Thermoeconomic Optimization of Steam Pressure of Heat Recovery Steam Generator in Combined Cycle Gas Turbine under Different Operation Strategies

Abstract

1. Introduction

2. System Description

2.1. GT Modeling

2.2. HRSG Modeling

2.3. ST Modeling

2.4. CCGT Thermodynamic Performance Evaluation Indexex

3. Unit Thermoeconomic Cost Modeling

3.1. Physical Structure and Productive Structure

3.2. Thermoeconomic Cost Equations

4. Optimization of High, Intermediate and Low Steam Pressures

4.1. Optimization Algorithm Based on the Orthogonal Experiment

- (1)

- Orthogonal experimental design: determining the optimal variables and the number of value levels;

- (2)

- Preliminary optimization: based on the sample points of orthogonal experiment, the corresponding thermoeconomic costs are calculated respectively, and the minimum level is determined by using the principle of minimizing the average thermoeconomic cost at each level;

- (3)

- Optimal solution: the optimal solution is determined in the minimum horizontal solution.

4.2. The Experiment of Orthogonal Design

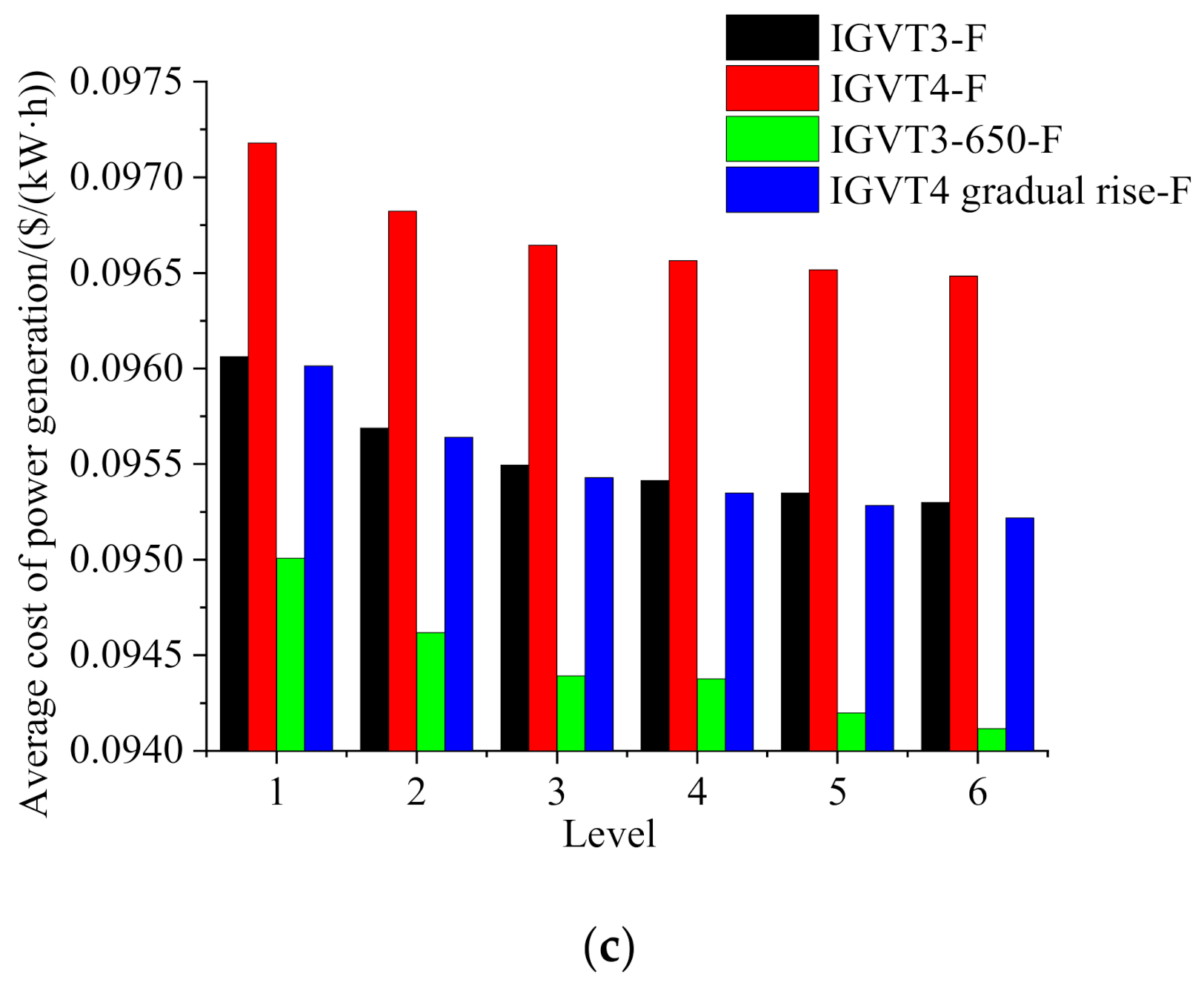

4.3. Orthogonal Experimental Samples and Preliminary Optimization

4.4. Analysis of Orthogonal Test Results

5. Conclusions

- (1)

