A New Evaluation Method of Shale Oil Sweet Spots in Chinese Lacustrine Basin and Its Application

Abstract

:1. Introduction

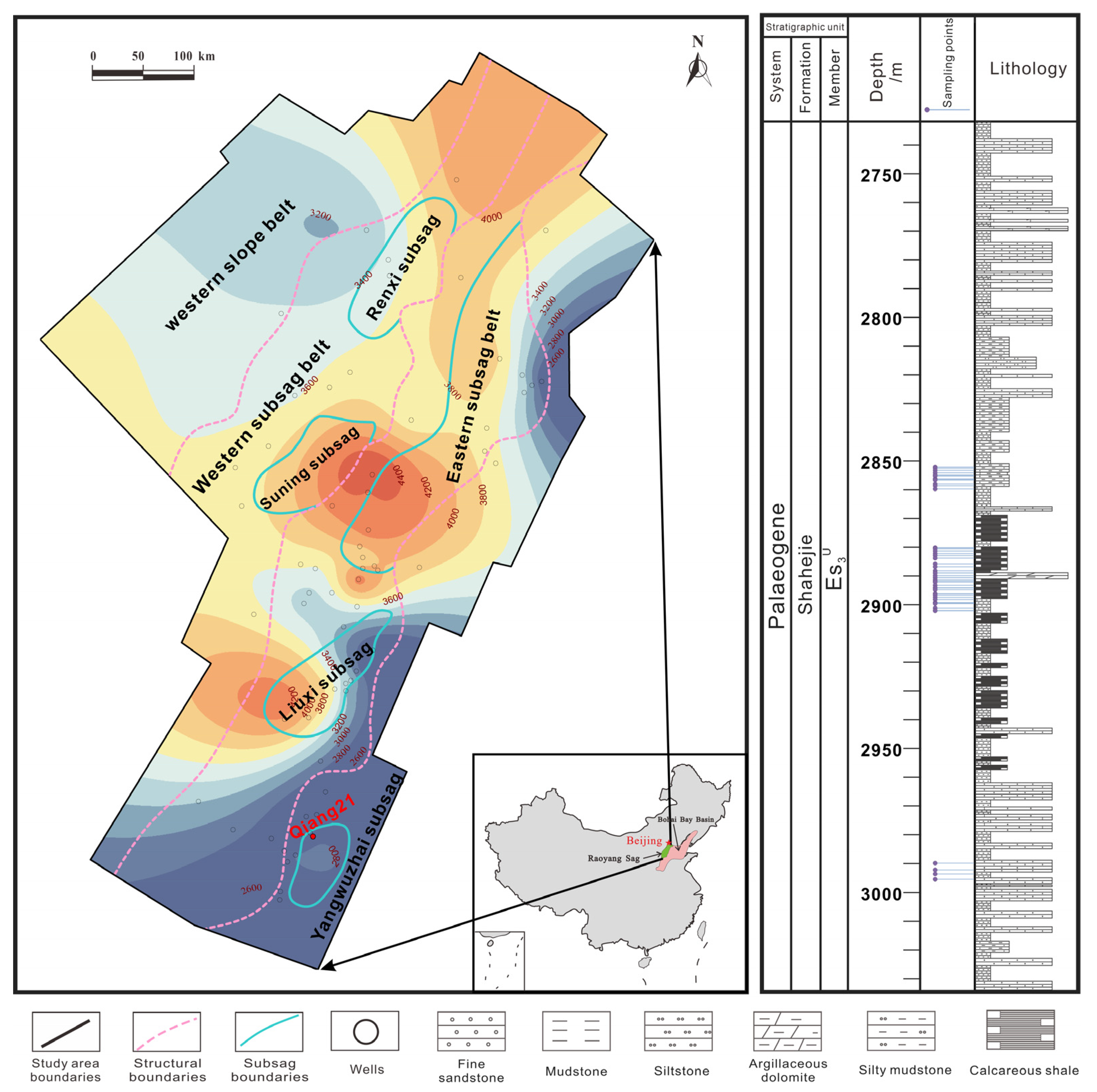

2. Geological Settings

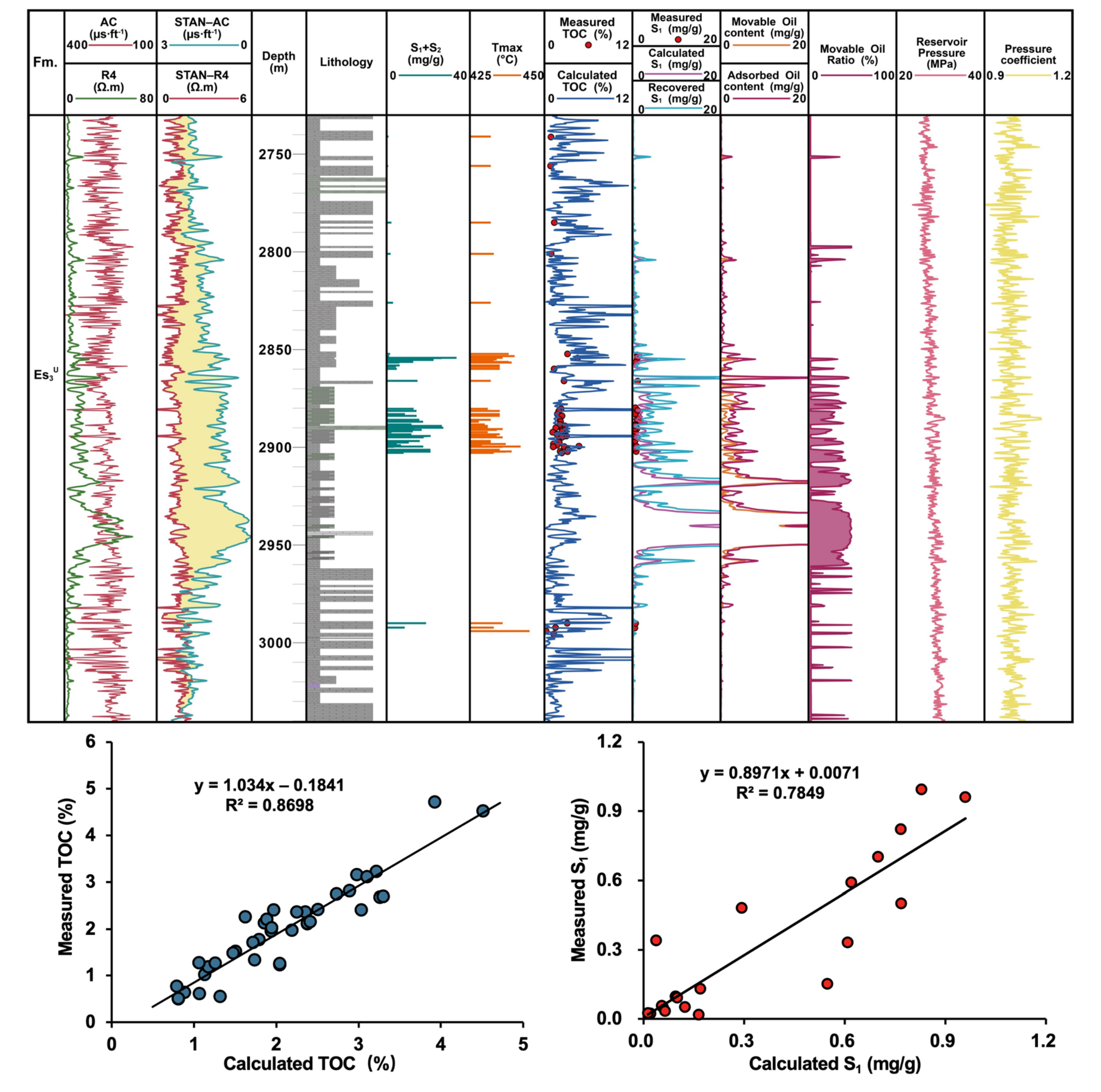

3. Determination of Primary Parameters

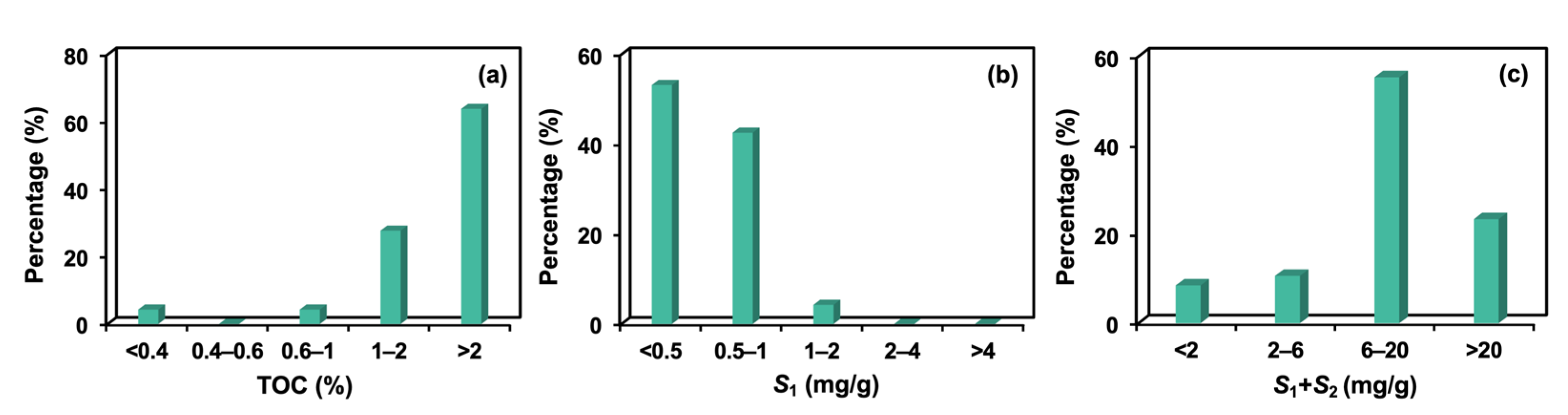

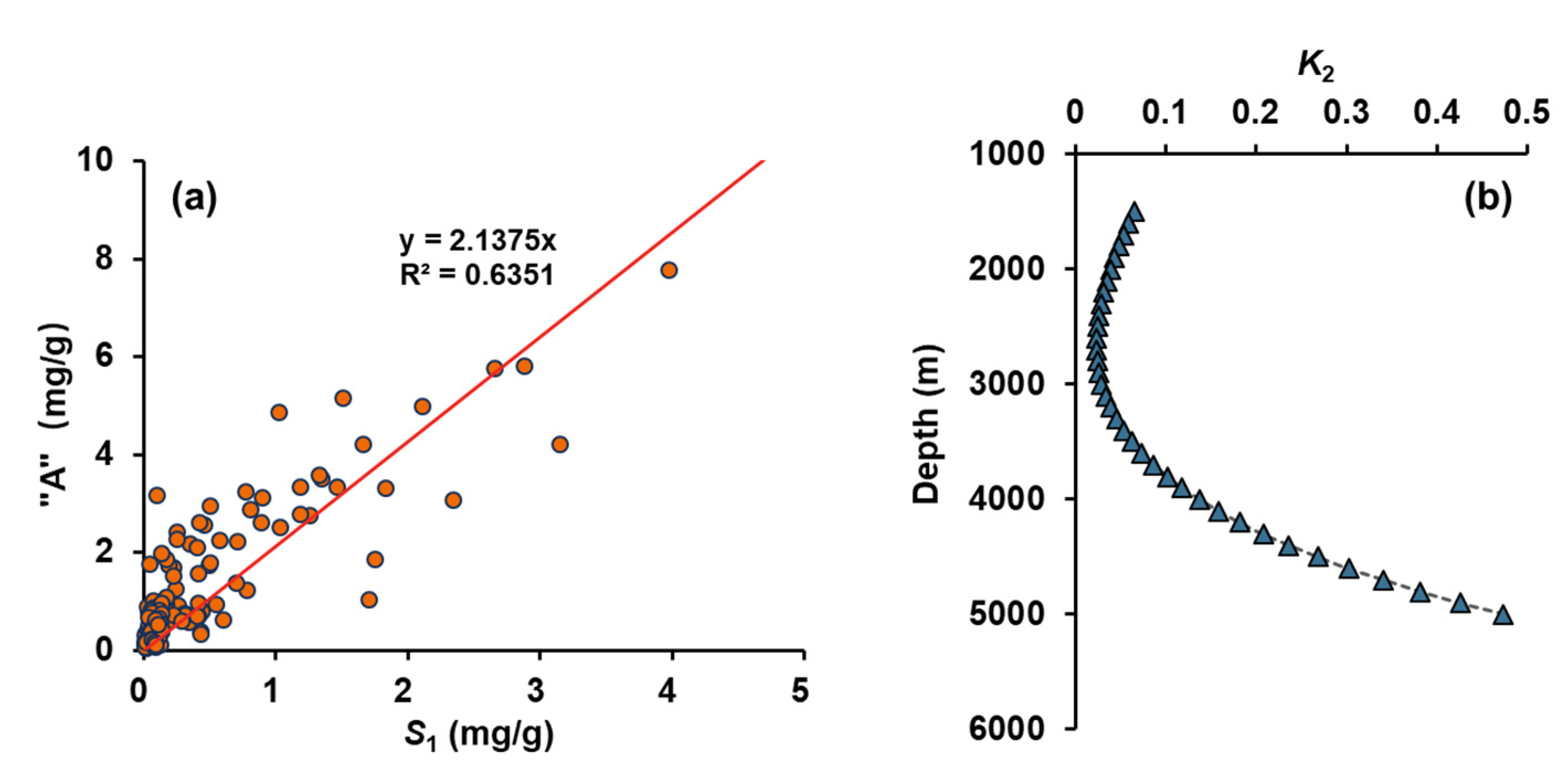

