Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends

Abstract

:1. Introduction

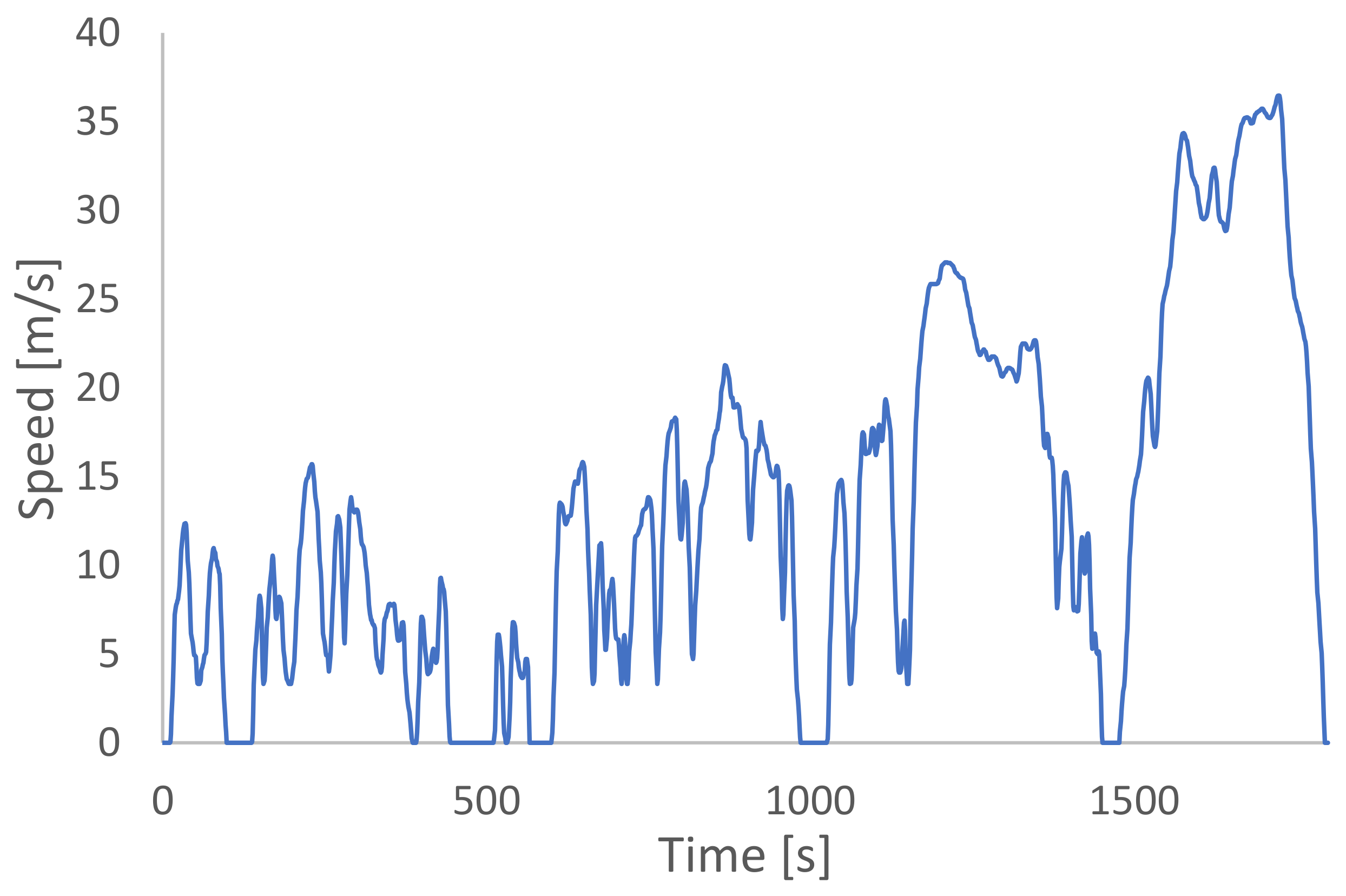

2. Off-Highway Vehicles’ Categories

3. Duty Cycles

4. Main Components and Architectures of Electric Vehicles

- tethered type: these need constant physical connection to an external electric source; this can be the power grid or an external electric generator.

- battery type: these work completely disconnected from any external power source, which is needed only to recharge the internal energy storage system when the vehicle is not in use.

- tethered-battery type: there is the possibility of using the vehicle even during charging.

4.1. Energy Storage Systems

4.2. Electric Motors

5. State of the Arts and Trends

6. Relevant Off-Highway Electric Vehicles

6.1. Tractor and Agricultural Machinery

6.2. Municipal and Property Maintenance

6.3. Transportation of Goods and Material Handling

6.4. Construction and Mining

7. Efficiency Enhancements

7.1. Hydraulics Systems and Actuators

7.2. Energy Recovery Systems

8. Hybrid Vehicles and Architectures

9. Conclusions

- In the off-highway machinery industry, the reduction of emission is not the only major driver for electrification. Indeed, the decrease of fuel consumption, the enhancement of productivity and, more generally, the clear convenience in terms of total cost of ownership are key points to successfully breaking into the market. Nonetheless, the political and technical choices of the authorities with respect to the environment and sustainability will be essential, with the presence of economic incentives and/or taxes being important variables to consider.

- The technical concept of mission and duty cycles has always been fundamental aspect of the off-highway industry, and these factors will be even more important for bringing effective, efficient and economically sustainable machinery to the market. Indeed, there are already work environments where battery or tethered electric vehicles represent the best technical and economical compromise, such as underground mining or indoor logistics. The continuous developments and the constant reduction in costs contributes to the introduction of new electric vehicles, even in highly complex work environments, like construction and agriculture.

