Analysis of Yield Potential and Regional Distribution for Bioethanol in China

Abstract

:1. Introduction

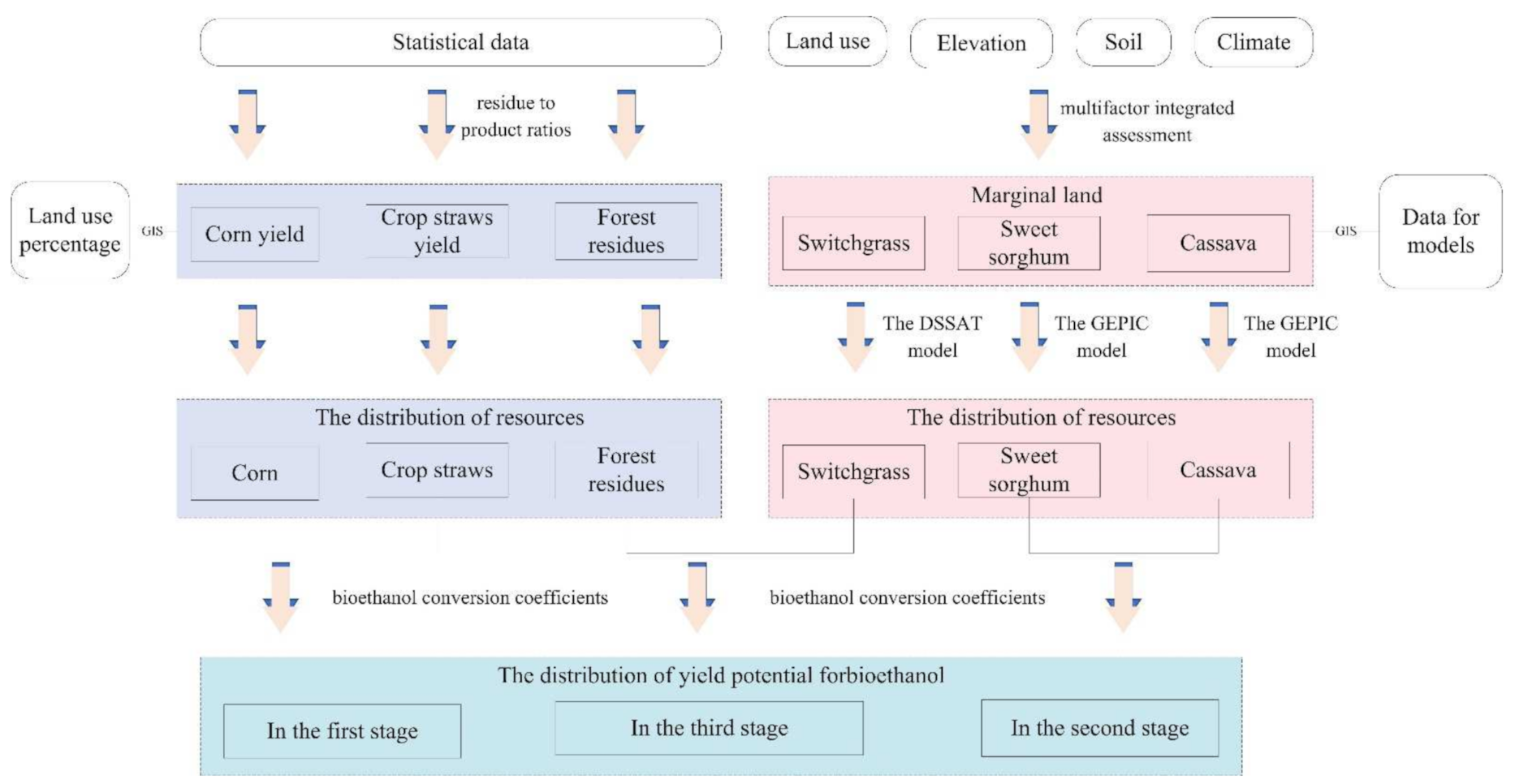

2. Materials and Methods

2.1. Evaluation of Feedstock Yields

