1. Introduction

Spray drying, a process first introduced by Percy in 1870 [

1], is the most widely used method for producing milk powders. The process requires atomization of a concentrated liquid feed into tiny droplets (typical 10–200 µm) that undergo evaporation to produce dry solid powder [

2,

3]. In the Netherlands, milk powder contributes to around 13% of the total dairy exports of the country [

4]. Despite being a mature technology, conventional dryers suffer from major challenges, such as large equipment size and high operational and maintenance costs. While counter-current dryers are thermally more efficient and require lesser energy input, owing to bigger temperature gradients between droplets and the air, than the co-current dryers [

5,

6], they are limited to thermally resistant materials such as detergents [

6,

7].

Although in the past years, many studies on spray drying have been published, less focus has been directed towards process intensification of the spray drying process with regard to reducing equipment sizes or increasing drying rates. According to Langrish [

8], reducing chamber volume is one of the biggest challenges concerning the spray drying industry. Therefore, taking into account the growing world population and increase in food demand [

9], combined with restrictions on CO

2 emissions [

10], industries are looking towards novel and improved technologies that can offer a lower carbon footprint, bigger capacities, and improved product characteristics [

11].

This study investigates a novel compact dryer for producing skim milk powder (heat-sensitive material) based on a counter-current mechanism. The concept of the design originates from the Radial Multizone Dryer (RMD) [

12,

13,

14], wherein a process intensified spray drying is achieved by applying high air inlet temperatures (300–400 °C) and high-G acceleration using vortex chamber technology. Recently, Rahman et al. [

15] studied numerically the benefits of RMD and identified optimum parameters (solids outlet location, droplet size, G-acceleration) for efficient spray drying operation in RMD. A central feature of RMD is the counter-current interaction of hot air and feed spray in the central hot zone of the dryer. This is investigated in detail via the Computational Fluid Dynamics (CFD) and experimental approach in this study.

CFD modeling of the spray drying process is a well-established technique that has been widely used for investigating airflow patterns in spray dryers [

16,

17], studying skim milk drying kinetics [

18], assessing wall depositions [

19], exploring new modeling approaches to predict particle agglomeration in dryers [

20,

21], and aiding in the assessment of novel technologies [

22,

23,

24]. Concerning dryer volume reduction, Frydman et al. [

25], with the help of CFD, demonstrated that high drying rates in a co-current dryer could be achieved using super-heated steam.

Kievet [

26] developed a 2D CFD model and validated it by comparing gas temperature and velocity profiles at different axial heights of a pilot-scale co-current dryer. It was found that the model accurately predicts the high-velocity core zone and the outer recirculation zones in the dryer. Subsequently, many authors [

27,

28,

29] have used the geometry and boundary conditions from the work of Kievet [

26] to study the influence of various parameters on spray drying performance. Huang et al. [

27,

30] studied the influence of air temperature, feed rate, swirl intensity, etc., Salem et al. [

29] used the model of Kievet [

23] to predict moisture distribution profiles of salt solution, and Anandharamakrishnan et al. [

28] compared short form and tall form dryers for drying of heat-sensitive materials.

Sadripour et al. [

31] validated a steady-state CFD model for spray drying of 20% skim milk and salt solutions. An average error of 5.5% was obtained. According to the authors, inlet temperature and initial droplet diameter are amongst the most important parameters controlling spray dryer performance.

Jin et al. [

32,

33] performed industrial-scale skim milk spray drying simulations using the Reaction Engineering Approach (REA). The authors found that the reflecting droplet-wall boundary condition resembles the industrial observations with the overprediction of the outlet temperature by 2–3 °C. Furthermore, the influence of spray cone angle on drying history and residence time was discussed.

Harvie et al. [

34] applied a steady-state CFD modeling approach to skim milk drying in tall form spray dryers. The study revealed a strong dependency of initial spray momentum (droplet sizes and velocity) on the particle trajectories. Here, the big particles impacted dryer walls or were caught in recirculation zones, whilst the smaller particles followed gas streamlines resulting in a wide range of particle residence times (1–30 s). The model results were compared with the experimental value of final particle moisture content. An underprediction of the data was attributed to the inadequate droplet-wall boundary condition.

