Assessing the Energy, Indoor Air Quality, and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Two: Integrating the Indoor Air Quality, Moisture, and Thermal Comfort

Abstract

:1. Introduction

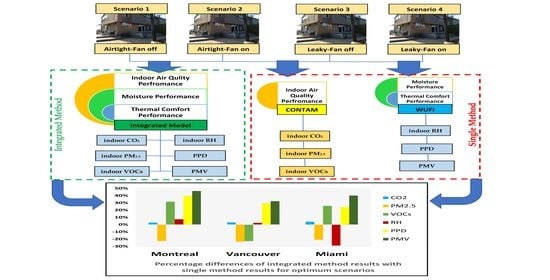

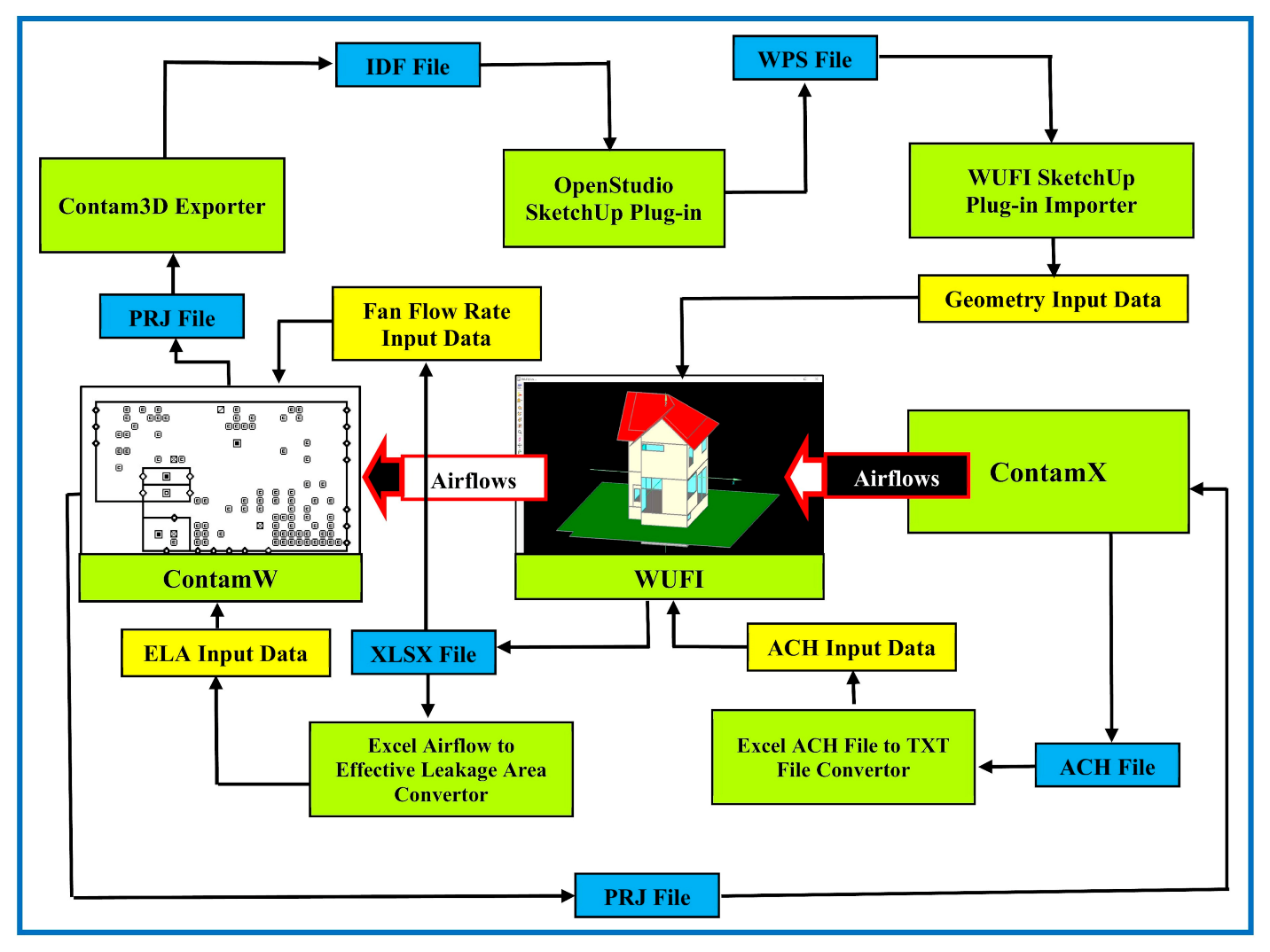

2. Methodology

2.1. Coupling Method of CONTAM and WUFI

- the outward contaminant α flow rate from zone i with the rate of

- the contaminant α removal in zone i with the rate of ; and

- the first-order chemical reactions with contaminant β at the rate of .

2.2. Description of the Case Study

2.3. Verification of the Developed Integrated Model

3. Results

3.1. Results of the Single Model of CONTAM

3.2. Result of the Single Model of WUFI

3.3. Results of the Integrated Model

4. Discussion

- Scenario 4 resulted in the optimal scenario for the indoor CO2 performance in both the CONTAM model and the integrated model methods in Montreal and Vancouver. The integrated model calculates the indoor CO2 performance for Scenario 4 in Montreal and Vancouver by differences of 2.80% and 3.02%, respectively, more than the CONTAM model. The reason for this difference is because in the CONTAM model method, the effective leakage area of 0.3 m2 and exhaust fan airflow of 24 L/s are defined by the users as airflows input data. In contrast, the airflows in the integrated model method are corrected by the co-simulation mechanism for CONTAM–WUFI.