- The system power generation cost decreases as the GT load rate increases. The T4 plays a dominant role in the selection of the optimal pressure level for HP steam. The GT regulation strategy of IGV participating in the regulation is conducive to maintaining higher T3 and T4, so as to ensure the better economic performance of the CCGT system. The GT regulation strategy with a higher T4 is more favorable to the system power generation cost.

- (2)

- The optimal steam pressure values at all levels are different under different operating strategies. Under a 100% GT load rate, the optimal pressure values of HP, IP and LP steam are obtained respectively as 16.5 MPa, 2.375 MPa and 0.4 MPa, the system power generation cost is 8.8590 × 10−2 $/kWh. Under 75% and 50% GT load rate, the optimal pressure values of HP, IP and LP steam are obtained respectively as 16.5 MPa, 2.375 MPa and 0.4 MPa, the system power generation costs are 9.3922 × 10−2 $/kWh and 1.0828 × 10−1 $/kWh, respectively. Under 25% GT load rate, the optimal pressure values of HP, IP and LP steam are obtained respectively as 13.00 MPa, 2.375 MPa and 0.45 MPa. The system power generation cost is 1.0828 × 10−1 $/kWh. Compared to those of before optimization (the IGV T3-650-F operation mode is not adopted), the CCGT power generation costs decreased by 1.57%, 2.92%, 8.42% and 13.18%, respectively. As the GT load factor decreases, the reduction of the CCGT power generation cost is more prominent when the CCGT system operates with the IGVT3- 650-F operation strategy.

- (3)

- Under four GT load rates, the system generation cost under the IGV T3 650-F is the lowest. Therefore, in order for the CCGT to obtain the optimum power generation cost, the IGV regulation strategy (IGV T3-650-F) should be adopted to keep the T4 at a high level. The economic performance of the CCGT can be improved by increasing the T4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duan, L.; Wang, Z.; Guo, Y. Off-design performance characteristics study on ISCC system with solar direct steam generation system. Energy 2020, 205, 118044. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, T.S.; Sohn, J.L.; Ro, S.T. Comparative Analysis of Off-Design Performance Characteristics of Single and Two-Shaft Industrial Gas Turbines. J. Eng. Gas Turbines Power 2003, 125, 954–960. [Google Scholar] [CrossRef]

- Domachovski, Z.; Dzida, M. Influence of inlet guide vane control on combined cycle power plant transients//ASME Turbo Expo 2002: Power for Land, Sea, and Air. Am. Soc. Mech. Eng. 2002, 36061, 953–957. [Google Scholar]

- Song, T.W.; Sohn, J.L.; Kim, J.H.; Kim, T.S.; Ro, S.T. Exergy-based performance analysis of the heavy-duty gas turbine in part-load operating conditions. Int. J. Exergy 2002, 2, 105–112. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, Y.; Wang, L. Factors influencing efficiency of heat recovery boiler in gas-steam combined cycle. J. Shenyang Inst. Technol. (Nat. Sci. Ed.) 2018, 14. (In Chinese) [Google Scholar]

- Li, Y. Performance optimization of the steam system of Jingfeng gas power station’s M701F combined cycle unit. North China Electr. Power Univ. (Beijing) 2006. (In Chinese) [Google Scholar]

- Ibrahim, T.K.; Rahman, M. Effective Parameters on Performance of Multipressure Combined Cycle Power Plants. Adv. Mech. Eng. 2014, 6, 781503. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Xiang, W.G.; Ding, L.Q. The performance study of 9FA gas turbine combined cycle. Gas Turbine Technol. 2006, 19, 21–24. [Google Scholar]

- Gu, H.; Cui, X.; Zhu, H.; Si, F.; Kong, Y. Multi-objective Optimization Analysis on Gas-steam Combined Cycle System with Exergy Theory. J. Clean. Prod. 2020, 278, 123939. [Google Scholar] [CrossRef]

