Ground Source and Sewage Water Source Heat Pump Systems for Block Heating and Cooling Network

Abstract

:1. Introduction

2. Methodology

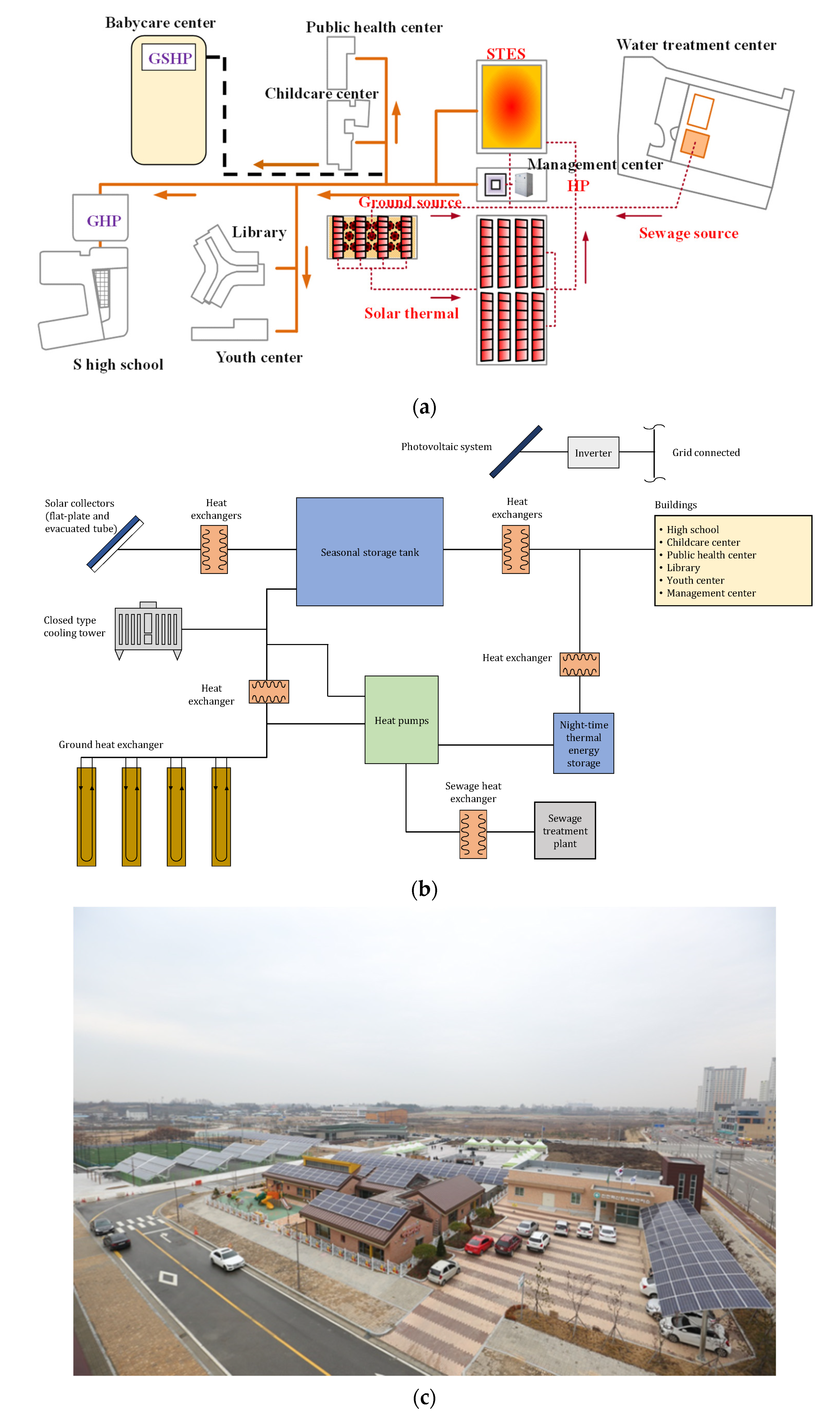

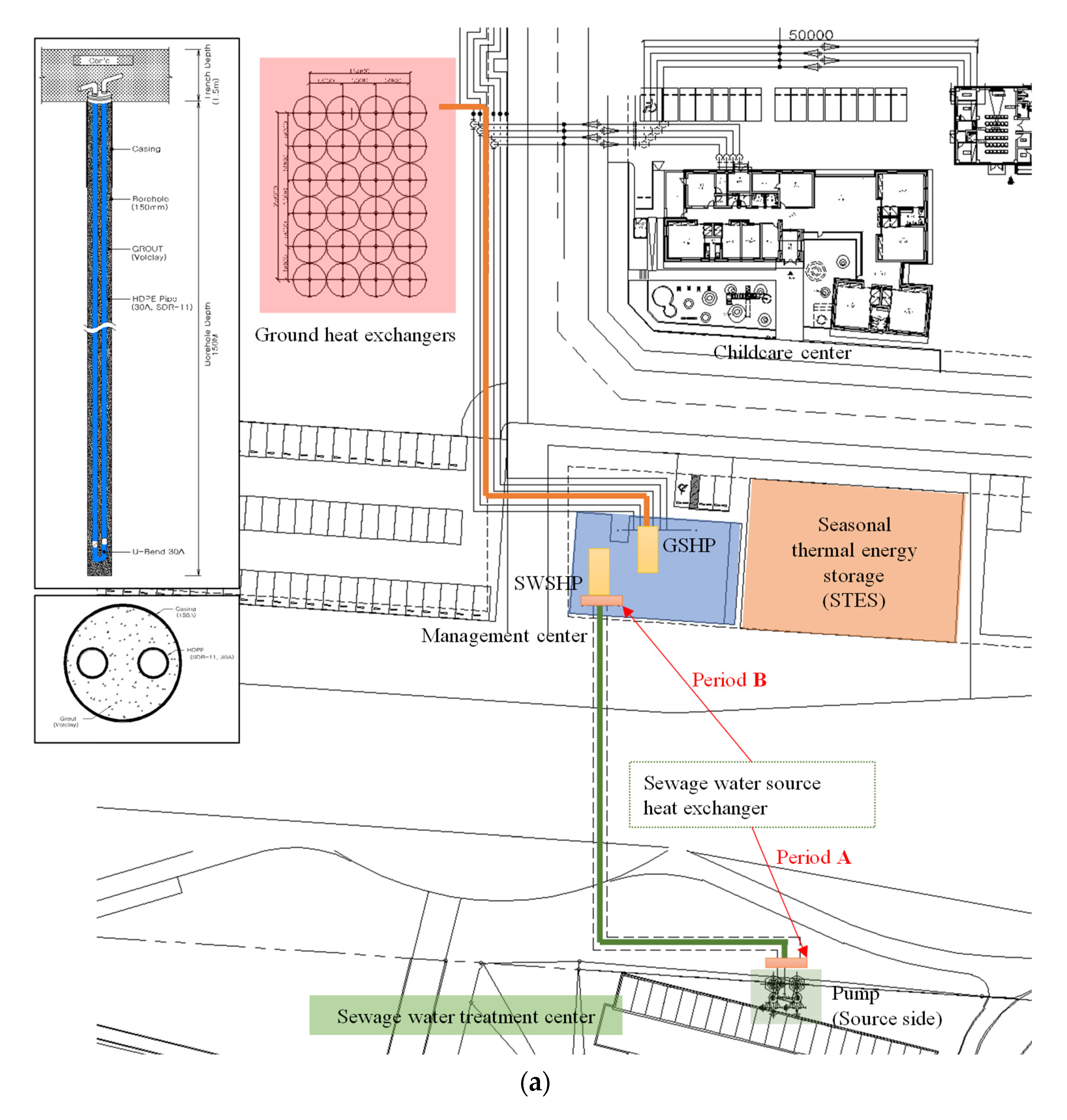

2.1. Overview of the Field Test Site

