Modeling of Interconnected Infrastructures with Unified Interface Design toward Smart Cities

Abstract

:1. Introduction

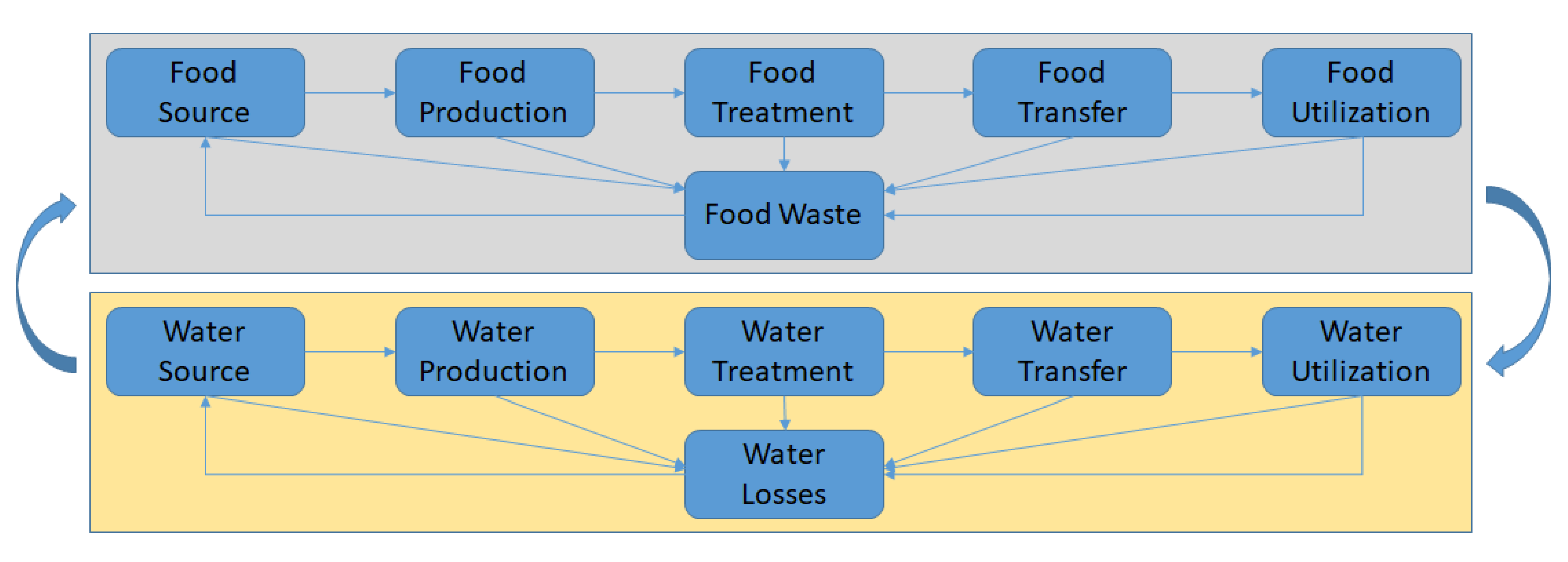

