Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA

Abstract

:1. Introduction

2. Methodology

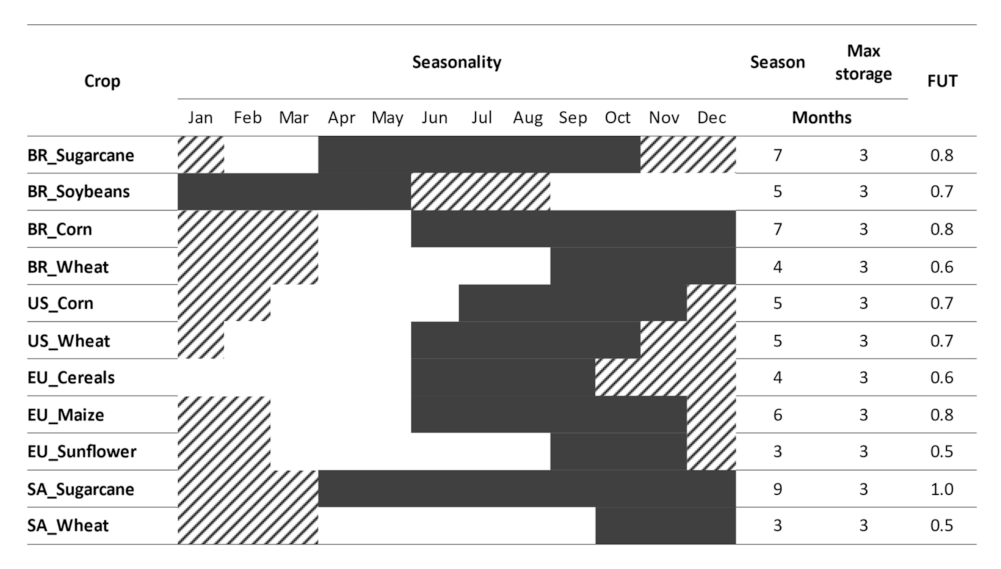

2.1. Feedstock Availability

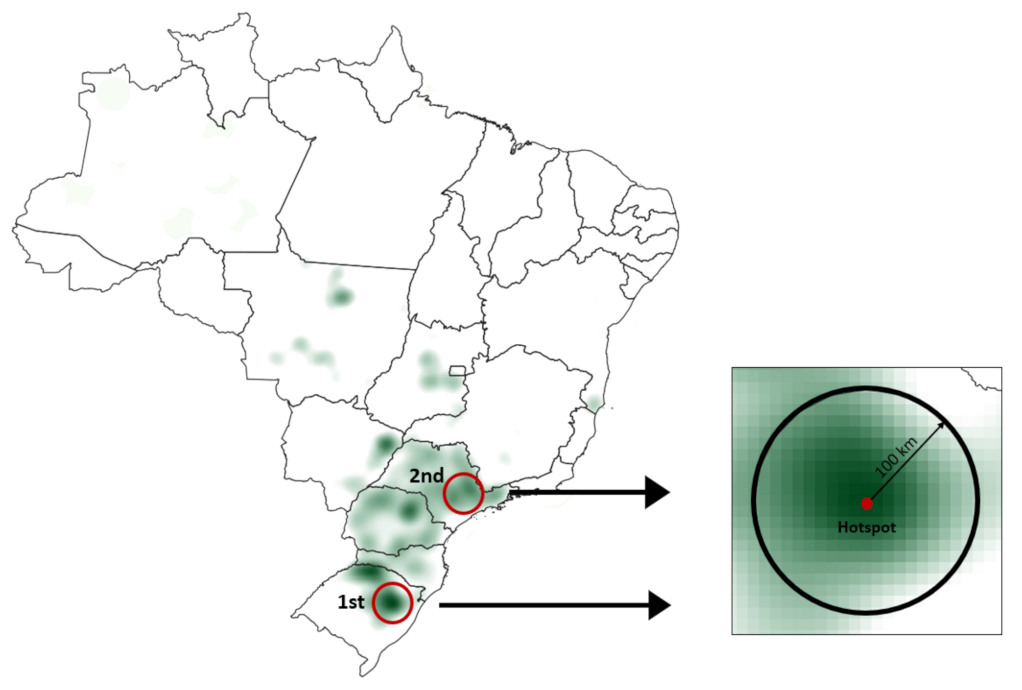

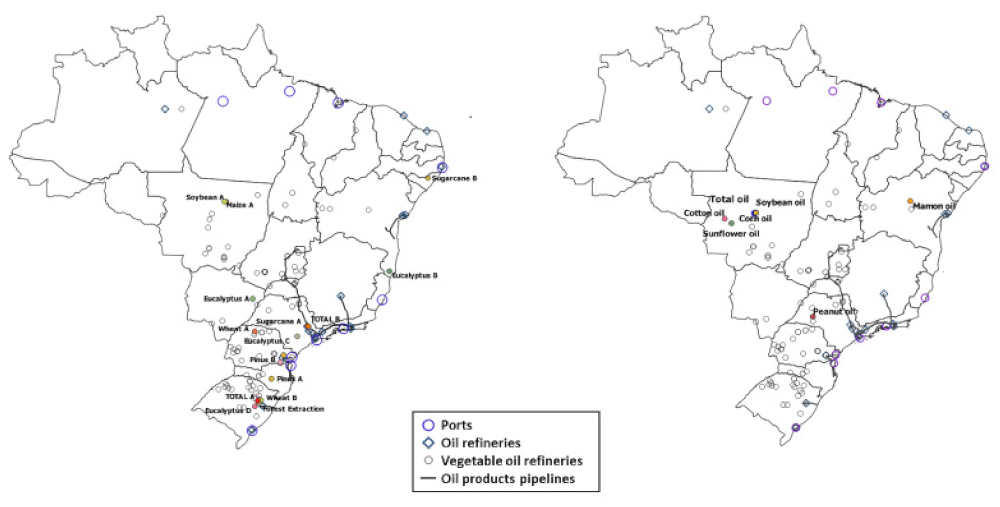

2.1.1. Brazil

- RPj: Residues technical potential (TJ/year)

- Ai: Agricultural area (ha)

- Pi: Crop productivity (kg/ha)

- RPRj,i: Residue-to-product ratio of residue j produced by crop i (Dimensionless. Mass basis.)

- ESRj: Environmentally sustainable removal rate of residue j (%)

- ARj: Availability rate of residue j (%)

- OPj: Vegetable oil potential (TJ/year)

- Pi: Oil crop i production (t/year)

- OSRj,i: Oil j content in oil crop i (Dimensionless. Mass basis)

- EEj: Oil j extraction efficiency (%)

- LHVj: Low heating value of oil j (MJ/kg)

- AOj: Oil j availability factor (%)