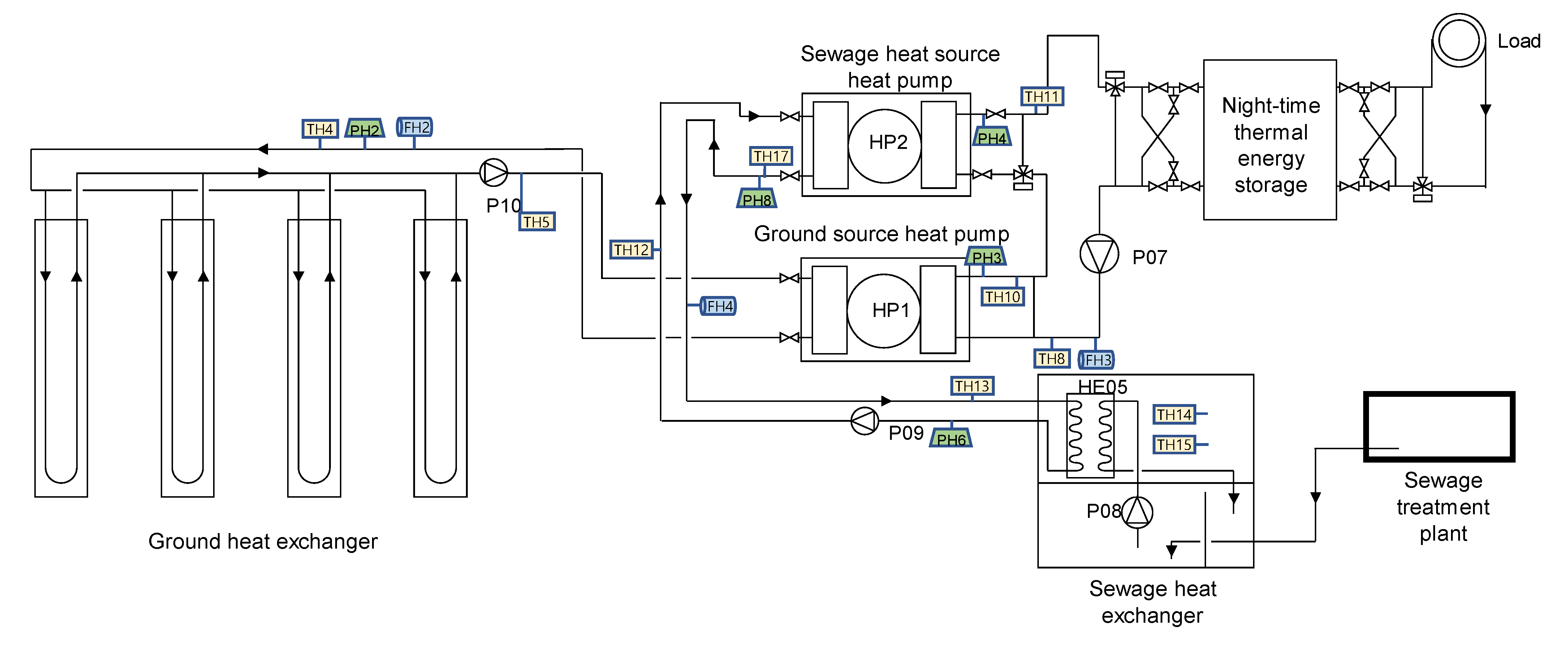

2.2. Overview of Ground and Sewage Water Source Heat Pumps