- To calculate indoor CO2 performance in Miami, the results of Scenario 4, the optimal scenario using the integrated model method, are 3.98% different from the results of Scenario 2, the optimal scenario using the CONTAM model method. The reason for this difference is that the calculation of indoor CO2 performance in Scenario 2 is defined by the user based on the effective leakage area of 0.04 m2 and exhaust fan airflow of 24 L/s. The integrated model method in Scenario 4 calculates indoor CO2 performance based on the corrected airflows using the co-simulation mechanism of CONTAM-WUFI.

- In calculating the indoor PM2.5 performance, the results of Scenario 2, the optimal scenario by the integrated model method, are −22.65% different from the CONTAM model method. The reason for this difference is that in the CONTAM model method, effective leakage area of 0.04 m2 and exhaust fan airflow of 24 L/s are defined as input airflows data by the user. Thus, in the integrated model method, with the help of the co-simulation mechanism of CONTAM–WUFI, the airflows values have been corrected.

- Scenarios 2 and 4 are predicted for both Vancouver and Miami in the optimal level of indoor PM2.5 performance. The indoor PM2.5 performance values calculated for these scenarios by the integrated model method are −23.4% and −20.95% different from the CONTAM model method for Vancouver and Miami, respectively. The reason for this difference is that in the CONTAM model method, the effective leakage areas of 0.04 m2 and 0.3 m2 and exhaust fan airflow rate of 24 L/s for Scenarios 2 and 4, respectively, are defined as input data airflows by the user. In contrast, the corrected airflows variables have been used by the integrated model method based on the co-simulation mechanism for CONTAM–WUFI.

- The values of the indoor VOCs performance for Scenario 4, the optimal scenario by the integrated model method, are 31.54% and −22.70% different from the CONTAM model method for Montreal and Vancouver, respectively. The reason for this difference is that in the CONTAM model method, the effective leakage area of 0.3 m2 and exhaust fan airflow of 24 L/s are defined as airflows input data by the user. In the integrated model, the airflows variables are corrected by the co-simulation mechanism of CONTAM–WUFI.

- To calculate the indoor VOCs performance in Miami, the results of Scenario 2, the optimal scenario through the integrated model method, are 25.86% different from Scenario 4, the optimal scenario through the CONTAM model method. The reason for this difference is that the effective leakage area of 0.3 (m2) and exhaust fan airflow of 24 L/s for Scenario 4 are defined by the user as the input airflows data in the CONTAM model method. As in the integrated model method in Scenario 2, the corrected airflows data is used by the co-simulation mechanism of CONTAM–WUFI.

- In Montreal, for the calculation of the indoor relative humidity (RH) performance, the results of Scenario 3, the optimal scenario through the integrated model method, are 7.39% different from the results of Scenario 4, the optimal scenario based on the WUFI model method. Therefore, the reason for this difference is that in the WUFI model method, infiltration of 3.2 h−1 and mechanical ventilation of 0.3 h−1 for Scenario 4 are defined as airflows input data by the user. In addition, in the integrated model method for Scenario 3, corrected airflows are used by the co-simulation mechanism of CONTAM–WUFI.

- The results of Scenario 4, the optimal scenario in calculating indoor relative humidity (RH) performance through the integrated model method, are 2.55% and −28.8% different from the WUFI model method results for Vancouver and Miami, respectively. The reason for this difference is that the infiltration of 3.2 h−1 and mechanical ventilation of 0.3 h−1 are defined by the user as the input airflows data in the WUFI model method. In the integrated model method, the airflows data is corrected by the co-simulation mechanism of CONTAM–WUFI.

- In calculating the indoor percentage of dissatisfied (PPD) performance, the results of Scenario 1, the optimal scenario through the integrated model method, resulted in a 39.58, 29.39, and 23.99% difference in Montreal, Vancouver, and Miami, respectively, from the WUFI model method. The reason for this difference is that the infiltration of 0.4 h−1 is defined as the input airflow data by the user in the WUFI model method. In contrast, in the integrated model method, air flow data corrected by the co-simulation mechanism of CONTAM–WUFI are used.

- In calculating the indoor predicted mean vote (PMV) performance, Scenario 1, the optimal scenario through the integrated model method, resulted in a 52.98, 32.41, and 40.18% difference in Montreal, Vancouver, and Miami, respectively, from the WUFI model method. The reason for this difference is that the infiltration of 0.4 h−1 is defined as airflow input data by the user in the WUFI model method. However, the airflow data is corrected through the co-simulation mechanism of CONTAM–WUFI in the integrated model method.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; de Dear, R.; Hancock, P. Effects of moderate thermal environments on cognitive performance: A multidisciplinary review. Appl. Energy 2019, 236, 760–777. [Google Scholar] [CrossRef]

- Heibati, S.M.; Atabi, F.; Khalajiassadi, M.; Emamzadeh, A. Integrated dynamic modeling for energy optimization in the building: Part 1: The development of the model. J. Build. Phys. 2013, 37, 28–54. [Google Scholar] [CrossRef]

