Integration of Portable Sedimentary Microbial Fuel Cells in Autonomous Underwater Vehicles

Abstract

:1. Introduction

2. Materials and Methods

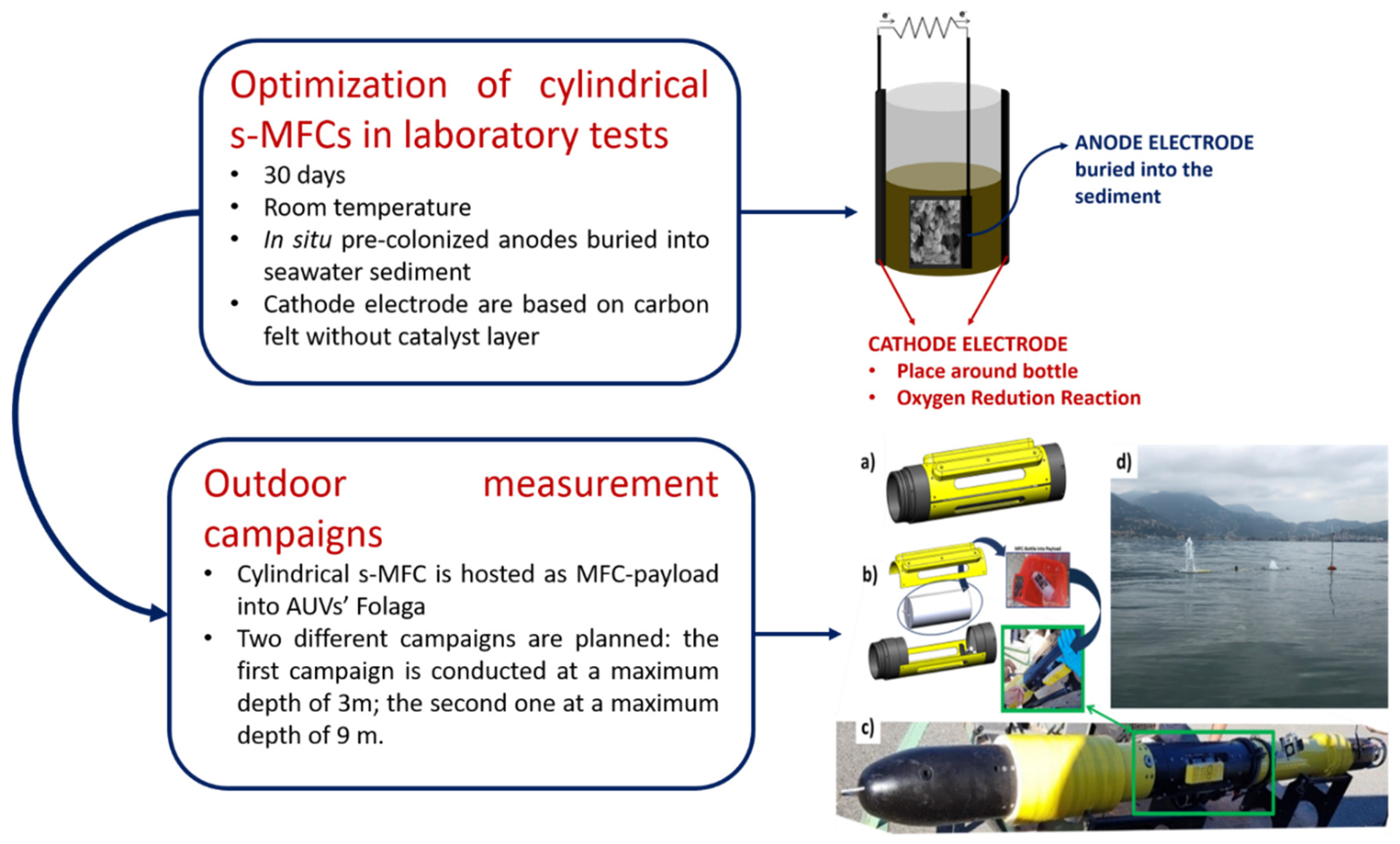

2.1. Structure of the Work/Laboratory Experiments

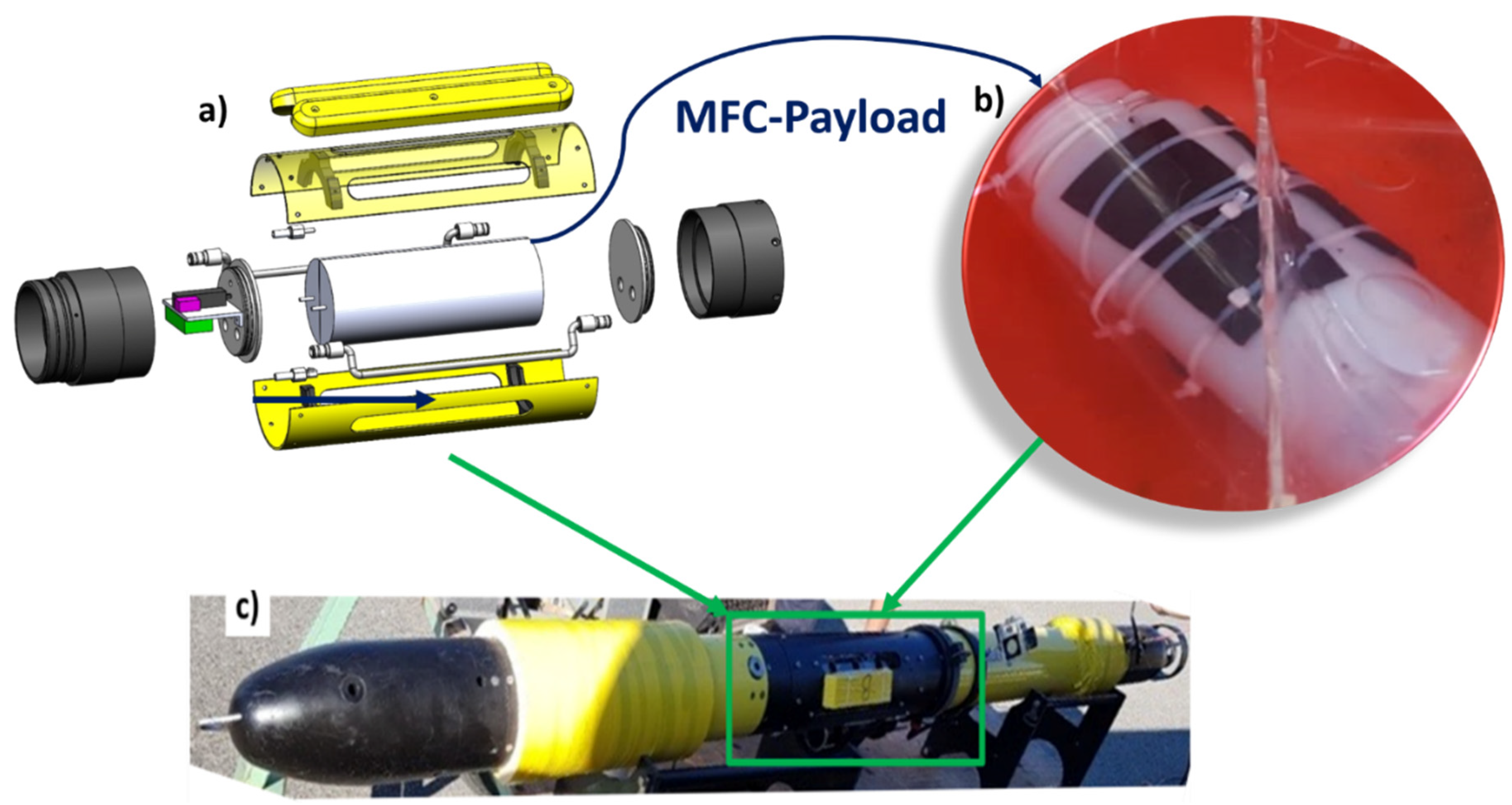

2.2. Development of s-MFCs as Payload

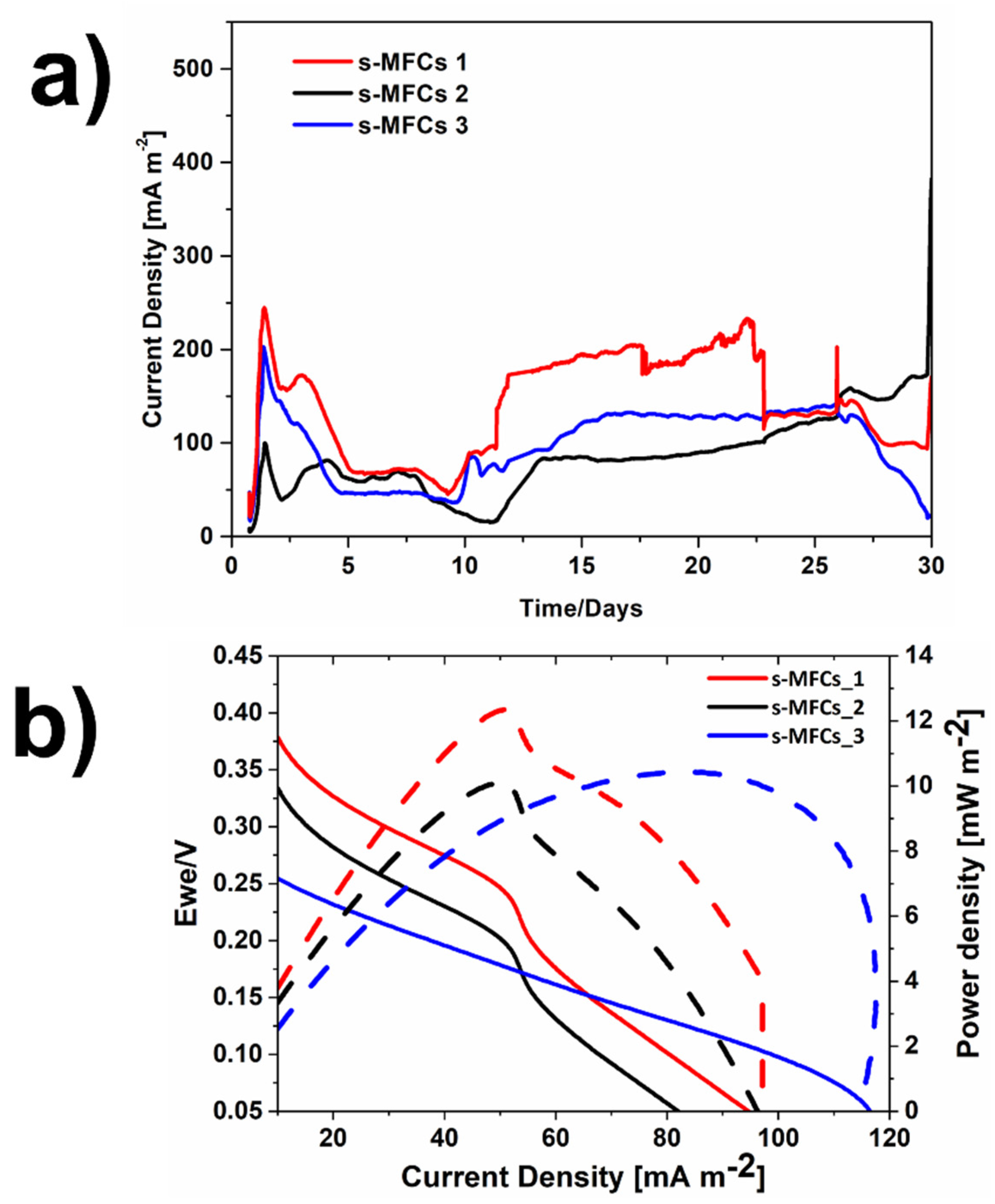

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Bellingham, J. Autonomous Underwater Vehicles (AUVs); MIT Sea Grant: Cambridge, MA, USA, 2001. [Google Scholar] [CrossRef]

- Bellingham, J.G.; Goudey, C.; Consi, T.R.; Chryssostomidis, C. A small long range vehicle for deep ocean exploration. In Proceedings of the Second (1992) International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 14–19 June 1992; pp. 151–159. [Google Scholar]

- Yazdani, A.M.; Sammut, K.; Yakimenko, O.; Lammas, A. A survey of underwater docking guidance systems. Robot. Auton. Syst. 2020, 124, 1–21. [Google Scholar] [CrossRef]

- Huang, H.; Tang, Q.; Li, J.; Zhang, W.; Bao, X.; Zhu, H.; Wang, G. A review on underwater autonomous environmental perception and target grasp, the challenge of robotic organism capture. Ocean. Eng. 2020, 195, 1–11. [Google Scholar] [CrossRef]

- Blidberg, D.R. The development of autonomous underwater vehicles (AUV); a brief summary. IEEE ICRA 2001, 4, 1. [Google Scholar]

