Environmental Life Cycle Assessment of Refrigerator Modelled with Application of Various Electricity Mixes and Technologies

Abstract

:1. Introduction

2. Relevance of Energy in the Life Cycle of Different Products

- ▪

- operational control over the energy generation process—energy can be generated on-site by the LCA commissioner (he/she has control and supervision of the process) or provided through the grid from the supplier (lack of supervision and operational control);

- ▪

- access to specific data—if the energy is generated on-site, the analyst has access to the primary data and this process falls under the so-called foreground system. However, if the energy is supplied by a supplier, the LCA commissioner may or may not have access to specific data. In the latter case, energy generation falls within the scope of the so-called background system and is modelled using secondary data.

3. Materials and Methods

4. Results

5. Discussion

6. Conclusions

- ▪

- From the life cycle perspective, not only may differences in national electricity systems between countries turn out to be important, but equally significant may be the choice between different types of mixes for a certain country. In our study, three countries were selected: Austria, Germany, and Poland. At the current time, they represent completely different situations. Austria has no residual mix, as all electricity is tracked. Germany has visibly different residual and supplier mixes because almost 60% of electricity is tracked. Poland has very similar residual and supplier mixes, as only a very small portion of electricity is tracked currently.

- ▪

- The downstream stages (distribution, retail, use, and end of life) often belong to a background system and are modelled with generic inventory data. Because of the high environmental relevance of the operation stage, the choice of a certain type of electricity mix to be used to model the energy consumption in the downstreams should be recognised as an important factor in LCA calculations for energy-related durable products.

- ▪

- The choice of the national electricity mix may be important also for upstream and core stages, especially in the case of passive products (not powered by energy). However, access to primary data may be easier for these processes, so it is probable that, instead of using national mixes, LCA practitioners may apply data for a specific technology of energy generation.

- ▪

- If more renewable energy sources are applied to produce the electricity consumed during operation, the relevance of the use stage is reduced. In our case study, this was very clear in the scenario 50%PL50%DE, where the share of production of raw materials and packaging increased from 7% to 22%, and, at the same time, the share of the use of the refrigerator decreased from 89% to 26%.

- ▪

- If EEE products are to be sold (and used) on the markets in countries with clearly different electricity systems, they may have very different life cycle environmental performance. So, in the case of this sort of product, the target market and sales structure should also be seen as important factors in creating the product strategy and impacting its environmental competitiveness. In this light, improving national energy mixes and increasing the share of energy covered by credible and reliable tracking systems should be considered a priority, not only from the point of view of national climate policy but also from the perspective of individual enterprises.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AIB | Association of Issuing Bodies |

| AT | Austria |

| DE | Germany |

| DISTR | Distribution |

| EEE | Electric and Electronic Equipment |

| EOL | End of Life |

| EUR | Europe |

| EPD | Environmental Product Declaration |

| GOO | Guarantee of Origin |

| HFC_ | 1,1-Difluoroethane |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