- Heibati, S.M.; Atabi, F. Integrated dynamic modeling for energy optimization in the building: Part 2: An application of the model to analysis of XYZ building. J. Build. Phys. 2013, 37, 153–169. [Google Scholar] [CrossRef]

- Rabani, M.; Bayera Madessa, H.; Nord, N. Building Retrofitting through Coupling of Building Energy Simulation-Optimization Tool with CFD and Daylight Programs. Energies 2021, 14, 2180. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort. Analysis and Applications in Environmental Engineering. In Thermal Comfort. Analysis and Applications in Environmental Engineering. 1970. Available online: https://www.cabdirect.org/?target=%2fcabdirect%2fabstract%2f19722700268 (accessed on 10 June 2021).

- ASHRAE. Thermal Environmental Conditions for Human Occupancy ANSI/ASHRAE Standard 55; ASHRAE: Atlanta, GA, USA, 2017. [Google Scholar]

- Schweiker, M. comf: An R Package for Thermal Comfort Studies. R. J. 2016, 8, 341. [Google Scholar] [CrossRef] [Green Version]

- Tartarini, F.; Schiavon, S. pythermalcomfort: A Python package for thermal comfort research. SoftwareX 2020, 12, 100578. [Google Scholar] [CrossRef]

- Schiavon, S.; Hoyt, T.; Piccioli, A. (Eds.) Web Application for Thermal Comfort Visualization and Calculation According to ASHRAE Standard 55. Building Simulation. pp. 321–334. Available online: https://link.springer.com/article/10.1007/s12273-013-0162-3 (accessed on 10 June 2021).

- Chen, Q. Ventilation performance prediction for buildings: A method overview and recent applications. Build. Environ. 2009, 44, 848–858. [Google Scholar] [CrossRef]

- Wang, L.L.; Chen, Q. Evaluation of some assumptions used in multizone airflow network models. Build. Environ. 2008, 43, 1671–1677. [Google Scholar] [CrossRef]

- Wang, L.; Wong, N.H. Coupled simulations for naturally ventilated residential buildings. Autom. Constr. 2008, 17, 386–398. [Google Scholar] [CrossRef]

- Gao, N.; Zhang, H.; Niu, J. Investigating indoor air quality and thermal comfort using a numerical thermal manikin. Indoor Built Environ. 2007, 16, 7–17. [Google Scholar] [CrossRef]

- Chang, S.J.; Wi, S.; Kang, S.G.; Kim, S. Moisture risk assessment of cross-laminated timber walls: Perspectives on climate conditions and water vapor resistance performance of building materials. Build. Environ. 2020, 168, 106502. [Google Scholar] [CrossRef]

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components. One-and Two-Dimensional Calculation Using Simple Parameters; IRB-Verlag Stuttgart: Stuttgart, Germany, 1995; p. 65. [Google Scholar]

- Details: Physics-Wufiwiki. Available online: https://www.wufi-wiki.com/mediawiki/index.php/Details:Physics (accessed on 15 June 2021).

- Ibrahim, M.; Sayegh, H.; Bianco, L.; Wurtz, E. Hygrothermal performance of novel internal and external super-insulating systems: In-situ experimental study and 1D/2D numerical modeling. Appl. Therm. Eng. 2019, 150, 1306–1327. [Google Scholar] [CrossRef]

- Mundt-Petersen, S.O.; Harderup, L.-E. Predicting hygrothermal performance in cold roofs using a 1D transient heat and moisture calculation tool. Build. Environ. 2015, 90, 215–231. [Google Scholar] [CrossRef]

- Le, A.D.T.; Zhang, J.S.; Liu, Z.; Samri, D.; Langlet, T. Modeling the similarity and the potential of toluene and moisture buffering capacities of hemp concrete on IAQ and thermal comfort. Build. Environ. 2020, 188, 107455. [Google Scholar]

- Zu, K.; Qin, M.; Rode, C.; Libralato, M. Development of a moisture buffer value model (MBM) for indoor moisture prediction. Appl. Therm. Eng. 2020, 171, 115096. [Google Scholar] [CrossRef]

- Hunter-Sellars, E.; Tee, J.; Parkin, I.P.; Williams, D.R. Adsorption of volatile organic compounds by industrial porous materials: Impact of relative humidity. Microporous Mesoporous Mater. 2020, 298, 110090. [Google Scholar] [CrossRef]

- Promis, G.; Dutra, L.F.; Douzane, O.; Le, A.T.; Langlet, T. Temperature-dependent sorption models for mass transfer throughout bio-based building materials. Constr. Build. Mater. 2019, 197, 513–525. [Google Scholar] [CrossRef]

- Rode, C.; Grunewald, J.; Liu, Z.; Qin, M.; Zhang, J. Models for Residential Indoor Pollution Loads Due to Material Emissions under Dynamic Temperature and Humidity Conditions. In Proceedings of the E3S Web of Conferences; p. 11002. Available online: https://www.e3s-conferences.org/articles/e3sconf/abs/2020/32/e3sconf_nsb2020_11002/e3sconf_nsb2020_11002.html (accessed on 10 July 2021).