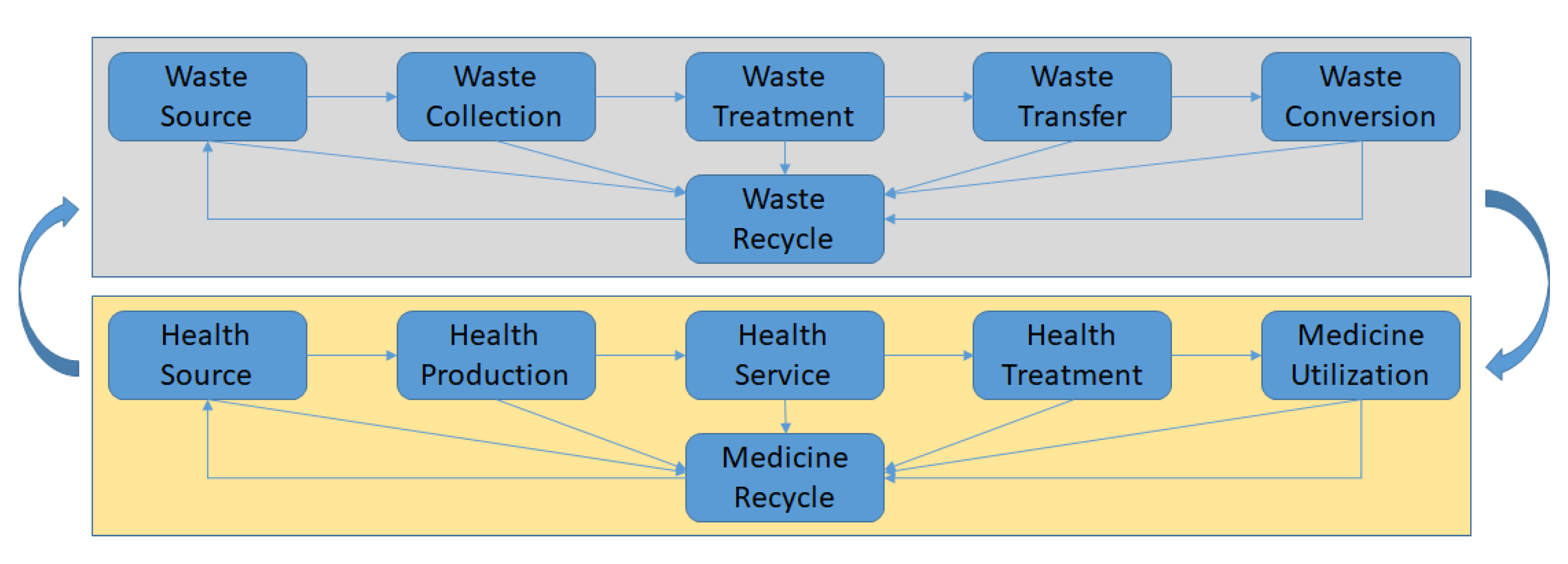

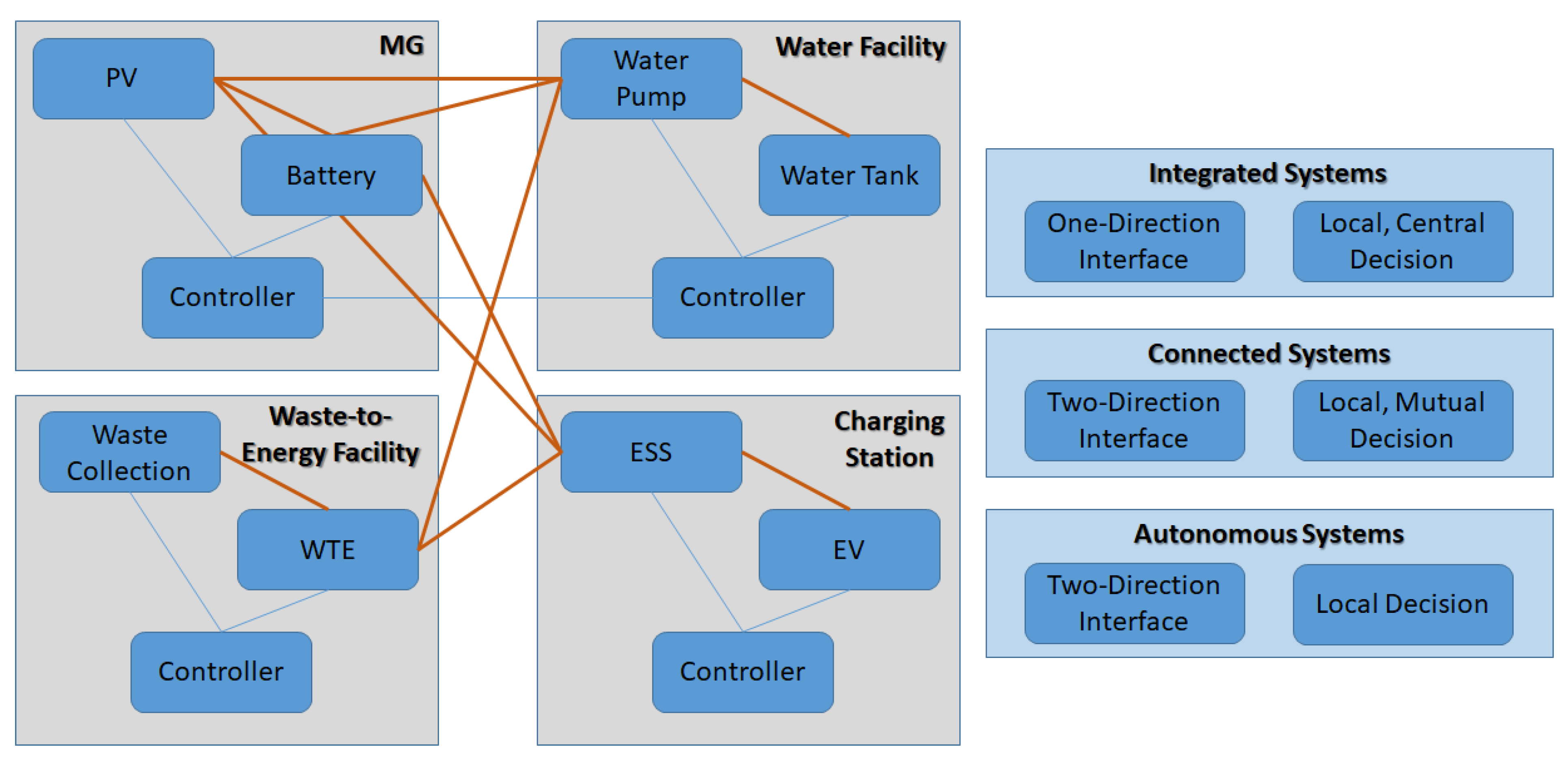

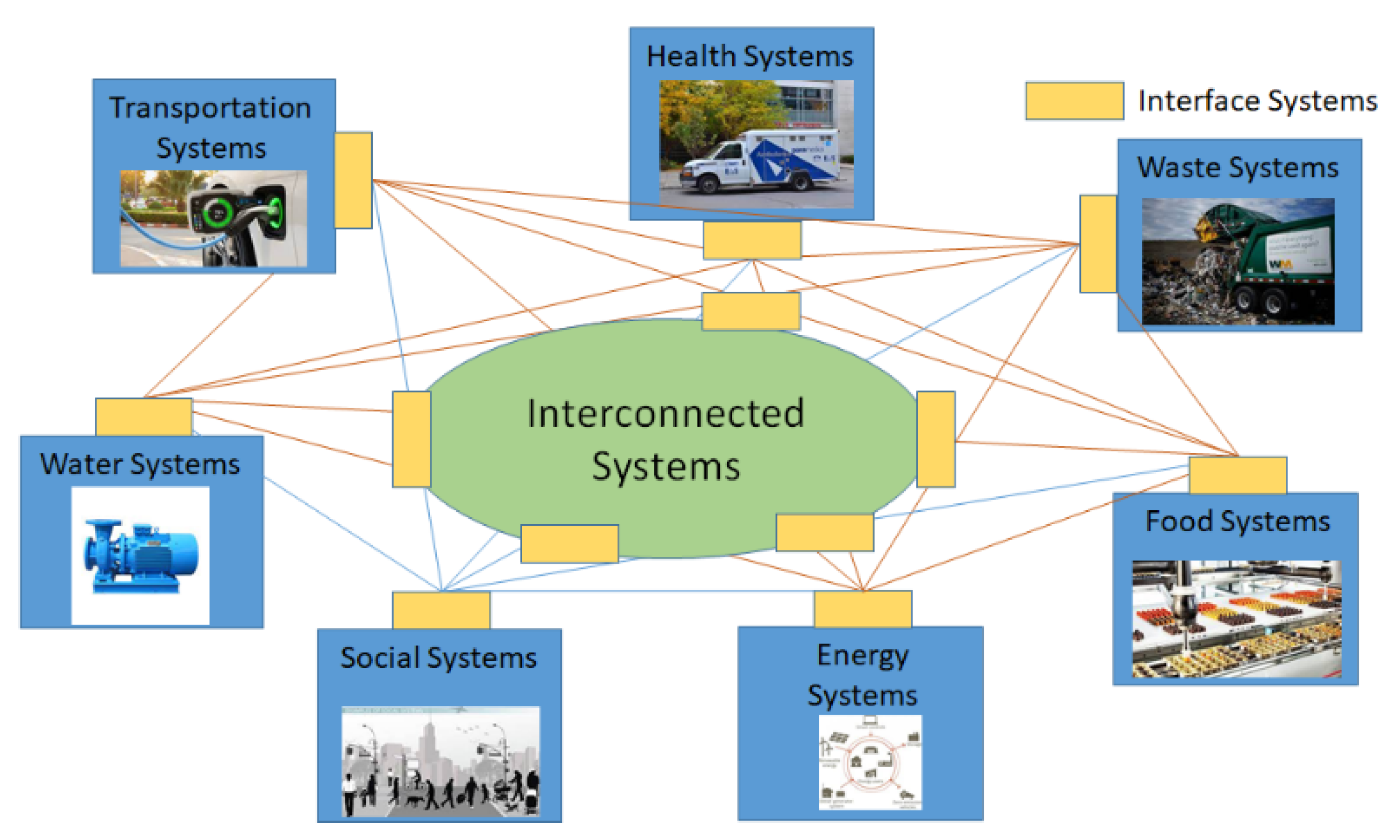

2. Interconnected System Modeling

3. Case Study

