Preliminary Analysis of an Aged RPV Subjected to Station Blackout

Abstract

:1. Introduction

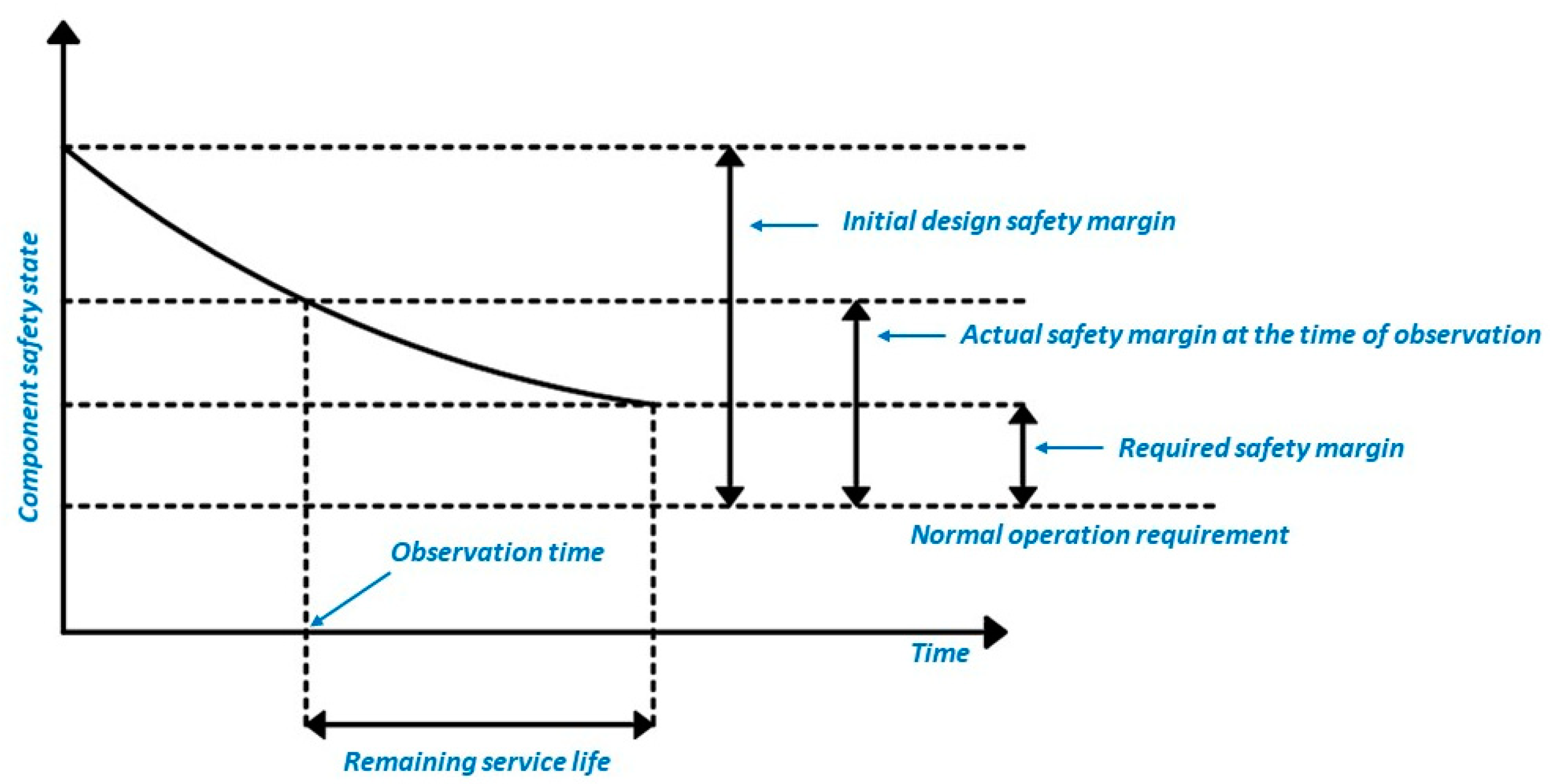

- Diagnosis of the actual state of plant equipment, based on ageing analysis and operating feedback [3].

- Prognosis of the ability of the main systems, structures, and components (SSCs) to continue operation, considering limitations and factors facilitating lifetime extension.

- Ageing management strategy (e.g., actions to detect and control in a timely manner the rate and extent of SSCs physical degradation), including also an exceptional maintenance programme, to ensure that the effects of ageing will not prevent SSCs from being able to accomplish their safety functions.

- -

- Radiation damage;

- -

- Material fatigue by cyclic loading;

- -

- Corrosion and flow accelerated corrosion;

- -

- Flow accelerated erosion;

- -

- Material ageing under elevated temperatures;