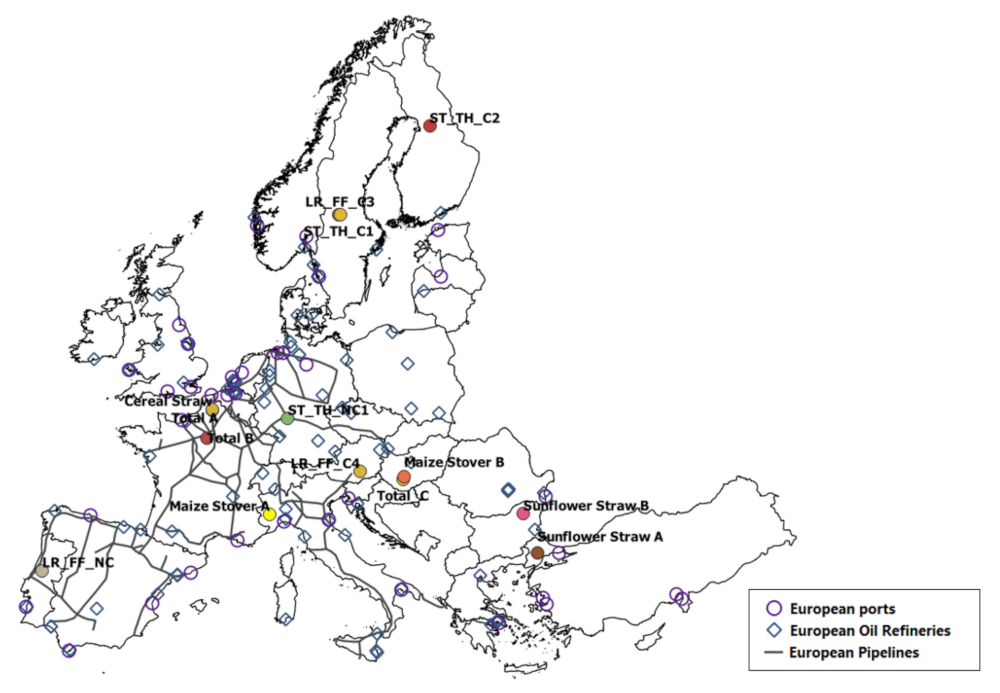

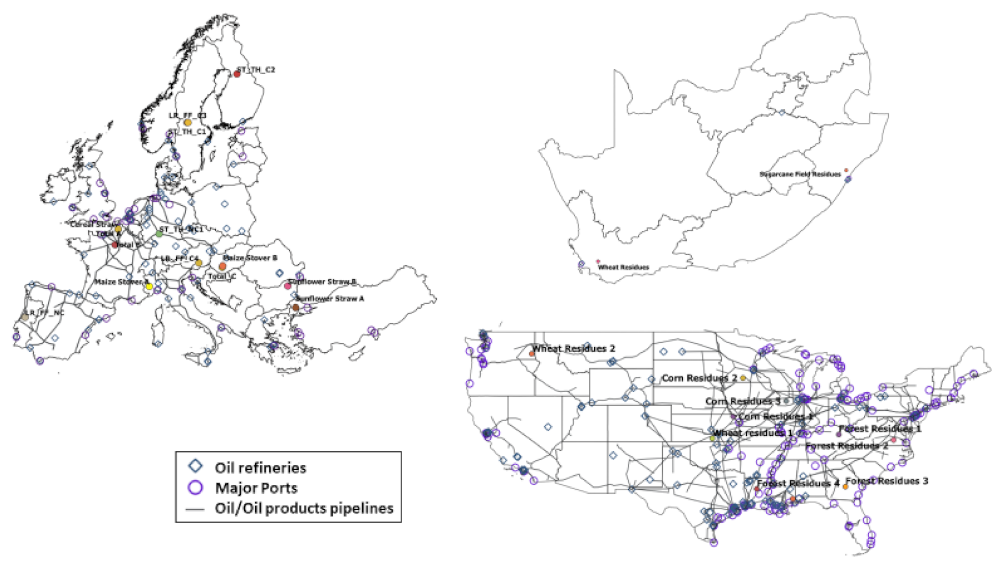

2.1.2. Europe

2.1.3. South Africa

2.1.4. United States (US)

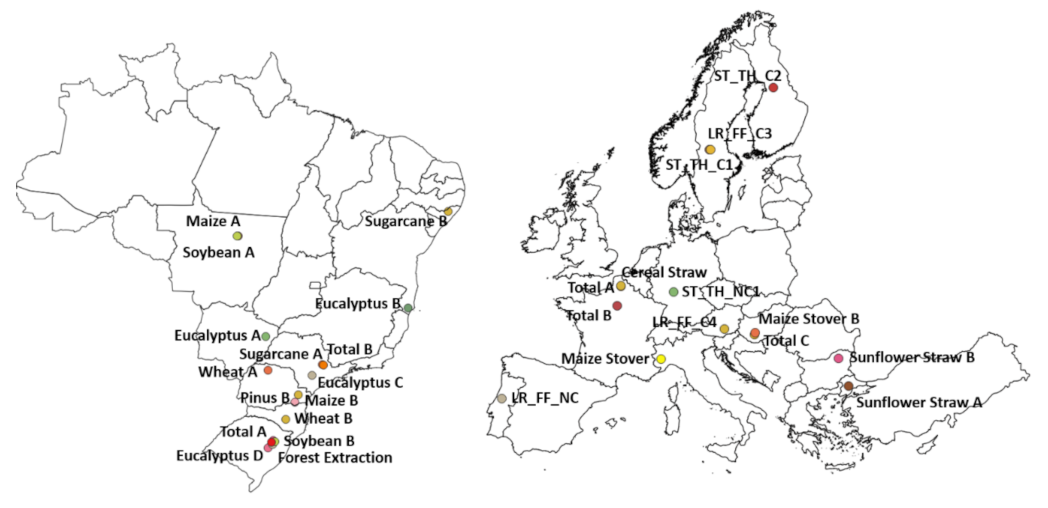

2.2. Georeferenced Analysis

2.3. Feedstock Cost Estimation

- Cf: Feedstock costs (USD/GJ)

- Ccb: Biomass collection costs (USD/GJ)

- Ctb: Biomass transport costs (USD/GJ.km)

- PSVO: Vegetable oil prices (USD/GJ)

- Cto: Vegetable oil transport costs (USD/GJ.km)

- d: Distances between each regional division inside the 100 km area and the hotspot (km)

- tf: tortuosity factor (−)