- There are technical limits to a more widespread electrification within the off-highway machinery industry, and these mainly depend on power demands and minimum operational runtime. Less energy-demanding duty cycles in urban or indoor environments or high profitable businesses like vineyards facilitate the use of electric vehicles, especially in case of the compact ones. Conversely, bigger machinery with more intense duty cycles in more harsh environments is less suitable for battery electrification in the near future, mainly because the operational runtime achievable with the current technology cannot guarantee the minimum number of working hours, and the charging infrastructures are usually very difficult to implement in such contexts.

- Among the common trends, the most evident is the retrofitting of existing vehicles, where the electric motors and the battery pack replace the ICE and the fuel tank, with the rest of the machinery remaining almost unchanged (hydraulics, actuators, overall design, etc.). This strategy allows manufacturers to put functional vehicles on the market in the nearest future, but there is usually some distance to go before they are fully optimized. Indeed, there is generally great room for improvement, especially with respect to hydraulics.

- The application of new technologies regarding hydraulics, actuators and energy recovery systems can greatly boost the efficiency of off-highway vehicles, both electric and ICE-powered ones. On the other hand, the introduction of innovative technologies can greatly increase the upfront costs, frequently exceeding the acceptable cost-benefit ratio, as has already occurred in case of hybrid excavators.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC | Direct Current |

| EM | Electric Motor |

| EMA | Electro-Mechanical Actuator |

| ICE | Internal Combustion Engine |

| IM | Induction Motor |

| IMC | Individual Metering Control |

| NCA | Lithium Nickel Cobalt Aluminum Oxide |

| NEDC | New European Driving Cycle |

| NMC | Lithium Nickel Manganese Cobalt Oxide |

| OEM | Original Equipment Manufacturer |

| PMSM | Permanent Magnet Synchronous Motor |

| PTO | Power Take-Off |

| SOC | State of Charge |

| SRM | Switched Reluctance Motor |

| WLTP | World harmonized Light-duty vehicles Test Procedure |

References

- The European Commission. The European Green Deal; The European Commission: Brussels, Belgium, 2019; Volume 1. [Google Scholar]

- Zawieska, J.; Pieriegud, J. Smart City as a Tool for Sustainable Mobility and Transport Decarbonisation. Transp. Policy 2018, 63, 39–50. [Google Scholar] [CrossRef]

- IEA Global EV Outlook 2019. Available online: https://www.iea.org/reports/global-ev-outlook-2019 (accessed on 21 January 2021).

- The European Commission. Comunicazione Della Commissione Al Parlamento Europeo, Al Consiglio Europeo, Al Consiglio, Al Comitato Economico e Sociale Europeo, Al Comitato Della Regioni e Alla Banca Europea per Gli Investimenti; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Lajunen, A.; Sainio, P.; Laurila, L.; Pippuri-Mäkeläinen, J.; Tammi, K. Overview of Powertrain Electrification and Future Scenarios for Non-Road Mobile Machinery. Energies 2018, 11, 1184. [Google Scholar] [CrossRef] [Green Version]

- Dallman, T.; Menon, A. Technology Pathways for Diesel Engines Used in Non-Road Vehicles and Equipment; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2016. [Google Scholar]

- United States Environmental Protection Agency. Regulations for Emissions from Heavy Equipment with Compression-Ignition (Diesel) Engines, Regulations for Emissions from Vehicles and Engines. Available online: https://www.epa.gov/regulations-emissions-vehicles-and-engines/regulations-emissions-heavy-equipment-compression#e-cfr (accessed on 21 January 2021).

- Emission Standards. Europe: Nonroad Engines. Available online: https://dieselnet.com/standards/eu/nonroad.php (accessed on 21 January 2021).

- Caban, J.; Vrabel, J.; Šarkan, B.; Zarajczyk, J.; Marczuk, A. Analysis of the Market of Electric Tractors in Agricultural Production. MATEC Web Conf. 2018, 244, 1–10. [Google Scholar] [CrossRef]

- Monnay, C. Potential and Trends in Off-Highway Vehicl’ Electrification; Semcon: Gothenburg, Sweden, 2017. [Google Scholar]

- Iora, P.G. Tecnologie per La Mobilità Sostenibile: Veicoli Elettrici, Ibridi e a Fuel Cell; Società Editrice Esculapio: Bologna, Itay, 2016; ISBN 978-88-7488-994-5. [Google Scholar]

- Hegazy, O.; Barrero, R.; Van den Bossche, P.; El Baghdadi, M.; Smekens, J.; Van Mierlo, J.; Vriens, W.; Bogaerts, B. Modeling, Analysis and Feasibility Study of New Drivetrain Architectures for off-Highway Vehicles. Energy 2016, 109, 1056–1074. [Google Scholar] [CrossRef]

- EPA. EPA Nonregulatory Nonroad Duty Cycles, MOVES and Other Mobile Source Emissions Models. Available online: https://www.epa.gov/moves/epa-nonregulatory-nonroad-duty-cycles#individual (accessed on 22 January 2021).

- Meeting, A.; Report, K.N. Experiences and Visions of an Implement Manufacturer; Club of Bologna: Bologna, Italy, 2010. [Google Scholar]

- Malavatu, J.; Kandke, S.R.; Gupta, S.; Agrawal, B. Design Challenges in Electrification of Off-Highway Applications. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019. [Google Scholar] [CrossRef]

- Mastrogiovanni, S. DLG-PowerMix. Available online: https://www.enama.it/userfiles/PaginaSezione/files/S._Mastrogiovanni_DLG.pdf (accessed on 3 March 2021).