2.3. Overview of the Monitoring Systems

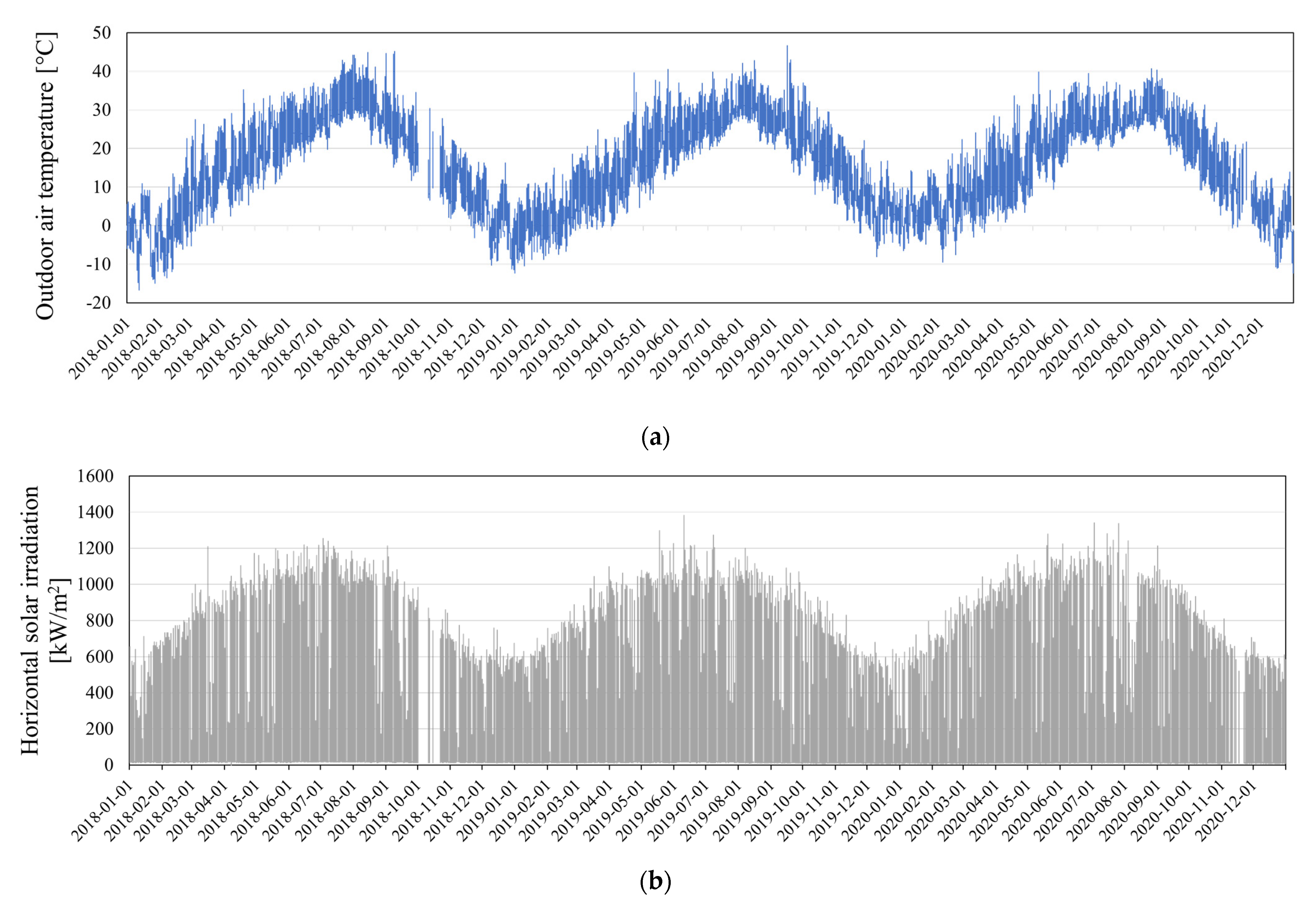

2.4. Outdoor Air Conditions during the Test