- Zhao, S.; Yuh, J. Experimental study on advanced underwater robot control. IEEE Trans. Robot. 2005, 21, 695–703. [Google Scholar] [CrossRef]

- Zeng, Z.; Lian, L.; Sammut, K.; He, F.; Tang, Y.; Lammas, A. A survey on path planning for persistent autonomy of autonomous underwater vehicles. Ocean. Eng. 2015, 110, 303–313. [Google Scholar] [CrossRef]

- Christ, R.D.; Wernli, R.L., Sr. The ROV Manual: A User Guide for Remotely Operated Vehicles; Butterworth-Heinemann: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Yuh, J. Design and Control of Autonomous Underwater Robots: A Survey. Auton. Robot. 2000, 8, 7–24. [Google Scholar] [CrossRef]

- Stewart, M.S.; Pavlos, J. A Means to Networked Persistent Undersea Surveillance. Submarine Technology Symposium; University of Washington: Tacoma, WA, USA, 2006. [Google Scholar]

- Stokey, R.P.; Roup, A.; Von Alt, C.; Allen, B.; Forrester, N.; Austin, T.; Goldsborough, R.; Purcell, M.; Jaffre, F.; Packard, G.; et al. Development of the REMUS 600 autonomous underwater vehicle. In Proceedings of the IEEE Oceans 2005 Conference, Washington, DC, USA, 17–23 September 2005; pp. 1301–1304. [Google Scholar]

- Bradley, A.M.; Feezor, M.D.; Singh, H.; Sorrell, F.Y. Power systems for autonomous underwater vehicles. IEEE J. Ocean. Eng. 2001, 26, 526–538. [Google Scholar] [CrossRef]

- Hagen, P.; Storkersen, N.; Vestgård, K.; Kartvedt, P. The HUGIN 1000 autonomous underwater vehicle for military applications. In Proceedings of the IEEE OCEANS 2003 Conference, 22–26 September. 2003, San Diego, CA, USA; pp. 1141–1145.

- Ferguson, J.; Pope, A. Explorer-a modular AUV for commercial site survey. In Proceedings of the 2000 IEEE International Symposium on Underwater Technology, Tokyo, Japan, 23–26 May 2000; pp. 129–132. [Google Scholar]

- Iqdal, J.; Khan, Z.H. The potential role of renewable energy sources in robot’s power system: A case study of Pakistan. Renew. Sustain. Energy Rev. 2017, 75, 106–122. [Google Scholar]

- Tyagi, V.; Rahim, N.A.; Rahim, N.A.; Jeyraj, A.; Selvaraj, L. Progress in solar PV technology: Research and achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Moosavian, S.; Rahim, N.; Selvaraj, J.; Solangi, K. Energy policy to promote photovoltaic generation. Renew. Sustain. Energy Rev. 2013, 25, 44–58. [Google Scholar] [CrossRef]

- Anusuya, S.; Thiruveni, M.M. Smart battery charger for solar-powered line follower robotic vehicle. Int. J. Comput. Sci. Mob. Comput. 2014, 3, 603–608. [Google Scholar]

- Lever, J.H.; Ray, L.; Streeter, A.; Price, A. Solar power for an Antarctic rover. Hydrol. Process. 2006, 20, 629–644. [Google Scholar] [CrossRef]

- Ackerman, E. AeroVironment’s Mola Robot Flies Underwater on Solar Power, IEEE Spectrum. 2012. Available online: https://spectrum.ieee.org/automaton/robotics/robotics-hardware/aerovironments-mola (accessed on 23 June 2021).

- GHJTL Beatman. Wave glider—A coastal restoration platform. A Liquid Robotics® White Paper, 12 February 2012. [Google Scholar]

- Khan, N.; Kalair, A.; Abas, N.; Haider, A. Review of ocean tidal, wave and thermal energy technologies. Renew. Sustain. Energy Rev. 2017, 72, 590–604. [Google Scholar] [CrossRef]

- Blidberg, D.R.; Chappel, S.; Jalbert, J.C. Long endurance sampling of the ocean with solar powered AUV’s. In Proceedings of the 5th IFAC/EURON Symposium on Intelligent Autonomous Vehicles Instituto Superior Tecnico, Lisboa, Portugal, 5–7 July 2004. [Google Scholar]

- Daniel Steinberg, A.B.; Friedman, A.; Jakuba, M.; Pizarro, O.; Williams, S. Analysis of propulsion methods long-range AUVs. Mar. Technol. Soc. J. 2010, 44, 46–65. [Google Scholar] [CrossRef]