- Jiang, Y. Optimization of Parameter Matching of Gas-Steam Combined Cycle. Shenyang Inst. Eng. 2019, 28, 283–293. (In Chinese) [Google Scholar]

- Li, H.; Chen, J.; Sheng, D.; Li, W. The improved distribution method of negentropy and performance evaluation of CCPPs based on the structure theory of thermoeconomics. Appl. Eng. 2016, 96, 64–75. [Google Scholar] [CrossRef]

- Evans, R.B. A contribution to the theory of thermo-economics. UCLA Rep. 1962. [Google Scholar]

- Evans, R.B.; Tribus, M. Thermo-economics of saline water conversion. Ind. Eng. Chem. Process Des. Dev. 1965, 4, 195–206. [Google Scholar] [CrossRef]

- Valero, A. On causality in organized energy systems: Part, I. Purpose, cause, irreversibility, cost. Int. Symp. A Future Energy FlorenceItaly Pergamon Press 1990, 90, 387–392. [Google Scholar]

- Carcasci, C.; Cosi, L.; Ferraro, R.; Pacifici, B. Effect of a real steam turbine on thermoeconomic analysis of combined cycle power plants. Energy 2017, 138, 32–47. [Google Scholar] [CrossRef]

- Jie, X. A synthetical Energy-Economy-Environment analysis & evaluation of oxy-combustion systems. Huazhong Univ. Sci. Technol. 2011. (In Chinese) [Google Scholar]

- Zhen, W.; Liqiang, D. Off-design Thermoeconomic Performance Analysis of Gas Turbine Combined Cycle under Different Operation Strategies. Proc. CSEE 2021, 1–12. [Google Scholar]

- Franco, A.; Casarosa, C. On some perspectives for increasing the efficiency of combined cycle power plants. Appl. Therm. Eng. 2002, 22, 1501–1518. [Google Scholar] [CrossRef]

- Kesser, K.F.; Hoffman, M.A.; Baughn, J.W. Analysis of a Basic Chemically Recuperated Gas Turbine Power Plant. J. Eng. Gas Turbines Power 1994, 116, 277. [Google Scholar] [CrossRef]

- Young, J.B.; Wilcock, R.C. Modeling the Air-Cooled GasTurbine: Part 1—General Thermodynamics. J. Turbomach. 2002, 124, 207–213. [Google Scholar] [CrossRef]

- Young, J.B.; Wilcock, R.C. Modeling the Air-Cooled GasTurbine: Part 2—Coolant Flows and Losses. J. Turbomach. 2002, 124, 214–221. [Google Scholar] [CrossRef]

- Wilcock, R.C.; Young, J.B.; Horlock, J.H. The Effect of Turbine Blade Cooling on the Cycle Efficiency of Gas Turbine Power Cycles. J. Eng. Gas Turbines Power 2005, 127, 109–120. [Google Scholar] [CrossRef]

- Zhang, G.; Zheng, J.; Yang, Y.; Liu, W. Thermodynamic performance simulation and concise formulas for triple-pressure reheat HRSG of gas–steam combined cycle under off-design condition. Energy Convers. Manag. 2016, 122, 372–385. [Google Scholar] [CrossRef]

- Lippke, F. Simulation of the part-load behavior of a 30 MWe SEGS plant. Off. Sci. Tech. Inf. Tech. Rep. 1995. [Google Scholar]

- Liu, T.; Zhang, G.; Li, Y.; Yang, Y. Performance analysis of partially recuperative gas turbine combined cycle under off-design conditions. Energy Convers. Manag. 2018, 162, 55–65. [Google Scholar] [CrossRef]

- Bai, Z. Strategy Optimization and Performance Improvement of Gas-steam Combined Cycles under Design/Off-design Conditions. North China Electr. Power Univ. 2019. (in Chinese). [Google Scholar]

- Zhang, C.; Wang, Y.; Zheng, C.; Lou, X. Exergy cost analysis of a coal fired power plant based on structural theory of thermoeconomics. Energy Convers. Manag. 2006, 47, 817–843. [Google Scholar] [CrossRef]

- Taal, M.; Bulatov, I.; Klemeš, J.; Stehlı́k, P. Cost estimation and energy price forecasts for economic evaluation of retrofit projects. Appl. Eng. 2003, 23, 1819–1835. [Google Scholar] [CrossRef]

- Yao, H.; Sheng, D.; Chen, J.; Li, W.; Wan, A.; Chen, H. Exergoeconomic analysis of a combined cycle system utilizing associated gases from steel production process based on structural theory of thermoeconomics. Appl. Eng. 2013, 51, 476–489. [Google Scholar] [CrossRef]