Computational studies on counter-current spray drying are limited, mainly due to the complex hydrodynamics, low availability of such dryers in the Research and Development sector [

6,

35], and possibly because of the relatively narrow product range. Ali et al. [

6] conducted a CFD study of a pilot-scale counter-current tower for detergent production. The model showed overprediction of the final moisture content and outlet temperature attributed to the droplet-wall boundary condition and longer particle residence times.

Wawrzyniak et al. [

36] validated a 3D, transient CFD model to the experimental temperature and velocity measurements for an industrial spray drying tower. The model followed a similar trend with the experiments; however, due to the high swirling and an unsteady flow near the inlets and mixing zones, large discrepancies were observed. It was concluded that despite complex, unsteady flow phenomena, the model was able to show a good approximation of air velocity fields to the measured values.

In the above-presented literature for modeling the two-phase spray drying processes, authors used the Eulerian–Lagrangian multiphase modeling approach based on the Particle-Source-In Cell (PSI-CELL) model of Crowe et al. [

37] The choice for the turbulence model depended on the type of inlet flow. For low to moderate swirling flows, as encountered in co-current spray dryer geometries, the standard k-epsilon turbulence model has shown good accuracy [

28,

31,

32,

34,

38,

39], while for highly swirling flows such as those encountered in counter-current dryers, the Reynolds Stress Model [

6,

36,

40], k-omega SST model [

41], or k-epsilon RNG [

29,

42,

43] were recommended. Furthermore, using reflecting particle-wall boundary conditions provided more accurate results than escape particle-wall boundary conditions [

6,

32].

Recently, Rahman et al. [

44] conducted experimental trials of skim milk drying in a counter-current mechanism. In the study, unevaporated milk droplets were found to accumulate on the bottom wall; parts of them also entered the hot air inlet section. For a stable spray drying operation, it is crucial that milk droplets do not enter the hot air inlet section as this can lead to milk burning due to high temperatures and long exposure time and thus can cause explosion risks.

