | 28.1 | 32.0 | 34.0 | 0.8 | 40.0 | 240 | 4.627 | 0.543 | 7.635 | 0.433 | 0.227 | 27.1 | 10.1 | 8.7 | 15.3 |

| 456 | 28.1 | 31.7 | 33.0 | 0.8 | 40.0 | 230 | 4.627 | 0.543 | 7.317 | 0.433 | 0.228 | 27.3 | 6.7 | 5.8 | 13.3 |

| 506 | 28.0 | 32.3 | 34.0 | 0.7 | 40.0 | 215 | 4.158 | 0.535 | 6.840 | 0.427 | 0.229 | 27.6 | 8.4 | 7.2 | 14.4 |

| 556 | 28.0 | 32.3 | 34.0 | 0.7 | 40.0 | 200 | 4.158 | 0.535 | 6.363 | 0.427 | 0.231 | 27.9 | 8.4 | 7.2 | 14.5 |

| 606 | 28.0 | 32.7 | 34.0 | 0.7 | 41.0 | 185 | 4.158 | 0.535 | 5.886 | 0.427 | 0.233 | 30.5 | 6.7 | 5.7 | 14.3 |

| 656 | 27.9 | 32.3 | 34.0 | 0.7 | 41.0 | 170 | 4.158 | 0.535 | 5.408 | 0.427 | 0.236 | 31.1 | 8.4 | 7.2 | 15.6 |

| 706 | 27.9 | 32.0 | 33.0 | 0.6 | 41.0 | 155 | 3.676 | 0.525 | 4.931 | 0.419 | 0.236 | 31.1 | 5.0 | 4.2 | 13.5 |

| 756 | 27.8 | 31.3 | 34.0 | 0.6 | 41.0 | 141 | 3.676 | 0.525 | 4.486 | 0.419 | 0.239 | 31.8 | 13.4 | 11.3 | 18.8 |

| 806 | 27.8 | 31.7 | 35.0 | 0.6 | 41.0 | 125 | 3.676 | 0.525 | 3.977 | 0.419 | 0.243 | 32.3 | 16.8 | 14.1 | 21.1 |

| 856 | 27.8 | 32.0 | 35.0 | 0.6 | 41.0 | 112 | 3.676 | 0.525 | 3.563 | 0.419 | 0.247 | 32.7 | 15.1 | 12.7 | 20.2 |

| 906 | 27.7 | 32.3 | 35.0 | 0.5 | 41.0 | 97 | 3.177 | 0.512 | 3.086 | 0.409 | 0.248 | 33.1 | 13.4 | 11.0 | 19.2 |

| 956 | 27.7 | 32.3 | 36.0 | 0.5 | 41.0 | 82 | 3.177 | 0.512 | 2.609 | 0.409 | 0.253 | 33.8 | 18.5 | 15.1 | 22.5 |

| 1006 | 27.6 | 32.0 | 35.0 | 0.5 | 42.0 | 65 | 3.177 | 0.512 | 2.068 | 0.409 | 0.260 | 37.6 | 15.1 | 12.4 | 21.7 |

| 1056 | 27.6 | 32.0 | 36.0 | 0.5 | 42.0 | 51 | 3.177 | 0.512 | 1.623 | 0.409 | 0.267 | 38.7 | 20.2 | 16.5 | 25.1 |

| 1106 | 27.5 | 32.3 | 36.0 | 0.5 | 42.0 | 35 | 3.177 | 0.512 | 1.114 | 0.409 | 0.279 | 40.6 | 18.5 | 15.1 | 24.7 |

| 1156 | 27.4 | 32.3 | 36.0 | 0.4 | 42.0 | 22 | 2.658 | 0.495 | 0.700 | 0.395 | 0.285 | 41.9 | 18.5 | 14.6 | 25.0 |

| 1206 | 27.3 | 33.0 | 36.0 | 0.4 | 42.0 | 5 | 2.658 | 0.495 | 0.159 | 0.395 | 0.324 | 47.9 | 15.1 | 11.9 | 25.0 |

| 1256 | 27.2 | 32.7 | 36.0 | 0.4 | 42.0 | 3 | 2.658 | 0.495 | 0.095 | 0.395 | 0.335 | 49.9 | 16.8 | 13.3 | 26.7 |

| Data and Results | Heat Flow Rate acc. to (10) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| s | Ta | v | θvr | τ | α0-f | Bi-f | Fo-f | Kf | qf |

