Adaptive Impedance Control of a Novel Automated Umbilical System for Propellant Loading

Abstract

:1. Introduction

2. System Description

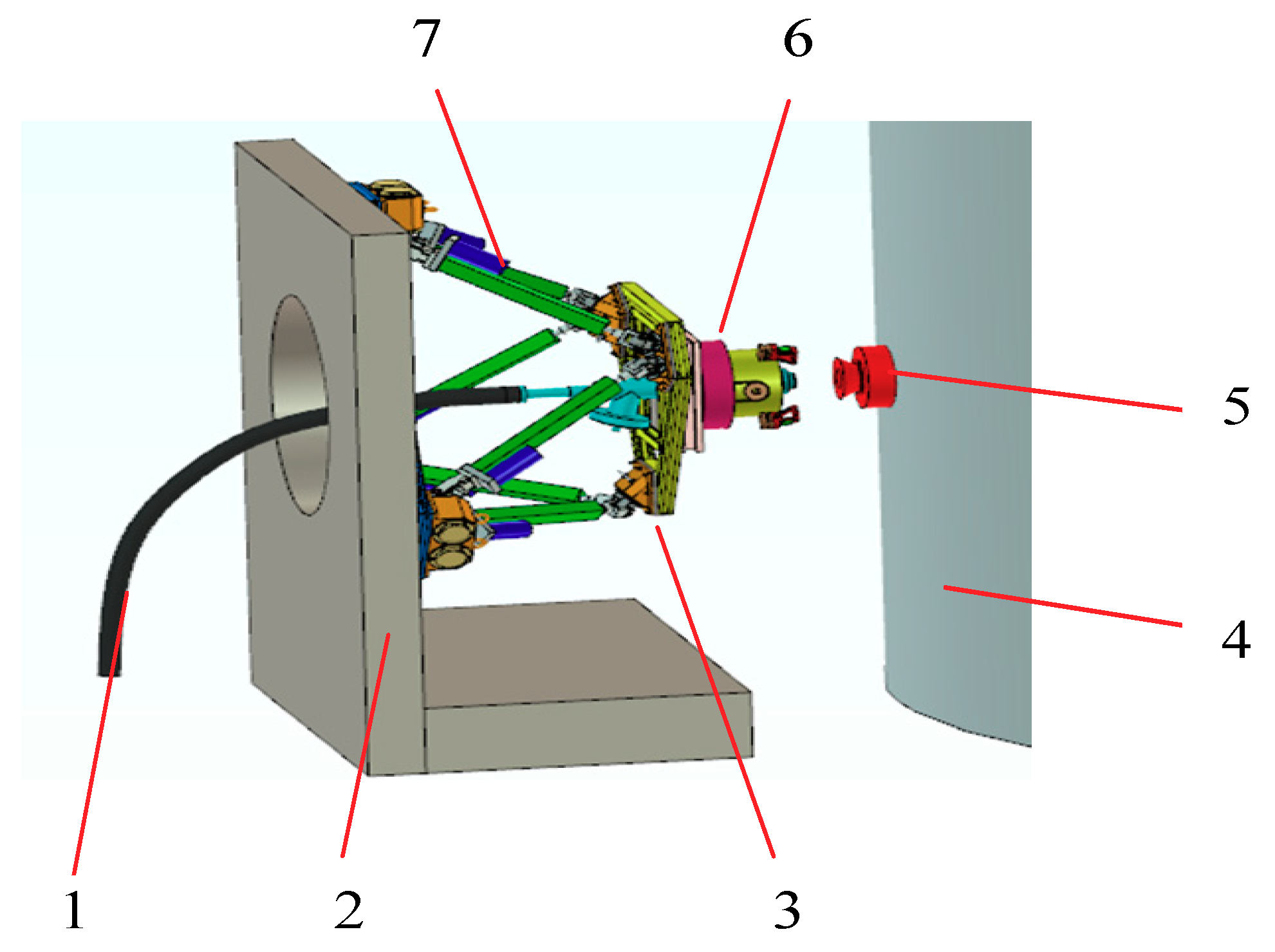

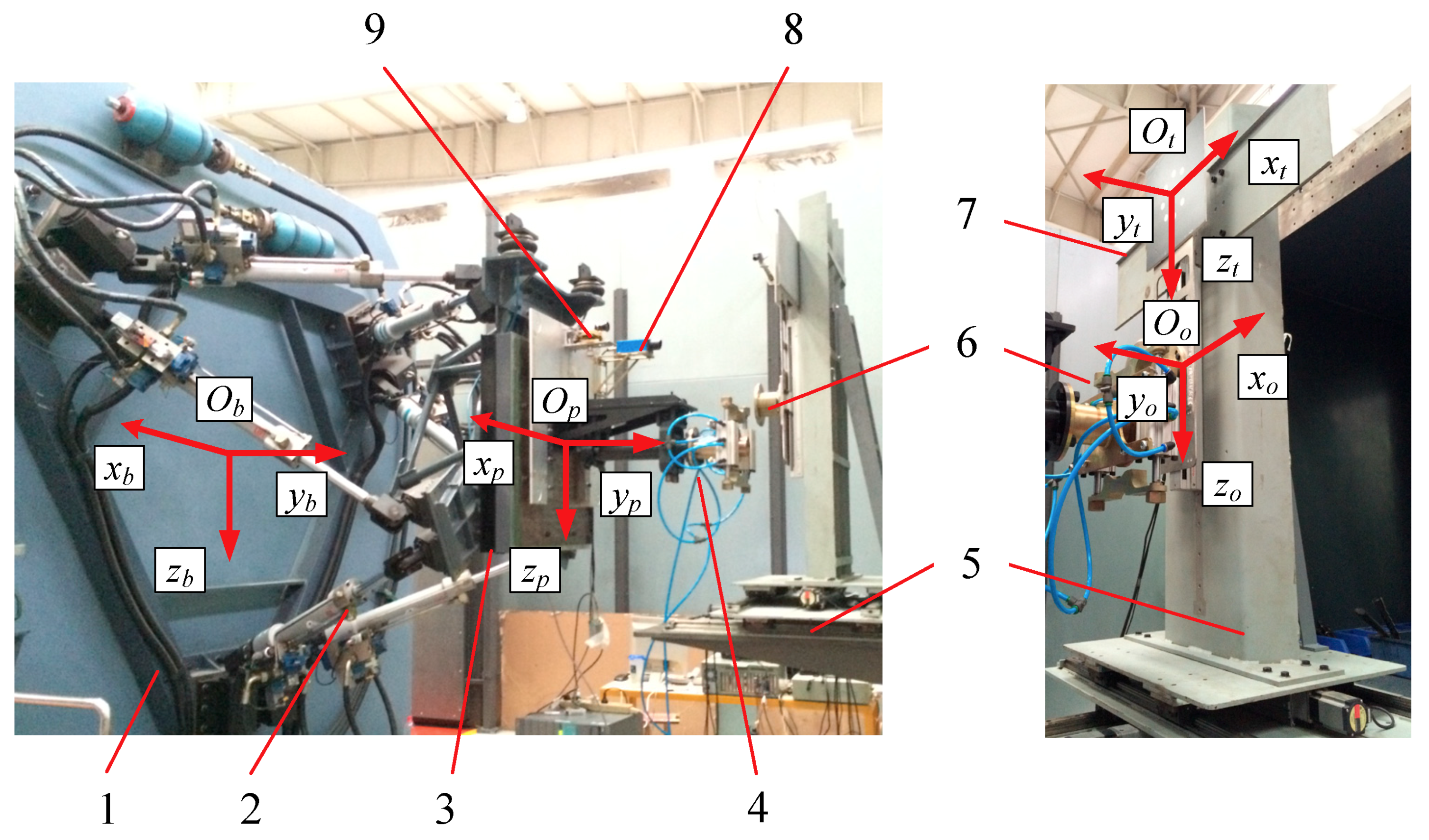

2.1. System Components

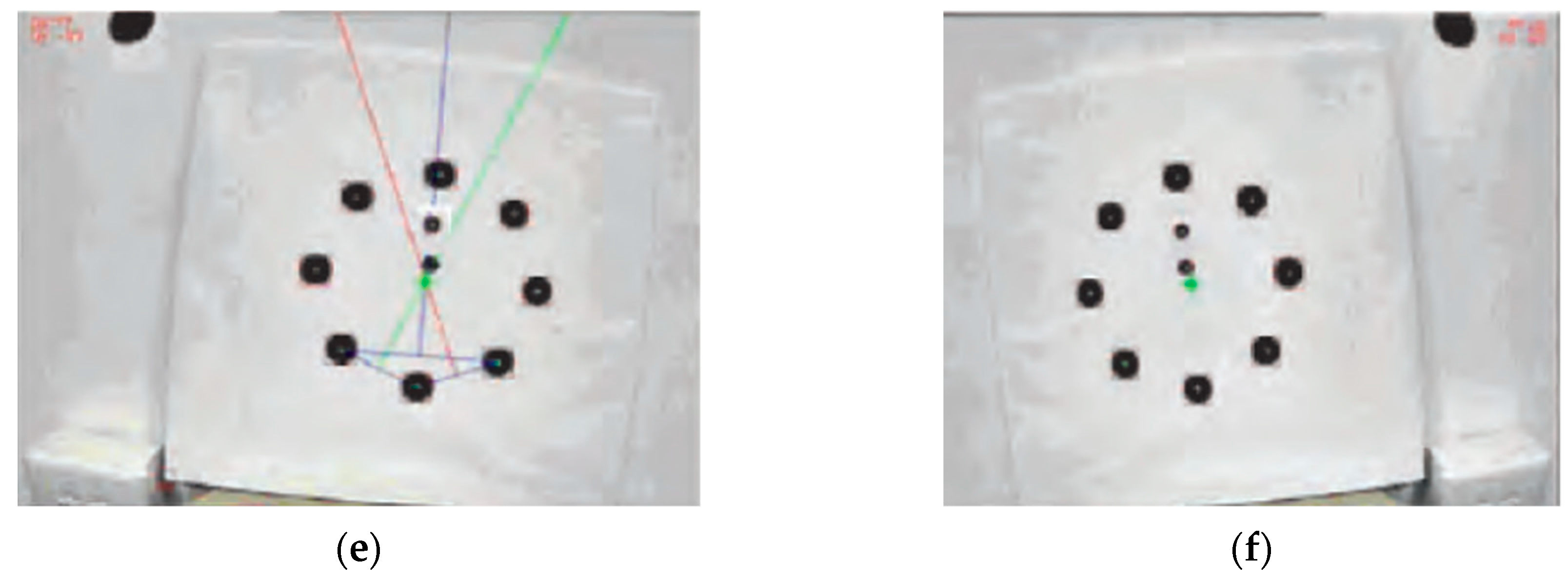

2.2. Vision Positioning Method

2.3. Manipulator Modeling

3. Hydraulic System Control Scheme