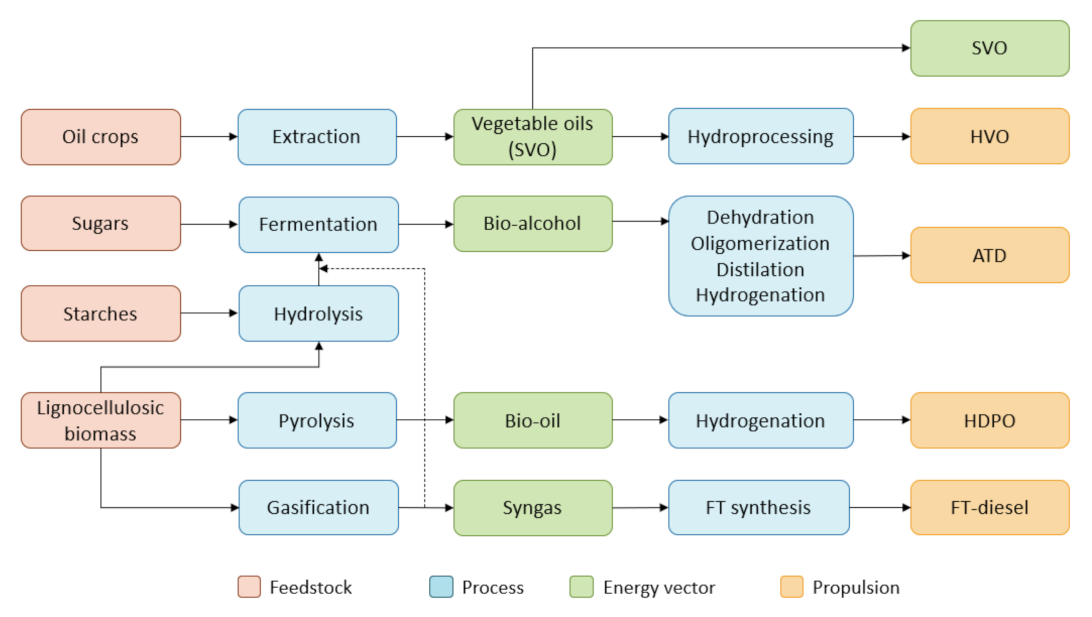

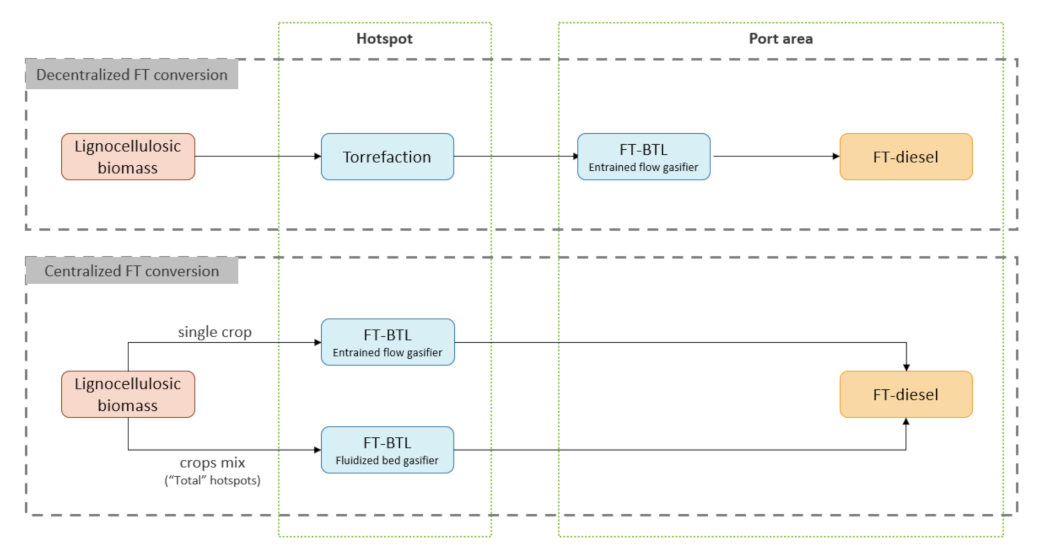

2.4. Techno-Economic Pathways to Produce Maritime Biofuels

- Chotspot: Equipment costs in the hotspot scale (USD)

- Cref: Equipment costs in the reference plant scale (USD)

- Shotspot: Scale in the hotspot plant

- Sref: Scale in the reference plant

- FE: Escalation factor

- C2018: Costs adjusted to 2018 values (USD)

- Ct: Costs in the reference year (USD)

- CEPCI2018: CEPCI value for 2018

- CEPCIt: CEPCI value the reference year

- n: Plant lifetime (30 years)

- Pbiobunker: Biobunker production (GJ)

- r: Discount rate (%)