- Li, H.K.; Chen, J.H.; Sheng, D.R.; Li, W. Thermoeconomic analysis and performance evaluation of gas-steam combined cycle power plant based on H&S model. J. Zhejiang Univ. (Eng. Sci.) 2016, 1. [Google Scholar]

- Zheng, Y. Pressure Drop Research and Design Optimization of Main Steam System in Advanced F Class Gas-steam Combined Cycle Power Plants. Energy Constr. 2015, 2, 46–50. [Google Scholar]

- Zhang, G.; Zheng, J.; Xie, A. Thermodynamic analysis of combined cycle under design/off-design conditions for its efficient design and operation. Energy Convers. Manag. 2016, 126, 76–88. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, C.; Li, Y. Investigation on the Generation Cost of Combined Cycle Power Plant Based on the Structural Theory of Thermoeconomics. J. Nanjing Norm. Univ. (Eng. Technol. Ed.) 2013, 13, 32–39. [Google Scholar]

- Peng, H.; Nie, W.; Liu, Z.; Xiu, Z.; Yang, S.; Xu, C.; Ma, Q.; Guo, C. Optimization of external spray negative-pressure mist-curtain dust suppression devices for roadheaders based on a multi-factor orthogonal experiment. J. Clean. Prod. 2020, 275, 123603. [Google Scholar] [CrossRef]

- Wen, Y.; Lai, N.; Du, Z.; Xu, F.; Zhang, X.; Han, L.; Yuan, L. Application of orthogonal experiment method in foam flooding system composition and injection parameter optimization. J. Pet. Sci. Eng. 2021, 204, 10866. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values | ||

|---|---|---|---|---|---|

| Fuel lower heating value | 48,435 kJ/kg | Stage numbers | 18 | ||

| Compressor | Inlet temperature | 15 °C | Gas Turbine | Inlet temperature | 1318 °C |

| Pressure ratio | 15.4 | Outlet temperature | 609 °C | ||

| Inlet flow | 621 kg/s | Rated power output | 255.6 MW | ||

| Speed | 3000 r/min | Rated thermal efficiency | 36.9% |

| Parameters | GT Load Rate/% (Operation Data of the Power Plant/Simulation Results) | |||

|---|---|---|---|---|

| 100 | 75 | 50 | 25 | |

| GT efficiency/% | 36.90/36.21 | 33.90/34.26 | 30.52/29.88 | 22.63/22.54 |

| GT output power/MW | 255.60/256.64 | 191.70/192.47 | 127.80/128.31 | 63.90/64.16 |

| ST efficiency/% | 36.50/36.21 | 36.87/36.57 | 33.01/32.79 | 27.97/27.83 |

| ST output power/MW | 132.52/134.35 | 114.95/116.51 | 80.65/81.43 | 48.78/48.83 |

| CCGT efficiency/% | 56.27/56.17 | 54.84/54.77 | 48.59/48.54 | 37.89/37.66 |

| CCGT output power/MW | 388.12/390.99 | 306.65/308.98 | 208.45/209.74 | 112.68/112.99 |

| Components | AC | CC | GT | HRSG | HPT | IPT | LPT | CND | CP | GEN |

|---|---|---|---|---|---|---|---|---|---|---|

| Value | 16.28 | 17.58 | 40.04 | 24.52 | 7.67 | 11.14 | 9.25 | 3.20 | 0.08 | 12.55 |