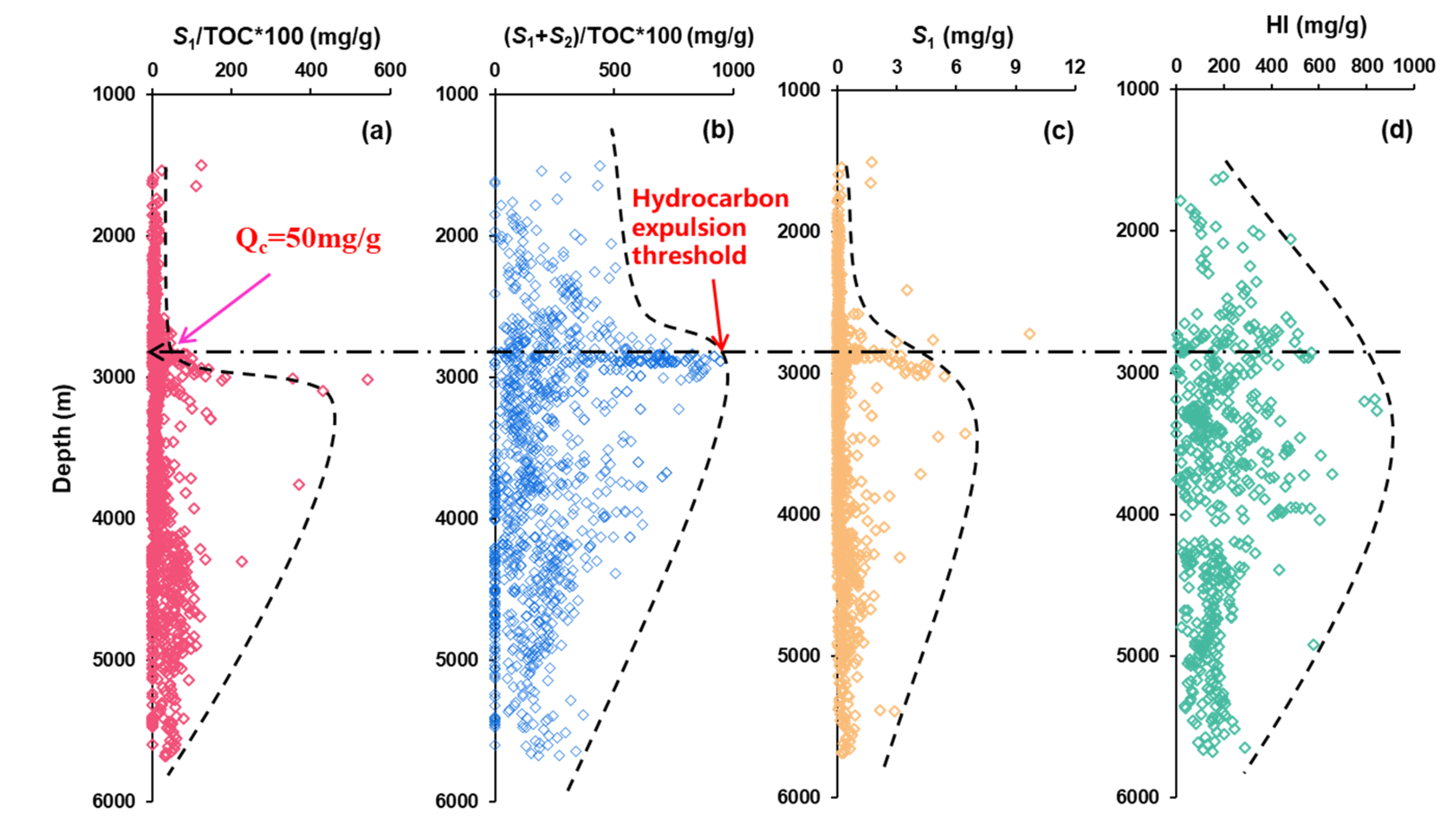

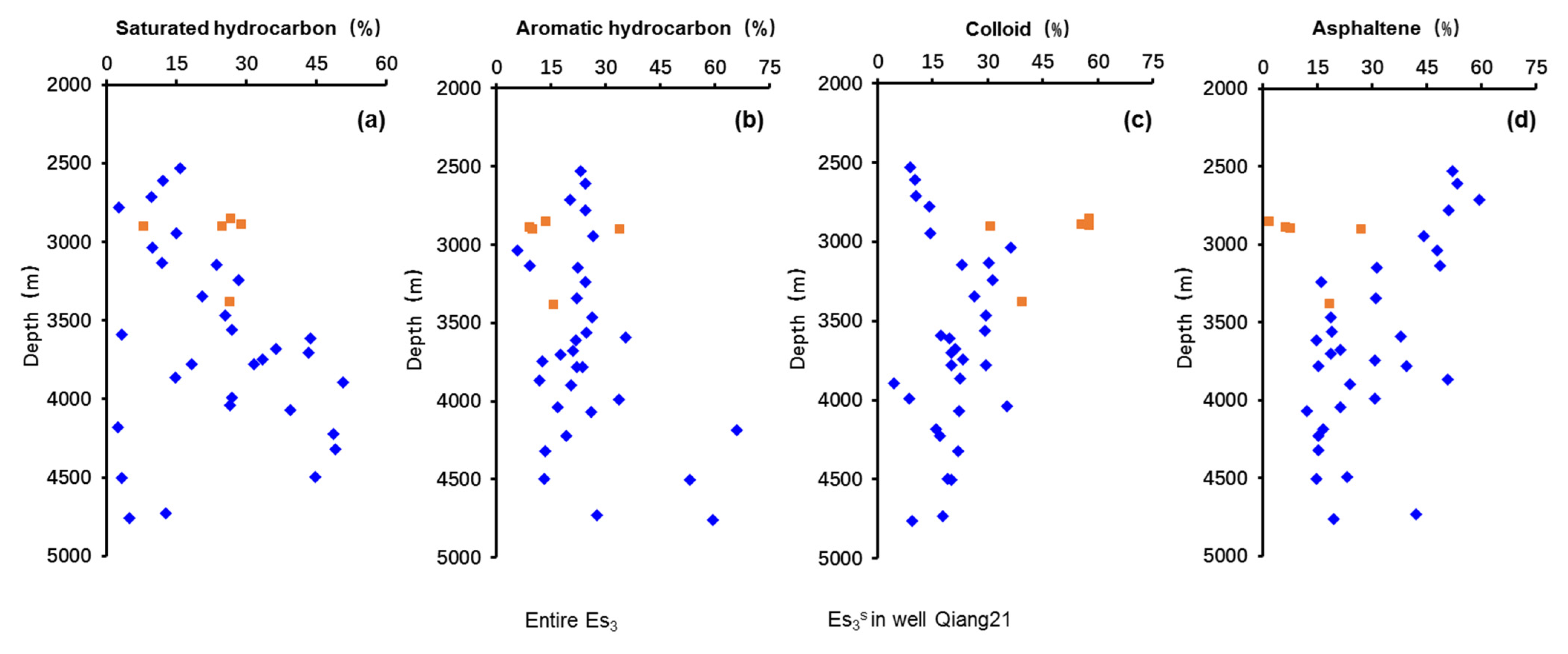

3.1. Shale Oil Content

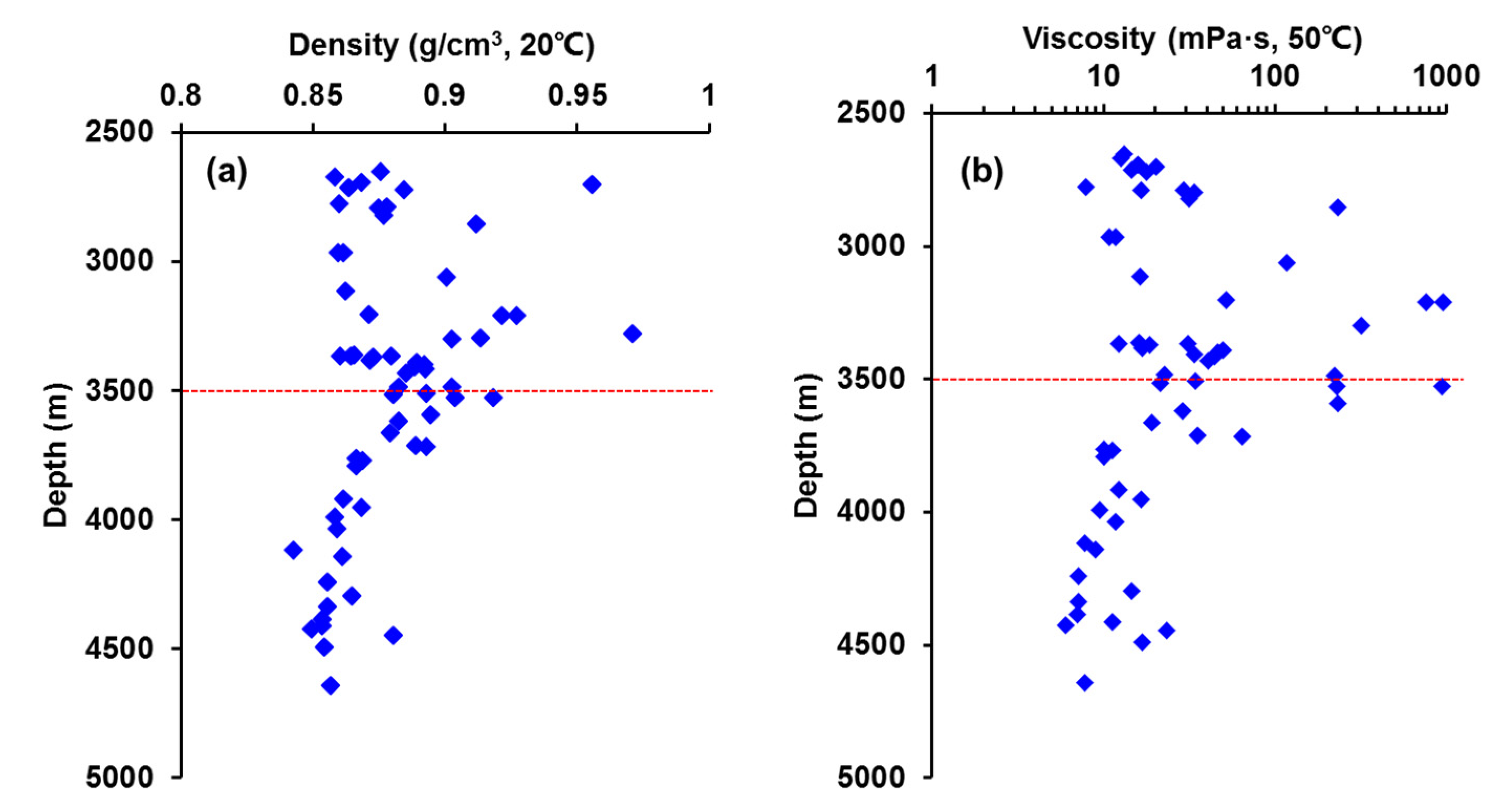

3.2. Movable Oil Ratio and Reservoir Pressure Coefficient

3.2.1. Movable Oil Ratio

3.2.2. Pressure Coefficient of Reservoir Fluid

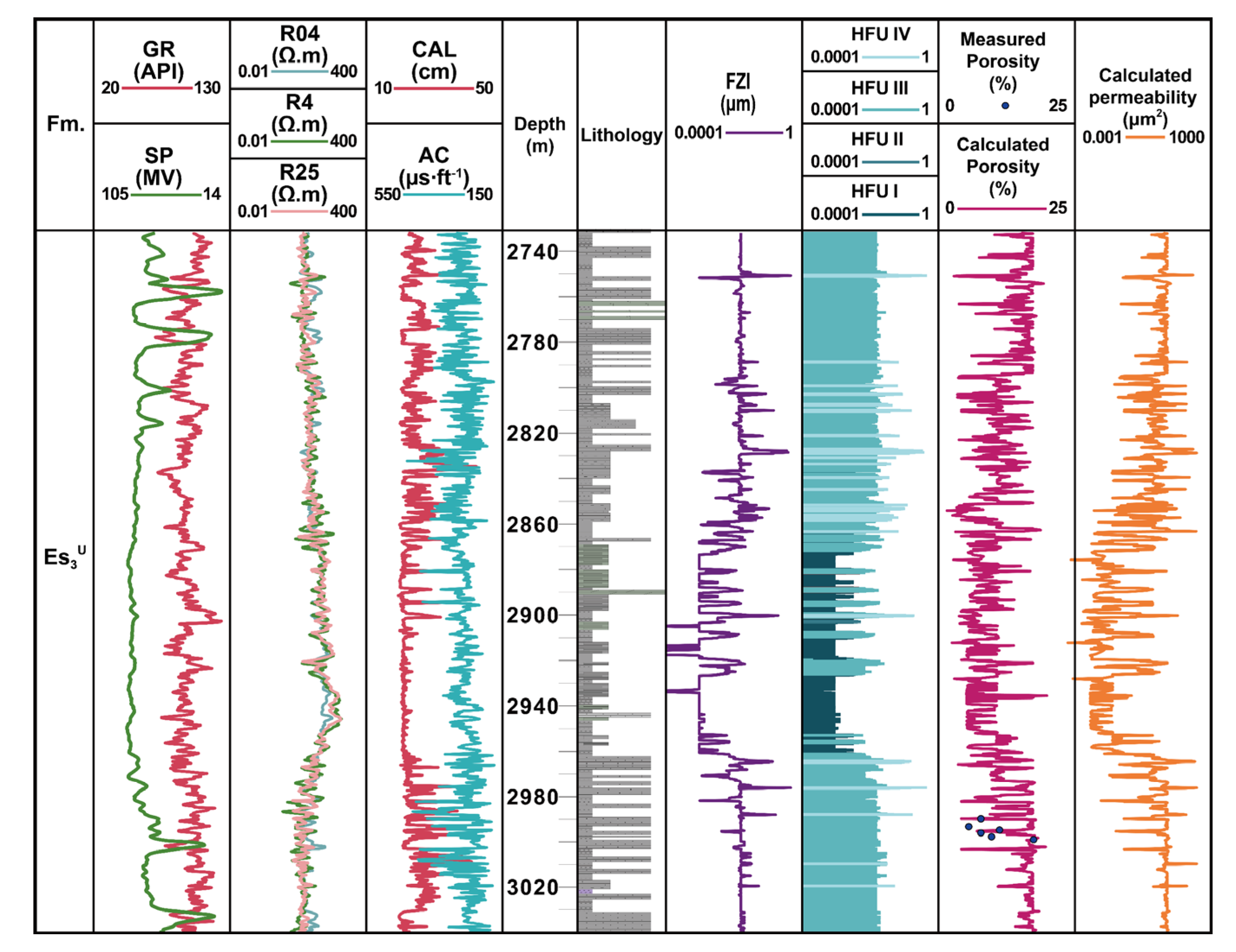