2.2. Evaluation of Bioethanol Potential

2.3. Data

3. Results and Analysis

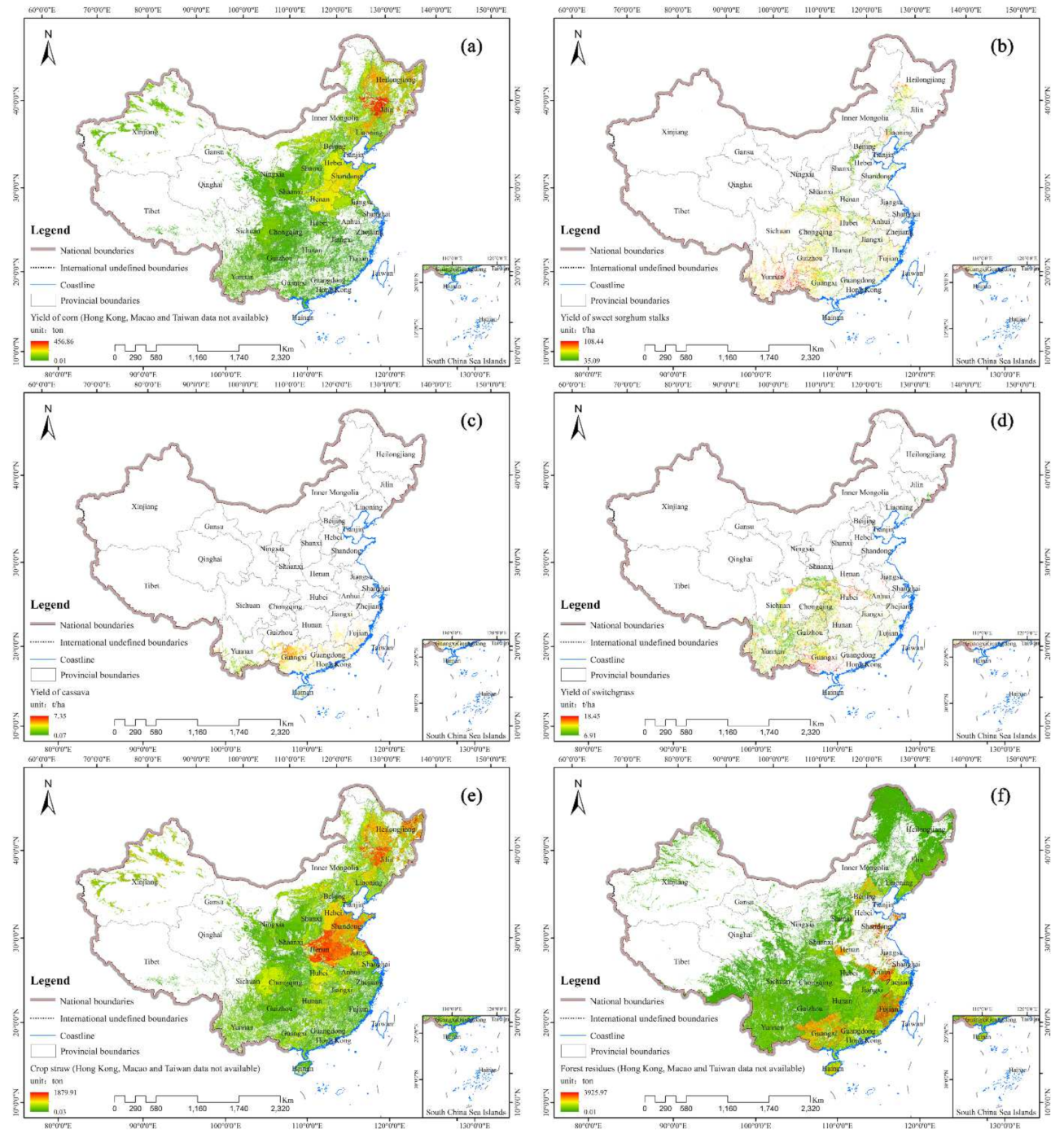

3.1. Distribution of Bioethanol Feedstock Resources

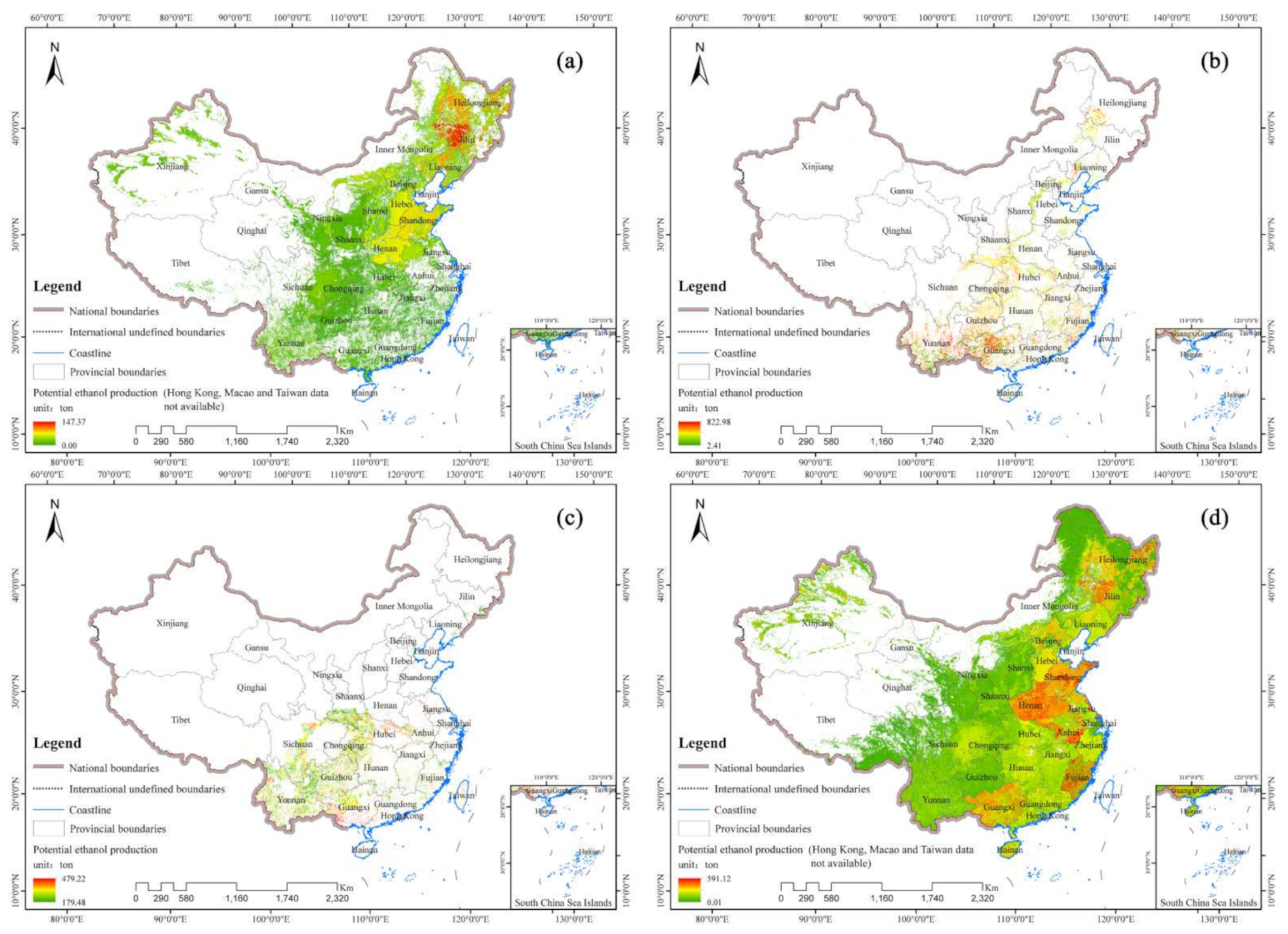