- Sowa, J.; Mijakowski, M. Humidity-Sensitive, Demand-Controlled Ventilation Applied to Multiunit Residential Building—Performance and Energy Consumption in Dfb Continental Climate. Energies 2020, 13, 6669. [Google Scholar] [CrossRef]

- Moschetti, R.; Carlucci, S. The impact of design ventilation rates on the indoor air quality in residential buildings: An Italian case study. Indoor Built Environ. 2017, 26, 1397–1419. [Google Scholar] [CrossRef]

- Dols, W.S.; Emmerich, S.J.; Polidoro, B.J. Coupling the Multizone Airflow and Contaminant Transport Software CONTAM with EnergyPlus Using Co-Simulation. Building Simulation. pp. 469–479. Available online: https://link.springer.com/content/pdf/10.1007/s12273-016-0279-2.pdf (accessed on 10 July 2021).

- Moujalled, B.; Aït Ouméziane, Y.; Moissette, S.; Bart, M.; Lanos, C.; Samri, D. Experimental and numerical evaluation of the hygrothermal performance of a hemp lime concrete building: A long term case study. Build. Environ. 2018, 136, 11–27. [Google Scholar] [CrossRef]

- Chang, S.J.; Kang, Y.; Wi, S.; Jeong, S.-G.; Kim, S. Hygrothermal performance improvement of the Korean wood frame walls using macro-packed phase change materials (MPPCM). Appl. Therm. Eng. 2017, 114, 457–465. [Google Scholar] [CrossRef]

- Fedorik, F.; Alitalo, S.; Savolainen, J.-P.; Räinä, I.; Illikainen, K. Analysis of hygrothermal performance of low-energy house in Nordic climate. J. Build. Phys. 2021. [Google Scholar] [CrossRef]

- Heibati, S.; Maref, W.; Saber, H.H. Assessing the Energy and Indoor Air Quality Performance for a Three-Story Building Using an Integrated Model, Part One: The Need for Integration. Energies 2019, 12, 4775. [Google Scholar] [CrossRef] [Green Version]

- CONTAM 3.2. National Institute of Standards and Technology Engineering Laboratory: USA, 2016; Ver. 3.2.0.2. Available online: https://www.nist.gov/el/energy-and-environment-division-73200/nist-multizone-modeling/software/contam/download (accessed on 11 July 2021).

- WUFI® Plus. Thermal, Energy and Moisture Simulation of Building, Ver.3.2.0.1 ed.; Fraunhofer Institute for Building Physics: Stuttgart, Germany, 2021; Available online: https://wufi.de/en/webshop/ (accessed on 12 July 2021).

- Heibati, S.; Maref, W.; Saber, H.H. Developing a model for predicting optimum daily tilt angle of a PV solar system at different geometric, physical and dynamic parameters. Adv. Build. Energy Res. 2019, 179–198. [Google Scholar] [CrossRef]

- Mckeen, P.; Liao, Z. (Eds.) The Influence of Airtightness on Contaminant Spread in MURBs in Cold Climates. Building Simulation; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Dols, W.S.; Dols, W.S.; Polidoro, B.J. CONTAM User Guide and Program Documentation: Version 3.2. 2015. Available online: https://nvlpubs.nist.gov/nistpubs/TechnicalNotes/NIST.TN.1887.pdf (accessed on 15 July 2021).

- Sherman, M.H.; Dickerhoff, D.J. Air-tightness of US dwellings. Trans. Am. Soc. Heat. Refrig. Air Cond. Eng. 1998, 104, 1359–1367. [Google Scholar]

- Chan, W.R.; Price, P.N.; Sohn, M.D.; Gadgil, A.J. Analysis of US Residential Air Leakage Database; Lawrence Berkeley National Laboratory. 2003. Available online: https://escholarship.org/content/qt6pk6r4gs/qt6pk6r4gs.pdf (accessed on 17 June 2021).

- EnergyPlus. EnergyPlus Documentation, Engineering Reference, The Reference to EnergyPlus Calculations 2015. Available online: https://energyplus.net/sites/default/files/pdfs_v8.3.0/EngineeringReference.pdf (accessed on 20 June 2021).

- ASHRAE. Fundamentals Handbook. American Society of Heating, Refrigerating, and Air-Conditioning Engineers. 2017. Available online: https://www.ashrae.org/advertising/handbook-advertising/fundamentals (accessed on 25 June 2021).

- Antretter, F.; Künzel, H.; Winkler, M.; Pazold, M.; Radon, J.; Kokolsky, C.; Stadler, S. WUFI® Plus, Fundamentals; Fraunhofer Institute for Building Physics: Germany, 2018; Available online: https://wufi.de/en/software/wufi-plus/#:~:text=WUFI%20%C2%AE%20Plus%20is%20the%20most%20complete%20heat,for%20addressing%20comfort%20and%20energy%20consumption%20in%20buildings (accessed on 22 June 2021).

- Dols, W.S. A tool for modeling airflow & contaminant transport. Ashrae J. 2001, 43, 35–43. [Google Scholar]

- Heibati, S.; Maref, W.; Saber, H.H. Assessing the Energy, Indoor Air Quality and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Three: Development of Integrated Model and Applications. Energies 2021. submitted. [Google Scholar] [CrossRef]

- HVAC Sizing. Available online: https://michaelbluejay.com/electricity/hvac-sizing.html (accessed on 27 January 2021).