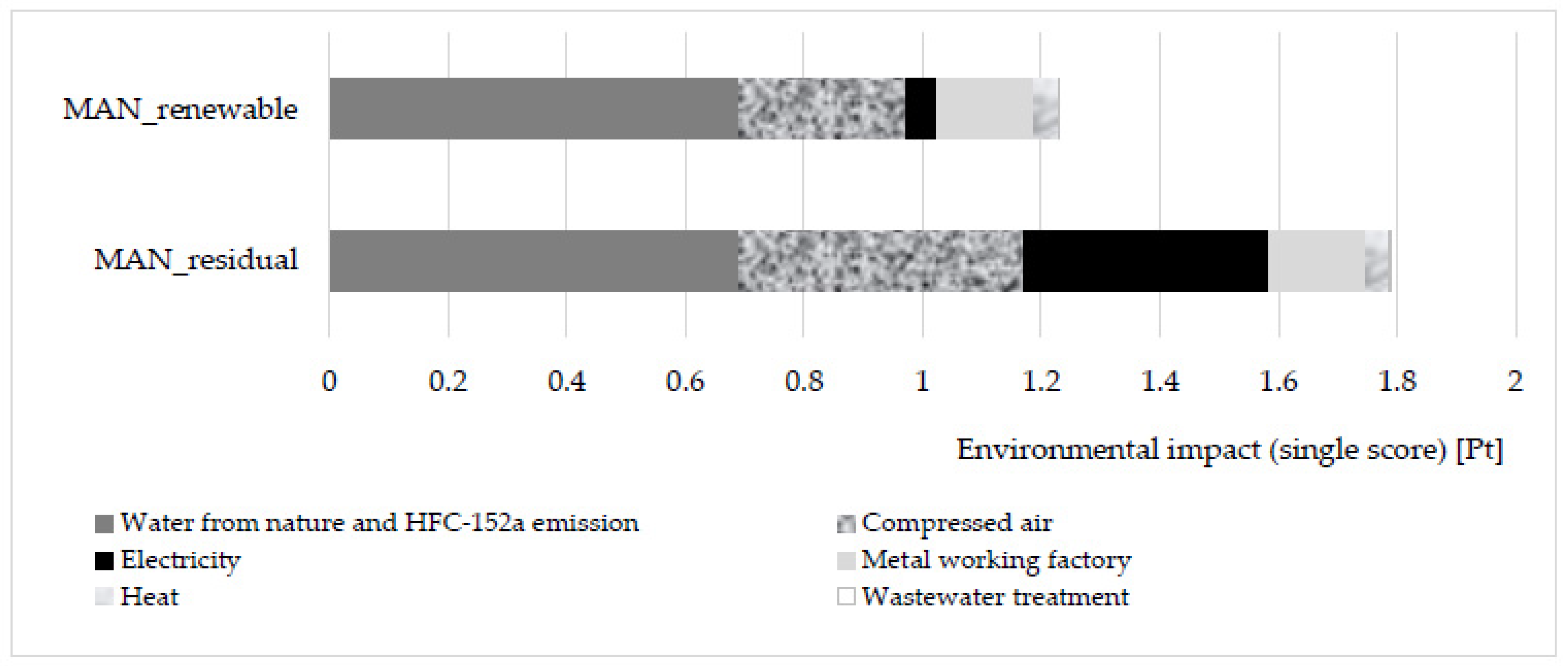

| MAN | Manufacturing |

| PEF | Product Environmental Footprint |

| PL | Poland |

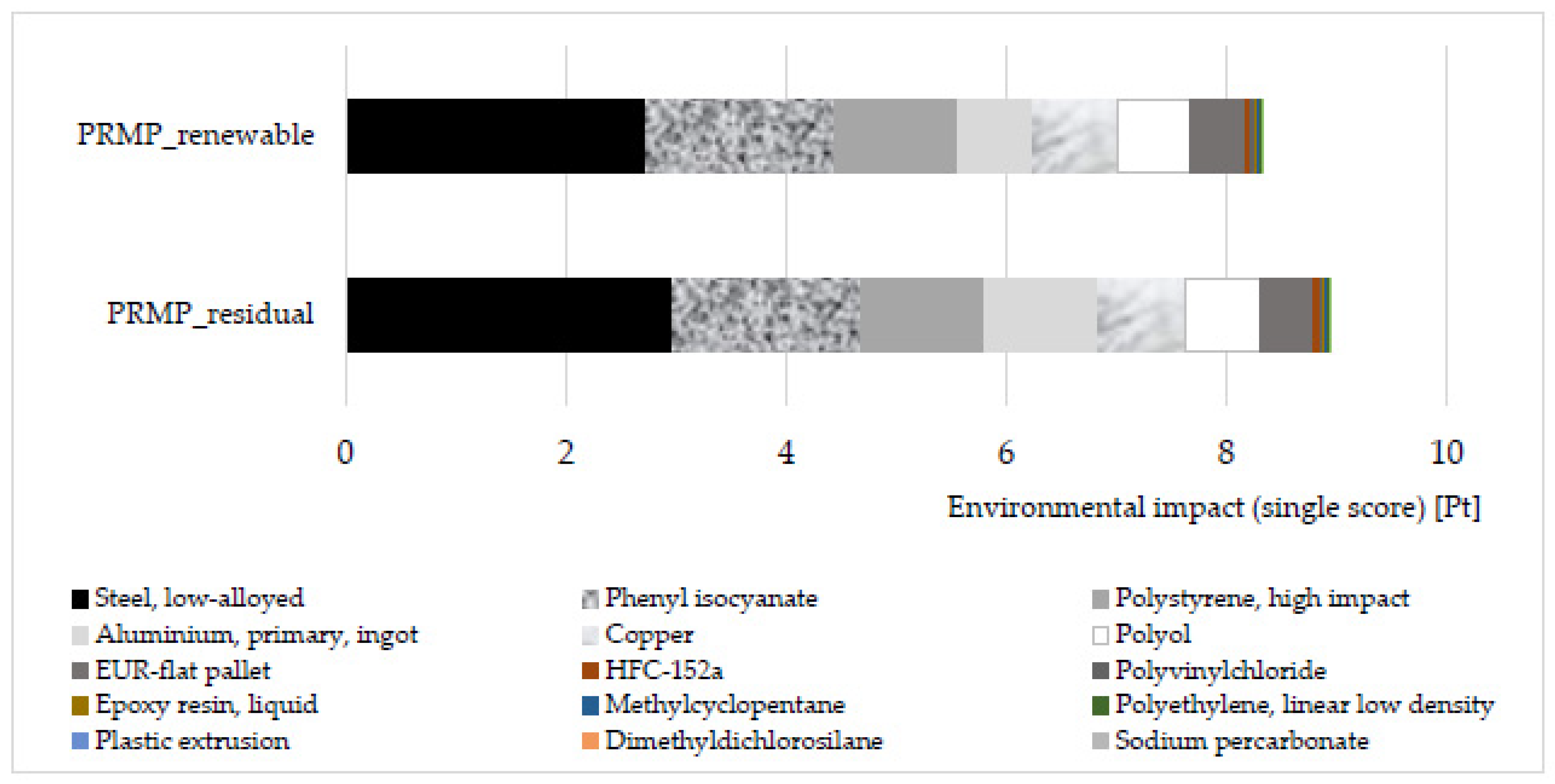

| PRMP | Production of Raw Materials and Packaging |

| Pt | point |

| RETA | Retail |

| TRANS | Transport |

| TRANSW | Transport of Waste |

| 100%PL | 100% of sale, use and end of life located in Poland |

| 50%PL50%DE | 50% of sale, use and end of life located in Poland and 50% in Germany |

| 100% DE | 100% of sale, use and end of life located in Germany |

References

- Ekvall, T. Attributional and Consequentia Life Cycle Assessment. Available online: https://www.intechopen.com/chapters/69212 (accessed on 28 July 2021).

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinee, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Frischknecht, R.; Stucki, M. Scope-dependent modelling of electricity supply in life cycle assessments. Int. J. Life Cycle Assess. 2010, 15, 806–816. [Google Scholar] [CrossRef]

- Vandepaer, L.; Treyer, K.; Mutel, C.; Bauer, C.; Amor, B. The integration of long-term marginal electricity supply mixes in the ecoinvent consequential database version 3.4 and examination of modelling choices. Int. J. Life Cycle Assess. 2019, 24, 1409–1428. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, J.H.; Thrane, M.; Merciai, S.; Dalgaard, R. Inventory of Country Specific Electricity in LCA—Consequential and Attributional Scenarios. Methodology Report v2. 2.-0 LCA Consultants. 2011. Available online: http://www.lca-net.com/projects/electricity_in_lca/ (accessed on 28 July 2021).

- Jones, C.; Gilbert, P.; Raugei, M.; Mander, S.; Leccisi, E. An approach to prospective consequential life cycle assessment and net energy analysis of distributed electricity generation. Energy Policy 2017, 100, 350–358. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Ocłoń, P.; Stelmach, S. Location of the waste incineration plant with particular emphasis on the environmental criteria. J. Clean Prod. 2021, 303, 126887. [Google Scholar] [CrossRef]

- Rossi, B.; Marique, A.F.; Reiter, S. Life-cycle assessment of residential buildings in three different European locations, case study. Build. Environ. 2012, 51, 402–407. [Google Scholar] [CrossRef]

- Olindo, R.; Schmitt, N.; Vogtländer, J. Life Cycle Assessments on Battery Electric Vehicles and Electrolytic Hydrogen: The Need for Calculation Rules and Better Databases on Electricity. Sustainability 2021, 13, 5250. [Google Scholar] [CrossRef]

- Environmental Product Declarations. Available online: https://www.environdec.com/home (accessed on 7 June 2021).