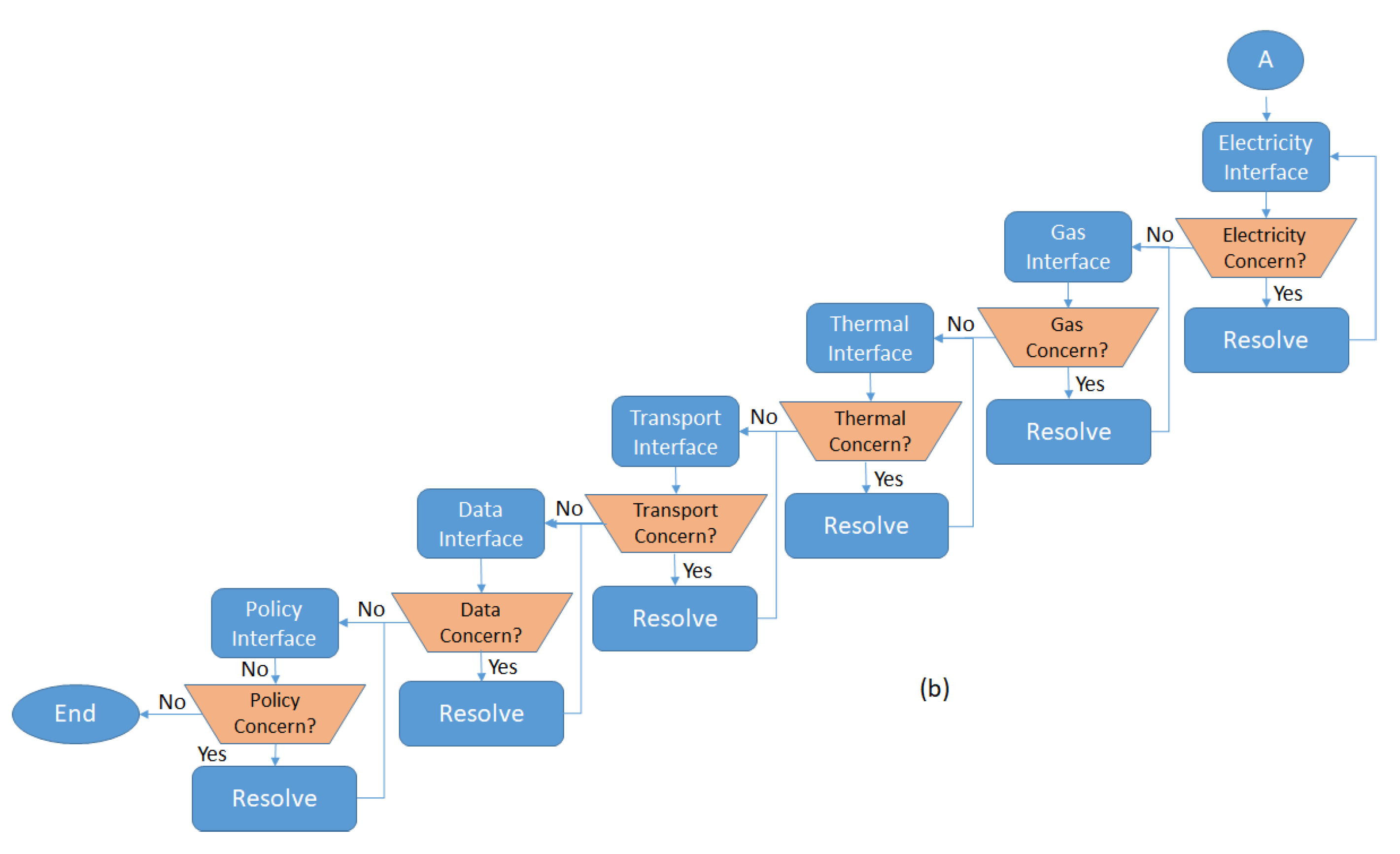

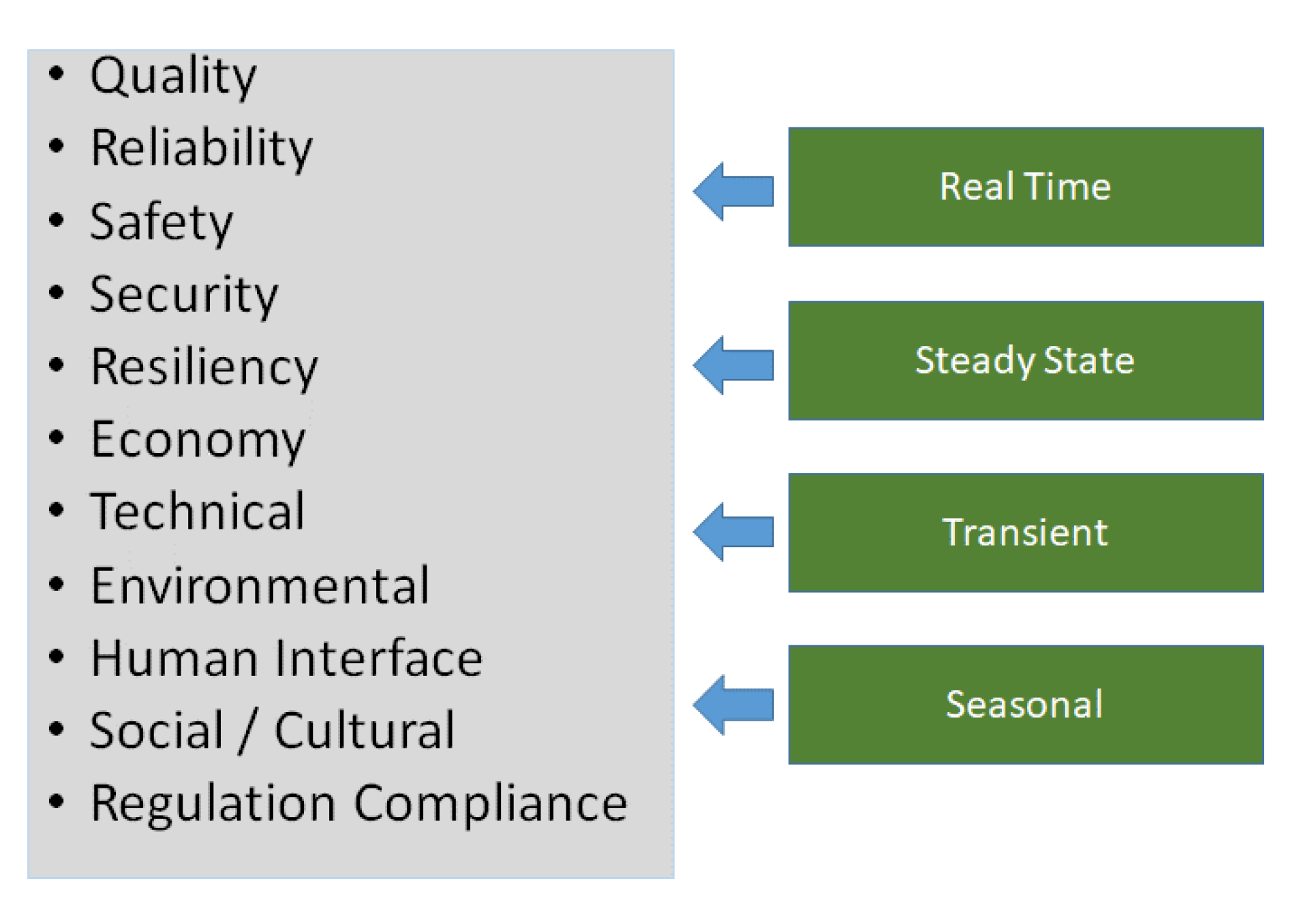

4. Unified Interface Modeling

5. Analysis of Unified Interface System Implementation

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- UN World Population Prospects: The 2017 Revision; Population Division, Department of Economic and Social Affairs, United Nations: New York, NY, USA, 2017.