| m | °C | m/s | °C | Days | W/(m2·K) | - | - | - | W/m |

| 6 | 27.8 | 0.9 | 40.0 | 372 | 5.967 | 2.139 | 58.633 | 0.239 | 26.9 |

| 56 | 28.0 | 0.9 | 40.0 | 347 | 5.967 | 2.139 | 54.692 | 0.243 | 26.8 |

| 106 | 28.2 | 0.9 | 40.0 | 332 | 5.967 | 2.139 | 52.328 | 0.245 | 26.6 |

| 156 | 28.3 | 0.9 | 40.0 | 317 | 5.914 | 2.120 | 49.964 | 0.248 | 27.9 |

| 206 | 28.3 | 0.9 | 40.0 | 300 | 5.807 | 2.081 | 47.285 | 0.250 | 29.5 |

| 256 | 28.2 | 0.9 | 40.0 | 290 | 5.700 | 2.043 | 45.708 | 0.252 | 29.9 |

| 306 | 28.2 | 0.8 | 40.0 | 273 | 5.592 | 2.005 | 43.029 | 0.255 | 30.2 |

| 356 | 28.1 | 0.8 | 40.0 | 258 | 5.430 | 1.946 | 40.665 | 0.257 | 30.8 |

| 406 | 28.1 | 0.8 | 40.0 | 240 | 5.321 | 1.907 | 37.828 | 0.261 | 31.2 |

| 456 | 28.1 | 0.8 | 40.0 | 230 | 5.157 | 1.848 | 36.252 | 0.263 | 31.4 |

| 506 | 28.0 | 0.7 | 40.0 | 215 | 5.047 | 1.809 | 33.887 | 0.266 | 32.1 |

| 556 | 28.0 | 0.7 | 40.0 | 200 | 4.880 | 1.749 | 31.523 | 0.269 | 32.5 |

| 606 | 28.0 | 0.7 | 41.0 | 185 | 4.768 | 1.709 | 29.159 | 0.273 | 35.7 |

| 656 | 27.9 | 0.7 | 41.0 | 170 | 4.599 | 1.648 | 26.795 | 0.277 | 36.4 |

| 706 | 27.9 | 0.6 | 41.0 | 155 | 4.486 | 1.608 | 24.430 | 0.281 | 37.1 |

| 756 | 27.8 | 0.6 | 41.0 | 141 | 4.314 | 1.546 | 22.224 | 0.286 | 37.9 |

| 806 | 27.8 | 0.6 | 41.0 | 125 | 4.198 | 1.505 | 19.702 | 0.292 | 38.7 |

| 856 | 27.8 | 0.6 | 41.0 | 112 | 4.082 | 1.463 | 17.653 | 0.298 | 39.5 |

| 906 | 27.7 | 0.5 | 41.0 | 97 | 3.906 | 1.400 | 15.289 | 0.305 | 40.7 |

| 956 | 27.7 | 0.5 | 41.0 | 82 | 3.788 | 1.358 | 12.924 | 0.314 | 42.0 |

| 1006 | 27.6 | 0.5 | 42.0 | 65 | 3.669 | 1.315 | 10.245 | 0.328 | 47.5 |

| 1056 | 27.6 | 0.5 | 42.0 | 51 | 3.548 | 1.272 | 8.038 | 0.343 | 49.6 |

| 1106 | 27.5 | 0.5 | 42.0 | 35 | 3.427 | 1.228 | 5.517 | 0.368 | 53.6 |

| 1156 | 27.4 | 0.4 | 42.0 | 22 | 3.305 | 1.184 | 3.468 | 0.401 | 58.8 |

| 1206 | 27.3 | 0.4 | 42.0 | 5 | 3.243 | 1.162 | 0.788 | 0.535 | 79.0 |

| 1256 | 27.2 | 0.4 | 42.0 | 3 | 3.119 | 1.118 | 0.473 | 0.577 | 85.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szlązak, N.; Obracaj, D.; Swolkień, J. Thermal Insulation of Excavations and Its Effect on Climate Conditions. Energies 2021, 14, 4170. https://doi.org/10.3390/en14144170

Szlązak N, Obracaj D, Swolkień J. Thermal Insulation of Excavations and Its Effect on Climate Conditions. Energies. 2021; 14(14):4170. https://doi.org/10.3390/en14144170

Chicago/Turabian StyleSzlązak, Nikodem, Dariusz Obracaj, and Justyna Swolkień. 2021. "Thermal Insulation of Excavations and Its Effect on Climate Conditions" Energies 14, no. 14: 4170. https://doi.org/10.3390/en14144170

APA StyleSzlązak, N., Obracaj, D., & Swolkień, J. (2021). Thermal Insulation of Excavations and Its Effect on Climate Conditions. Energies, 14(14), 4170. https://doi.org/10.3390/en14144170