2.5. Total Biobunker Costs

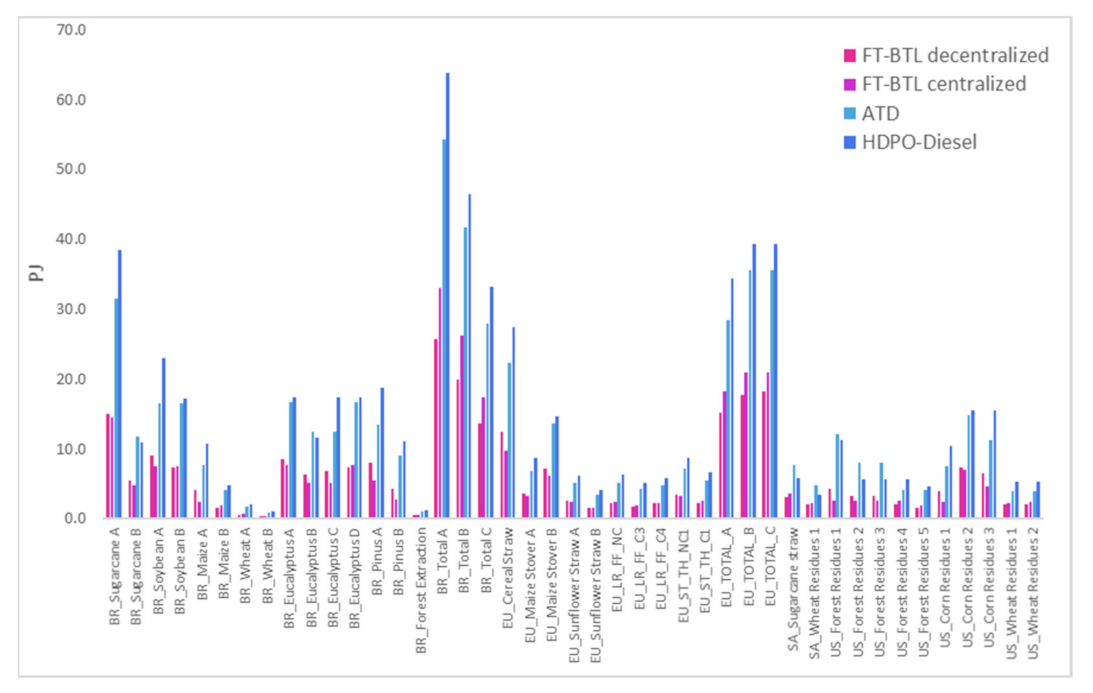

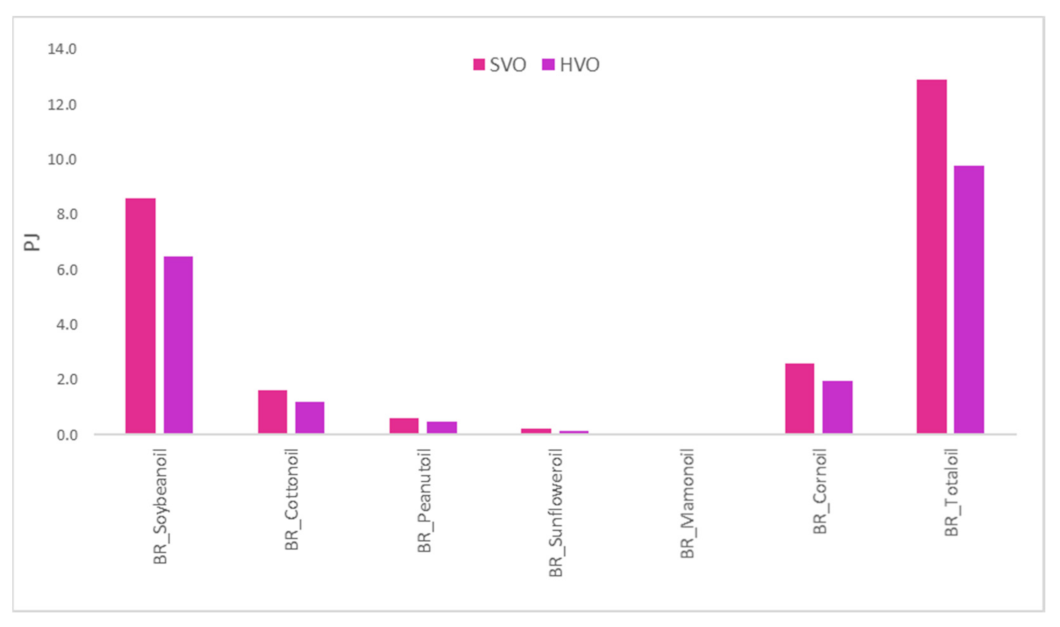

3. Results

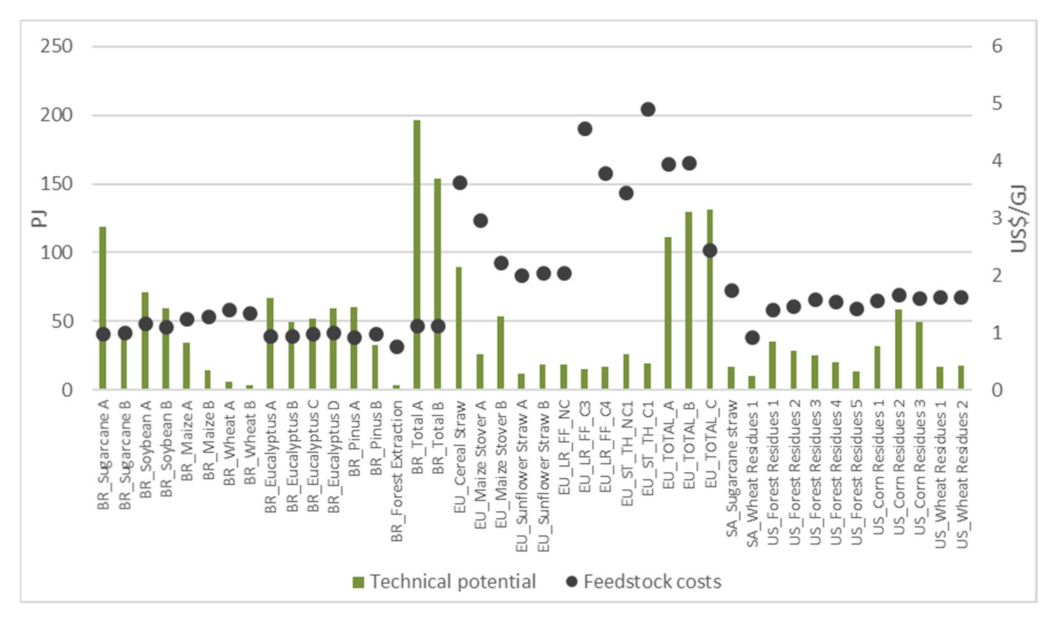

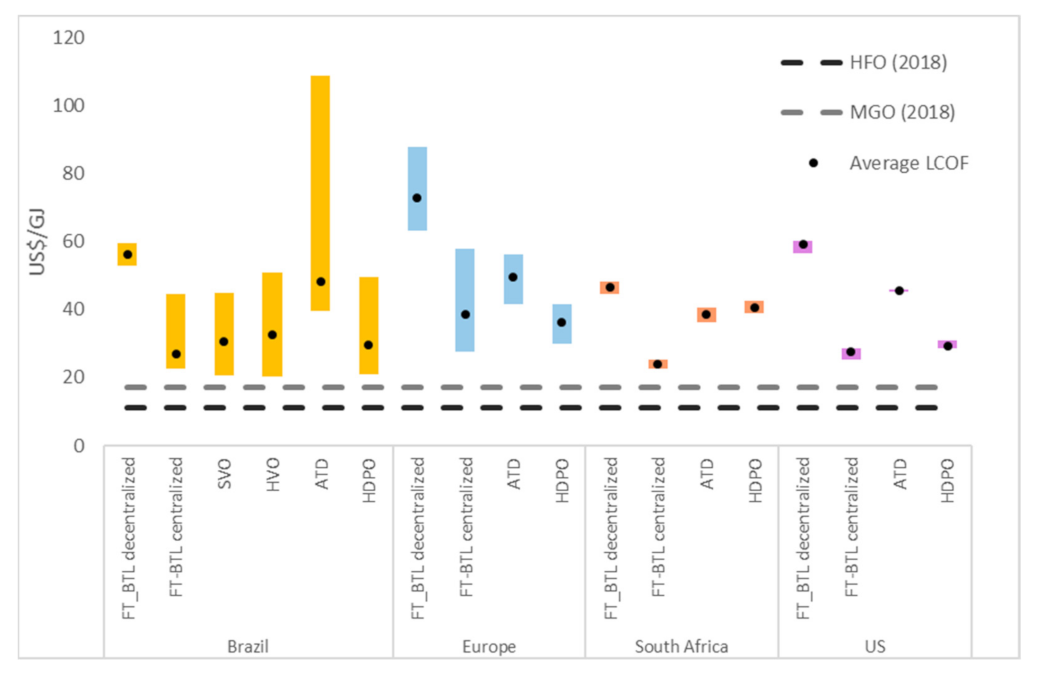

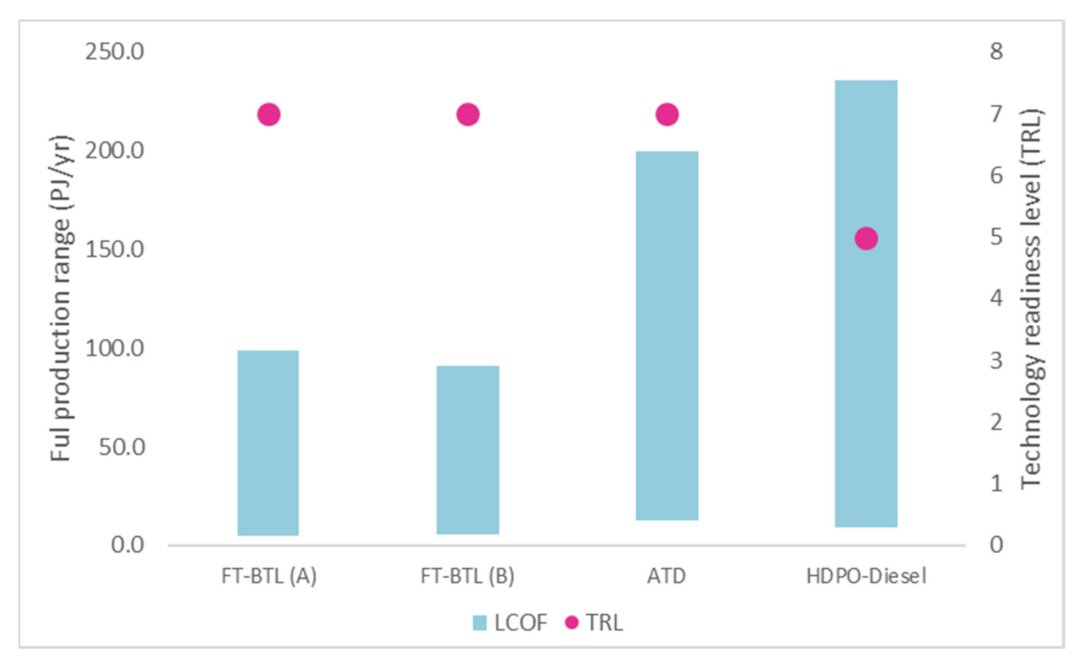

3.1. Levelized Costs of Fuel

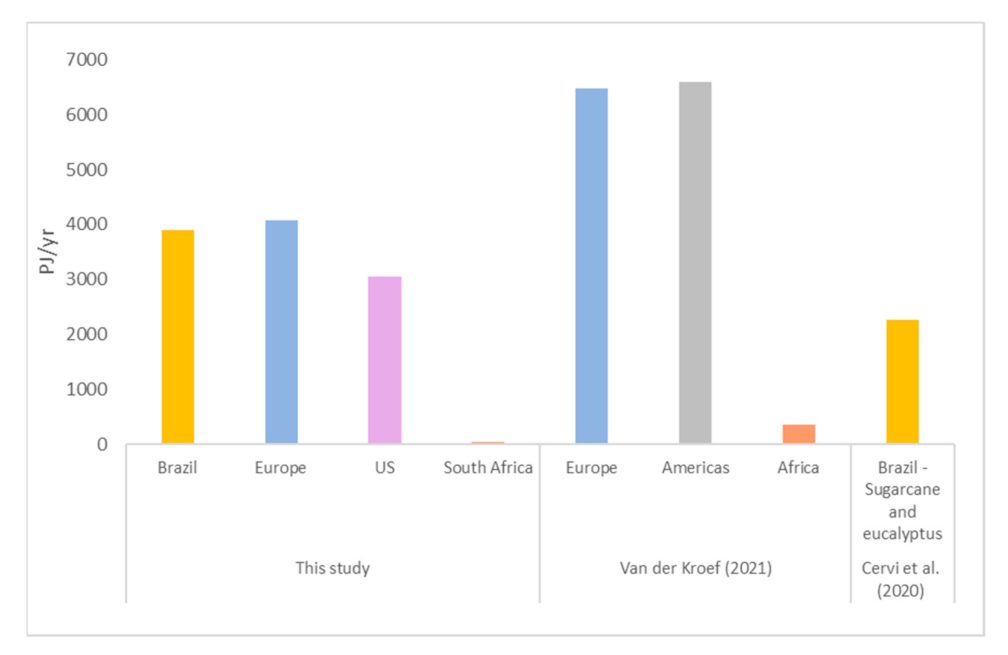

3.2. Total Biobunker Costs

4. Discussion

5. Conclusions

- Feedstock availability assessment has not considered biomass use in other hard-to-decarbonize sectors, such as aviation and industry;

- Fuel transport mode choice was based on proximity to infrastructure and not to main transport stations, which could increase fuel transportation costs;

- Perform an integrated assessment to capture in greater detail the impacts in energy and land use of replacing conventional maritime fuels for biofuels.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IMO. Fourth IMO GHG Study 2020; IMO: London, UK, 2020. [Google Scholar]

- ECOFYS. Potential of Biofuels for Shipping; ECOFYS: Utrecht, The Netherlands, 2012; pp. 1–114. [Google Scholar]

- IEA International Shipping. Tracking Clean Energy Progess. Available online: https://www.iea.org/tcep/transport/shipping/ (accessed on 1 October 2018).