3.3. Shale Permeability

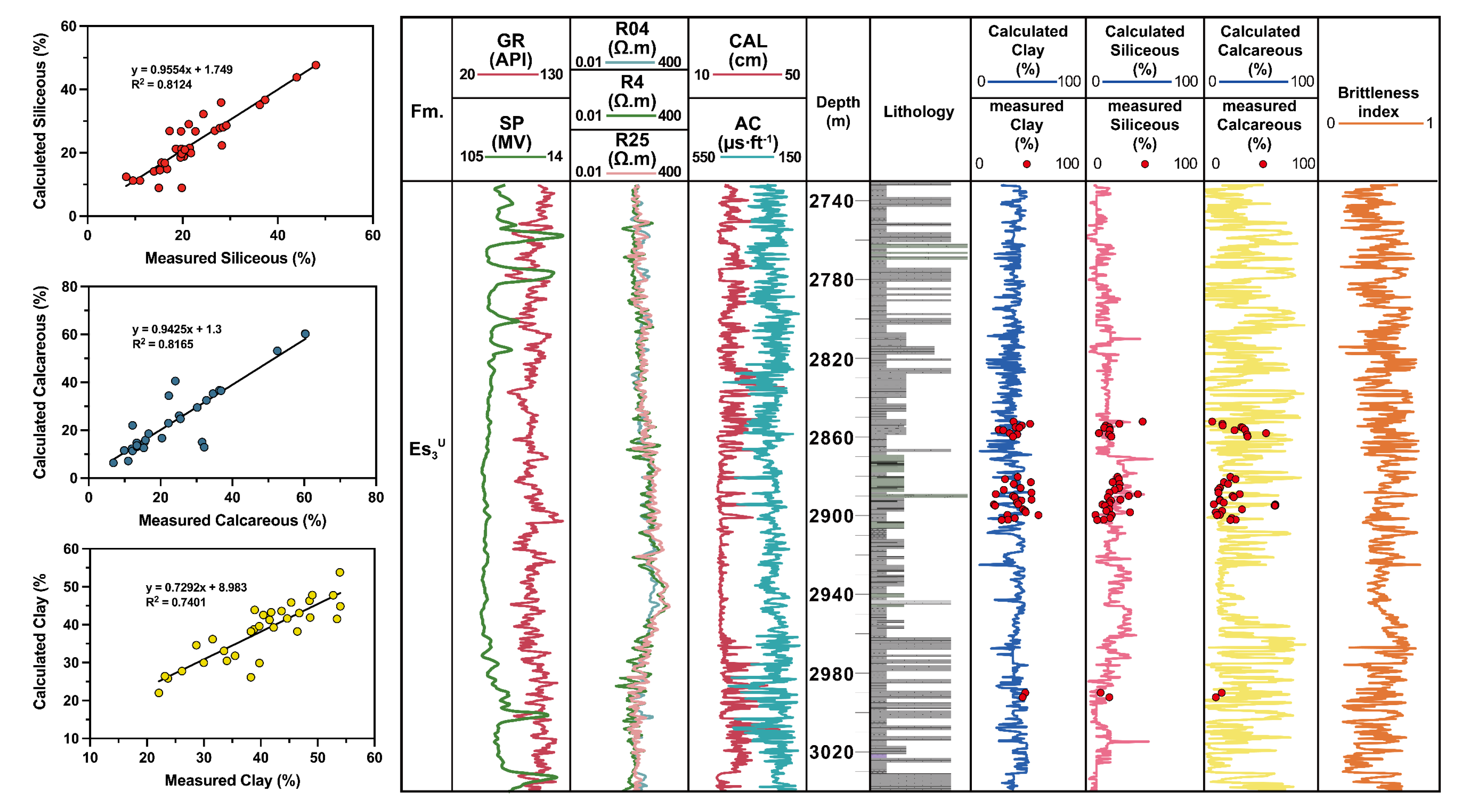

3.4. Brittleness Index

4. Determination of Comprehensive Sweet Spots

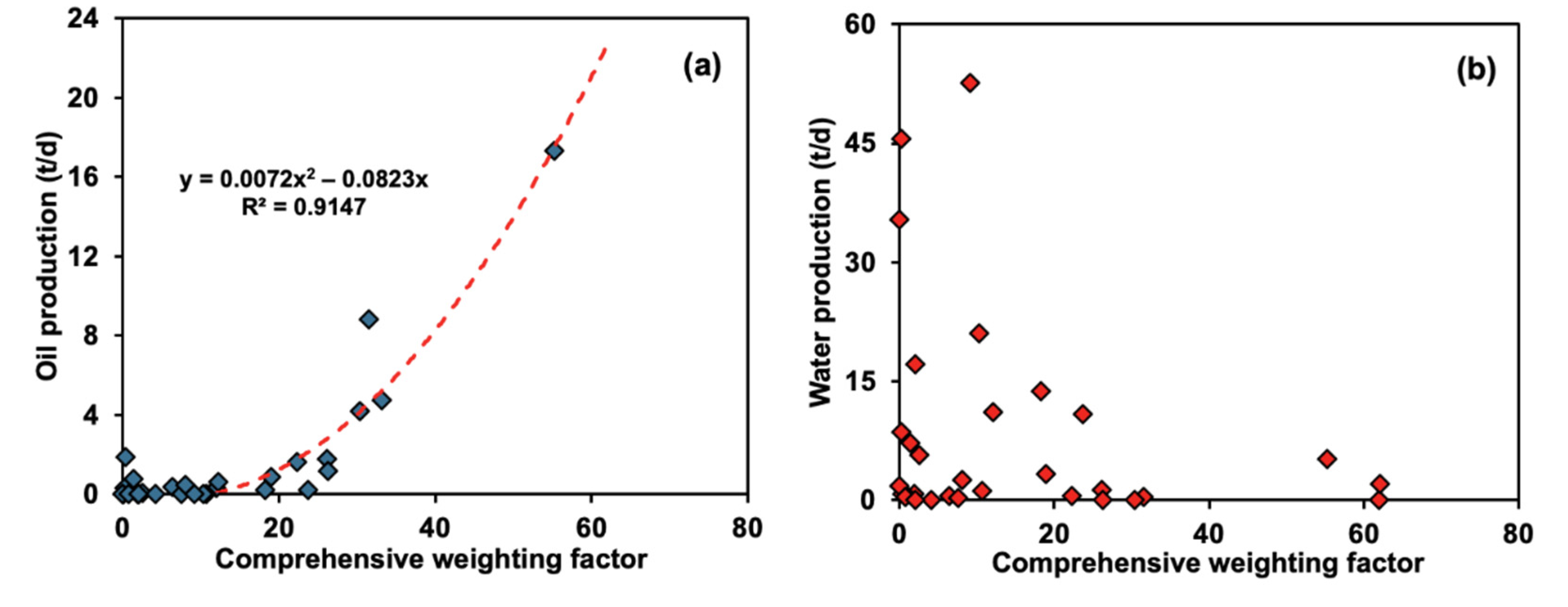

4.1. Calculation of Comprehensive Weighting Factor

4.2. Comprehensive Evaluation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tunstall, T. Iterative bass model forecasts for unconventional oil production in the Eagle Ford shale. Energy 2015, 93, 580–588. [Google Scholar] [CrossRef]

- Misch, D.; Gross, D.; Mahlstedt, N.; Makogon, V.; Sachsenhofer, R.F. Shale gas/shale oil potential of Upper Visean Black Shales in the Dniepr-Donets Basin (Ukraine). Mar. Pet. Geol. 2016, 75, 203–219. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Z.; Guo, Z.; Hong, W.; Dun, C.; Zhang, X.; Li, B.; Wu, L. Enrichment and distribution of shale oil in the Cretaceous Qingshankou Formation, Songliao Basin, Northeast China. Mar. Pet. Geol. 2017, 86, 751–770. [Google Scholar] [CrossRef]

- Zhao, Y.; Jin, Z. Hydrocarbon mixture phase behavior in multi-scale systems in relation to shale oil recovery: The effect of pore size distributions. Fuel 2021, 291, 120141. [Google Scholar] [CrossRef]

- Feng, Q.; Xu, S.; Xing, X.; Zhang, W.; Wang, S. Advances and challenges in shale oil development: A critical review. Adv. Geo-Energy Res. 2020, 4, 406–418. [Google Scholar] [CrossRef]