- -

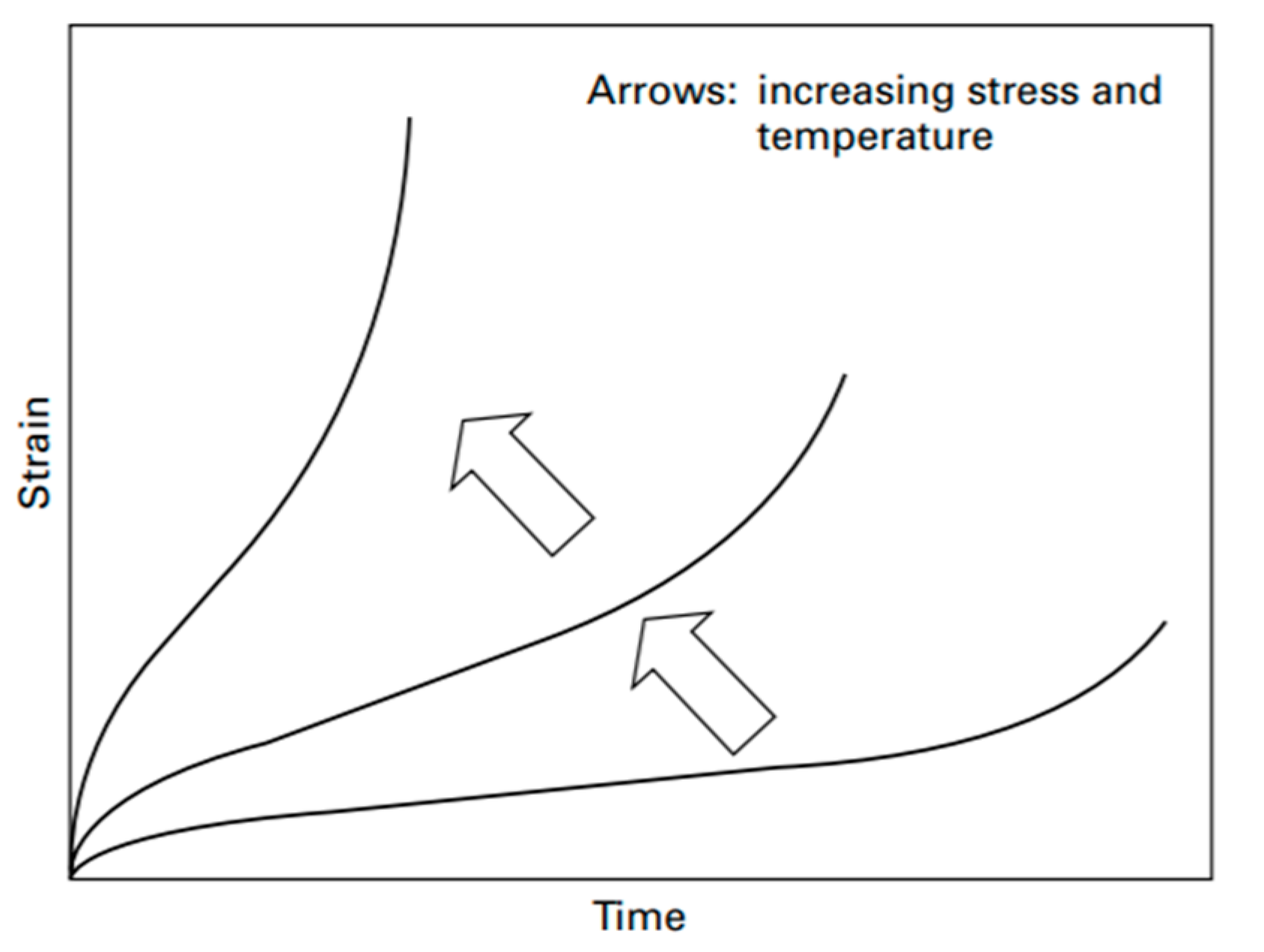

- Material creep under elevated temperatures.

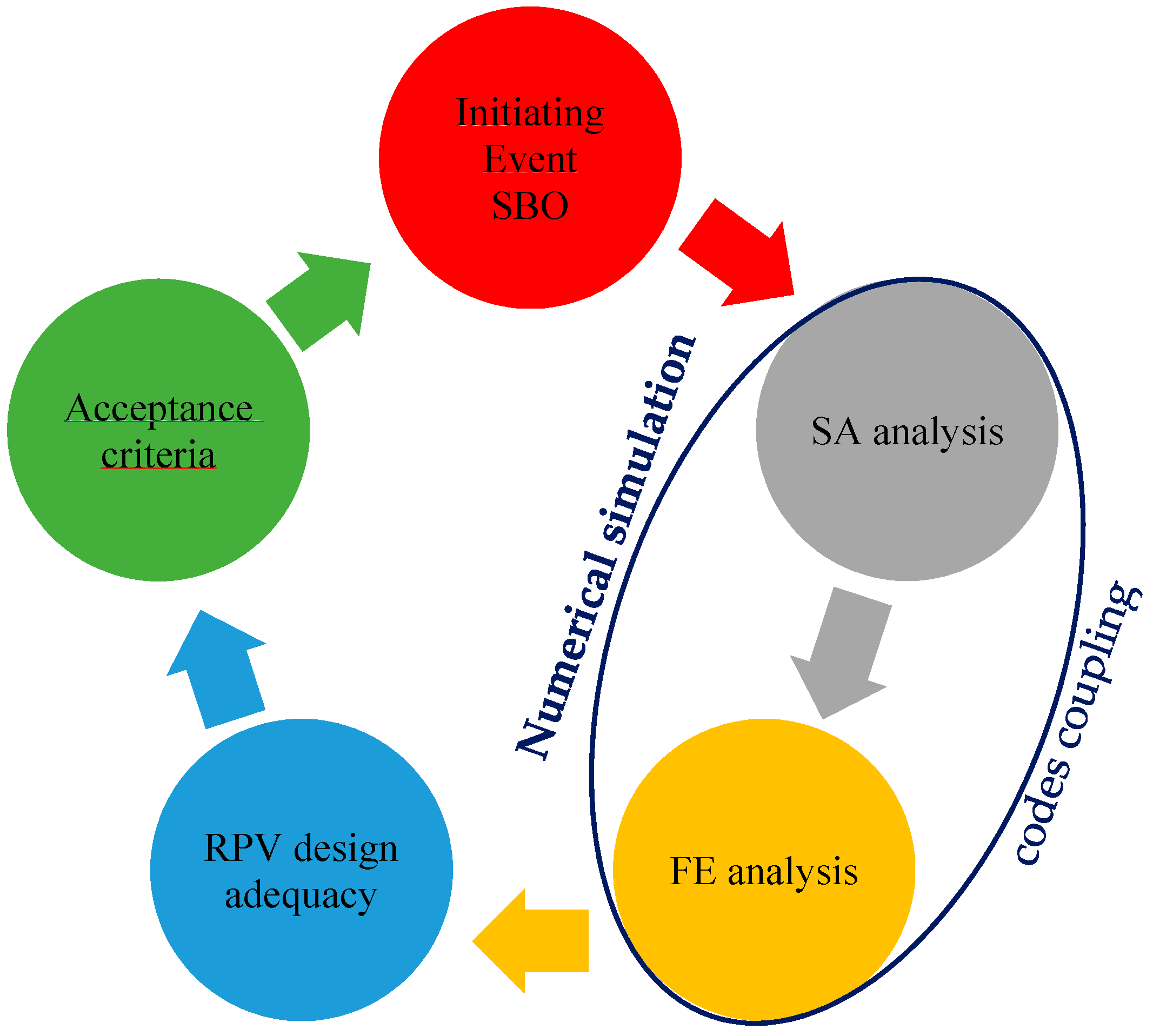

2. Methodological Approach

- (a)

- Identification of critical SSCs from the standpoint of the plant operation and safety (i.e., RPV in this study);

- (b)