- ASHRAE. Energy Standard for Buildings Except Low-Rise Residential Buildings (I-P Edition); ANSI/ASHRAE/IES Standard 90.1; ASHRAE: Atlanta, GA, USA, 2019. [Google Scholar]

- EnergyPlus. Weather Data Sources; U.S. Department of Energy’s (DOE) Building Technologies Office (BTO), and National Renewable Energy Laboratory (NREL): 2020. Available online: https://energyplus.net/weather (accessed on 26 June 2020).

- CONTAM Utilities—CONTAM Weather File Creator, Version: 1.1; National Institute of Standards and Technology (NIST): 2014. Available online: https://www.nist.gov/el/energy-and-environment-division-73200/nist-multizone-modeling/software/contam-weather-file#:~:text=You%20can%20use%20the%20CONTAM%20Weather%20File%20Creator,Energy%20Plus%20weather%20files%20%28EPW%29%20to%20WTH%20files (accessed on 29 June 2021).

- Haghighat, F.; Donnini, G.; D’Addario, R. Relationship between occupant discomfort as perceived and as measured objectively. Indoor Environ. 1992, 1, 112–118. [Google Scholar]

- Emmerich, S.J.; Emmerich, S.J.; Gupte, A.; Howard-Reed, C. Modeling the IAQ Impact of HHI Interventions in Inner-City Housing; US Department of Commerce, National Institute of Standards and Technology: 2005. Available online: https://nvlpubs.nist.gov/nistpubs/Legacy/IR/nistir7212.pdf (accessed on 30 June 2021).

- Canada, E.C.C. Canadian Environmental Sustainability Indicators Air Quality. 2018. Available online: https://www.canada.ca/content/dam/eccc/documents/pdf/cesindicators/air-quality/air-quality-en.pdf (accessed on 1 July 2021).

- Division of Air Resource Management, FDoEP. 2019 Design Values for Fine Particulate Matter, PM2.5. Available online: https://floridadep.gov/sites/default/files/2019-PM2.5%20Design%20Values-Update.pdf (accessed on 3 July 2021).

- Wallace, L.A.; Emmerich, S.J.; Howard-Reed, C. Source strengths of ultrafine and fine particles due to cooking with a gas stove. Environ. Sci. Technol. 2004, 38, 2304–2311. [Google Scholar] [CrossRef]

- Howard-Reed, C.; Wallace, L.A.; Emmerich, S.J. Effect of ventilation systems and air filters on decay rates of particles produced by indoor sources in an occupied townhouse. Atmos. Environ. 2003, 37, 5295–5306. [Google Scholar] [CrossRef]

- Ho, D.X.; Kim, K.-H.; Ryeul Sohn, J.; Hee Oh, Y.; Ahn, J.-W. Emission rates of volatile organic compounds released from newly produced household furniture products using a large-scale chamber testing method. Sci. World J. 2011, 11, 1597–1622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Craig, D.; Richard, S.; Gniffin, B. Finding System-Required Airflow. Available online: https://www.contractingbusiness.com/archive/article/20863033/finding-systemrequired-airflow (accessed on 27 January 2021).

- Montreal, Quebec Climate & Temperature. Available online: http://www.montreal.climatemps.com/index.php (accessed on 5 July 2020).

- Miami, Florida Climate & Temperature. Available online: http://www.miami.climatemps.com/index.php (accessed on 10 June 2020).

- Vancouver, British Columbia Climate & Temperature. Available online: http://www.vancouver.climatemps.com/index.php (accessed on 20 April 2020).

- IBM SPSS Statistics, 22.0 ed.; Armonk, NY, USA. 2021. Available online: https://www-01.ibm.com/common/ssi/ShowDoc.wss?docURL=/common/ssi/rep_ca/9/897/ENUS213-309/index.html&request_locale=en (accessed on 20 July 2021).

- Zhu, Y. Applying computer-based simulation to energy auditing: A case study. Energy Build. 2006, 38, 421–428. [Google Scholar] [CrossRef]

- ASHRAE. Ventilation for Acceptable Indoor Air Quality; ANSI/ASHRAE Standard 62.1; ASHRAE: Atlanta, GA, USA, 2019. [Google Scholar]

- ASHRAE. Criteria for Moisture-Control Design Analysis in Buildings; ANSI/ASHRAE Standard 160; ASHRAE: Atlanta, GA, USA, 2016. [Google Scholar]

| Program | Parameter | Values |

|---|---|---|

| Weather Data | Montreal, Vancouver, and Miami: CONTAM (WTH file); WUFI (database) | |

| CONTAM | Envelope Effective Leakage Area (m2 @4 Pa, Exponent: 0.65, Discharge Coefficient: 1) [37] | Airtight = 0.04 Leaky = 0.3 |

| Exhaust Fan (L/S) | Fan On = 24, Fan Off = 0 | |

| Number of Envelope Paths | 42 | |

| Number of Zones | 15 | |

| Contaminants, 3 | CO2, PM2.5, and VOCs | |

| Outdoor Contaminant Concentration (mg/m3) [47,48,49,50] | CO2: 665.8 (Montreal), 665.8 (Vancouver), and 630 (Miami). PM2.5: 0.027 (Montreal), 0.027 (Vancouver), and 0.035 (Miami). VOCs: 0.132 (Montreal), 0.322 (Vancouver), and 0.100 (Miami) | |