- Environmental Footprints of Products and Organisations. Available online: https://ec.europa.eu/environment/eussd/smgp/ef_transition.htm (accessed on 7 June 2021).

- Monfared, B.; Furberg, R.; Palm, P. Magnetic vs. vapor-compression household refrigerators: A preliminary comparative life cycle assessment. Int. J. Refrig. 2014, 42, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Gallego-Schmid, A.; Mendoza, J.M.F.; Jeswani, H.K.; Azapagic, A. Life cycle environmental impacts of vacuum cleaners and the effects of European regulation. Sci. Total Environ. 2016, 559, 192–203. [Google Scholar] [CrossRef] [PubMed]

- Landi, D.; Consolini, A.; Germani, M.; Favi, C. Comparative life cycle assessment of electric and gas ovens in the Italian context: An environmental and technical evaluation. J. Clean Prod. 2019, 221, 189–201. [Google Scholar] [CrossRef]

- Asdrubali, F.; Grazieschi, G. Life cycle assessment of energy efficient buildings. Energy Rep. 2020, 6, 270–285. [Google Scholar] [CrossRef]

- Ali, A.A.M.; Negm, A.M.; Bady, M.F.; Ibrahim, M.G.E. Environmental life cycle assessment of a residential building in Egypt: A case study. Proc. Technol. 2015, 19, 349–356. [Google Scholar] [CrossRef] [Green Version]

- Eder, P.; Delgado, L. Environmental Impact of Products (EIPRO) Analysis of the Life Cycle Environmental Impacts Related to the Final Consumption of the EU-25 IPTS/ESTO Project. 2006. Available online: https://op.europa.eu/en/publication-detail/-/publication/3b4b06b7-4bc0-4350-a20b-accdc70d1d94/language-en (accessed on 5 June 2021).

- Dettling, J.; Tu, Q.; Faist, M.; DelDuce, A.; Mandlebaum, S. Assessing the Environmental Benefits of Plant-Based Dietary Choices Through: A Comparison of Meal Choices, and a Comparison of Meat Products and Morning Star Farms® Veggie Products. 2016. Available online: https://www.morningstarfarms.com/content/dam/NorthAmerica/morningstarfarms/pdf/MSFPlantBasedLCAReport_2016-04-10_Final.pdf (accessed on 5 June 2021).

- Usva, K.; Sinkko, T.; Silvenius, F.; Riipi, I.; Heusala, H. Carbon and water footprint of coffee consumed in Finland—Life cycle assessment. Int. J. Life Cycle Assess. 2020, 25, 1976–1990. [Google Scholar] [CrossRef]

- González-García, S.; Castanheira, E.G.; Dias, A.C.; Arroja, L. Environmental life cycle assessment of a dairy product: The yoghurt. Int. J. Life Cycle Assess. 2013, 18, 796–811. [Google Scholar] [CrossRef]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat alternatives: Life cycle assessment of most known meat substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Laitala, L.; Klepp, I.G.; Henry, B. Use phase of apparel: A Literature review for Life Cycle Assessment with focus on wool. In SIFO Professional Report No. 6-2017; Oslo, Norway, 2017; Available online: https://oda.oslomet.no/oda-xmlui/bitstream/handle/20.500.12199/5343/FR%206-2017%20-%20A%20literature%20review%20for%20Life%20Cycle%20Assesement%20with%20focus%20on%20wool.pdf?sequence=1&isAllowed=y (accessed on 28 July 2021).

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; Publications Office of the European Union: Luxembourg, 2019; Available online: https://eplca.jrc.ec.europa.eu/permalink/PEF_method.pdf (accessed on 7 June 2021).

- ISO 14044 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006.

- Huijbregts, M.A.J.; Steinmann, Z.J.J.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Ecoinvent. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-36/ecoinvent-36.html (accessed on 28 July 2021).

- Saternus, M. The primary aluminium technology, production, prospects. Rudy Met. 2006, 6, 316–325. [Google Scholar]

- Aho, J.; Ali-Raatikainen, A.; Leino, K.; Heinonen, U. Screening Carbon Footprint for Aluminium Wine Packaging Final Report Gaia Consulting. 2019. Available online: https://www.omsystembolaget.se/globalassets/pdf/hallbarhet/alko-aluminium-bottle-co2-calculation-final-report.pdf (accessed on 29 July 2021).