3.2. Distribution of Bioethanol Yield Potential in Three Stages

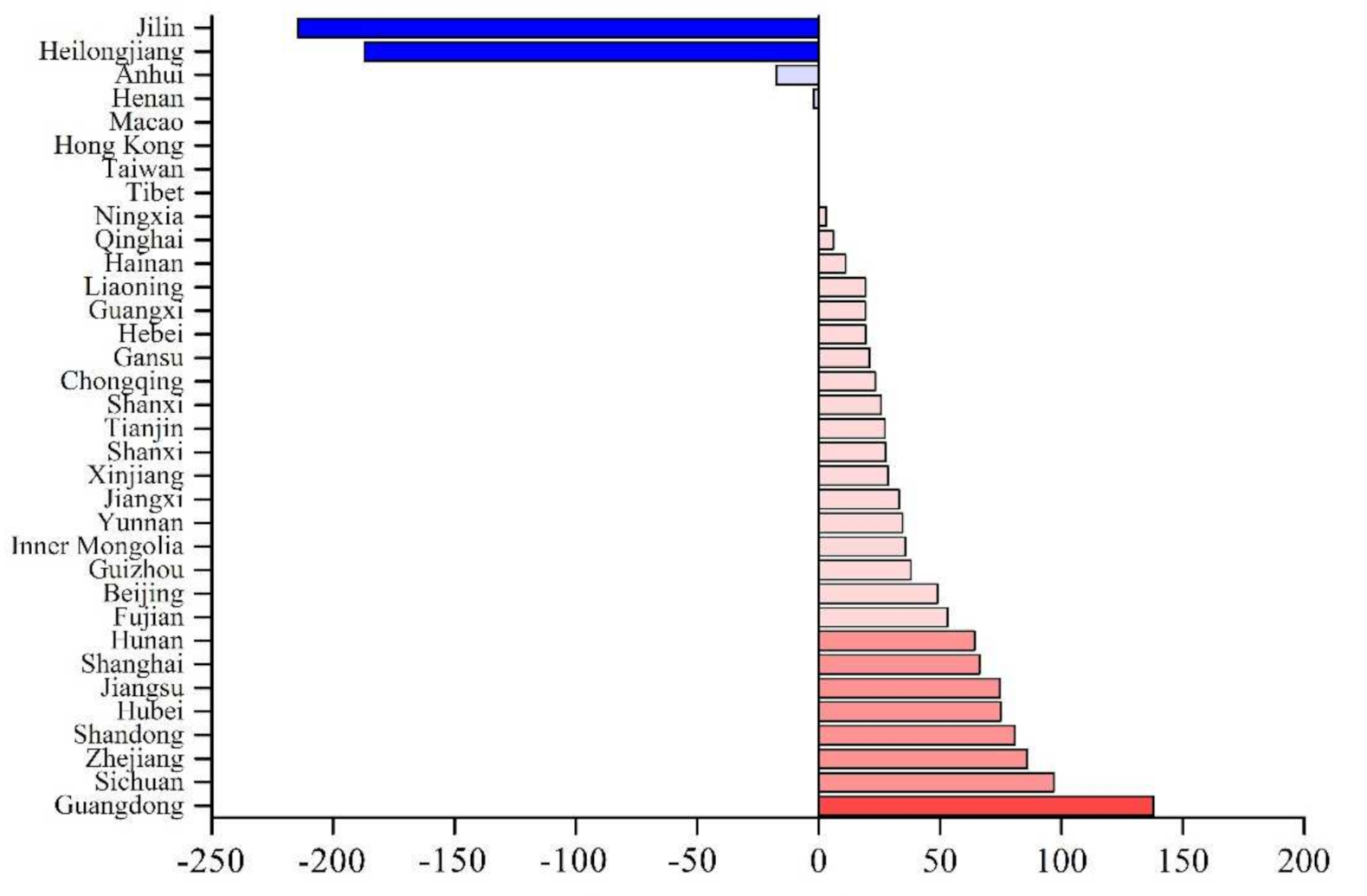

3.3. Comparison of Bioethanol Production Potential and Demand

4. Discussion

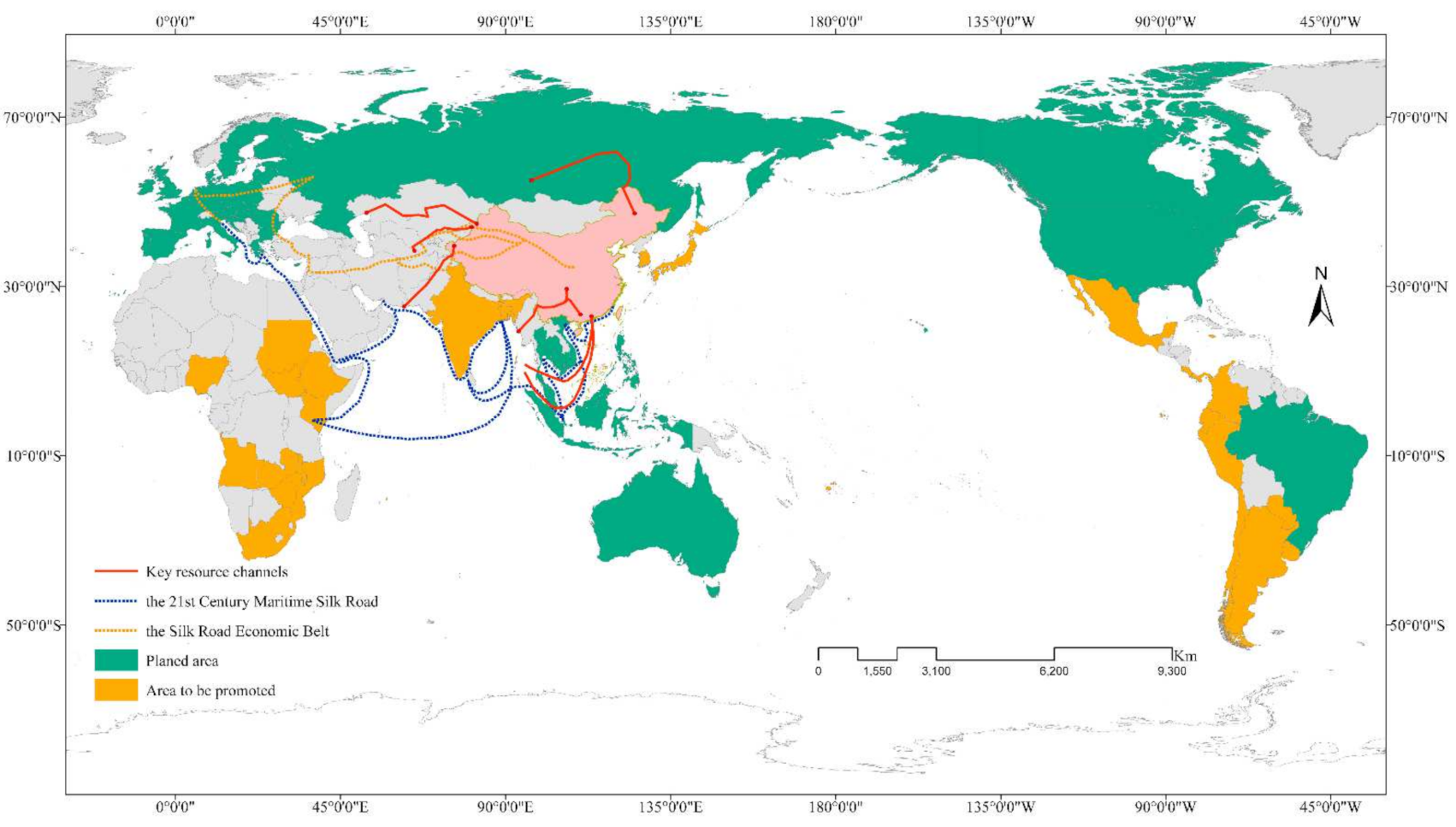

4.1. Prospects for International Development

4.2. Comparison with Other Studies

4.3. Research Uncertainties and Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- 1.

- Evaluation of Straw Yields

| RPR | RPRs | |||

|---|---|---|---|---|

| grain | rice | 1.0 | cotton | 3.0 |

| wheat | 1.1 | oil crops | 2.0 | |

| corn | 2.0 | fiber | 1.7 | |

| beans | 1.7 | sugar cane | 0.1 | |

| tubers | 1.0 | sugar beet | 0.1 |

- 2.