- Brenna, M.; Foiadelli, F.; Leone, C.; Longo, M.; Zaninelli, D. Feasibility Proposal for Heavy Duty Farm Tractor. In Proceedings of the 2018 International Conference of Electrical and Electronic Technologies for Automotive, Milan, Italy, 9–11 July 2018. [Google Scholar] [CrossRef]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L.; Mattetti, M. A Feasibility Study for Agriculture Tractors Electrification: Duty Cycles Simulation and Consumption Comparison. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Novi, MI, USA, 1 June 2019; IEEE: New York, NY, USA, 2019; pp. 1–6. [Google Scholar]

- Bertini, A.; Ceraolo, M.; Lutzemberger, G. Systematic Approach in the Hybridization of a Hydraulic Skid Loader. Autom. Constr. 2015, 58, 144–154. [Google Scholar] [CrossRef]

- Bertini, A.; Ceraolo, M.; Lutzemberger, G. Development of a Hybrid Skid Loader through Modelling. In Proceedings of the 2012 IEEE International Energy Conference and Exhibition (ENERGYCON), Florence, Italy, 9–12 September 2012; pp. 1022–1027. [Google Scholar] [CrossRef]

- Alan, C.; Ali, S.; Alaa, H.; Eric, B. Optimal Sizing of an Energy Storage System for a Hybrid Vehicle Applied to an Off-Road Application. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besancon, France, 8–11 July 2014; IEEE: New York, NY, USA; pp. 775–780. [Google Scholar]

- Nevrly, J.; Fichta, M.; Jurik, M.; Nemec, Z.; Koutny, D.; Vorel, P.; Prochazka, P. Battery Electric Drive of Excavator Designed with Support of Computer Modeling and Simulation. Proceedings 2020, 58, 25. [Google Scholar] [CrossRef]

- Schneider, S.; Vincenz, D. SUNCAR Elektrobagger. Available online: https://www.aramis.admin.ch/Default?DocumentID=46789&Load=true (accessed on 3 September 2021).

- Vauhkonen, N.; Liljeström, J.; Maharjan, D.; Mahat, C.; Sainio, P.; Kiviluoma, P.; Kuosmanen, P. Electrification of Excavator. In Proceedings of the 9th International DAAAM Baltic Conference “INDUSTRIAL ENGINEERING”, Tallinn, Estonia, 24–26 April 2014; pp. 305–310. [Google Scholar]

- Salomaa, V.; Minav, T.; Mattila, J.; Pietola, M. Efficiency Study of an Electro-Hydraulic Excavator. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2017. [Google Scholar]

- Casoli, P.; Riccò, L.; Campanini, F.; Bedotti, A. Hydraulic Hybrid Excavator-Mathematical Model Validation and Energy Analysis. Energies 2016, 9, 1002. [Google Scholar] [CrossRef] [Green Version]

- Construction Mechanization Association. Earth-Moving Machinery—Test Methods for Energy Consumption—Hydraulic Excavators; JCMAS: Tokyo, Japan, 2010. [Google Scholar]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Chen, Q.; Li, Z. Development and Key Technologies of Pure Electric Construction Machinery. Renew. Sustain. Energy Rev. 2020, 132, 110080. [Google Scholar] [CrossRef]

- Liebherr Liebherr Mining Goes Electric—Liebherr. Available online: https://www.liebherr.com/en/ita/latest-news/news-press-releases/detail/liebherr-mining-goes-electric.html (accessed on 5 March 2021).

- Paraszczak, J.; Svedlund, E.; Fytas, K.; Laflamme, M. Electrification of Loaders and Trucks – A Step towards More Sustainable Underground Mining. Renew. Energy Power Qual. J. 2014, 1, 81–86. [Google Scholar] [CrossRef]

- Połom, M. Trends in the Development of Trolleybus Transport in Poland at the End of the Second Decade of the 21st Century. Pr. Kom. Geogr. Komun. PTG 2018, 21, 44–59. [Google Scholar] [CrossRef]

- Tribioli, L.; Chiappini, D.; Vukotić, M.; Miljavec, D. Performance Evaluation of an Electric Vehicle with Multiple Electric Machines for Increased Overall Drive Train Efficiency; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Sobotzik, J. Electric Drives Potentials on Tractors and Implements; John Deere: Moline, IL, USA, 2011. [Google Scholar]

- Nishanth, F.N.U.; Khamitov, A.; Severson, E.L. Comparison of Linear and Rotary Electric Machine Topologies for a Hybrid Hydraulic Electric Architecture of Off-Highway Vehicles. In Proceeding of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; pp. 1063–1068. [Google Scholar] [CrossRef]

- Jo, D.Y.; Kwak, S.; Kim, N. Development of Fuel-Efficient Construction Equipment. In “Green World with Power Electronics”, Proceedings of the 8th International Conference on Power Electronics—ECCE Asia, Jeju, Korea, 30 May–3 June 2011; IEEE: New York, NY, USA, 2011; pp. 31–37. [Google Scholar]

- Emadi, A. Advanced Electric Drive Vehicles, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Nykvist, B.; Nilsson, M. Rapidly Falling Costs of Battery Packs for Electric Vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Ding, Y.; Cano, Z.P.; Yu, A.; Lu, J.; Zhongwei, C. Automotive Li-Ion Batteries: Current Status and Future Perspectives. Electrochem. Energy Rev. 2019, 2, 1–28. [Google Scholar] [CrossRef]