| Level | Factor | ||

|---|---|---|---|

| LP Value/MPa | IP Value/MPa | HP Value/MPa | |

| 1 | 0.200 | 2.000 | 9.500 |

| 2 | 0.250 | 2.375 | 11.250 |

| 3 | 0.300 | 2.750 | 13.000 |

| 4 | 0.350 | 3.125 | 14.750 |

| 5 | 0.400 | 3.500 | 16.500 |

| 6 | 0.450 | 3.875 | 18.250 |

| Experiment Number | Factor | ||

|---|---|---|---|

| LP Value/MPa | IP Value/MPa | HP Value/MPa | |

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 |

| 3 | 1 | 3 | 3 |

| 4 | 1 | 4 | 4 |

| 5 | 1 | 5 | 5 |

| 6 | 1 | 6 | 6 |

| 7 | 2 | 1 | 2 |

| 8 | 2 | 2 | 3 |

| 9 | 2 | 3 | 4 |

| 10 | 2 | 4 | 5 |

| 11 | 2 | 5 | 6 |

| 12 | 2 | 6 | 1 |

| 13 | 3 | 1 | 3 |

| 14 | 3 | 2 | 4 |

| 15 | 3 | 3 | 5 |

| 16 | 3 | 4 | 6 |

| 17 | 3 | 5 | 1 |

| 18 | 3 | 6 | 2 |

| 19 | 4 | 1 | 4 |

| 20 | 4 | 2 | 5 |

| 21 | 4 | 3 | 6 |

| 22 | 4 | 4 | 1 |

| 23 | 4 | 5 | 2 |

| 24 | 4 | 6 | 3 |

| 25 | 5 | 1 | 5 |

| 26 | 5 | 2 | 6 |

| 27 | 5 | 3 | 1 |

| 28 | 5 | 4 | 2 |

| 29 | 5 | 5 | 3 |

| 30 | 5 | 6 | 4 |

| 31 | 6 | 1 | 6 |

| 32 | 6 | 2 | 1 |

| 33 | 6 | 3 | 2 |

| 34 | 6 | 4 | 3 |

| 35 | 6 | 5 | 4 |

| 36 | 6 | 6 | 5 |

| Experiment Number | GT 100% Load Rate /($/kWh) | GT 75% Load Rate /($/kWh) | |||

|---|---|---|---|---|---|

| IGVT3-F | IGVT4-F | IGVT3-650-F | IGVT4 Gradual Rise-F | ||

| 1 | 8.8898 × 10−2 | 9.5640 × 10−2 | 9.6759 × 10−2 | 9.4587 × 10−2 | 9.5592 × 10−2 |

| 2 | 8.8752 × 10−2 | 9.5446 × 10−2 | 9.6580 × 10−2 | 9.4360 × 10−2 | 9.5397 × 10−2 |

| 3 | 8.8801 × 10−2 | 9.5494 × 10−2 | 9.6661 × 10−2 | 9.4376 × 10−2 | 9.5446 × 10−2 |

| 4 | 8.8898 × 10−2 | 9.5592 × 10−2 | 9.6775 × 10−2 | 9.4441 × 10−2 | 9.5527 × 10−2 |

| 5 | 8.9011 × 10−2 | 9.5705 × 10−2 | 9.6904 × 10−2 | 9.4538 × 10−2 | 9.5640 × 10−2 |

| 6 | 8.8947 × 10−2 | 9.5624 × 10−2 | 9.6840 × 10−2 | 9.4408 × 10−2 | 9.5559 × 10−2 |

| 7 | 8.8703 × 10−2 | 9.5397 × 10−2 | 9.6532 × 10−2 | 9.4344 × 10−2 | 9.5348 × 10−2 |

| 8 | 8.8574 × 10−2 | 9.5235 × 10−2 | 9.6386 × 10−2 | 9.4149 × 10−2 | 9.5186 × 10−2 |

| 9 | 8.8622 × 10−2 | 9.5284 × 10−2 | 9.6451 × 10−2 | 9.4149 × 10−2 | 9.5219 × 10−2 |

| 10 | 8.8703 × 10−2 | 9.5365 × 10−2 | 9.6532 × 10−2 | 9.4198 × 10−2 | 9.5284 × 10−2 |

| 11 | 8.8849 × 10−2 | 9.5462 × 10−2 | 9.6661 × 10−2 | 9.4279 × 10−2 | 9.5381 × 10−2 |

| 12 | 8.9854 × 10−2 | 9.6742 × 10−2 | 9.7877 × 10−2 | 9.5624 × 10−2 | 9.6694 × 10−2 |

| 13 | 8.8606 × 10−2 | 9.5284 × 10−2 | 9.6434 × 10−2 | 9.4198 × 10−2 | 9.5235 × 10−2 |

| 14 | 8.8493 × 10−2 | 9.5138 × 10−2 | 9.6288 × 10−2 | 9.4019 × 10−2 | 9.5073 × 10−2 |

| 15 | 8.8525 × 10−2 | 9.5154 × 10−2 | 9.6321 × 10−2 | 9.4019 × 10−2 | 9.5089 × 10−2 |

| 16 | 8.8655 × 10−2 | 9.5219 × 10−2 | 9.642 × 10−2 | 9.4052 × 10−2 | 9.5154 × 10−2 |

| 17 | 8.9498 × 10−2 | 9.6353 × 10−2 | 9.7472 × 10−2 | 9.5300 × 10−2 | 9.6305 × 10−2 |

| 18 | 8.9433 × 10−2 | 9.5997 × 10−2 | 9.7131 × 10−2 | 9.4911 × 10−2 | 9.5948 × 10−2 |