- Evaluation of Non-Grain Energy Plant Yields

| Factors | Specific Parameters | Sweet Sorghum [17,40,41] | Cassava [41,42] | Switchgrass [17,43] |

|---|---|---|---|---|

| Threshold | ||||

| Land use | land use type | shrub land, sparse forest land, grassland, shoal/bottomland, alkaline land, and bare land | ||

| nature reserve | excluding nature reserve | |||

| grassland | excluding middle and high coverage grassland in Qinghai, Xinjiang, Inner Mongolia, Tibet, and Ningxia Province | |||

| Terrain | slope/° | <25 | <25 | <25 |

| elevation/m | - | <2000 | - | |

| Soil | organic matter content/% | >1.5 | >1.5 | >1.5 |

| PH (H2O) | 5.0–8.5 | - | 4.9–7.6 | |

| effective depth/cm | ≥30 | ≥30 | - | |

| sand content/% | ≤85 | ≤85 | - | |

| salinity/% | <0.6 | - | - | |

| Temperature | annual average temperature/°C | - | ≥18 | - |

| ≥10 °C accumulated temperature/°C | ≥1500 | ≥2000 | - | |

| minimum temperature in April–June | >15 | - | - | |

| Moisture | annual precipitation/mm | ≥300 | 600–6000 | ≥800 |

| Minimum continuous growth area | area/hm2 | ≥200 | ≥200 | ≥200 |

References

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- REN21. Renewable 2009 Global Status Report; REN21 Secretariat: Paris, France; Worldwatch Institute: Washington, DC, USA, 2009. [Google Scholar]

- REN21. Renewable 2019 Global Status Report; REN21 Secretariat: Paris, France; Worldwatch Institute: Washington, DC, USA, 2019. [Google Scholar]

- Balat, M.; Balat, H. Recent trends in global production and utilization of bio-ethanol fuel. Appl. Energy 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenerg 2004, 26, 361–375. [Google Scholar] [CrossRef]

- Wu, C.; Zhou, Z.; Yin, X.; Yi, W. Current Status of Biomass Energy Development in China. Trans. Chin. Soc. Agric. Mach. 2009, 40, 97–105. [Google Scholar]

- Galbe, M.; Zacchi, G. Pretreatment of Lignocellulosic Materials for Efficient Bioethanol Production. Adv. Biochem. Eng. Biotechnol. 2007, 108, 41–65. [Google Scholar]

- Limayem, A.; Ricke, S.C. Lignocellulosic biomass for bioethanol production: Current perspectives, potential issues and future prospects. Prog. Energy Combust. Sci. 2012, 38, 449–467. [Google Scholar] [CrossRef]

- Jiang, D.; Hao, M.; Fu, J.; Liu, K.; Yan, X. Potential bioethanol production from sweet sorghum on marginal land in China. J. Clean. Prod. 2019, 220, 225–234. [Google Scholar] [CrossRef]

- Huang, J.; Khan, M.T.; Perecin, D.; Coelho, S.T.; Zhang, M. Sugarcane for bioethanol production: Potential of bagasse in Chinese perspec-tive. Renew. Sustain. Energy Rev. 2020, 133, 110296. [Google Scholar] [CrossRef]

- Wang, C.; Malik, A.; Wang, Y.; Chang, Y.; Pang, M.; Zhou, D. Understanding the resource-use and environmental impacts of bioethanol production in China based on a MRIO-based hybrid LCA model. Energy 2020, 203, 117877. [Google Scholar] [CrossRef]

- Tian, S.; Youssef, M.A.; Chescheir, G.M.; Skaggs, R.W.; Cacho, J.; Nettles, J. Development and preliminary evaluation of an integrated field scale model for perennial bioenergy grass ecosystems in lowland areas. Environ. Model. Softw. 2016, 84, 226–239. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.R.; Wu, Y.; Xie, G.H. Crop residue utilizations and potential for bio-ethanol production in China. Renew. Sustain. Energy Rev. 2019, 113, 109288. [Google Scholar] [CrossRef]

- China National Renewable Energy Centre. China Liquid Biofuel Development Roadmap; China National Renewable Energy Centre: Beijing, China, 2018. [Google Scholar]

- Liu, G.; Shen, L. Quantitive Appraisal of Biomass Energy and Its Geographical Distribution in China. J. Nat. Resour. 2007, 22, 9–19. [Google Scholar]

- Yan, X. Assessing the Sweet Sorghum-Based Ethanol Energy Potential with DSSAT Model and Life Cycle Assessment Approaches; University of Chinese Academy of Sciences: Beijing, China, 2018. [Google Scholar]

- Fu, J. Assessment of the Non-Grain Based Fuel Ethanol Potential in China; University of Chinese Academy of Sciences: Beijing, China, 2015. [Google Scholar]