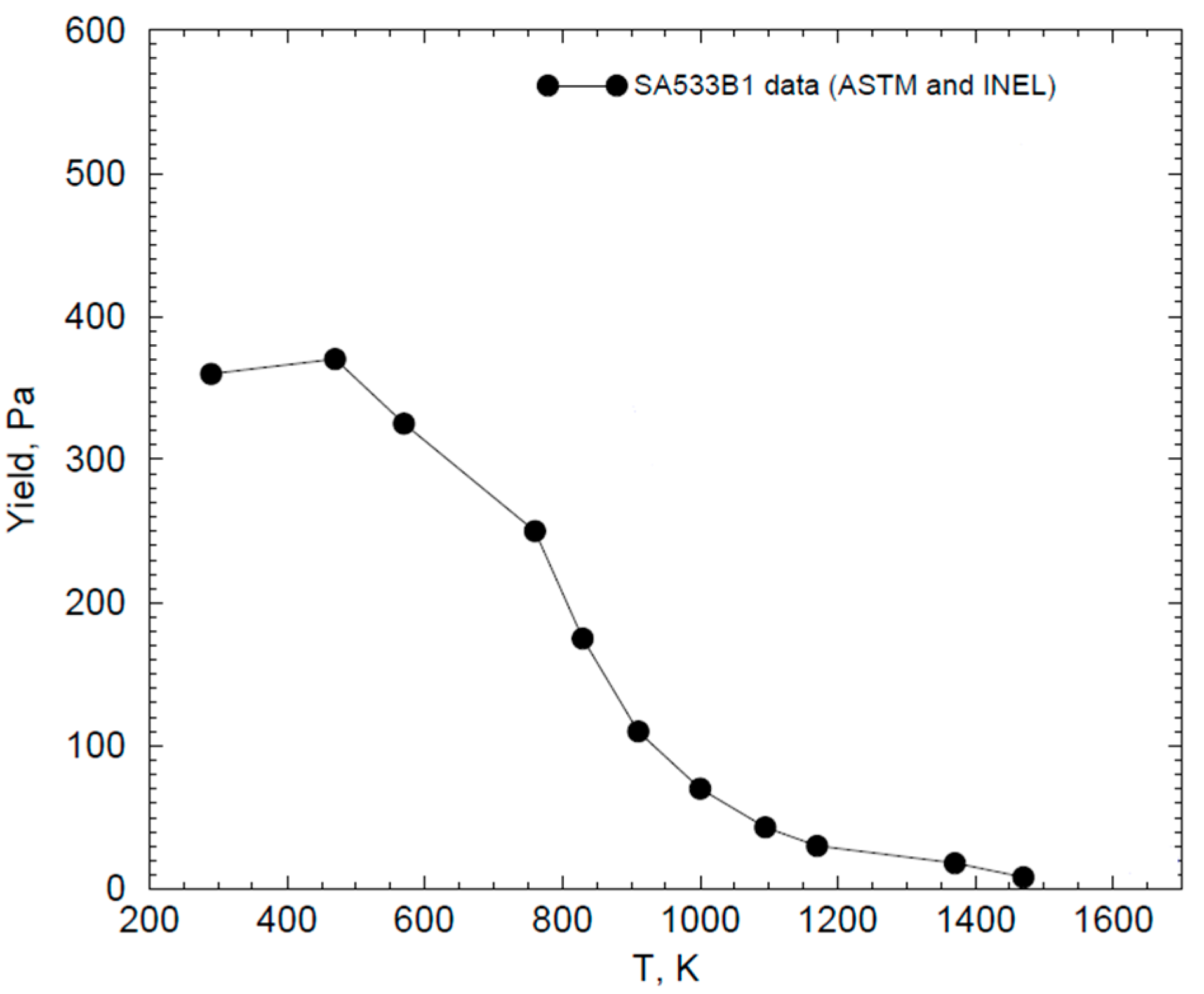

- Definition of materials and environmental conditions;

- (c)

- Identification of the operational loadings, stressors, and essential mechanisms and effects associated with ageing;

- (d)

- Numerical simulation:

- d.1

- For severe accident simulation, points (a) and (b) are implemented in, e.g., MELCOR code 4.

- d.2

- For thermo-mechanical analysis by FE code [18], which allowed for verification of the component structural integrity, points (a), (b), and (c) are implemented;

- d.2.1

- Verification and validation of numerical modelling.