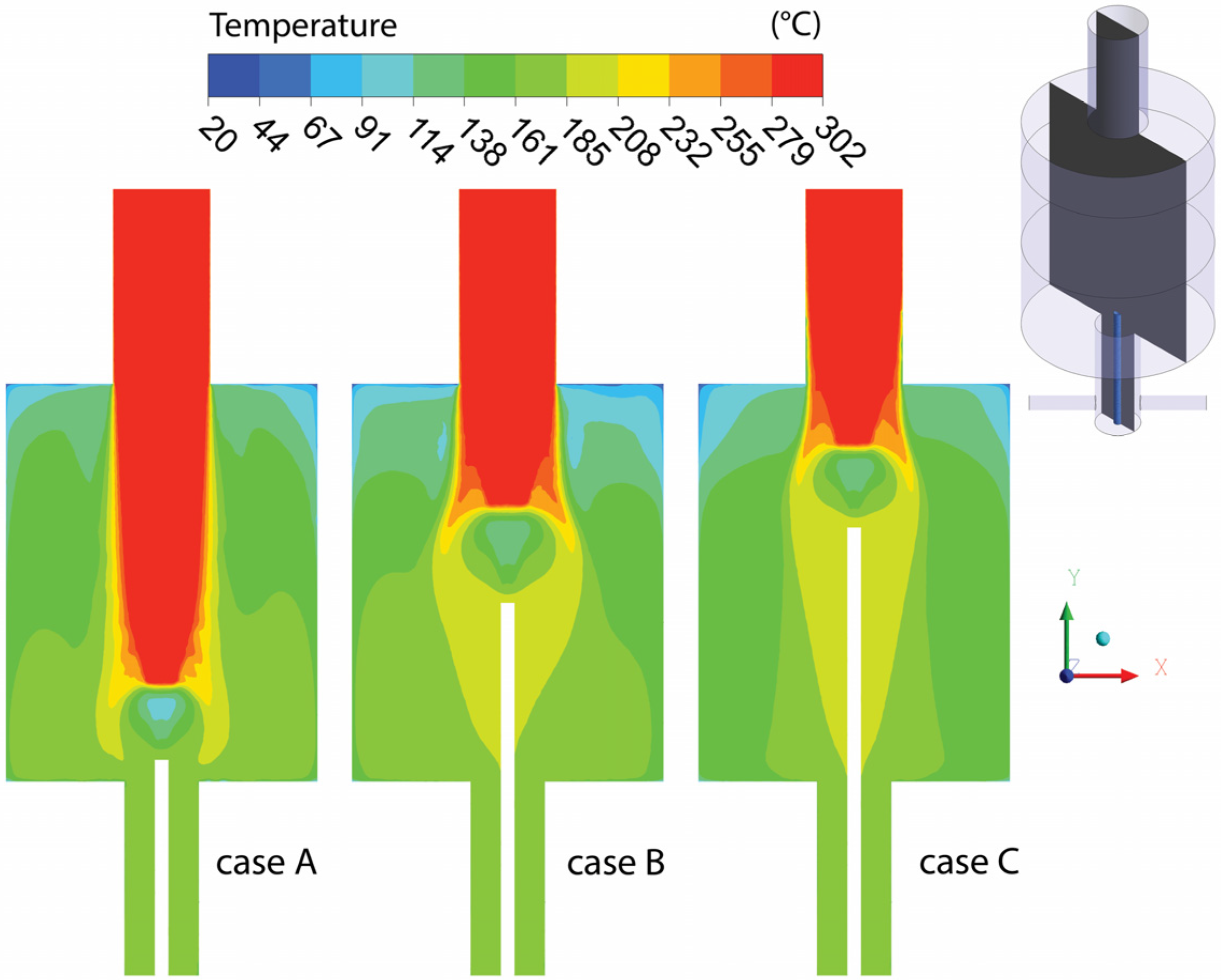

Hence, in this study, we modify this setup by injecting feed from the bottom and hot air from the top. It is our hypothesis that injecting feed from the bottom (see

Figure 1), in the direction opposite to gravity, would increase the overall residence time of the droplets/particles, and thus particles can be dry before impinging dryer walls. Moreover, we believe that it can reduce the risks of droplets entering the air inlet and, consequently, minimize product deposition on the walls of the air inlet section.

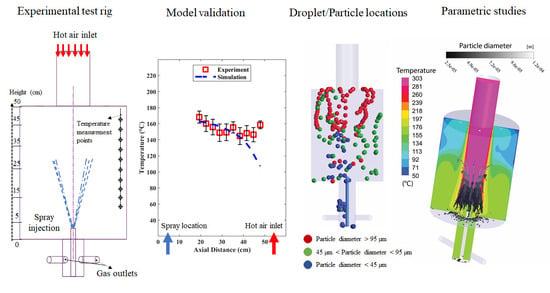

In the present paper, we extend the understanding of the counter-current spray drying mechanism of skim milk using a CFD technique. Validation of the model is carried out by comparing the numerical results with experimental temperature measurements. The influence of nozzle position and operating parameters such as initial spray Sauter Mean Diameter (SMD), air inlet temperature, and feed rate on the temperature and moisture fields, particle drying histories, and product recovery is discussed in detail.

4. Conclusions

In this study, a CFD model of skim milk drying in a novel counter flow dryer was presented. Three-dimensional, steady-state simulations were carried out using two-way coupling between the gas and discrete phase employing the Eulerian–Lagrangian multiphase model. Drying kinetics of skim milk was incorporated using the REA approach. For model validation, numerical predictions were compared to the experimental data (temperature profiles and final SMD) obtained during the skim milk test. The model showed good agreement with a maximum average error of 5% for the radial probes, while an overprediction of the mean diameter was observed (30 µm against 27 µm).