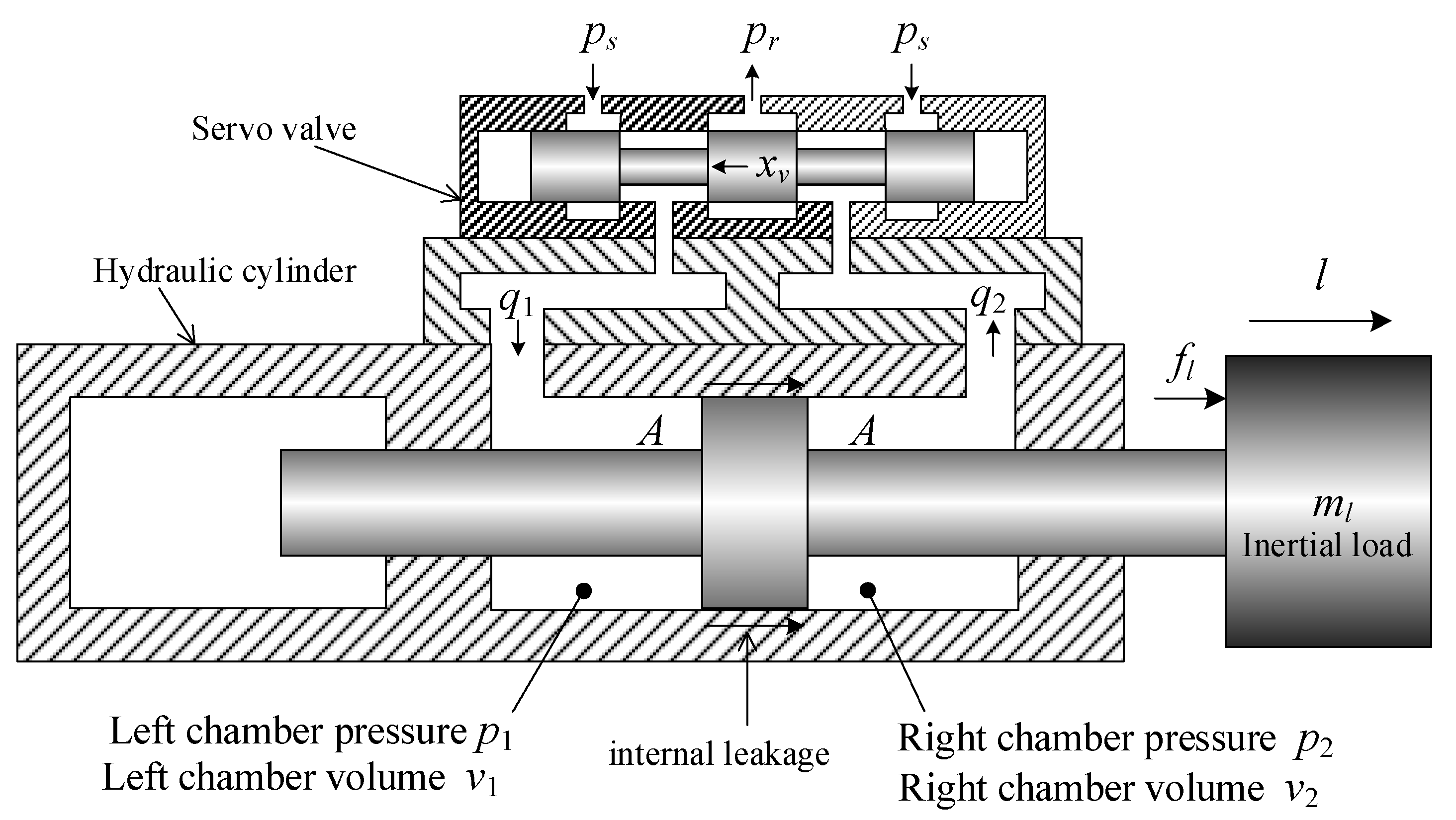

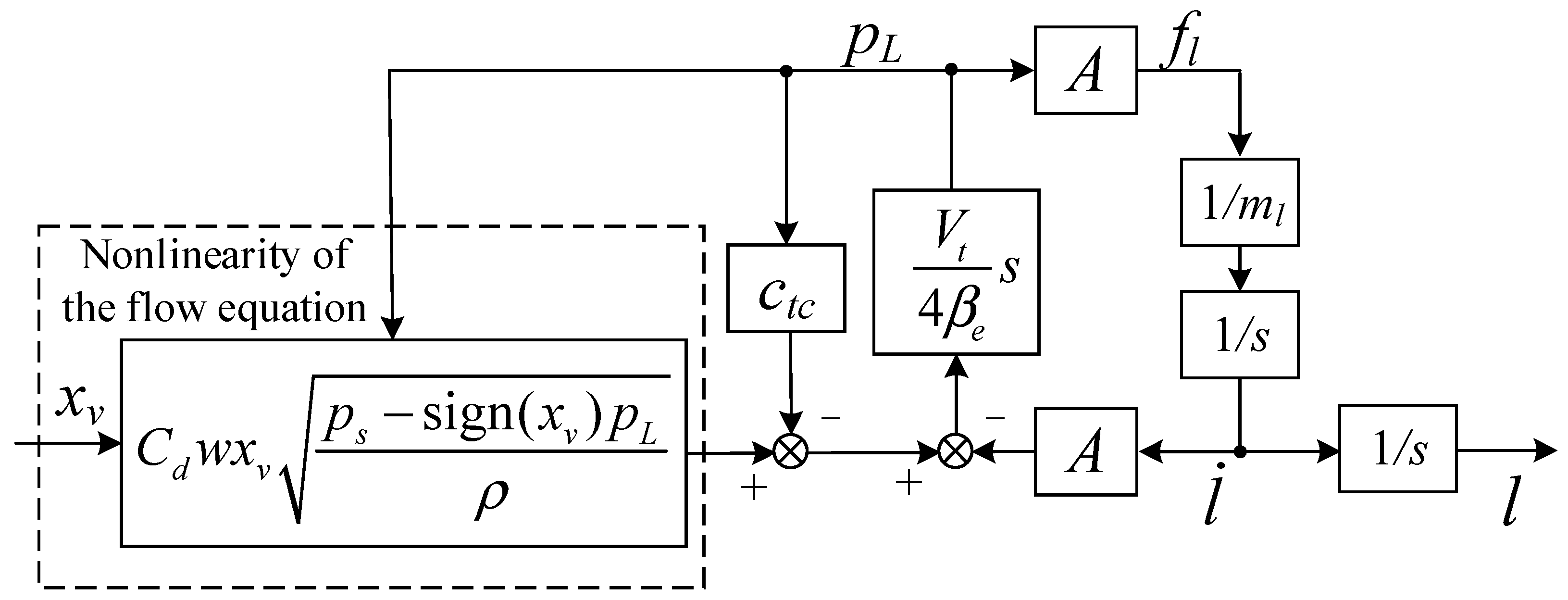

3.1. Hydraulic System Modeling

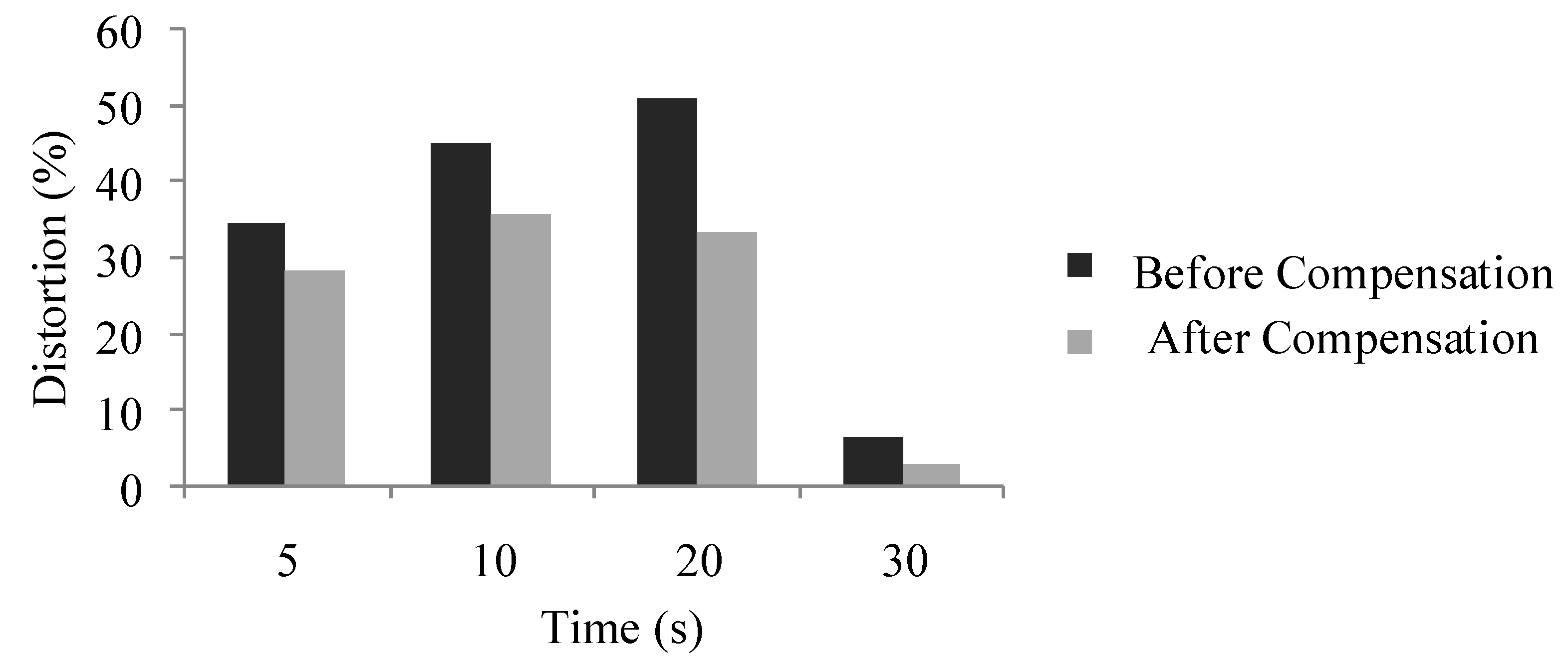

3.2. Hydraulic System Nonlinear Compensation

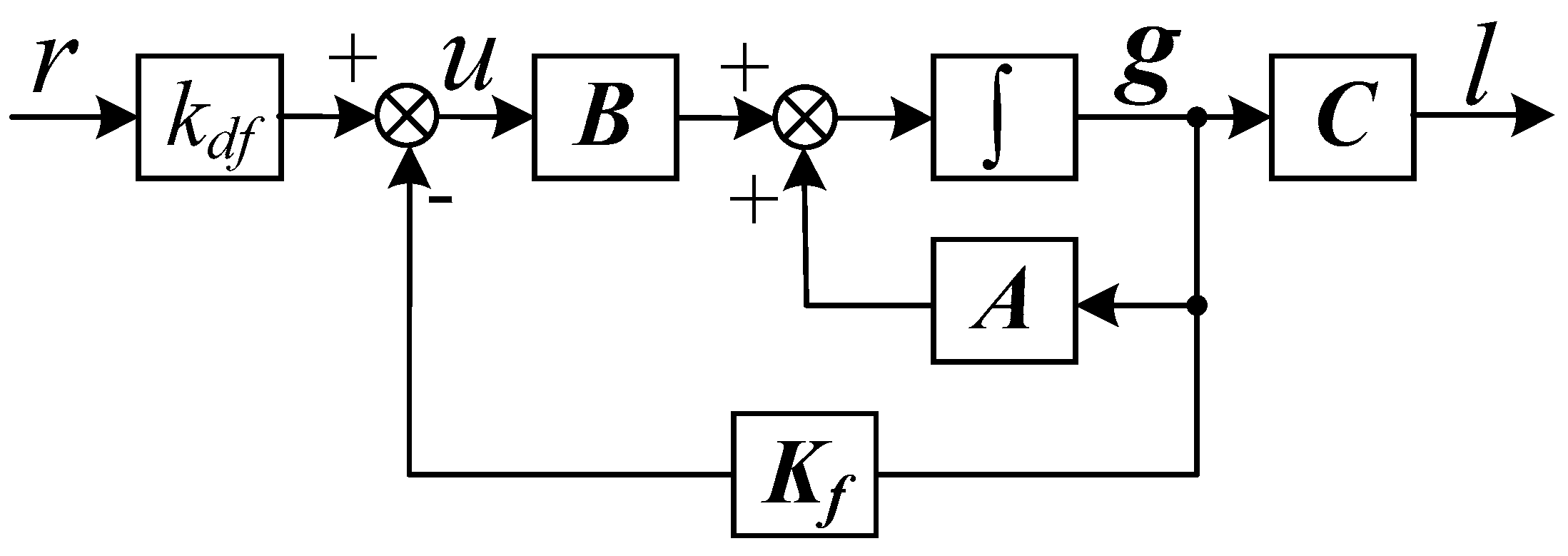

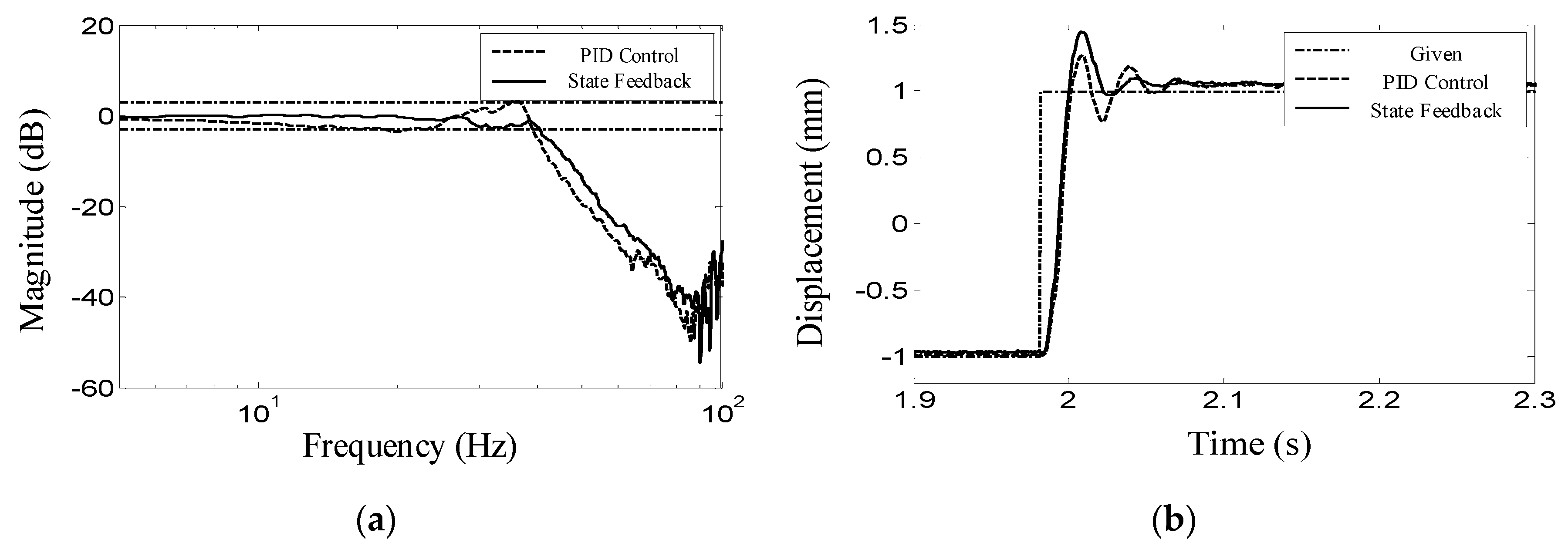

3.3. Three-State Feedback Control

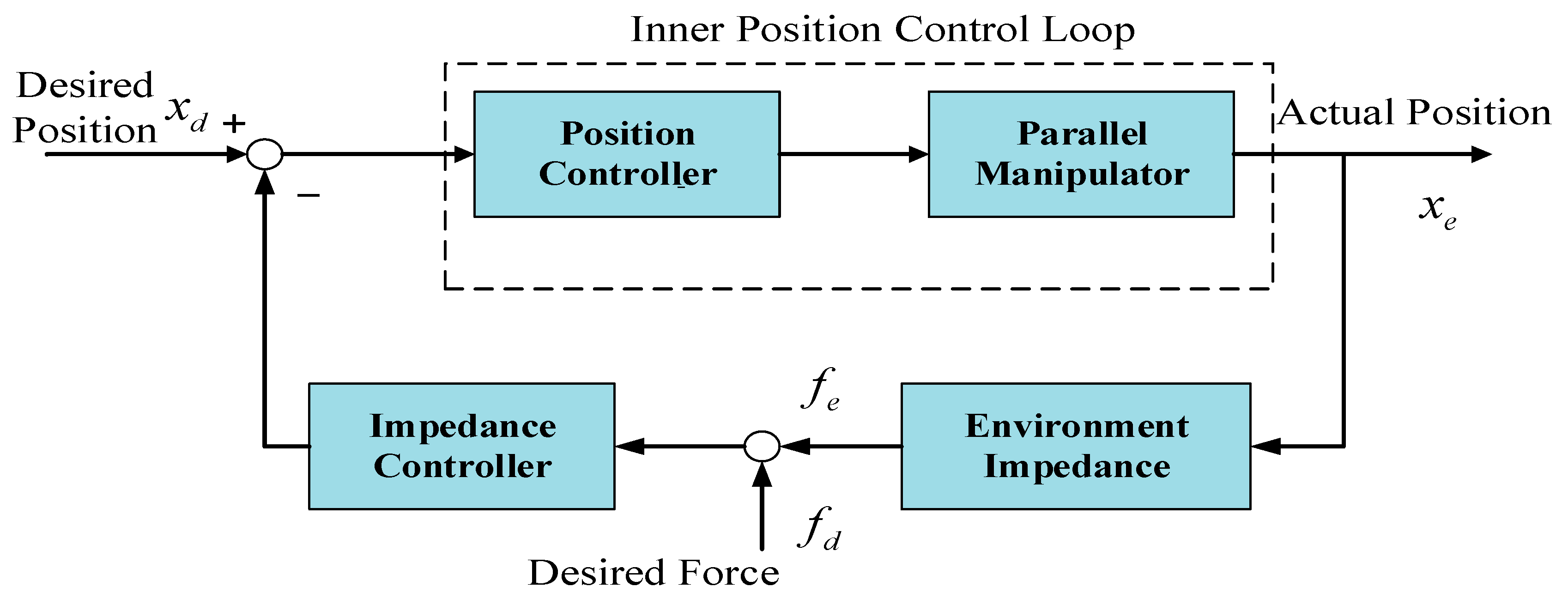

