A Study to Investigate the Effect of Valve Mechanisms on Exhaust Residual Gas and Effective Release Energy of a Motorcycle Engine

Abstract

:1. Introduction

2. Methodology of the Study

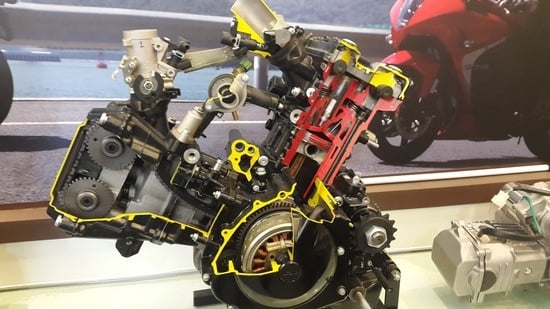

2.1. Experimental Setup

2.2. Simulation Method

2.3. Development Process

3. Results and Discussions

3.1. Model Validation

3.2. Simulation Results

- -

- Engine bore, stroke, and connecting rod length affect the total displacement volume VD;

- -

- Valve lifts and lengths, diameters of intake tube, air–fuel ratio, and ignition timing affect the air mass flow, ERG, and ERE;

- -

- The air mass flow affects the brake specific fuel (BSFC), and indicates the mean affective pressure (IMEP) and the fuel consumption (ISFC).

- -

- VD has a direct influence on the engine effective torque (Teff) as described in Equation (7).