- Prussi, M.; Scarlat, N.; Acciaro, M.; Kosmas, V. Potential and limiting factors in the use of alternative fuels in the European maritime sector. J. Clean. Prod. 2021, 291, 125849. [Google Scholar] [CrossRef] [PubMed]

- IEA. Bioenergy Biofuels for the Marine Shipping Sector; IEA: Copenhagen, Denmark, 2017; pp. 1–86. [Google Scholar]

- EC European Maritime Sector. Technical Report; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- ETIP. Use of Biofuels in Shipping; ETIP: Brussels, Belgium, 2017; pp. 2015–2018. [Google Scholar]

- Andersson, K.; Brynolf, S.; Hansson, J.; Grahn, M. Criteria and decision support for a sustainable choice of alternative marine fuels. Sustainability 2020, 12, 3623. [Google Scholar] [CrossRef]

- Müller-Casseres, E.; Carvalho, F.; Nogueira, T.; Fonte, C.; Império, M.; Poggio, M.; Wei, H.K.; Portugal-Pereira, J.; Rochedo, P.R.R.; Szklo, A.; et al. Production of alternative marine fuels in Brazil: An integrated assessment perspective. Energy 2021, 219, 119444. [Google Scholar] [CrossRef]

- Lloyd’s Register. UMAS Techno-Economic Assessment of Zero-Carbon Fuels; Lloyds Register: London, UK, 2020. [Google Scholar]

- SSI. The Role of Sustainable Biofuels in the Decarbonisation of Shipping; SSI: Madrid, Spain, 2019. [Google Scholar]

- Schulze, R.E.; Maharaj, M.; Warburton, M.L.; Gers, C.J.; Horan, M.J.C.; Kunz, R.P.; Clark, D.J. South African Atlas of Climatology and Agrohydrology; Water Research Community: Pretoria, South Africa, 2008. [Google Scholar]

- Hugo, W. BioEnergy Atlas for South Africa; SAEON: Pretoria, South Africa, 2016; pp. 1–193. [Google Scholar]

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Port Economics, Management and Policy; Routledge: New York, NY, USA, 2019. [Google Scholar]

- Al-Enazi, A.; Okonkwo, E.C.; Bicer, Y.; Al-Ansari, T. A review of cleaner alternative fuels for maritime transportation. Energy Rep. 2021, 7, 1962–1985. [Google Scholar] [CrossRef]

- Ecofys Shipping: A Missing Opportunity? Available online: https://www.ecofys.com/files/files/ecofys-2012-biofuels-in-shipping-biofuels-international-2012-05.pdf (accessed on 10 September 2018).

- Moirangthem, K. Alternative Fuels for Marine and Inland Waterways; European Commission: Brussels, Belgium, 2016; ISBN 978-92-79-56957-9. [Google Scholar]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Brynolf, S.; Fridell, E.; Andersson, K. Environmental assessment of marine fuels: Liquefied natural gas, liquefied biogas, methanol and bio-methanol. J. Clean. Prod. 2014, 74, 86–95. [Google Scholar] [CrossRef]

- Gilbert, P. From reductionism to systems thinking: How the shipping sector can address sulphur regulation and tackle climate change. Mar. Policy 2014, 43, 376–378. [Google Scholar] [CrossRef]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of full life-cycle air emissions of alternative shipping fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Gilbert, P.; Bows-Larkin, A.; Mander, S.; Walsh, C. Technologies for the high seas: Meeting the climate challenge. Carbon Manag. 2014, 5, 447–461. [Google Scholar] [CrossRef]

- DNV GL. Comparison of Alternative Marine Fuels; DNV GL: Høvik, Norway, 2019. [Google Scholar]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Biofuel as an alternative shipping fuel: Technological, environmental and economic assessment. Sustain. Energy Fuels 2019, 3, 899–909. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Pavlenko, N.; Rutherford, D.; Osipova, L.; Comer, B. The potential of liquid biofuels in reducing ship emissions. Int. Counc. Clean Transp. 2020, 1, 31. [Google Scholar]

- Tanzer, S.E.; Posada, J.; Geraedts, S.; Ramírez, A. Lignocellulosic marine biofuel: Technoeconomic and environmental assessment for production in Brazil and Sweden. J. Clean. Prod. 2019, 239, 117845. [Google Scholar] [CrossRef]

- Portugal-Pereira, J.; Soria, R.; Rathmann, R.; Schaeffer, R.; Szklo, A. Agricultural and agro-industrial residues-to-energy: Techno-economic and environmental assessment in Brazil. Biomass Bioenergy 2015, 81, 521–533. [Google Scholar] [CrossRef]

- Carvalho, F.; da Silva, F.T.F.; Szklo, A.; Portugal-Pereira, J. Potential for biojet production from different biomass feedstocks and consolidated technological routes: A georeferencing and spatial analysis in Brazil. Biofuels Bioprod. Biorefining 2019, 13, 22. [Google Scholar] [CrossRef]

- IBGE. Municipal Agricultural Production: Temporary and Permanent Crops. Available online: https://biblioteca.ibge.gov.br/index.php/biblioteca-catalogo?view=detalhes&id=766 (accessed on 20 August 2018).

- IBGE. Vegetal Extraction and Forestry Production. Available online: https://biblioteca.ibge.gov.br/visualizacao/periodicos/74/pevs_2018_v33_informativo.pdf (accessed on 1 August 2018).

- IPEA. Diagnóstico dos Resíduos Orgânicos do Setor Agrossilvopastoril e Agroindústrias Associadas; IPEA: Brasília, Brazil, 2012. [Google Scholar]

- Dias, J.M.C.D.S.; De Souza, D.T.; Braga, M.; Onoyama, M.M.; Miranda, C.H.B.; Barbosa, P.F.D.; Rocha, J.D. Produção de Briquetes e Péletes a Partir de Resíduos Agrícolas, Agroindustrais e Florestais; Embrapa Agroenergia: Brazilia, Brazil, 2012; p. 132. [Google Scholar]

- Macedo, I.C.; Seabra, J.E.A.; Silva, J.E.A.R. Green house gases emissions in the production and use of ethanol from sugarcane in Brazil: The 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 2008, 32, 582–595. [Google Scholar] [CrossRef]

- Santos, V.E.N. Proposta Metodológica Para a Criação de Biorrefinaria de Bagaço de Cana Produtora de Bioplataformas Químicas: Um Ensaio Preliminar Como Parte de um Sistema de Simbiose Industrial em Campos dos Goytacazes—RJ. Master’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2013. [Google Scholar]

- BiodieselBR Rendimento Sementes Óleo. Available online: https://www.biodieselbr.com/biodiesel/sementes/rendimento-sementes-oleo (accessed on 10 April 2020).

- EMBRAPA Tecnologia de Alimentos. Available online: https://www.agencia.cnptia.embrapa.br/gestor/tecnologia_de_alimentos/arvore/CONT000gc8yujq302wx5ok01dx9lcx1g7v3u.html (accessed on 5 February 2020).