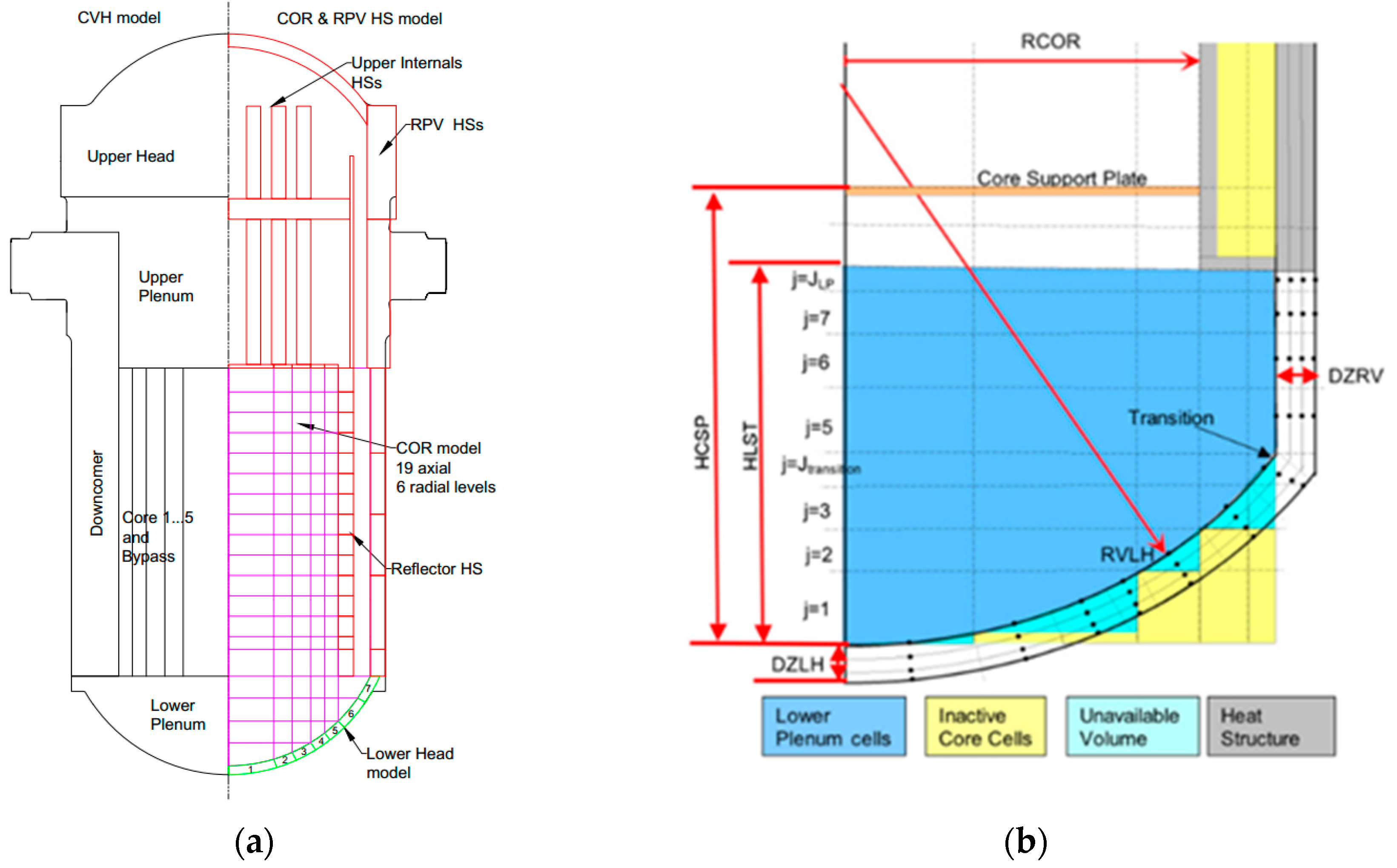

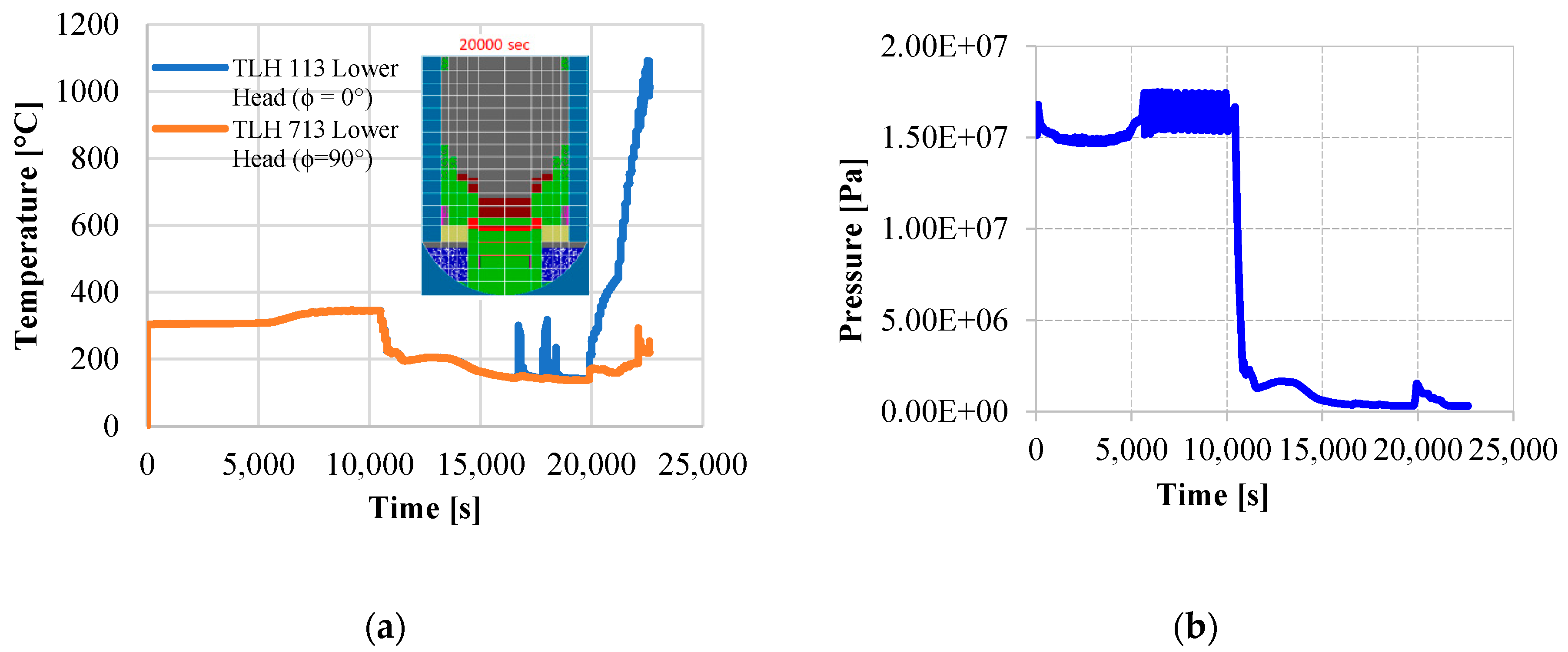

2.1. Description of the MELCOR Model