- Yang, X.G.; Liu, T.; Wang, C.Y. Thermally Modulated Lithium Iron Phosphate Batteries for Mass-Market Electric Vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Hu, B. A Review of Developments in Energy Storage Systems for Hybrid Excavators. Autom. Constr. 2017, 80, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Liu, S.; Zhang, Q.; Han, Y. A Comprehensive Overview of Hybrid Construction Machinery. Adv. Mech. Eng. 2016, 8, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Hui, S.; Lifu, Y.; Junqing, J. Hydraulic/Electric Synergy System (HESS) Design for Heavy Hybrid Vehicles. Energy 2010, 35, 5328–5335. [Google Scholar] [CrossRef]

- Casoli, D.-I.P.; Riccò, I.L.; Campanini, I.F.; Lettini, I.A.; Dolcin, I.C. Hydraulic Hybrid Excavator: Layout Definition, Experimental Activity, Mathematical Model Validation and Fuel Consumption Evaluation. In Proceedings of the 10th International Conference on Fluid Power (IFK), Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Lin, T.; Wang, L.; Huang, W.; Ren, H.; Fu, S.; Chen, Q. Performance Analysis of an Automatic Idle Speed Control System with a Hydraulic Accumulator for Pure Electric Construction Machinery. Autom. Constr. 2017, 84, 184–194. [Google Scholar] [CrossRef]

- Rizzoni, G. Fundamentals of Electrical Engineering by Giorgio Rizzoni, 1st ed.; McGraw-Hill: New York, NY, USA, 2009; ISBN 978-0-07-338037-7. [Google Scholar]

- Rajashekara, K. Present Status and Future Trends in Electric Vehicle Propulsion Technologies. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- Moreda, G.P.; Muñoz-García, M.A.; Barreiro, P. High Voltage Electrification of Tractor and Agricultural Machinery—A Review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Mapelli, F.L. The Role of Motor Controllers in the Electrification Process. In Proceedings of the Industrial Vehicle Technology Virtual Expo, London, UK, 9–10 February 2021. [Google Scholar]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Nurunnabi Mollah, M.; Hossain, E.; Saponara, S. A Comprehensive Study of Key Electric Vehicle (EV) Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative Study of Interior Permanent Magnet, Induction, and Switched Reluctance Motor Drives for EV and HEV Applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Boldea, I.; Tutelea, L.N.; Parsa, L.; Dorrell, D. Automotive Electric Propulsion Systems with Reduced or No Permanent Magnets: An Overview. IEEE Trans. Ind. Electron. 2014, 61, 5696–5711. [Google Scholar] [CrossRef]

- Riba, J.R.; López-Torres, C.; Romeral, L.; Garcia, A. Rare-Earth-Free Propulsion Motors for Electric Vehicles: A Technology Review. Renew. Sustain. Energy Rev. 2016, 57, 367–379. [Google Scholar] [CrossRef] [Green Version]

- Grayson, W. Bobcat’s Electric Excavator Retrofit a First Step Toward an All-Electric Future, Equipment World. Available online: https://www.equipmentworld.com/alternative-power/battery-electric/video/14972534/bobcats-electric-excavator-retrofit-a-first-step-toward-an-allelectric-future (accessed on 11 March 2021).

- Clean Air Action Plan; Municipality of Amsterdam: Amsterdam, The Netherlands, 2019; pp. 1–93.

- Volvo. Volvo CE and Volvo Trucks Customer Deliveries of All-Electric Products. Available online: https://www.volvoce.com/global/en/news-and-events/press-releases/2020/volvo-ce-and-volvo-trucks-customer-deliveries-of-all-electric-products/ (accessed on 12 March 2021).

- Wordsworth, S. Wacker Neuson and the Emissions-Free Worksite. Available online: https://www.ivtinternational.com/videos/video-wacker-neuson-and-the-emissions-free-worksite.html (accessed on 12 March 2021).

- Big Buyers Zero-Emission Construction Sites. Available online: https://bigbuyers.eu/working-groups/past/zero-emission-construction-sites (accessed on 21 April 2021).

- ISO. ISO—ISO 6469-3:2018—Electrically Propelled Road Vehicles—Safety Specifications—Part 3: Electrical Safety. Available online: https://www.iso.org/standard/68667.html (accessed on 12 March 2021).

- Bilo, J.; Burghoff, H.-G.; dos Santos, H.; Engbring, J. 48 Volt Electrical Systems–A Key Technology Paving to the Road to Electric Mobility; Zwei: Frankfurt, Germany, 2016. [Google Scholar]

- Fischer, H.-M.; Dorn, L. Voltage Classes for Electric Mobility; ZWEI: Franfurt, Germany, 2013. [Google Scholar]

- Jenkins, J. High-Voltage EV Battery Packs: Benefits and Challenges. More Voltage, More Better?—Charged EVs. Available online: https://chargedevs.com/features/high-voltage-ev-battery-packs-benefits-and-challenges-more-voltage-more-better/ (accessed on 12 March 2021).

- Global Off-Highway Vehicle Electrification Trends, Forecast to 2030; Frost and Sullivan: Santa Clara, CA, USA, 2019.

- JCB. JCB 525-60E, Electric Telehandler. Available online: https://www.jcb.com/en-gb/products/telescopic-handlers/525-60e-hi-viz (accessed on 16 April 2021).

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the Development of the Electric Tractor-Specifications and Traveling and Tilling Performance of a Prototype Electric Tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar] [CrossRef]

- E-mining AG Products, E-Mining AG. Available online: https://www.emining.ch/en/products (accessed on 16 April 2021).