- Naveed, K.; Khan, Z.H.; Salman, M.; Malik, M.B.; Ali, M.U. Adaptive Trajectory Control of Wheeled Mobile Robot (WMR). In Proceedings of the IEEE International Conference on Modeling and Simulation (ICOMS), Melbourne, Australia, 25–27 June 2013. [Google Scholar]

- Manley, J.E. Unmanned surface vehicles, 15 years of development. In Proceedings of the IEEE Unmanned Surface Vehicles, 15 Years of Development, Kobe, Japan, 8–11 April 2008; pp. 1–4. [Google Scholar]

- Mendez, A.; Leo, T.J.; Herreros, M.A. Current State of Technology of Fuel Cell Power Systems for Autonomous Underwater Vehicles. Energies 2014, 7, 4676–4693. [Google Scholar] [CrossRef] [Green Version]

- Ieropoulos, I.A.; Greenman, J.; Melhuish, C.; Horsfield, I. Microbial Fuel Cells for Robotics: Energy Autonomy through Artificial Symbiosis. Chem. Sustain. Chem. 2012, 5, 1020. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E. Microbial Fuel Cells; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Trapero, J.R.; Horcajada, L.; Linares, J.J.; Lobato, J. Is microbial fuel cell technology ready? An economic answer towards industrial commercialization. Appl. Energy 2017, 185, 698–707. [Google Scholar] [CrossRef]

- Christwardana, M.; Frattini, D.; Accardo, G.; Yoon, S.P.; Kwon, Y. Early-stage performance evaluation of flowing microbial fuel cells using chemically treated carbon felt and yeast biocatalyst. Appl. Energy 2018, 222, 369–382. [Google Scholar] [CrossRef]

- Han, H.-X.; Shi, C.; Yuan, L.; Sheng, G.-P. Enhancement of methyl orange degradation and power generation in a photoelectrocatalytic microbial fuel cell. Appl. Energy 2017, 204, 382–389. [Google Scholar] [CrossRef]

- Pandey, P.; Shinde, V.N.; Deopurkar, R.L.; Kale, S.P.; Patil, S.A.; Pant, D. Recent advances in the use of different substrates in microbial fuel cells toward wastewater treatment and simultaneous energy recovery. Appl. Energy 2016, 168, 706–723. [Google Scholar] [CrossRef]

- Tanikkul, P.; Pisutpaisal, N. Membrane-less MFC based biosensor for monitoring wastewater quality. Int. J. Hydrog. Energy 2018, 43, 483–489. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Jafary, T. Power generation from organic substrate in batch and continuous flow microbial fuel cell operations. Appl. Energy 2011, 88, 3999–4004. [Google Scholar] [CrossRef]

- Garino, N.; Sacco, A.; Castellino, M.; Muñoz-Tabares, J.A.; Chiodoni, A.; Agostino, V.; Margaria, V.; Gerosa, M.; Massaglia, G.; Quaglio, M. Microwave-Assisted Synthesis of Reduced Graphene Oxide/SnO2 Nanocomposite for Oxygen Reduction Reaction in Microbial Fuel Cells. Acs Appl. Mater. Interfaces 2016, 8, 4633–4643. [Google Scholar] [CrossRef] [PubMed]

- Ewing, T.; Ha, P.T.; Beyenal, H. Evaluation of long-term performance of sediment microbial fuel cells and the role of natural resources. Appl. Energy 2017, 192, 490–497. [Google Scholar] [CrossRef]

- Song, T.-S.; Jiang, H.-L. Effects of sediment pretreatment on the performance of sediment microbial fuel cells. Bioresour. Technol. 2011, 102, 10465–10470. [Google Scholar] [CrossRef] [PubMed]

- Tender, L.M.; Gray, S.A.; Groveman, E.; Lowy, D.A.; Kauffman, P.; Melhado, J.; Tyce, R.C.; Flynn, D.; Petrecca, R.; Dobarro, J. The first demonstration of a microbial fuel cell as a viable power supply: Powering a meteorological buoy. J. Power Sources 2008, 179, 571–575. [Google Scholar] [CrossRef]

- Massaglia, G.; Margaria, V.; Sacco, A.; Tommasi, T.; Pentassuglia, S.; Ahmed, D.; Mo, R.; Pirri, C.F.; Quaglio, M. In situ continuous current production from marine floating microbial fuel cells. Appl. Energy 2018, 230, 78–85. [Google Scholar] [CrossRef]