- Feng, W. Research on Life Circle Energy Balance and Carbon Emission of Whole-Plant Corn Fuel Ethanol; Zhengzhou University: Zhengzhou, China, 2013. [Google Scholar]

- Tian, Y.; Li, S.; Zhao, L.; Meng, H.; Huo, L. Life Cycle Assessment on Fuel Ethanol Producing from Sweet Sorghum Stalks. Trans. Chin. Soc. Agric. Mach. 2011, 42, 132–137. [Google Scholar]

- Xia, X.; Zhang, J.; Xi, B. Fuel Ethanol Analysis and Policy Research Based on the Life Cycle; China Environmental Science Press: Beijing, China, 2012. [Google Scholar]

- Li, Z.; Li, D.; Huang, G.; Wei, H. Insights on current development of fuel ethanol. Chem. Ind. Eng. Prog. 2013, 32, 1457–1467. [Google Scholar]

- Nie, Y.; Chang, S.; Cai, W.; Wang, C.; Fu, J.; Hui, J.; Yu, L.; Zhu, W.; Huang, G.; Kumar, A.; et al. Spatial distribution of usable biomass feedstock and technical bioenergy potential in China. Glob. Chang. Biol. Bioenergy 2020, 12, 54–70. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.; Zhang, C.; Yu, D. Assessment of the Potential of Forest Biomass Energy in China. J. Beijing For. Univ. (Soc. Sci.) 2015, 14, 52–55. [Google Scholar]

- Zhang, Z. Current Situation and Development Trend of Domestic Bioethanol Processing Industry. China Grain Econ. 2011, 11, 17–20. [Google Scholar]

- ETRI. China Energy Outlook 2050; ETRI: Beijing, China, 2017. [Google Scholar]

- An, F.; Kang, L.; Qin, L.; Mao, S.; Wang, W.; Dror, M.B. Study on the phasing-out timetable of China’s traditional ICE-vehicles. Int. Pet. Econ. 2019, 27, 1–8. [Google Scholar]

- Lou, Y. The supply and demand market for ethanol gasoline and fuel ethanol in China. Int. Pet. Econ. 2019, 27, 68–74. [Google Scholar]

- Wang, H.; Tu, Y.; Zhang, N.; Si, B.; Ma, T.; Rula, S.; Na, Y.; Diao, Q. Chinese crop straw resource and its utilization status. Sci. Technol. Rev. 2017, 35, 81–88. [Google Scholar]

- Yu, J.; Shi, K.; Wang, S.; Xu, Z.; Zhai, R.; Wen, Z.; Jin, M. Analysis of crop straw distribution in China and research progress on converting crop straw into fuel ethanol. Biotechnol. Bus. 2018, 4, 33–40. [Google Scholar]

- Yan, X.; Jiang, D.; Fu, J.; Hao, M. Assessment of Sweet Sorghum-Based Ethanol Potential in China within the Water-Energy-Food Nexus Framework. Sustainability 2018, 10, 1046. [Google Scholar] [CrossRef] [Green Version]

- Dai, D.; Hu, Z.; Pu, G.; Li, H.; Wang, C. Energy efficiency and potentials of cassava fuel ethanol in Guangxi region of China. Energy Convers. Manag. 2006, 47, 1686–1699. [Google Scholar] [CrossRef]

- Jiang, D.; Hao, M.; Fu, J.; Huang, Y.; Liu, K. Evaluating the bioenergy potential of cassava on marginal land using a biogeochemical process model in GuangXi, China. J. Appl. Remote Sens. 2015, 9, 097699. [Google Scholar] [CrossRef]

- Fu, H.M.; Meng, F.Y.; Molatudi, R.L.; Zhang, B.G. Sorghum and Switchgrass as Biofuel Feedstocks on Marginal Lands in Northern China. Bioenergy Res. 2016, 9, 633–642. [Google Scholar] [CrossRef]

- Duan, X.; Zhou, Z.; Xu, J.; Tian, Y.; Wang, R. Utilization Situation and Suggestion of Forestry Residues Resources in China. China Wood-Based Panels 2017, 24, 1–5. [Google Scholar]

- Wu, C.W.; Chen, X.B.; Sun, Y.P.; Jiang, M.L.; Yan, K.; Zhang, L.H. Marginal Land-Based Biomass Energy Production in Yellow River Delta. Adv. Mater. Res. 2014, 860–863, 544–549. [Google Scholar] [CrossRef]