- Kaundinya, D.P.; Balachandra, P.; Ravindranath, N.H. Grid-connected versus stand-alone energy systems for decentralized power—A review of literature. Renew. Sustain. Energy Rev. 2009, 13, 2041–2050. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Optimum design of hybrid renewable energy systems: Overview of different approaches. Renew. Sustain. Energy Rev. 2012, 16, 1412–1425. [Google Scholar] [CrossRef]

- Levina, T.; Thomas, V.M. Least-cost network evaluation of centralized and decentralized contributions to global electrification. Energy Policy 2012, 41, 286–302. [Google Scholar] [CrossRef]

- Ma, T.; Wu, J.; Hao, L.; Lee, W.; Yan, H.; Li, D. The optimal structure planning and energy management strategies of smart multi energy systems. Energy 2018, 160, 122–141. [Google Scholar] [CrossRef]

- Shabanpour-Haghighi, A.; Seif, A.R. Effects of district heating networks on optimal energy flow of multi-carrier systems. Renew. Sustain. Energy Rev. 2016, 59, 379–387. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M. Load management in a residential energy hub with renewable distributed energy resources. Energy Build. 2015, 107, 234–242. [Google Scholar] [CrossRef]

- Mohammadia, M.; Noorollahia, Y.; Mohammadi-ivatloo, B.; Hosseinzadehc, M.; Yousefia, H.; Khorasani, S.T. Optimal management of energy hubs and smart energy hubs—A review. Renew. Sustain. Energy Rev. 2018, 89, 33–50. [Google Scholar] [CrossRef]

- Lund, H.; Andersen, A.N.; Østergaard, P.A.; Mathiesen, B.V.; Connolly, D. From electricity smart grids to smart energy systems e A market operation based approach and understanding. Energy 2012, 42, 96–102. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart energy and smart energy systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Abedi, S.; Alimardani, A.; Gharehpetian, G.B.; Riahy, G.H.; Hosseinian, S.H. A comprehensive method for optimal power management and design of hybrid RES-based autonomous energy systems. Renew. Sustain. Energy Rev. 2012, 16, 1577–1587. [Google Scholar] [CrossRef]

- Nasiakou, A.; Vavalis, M.; Zimeris, D. Smart energy for smart irrigation. Comput. Electron. Agric. 2016, 129, 74–83. [Google Scholar] [CrossRef]

- Pazouki, S.; Haghifam, M.R. Optimal planning and scheduling of energy hub in presence of wind, storage and demand response under uncertainty. Electr. Power Energy Syst. 2016, 80, 219–239. [Google Scholar] [CrossRef]

- Wasilewski, J. Integrated modelling of microgrid for steady-state analysis using the modified concept of a multi-carrier energy hub. Electr. Power Energy Syst. 2015, 73, 891–898. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, J.; Zhang, N.; Kang, C. Automatic and linearized modeling of energy hub and its flexibility analysis. Appl. Energy 2018, 211, 705–714. [Google Scholar] [CrossRef]

- Maśloch, P.; Maśloch, G.; Kuźmiński, Ł.; Wojtaszek, H.; Miciuła, I. Autonomous Energy Regions as a Proposed Choice of Selecting Selected EU Regions—Aspects of Their Creation and Management. Energies 2020, 13, 6444. [Google Scholar] [CrossRef]

- Belleville, M.; Fanet, H.; Fiorini, P.; Nicole, P.; Pelgrom, M.J.M.; Piguet, C.; Hahn, R.; van Hoof, C.; Vullers, R.; Tartagni, M.; et al. Energy autonomous sensor systems: Towards a ubiquitous sensor technology. Microelectron. J. 2010, 41, 740–745. [Google Scholar] [CrossRef]

- Bieber, N.; Ker, J.H.; Wang, X.; Triantafyllidis, C.; van Dam, K.H.; Koppelaar, R.H.E.M.; Shah, N. Sustainable planning of the energy-water-food nexus using decision-making tools. Energy Policy 2018, 113, 584–607. [Google Scholar] [CrossRef]

- Barbosa, A.; Martín, B.; Hermoso, V.; Arévalo-Torres, J.; Barbière, J.; Martínez-López, J.; Domisch, S.; Langhans, S.D.; Balbi, S.; Villa, F.; et al. Cost-effective restoration and conservation planning in Green and Blue Infrastructure designs. A case study on the Intercontinental Biosphere Reserve of the Mediterranean: Andalusia (Spain)—Morocco. Sci. Total Environ. 2019, 652, 1463–1473. [Google Scholar] [CrossRef]