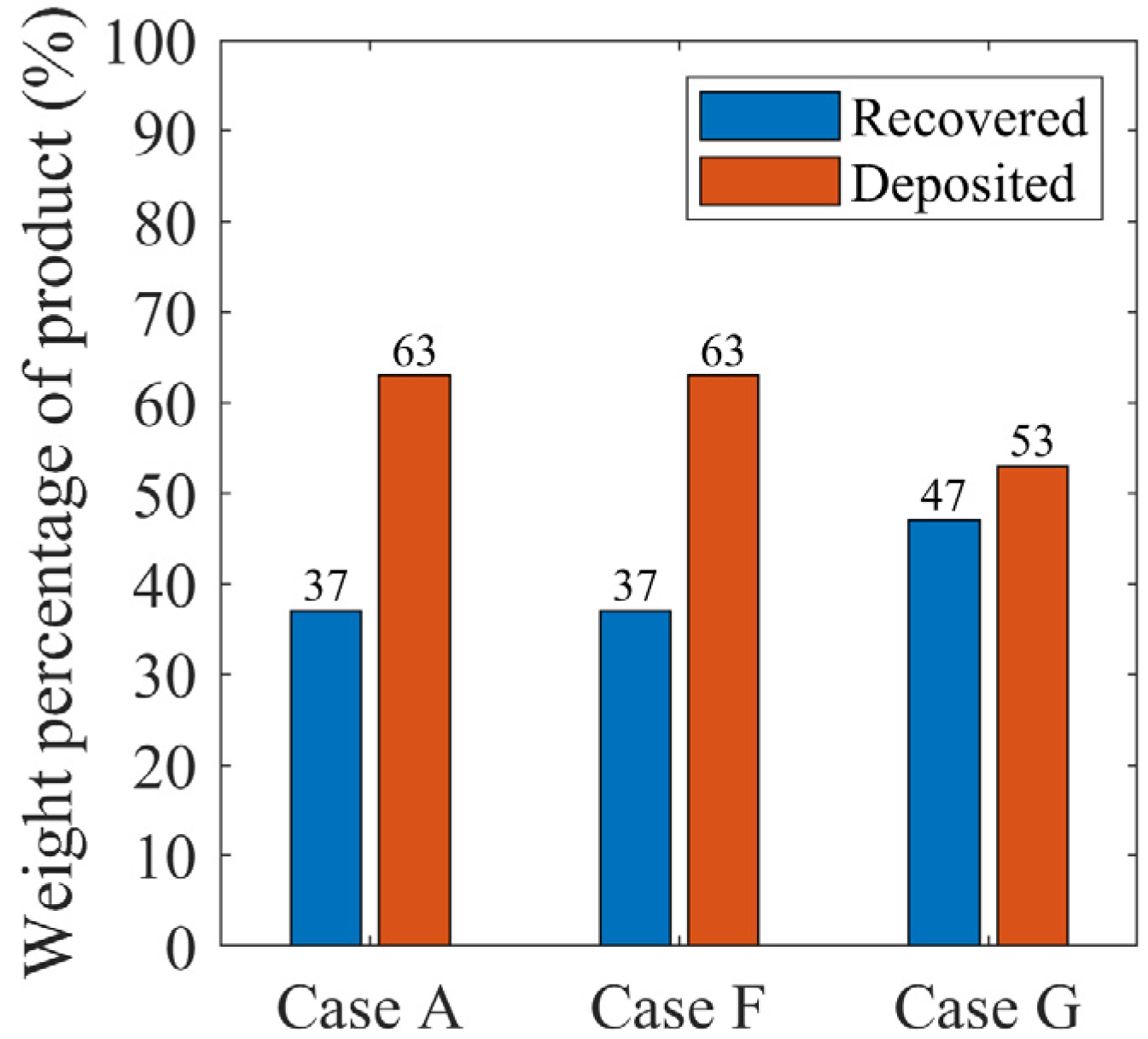

Furthermore, to evaluate the dryer performance, multiple cases were studied. The results revealed that nozzle position and feed rate had the most pronounced effect on product recovery, mean particle diameter, and mean residence time. Placing the nozzle at around mid-height of the dryer (≈23 cm) resulted in maximum product recovery, mean particle diameter, and mean residence time. Similar trends were observed with the maximum feed rate of 26 kg/h. Here, due to increased spray penetration upstream in the dryer, the final mean particle diameter and residence time also increased.

The influence of the initial spray SMD and air inlet temperatures on the evaporation zones were also discussed. It was found that due to the difference in spray penetration inside the dryer, the maximum evaporation zones vary significantly. In the case of an initial spray SMD of 58 µm, the maximum evaporation occurred upstream of the dryer (35–50 cm), whereas, in the case of the smallest SMD of 38 µm, the maximum evaporation zone occurred close to the atomizer (0–10 cm). In a similar fashion, drying and evaporation rates in the dryer were found to be a function of air inlet temperature; however, high evaporation rates were noted only in the initial 10–20 cm of distance from the atomizer where droplet concentration was highest in the central core flow. Further downstream of the atomizer (>20 cm), droplets/particles moved radially outwards in the mixing zone (recirculation zones), where evaporation rates were low for all investigated cases.

The results of this study show the potential of using high air inlet temperature in a small volume. The data can be used to optimize the dryer by including swirling/rotating flows in the periphery of the dryer for efficient separation of dried particles and their removal to a mild temperature zone in order to avoid product degradation.