| Number of Indoor Contaminant Source Elements | 21 | |

| Indoor CO2 Source Generation Rate (mg/s) [48] | Awake: [11 (adult male), 9.8 (adult female), 8.6 (child 13 years old), 6.8 (child 10 years old), and 3.8 (child 4 years old)]. Sleeping: [6.6 (adult male), 6.2 (adult female), 5.2 (child 13 years old), 4.1 (child 10 years old), and 2.3 (child 4 years old)] | |

| Indoor PM2.5 Source Generation Rate (mg/h) [51,52] | Kitchen cooking: [65.45 (breakfast), 40.90 (lunch), and 8.18 (dinner)]. Living room: [5.5 (kitty litter)] | |

| Indoor VOCs Source Generation Rate (mg/h·unit) [53] | 10 (dining table), 3 (sofa), 2 (desk-chair), 1 (bedside table), and 0.5 (cabinet) | |

| Filtration-Minimum Efficiency Reporting Value (MERV) rating | 4 | |

| Occupants | 5 (An adult male, adult female, and three children of ages 4, 10, and 13 years old) | |

| Air Handling System (AHS) Airflow Rate (m3/s) | 0.35 (supply), 0.35 (return) | |

| WUFI | Geometry | Total floor area 109.72 (m2), net volume 329.16 (m3), floor-to-ceiling height 2.7 (m), orientation 0°–180°,and window-to-wall ratio: S, E, N, 40% |

| Component Assembly RSI (m2·K/W) [44] | Montreal: 13.221 (ground floor), 5.445 (below grade wall), 7.070 (above grade wall), 6.801 (intermediate floor–ceiling), 10.488 (roof), 0.366 (reflected double glazed windows), 0.350 (external door), and 1.2 (interior wall) Vancouver: 10.671 (ground floor), 3.695 (below grade wall), 7.070 (above grade wall), 6.801 (intermediate floor–ceiling), 10.488 (roof), 0.366 (reflected double glazed windows), 0.350 (external door), and 1.2 (interior wall) Miami: 5.241 (ground floor), 0.695 (below grade wall), 4.445 (above grade wall), 0.651 (intermediate floor–ceiling), 4.678 (roof), 0.277 (reflective aluminum frame-fixed windows), 0.350 (external door), and 1.2 (interior wall) | |

| Internal Load Category | Family household (5 persons) | |

| Design Temperature (℃) | 20 | |

| Infiltration and Ventilation Rates (h−1) [37] | Airtight: 0.4 (fan off) and 0.7 (fan on); Leaky: 3.2 (fan off) and 3.5 (fan on) | |

| HVAC Load Capacity [43,44] | Montreal: 18.16 (heating load) and 5.2 (cooling load); Vancouver: 15.10 (heating load) and 5.2 (cooling load); and Miami: 10.59 (heating load) and 7 (cooling load) | |

| HVAC Airflow Capacity (m3/s) [54] | 0.4 (Montreal), 0.365 (Vancouver), and 0.377 (Miami) | |