- Simpson, G.B.; Jewitt, G.P.W. The development of the water-energy-food nexus as a framework for achieving resource security: A review. Front. Environ. Sci. 2019, 7, 8. [Google Scholar] [CrossRef] [Green Version]

- Alzard, M.H.; Maraqa, M.A.; Chowdhury, R.; Khan, Q.; Albuquerque, F.D.B.; Mauga, T.I.; Aljunadi, K.N. Estimation of Greenhouse Gas Emissions Produced by Road Projects in Abu Dhabi, United Arab Emirates. Sustainability 2019, 11, 2367. [Google Scholar] [CrossRef] [Green Version]

- Marcilio, G.P.; Rangel, J.J.; de Souza, C.L.M.; Shimoda, E.; da Silva, F.F.; Peixoto, T.A. Analysis of greenhouse gas emissions in the road freight transportation using simulation. J. Clean. Prod. 2018, 170, 298–309. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (US EPA). MOVES2014a: Latest Version of Motor Vehicle Emission Simulator (MOVES). Available online: https://www.epa.gov/moves/moves2014a-latest-versionmotor-vehicle-emission-simulator-moves (accessed on 3 September 2017).

- United States Department of Energy (US DoE). Method for Calculating Carbon Sequestration by Trees in Urban and Suburban Settings; U.S. Department of Energy: Washington, DC, USA, 1998.

- Biggs, E.M.; Bruce, E.; Boruff, B.; Duncan, J.M.A.; Horsley, J.; Pauli, N.; McNeill, K.; Neef, A.; Van Ogtrop, F.; Curnow, J.; et al. Sustainable development and the water-energy-food nexus: A perspective on livelihoods. Environ. Sci. Policy 2015, 54, 389–397. [Google Scholar] [CrossRef] [Green Version]

- Smith, K.; Liu, S.; Liu, Y.; Guo, S. Can China reduce energy for water? A review of energy for urban water supply and wastewater treatment and suggestions for change. Renew. Sustain. Energy Rev. 2018, 91, 41–58. [Google Scholar] [CrossRef]

- Helmdach, D.; Yaseneva, P.; Heer, P.K.; Schweidtmann, A.M.; Lapkin, A. A Multiobjective Optimization Including Results of Life Cycle Assessment in Developing Biorenewables-Based Processes. ChemSusChem 2017, 10, 3632–3643. [Google Scholar] [CrossRef] [PubMed]

- Vadenbo, C.; Hellweg, S.; Guillén-Gosálbez, G. Multi-objective optimization of waste and resource management in industrial networks—Part I: Model description Resources, conservation and recycling. Resour. Conserv. Recycl. 2014, 89, 52–63. [Google Scholar] [CrossRef]

- P11—Standard for Rotating Electric Machinery for Rail and Road Vehicles. Available online: https://standards.ieee.org/project/11.html (accessed on 23 June 2021).

- CAN/CSA-C22.2 No. 108-01 (R2010). Available online: https://www.scc.ca/en/standardsdb/standards/7615 (accessed on 23 June 2021).

- CSA C22.2 NO 130, Requirements for Electrical Resistance Trace Heating and Heating Device Sets. Available online: https://standards.globalspec.com/std/14273886/csa-c22-2-no-130 (accessed on 23 June 2021).

- CSA C22.2 NO 3, Electrical Features of Fuel-Burning Equipment. Available online: https://standards.globalspec.com/std/1607301/CSA%20C22.2%20NO%203 (accessed on 23 June 2021).

- CSA C22.2 NO 14, Industrial Control Equipment. Available online: https://standards.globalspec.com/std/10283986/csa-c22-2-no-14 (accessed on 23 June 2021).

- IEEE 1636-2009—IEEE Standard for Software Interface for Maintenance Information Collection and Analysis (SIMICA). Available online: https://standards.ieee.org/standard/1636-2009.htm (accessed on 23 June 2021).

- Available online: https://www.greenvehicleguide.gov.au/pages/Information/VehicleEmissions (accessed on 11 July 2021).

- Available online: https://www.epa.gov/sites/production/files/2021-06/documents/420f21049.pdf (accessed on 11 July 2021).

- Available online: https://theicct.org/sites/default/files/publications/EV-life-cycle-GHG_ICCT-Briefing_09022018_vF.pdf (accessed on 11 July 2021).

- Available online: https://business.edf.org/insights/green-freight-math-how-to-calculate-emissions-for-a-truck-move/ (accessed on 11 July 2021).

- Available online: https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions (accessed on 11 July 2021).

- Available online: https://www.energysage.com/electric-vehicles/costs-and-benefits-evs/evs-vs-fossil-fuel-vehicles/ (accessed on 11 July 2021).

- Available online: https://www.energy.gov/articles/egallon-what-it-and-why-it-s-important (accessed on 11 July 2021).

- Available online: https://www.edmunds.com/fuel-economy/decoding-electric-car-mpg.html (accessed on 11 July 2021).