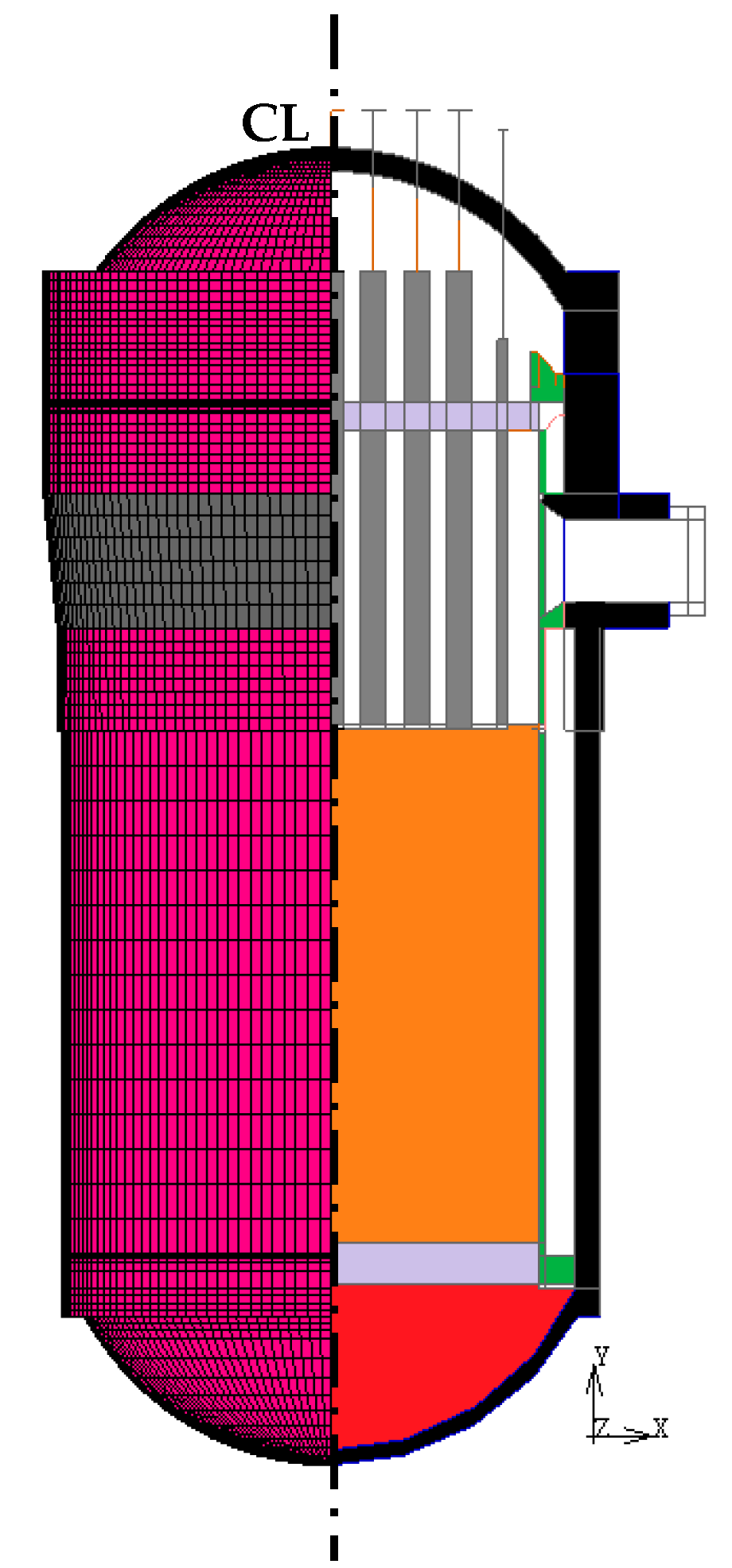

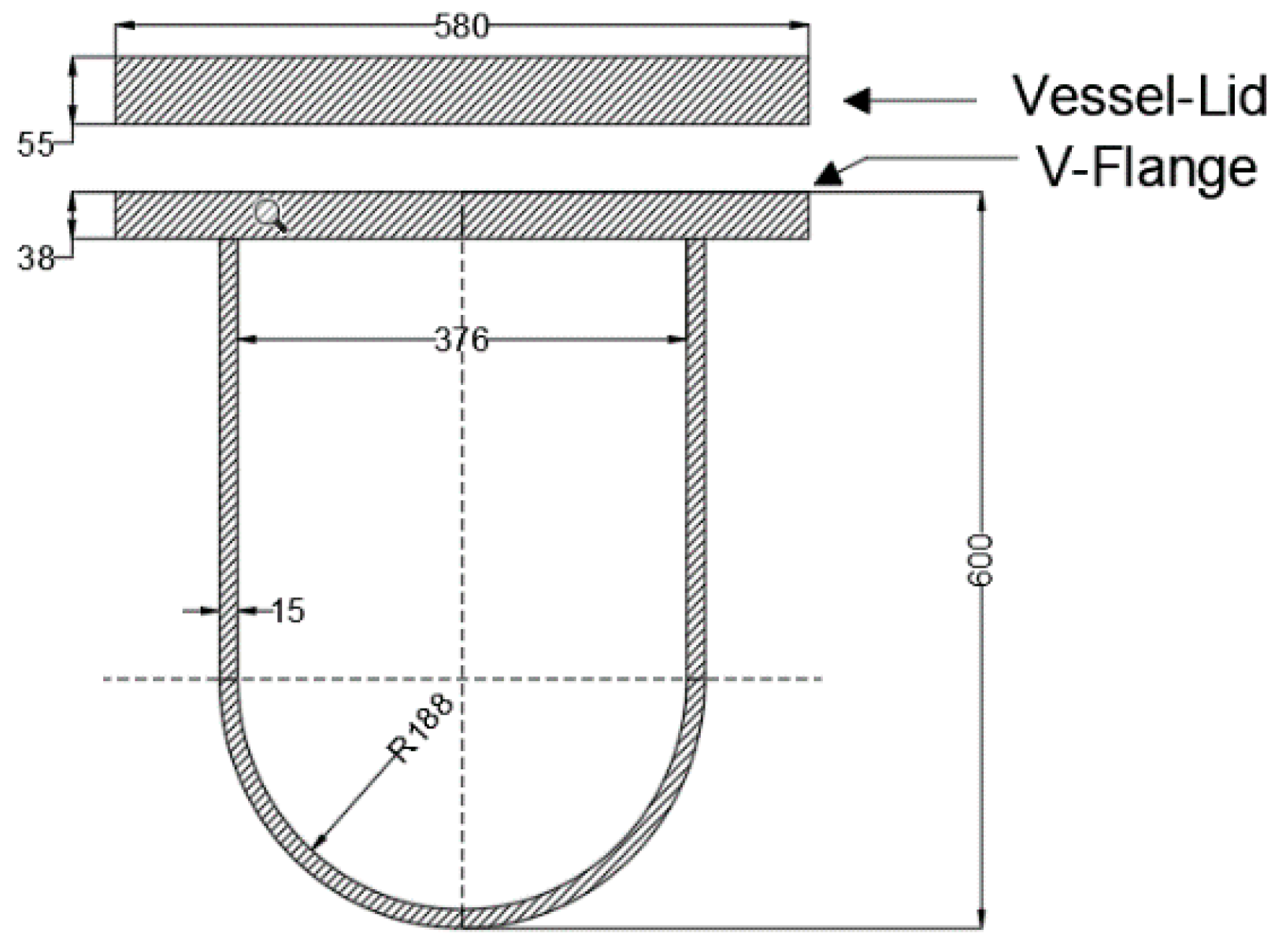

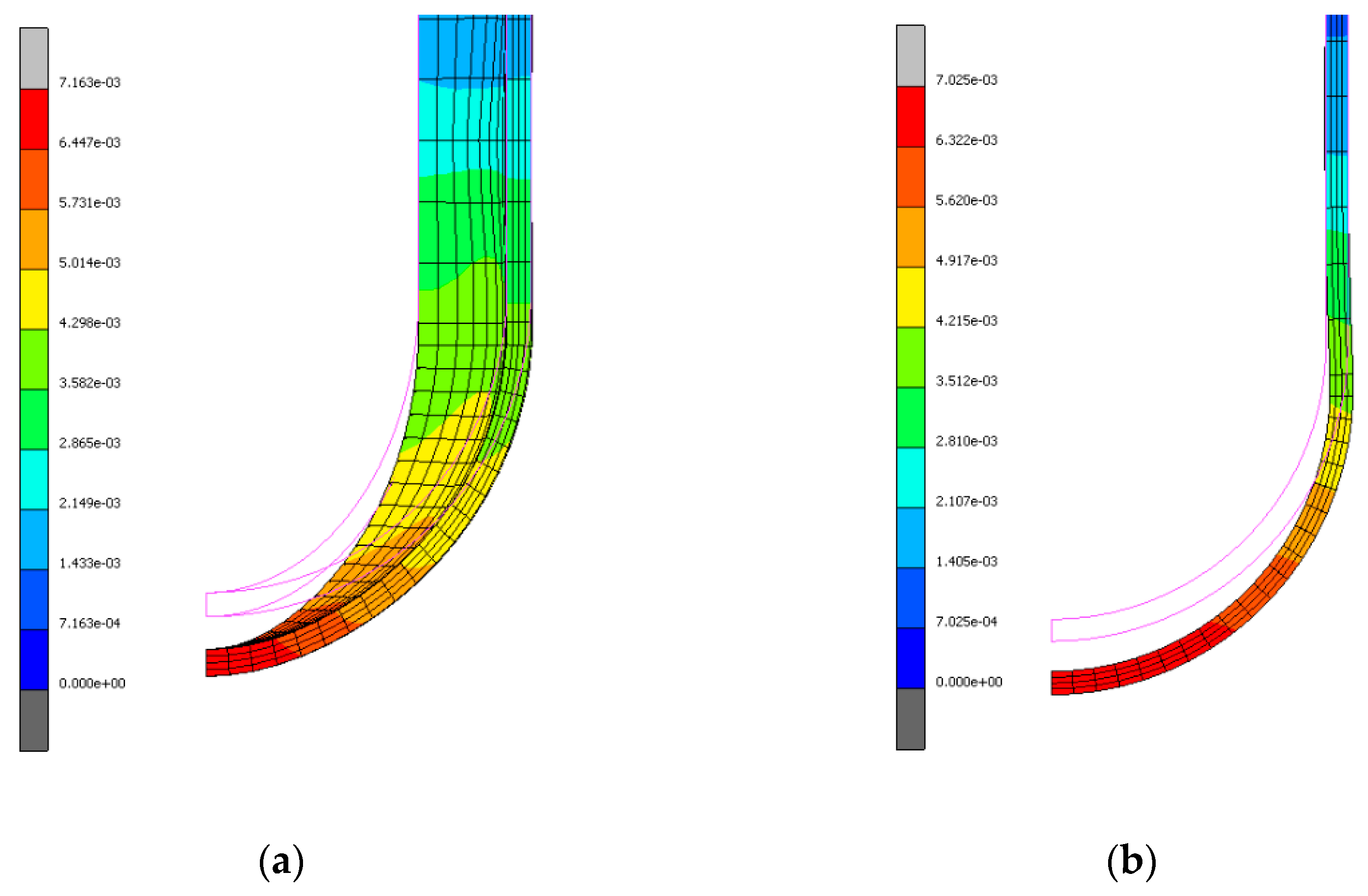

2.2. Description of the FE Model

- σ: stress,

- ε: strain,

- T: temperature,

- t: time.