- Canto, J.L. Do Colheita Mecanizada de Biomassa Florestal Para Energia; Universidade Federal de Viçosa: Viçosa, Brazil, 2009. [Google Scholar]

- OECD. OECD-FAO Agricultural Outlook 2019–2028; OECD: Paris, France, 2019; pp. 1–27. [Google Scholar]

- Jiménez Espadafor, F.; Torres García, M.; Becerra Villanueva, J.; Moreno Gutiérrez, J. The viability of pure vegetable oil as an alternative fuel for large ships. Transp. Res. Part D Transp. Environ. 2009, 14, 461–469. [Google Scholar] [CrossRef]

- Dees, M.; Elbersen, B.; Fitzgerald, J.; Vis, M.W.; Antilla, P.; Forsell, N.; Ramirez-Almeyda, J.; Garcia Galindo, D.; Glavinjic, B.; Staritsky, I.; et al. A Spatial Data Base on Sustainable Biomass Cost—Supply of Lignocellulosic Biomass in Europe—Methods & Data Sources; Project Report. S2BIOM—A Project Funded under the European Union 7th Framework Programme for Research; Grant Agreement no. 608622; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- S2biom Annex D2.4—Biomass Properties. Available online: https://www.s2biom.eu/images/Publications/Annex_D2.4_S2BIOM_biomass_properties.pdf (accessed on 15 July 2020).

- SAEON South Africa Bioernergy Atlas Portal. Available online: http://bea.dirisa.org/atlas/biomass (accessed on 20 April 2020).

- Hugo, W. Biomass from Agricultural Residues—Annual Availability of Biomass and Estimated Energy Value. In BioEnergy Atlas for South Africa; SAEON: Pretoria, South Africa, 2015; pp. 1–7. [Google Scholar]

- Hugo, W. SAEON Potential and Yields. Yield Rations and Yield Improvements Possibilities. In BioEnergy Atlas for South Africa; SAEON: Pretoria, South Africa, 2015. [Google Scholar]

- Hugo, W. Fact Sheet: Potential, Availability and Realistic Energy Conversion. In BioEnergy Atlas for South Africa; SAEON: Pretoria, South Africa, 2017; p. 33. [Google Scholar]

- Sugartech SA Bagasse Calorific Values. Available online: http://www.sugartech.co.za/extraction/bagasseCV/index.php (accessed on 30 April 2020).

- U.S. Department of Energy. NREL The Biofuel Atlas. Available online: https://maps.nrel.gov/biomass/?aL=QCty_y%255Bv%255D%3Dt&bL=clight&cE=0&lR=0&mC=40.21244%2C-91.625976&zL=4 (accessed on 5 November 2020).

- Milbrandt, A. A Geographic Perspective on the Current Biomass Resource Availability in the United States; NREL Tech. Rep.; NREL: Denver, CO, USA, 2005; pp. 1–50. [Google Scholar]

- USDA National Agricultural Statistics Service Census of Agriculture. Available online: https://www.nass.usda.gov/Statistics_by_Subject/index.php?sector=CROPS (accessed on 19 May 2021).

- U.S. Department of Energy. U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; Office of the Biomass Program: Oak Ridge, TN, USA, 2011. [Google Scholar]

- ECN Phyllis2—Database for the Physico-Chemical Composition of (Treated) Lignocellulosic Biomass, Micro- and Macroalgae, Various Feedstocks for Biogas Production and Biochar. Available online: https://phyllis.nl/ (accessed on 10 January 2020).

- U.S. Forest Inventory Analysis Timber Products Output. Available online: https://www.fia.fs.fed.us/program-features/tpo/ (accessed on 5 November 2020).

- Hoffmann, B.S.; Salem, A.; Schaeffer, R.O. Potencial Termelétrico a Carvão no Rio Grande do Sul Diante Restrições de Disponibilidade de Água e Objetivos de Redução de Emissões de CO2, Aplicando a Queima em Leito Fluidizado; Universidade Federal do Rio de Janeiro: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Sultana, A.; Kumar, A. Development of tortuosity factor for assessment of lignocellulosic biomass delivery cost to a biorefinery. Appl. Energy 2014, 119, 288–295. [Google Scholar] [CrossRef]

- IFPEN Biofuels Dashboard 2020. Available online: https://www.ifpenergiesnouvelles.com/article/biofuels-dashboard-2020 (accessed on 5 April 2021).

- JCR for the European Commission’s Knowledge Centre for Bioeconomy Brief on biomass for energy in the European Union. Publ. Off. Eur. Union 2019, 1, 1–8. [CrossRef]

- Geleynse, S.; Brandt, K.; Garcia-Perez, M.; Wolcott, M.; Zhang, X. The Alcohol-to-Jet Conversion Pathway for Drop-In Biofuels: Techno-Economic Evaluation. ChemSusChem 2018, 11, 3728–3741. [Google Scholar] [CrossRef]

- Guell, B.M.; Bugge, M.; Kempegowda, R.S.; George, A.; Paap, S.M. Report Benchmark of Conversion and Production Technologies for Synthetic Biofuels for Aviation; Sintef: Trondheim, Norway, 2012. [Google Scholar]

- Jones, S.; Meyer, P.; Snowden-Swan, L.; Susanne, K.J.; Pimphan, M.; Snowden-Swan, L.; Asanga, P.; Eric, T.; Abhijit, D.; Jacob, J.; et al. Process design and economics for the conversion of lignocellulosic biomass to hydrocarbon fuels: Fast pyrolysis and hydrotreating bio-oil pathway. Energy 2013, 1, 97. [Google Scholar]

- Kenney, K.; Cafferty, K.G.; Jacobson, J.J.; Bonner, I.J.; Gresham, G.L.; Smith, W.A.; Thompson, D.N.; Thompson, V.S.; Tumuluru, J.S.; Yancey, N. Feedstock Supply System Design and Economics for Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels. Conversion Pathway: Biological Conversion of Sugars to Hydrocarbons; US Department of Energy: Washington, DC, USA, 2013; p. 70.

- Khan, M.Y. Waste Vegetable Oils (WVO) as Compression Ignition Engine Fuel: A Review. In Proceedings of the 2nd International conference on Science, Technology & Management (ICSTM-2018), Chandigarh, India, 16 September 2018. [Google Scholar]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; de Fatima Cardoso, T.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Meyer, P.A.; Snowden-Swan, L.J.; Jones, S.B.; Rappé, K.G.; Hartley, D.S. The effect of feedstock composition on fast pyrolysis and upgrading to transportation fuels: Techno-economic analysis and greenhouse gas life cycle analysis. Fuel 2020, 259, 116218. [Google Scholar] [CrossRef]

- Pearlson, M.N. A Techno-Economic and Environmental Assessment of Hydroprocessed Renewable Distillate Fuels. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2011. [Google Scholar]

- Priharto, N.; Ronsse, F.; Prins, W.; Hita, I.; Deuss, P.J.; Heeres, H.J. Hydrotreatment of pyrolysis liquids derived from second-generation bioethanol production residues over NiMo and CoMo catalysts. Biomass Bioenergy 2019, 126, 84–93. [Google Scholar] [CrossRef]

- Samavati, M.; Santarelli, M.; Martin, A.; Nemanova, V. Production of Synthetic Fischer-Tropsch Diesel from renewables : Thermoeconomic and Environmental Analysis. Energy Fuels 2017, 32, 1744–1753. [Google Scholar] [CrossRef]

- Tagomori, I.S.; Rochedo, P.R.R.; Szklo, A. Techno-economic and georeferenced analysis of forestry residues-based Fischer-Tropsch diesel with carbon capture in Brazil. Biomass Bioenergy 2019, 123, 134–148. [Google Scholar] [CrossRef]

- Wang, W.-C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2015, 53, 801–822. [Google Scholar] [CrossRef] [Green Version]