- Available online: https://insideevs.com/reviews/443791/ev-range-test-results/ (accessed on 11 July 2021).

| System | Model Parameters | KPIs |

|---|---|---|

| Farm | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Waste Generated: (tons) | Annual Yield: (ton/year) Annual Waste: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Food factory | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Waste Generated: (tons) | Annual Yield: (ton/year) Annual Waste: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Food transfer | Region: (latitude-1,2 and longitude-1,2) Distance: (km) Energy Demand: (kWh) Food Transferred: (tons) Waste Generated: (tons) | Annual Yield: (ton/km/year) Annual Waste: (ton/km/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Water well | Location: (latitude and longitude) Size: (depth, m) Energy Demand: (kWh) Water Demand: () | Annual Yield: (/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) |

| River | Region: (latitude 1, 2 and longitude 1, 2) Distance: (km) Size: (width, depth, m) Water Flow: (cubic meter per second (cms)) River Ship Capacity: (ships/h) | Annual Water Flow: (/year) Annual Transfer of Goods: (ton/year) Annual Ships: (ship/year) Annual Cost of Maintenance: ($/year) Annual GHG Emissions: (ton/year) |

| Water pipe | Region: (latitude-1,2 and longitude-1,2) Distance: (km) Size: (diameter, depth, m) Water Flow: (cubic m per second (cms)) | Annual Water Flow: (/year) Annual Cost of Maintenance: ($/year) Annual GHG Emissions: (ton/year) |

| Building | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Waste Generated: (tons) | Annual Occupancy: (occupant/year) Annual Waste Generate: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| House | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Waste Generated: (tons) | Annual Occupancy: (occupant/year) Annual Waste Generate: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Vehicle | Type: (engine size, L) Fuel: (L/100 km) Energy Demand: (kWh) Water Demand: () GHG Emission: (tons) | Annual Occupancy: (occupant/year) Annual Cost of Maintenance: ($/year) Annual Cost of Energy: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Station | Location: (latitude and longitude) Size: (square meter) Vehicle Served: (vehicle/h) Energy Demand: (kWh) Water Demand: () Waste Generated: (tons) | Annual Occupancy: (occupant/year) Annual Vehicle Served: (vehicle/year) Annual Waste Generated: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual GHG Emissions: (ton/year) |

| Waste collection | Location: (latitude and longitude) Size: (cubic foot) | Annual Waste Collected: (ton/year) Annual Cost of Maintenance: ($/year) |

| Waste-to-energy | Location: (latitude and longitude) Size: (square meter) Energy Demand: (kWh) Water Demand: () Energy Generated: (kWh) | Annual Waste Generated: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual Cost of Maintenance: ($/year) Annual GHG Emissions: (ton/year) |

| Oil and gas well | Location: (latitude and longitude) Size: (depth, m) Reservoir: (cubic meter) | Annual Yield: (/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) |

| Oil and gas production | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Oil/Gas Produced: () | Annual Production: (/year) Annual Cost of Energy: ($/year) Annual Cost of Maintenance: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) |

| Power plant | Location: (latitude and longitude) Size: (square foot) Energy Demand: (kWh) Water Demand: () Energy Generated: (kWh) | Annual Waste Generated: (ton/year) Annual Cost of Energy: ($/year) Annual Cost of Water: ($/year) Annual Energy Generated: (kWh/year) Annual Cost of Maintenance: ($/year) Annual GHG Emissions: (ton/year) |

| Function | Parameters | KPIs |

|---|---|---|

| F1: Health Interface | F1.SV1: input medicine F1.SV2: input health services F1.SV3: output medicine F1.SV4: output health services F1.SV5: infectious diseases | F1.KPI1: health Index F1.KPI2: annual produced medicine F1.KPI3: annual consumed medicine F1.KPI4: annual healthcare served persons F1.KPI5: annual infection rate F1.KPI6: annual death rate F1.KPI7: annual recovery rate |

| F2: Material Interface | F2.SV1: input material mass F2.SV2: output material mass | F2.KPI1: annual GHG emissions F2.KPI2: annual material losses F3.KPI3: annual material processing costs |

| F3: Electricity Interface | F3.SV1: input current F3.SV2: input voltage F3.SV3: output current F3.SV4: output current F3.SV5: AC or DC | F3.KPI1: power factor F3.KPI2: power losses F3.KPI3: safety index F3.KPI4: risk index |

| F4: Gas Interface | F4.SV1: input gas flow F4.SV2: input gas type F4.SV3: output gas flow F4.SV4: output gas type F4.SV5: gas production capacity F4.SV6: gas energy conversion factor | F4.KPI1: annual gas production F4.KPI2: annual gas consumption F4.KPI3: gas processing exergy index F4.KPI4: annual GHG emissions F4.KPI5. annual processing costs |

| F5: Thermal Interface | F5.SV1: input thermal energy F5.SV2: output thermal energy F5.SV3: thermal power cycle F5.SV4: thermal efficiency F5.SV5: thermal storage capacity | F5.KPI1: annual thermal production F5.KPI2: annual thermal consumption F5.KPI3. annual thermal processing costs |

| F6: Environment Interface | F6.SV1: air contaminants F6.SV2: soil contaminants F6.SV3: water contaminants F6.SV4: water areas F6.SV5: occupants | F6.KPI1: air quality index F6.KPI2: lifecycle index F6.KPI3: sustainability index F6.KPI4: annual GHG emissions |