- Environmental Profile Report for the European Aluminum Industry. Life Cycle Inventory Data for Aluminium Production and Transformation processes in Europe. Report of European Aluminum Association. 2013. Available online: https://www.european-aluminium.eu/media/1329/environmental-profile-report-for-the-european-aluminium-industry.pdf (accessed on 29 July 2021).

- World Steel in Figures. Report of World Steel Association Report. 2020. Available online: https://www.worldsteel.org/steel-by-topic/statistics/World-Steel-in-Figures.html (accessed on 29 July 2021).

- Gajdzik, B. Analysis and prediction of steel production technology trends in Poland, Europe and in the world. Pr. Inst. Metal. Żelaza 2017, 69, 58–67. [Google Scholar]

- DIRECTIVE (EU). 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001&from=EN (accessed on 15 June 2021).

- Association of Issuing Bodies. European Residual Mixes Results of the Calculation of Residual Mixes for the Calendar Year 2020 AIB Report Version 1.0. 31 May 2021. Available online: https://www.aib-net.org/facts/european-residual-mix (accessed on 7 June 2021).

- Piotrowska, K.; Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Rudnicki, J.; Tomporowski, A.; Flizikowski, J.; Opielak, M. Assessment of the Environmental Impact of a Car Tire throughout Its Lifecycle Using the LCA Method. Materials 2019, 12, 4177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Name of Life Cycle Stage | Symbol of Life Cycle Stage | Inventory Results | ||||

|---|---|---|---|---|---|---|

| Flow Type and Process Location * | Flow Name | Amount (Virtual) | Unit | Electricity Source/Mix Used to Model Electricity Consumption in Each Process | ||

| Production of raw materials and packaging | PRMP | Input from technosphere (AT) | Phenyl isocyanate | 6.479 | kg | Photovoltaic electricity |

| Input from technosphere (DE) | Aluminium, primary, ingot | 2.189 | kg | Residual electricity mix DE, 2020 or Hydro, DE | ||

| Input from technosphere (PL) | Copper | 1.308 | kg | Residual electricity mix PL, 2020 or Photovoltaic | ||

| Input from technosphere (PL) | Steel, low-alloyed | 32.093 | kg | Residual electricity mix PL, 2020 or Wind, PL | ||

| Inputs from technosphere (EUR) | 1,1-difluoroethane, HFC-152a | 0.239 | kg | Average electricity mix representative of Europe | ||

| Dimethyldichlorosilane | 0.003 | kg | ||||

| Epoxy resin, liquid | 0.111 | kg | ||||

| Lithium fluoride | 0.003 | kg | ||||

| Methylcyclopentane | 0.479 | kg | ||||

| Polyol | 4.799 | kg | ||||

| Polyvinylchloride, suspension polymerised | 0.466 | kg | ||||

| Sodium hydroxide, without water, in 50% solution state | 0.001 | kg | ||||

| Sodium percarbonate, powder | 0.003 | kg | ||||

| Sodium silicate, solid | 0.004 | kg | ||||

| Polyethylene, linear low density, granulate | 0.297 | kg | ||||

| Plastic extrusion | 0.297 | kg | ||||

| EUR-wooden pallet | 25.000 | kg | ||||

| Polystyrene, high impact | 10.222 | kg | ||||

| Transport of materials and packaging to manufacturer | TRANS | Input from technosphere (PL→PL, 250 km) * | Transport, freight lorry, 16–32t, EURO4 | 0.835 | tkm | |

| Input from technosphere (DE→PL, 570 km) * | Transport, freight lorry, 16–32t, EURO4 | 1.248 | tkm | |||

| Input from technosphere (AT→PL, 670 km) * | Transport, freight lorry, 16–32t, EURO4 | 4.342 | tkm | |||

| Input from technosphere (EUR→PL, 1000 km) * | Transport, freight lorry, 16–32t, EURO4 | 41.633 | tkm | |||

| Manufacturing of refrigerator | MAN | Inputs from technosphere (PL) | Compressed air, 800 kPa gauge | 19.018 | m3 | Residual electricity mix PL, 2020 |

| Metal-working factory | 2.75 × 10−8 | P | ||||

| Energy and auxiliary inputs, metal-working factory | 2.75 × 10−8 | kg | Residual electricity mix PL, 2020 or Photovoltaic | |||