| 19 | 8.8590 × 10−2 | 9.5235 × 10−2 | 9.6386 × 10−2 | 9.4652 × 10−2 | 9.5186 × 10−2 |

| 20 | 8.8460 × 10−2 | 9.5089 × 10−2 | 9.6240 × 10−2 | 9.3938 × 10−2 | 9.5008 × 10−2 |

| 21 | 8.8558 × 10−2 | 9.5105 × 10−2 | 9.6272 × 10−2 | 9.3938 × 10−2 | 9.524 × 10−2 |

| 22 | 8.9238 × 10−2 | 9.6045 × 10−2 | 9.7164 × 10−2 | 9.5008 × 10−2 | 9.6013 × 10−2 |

| 23 | 8.9173 × 10−2 | 9.5948 × 10−2 | 9.7083 × 10−2 | 9.4878 × 10−2 | 9.5900 × 10−2 |

| 24 | 8.9157 × 10−2 | 9.5916 × 10−2 | 9.7066 × 10−2 | 9.4814 × 10−2 | 9.5851 × 10−2 |

| 25 | 8.8590 × 10−2 | 9.5235 × 10−2 | 9.642 × 10−2 | 9.4100 × 10−2 | 9.5170 × 10−2 |

| 26 | 8.8558 × 10−2 | 9.5073 × 10−2 | 9.6256 × 10−2 | 9.3906 × 10−2 | 9.5008 × 10−2 |

| 27 | 8.9060 × 10−2 | 9.5851 × 10−2 | 9.6953 × 10−2 | 9.4814 × 10−2 | 9.582 × 10−2 |

| 28 | 8.8979 × 10−2 | 9.5737 × 10−2 | 9.6856 × 10−2 | 9.4668 × 10−2 | 9.5689 × 10−2 |

| 29 | 8.8784 × 10−2 | 9.5478 × 10−2 | 9.6629 × 10−2 | 9.4376 × 10−2 | 9.5413 × 10−2 |

| 30 | 8.8963 × 10−2 | 9.5689 × 10−2 | 9.6840 × 10−2 | 9.4571 × 10−2 | 9.5624 × 10−2 |

| 31 | 8.8639 × 10−2 | 9.5267 × 10−2 | 9.6434 × 10−2 | 9.4100 × 10−2 | 9.5186 × 10−2 |

| 32 | 8.8963 × 10−2 | 9.5721 × 10−2 | 9.6840 × 10−2 | 9.4700 × 10−2 | 9.5689 × 10−2 |

| 33 | 8.8865 × 10−2 | 9.5592 × 10−2 | 9.6710 × 10−2 | 9.4538 × 10−2 | 9.5543 × 10−2 |

| 34 | 8.8817 × 10−2 | 9.5527 × 10−2 | 9.6661 × 10−2 | 9.4441 × 10−2 | 9.5478 × 10−2 |

| 35 | 8.8817 × 10−2 | 9.5511 × 10−2 | 9.6661 × 10−2 | 9.4392 × 10−2 | 9.5446 × 10−2 |

| 36 | 8.8849 × 10−2 | 9.5527 × 10−2 | 9.6694 × 10−2 | 9.4392 × 10−2 | 9.5462 × 10−2 |

| Experiment Number | GT 50% Load Rate/($/kWh) | GT 25% Load Rate/($/kWh) | ||||||

|---|---|---|---|---|---|---|---|---|

| IGVT3-F | IGVT4-F | IGVT3-650-F | IGVT4 Gradual Rise-F | IGVT3-F | IGVT4-F | IGVT3-650-F | IGVT4 Gradual Rise-F | |

| 1 | 1.165 × 10−1 | 1.117 × 10−1 | 1.091 × 10−1 | 1.093 × 10−1 | 1.375 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 |

| 2 | 1.166 × 10−1 | 1.115 × 10−1 | 1.088 × 10−1 | 1.090 × 10−1 | 1.383 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 |

| 3 | 1.169 × 10−1 | 1.116 × 10−1 | 1.089 × 10−1 | 1.090 × 10−1 | 1.392 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 |

| 4 | 1.172 × 10−1 | 1.117 × 10−1 | 1.090 × 10−1 | 1.091 × 10−1 | 1.402 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 |

| 5 | 1.176 × 10−1 | 1.119 × 10−1 | 1.091 × 10−1 | 1.092 × 10−1 | 1.413 × 10−1 | 1.230 × 10−1 | 1.230 × 10−1 | 1.230 × 10−1 |