| F7: Water Interface | F7.SV1: water flow F7.SV2: water contents F7.SV3: water storage | F7.KPI1: annual water usage F7.KPI2: annual water loss F7.KPI3: annual water flow F7.KPI4: annual water storage |

| F8: Transport Interface | F8.SV1: transport capacity F8.SV2: transport speed F8.SV3: transport delays F8.SV4: transport type | F8.KPI1: annual transport capacity F8.KPI2: annual transport delays F8.KPI3: annual transport cost |

| F9: Data Interface | F9.SV1: data transfer rate F9.SV2: data storage F9.SV3: data access users | F9.KPI1: annual data transfer F9.KPI2: annual data storage F9.KPI3: annual data access users |

| F10: Social Interface | F10.SV1: local population F10.SV2: number of interactions F10.SV3: number of groups F10.SV4: number per gender | F10.KPI1: annual interactions F10.KPI2: annual interaction groups F10.KPI3: annual interactions gender ratio |

| F11: Policy | F11.SV1: policy function coverage % F11.SV2: number of related policies | F11.KPI1: % compliance with policy F11.KPI2: system performance as per policy |

| P11—Standard for Rotating Electric Machinery for Rail and Road Vehicles [29] |

| CSA standards for Water Pumps (CAN/CSA-C22.2 No. 108-01) [30] |

| CSA standards for Thermal Devices (CSA C22.2 NO 130) [31] |

| CSA standards for Fuel Devices (CSA C22.2 NO 3) [32] |

| CSA Standard for Control equipment (CSA C22.2 NO 14) [33] |

| IEEE 1636-2009—IEEE Standard for Software Interface for Maintenance Information Collection and Analysis (SIMICA) [34] |

| Scenario | Transportation of Food via Vehicle from Point A to Point B |

|---|---|

| Parameter Changes | SO1: Change vehicle type: (a) gas vs. (b) electric SO2: Change route: (a) use highway vs. (b) use the shortest path Factors:

|

| Point A | 43.92258120910123, −79.3780351047355 |

| Point B | 43.900545798084586, −79.26182245727405 |

| Distance | 14.3 km |

| Interface parameters | F2.SV1: input material/food mass: 500 kg F2.SV2: output material mass: 480 kg F4.SV2: input gas type: gasoline F4.SV3: output gas flow: 8.0 L/100 km F4.SV4: output gas type: gasoline F4.SV5: gas production capacity: 0 F4.SV6: gas production efficiency: 80% F6.SV1: air contaminants: CO2 F6.SV2: soil contaminants: n/a F6.SV3: water contaminants: n/a F6.SV4: water areas: n/a F6.SV5: occupants: 2 persons F8.SV1: transport capacity: 2 persons F8.SV2: transport speed: 80 km/h F8.SV3: transport delays: 1 h/100 km F10.SV1: local population: 150,000 persons, based on comparative region population F10.SV2: number of interactions: 10/trip, based on average interactions during last year F10.SV3: number of groups: 4 (goods transport, food safety, food market, supermarket chain), based on a selected sample from the identified region F10.SV4: gender ratio, based on selected sample |

| KPI | KPI Value |

|---|---|

| F2.KPI1: annual GHG emissions | 15 kg |

| F2.KPI2: annual material losses | 400 kg |

| F3.KPI3: annual material processing costs | $400,000 |

| F4.KPI1: annual gas production | n/a |

| F4.KPI2: annual gas consumption | 580 L |

| F4.KPI3: gas processing exergy index | n/a |

| F4.KPI5: annual processing costs | $760 |

| F6.KPI1: air quality index | 70% |

| F6.KPI2: lifecycle index | 60% |

| F6.KPI3: sustainability index | 75% |

| F8.KPI1: annual transport capacity | 450,000 kg |

| F8.KPI2: annual transport delays | 270 |

| F8.KPI3: annual transport cost | 36,000 |

| F10.KPI1: annual interactions | 1800 |

| F10.KPI2: annual interaction groups | 72 |

| EV (Ford Focus) | |

| Within city roads | 110 MPGe [42] |

| Highway roads | 99 MPGe [43] |

| Within city roads | 30 MPG |

| Highway roads | 40 MPG |

| Annual GHG emission of carbon dioxide per kilowatt-hour of battery capacity (kg CO2/kWh) for electric vehicles | 56 to 494 kg [37] |

| Gasoline GHG emissions of CO2/ton-mile | 161.8 g [38] |

| Annual transport cost for EV in the United States | $485 [40] |

| Annual transport cost for gasoline car in the United States | $1117 [40] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabbar, H.A. Modeling of Interconnected Infrastructures with Unified Interface Design toward Smart Cities. Energies 2021, 14, 4572. https://doi.org/10.3390/en14154572

Gabbar HA. Modeling of Interconnected Infrastructures with Unified Interface Design toward Smart Cities. Energies. 2021; 14(15):4572. https://doi.org/10.3390/en14154572

Chicago/Turabian StyleGabbar, Hossam A. 2021. "Modeling of Interconnected Infrastructures with Unified Interface Design toward Smart Cities" Energies 14, no. 15: 4572. https://doi.org/10.3390/en14154572

APA StyleGabbar, H. A. (2021). Modeling of Interconnected Infrastructures with Unified Interface Design toward Smart Cities. Energies, 14(15), 4572. https://doi.org/10.3390/en14154572