- Blin, J.; Brunschwig, C.; Chapuis, A.; Changotade, O.; Sidibe, S.S.; Noumi, E.S.; Girard, P. Characteristics of vegetable oils for use as fuel in stationary diesel engines—Towards specifications for a standard in West Africa. Renew. Sustain. Energy Rev. 2013, 22, 580–597. [Google Scholar] [CrossRef] [Green Version]

- Cervi, W.R.; Lamparelli, R.A.C.; Seabra, J.E.A.; Junginger, M.; Jong, S.; Hilst, F. Spatial modeling of techno-economic potential of biojet fuel production in Brazil. GCB Bioenergy 2020, 12, 136–157. [Google Scholar] [CrossRef] [Green Version]

- de Jong, S.; Hoefnagels, R.; Faaij, A.; Slade, R.; Mawhood, R.; Junginger, M. The feasibility of short-term production strategies for renewable jet fuels—A comprehensive techno-economic comparison. Biofuels Bioprod. Biorefining 2015, 9, 778–800. [Google Scholar] [CrossRef]

- Diederichs, G.W. Techno-Economic Assessment of Processes that Produce Jet Fuel from Plant-Derived Sources. Available online: https://core.ac.uk/download/pdf/37440495.pdf (accessed on 16 December 2015).

- Diederichs, G.W.; Ali Mandegari, M.; Farzad, S.; Görgens, J.F. Techno-economic comparison of biojet fuel production from lignocellulose, vegetable oil and sugar cane juice. Bioresour. Technol. 2016, 216, 331–339. [Google Scholar] [CrossRef]

- Dimitriou, I.; Goldingay, H.; Bridgwater, A.V. Techno-economic and uncertainty analysis of Biomass to Liquid (BTL) systems for transport fuel production. Renew. Sustain. Energy Rev. 2018, 88, 160–175. [Google Scholar] [CrossRef]

- ETIP Bioenergy HVO/HEFA. Available online: http://www.etipbioenergy.eu/value-chains/products-end-use/products/hvo-hefa (accessed on 10 April 2019).

- Safarian, S.; Unnþórsson, R.; Richter, C. A review of biomass gasification modelling. Renew. Sustain. Energy Rev. 2019, 110, 378–391. [Google Scholar] [CrossRef]

- Ekşioğlu, S.D.; Acharya, A.; Leightley, L.E.; Arora, S. Analyzing the design and management of biomass-to-biorefinery supply chain. Comput. Ind. Eng. 2009, 57, 1342–1352. [Google Scholar] [CrossRef]

- He, X.; Lau, A.K.; Sokhansanj, S.; Lim, C.J.; Bi, X.T.; Melin, S. Investigating gas emissions and dry matter loss from stored biomass residues. Fuel 2014, 134, 159–165. [Google Scholar] [CrossRef]

- Memişoğlu, G.; Üster, H. Integrated Bioenergy Supply Chain Network Planning Problem. Transp. Sci. 2016, 50, 35–56. [Google Scholar] [CrossRef]

- Rentizelas, A.A. Biomass storage. In Biomass Supply Chains for Bioenergy and Biorefining; Elsevier: Amsterdam, The Netherlands, 2016; pp. 127–146. ISBN 9781782423874. [Google Scholar]

- Pavlenko, A.N.; Searle, S.; Christensen, A. The Cost of Supporting Alternative Jet Fuels in the European Union; ICCT: Berlin, Germany, 2019; p. 20. [Google Scholar]

- Hoefnagels, R.; Searcy, E.; Cafferty, K.; Cornelissen, T.; Junginger, M.; Jacobson, J.; Faaij, A. Lignocellulosic feedstock supply systems with intermodal and overseas transportation. Biofuels Bioprod Biorefining 2014, 8, 794–818. [Google Scholar] [CrossRef]

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118, 109506. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Comparing alternative cellulosic biomass biorefining systems: Centralized versus distributed processing systems. Biomass Bioenergy 2015, 74, 135–147. [Google Scholar] [CrossRef] [Green Version]

- Strogen, B.; Horvath, A.; McKone, T.E. Fuel Miles and the Blend Wall: Costs and Emissions from Ethanol Distribution in the United States. Environ. Sci. Technol. 2012, 46, 5285–5293. [Google Scholar] [CrossRef] [PubMed]

- Kroft, D.F.A. Van Der the Potential of Drop-in Biofuels for the Maritime Industry; TU Delft: Delft, The Netherlands, 2020. [Google Scholar]

- Cervi, W.R.; Lamparelli, R.A.C.; Gallo, B.C.; de Oliveira Bordonal, R.; Seabra, J.E.A.; Junginger, M.; van der Hilst, F. Mapping the environmental and techno-economic potential of biojet fuel production from biomass residues in Brazil. Biofuels Bioprod. Biorefining 2021, 15, 282–304. [Google Scholar] [CrossRef]

- Cerruti, E.; Di Gruttola, F.; Lauro, G.; Valentini, T.D.; Fiaschi, P.; Sorrenti, R.; Borello, D. Assessment of Feedstocks and Technologies for Advanced Biofuel Production. E3S Web Conf. 2020, 197. [Google Scholar] [CrossRef]

- IEA. Bioenergy Emerging Gasification Technologies for Waste & Biomass; IEA: Bridgend, UK, 2020; ISBN 9781910154847. [Google Scholar]

- Li, W.; Wright, M.M. Negative Emission Energy Production Technologies: A Techno-Economic and Life Cycle Analyses Review. Energy Technol. 2020, 8, 1–10. [Google Scholar] [CrossRef]

- Olbrich, W.; Boscagli, C.; Raffelt, K.; Zang, H.; Dahmen, N.; Sauer, J. Catalytic hydrodeoxygenation of pyrolysis oil over nickel-based catalysts under H2/CO2 atmosphere. Sustain. Chem. Process. 2016, 4, 9. [Google Scholar] [CrossRef] [Green Version]

- Sorunmu, Y.; Billen, P.; Spatari, S. A review of thermochemical upgrading of pyrolysis bio-oil: Techno-economic analysis, life cycle assessment, and technology readiness. GCB Bioenergy 2020, 12, 4–18. [Google Scholar] [CrossRef] [Green Version]

- Yun, Y. (Ed.) Alcohol Fuels—Current Technologies and Future Prospect; IntechOpen: London, UK, 2020; ISBN 978-1-78985-043-7. [Google Scholar]

- IndexMundi Jet Fuel Prices. Available online: https://www.indexmundi.com/commodities/?commodity=jet-fuel (accessed on 13 October 2020).

- Bengtsson, S.; Fridell, E.; Andersson, K. Environmental assessment of two pathways towards the use of biofuels in shipping. Energy Policy 2012, 44, 451–463. [Google Scholar] [CrossRef]

- Kass, M.; Abdullah, Z.; Biddy, M.; Drennan, C.; Hawkins, T.; Jones, S.; Holladay, J.; Longman, D.; Newes, E.; Theiss, T.; et al. Understanding the Opportunities of Biofuels for Marine Shipping; Oak Ridge National Lab: Oak Ridge, TN, USA, 2018; p. 26. [Google Scholar]

- Lapola, D.M.; Schaldach, R.; Alcamo, J.; Bondeau, A.; Koch, J.; Koelking, C.; Priess, J.A. Indirect land-use changes can overcome carbon savings from biofuels in Brazil. Proc. Natl. Acad. Sci. USA 2010, 107, 3388–3393. [Google Scholar] [CrossRef] [Green Version]

- Plevin, R.J.; Jones, A.D.; Torn, M.S.; Gibbs, H.K. Greenhouse Gas Emissions from Biofuels’ Indirect Land Use Change Are Uncertain but May Be Much Greater than Previously Estimated. Environ. Sci. Technol. 2010, 44, 8015–8021. [Google Scholar] [CrossRef]