| Building Envelope Conditions (outside to inside) | Ground floor: XPS surface skin (heat conductivity: 0.03 W/mK; bulk density: 40 kg/m3; porosity: 0.95; specific heat capacity: 1500 J/kgK; water vapor diffusion resistance factor: 450; and typical built-in moisture: 0 kg/m3); XPS Core (heat conductivity: 0.03 W/mK; bulk density: 40 kg/m3; porosity: 0.95; specific heat capacity: 1500 J/kgK; water vapor diffusion resistance factor: 100; and typical built-in moisture: 0 kg/m3); XPS surface skin, concrete (w/c: water-cement-ratio of 0.5; heat conductivity: 1.7 W/mK; bulk density: 2308 kg/m3; porosity: 0.15; specific heat capacity: 850 J/kgK; water vapor diffusion resistance factor: 179; and typical built-in moisture: 100 kg/m3); PVC roof membrane (heat conductivity: 0.16 W/mK; bulk density: 1000 kg/m3; porosity: 2E-4; specific heat capacity: 1500 J/kgK; water vapor diffusion resistance factor: 15000; and typical built-in moisture: 0 kg/m3); EPS (except for Miami) (heat conductivity: 0.04 W/mK; bulk density: 30 kg/m3, porosity: 0.95; specific heat capacity: 1500 J/kgK; water vapor diffusion resistance factor: 50; and typical built-in moisture: 0 kg/m3); and gypsum-fiberboard (heat conductivity: 0.32 W/mK; bulk density: 1153 kg/m3; porosity: 0.52; specific heat capacity: 1200 J/kgK; water vapor diffusion resistance factor: 16; and typical built-in moisture: 35 kg/m3). Below grade wall: mineral plaster (stucco, A-value: 0.1 kg/m2h0.5; heat conductivity: 0.8 W/mK; bulk density: 1900 kg/m3; porosity: 0.24; specific heat capacity: 850 J/kgK; water vapor diffusion resistance factor: 25; typical built-in moisture: 210 kg/m3; reference water content: 45 kg/m3; free water saturation: 210 kg/m3; and water absorption coefficient: 0.0017 kg/m2s0.5); oriented strand board (heat conductivity: 0.13 W/mK; bulk density: 630 kg/m3; porosity: 0.6; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 650; and typical built-in moisture: 95 kg/m3); wood-fiber board (heat conductivity: 0.05 W/mK; bulk density: 300 kg/m3; porosity: 0.8; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 12.5; and typical built-in moisture: 45 kg/m3); EPS (except for Miami); polyethylene-membrane (poly; 0.07 perm; heat conductivity: 2.3 W/mK; bulk density: 130 kg/m3; porosity: 0.001; specific heat capacity: 2300 J/kgK; water vapor diffusion resistance factor: 50000; and typical built-in moisture: 0 kg/m3); chipboard (heat conductivity: 0.11 W/mK; bulk density: 600 kg/m3; porosity: 0.5; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 70; and typical built-in moisture: 90 kg/m3); and gypsum board (heat conductivity: 0.2 W/mK; bulk density: 850 kg/m3; porosity: 0.65; specific heat capacity: 850 J/kgK; water vapor diffusion resistance factor: 8.3; and typical built-in moisture: 6.3 kg/m3). Above grade wall: mineral plaster (stucco, A-value: 0.1 kg/m2h0.5); oriented strand board; wood-fiber board; EPS; polyethylene-membrane; chipboard; and gypsum board. Intermediate floor–ceiling: oak-radial (heat conductivity: 0.13 W/mK; bulk density: 685 kg/m3; porosity: 0.72; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 140; and typical built-in moisture: 115 kg/m3); air layer 40 mm (heat conductivity: 0.23 W/mK; bulk density: 1.3 kg/m3; porosity: 0.999; specific heat capacity: 1000 J/kgK; water vapor diffusion resistance factor: 0.38; and typical built-in moisture: 0 kg/m3); EPS (except for Miami); softwood (heat conductivity: 0.09 W/mK; bulk density: 400 kg/m3; porosity: 0.73; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 200; and typical built-in moisture: 60 kg/m3); and gypsum board. Roof: 60 min building paper (heat conductivity: 12 W/mK; bulk density: 280 kg/m3; porosity: 0.001; specific heat capacity: 1500 J/kgK; water vapor diffusion resistance factor: 144; and typical built-in moisture: 0 kg/m3); mineral insulation board (heat conductivity: 0.043 W/mK; bulk density: 115 kg/m3; porosity: 0.95; specific heat capacity: 850 J/kgK; water vapor diffusion resistance factor: 3.4; and typical built-in moisture: 4.5 kg/m3); softwood; vapor retarder (1 perm) (heat conductivity: 2.3 W/mK; bulk density: 130 kg/m3; porosity: 0.001; specific heat capacity: 2300 J/kgK; water vapor diffusion resistance factor: 3300; and typical built-in moisture: 0 kg/m3); air layer 40 mm; wood-fiber insulation board (heat conductivity: 0.042 W/mK; bulk density: 155 kg/m3; porosity: 0.981; specific heat capacity: 1400 J/kgK; water vapor diffusion resistance factor: 3; and typical built-in moisture: 19 kg/m3); polyethylene-membrane (poly; 0.07 perm); and softwood. |

| Climate Characteristics | |||

|---|---|---|---|

| Parameters | Montreal | Vancouver | Miami |

| Altitude (m) | 27 | 4 | 5 |

| Latitude | 45°30′ N | 49°11’ N | 25°45′ N |

| Longitude | 73°25′ W | 123°10′ W | 80°23′ W |

| Average Annual Max. Temperature (°C) | 11 | 14 | 28 |

| Average Annual Temperature (°C) | 6 | 10 | 24 |

| Average Min. Temperature (°C) | 1 | 6 | 21 |

| Average Annual Precipitation (mm) | 1017 | 1167 | 1420 |

| Annual Number of Wet Days | 166 | 164 | 132 |

| Average Annual Sunlight (hours/day) | 5 h 05′ | 5 h 01′ | 8 h 03′ |

| Average Annual Daylight (hours/day) | 12 h 00′ | 12 h 00′ | 12 h 00′ |

| Annual Percentage of Sunny Daylight Hours (cloudy) | 42 (58) | 42 (58) | 67 (33) |

| Annual Sun Altitude at Solar Noon on the 21st day | 44.8° | 41.1° | 64.5° |

| Data ((kg/kg) × 10−4) | Month | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| Simulated | 8.24 | 8.79 | 8.82 | 8.29 | 8.84 | 8.85 | 8.35 | 8.87 | 8.87 | 8.33 | 8.83 | 8.78 |

| Actual | 8.44 | 8.72 | 8.74 | 8.48 | 8.75 | 8.75 | 8.50 | 8.75 | 8.73 | 8.45 | 8.68 | 8.61 |

| Data (%) | Month | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| Simulated | 21.02 | 32.11 | 44.45 | 26.88 | 45.70 | 46.56 | 60.63 | 59.06 | 56.17 | 30.39 | 35.31 | 19.53 |

| Actual | 22.39 | 31.04 | 43.51 | 27.92 | 44.65 | 47.55 | 60.79 | 60.01 | 55.61 | 29.77 | 33.38 | 18.68 |

| Simulated versus Actual Data | Paired Differences | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Standard Deviation | Standard Error Mean | 95% Confidence Interval of the Difference | t-Statistic | df | Significance (Two-Tailed) | |||