| 6 | 1.177 × 10−1 | 1.118 × 10−1 | 1.089 × 10−1 | 1.091 × 10−1 | 1.421 × 10−1 | 1.230 × 10−1 | 1.230 × 10−1 | 1.230 × 10−1 |

| 7 | 1.164 × 10−1 | 1.114 × 10−1 | 1.088 × 10−1 | 1.090 × 10−1 | 1.376 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 |

| 8 | 1.164 × 10−1 | 1.112 × 10−1 | 1.086 × 10−1 | 1.087 × 10−1 | 1.383 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 |

| 9 | 1.166 × 10−1 | 1.113 × 10−1 | 1.086 × 10−1 | 1.087 × 10−1 | 1.391 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 |

| 10 | 1.169 × 10−1 | 1.114 × 10−1 | 1.086 × 10−1 | 1.088 × 10−1 | 1.400 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 |

| 11 | 1.173 × 10−1 | 1.116 × 10−1 | 1.087 × 10−1 | 1.089 × 10−1 | 1.409 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 |

| 12 | 1.182 × 10−1 | 1.131 × 10−1 | 1.105 × 10−1 | 1.106 × 10−1 | 1.41 × 10−1 | 1.240 × 10−1 | 1.240 × 10−1 | 1.240 × 10−1 |

| 13 | 1.163 × 10−1 | 1.113 × 10−1 | 1.086 × 10−1 | 1.088 × 10−1 | 1.379 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 |

| 14 | 1.164 × 10−1 | 1.111 × 10−1 | 1.084 × 10−1 | 1.086 × 10−1 | 1.386 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 |

| 15 | 1.166 × 10−1 | 1.111 × 10−1 | 1.084 × 10−1 | 1.086 × 10−1 | 1.393 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 |

| 16 | 1.168 × 10−1 | 1.112 × 10−1 | 1.085 × 10−1 | 1.086 × 10−1 | 1.41 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 |

| 17 | 1.175 × 10−1 | 1.126 × 10−1 | 1.100 × 10−1 | 1.102 × 10−1 | 1.390 × 10−1 | 1.232 × 10−1 | 1.232 × 10−1 | 1.232 × 10−1 |

| 18 | 1.172 × 10−1 | 1.122 × 10−1 | 1.096 × 10−1 | 1.097 × 10−1 | 1.390 × 10−1 | 1.227 × 10−1 | 1.227 × 10−1 | 1.227 × 10−1 |

| 19 | 1.164 × 10−1 | 1.112 × 10−1 | 1.092 × 10−1 | 1.087 × 10−1 | 1.385 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 | 1.216 × 10−1 |

| 20 | 1.164 × 10−1 | 1.110 × 10−1 | 1.083 × 10−1 | 1.085 × 10−1 | 1.391 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 | 1.215 × 10−1 |

| 21 | 1.166 × 10−1 | 1.111 × 10−1 | 1.083 × 10−1 | 1.085 × 10−1 | 1.397 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 |

| 22 | 1.170 × 10−1 | 1.122 × 10−1 | 1.097 × 10−1 | 1.098 × 10−1 | 1.382 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 |

| 23 | 1.171 × 10−1 | 1.121 × 10−1 | 1.095 × 10−1 | 1.097 × 10−1 | 1.388 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 | 1.226 × 10−1 |

| 24 | 1.173 × 10−1 | 1.121 × 10−1 | 1.094 × 10−1 | 1.096 × 10−1 | 1.395 × 10−1 | 1.228 × 10−1 | 1.228 × 10−1 | 1.228 × 10−1 |

| 25 | 1.166 × 10−1 | 1.112 × 10−1 | 1.085 × 10−1 | 1.087 × 10−1 | 1.392 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 | 1.218 × 10−1 |

| 26 | 1.167 × 10−1 | 1.110 × 10−1 | 1.083 × 10−1 | 1.084 × 10−1 | 1.397 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 | 1.217 × 10−1 |

| 27 | 1.165 × 10−1 | 1.119 × 10−1 | 1.094 × 10−1 | 1.096 × 10−1 | 1.376 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 |

| 28 | 1.168 × 10−1 | 1.118 × 10−1 | 1.093 × 10−1 | 1.094 × 10−1 | 1.382 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 | 1.222 × 10−1 |

| 29 | 1.168 × 10−1 | 1.115 × 10−1 | 1.089 × 10−1 | 1.090 × 10−1 | 1.390 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 |

| 30 | 1.171 × 10−1 | 1.118 × 10−1 | 1.091 × 10−1 | 1.093 × 10−1 | 1.396 × 10−1 | 1.225 × 10−1 | 1.225 × 10−1 | 1.225 × 10−1 |