2.5. Water-to-Water Heat Pump Model

3. Results and Discussion

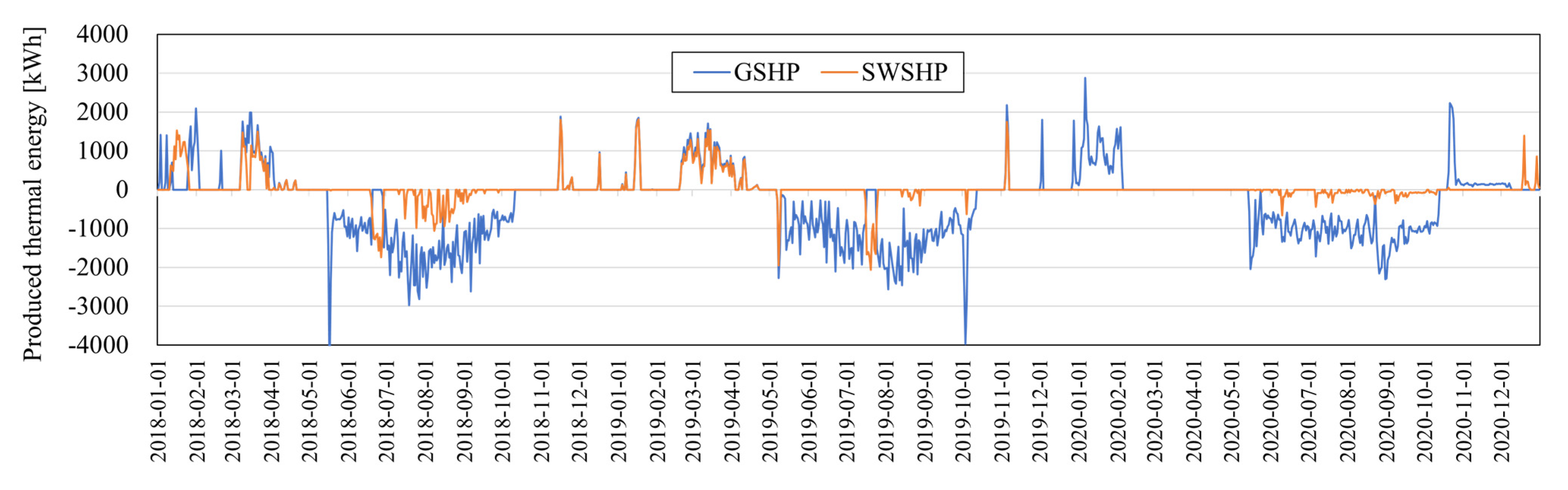

3.1. Thermal Loads during the Test