| Electricity, high voltage | 10.948 | kWh | Residual electricity mix PL, 2020 or Photovoltaic | |||

| Heat, natural gas | 10.53 | MJ | Residual electricity mix PL, 2020 | |||

| Steam, in the chemical industry | 7.777 | kg | Residual electricity mix PL, 2020 | |||

| Emission to air (PL) | Ethane, 1,1-difluoro-, HFC-152a | 0.0239 | kg | |||

| Output to technosphere (PL) | Wastewater, average | 0.055 | m3 | Residual electricity mix PL, 2020 | ||

| Distribution of refrigerator 10 days, 0.96 m2 | DISTR | Input from technosphere (PL) | Electricity, low voltage | 0.789 | kWh | Supplier electricity mix PL, 2020 |

| Input from technosphere (PL) | Heat | 9.468 | MJ | Supplier electricity mix PL, 2020 | ||

| Input from technosphere (PL and/or DE) | Transport, freight lorry, 16–32t, EURO4 | 42.65 or 63.98 or 85.3 | tkm | 42.65 tkm—100% of products destined for the Polish market 63.98 tkm—50%/50% Polish and German markets 85.3 tkm—100% German market | ||

| Retail of refrigerator 81 days, 0.96 m2 | RETA | Input from technosphere (PL and/or DE) | Electricity | 31.956 | kWh | Supplier electricity mix PL, 2020 and/or Supplier electricity mix DE, 2020 |

| Use of refrigerator (10 years) | USE | Inputs from technosphere (PL and/or DE) | Electricity | 3030 | kWh | Supplier electricity mix PL, 2020 and/or Supplier electricity mix DE, 2020 |

| Tap water | 100 | kg | Average electricity mix representative of Europe | |||

| Soap | 0.02 | kg | ||||

| 1,1-difluoroethane, HFC-152a | 0.0239 | kg | ||||

| Emission to air (PL and/or DE) | Ethane, 1,1-difluoro-, HFC-152a | 0.0239 | kg | |||

| Output to technosphere (PL and/or DE) | Wastewater, average | 100.2 | dm3 | Average electricity mix representative of Europe | ||

| Transport of waste to EoL | TRANSW | Input from technosphere (100 km) (PL and/or DE) | Transport, freight lorry, 16–32t, EURO4 | 8.370 | tkm | |

| End of life | EOL | Outputs to technosphere (PL and/or DE) | Scrap aluminium, market for scrap aluminium | 2.189 | kg | Average electricity mix representative of Europe |

| Scrap copper, market for scrap copper | 1.308 | kg | ||||

| Scrap steel, market for scrap steel | 32.093 | kg | ||||

| Waste polystyrene, market for waste polystyrene | 10.222 | kg | ||||

| Waste polyvinylchloride, market for waste polyvinylchloride | 0.577 | kg | ||||

| Waste polyethylene, market for waste polyethylene | 0.297 | kg | ||||

| 25.000 | kg | |||||

| Germany (DE) | Poland (PL) | |||

|---|---|---|---|---|

| Supplier Mix2020 | Residual Mix 2020 | Supplier Mix 2020 | Residual Mix 2020 | |

| Energy from unspecified renewable carriers | 0.52% | 0.00% | 0.00% | 0.00% |

| Energy from biomass | 3.90% | 0.00% | 3.24% | 2.60% |

| Solar energy | 9.79% | 0.89% | 1.48% | 1.50% |

| Geothermal energy | 0.24% | 0.00% | 0.00% | 0.00% |

| Energy from wind | 29.59% | 0.04% | 6.92% | 2.92% |

| Hydro energy | 24.97% | 0.00% | 1.44% | 0.98% |

| Nuclear energy | 6.64% | 21.23% | 3.78% | 4.01% |

| Energy from unspecified fossil carriers | 1.73% | 5.53% | 2.50% | 2.52% |

| Energy from hard coal | 13.4% | 42.82% | 66.53% | 70.51% |

| Energy from lignite | 0.00% | 0.00% | 0.15% | 0.16% |

| Energy from oil | 0.43% | 1.36% | 0.12% | 0.12% |

| Energy from gas | 8.80% | 28.14% | 13.84% | 14.67% |

| Untracked energy | 41.89% | 100.00% | 94.35% | 100.00% |

| Tracked energy | 58.11% | 0.00% | 5.65% | 0.00% |

| Life-Cycle Impact Assessment Method | Impact Category | Unit | Germany (DE) | Poland (PL) | ||