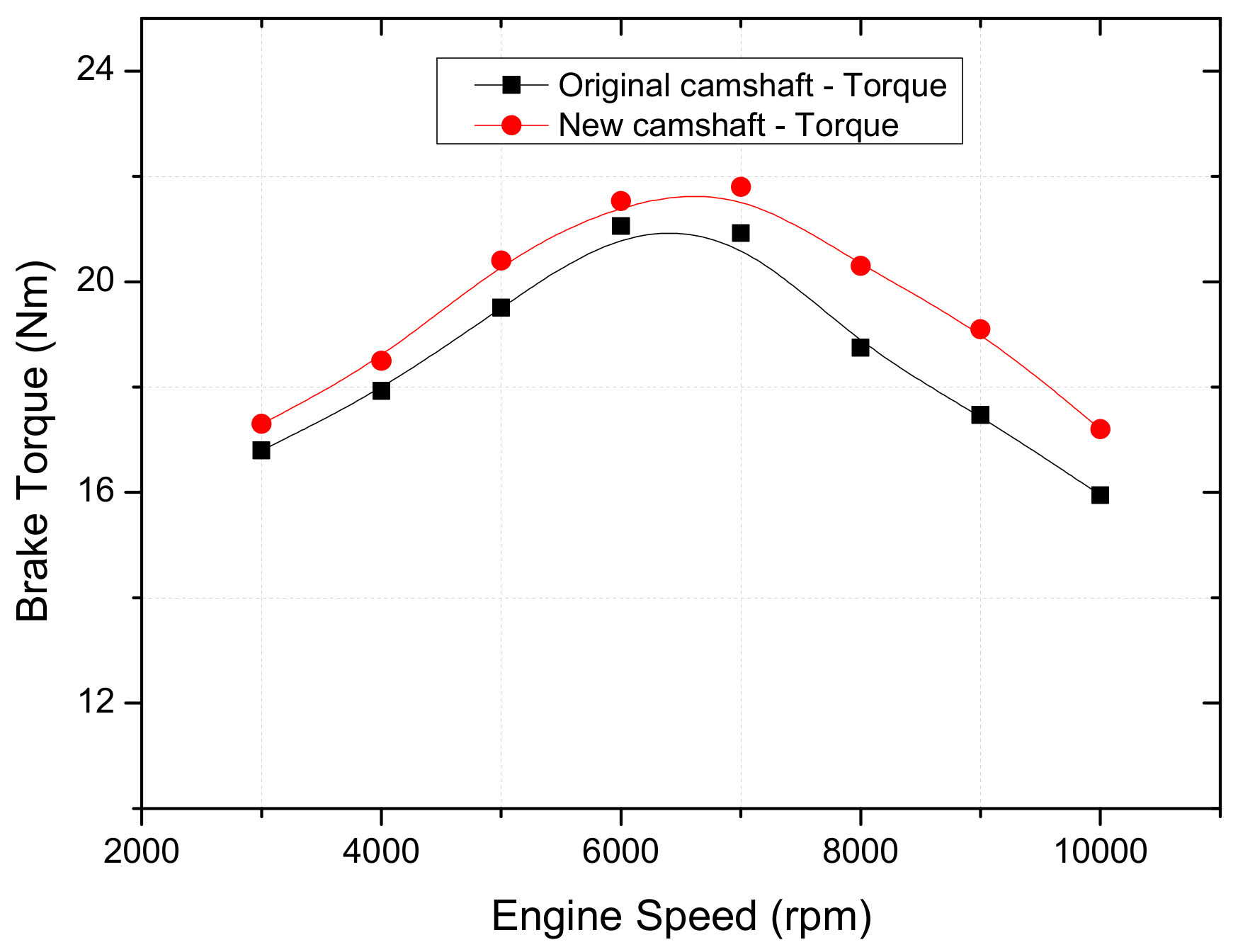

3.3. New Valve Mechanisms Verification by Doing Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pogorevc, P.; Kegl, B. Intake and exhaust influence on engine performance. J. KONES Intern. Combust. Engines 2004, 11, 125–132. [Google Scholar]

- Sui, W.; González, J.P.; Hall, C.M. Combustion Phasing Modelling of Dual Fuel Engines. IFAC-PapersOnLine 2018, 51, 319–324. [Google Scholar] [CrossRef]

- Li, Y.; Gong, J.; Deng, Y.; Yuan, W.; Fu, J.; Zhang, B. Experimental comparative study on combustion, performance and emissions characteristics of methanol, ethanol and butanol in a spark ignition engine. Appl. Therm. Eng. 2017, 115, 53–63. [Google Scholar] [CrossRef]

- Wei, H.; Shao, A.; Hua, J.; Zhou, L.; Feng, D. Effects of applying a Miller cycle with split injection on engine performance and knock resistance in a downsized gasoline engine. Fuel 2018, 214, 98–107. [Google Scholar] [CrossRef]

- Jung, D.; Iida, N. An investigation of multiple spark discharge using multi-coil ignition system for improving thermal efficiency of lean SI engine operation. Appl. Energy 2018, 212, 322–332. [Google Scholar] [CrossRef]

- Rajeevan, J.; Hans, M.; Joseph, A.; Kiran, T.; Thampi, G.K. Hybrid Turbocharged SI engine with Cooled Exhaust Gas Recirculation for Improved Performance. Procedia Technol. 2016, 24, 444–451. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Park, C.; Kim, Y.; Choi, Y.; Bae, J.; Lim, B. Effect of turbocharger on performance and thermal efficiency of hydrogen-fueled spark ignition engine. Int. J. Hydrogen Energy 2019, 44, 4350–4360. [Google Scholar] [CrossRef]

- Cinar, C.; Uyumaz, A.; Solmaz, H.; Topgul, T. Effects of valve lift on the combustion and emissions of a HCCI gasoline engine. Energy Convers. Manag. 2015, 94, 159–168. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, H.; Xie, H.; He, B.-Q. Variable-valve-actuation-enabled high-efficiency gasoline engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2010, 224, 1081–1095. [Google Scholar] [CrossRef]

- Nora, M.D.; Lanzanova, T.; Zhao, H. Effects of valve timing, valve lift and exhaust backpressure on performance and gas exchanging of a two-stroke GDI engine with overhead valves. Energy Convers. Manag. 2016, 123, 71–83. [Google Scholar] [CrossRef] [Green Version]

- Çinar, C.; Şahin, F.; Can, Ö.; Uyumaz, A. A comparison of performance and exhaust emissions with different valve lift profiles between gasoline and LPG fuels in a SI engine. Appl. Therm. Eng. 2016, 107, 1261–1268. [Google Scholar] [CrossRef]

- Liu, K.; Yang, J.; Jiang, W.; Li, Y.; Wang, Y.; Feng, R.; Chen, X.; Ma, K. Effect of asynchronous valve timing on combustion characteristic and performance of a high speed SI marine engine with five valves. Energy Convers. Manag. 2016, 123, 185–199. [Google Scholar] [CrossRef]

- Khoa, N.X.; Lim, O. The effects of combustion duration on residual gas, effective release energy, engine power and engine emissions characteristics of the motorcycle engine. Appl. Energy 2019, 248, 54–63. [Google Scholar] [CrossRef]