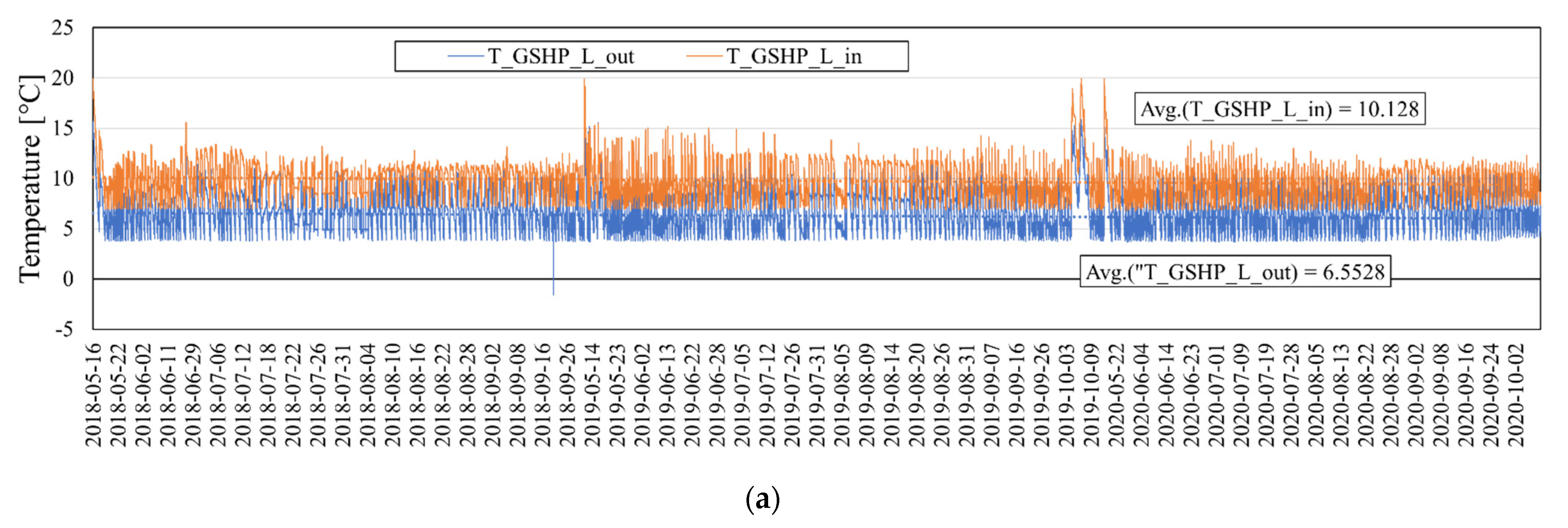

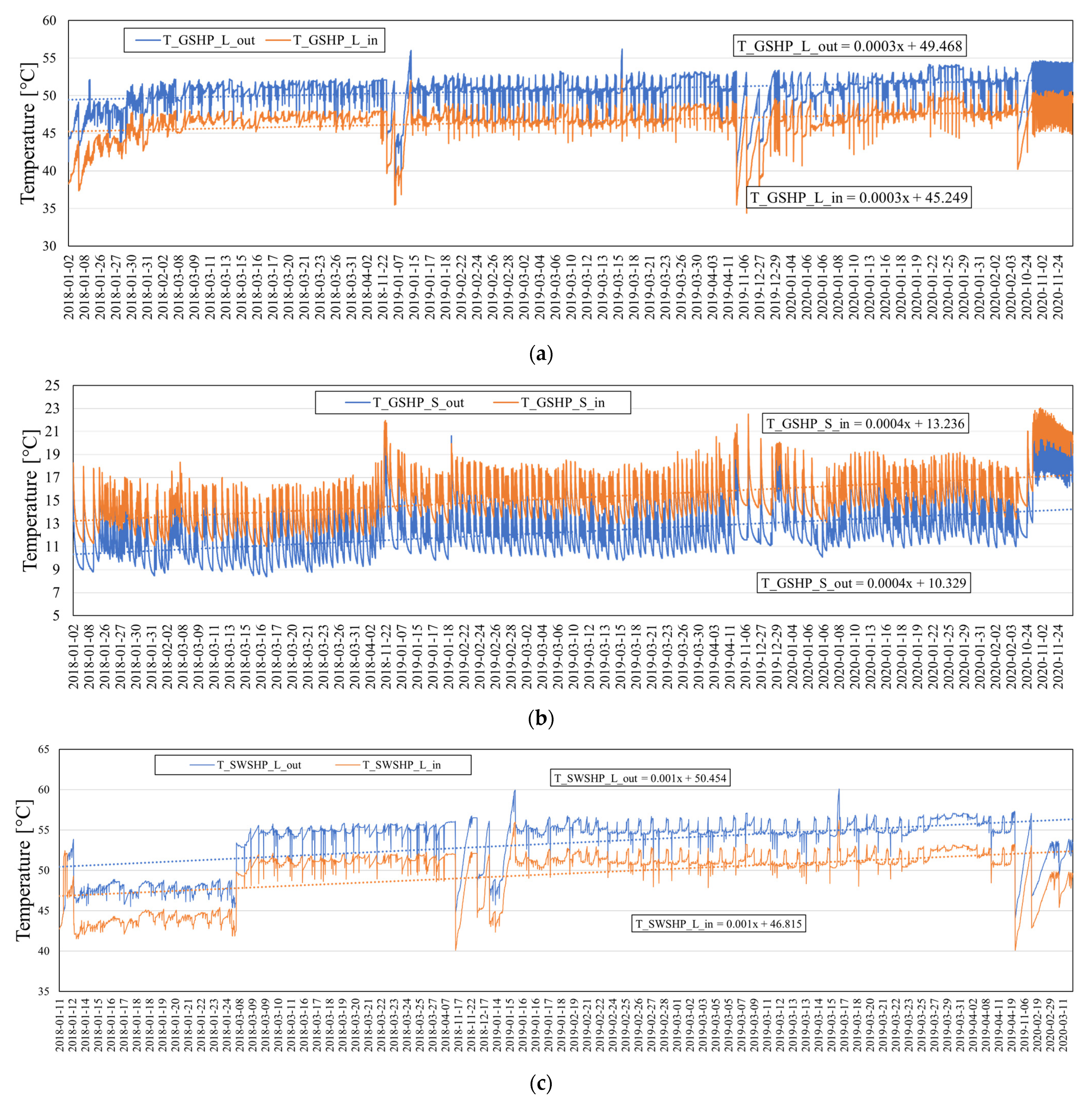

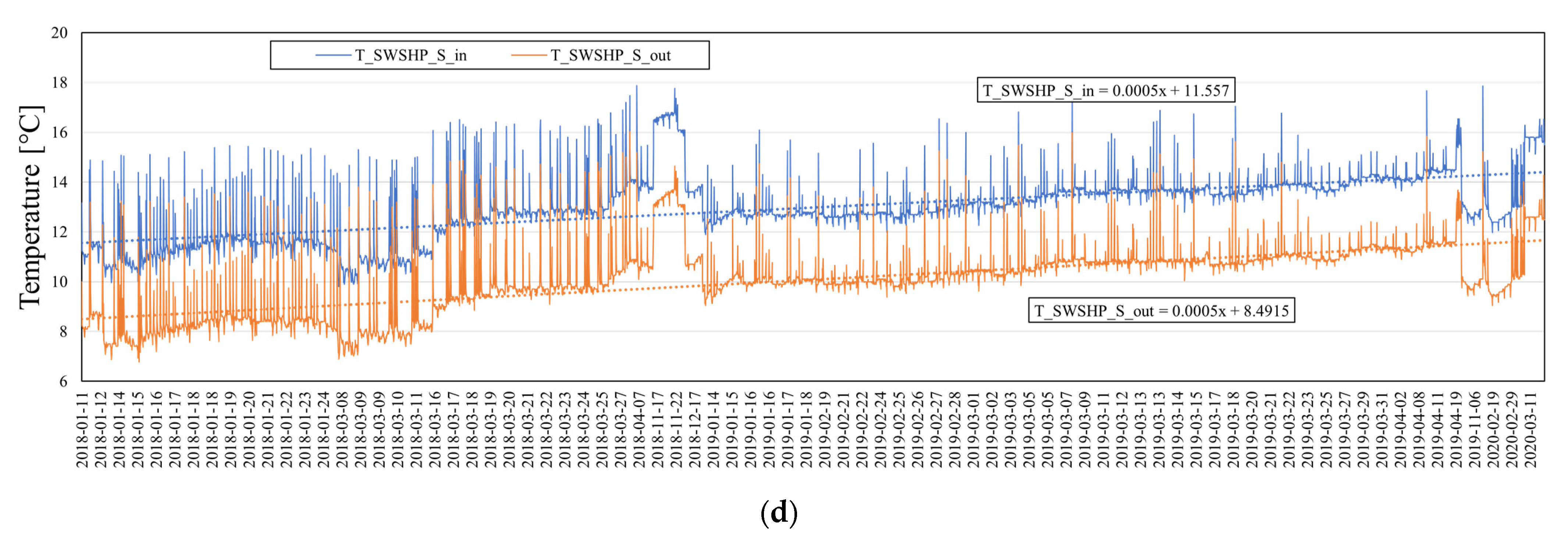