2.2.1. Modelling Validation

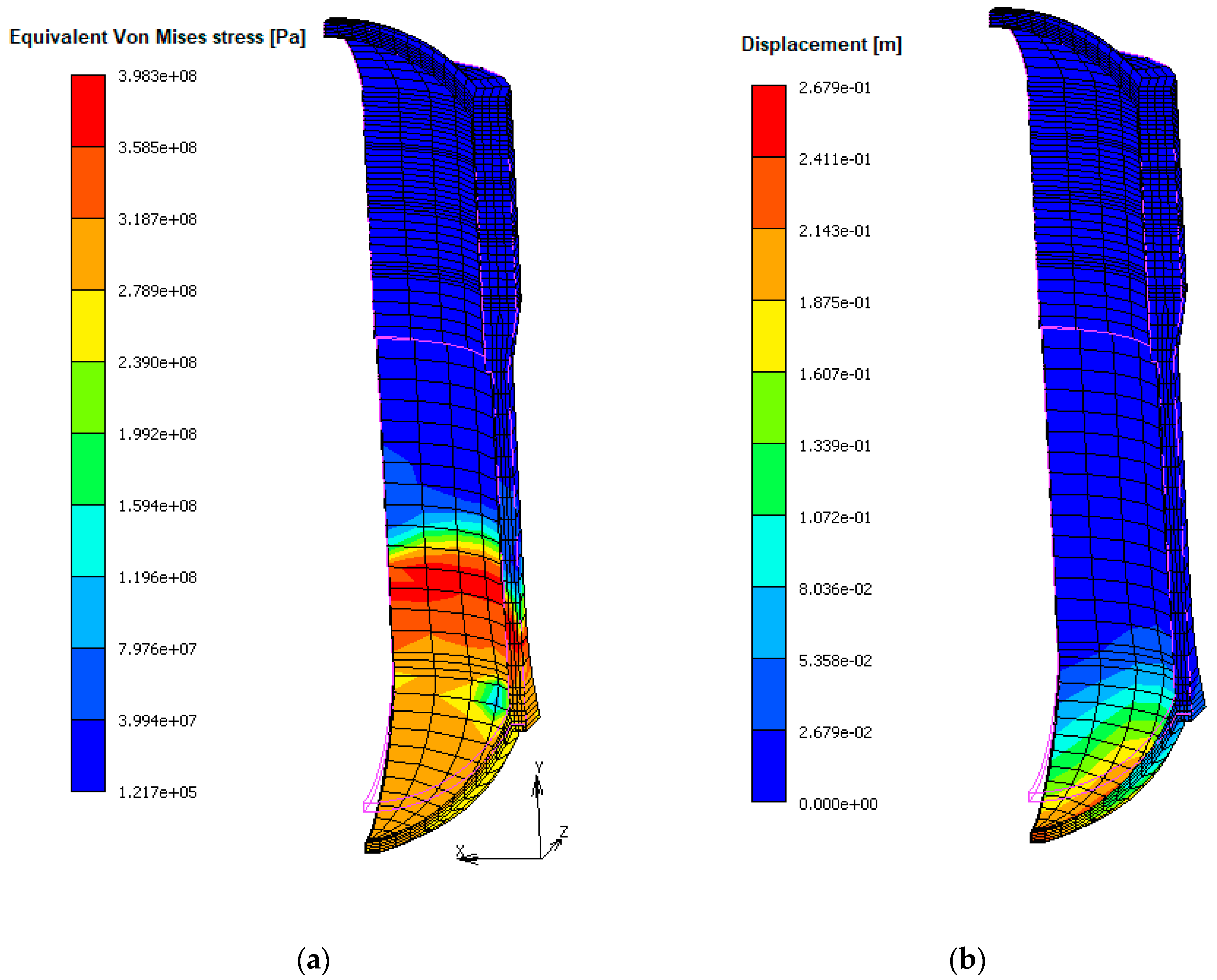

3. Results and Discussion

- Unaged RPV, no creep accounted

- Unaged RPV, creep is accounted

- Aged RPV, no creep accounted

- Aged RPV, creep accounted

4. Conclusions

- The vessel lower head bends downwards under the applied pressure and temperature.

- The aged RPV lower head radially expands about 260 mm.

- When the RPV temperature overcomes about 850 K, the main thermomechanical properties reduce by more than 50%.

- The ageing and long heat-up strongly may compromise severely the RPV integrity in the absence of or delayed emergency intervention.

- An aged RPV system, in end-of-life conditions, may collapse earlier, and in less time, with the same accidental conditions.

- The developed creep constitutive equation can be used to predict vessel deformations under severe accident conditions.

- The FE code is not capable of simulating irradiation embrittlement, which is the reason why it was not considered in the study (to account for such an effect [15,23], a different strategy considering the results of neutron damage in terms of deformed geometry or degraded material properties should be applied).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

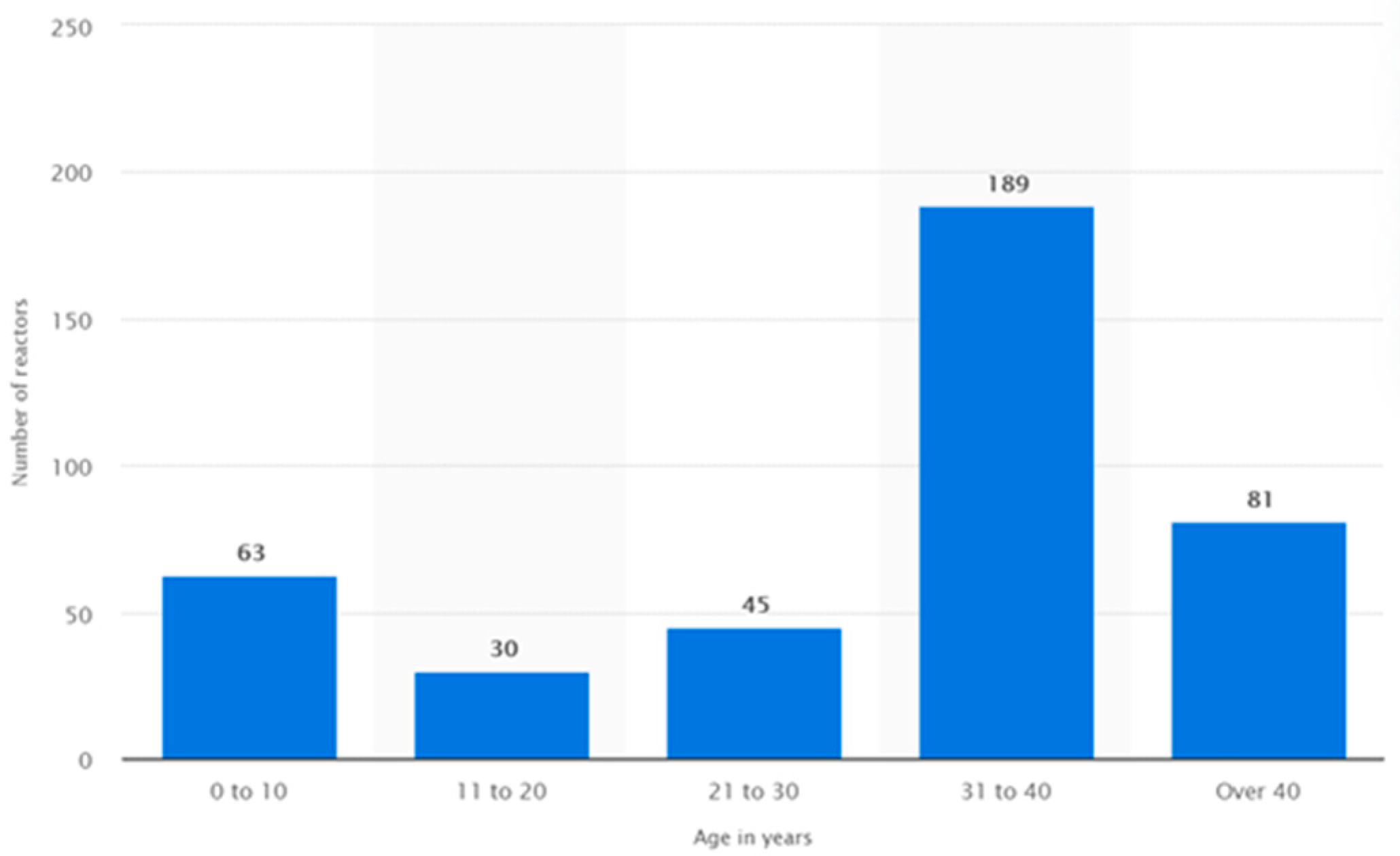

- Statista. Number of operable nuclear reactors by average age worldwide as of July 2020. In Plant Life Management Models for Long Term Operation of Nuclear Power Plants; IAEA Nuclear Energy Series; No. NP-T-3.18; 2015; Available online: https://www.statista.com/statistics/517060/average-age-of-nuclear-reactors-worldwide/IAEA (accessed on 2 January 2021).