| Lower | Upper | ||||||||

| 1 | Indoor CO2 concentration ((kg/kg) × 10−4) | 0.02167 | 0.14212 | 0.04103 | −0.06863 | 0.11196 | 0.528 | 11 | 0.608 |

| 2 | Indoor relative humidity (%) | 0.20917 | 1.07103 | 0.30918 | −0.47133 | 0.88966 | 0.677 | 11 | 0.513 |

| Simulated Versus Actual Data | Measurers | |||

|---|---|---|---|---|

| N | Correlation | Level of Significance | ||

| 1 | Indoor CO2 concentration ((kg/kg) ×10−4) | 12 | 0.965 | 0.000 |

| 2 | Indoor relative humidity (%) | 12 | 0.997 | 0.000 |

| Status | Airtight | Leaky | Fan Off | Fan On | |

|---|---|---|---|---|---|

| 1 | Scenario 1 | Yes | No | Yes | No |

| 2 | Scenario 2 | Yes | No | No | Yes |

| 3 | Scenario 3 | No | Yes | Yes | No |

| 4 | Scenario 4 | No | Yes | No | Yes |

| IAQ | Indoor CO2 | Indoor PM2.5 | Indoor VOCs | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cities | Montreal | Vancouver | Miami | Montreal | Vancouver | Miami | Montreal | Vancouver | Miami | |||||||||

| Models | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model | CONTAM Model | Integrated Model |

| S1 | −79.17% | −81.51% | −79.08% | −81.17% | −79.63% | −80.63% | 465.31% | 450.39% | 465.31% | 464.63% | 518.94% | 509.56% | −19.65% | −26.40% | 43.92% | 38.55% | −30.17% | −34.55% |

| S2 | −79.62% | −83.34% | −79.59% | −83.33% | −80.14% | −83.86% | 438.50% | 339.15% | 452.59% | 346.59% | 506.19% | 400.13% | −21.10% | −33.11% | 42.34% | 30.26% | −31.67% | −43.70% |

| S3 | −80.95% | −82.13% | −80.66% | −81.64% | −80.29% | −80.80% | 452.92% | 423.43% | 465.23% | 457.48% | 516.77% | 505.07% | −24.51% | −28.69% | 39.99% | 36.92% | −33.67% | −35.05% |

| S4 | −81.25% | −83.53% | −80.96% | −83.41% | −80.65% | −83.85% | 440.76% | 339.77% | 452.59% | 346.59% | 506.19% | 400.13% | −25.58% | −33.65% | 38.89% | 30.06% | −34.78% | −43.67% |

| Moisture | Indoor Relative Humidity (RH) | Predicted Percentage of Dissatisfied (PPD) | Predicted Mean Vote (PMV) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cities | Montreal | Vancouver | Miami | Montreal | Vancouver | Miami | Montreal | Vancouver | Miami | |||||||||

| Models | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model | WUFI Model | Integrated Model |

| S1 | −12.19% | −41.06% | −8.36% | −32.23% | 12.01% | 0.73% | 9.75% | 13.54% | 9.90% | 12.81% | 4.21% | 5.22% | 36.19% | 52.98% | 38.07% | 50.41% | 10.65% | 14.93% |

| S2 | −25.62% | −41.04% | −19.58% | −32.34% | 9.21% | 0.69% | 10.68% | 13.72% | 10.86% | 12.87% | 4.55% | 5.24% | 39.87% | 54.07% | 42.09% | 50.67% | 12.28% | 14.98% |

| S3 | −40.30% | −40.62% | −31.44% | −32.539% | 0.99% | 0.65% | 12.57% | 14.73% | 12.59% | 13.26% | 5.15% | 5.25% | 48.34% | 60.75% | 49.55% | 52.32% | 14.64% | 15.04% |

| S4 | −40.59% | −40.50% | −31.71% | −32.543% | 0.90% | 0.64% | 12.72% | 14.85% | 12.65% | 13.34% | 5.17% | 5.26% | 49.00% | 61.50% | 49.76% | 52.73% | 14.72% | 15.07% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heibati, S.; Maref, W.; Saber, H.H. Assessing the Energy, Indoor Air Quality, and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Two: Integrating the Indoor Air Quality, Moisture, and Thermal Comfort. Energies 2021, 14, 4915. https://doi.org/10.3390/en14164915

Heibati S, Maref W, Saber HH. Assessing the Energy, Indoor Air Quality, and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Two: Integrating the Indoor Air Quality, Moisture, and Thermal Comfort. Energies. 2021; 14(16):4915. https://doi.org/10.3390/en14164915

Chicago/Turabian StyleHeibati, Seyedmohammadreza, Wahid Maref, and Hamed H. Saber. 2021. "Assessing the Energy, Indoor Air Quality, and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Two: Integrating the Indoor Air Quality, Moisture, and Thermal Comfort" Energies 14, no. 16: 4915. https://doi.org/10.3390/en14164915

APA StyleHeibati, S., Maref, W., & Saber, H. H. (2021). Assessing the Energy, Indoor Air Quality, and Moisture Performance for a Three-Story Building Using an Integrated Model, Part Two: Integrating the Indoor Air Quality, Moisture, and Thermal Comfort. Energies, 14(16), 4915. https://doi.org/10.3390/en14164915