- Khoa, N.; Lim, O. The Internal Residual Gas and Effective Release Energy of a Spark-Ignition Engine with Various Inlet Port–Bore Ratios and Full Load Condition. Energies 2021, 14, 3773. [Google Scholar] [CrossRef]

- Khoa, N.X.; Lim, O. Comparative Study of the Effective Release Energy, Residual Gas Fraction, and Emission Characteristics with Various Valve Port Diameter-Bore Ratios (VPD/B) of a Four-Stroke Spark Ignition Engine. Energies 2020, 13, 1330. [Google Scholar] [CrossRef] [Green Version]

- Rubio, J.A.P.; Vera-García, F.; Grau, J.H.; Cámara, J.M.; Hernandez, D.A. Marine diesel engine failure simulator based on thermodynamic model. Appl. Therm. Eng. 2018, 144, 982–995. [Google Scholar] [CrossRef]

- Melaika, M.; Rimkus, A.; Vipartas, T. Air Restrictor and Turbocharger Influence for the Formula Student Engine Performance. Procedia Eng. 2017, 187, 402–407. [Google Scholar] [CrossRef]

- Khoa, N.X.; Nhu, Y.Q.; Lim, O. Estimation of parameters affected in internal exhaust residual gases recirculation and the influence of exhaust residual gas on performance and emission of a spark ignition engine. Appl. Energy 2020, 278, 115699. [Google Scholar] [CrossRef]

- Praptijanto, A.; Muharam, A.; Nur, A.; Putrasari, Y. Effect of Ethanol Percentage for Diesel Engine Performance Using Virtual Engine Simulation Tool. Energy Procedia 2015, 68, 345–354. [Google Scholar] [CrossRef] [Green Version]

- AVL. Theory AVL BOOST. 2017. Available online: https://www.avl.com/boost (accessed on 20 May 2018).

- Yao, M.; Zheng, Z.; Liang, X. Numerical study on the Chemical Reaction Kinetics of DME/Methanol for HCCI Combustion Process. SAE Tech. Pap. 2006, 12. [Google Scholar] [CrossRef]

- Nguyen, V.-T.; Kim, D.-J. Flexible cam profile synthesis method using smoothing spline curves. Mech. Mach. Theory 2007, 42, 825–838. [Google Scholar] [CrossRef]

- Lampinen, J. Cam shape optimization by genetic algorithm. Comput. Aided Des. 2003, 35, 727–737. [Google Scholar] [CrossRef]

| Specifications | Unit | Values |

|---|---|---|

| Cylinder-number | - | 2 |

| Compression-ratio | - | 11.8:1 |

| Bore-stroke | Mm | 57–53.8 |

| Connecting-rod | Mm | 107.9 |

| Intake-valves | - | 2 |

| Exhaust-valves | - | 2 |

| Experimental Value | Simulation Value | Unit | |

|---|---|---|---|

| Ignition timing | 28 | 28 | Deg |

| Air-mass flow | 16 | 15 | g/s |

| Peak pressure rise | 2 | 1.5 | Bar/deg |

| Peak temperature | 2300 | 2200 | K |

| Engine brake torque | 18.7 | 18.3 | Nm |

| NOx emission | 9 | 9.2 | g/kWh |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoa, N.X.; Lim, O. A Study to Investigate the Effect of Valve Mechanisms on Exhaust Residual Gas and Effective Release Energy of a Motorcycle Engine. Energies 2021, 14, 5564. https://doi.org/10.3390/en14175564

Khoa NX, Lim O. A Study to Investigate the Effect of Valve Mechanisms on Exhaust Residual Gas and Effective Release Energy of a Motorcycle Engine. Energies. 2021; 14(17):5564. https://doi.org/10.3390/en14175564

Chicago/Turabian StyleKhoa, Nguyen Xuan, and Ocktaeck Lim. 2021. "A Study to Investigate the Effect of Valve Mechanisms on Exhaust Residual Gas and Effective Release Energy of a Motorcycle Engine" Energies 14, no. 17: 5564. https://doi.org/10.3390/en14175564

APA StyleKhoa, N. X., & Lim, O. (2021). A Study to Investigate the Effect of Valve Mechanisms on Exhaust Residual Gas and Effective Release Energy of a Motorcycle Engine. Energies, 14(17), 5564. https://doi.org/10.3390/en14175564