- Friedrichschafen, Z.F. ZF ETRAC Driveline System for Electric Vehicles. Available online: https://www.oemoffhighway.com/drivetrains/product/21126638/zf-friedrichshafen-ag-zf-etrac-driveline-system-for-electric-vehicles (accessed on 11 March 2021).

- Electrification of Mobile Applications; Boasch Rexroth AG: Lohr am Main, Germany, 2018.

- Market Positioning; Deutz AG E-DEUTZ: Cologne, Germany, 2018.

- Buning, E.A. Electric Drives in Agricultural Machinery-Approach from the Tractor Side. J. Agric. Eng. 2010, 47, 30. [Google Scholar]

- CEMA. European Agricultural Machinery Industry: CEMA Priorities and Key Figures; CEMA: Brussels, Belgium, 2019; pp. 1–15. [Google Scholar]

- Fendt. Fendt E100 Vario, Fendt FutureFarm—Fendt. Available online: https://www.fendt.com/it/e100-vario (accessed on 1 April 2021).

- Rigitrac. Rigitrac SKE 40 Electric—Rigitracs Webseite! Available online: https://www.rigitrac.ch/produkte-1/rigitrac-ske-40-electric/ (accessed on 1 April 2021).

- Tractor, M. Monarch Tractor Electric Tractor. Available online: https://www.monarchtractor.com/ (accessed on 1 April 2021).

- Farmtrac Farmtrac—Trattori. Available online: https://www.farmtracitalia.it/trattori (accessed on 20 April 2021).

- Van Leeuwen, L.B. Hydrogen or Battery Tractors: What Potential for Sustainable Grape Growing? IVES Tech. Rev. Vine Wine 2020. [Google Scholar] [CrossRef]

- Allen, J.; Deere, J. Develops Fully Electric, Autonomous Tractor, Industrial Vehicle Technology International. Available online: https://www.ivtinternational.com/news/agriculture/john-deere-develops-fully-electric-autonomous-tractor.html (accessed on 18 May 2021).

- E-OX EOX—175. Available online: https://www.e-ox.nl/eox-175 (accessed on 20 April 2021).

- Pialorsi, R. Stato Dell’arte Dei Veicoli Elettrici e Studio Dell’elettrificazione Di Un Veicolo Industriale Con Trasmissione Meccanica. Master’s Thesis, Università degli Studi di Brescia, Brescia, Italy, 2019. [Google Scholar]

- DULEVO Scopri La Nuova Spazzatrice Stradale Elettrica DZero2. Available online: https://dzero2.dulevo.com/it/index.xhtml (accessed on 2 April 2021).

- Boschung Urban-Sweeper S2.0—Electric Street Sweeper Releasing 0 (Zero) Emissions. Available online: https://www.boschung.com/product/urban-sweeper-s2-0/ (accessed on 2 April 2021).

- Uberti, S.; Azzini, G.; Beltrami, D.; Tribioli, L.; Iora, P. Modelling of a 15-KW Electric Utility Vehicle and Range Assessment through Driving Cycle Analysis Based on GPS Experimental Data; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Esagono Energia Home—Esagono Energia, S.r.l.—Veicoli Elettrici. Available online: https://www.esagonoenergia.com/ (accessed on 26 April 2021).

- Morris, C. Charged EVs, Dennis Eagle’s New Electric Refuse Trucks Hit the Streets, Earn Rave Reviews—Charged EVs. Available online: https://chargedevs.com/newswire/dennis-eagles-new-electric-refuse-trucks-hit-the-streets-earn-rave-reviews/ (accessed on 21 April 2021).

- Sullivan, J. Gas Versus Electric Forklifts–Which Is Better? Available online: https://www.tmhnc.com/blog/gas-versus-electric-forklifts-which-is-better (accessed on 6 April 2021).

- Fu, S.; Chen, H.; Ren, H.; Lin, T.; Miao, C.; Chen, Q. Potential Energy Recovery System for Electric Heavy Forklift Based on Double Hydraulic Motor-Generators. Appl. Sci. 2020, 10, 3996. [Google Scholar] [CrossRef]

- Keränen, T.M.; Karimäki, H.; Viitakangas, J.; Vallet, J.; Ihonen, J.; Hyötylä, P.; Uusalo, H.; Tingelöf, T. Development of Integrated Fuel Cell Hybrid Power Source for Electric Forklift. J. Power Sources 2011, 196, 9058–9068. [Google Scholar] [CrossRef]

- Hosseinzadeh, E.; Rokni, M.; Advani, S.G.; Prasad, A.K. Performance Simulation and Analysis of a Fuel Cell/Battery Hybrid Forklift Truck. Int. J. Hydrogen Energy 2013, 38, 4241–4249. [Google Scholar] [CrossRef]

- Yale, H. CLS Cls-Hyster.It—CLS S.p.A.—CGT Logistica Sistemi. Available online: https://cls-hyster.it/ (accessed on 26 April 2021).

- Simai Simai—Europe’s Widest Range of Electric Tow Tractors and Platform Trucks. Available online: https://www.simai.it/en/home-2/ (accessed on 26 April 2021).

- Sennebogen. SENNEBOGEN 817 E: Compact Material Handler for the Waste Industry—SENNEBOGEN Maschinenfabrik GmbH. Available online: https://www.sennebogen.com/en/news/news-press/sennebogen-817-e-compact-material-handler-for-the-waste-industry (accessed on 26 April 2021).