- Li, X.F.; Hou, S.L.; Su, M.; Yang, M.F.; Shen, S.H.; Jiang, G.M.; Qi, D.M.; Chen, S.Y.; Liu, G.S. Major Energy Plants and Their Potential for Bioenergy Development in China. Environ. Manag. 2010, 46, 579–589. [Google Scholar] [CrossRef]

- Lu, Q.; Zhao, X.B.; Zheng, Z.M. Technology and Engineering for Liquid Biofuels; Shanghai Scientific & Technical Publishers: Shanghai, China, 2003. [Google Scholar]

- Fu, J.; Jiang, D.; Huang, Y.; Zhuang, D.; Ji, W. Evaluating the Marginal Land Resources Suitable for Developing Bioenergy in Asia. Adv. Meteorol. 2014, 2014, 238945. [Google Scholar] [CrossRef] [Green Version]

- Jiang, D.; Hao, M.; Fu, J.; Zhuang, D.; Huang, Y. Spatial-temporal variation of marginal land suitable for energy plants from 1990 to 2010 in China. Sci. Rep. 2014, 4, 5816. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Chen, G.; Zhang, H.; Liu, B.; Yang, Y.; Qin, L.; Chen, E.; Guan, Y. Identification of QTLs for salt tolerance at germination and seedling stage of Sorghum bicolor L. Moench. Euphytica 2014, 196, 117–127. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, C.; Zhang, B.; Xie, G. Methodology and certification criteria of non-food land suitable for energy plant production in China. J. China Agric. Univ. 2015, 20, 11–20. [Google Scholar]

- Hao, M. Evaluation of Energy Saving Potential and GHG Reduction Potential of Bio-Fuel Ethanol Fromcassava at Large Scale; University of Chinese Academy of Sciences: Beijing, China, 2015. [Google Scholar]

- Xie, G.; Zhuang, H.; Wei, W.; Zhuo, Y.; Guo, X. Non-Grain Energy Plants: Production Principle and Cultivation in Marginal Land; China Agricultural University Press: Beijing, China, 2011. [Google Scholar]

| USA | Brazil | China | Canada | Thailand | India | Argentina | EU-28 | Others | |

|---|---|---|---|---|---|---|---|---|---|

| Ethanol | 60.9 | 33.0 | 4.1 | 1.9 | 1.5 | 1.4 | 1.2 | 4.4 | 3.5 |

| Share of total (%) | 54.42 | 29.49 | 3.66 | 1.70 | 1.34 | 1.25 | 1.07 | 3.93 | 3.13 |

| Corn | Sweet Sorghum | Cassava | Switchgrass | Crop Straw | Forest Residue | |

|---|---|---|---|---|---|---|

| conversion coefficient | 3.1 [18] | 16 [19] | 2.9 [20] | 3.85 [17] | 6 [21] | 7.5 [21] |

| Factors | Specific Parameter | Resolution | Data Source |

|---|---|---|---|

| Land use | land use type | 1 km | RESDC 1 |

| land use percentage data | 1 km | RESDC | |

| DEM 2 | 1 km | SRTM 3. V4 | |

| Soil | PH (H2O), organic matter content, effective depth, sand content, and salinity | 1 km | RESDC, CARD 4 |

| Temperature | annual average temperature, monthly minimum temperature, and ≥10 °C accumulated temperature | 1 km | RESDC, CMA 5 |

| Moisture | annual precipitation | 1 km | RESDC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, J.; Du, J.; Lin, G.; Jiang, D. Analysis of Yield Potential and Regional Distribution for Bioethanol in China. Energies 2021, 14, 4554. https://doi.org/10.3390/en14154554

Fu J, Du J, Lin G, Jiang D. Analysis of Yield Potential and Regional Distribution for Bioethanol in China. Energies. 2021; 14(15):4554. https://doi.org/10.3390/en14154554

Chicago/Turabian StyleFu, Jingying, Jinshuang Du, Gang Lin, and Dong Jiang. 2021. "Analysis of Yield Potential and Regional Distribution for Bioethanol in China" Energies 14, no. 15: 4554. https://doi.org/10.3390/en14154554