|---|---|---|---|---|---|---|

| Supplier Mix 2020 | Residual Mix 2020 | Supplier Mix 2020 | Residual Mix 2020 | |||

| IPCC 2013, 100a | Global warming | kg CO2 eq. | 0.298 | 0.689 | 0.938 | 0.988 |

| ReCiPe 2016, midpoint | Global warming | kg CO2 eq. | 0.302 | 0.699 | 0.952 | 1.003 |

| EF 2.0 method, adapted | Climate change | kg CO2 eq. | 0.303 | 0.700 | 0.954 | 1.006 |

| ReCiPe 2016, endpoint | Single score | Pt | 0.008 | 0.018 | 0.036 | 0.038 |

| PRMP | TRANS | MAN | DISTR | RETA | USE | TRANSW | EOL | TOTAL | Unit | |

|---|---|---|---|---|---|---|---|---|---|---|

| Residual 100%PL | 8.95 | 0.31 | 1.79 | 0.28 | 1.20 | 113.50 | 0.05 | 0.36 | 124.44 | Pt |

| 7.08 | 0.25 | 1.41 | 0.22 | 0.95 | 89.77 | 0.04 | 0.28 | 100 | % | |

| Renewable 100%PL | 8.33 | 0.31 | 1.23 | 0.28 | 1.20 | 113.50 | 0.05 | 0.36 | 125.25 | Pt |

| 6.65 | 0.25 | 0.98 | 0.23 | 0.95 | 90.61 | 0.04 | 0.29 | 100 | % | |

| Residual 50%PL50%DE | 8.95 | 0.31 | 1.79 | 0.40 | 0.71 | 67.51 | 0.05 | 0.51 | 80.24 | Pt |

| 11.16 | 0.39 | 2.23 | 0.50 | 0.89 | 84.14 | 0.06 | 0.64 | 100 | % | |

| Renewable 50%PL50%DE | 8.33 | 0.31 | 1.23 | 0.40 | 0.71 | 67.51 | 0.05 | 0.51 | 79.06 | Pt |

| 10.54 | 0.40 | 1.56 | 0.51 | 0.90 | 85.40 | 0.06 | 0.65 | 100 | % | |

| Residual 100%DE | 8.95 | 0.31 | 1.79 | 0.52 | 0.27 | 25.83 | 0.05 | 0.66 | 39.838 | Pt |

| 23.32 | 0.81 | 4.66 | 1.36 | 0.71 | 67.29 | 0.12 | 1.72 | 100 | % | |

| Renewable_ 100%DE | 8.33 | 0.31 | 1.23 | 0.52 | 0.27 | 25.83 | 0.05 | 0.66 | 37.20 | Pt |

| 22.39 | 0.84 | 3.31 | 1.41 | 0.73 | 69.42 | 0.13 | 1.78 | 100 | % |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lewandowska, A.; Kurczewski, P.; Joachimiak-Lechman, K.; Zabłocki, M. Environmental Life Cycle Assessment of Refrigerator Modelled with Application of Various Electricity Mixes and Technologies. Energies 2021, 14, 5350. https://doi.org/10.3390/en14175350

Lewandowska A, Kurczewski P, Joachimiak-Lechman K, Zabłocki M. Environmental Life Cycle Assessment of Refrigerator Modelled with Application of Various Electricity Mixes and Technologies. Energies. 2021; 14(17):5350. https://doi.org/10.3390/en14175350

Chicago/Turabian StyleLewandowska, Anna, Przemysław Kurczewski, Katarzyna Joachimiak-Lechman, and Marek Zabłocki. 2021. "Environmental Life Cycle Assessment of Refrigerator Modelled with Application of Various Electricity Mixes and Technologies" Energies 14, no. 17: 5350. https://doi.org/10.3390/en14175350

APA StyleLewandowska, A., Kurczewski, P., Joachimiak-Lechman, K., & Zabłocki, M. (2021). Environmental Life Cycle Assessment of Refrigerator Modelled with Application of Various Electricity Mixes and Technologies. Energies, 14(17), 5350. https://doi.org/10.3390/en14175350