- Electric Motor Engineering Partnership for the Industrial Full Electric Loader—Electric Motor Engineering. Available online: https://www.electricmotorengineering.com/partnership-for-the-industrial-full-electric-loader/ (accessed on 20 April 2021).

- JCB 19C-1. JCB E-TECH, JCB.Com. Available online: https://www.jcb.com/it-it/products/mini-escavatori/19c-1e (accessed on 6 April 2021).

- Tobroco Giant Electric Loaders from Tobroco-Giant Can Be Used All Year Long. Available online: https://www.tobroco-giant.com/en/products/wheel-loaders/giant-g2200e-x-tra/ (accessed on 6 April 2021).

- Volvo Prototype Electric Excavator. Available online: https://www.volvoce.com/global/en/this-is-volvo-ce/what-we-believe-in/innovation/prototype-electric-excavator/ (accessed on 6 April 2021).

- Zhang, S.; Minav, T.; Pietola, M. Decentralized Hydraulics for Micro Excavator. In Proceedings of the 15th Scandinavian International Conference on Fluid Power, SICFP’, Linköping, Sweden, 7–9 June 2017; pp. 17187–17195. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Minav, T.; Pietola, M.; Kauranne, H.; Kajaste, J. The Effects of Control Methods on Energy Efficiency and Position Tracking of an Electro-Hydraulic Excavator Equipped with Zonal Hydraulics. Autom. Constr. 2019, 100, 129–144. [Google Scholar] [CrossRef]

- Arnulfo, S. JCB Dà Il Benvenuto Al 1° Escavatore 100% Elettrico: JCB 19C-1 E-TEC. Available online: http://www.veicolidalavoro.it/jcb-escavatore-100-elettrico-jcb-19c-1-tec/ (accessed on 26 April 2021).

- Tobroco Giant G2200E Series, Giant Loaders. Available online: https://giantloaders.com/products/g2200e-series/ (accessed on 26 April 2021).

- Volvo Construction Equipment. Volvo CE Unveils 100 Percent Electric Compact Excavator Prototype: Volvo Construction Equipment. Available online: https://www.volvoce.com/global/en/news-and-events/press-releases/2017/volvo-ce-unveils-100-percent-electric-compact-excavator-prototype/ (accessed on 26 April 2021).

- Volvo. Volvo CE Unveils the next Generation of Its Electric Load Carrier Concept: Volvo Construction Equipment. Available online: https://www.volvoce.com/global/en/news-and-events/press-releases/2017/conexpo-vegas-2017/volvo-ce-unveils-the-next-generation-of-its-electric-load-carrier-concept/ (accessed on 21 April 2021).

- Vukovic, M.; Leifeld, R.; Murrenhoff, H. Reducing Fuel Consumption in Hydraulic Excavators—A Comprehensive Analysis. Energies 2017, 10, 687. [Google Scholar] [CrossRef] [Green Version]

- Minav, T.A.; Heikkinen, J.E.; Pietola, M. Direct Driven Hydraulic Drive for New Powertrain Topologies for Non-Road Mobile Machinery. Electr. Power Syst. Res. 2017, 152, 390–400. [Google Scholar] [CrossRef]

- An, K.; Kang, H.; An, Y.; Park, J.; Lee, J. Methodology of Excavator System Energy Flow-Down. Energies 2020, 13, 951. [Google Scholar] [CrossRef] [Green Version]

- Jensen, S. A Shifting Fluid Power Industry, OEM Off-Highway. Available online: https://www.oemoffhighway.com/fluid-power/article/21244542/a-shifting-fluid-power-industry (accessed on 17 February 2021).

- Ge, L.; Quan, L.; Zhang, X.; Zhao, B.; Yang, J. Efficiency Improvement and Evaluation of Electric Hydraulic Excavator with Speed and Displacement Variable Pump. Energy Convers. Manag. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Choi, K.; Seo, J.; Nam, Y.; Kim, K.U. Energy-Saving in Excavators with Application of Independent Metering Valve. J. Mech. Sci. Technol. 2015, 29, 387–395. [Google Scholar] [CrossRef]

- Pellegri, M.; Green, M.; Macpherson, J.; McKay, C.; Caldwell, N. Applying a Multi-Service Digital Displacement® Pump to an Excavator to Reduce Valve Losses. In Fluid Power Future Technology, Proceedings of the 12th International Fluid Power Conference, Dresden, Germany, 12–14 October 2020; Technische Universität Dresden: Dresden, Gemnary, 2020; pp. 59–68. [Google Scholar] [CrossRef]

- The European Commission. NorrDigi Revolutionary Energy Saver, Norrdigi Project, H2020, CORDIS, European Commission. Available online: https://cordis.europa.eu/project/id/830085/it (accessed on 25 March 2021).

- Gehm, R. Volvo CE and Norrhydro Digital Hydraulics. Available online: https://www.sae.org/news/2020/12/volvo-ce-and-norrhydro-digital-hydraulics (accessed on 25 March 2021).

- Qiao, G.; Liu, G.; Shi, Z.; Wang, Y.; Ma, S.; Lim, T.C. A Review of Electromechanical Actuators for More/All Electric Aircraft Systems. J. Mech. Eng. Sci. 2018, 232, 4128–4151. [Google Scholar] [CrossRef] [Green Version]

- Lotz, T. Best Practices for Electrification of Mobile Machines. Available online: https://www.oemoffhighway.com/trends/electrification/article/21342313/best-practices-for-electrification-of-mobile-machines (accessed on 1 April 2021).