4. Force Tracking Control Scheme

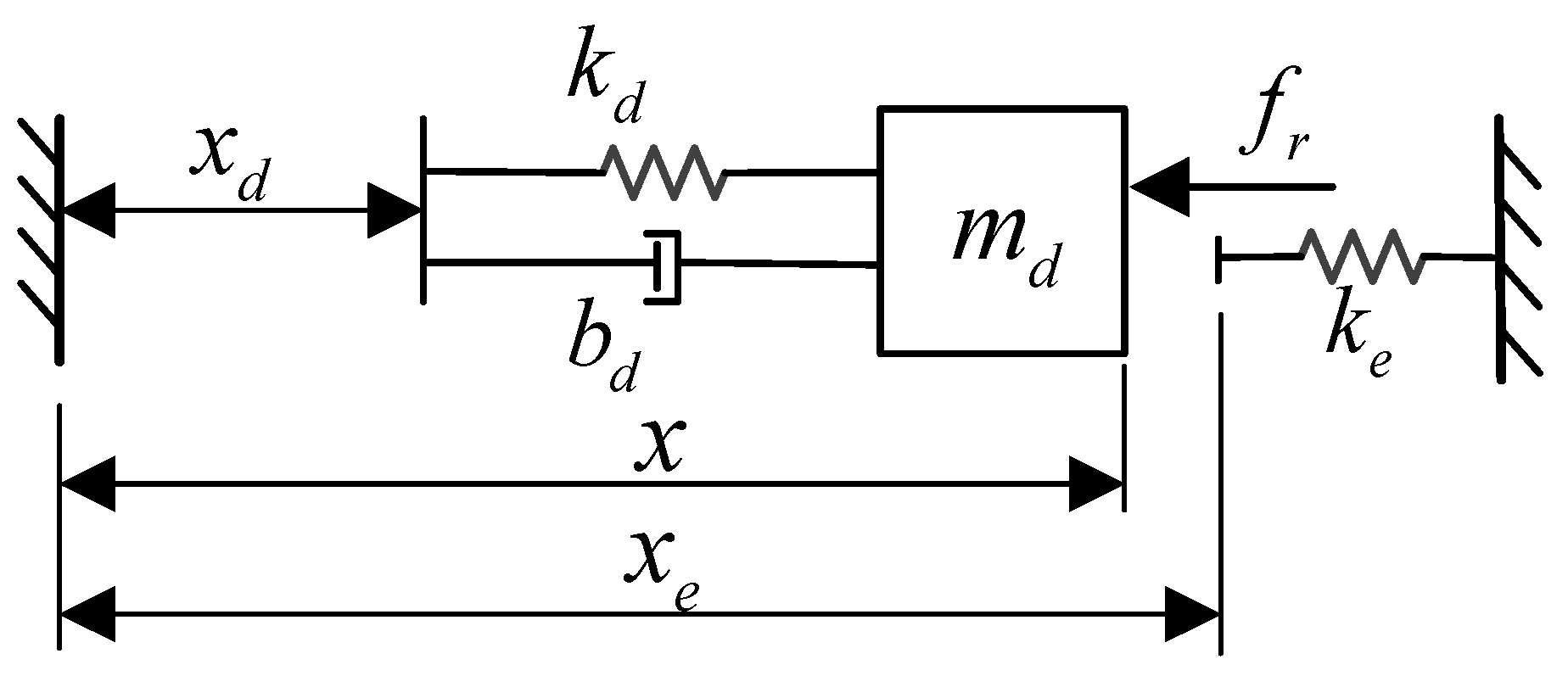

4.1. Analysis and Design of Impedance Controller

4.2. Stability Analysis of Impedance Control

4.3. Force Tracking Error Analysis

4.4. Impedance Control Based on Online Estimation of Environmental Parameters

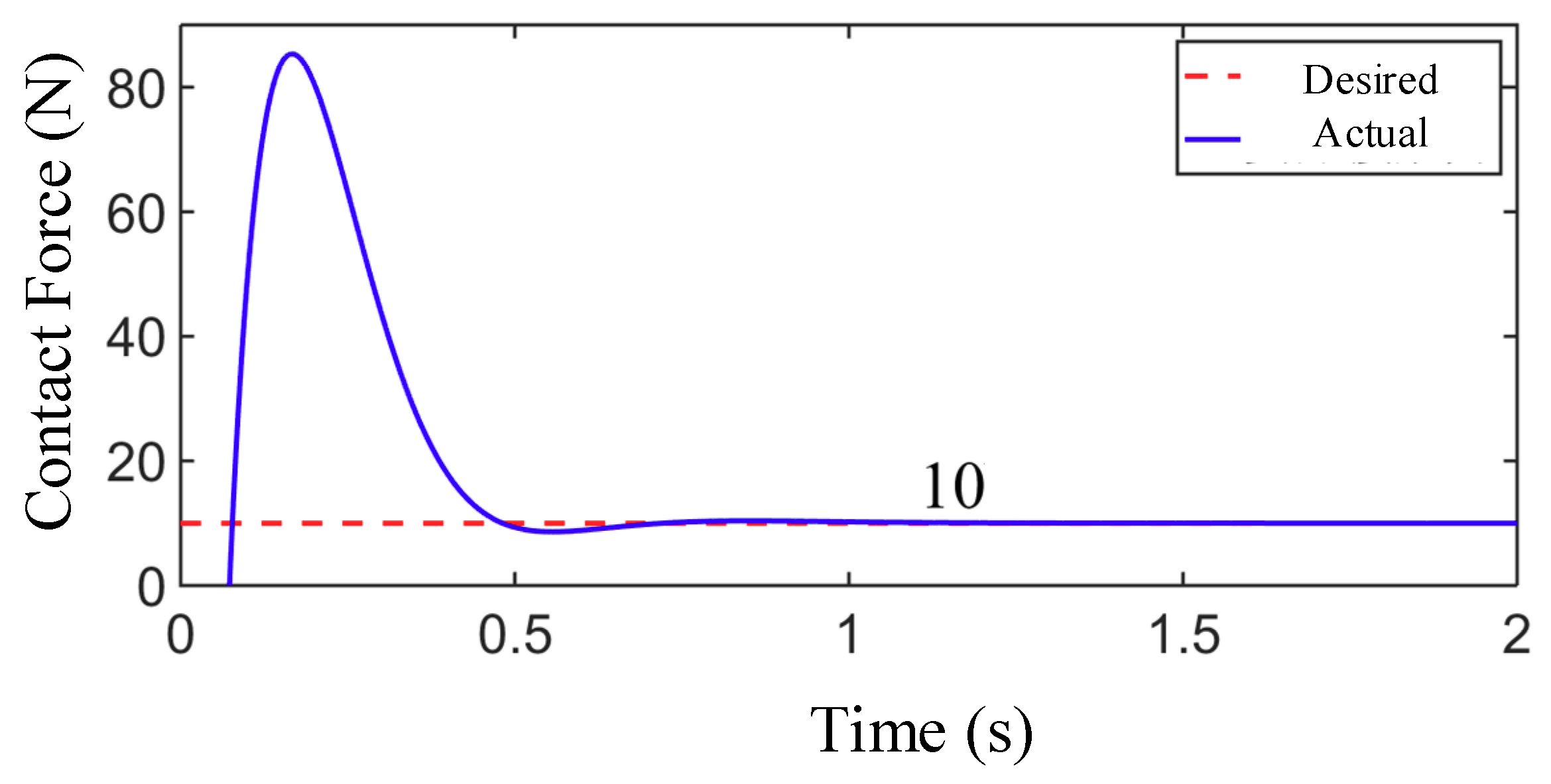

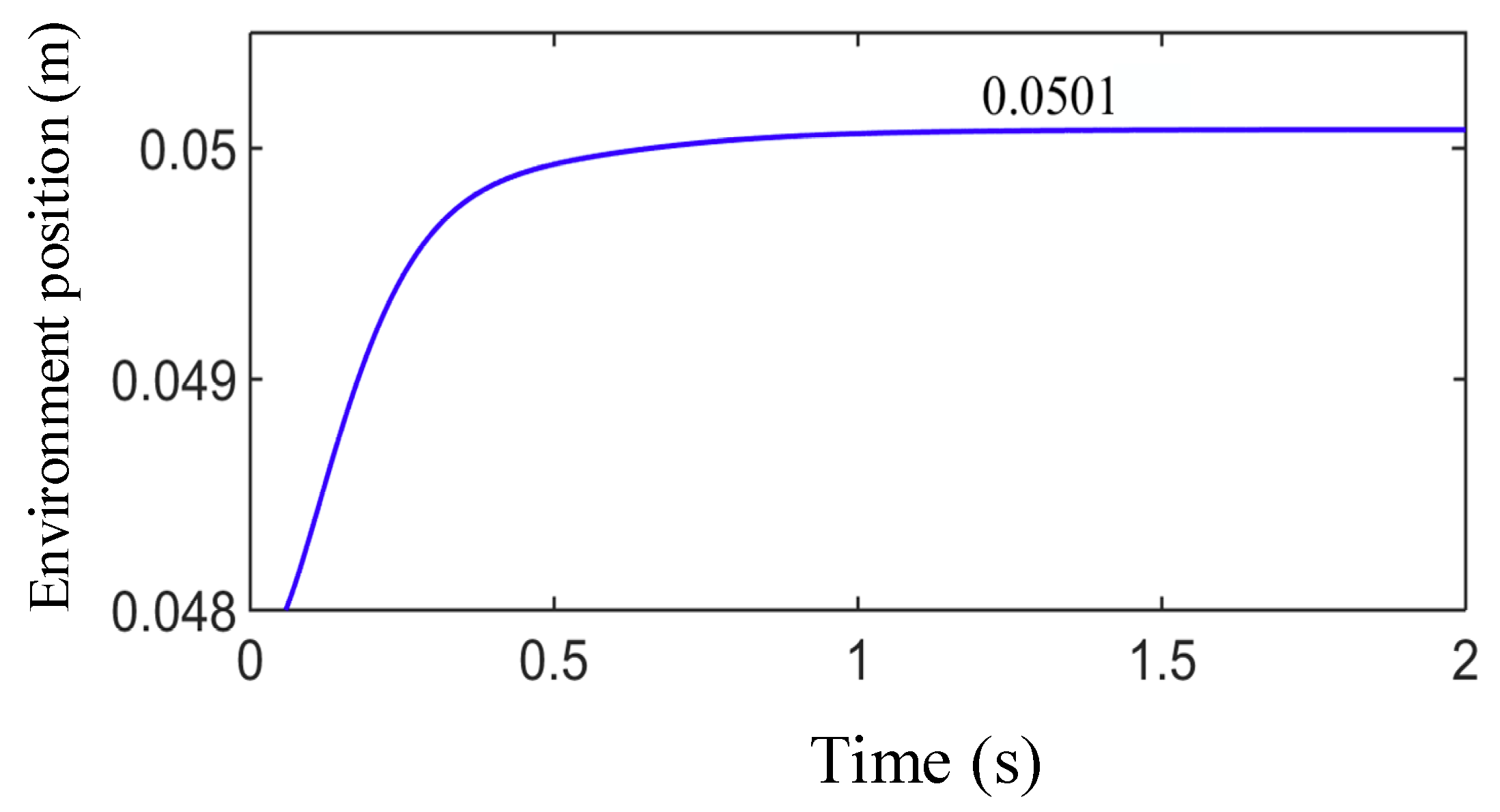