- Hackley, P.C.; Cardott, B.J. Application of organic petrography in North American shale petroleum systems: A review. Int. J. Coal Geol. 2016, 163, 8–51. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, P.; Lu, S.; Xue, H.; Zhang, P.; Ma, F. Microstructural characterization of the clay-rich oil shales by nuclear magnetic resonance (NMR). J. Nanosci. Nanotechnol. 2017, 17, 7026–7034. [Google Scholar] [CrossRef]

- Yang, Z.; Zou, C.; Wu, S.; Lin, S.; Pan, S.; Niu, X.; Meng, G.; Tang, Z.; Li, G.; Zhao, J.; et al. Formation, distribution and resource potential of the “sweet areas (sections)” of continental shale oil in China. Mar. Pet. Geol. 2019, 102, 48–60. [Google Scholar]

- Jarvie, D.M. Shale resource systems for oil and gas: Part 2—Shale oil resource systems. AAPG Mem. 2012, 97, 89–119. [Google Scholar]

- Hu, T.; Pang, X.; Jiang, F.; Wang, Q.; Liu, X.; Wang, Z.; Jiang, S.; Wu, G.; Li, C.; Xu, T.; et al. Movable oil content evaluation of lacustrine organic-rich shales: Methods and a novel quantitative evaluation model. Earth Sci. Rev. 2021, 214, 103545. [Google Scholar] [CrossRef]

- Piane, C.D.; Almqvist, B.; Macrae, C.M.; Torpy, A.; Mory, A.J.; Dewhurst, D.N. Texture and diagenesis of Ordovician shale from the Canning Basin, Western Australia: Implications for elastic anisotropy and geomechanical properties. Mar. Pet. Geol. 2015, 59, 56–71. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, L.; Tao, S.; Cui, J.; Wu, S.; Lin, S.; Pan, S. Formation conditions and “sweet spot” evaluation of tight oil and shale oil. Pet. Explor. Dev. 2015, 42, 555–565. [Google Scholar]

- Yin, J.; Hao, F.; Wang, Z.; Chen, X.; Zou, H. Lacustrine conditions control on the distribution of organic-rich source rocks: An instance analysis of the lower 1st member of the Shahejie Formation in the Raoyang Sag, Bohai Bay Basin. J. Nat. Gas Sci. Eng. 2020, 78, 103320. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, J.; Yang, G.; Jia, W.; Liu, S.; Kong, X.; Li, S. An innovative method for the characterization of oil content in lacustrine shale-oil systems: A case study from the middle Permian Lucaogou Formation in the Jimusaer sag, Junggar basin. Mar. Pet. Geol. 2021, 130, 105112. [Google Scholar] [CrossRef]

- Falk, K.; Coasne, B.; Pellenq, R.; Ulm, F.J.; Bocquet, L. Subcontinuum mass transport of condensed hydrocarbons in nanoporous media. Nat. Commun. 2015, 6, 6949. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Lu, S.; Xie, L.; Zhang, J.; Xue, H.; Zhang, P.; Tian, S. Modeling of hydrocarbon adsorption on continental oil shale: A case study on n-alkane. Fuel 2017, 206, 603–613. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X.; Wu, S.; Lin, S.; Wang, L.; et al. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 14–26. [Google Scholar] [CrossRef]

- Zhou, L.; Zhao, X.; Chai, G.; Jiang, W.; Pu, X.; Wang, X.; Han, W.; Guan, Q.; Feng, J.; Liu, X. Key exploration & development technologies and engineering practice of continental shale oil: A case study of Member 2 of Paleogene Kongdian Formation in Cangdong Sag, Bohai Bay Basin, East China. Pet. Explor. Dev. 2020, 47, 1059–1066. [Google Scholar]

- Gao, Q.; Tan, M.; Zhang, Y.; Song, L.; Wei, X.; Zhang, M.; Zhang, P. Well-seismic joint technology for quantitative evaluation of “sweet spot” in continental shale oil: A case study of Lower Es3 Member of Luojia area in Jiyang Depression. Pet. Geol. Recovery Effic. 2019, 26, 165–173. [Google Scholar]

- Li, J.; Wang, M.; Lu, S.; Chen, G.; Tian, W.; Jiang, C.; Li, Z. A new method for predicting sweet spots of shale oil using conventional well logs. Mar. Pet. Geol. 2020, 113, 104097. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, X.; Bai, J.; Liu, W.; Chen, S.; Liu, C.; Li, Y. Enrichment and exploration of deep lacustrine shale oil in the first Member of Cretaceous Qingshankou Formation, southern Songliao Basin, NE China. Pet. Explor. Dev. 2020, 47, 637–652. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Xue, H.; Xie, L.; Zhang, P. Quantitative evaluation on the elastic property of oil-bearing mudstone/shale from a Chinese continental basin. Energy Explor. Exploit. 2015, 33, 851–868. [Google Scholar] [CrossRef] [Green Version]

- Mao, L.; Xiao, A.; Zhang, H.; Wu, Z.; Yi, L.; Wu, L.; Zhao, X. Structural patterns of the late Mesozoic crustal detachment system in the Raoyang Sag, Bohai Bay Basin, eastern China: New insights from 3D seismic data. Mar. Pet. Geol. 2017, 84, 215–224. [Google Scholar] [CrossRef]

- Chen, F.; Zheng, Q.; Lu, S.; Ding, X.; Ju, Y.; Zhao, H. Classification of the tight oil reservoir storage space in the Raoyang Sag of the Jizhong Depression in the Bohai Bay Basin, China. Energy Sci. Eng. 2019, 8, 74–88. [Google Scholar] [CrossRef]

- Lu, S.; Huang, W.; Chen, F.; Li, J.; Wang, M.; Xue, H.; Wang, W.; Cai, X. Classification and evaluation criteria of shale oil and gas resources: Discussion and application. Pet. Explor. Dev. 2012, 39, 268–276. [Google Scholar] [CrossRef]

- Curiale, J.A.; Curtis, J.B. Organic geochemical applications to the exploration for source-rock reservoirs-A review. J. Unconv. Oil Gas Resour. 2016, 13, 1–31. [Google Scholar] [CrossRef]