- Olias, L.G.; Di Lorenzo, M. Microbial fuel cells for in-field water quality monitoring. Rsc Adv. 2021, 11, 16307–16317. [Google Scholar] [CrossRef]

- Abbas, S.Z.; Rafatullah, M.; Ismail, N.; Syakir, M.I. A review on sediment microbial fuel cells as a new source of sustainable energy and heavy metal remediation: Mechanisms and future prospective. Int. J. Energy Res. 2017, 41, 1242–1264. [Google Scholar] [CrossRef]

- Algar, C.K.; Howard, A.; Ward, C.; Wanger, G. Sediment microbial fuel cells as a barrier to sulfide accumulation and their potential for sediment remediation beneath aquaculture pens. Sci. Rep. 2020, 10, 13087. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.M.; Min, B.-K.; Cho, M.H. Microbial fuel cell assisted band gap narrowed TiO2 for visible light-induced photocatalytic activities and power generation. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.E.; Han, T.H.; Khan, M.M.; Karim, M.R.; Cho, M.H. Environmentally Sustainable Fabrication of Ag@g-C3N4 Nanostructures and Their Multifunctional Efficacy as Antibacterial Agents and Photocatalysts. Acs Appl. Nano Mater. 2018, 1, 2912–2922. [Google Scholar] [CrossRef]

- Wilkinson, S. “Gastrobots”—Benefits and Challenges of Microbial Fuel Cells in Food Powered Robot Applications. Auton. Robot. 2000, 9, 99–111. [Google Scholar] [CrossRef]

- Ieropoulos, I.; Melhuish, C.; Greenman, J.; Horsfield, I. EcoBot-II: An artificial agent with a natural metabolism. Int. J. Adv. Robot. Syst. 2005, 2, 295–300. [Google Scholar] [CrossRef]

- Ieropoulos, I.; Greenman, J.; Melhuish, C.; Horsfield, I. EcoBot-III-A Robot with Guts. ALIFE 2010, 733, e40. [Google Scholar]

- Hong, S.W.; Chang, I.S.; Choi, Y.S.; Chung, T.H. Experimental evaluation of influential factors for electricity harvesting from sediment using microbial fuel cell. Bioresour. Technol. 2009, 100, 3029–3035. [Google Scholar] [CrossRef]

- Hsu, L.; Mohamed, A.; Ha, P.T.; Bloom, J.; Ewing, T.; Arias-Thode, M.; Chadwick, B.; Beyenal, H. The Influence of Energy Harvesting Strategies on Performance and Microbial Community for Sediment Microbial Fuel Cells. J. Electrochem. Soc. 2017, 164, H3109–H3114. [Google Scholar] [CrossRef]

- Wetser, K.; Dieleman, K.; Buisman, C.; Strik, D. Electricity from wetlands: Tubular plant microbial fuels with silicone gas-diffusion biocathodes. Appl. Energy 2017, 185, 642–649. [Google Scholar] [CrossRef] [Green Version]

- Massaglia, G.; Fiorello, I.; Sacco, A.; Margaria, V.; Pirri, C.F.; Quaglio, M. Biohybrid Cathode in Single Chamber Microbial Fuel Cell. Nanomaterials 2019, 9, 36–47. [Google Scholar] [CrossRef] [Green Version]

- Nastro, R.A.; Jannelli, N.; Minutillo, M.; Guida, M.; Trifuoggi, M.; Andreassi, L.; Facci, A.L.; Krastev, V.K.; Falcucci, G. Performance evaluation of Microbial Fuel Cells fed by solid organic waste: Parametric comparison between three generations. Energy Procedia 2017, 105, 1102–1108. [Google Scholar] [CrossRef]

- Jannelli, N.; Nastro, R.A.; Cigolotti, V.; Minutillo, M.; Falcucci, G. Low pH, high salinity: Too much for microbial fuel cells? Appl. Energy 2017, 192, 543–550. [Google Scholar] [CrossRef] [Green Version]