- Wang, L.; Zhao, D.; Li, Y.; Du, M.; Chen, H. Energy Management Strategy Development of a Forklift with Electric Lifting Device. Energy 2017, 128, 435–446. [Google Scholar] [CrossRef]

- He, X.; Xiao, G.; Hu, B.; Tan, L.; Tang, H.; He, S.; He, Z. The Applications of Energy Regeneration and Conversion Technologies Based on Hydraulic Transmission Systems: A Review. Energy Convers. Manag. 2020, 205, 112413. [Google Scholar] [CrossRef]

- Ishida, K.; Higurashi, M. Hybrid Wheel Loaders Incorporating Power Electronics. Hitachi Rev. 2015, 64, 398–402. [Google Scholar]

- Wirtgen Group. HD + 90i PH VO, Rulli Tandem, HAMM. Available online: https://www.wirtgen-group.com/ocs/it-it/hamm/hd-90i-ph-vo-1878-p/ (accessed on 18 April 2021).

- He, X.; Liu, H.; He, S.; Hu, B.; Xiao, G. Research on the Energy Efficiency of Energy Regeneration Systems for a Battery-Powered Hydrostatic Vehicle. Energy 2019, 178, 400–418. [Google Scholar] [CrossRef]

- Yu, Y.-X.; Ahn, K.K. Energy Saving and Control of a Hybrid Hydraulic Excavator Swing System; IEEE: New York, NY, USA, 2020. [Google Scholar] [CrossRef]

- Hitachi Construction Machinery ZH210-5 Hybrid—Hitachi Construction Machinery. Available online: https://www.hitachicm.eu/it/prodotti/escavatori/escavatori-medi/zh210-5-hybrid/ (accessed on 18 April 2021).

- Edamura, M.; Ishida, S.; Imura, S.; Izumi, S. Adoption of Electrification and Hybrid Drive for More Energy-Efficient Construction Machinery. Hitachi Rev. 2013, 62, 118–122. [Google Scholar]

- Ge, L.; Dong, Z.; Quan, L.; Li, Y. Potential Energy Regeneration Method and Its Engineering Applications in Large-Scale Excavators. Energy Convers. Manag. 2019, 195, 1309–1318. [Google Scholar] [CrossRef]

- Zhao, P.-Y.; Chen, Y.-L.; Zhou, H. Simulation Analysis of Potential Energy Recovery System of Hydraulic Hybrid Excavator. Int. J. Precis. Eng. Manuf. 2017, 18, 1575–1589. [Google Scholar] [CrossRef]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Research on the Energy Regeneration Systems for Hybrid Hydraulic Excavators. Autom. Constr. 2010, 19, 1016–1026. [Google Scholar] [CrossRef]

- MMT Italia Hitachi ZH 210-5 Hybrid. Available online: https://www.mmtitalia.it/macchine_edili/marchi/hitachi/modelli/escavatori_cingolati/hitachi_zh_210-5_hybrid (accessed on 26 April 2021).

- Konecranes Reach Stackers, Konecranes. Available online: https://www.konecranes.com/equipment/lift-trucks/reach-stackers (accessed on 26 April 2021).

- Lajunen, A.; Suomela, J.; Pippuri, J.; Tammi, K.; Lehmuspelto, T.; Sainio, P. Electric and Hybrid Electric Non-Road Mobile Machinery—Present Situation and Future Trends. World Electr. Veh. J. 2016, 8, 172–183. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Jiang, Y. Review of Hybrid Electric Systems for Construction Machinery. Autom. Constr. 2018, 92, 286–296. [Google Scholar] [CrossRef]

- Soma, A.; Bruzzese, F.; Mocera, F.; Viglietti, E. Hybridization Factor and Performance of Hybrid Electric Telehandler Vehicle. IEEE Trans. Ind. Appl. 2016, 52, 5130–5138. [Google Scholar] [CrossRef]

- Truong, D.Q.; Marco, J.; Greenwood, D.; Harper, L.; Corrochano, D.G.; Yoon, J.I. Challenges of Micro/Mild Hybridisation for Construction Machinery and Applicability in UK. Renew. Sustain. Energy Rev. 2018, 91, 301–320. [Google Scholar] [CrossRef] [Green Version]

- Huria, T.; Lutzemberger, G.; Sanna, G.; Pede, G. Systematic Development of Series-Hybrid Bus through Modelling. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar] [CrossRef]

- Inoue, H. Introduction of PC200-8 Hybrid Hydraulic Excavators. Komatsu Tech. Rep. 2008, 54, 1–6. [Google Scholar]

- Kobelco Europe. HYBRID–Kobelco Construction Machinery Europe B.V. Available online: https://www.kobelco-europe.com/innovation/hybrid/ (accessed on 8 April 2021).

- TU Dresden Rigitrac EWD 120. Available online: https://tu-dresden.de/ing/maschinenwesen/int/ast/ressourcen/dateien/forschung/files/flyer_rigitrac.pdf?lang=en (accessed on 8 April 2021).

- Stoss, K.J.; Sobotzik, J.; Shi, B.; Kreis, E.R. Tractor Power for Implement Operation—Mechanical, Hydraulic, and Electrical: An Overview. Agric. Equip. Technol. Conf. 2013, 1–25. [Google Scholar]

- Huddig Tigon Huddig World’s Best Backhoe Loaders Made in Sweden. Available online: https://www.huddig.com/products/machines/tigon/ (accessed on 8 April 2021).

- Troncon, D.; Alberti, L.; Bolognani, S.; Bettella, F.; Gatto, A. Electrification of Agricultural Machinery: A Feasibility Evaluation. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 8–10 May 2019; IEEE: New York, NY, USA; pp. 1–7. [Google Scholar]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Landini Landini REX4 Electra–Evolving Hybrid—Landini. Available online: https://www.landini.it/en/landini-rex4-electra-evolving-hybrid/ (accessed on 20 April 2021).