- Liu, B.; Bai, L.; Chi, Y.; Jia, R.; Fu, X.; Yang, L. Geochemical characterization and quantitative evaluation of shale oil reservoir by two-dimensional nuclear magnetic resonance and quantitative grain fluorescence on extract: A case study from the Qingshankou Formation in Southern Songliao Basin, northeast China. Mar. Pet. Geol. 2019, 109, 561–573. [Google Scholar]

- Passey, Q.R.; Creaney, S.; Kulla, J.B.; Moretti, F.J.; Stroud, J.D. A practical model for organic richness from porosity and resistivity logs. AAPG Bull. 1990, 74, 1777–1794. [Google Scholar]

- Huang, W.; Deng, S.; Lu, S.; Yu, L.; Hu, S.; Zhang, J. Shale organic heterogeneity evaluation method and its application to shale oil resource evaluation—A case study from Qingshankou Formation, southern Songliao Basin. Oil Gas Geol. 2014, 35, 704–711. [Google Scholar]

- Li, J.; Lu, S.; Cai, J.; Zhang, P.; Xue, H.; Zhao, X. Adsorbed and free oil in lacustrine nanoporous shale: A theoretical model and a case study. Energy Fuels 2018, 32, 12247–12258. [Google Scholar]

- Li, J.; Wang, S.; Lu, S.; Zhang, P.; Cai, J.; Zhao, J.; Li, W. Microdistribution and mobility of water in gas shale: A theoretical and experimental study. Mar. Pet. Geol. 2019, 102, 496–507. [Google Scholar] [CrossRef]

- Zhang, L.; Bao, Y.; Li, J.; Li, Z.; Zhu, R.; Zhang, J. Movability of lacustrine shale oil: A case study of Dongying Sag, Jiyang Depression, Bohai Bay Basin. Pet. Explor. Dev. 2014, 41, 641–649. [Google Scholar] [CrossRef]

- Eaton, B.A. The effect of overburden stress on geopressure prediction from well logs. J. Pet. Technol. 1972, 24, 929–934. [Google Scholar] [CrossRef]

- Eaton, B.A. The equation for geopressure prediction from well logs. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Dallas, TX, USA, 28 September–1 October 1975. [Google Scholar]

- Gurevich, A.E.; Chilingar, G.V.; Aminzadeh, F. Origin of the formation fluid pressure distribution and ways of improving pressure prediction methods. J. Pet. Sci. Eng. 1994, 12, 67–77. [Google Scholar] [CrossRef]

- Bowers, G.L. Pore pressure estimation from velocity data: Accounting for overpressure mechanisms besides undercompaction. SPE Drill. Complet. 1995, 10, 89–95. [Google Scholar] [CrossRef]

- Liu, L.; Shen, G.; Wang, Z.; Yang, H.; Han, H.; Cheng, Y. Abnormal formation velocities and applications to pore pressure prediction. J. Appl. Geophys. 2018, 153, 1–6. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Jiang, Y.; Yuan, F.; Chen, K.; Guo, Z. Quantification models of overpressuring in Paleogene source rocks of the Raoyang Depression, Bohai Bay Basin, China. Mar. Pet. Geol. 2019, 109, 607–622. [Google Scholar] [CrossRef]

- Du, F.; Huang, J.; Chai, Z.; Killough, J. Effect of vertical heterogeneity and nano-confinement on the recovery performance of oil-rich shale reservoir. Fuel 2020, 267, 117199. [Google Scholar] [CrossRef]

- Goral, J.; Panja, P.; Deo, M.; Andrew, M.; Linden, S.; Schwarz, J.O.; Wiegmann, A. Confinement effect on porosity and permeability of shales. Sci. Rep. 2020, 10, 49. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Hao, Y.; Lv, Y.; Wang, C.; Yao, C.; Zhao, Q.; Xiao, P. Experimental investigation on low-velocity seepage characteristics and influencing factors in a shale oil reservoir. J. Pet. Sci. Eng. 2020, 195, 107732. [Google Scholar] [CrossRef]

- Shao, W.; Xie, J.; Chi, X.; Li, J.; Wu, S.; Xiao, F. On the relation of porosity and permeability in low porosity and low permeability rock. Well Logging Technol. 2013, 37, 149–153. [Google Scholar]

- Hearn, C.L.; Ebanks, W.J.; Tye, R.S.; Ranganathan, V. Geological Factors Influencing Reservoir Performance of the Hartzog Draw Field, Wyoming. J. Pet. Technol. 1984, 36, 1335–1344. [Google Scholar] [CrossRef]

- Nooruddin, H.A.; Hossain, M.E. Modified Kozeny-Carmen correlation for enhanced hydraulic flow unit characterization. J. Pet. Sci. Eng. 2011, 80, 107–115. [Google Scholar] [CrossRef]

- Ghiasi-Freez, J.; Kadkhodaie-Ilkhchi, A.; Ziaii, M. Improving the accuracy of flow units prediction through two committee machine models: An example from the South Pars Gas Field, Persian Gulf Basin, Iran. Comput. Geosci. 2012, 46, 10–23. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, S.; Li, J.; Zhang, J.; Xue, H.; Chen, C. Permeability evaluation on oil-window shale based on hydraulic flow unit: A new approach. Adv. Geo-Energy Res. 2018, 2, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Bowker, K.A. Barnett Shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Chen, K.; Li, P.; Li, J.; Geng, H.; Li, B.; Li, X.; Wang, H.; Zang, L.; Wei, Y.; et al. A New Evaluation Method of Shale Oil Sweet Spots in Chinese Lacustrine Basin and Its Application. Energies 2021, 14, 5519. https://doi.org/10.3390/en14175519

Li X, Chen K, Li P, Li J, Geng H, Li B, Li X, Wang H, Zang L, Wei Y, et al. A New Evaluation Method of Shale Oil Sweet Spots in Chinese Lacustrine Basin and Its Application. Energies. 2021; 14(17):5519. https://doi.org/10.3390/en14175519

Chicago/Turabian StyleLi, Xiaodong, Ketong Chen, Peng Li, Junqian Li, Haiyan Geng, Bin Li, Xiwei Li, Haiyan Wang, Liyuan Zang, Yongbo Wei, and et al. 2021. "A New Evaluation Method of Shale Oil Sweet Spots in Chinese Lacustrine Basin and Its Application" Energies 14, no. 17: 5519. https://doi.org/10.3390/en14175519