4.5. Simulation of Force Control Based on Online Environmental Parameter Estimation

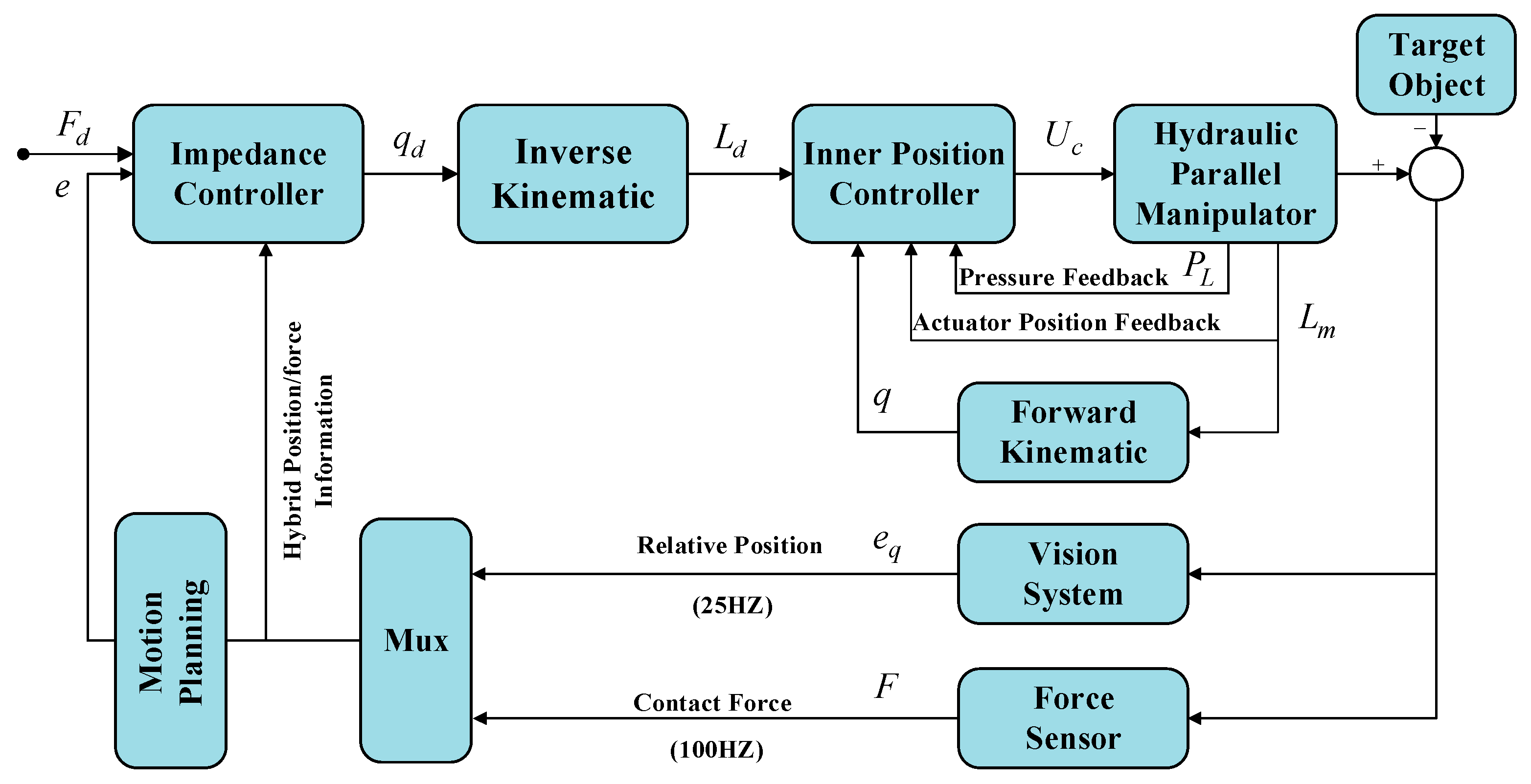

4.6. Overall Control Loop

5. Experimental Result

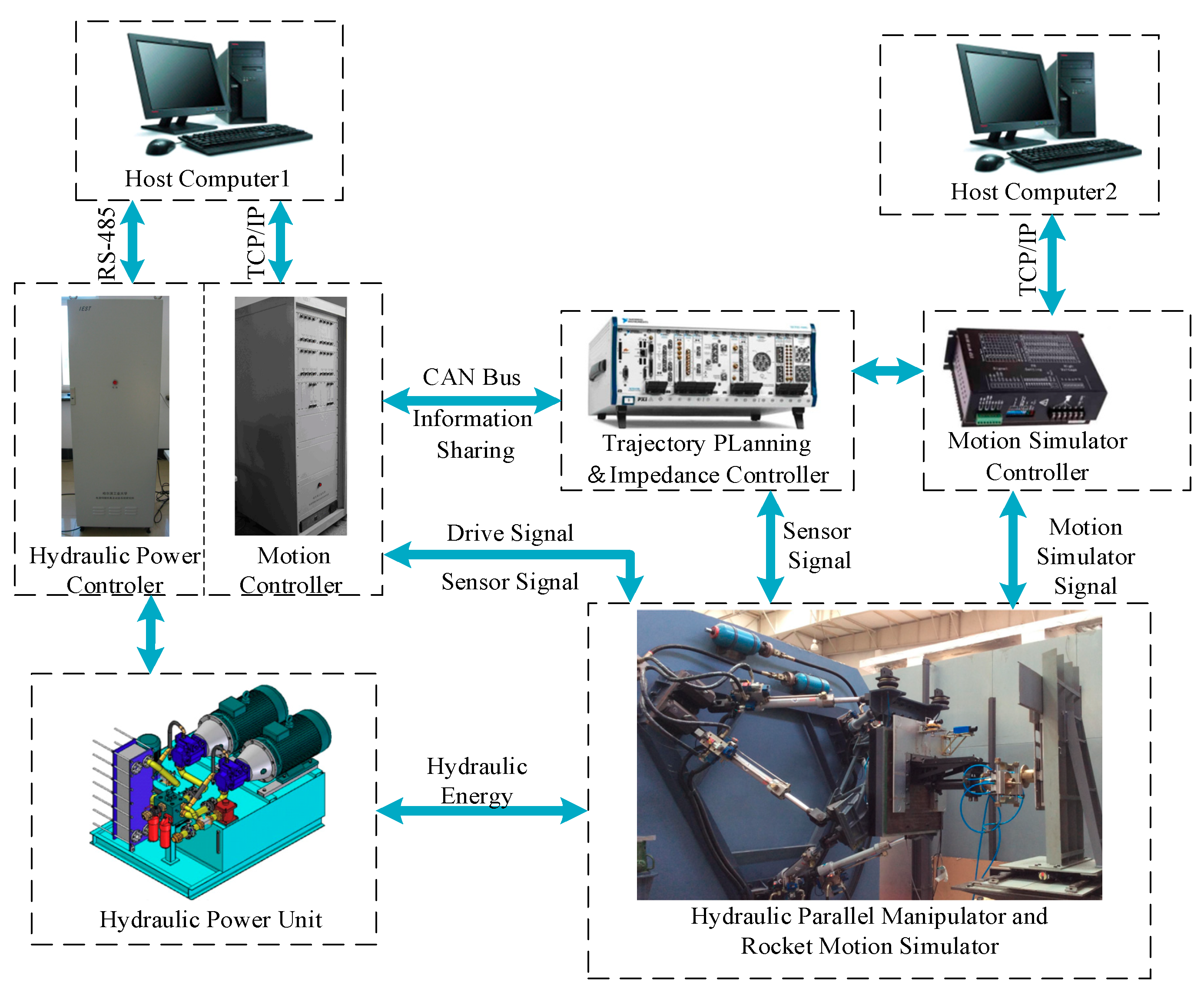

5.1. Experiment System Introduction

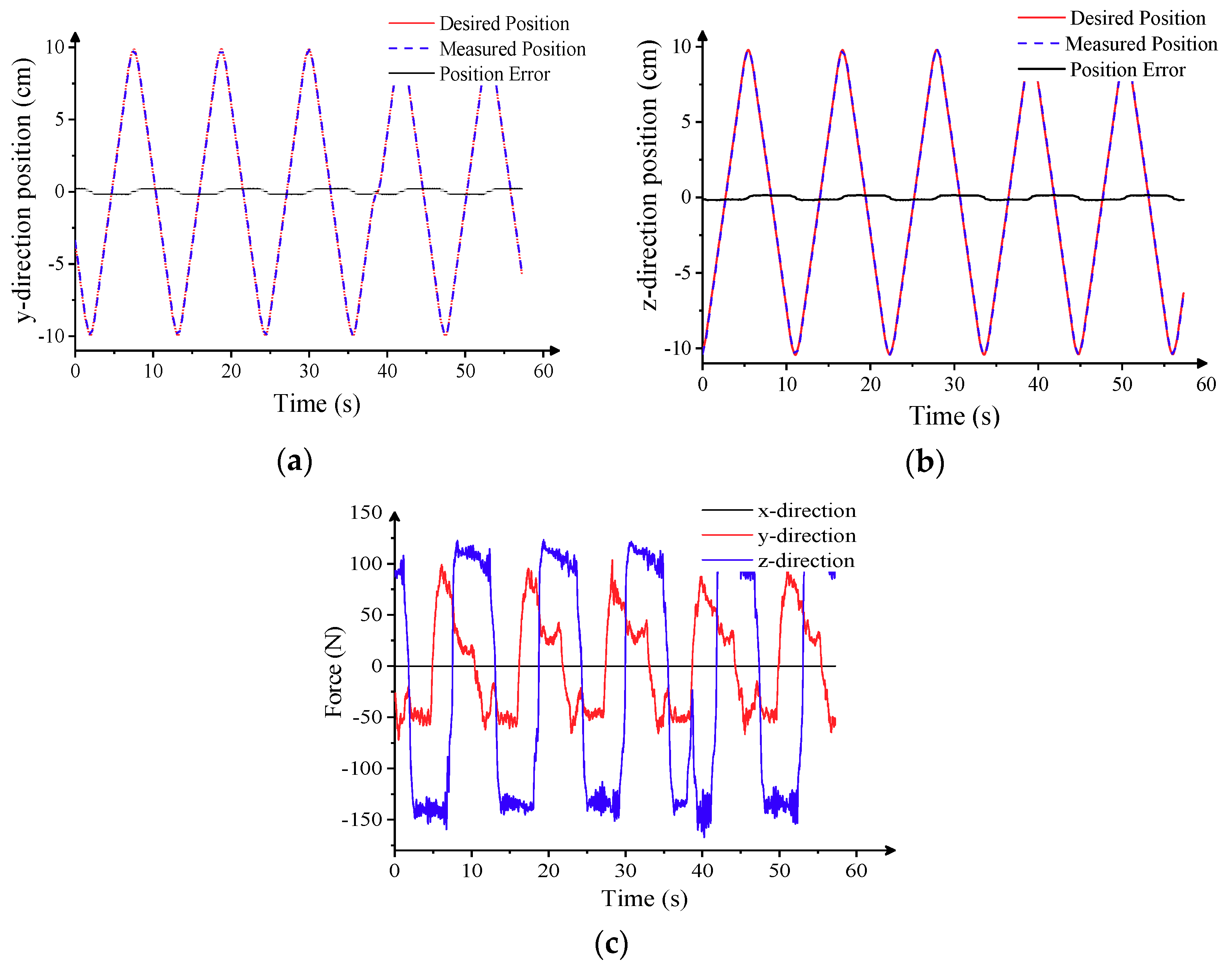

5.2. Dynamic Tracking Experiment

5.3. Dynamic Inserting Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gosselin, A.M. Automated ground umbilical systems (AGUS) Project. In Proceedings of the Space Visions Congress, Cocoa Beach, FL, USA, 26–27 April 2007. [Google Scholar]

- Li, L.; Chen, J.; Yu, H.; Liu, Q.; Mao, Z. Riseeso control of automatic docking servo system for rocket fuel filling. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2020), Online, 18–21 September 2020; pp. 610–615. [Google Scholar]

- McLean, C.H. Green propellant infusion mission program overview. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Big Sky, MT, USA, 1–8 March 2014; p. 3847. [Google Scholar]

- Walker, M.; Figueroa, F.; Toro-Medina, J. PHM enabled autonomous propellant loading operations. In Proceedings of the 2017 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017; pp. 1–11. [Google Scholar]

- Dun, X.; Yuan, J.; Chen, L. The auto-docking system design for the fuel loading robot used in hazardous environment. In Proceedings of the 2006 IEEE International Conference on Robotics and Biomimetics, Kunming, China, 17–20 December 2006; pp. 485–490. [Google Scholar]