- Li, T.; Huang, L.; Liu, H. Energy Management and Economic Analysis for a Fuel Cell Supercapacitor Excavator. Energy 2019, 172, 840–851. [Google Scholar] [CrossRef]

- H2ports First Application of Hydrogen Technologies in Port Handling Equipment in Europe. Available online: https://h2ports.eu/wp-content/uploads/2020/03/H2PORTS-Brochure.pdf (accessed on 26 August 2021).

| Category | Vehicle |

|---|---|

| Tractors and agricultural. | Tractors, combine harvesters, field choppers, etc. |

| Municipal and property maintenance. | Turf cutters, street sweeping machines, etc. |

| Transportation of goods and material handling. | Forklift machines, material handlers, etc. |

| Construction, forestry and mining. | Excavators, frontend loaders, backhoes, etc. |

| Flywheel | Supercapacitor | Hydraulic Accumulator | Lead-Acid Battery | Ni-MH Battery | Lithium Battery | |

|---|---|---|---|---|---|---|

| Specific power (W/kg) | 400–1500 | 500–5000 | 2000–19,000 | 75–300 | 150–200 | 250–340 |

| Specific energy (Wh/kg) | 10–30 | 2.5–5.5 | 2 | 30–50 | 60–120 | 75–200 |

| Energy density (Wh/L) | 20–80 | 35 | 5 | 50–80 | 150–180 | 200–250 |

| Cycles | 20,000 | 100,000 | 100,000 | 500–1500 | 2500 | 2000–10,000 |

| Efficiency (%) | <96 | <95 | <90 | <80 | <90 | <95 |

| Induction Motor (IM) | Permanent Magnet Synchronous Motor (PMSM) | Switched Reluctance Motor (SRM) | |

|---|---|---|---|

| Advantages | Very robust Low cost Easy to control | High torque density Very high efficiency Good thermal | Good torque density Very robust Low cost |

| Disadvantages | Low efficiency Narrow speed range | High cost Magnets decay | Complex control Loud noise Big torque ripples |

| Strategy | Comment | Vehicle | References |

|---|---|---|---|

| Reducing idle losses | |||

| Variable displacement pump | Main valve causes 60% of losses | Excavator | [26] |

| Variable displacement and variable speed pump | Efficiency gain up to 28.5% | Excavator | [106] |

| Decentralized drive | Independent drive of ancillaries | Excavator | [105] |

| Reducing hydraulic losses | |||

| Individual Metering Control | Energy saving up to 44% | Excavator | [107] |

| Direct-driven hydraulics | Overall efficiency up to 73% | Excavator | [96,97] |

| Digital hydraulics | Fuel reduction up to 30% | Excavator | [108] |

| Multi-chamber actuators | Fuel efficiency gain up to 50% | Excavator | [110] |

| Replacement of the whole hydraulics | |||

| Electro-mechanical actuators | Efficiency gain up to 83% | Forklift | [113] |

| Strategy | Comment | Energy accumulator | Vehicle | References |

|---|---|---|---|---|

| Potential energy | ||||

| Third boom actuator | Energy saving ratio up to 25.5% | Hydraulic accumulator | Excavator | [121] |

| Multi-chamber actuator | Reduction power consumption up to 50% | Hydraulic accumulator | Excavator | [122] |

| IMC | Energy saving up to 44% | Hydraulic accumulator | Excavator | [107] |

| Direct-driven hydraulics | Overall efficiency up to 73% | Battery | Excavator | [96,97] |

| Kinetic energy | ||||

| Regenerative braking | 31% fuel reduction | Super capacitator | Wheel loader | [115] |

| ICE downsizing from 85 kW to 55.6 kW | Hydraulic accumulator | Tandem roller | [116] | |

| Swing system | Regenerative efficiency up to 70% | Battery, capacitator | Excavator | [118] |

| Manufacturer | Vehicle | Hybrid Architecture | Energy Accumulator | Energy Saving | References |

|---|---|---|---|---|---|

| Komatsu | 20-ton excavator | Parallel hybrid | Super capacitor | 25–41% | [131] |

| Hitachi | 20-ton excavator | Parallel hybrid | Super capacitor | 25% | [120] |

| Kobelco | 20-ton excavator | Parallel hybrid | Lithium battery | 16% | [132] |

| Hitachi | 18-ton wheel loader | Series hybrid | Super capacitor | 31% | [115] |

| Rigitrac | 91 kW tractor | Series hybrid | \ | Unknown | [133] |

| John Deere | 140 kW tractor | Series hybrid | \ | Unknown | [134] |

| Huddig | 116 kW backhoe loader | Series hybrid | \ | Unknown | [135] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beltrami, D.; Iora, P.; Tribioli, L.; Uberti, S. Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies 2021, 14, 5565. https://doi.org/10.3390/en14175565

Beltrami D, Iora P, Tribioli L, Uberti S. Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies. 2021; 14(17):5565. https://doi.org/10.3390/en14175565

Chicago/Turabian StyleBeltrami, Daniele, Paolo Iora, Laura Tribioli, and Stefano Uberti. 2021. "Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends" Energies 14, no. 17: 5565. https://doi.org/10.3390/en14175565

APA StyleBeltrami, D., Iora, P., Tribioli, L., & Uberti, S. (2021). Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies, 14(17), 5565. https://doi.org/10.3390/en14175565