- Aguzzi, J.; Costa, C.; Calisti, M.; Funari, V.; Stefanni, S.; Danovaro, R.; Gomes, H.I.; Vecchi, F.; Dartnell, L.R.; Weiss, P.; et al. Research Trends and Future Perspectives in Marine Biomimicking Robotics. Sensors 2021, 21, 3778. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Molognoni, D.; Dallago, E.; Liberale, A.; Cella, R.; Longoni, P.; Pantaleoni, L. Microbial Fuel Cells for Direct Electrical Energy Recovery from Urban Wastewaters. Sci. World J. 2013, 2013, 634738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Massaglia, G.; Frascella, F.; Chiadò, A.; Sacco, A.; Marasso, S.L.; Cocuzza, M.; Pirrin, C.F.; Quaglio, M. Electrospun Nanofibers: From Food to Energy by Engineered Electrodes in Microbial Fuel Cells. Nanomaterials 2020, 10, 523–534. [Google Scholar] [CrossRef] [Green Version]

- Heidrich, E.S.; Wade, M.J.; Sloan, W.T.; Quince, C.; Curtis, T.P. Temperature, inocula and substrate: Contrasting electroactive consortia, diversity and performance in microbial fuel cells. Bioelectrochemistry 2018, 119, 43–50. [Google Scholar] [CrossRef]

- Jadhav, G.; Ghangrekar, M. Performance of microbial fuel cell subjected to variation in pH, temperature, external load and substrate concentration. Bioresour. Technol. 2009, 100, 717–723. [Google Scholar] [CrossRef] [PubMed]

- Gadkari, S.; Fotnmorin, J.M.; Yu, E.; Sadhukhan, J. Influence of temperature and other system parameters on microbial fuel cells performance: Numerical and experimental investigation. Chem. Eng. J. 2020, 388, 124176. [Google Scholar] [CrossRef]

- Margaria, V.; Tommasia, T.; Pentassuglia, S.; Agostino, V.; Sacco, A.; Armato, C.; Chiodoni, A.; Schilirò, A.; Quaglio, M. Effects of pH variations on anodic marine consortia in a dual chamber microbial fuel cell. Int. J. Hydrog. Energy 2017, 42, 1820–1829. [Google Scholar] [CrossRef]

| Depth [m] | Temperature [°C] | Conductivity [mS/cm) | Salinity [ppt] | pH Values |

|---|---|---|---|---|

| 0 | 26.65 ± 0.02 | 58.98 ± 0.08 | 38.11 ± 0.02 | 8.06 |

| 1 | 18.72 ± 0.01 | 50.09 ± 0.02 | 37.95 ± 0.01 | 7.99 |

| 3 | 13.28 ± 0.03 | 41.46 ± 0.21 | 35.21 ± 0.22 | 7.64 |

| 6 | 13.07 ± 0.08 | 37.74 ± 0.77 | 31.88 ± 0.76 | 7.79 |

| Depth [m] | Voltage [mV] | Current [mA] | Power [mW] |

|---|---|---|---|

| 0 | 440 | 0.647 | 0.285 |

| 1 | 290 | 0.426 | 0.124 |

| 3 | 210 | 0.309 | 0.065 |

| 4 | 220 | 0.324 | 0.071 |

| 6 | 190 | 0.279 | 0.053 |

| 9 | 192 | 0.282 | 0.054 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massaglia, G.; Sacco, A.; Favetto, A.; Scaltrito, L.; Ferrero, S.; Mo, R.; Pirri, C.F.; Quaglio, M. Integration of Portable Sedimentary Microbial Fuel Cells in Autonomous Underwater Vehicles. Energies 2021, 14, 4551. https://doi.org/10.3390/en14154551

Massaglia G, Sacco A, Favetto A, Scaltrito L, Ferrero S, Mo R, Pirri CF, Quaglio M. Integration of Portable Sedimentary Microbial Fuel Cells in Autonomous Underwater Vehicles. Energies. 2021; 14(15):4551. https://doi.org/10.3390/en14154551

Chicago/Turabian StyleMassaglia, Giulia, Adriano Sacco, Alain Favetto, Luciano Scaltrito, Sergio Ferrero, Roberto Mo, Candido F. Pirri, and Marzia Quaglio. 2021. "Integration of Portable Sedimentary Microbial Fuel Cells in Autonomous Underwater Vehicles" Energies 14, no. 15: 4551. https://doi.org/10.3390/en14154551

APA StyleMassaglia, G., Sacco, A., Favetto, A., Scaltrito, L., Ferrero, S., Mo, R., Pirri, C. F., & Quaglio, M. (2021). Integration of Portable Sedimentary Microbial Fuel Cells in Autonomous Underwater Vehicles. Energies, 14(15), 4551. https://doi.org/10.3390/en14154551