- Ren, H.; Chai, Y.; Qu, J.; Ye, X.; Tang, Q. A novel adaptive fault detection methodology for complex system using deep belief networks and multiple models: A case study on cryogenic propellant loading system. Neurocomputing 2018, 275, 2111–2125. [Google Scholar] [CrossRef]

- Song, Z.; Xie, Z.; Qiu, L.; Xiang, D.; LI, J. Prospects of sea launches for Chinese cryogenic liquid-fueled medium-lift launch vehicles. Chin. J. Aeronaut. 2021, 34, 424–437. [Google Scholar] [CrossRef]

- Zhou, C.; Yu, C. A Position and Orientation Compensation Mechanism for Automatic Docking Device of Launch Rocket. Trans. Nanjing Univ. Aeronaut. Astronaut. 2018, 35, 1064–1072. [Google Scholar]

- You, J.; Huang, Y.; Dun, X. Design and Experimental Study of Automatic Docking and Undocking Robot System for Launch Vehicle Propellant Filling. In Proceedings of the International Conference on Aerospace System Science and Engineering; Springer: Singapore, 2020; pp. 565–578. [Google Scholar]

- Han, T.; Dacheng, C. Research on Vision-based Position Measurement System for Rocket Propellant Loading. E3S Web Conf. EDP Sci. 2021, 267, 01046. [Google Scholar] [CrossRef]

- Zhong, Y.; Yang, M.; Chen, F. The Response of Vertical Launch Vehicle to Ground Wind. Sci. Technol. Eng. 2010, 24, 6109–6112. [Google Scholar]

- Deng, L.; Janabi-Sharifi, F.; Hassanzadeh, I. Comparison of combined vision/force control strategies for robot manipulators. Int. Soc. Opt. Photonics 2005, 6052, 605202. [Google Scholar]

- Bellakehal, S.; Andreff, N.; Mezouar, Y.; Tadjine, M. Vision/force control of parallel robots. Mech. Mach. Theory 2011, 46, 1376–1395. [Google Scholar] [CrossRef]

- Baeten, J.; Bruyninckx, H.; De Schutter, J. Integrated vision/force robotic servoing in the task frame formalism. Int. J. Robot. Res. 2003, 22, 941–954. [Google Scholar] [CrossRef]

- Gao, X.S.; Lei, D.; Liao, Q.; Zhang, G.-F. Generalized Stewart-Gough platforms and their direct kinematics. IEEE Trans. Robot. 2005, 21, 141–151. [Google Scholar]

- Ta, T.N.; Tran, C.S.; Hwang, Y.L. The Kinematic and Dynamic Analysis of Hydraulic Control System Based on the Lagrangian Force Method. Int. J. Comput. Methods 2017, 15, 1850041. [Google Scholar] [CrossRef]

- Gao, C.; Cong, D.; Liu, X.; Yang, Z.; Tao, H. Hybrid position/force control of 6-dof hydraulic parallel manipulator using force and vision. Ind. Robot Int. J. 2016, 45, 274–283. [Google Scholar] [CrossRef]

- Gallardo, J.; Alcaraz, L.A. Kinematics of the Gough-Stewart platform by means of the Newton-homotopy method. IEEE Lat. Am. Trans. 2018, 16, 2850–2856. [Google Scholar] [CrossRef]

- Cai, Y.; Zheng, S.; Liu, W.; Qu, Z.; Zhu, J.; Han, J. Sliding-mode control of ship-mounted Stewart platforms for wave compensation using velocity feedforward. Ocean Eng. 2021, 236, 109477. [Google Scholar] [CrossRef]

- Lyu, L.; Chen, Z.; Yao, B. Development of pump and valves combined hydraulic system for both high tracking precision and high energy efficiency. IEEE Trans. Ind. Electron. 2018, 66, 7189–7198. [Google Scholar] [CrossRef]

- Manring, N.D.; Fales, R.C. Hydraulic Control Systems; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Yang, C.; Huang, Q.; Jiang, H.; Ogbobe, P. PD control with gravity compensation for hydraulic 6-DOF parallel manipulator. Mech. Mach. Theory 2010, 45, 666–677. [Google Scholar] [CrossRef]

- Zhang, C. PD plus dynamic pressure feedback control for a direct drive stewart manipulator. Energies 2020, 13, 1125. [Google Scholar] [CrossRef] [Green Version]

- Yao, J.; Deng, W.; Sun, W. Precision motion control for electro-hydraulic servo systems with noise alleviation: A desired compensation adaptive approach. IEEE ASME Trans. Mechatron. 2017, 22, 1859–1868. [Google Scholar] [CrossRef]

- Ba, K.; Ma, G.; Yu, B.; Jin, Z.-G. A nonlinear model-based variable impedance parameters control for position-based impedance control system of hydraulic drive unit. Int. J. Control Autom. Syst. 2020, 18, 1806–1817. [Google Scholar] [CrossRef]

- Barmish, B.R.; Tempo, R. The robust root locus. Automatica 1990, 26, 283–292. [Google Scholar] [CrossRef]

- Michiels, W.; Engelborghs, K.; Vansevenant, P.; Roose, D. Continuous pole placement for delay equations. Automatica 2002, 38, 747–761. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W. Parameter adjustment strategy and experimental development of hydraulic system for wave energy power generation. Symmetry 2020, 12, 711. [Google Scholar] [CrossRef]

- Seraji, H.; Colbaugh, R. Force tracking in impedance control. Int. J. Robot. Res. 1997, 16, 97–117. [Google Scholar] [CrossRef]

- Jung, S.; Hsia, T.C.; Bonitz, R.G. Force tracking impedance control of robot manipulators under unknown environment. IEEE Trans. Control Syst. Technol. 2004, 12, 474–483. [Google Scholar] [CrossRef]

- Surdilovic, D.T. Contact transition stability in the impedance control. In Proceedings of the International Conference on Robotics and Automation, Albuquerque, NM, USA, 25 April 1997; pp. 847–852. [Google Scholar]

- Duan, J.; Gan, Y.; Chen, M.; Dai, X. Adaptive variable impedance control for dynamic contact force tracking in uncertain environment. Robot. Auton. Syst. 2018, 102, 54–65. [Google Scholar] [CrossRef]

- Maschke, B.; Ortega, R.; Van Der Schaft, A.J. Energy-based Lyapunov functions for forced Hamiltonian systems with dissipation. IEEE Trans. Autom. Control 2000, 45, 1498–1502. [Google Scholar] [CrossRef] [Green Version]

| Symbol | Name | Value |

|---|---|---|

| D1 | Piston diameter | 40 mm |

| D2 | Piston rod diameter | 28 mm |

| Lw | Hydraulic cylinder stroke | ±196 mm |

| ε | Cylinder buffer length | 25 mm |

| l0 | Cylinder initial length | 1200 mm |

| lmax | Cylinder initial length | 1617 mm |

| vma | Piston rod maximum speed | 0.25 m/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, H.; Cong, D. Adaptive Impedance Control of a Novel Automated Umbilical System for Propellant Loading. Energies 2021, 14, 4900. https://doi.org/10.3390/en14164900

Tao H, Cong D. Adaptive Impedance Control of a Novel Automated Umbilical System for Propellant Loading. Energies. 2021; 14(16):4900. https://doi.org/10.3390/en14164900

Chicago/Turabian StyleTao, Han, and Dacheng Cong. 2021. "Adaptive Impedance Control of a Novel Automated Umbilical System for Propellant Loading" Energies 14, no. 16: 4900. https://doi.org/10.3390/en14164900

APA StyleTao, H., & Cong, D. (2021). Adaptive Impedance Control of a Novel Automated Umbilical System for Propellant Loading. Energies, 14(16), 4900. https://doi.org/10.3390/en14164900