| 31 | 1.168 × 10−1 | 1.113 × 10−1 | 1.085 × 10−1 | 1.087 × 10−1 | 1.400 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 |

| 32 | 1.165 × 10−1 | 1.118 × 10−1 | 1.093 × 10−1 | 1.094 × 10−1 | 1.373 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 |

| 33 | 1.166 × 10−1 | 1.116 × 10−1 | 1.091 × 10−1 | 1.092 × 10−1 | 1.379 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 | 1.219 × 10−1 |

| 34 | 1.167 × 10−1 | 1.116 × 10−1 | 1.090 × 10−1 | 1.091 × 10−1 | 1.385 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 | 1.220 × 10−1 |

| 35 | 1.168 × 10−1 | 1.116 × 10−1 | 1.089 × 10−1 | 1.090 × 10−1 | 1.392 × 10−1 | 1.221 × 10−1 | 1.221 × 10−1 | 1.221 × 10−1 |

| 36 | 1.170 × 10−1 | 1.116 × 10−1 | 1.089 × 10−1 | 1.090 × 10−1 | 1.399 × 10−1 | 1.223 × 10−1 | 1.223 × 10−1 | 1.223 × 10−1 |

| Parameters | GT Load Rate/% (Designed/Simulated) | |||

|---|---|---|---|---|

| 100 | 75 | 50 | 25 | |

| GEN unit thermoeconomic costs of product (Power generation cost)/($/kW·h) | 0.084/0.086 | 0.092/0.094 | 0.109/0.110 | 0.130/0.0131 |

| Level | Factor | ||

|---|---|---|---|

| LP Value/($/kWh) | IP Value/($/kWh) | HP Value/($/kWh) | |

| 1 | 8.8884 × 10−2 | 8.8671 × 10−2 | 8.9252 × 10−2 |

| 2 | 8.8884 × 10−2 | 8.8633 × 10−2 | 8.8984 × 10−2 |

| 3 | 8.8868 × 10−2 | 8.8739 × 10−2 | 8.8790 × 10−2 |

| 4 | 8.8863 × 10−2 | 8.8882 × 10−2 | 8.8730 × 10−2 |

| 5 | 8.8822 × 10−2 | 8.9022 × 10−2 | 8.8690 × 10−2 |

| 6 | 8.8825 × 10−2 | 8.9200 × 10−2 | 8.8701 × 10−2 |

| Operation Strategy | GT100% Load Rate/($/kWh) | GT 75% Load Rate/($/kWh) | GT 50% Load Rate/($/kWh) | GT 25% Load Rate/($/kWh) |

|---|---|---|---|---|

| Before optimization | 9.0007 × 10−2 | 9.6751 × 10−2 | 1.1824 × 10−1 | 1.3989 × 10−1 |

| IGVT3-F | 8.8590 × 10−2 | 9.5073 × 10−2 | 1.1647 × 10−1 | 1.3734 × 10−1 |

| IGVT4-F | 8.8590 × 10−2 | 9.6256 × 10−2 | 1.1105 × 10−1 | 1.2146 × 10−1 |

| IGVT3-650-F | 8.8590 × 10−2 | 9.3922 × 10−2 | 1.0828 × 10−1 | 1.2146 × 10−1 |

| IGVT4 gradual rise-F | 8.8590 × 10−2 | 9.5008 × 10−2 | 1.0844 × 10−1 | 1.2146 × 10−1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Duan, L. Thermoeconomic Optimization of Steam Pressure of Heat Recovery Steam Generator in Combined Cycle Gas Turbine under Different Operation Strategies. Energies 2021, 14, 4991. https://doi.org/10.3390/en14164991

Wang Z, Duan L. Thermoeconomic Optimization of Steam Pressure of Heat Recovery Steam Generator in Combined Cycle Gas Turbine under Different Operation Strategies. Energies. 2021; 14(16):4991. https://doi.org/10.3390/en14164991

Chicago/Turabian StyleWang, Zhen, and Liqiang Duan. 2021. "Thermoeconomic Optimization of Steam Pressure of Heat Recovery Steam Generator in Combined Cycle Gas Turbine under Different Operation Strategies" Energies 14, no. 16: 4991. https://doi.org/10.3390/en14164991

APA StyleWang, Z., & Duan, L. (2021). Thermoeconomic Optimization of Steam Pressure of Heat Recovery Steam Generator in Combined Cycle Gas Turbine under Different Operation Strategies. Energies, 14(16), 4991. https://doi.org/10.3390/en14164991