- Staples, M.D.; Malina, R.; Olcay, H.; Pearlson, M.N.; Hileman, J.I.; Boies, A.; Barrett, S.R.H. Lifecycle greenhouse gas footprint and minimum selling price of renewable diesel and jet fuel from fermentation and advanced fermentation production technologies. Energy Environ. Sci. 2014, 7, 1545–1554. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Simulation and life cycle assessment of biofuel production via fast pyrolysis and hydroupgrading. Fuel 2015, 139, 441–456. [Google Scholar] [CrossRef]

- Vienescu, D.N.; Wang, J.; Le Gresley, A.; Nixon, J.D. A life cycle assessment of options for producing synthetic fuel via pyrolysis. Bioresour. Technol. 2018, 249, 626–634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carvalho, F.; Portugal-Pereira, J.; Szklo, A.S. Two Capitains will not sink the ship: Evaluation of bio-based bunker fuel production and distribution logistics in Brazil. In Proceedings of the 27th European Biomass Conference and Exhibition, Lisbon, Portugal, 27–30 May 2019; pp. 681–683. [Google Scholar]

- Stengel, B.; Vium, J.H. Synthesis, Characterization, and Use of Hydro-Treated Oils and Fats for Engine Operation; Rostock, G.E., Ed.; IEA: Tasstrup, Demark, 2015. [Google Scholar]

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkes, A.; Staffell, I. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- IEA. Bioenergy The Potential and Challenges of “Drop-in” Biofuels—The key role that co-processing will play in production. Task 2019, 1, 156. [Google Scholar]

- Pinho, A.D.R.; De Almeida, M.B.B.; Mendes, F.L.; Ximenes, V.L.; Casavechia, L.C. Co-processing raw bio-oil and gasoil in an FCC Unit. Fuel Process. Technol. 2015, 131, 159–166. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Mcmillan, J.D.; Saddler, J. Potential synergies of drop-in biofuel production with further co-processing at oil refineries. Biofuels Bioprod. Biorefining 2019, 13, 760–775. [Google Scholar] [CrossRef] [Green Version]

- Lloyds. Zero-Emission Vessels 2030. How Do We Get There? Lloyds Register: London, UK, 2017. [Google Scholar]

- Merrow, E.W.; Phillips, K.E.; Myers, C.W. Understanding Cost Growth and Performance Shortfalls in Pioneer Process Plants; Libr. Congr. Cat. Publ. Data; Library of Congress: New York, NY, USA, 1981; pp. 1–102. [Google Scholar]

- Morrison, G.M.; Witcover, J.; Parker, N.C.; Fulton, L. Three routes forward for biofuels: Incremental, leapfrog, and transitional. Energy Policy 2016, 88, 64–73. [Google Scholar] [CrossRef]

| Crop. | Agricultural and Forest Residues a | RPR b | ESR c | AR d | LHV (MJ/kg) e | Reference |

|---|---|---|---|---|---|---|

| Sugarcane | Straw | 0.22 | 34% | 65% | 18.6 | [27] |

| Soybean | Straw | 2.01 | 30% | 100% | 20.1 | |

| Corn | Stover | 1.53 | 25% | 100% | 18.7 | |

| Wheat | Straw | 1.55 | 15% | 100% | 19.5 | |

| Eucalyptus | Forestry residues | 0.10 | 50% | 100% | 25.2 | [31,37] |

| Wood cuts | 0.45 | 100% | 100% | 20.3 | ||

| Pinus | Forestry residues | 0.10 | 50% | 100% | 25.2 | |

| Wood cuts | 0.45 | 100% | 100% | 21.8 | ||

| Forest extraction | Forestry residues | 0.60 | 50% | 100% | 25.2 | |

| Wood cuts | 0.18 | 100% | 100% | 19.4 | ||

| Crop | Straight Vegetable Oils | OSR a | EE b (%) | LHV (MJ/kg) | AO c (%) | Reference |

| Cotton | Cotton oil | 22% | 95% | 39.5 | 15% | [35,36,38,39] |

| Peanut | Peanut oil | 43% | 95% | 39.8 | 15% | |

| Sunflower | Sunflower oil | 43% | 95% | 39.6 | 15% | |

| Mamon | Mamon oil | 46% | 95% | 39.5 | 15% | |

| Soybean | Soybean oil | 18% | 95% | 39.6 | 15% | |

| Corn | Corn oil | 4% | 95% | 39.5 | 15% |

| Biomass Residues Potential from S2Biom | Moisture Content b (%) | LHV c (MJ/kg) | |

|---|---|---|---|

| Agricultural Residues | Cereal Straw | 15 | 17.0 |

| Maize Stover | 15 | 16.0 | |

| Sunflower straw | 20 | 16.7 | |

| Forest residues | Logging residues from final fellings from conifers (LR_FF_C) | 53.6 | 19.2 |

| Logging residues from final fellings from non-conifers trees (LR_FF_NC) | 53.6 | 19.2 | |

| Logging residues from thinning from conifers trees (LR_TH_C) | 53.6 | 18.7 | |

| Logging residues from thinning from non-conifers trees (LR_TH_NC) | 53.6 | 18.7 | |

| Stem wood from final felling from conifers and trees (ST_FF_C) a | 53.9 | 19.3 | |

| Stem wood from final felling from non-conifers trees (ST_FF_NC) a | 53.6 | 19.3 | |

| Stem wood from thinning from conifers trees (ST_TH_C) a | 53.6 | 19.2 | |

| Stem wood from thinning from non-conifers trees (ST_TH_NC) a | 53.6 | 19.2 | |

| Crop a | Residue | RPR b | ESR (%) c | AR (%) d | Moisture Content e (%) | LHV f (MJ/kg) |

|---|---|---|---|---|---|---|

| Sugarcane | Bagasse | 0.9 | 100% | - | 50% | 10.0 |

| Field residues (Straw) | 0.9 | 50% | 100% | 42% | 7.1 | |

| Maize | Stover | 2.6 | 50% | 35% | 42% | 11.5 |

| Wheat | Straw | 1.3 | 50% | 35% | 42% | 11.5 |

| Crop a | Residue | RPR a (%) | ESR b (%) | AF c (%) | OU d (%) | Moisture Content e (%) | LHV f (MJ/kg) |

|---|---|---|---|---|---|---|---|

| Corn | Stover | 1.0 | 70% | 20–25% | 10–15% | 15.5 | 17.3 |

| Wheat | Straw | 1.3 | 13.5 | 17.8 |

| Carbon Intensity gCO2/MJ Fuel | USD/tCO2 | ||||

|---|---|---|---|---|---|

| BR | EU | SA | USA | ||

| FT-decentralized | 27 a | 195 | 516 | 288 | 390 |

| FT-centralized | 27 b | 120 | 237 | 68 | 103 |

| ATD | 38 c | 320 | 336 | 221 | 290 |

| HDPO | 23 d | 116 | 175 | 210 | 125 |

| SVO | 58 e | 217 | - | - | - |

| HVO | 58 f | 175 | - | - | - |

| MGO | 137 g | ||||

| Max USD/tCO2 | 516 | FT-decentralized (EU) | |||

| Min USD/tCO2 | 68 | FT-centralized (SA) | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, F.; Portugal-Pereira, J.; Junginger, M.; Szklo, A. Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA. Energies 2021, 14, 4980. https://doi.org/10.3390/en14164980

Carvalho F, Portugal-Pereira J, Junginger M, Szklo A. Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA. Energies. 2021; 14(16):4980. https://doi.org/10.3390/en14164980

Chicago/Turabian StyleCarvalho, Francielle, Joana Portugal-Pereira, Martin Junginger, and Alexandre Szklo. 2021. "Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA" Energies 14, no. 16: 4980. https://doi.org/10.3390/en14164980

APA StyleCarvalho, F., Portugal-Pereira, J., Junginger, M., & Szklo, A. (2021). Biofuels for Maritime Transportation: A Spatial, Techno-Economic, and Logistic Analysis in Brazil, Europe, South Africa, and the USA. Energies, 14(16), 4980. https://doi.org/10.3390/en14164980