- International Atomic Energy Agency. Assessment and Management of Ageing of Major Nuclear Power Plant Components Important to Safety Primary Piping in PWRs; IAEA-TECDOC-1361; International Atomic Energy Agency: Vienna, Austria, 2003. [Google Scholar]

- International Atomic Energy Agency. Deterministic Safety Analysis for Nuclear Power Plants; SSG-2 (rev.1); IAEA: Vienna, Austria, 2019. [Google Scholar]

- Lo Frano, R.; Darnowski, P. Study of the ageing effects on the lower head failure in a PWR reactor. In Proceedings of the 2020 ICONE Virtual Conference, Online, USA, 4–5 August 2020. [Google Scholar]

- Sehgal, B.R.; Dinh, T.N.; Nourgaliev, R.R.; Bui, V.A.; Green, J.; Kolb, G.; Karbojian, A.; Theerthan, S.A.; Gubaidulline, A.; Helle, M.; et al. Final Report for the Melt-Vessel Interactions’ Project. European Union R and TD Program 4th Framework. MVI Project Final Research Report; Swedish Nuclear Power Inspectorate: Stockholm, Sweden, 1999. [Google Scholar]

- Sehgal, B.R. (Ed.) Nuclear Safety in Light Water Reactors, Severe Accident Phenomenology; Chapter 2–In-Vessel Core Degradation; Academic Press, MIT: Cambridge, MA, USA, 2012; pp. 89–183. ISBN 9780123884466. [Google Scholar]

- Sharma, T. Effect of thermal aging on embrittlement of Cr-Mo-V pressure vessel steel. J. Nucl. Mater. 2019, 527, 151817. [Google Scholar] [CrossRef]

- Yupeng, C. Evaluation of irradiation embrittlement of the weld metals in the Chinese RPV. In Proceedings of the 2020 ICONE Virtual Conference, Online, USA, 4–5 August 2020. [Google Scholar]

- Tipping, P.G. Understanding and Mitigating Ageing in Nuclear Power Plants; Woodhead Publishing Series in Energy Number 4; Woodhead Publishing: Sawston, UK, 2010; ISBN 978-1-84569-511-8. [Google Scholar]

- Kim, H. Swelling resistance of advanced austenitic alloy A709 and its comparison with 316 stainless steel at high damage levels. J. Nucl. Mater. 2019, 527, 151818. [Google Scholar] [CrossRef]

- Tipping, P. Lifetime and ageing management of nuclear power plants: A brief overview of some light water reactor component ageing degradation problems and ways of mitigation. Int. J. Press. Vessel. Pip. 1996, 66, 17–25. [Google Scholar] [CrossRef]

- Timofeev, B.T. Assessment of the first-generation PV state after designed lifetime. Int. J. Press. Vessel. Pip. 2004, 81, 703–712. [Google Scholar] [CrossRef]

- Karzov, G.; Timofeev, B.T. Ageing of RPV and primary circuit piping materials for NPP with WWER during a design operation time. In Proceedings of the International Topical Meeting VVER-2004-experience and perspectives, Prague, Czech Republic, 19–22 October 2004. [Google Scholar]

- Cancemi, S.A.; Lo Frano, R. Preliminary study of the effects of ageing on the long-term performance of NPP pipe. Prog. Nucl. Energy 2021, 131, 103573. [Google Scholar] [CrossRef]

- Cancemi, S.A.; Lo Frano, R. Preliminary analysis of long-term performance of a piping: Aging and creep effects. Materials 2021, 14, 1703. [Google Scholar] [CrossRef] [PubMed]

- Humphries, L.L. MELCOR 2.2 Computer Code Manuals-Vol. 1: Primer and Users’ Guide; Sandia National Laboratories: Albuquerque, NM, USA, 2017. [Google Scholar]

- Humphries, L.L. MELCOR 2.2 Computer Code Manuals-Vol. 2: Reference Manual; Sandia National Laboratories: Albuquerque, NM, USA, 2017. [Google Scholar]

- MSC. Marc Manuals, Vol. A: Theory and User Information; MSC Corp: Vienna, Austria, 2020. [Google Scholar]

- Total Material Database. Available online: https://www.totalmateria.com/ (accessed on 2 January 2021).

- Rempe, J.L.; Knudson, D.L. High temperature thermal and structural material properties for metals used in LWR vessels. In Proceedings of the ICAPP ’08, Anaheim, CA, USA, 8–12 June 2008; p. 8220. [Google Scholar]

- EU H2020 NARSIS Project. Available online: http://www.narsis.eu/ (accessed on 2 January 2021).

- Abe, F. Creep-Resistant Steels; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Cancemi, S.A.; Lo Frano, R. Pipe performance in LTO framework: Ageing issues. In Proceedings of the 2021 ICONE Virtual Conference, Online, USA, 4–6 August 2021. [Google Scholar]

| A | n | m | k |

|---|---|---|---|

| 3.41 × 10−34 | 3.1 | 0.2 | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lo Frano, R.; Cancemi, S.A.; Darnowski, P.; Ciolini, R.; Paci, S. Preliminary Analysis of an Aged RPV Subjected to Station Blackout. Energies 2021, 14, 4394. https://doi.org/10.3390/en14154394

Lo Frano R, Cancemi SA, Darnowski P, Ciolini R, Paci S. Preliminary Analysis of an Aged RPV Subjected to Station Blackout. Energies. 2021; 14(15):4394. https://doi.org/10.3390/en14154394

Chicago/Turabian StyleLo Frano, Rosa, Salvatore Angelo Cancemi, Piotr Darnowski, Riccardo Ciolini, and Sandro Paci. 2021. "Preliminary Analysis of an Aged RPV Subjected to Station Blackout" Energies 14, no. 15: 4394. https://doi.org/10.3390/en14154394

APA StyleLo Frano, R., Cancemi, S. A., Darnowski, P., Ciolini, R., & Paci, S. (2021). Preliminary Analysis of an Aged RPV Subjected to Station Blackout. Energies, 14(15), 4394. https://doi.org/10.3390/en14154394