3.2. Operation Results of the Heat Pump Systems

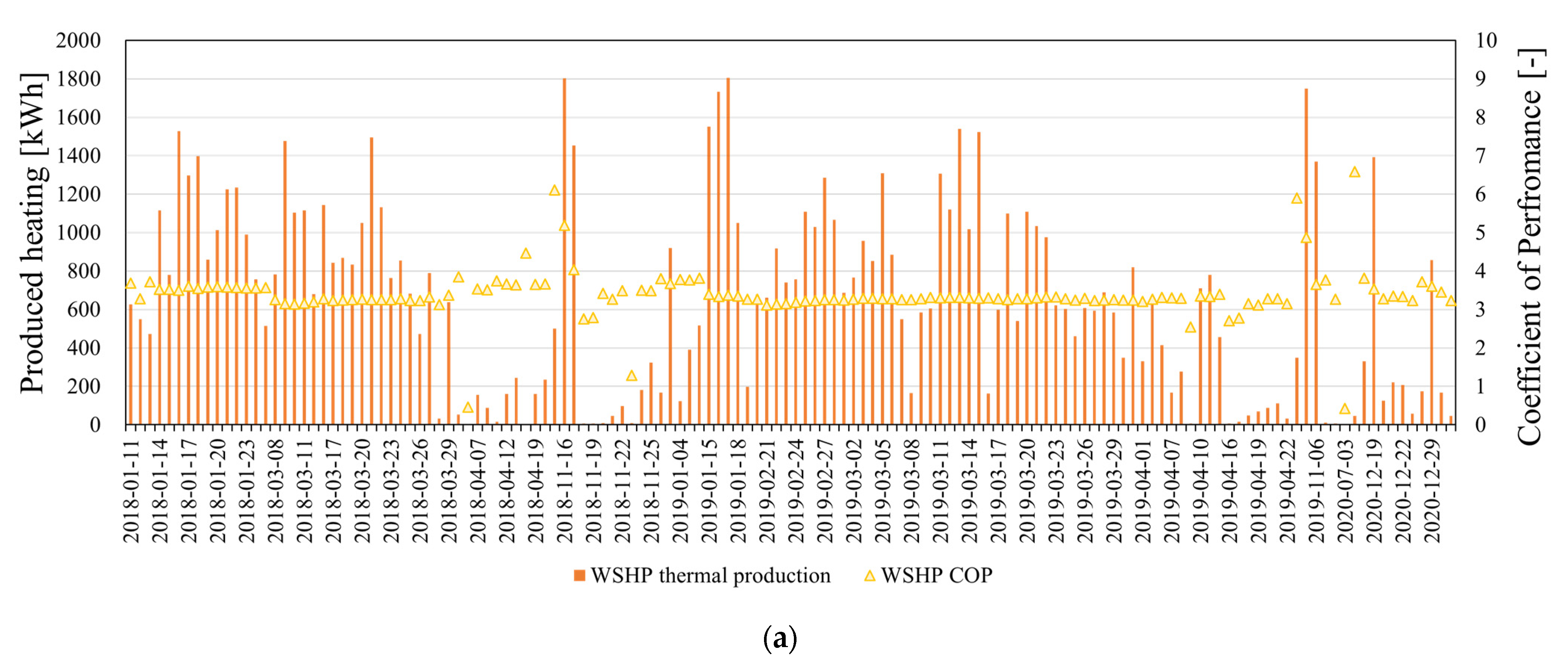

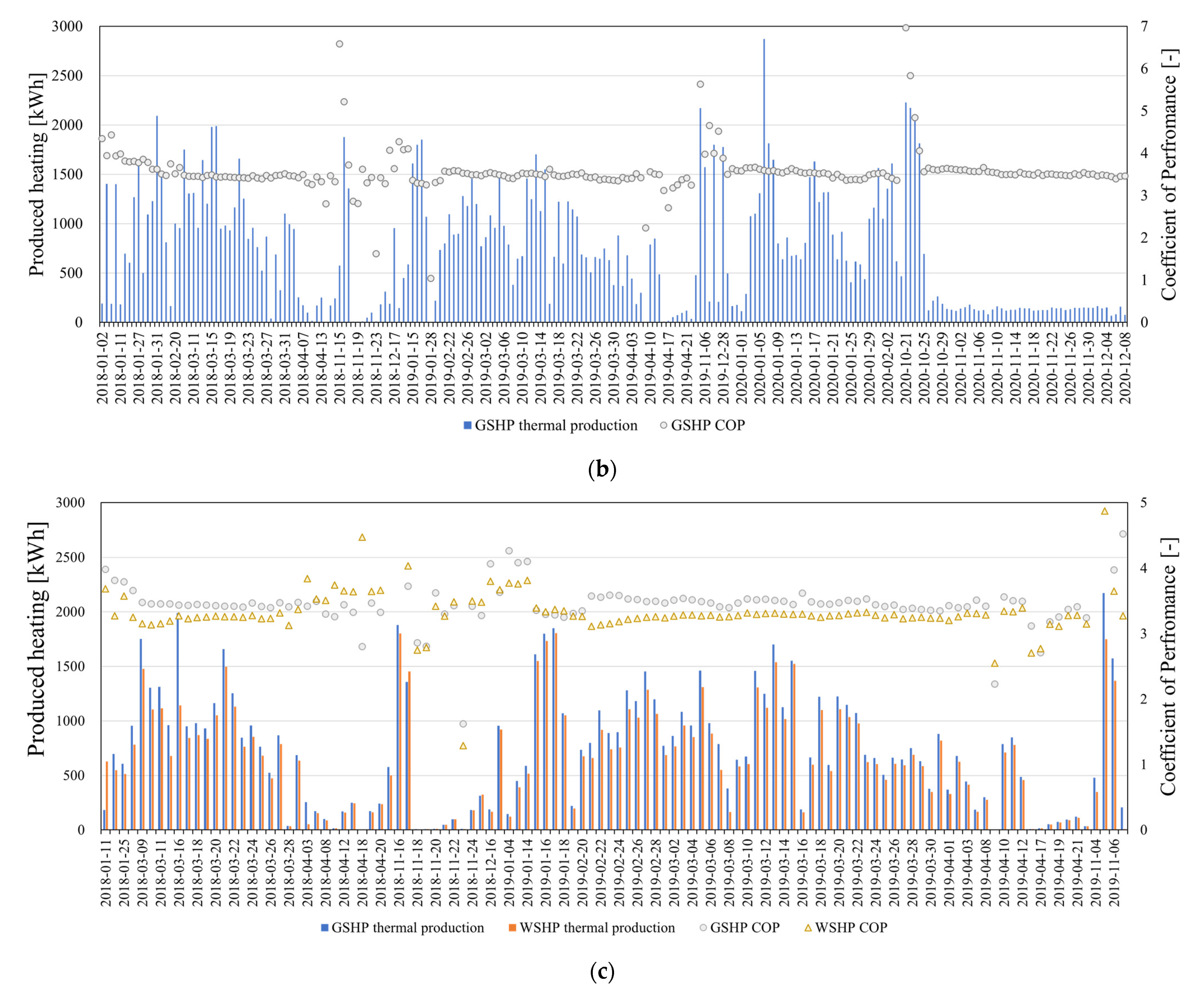

3.2.1. Comparison of GSHP and WSHP during Cooling Seasons

3.2.2. Comparison of GSHP and WSHP during Heating Seasons

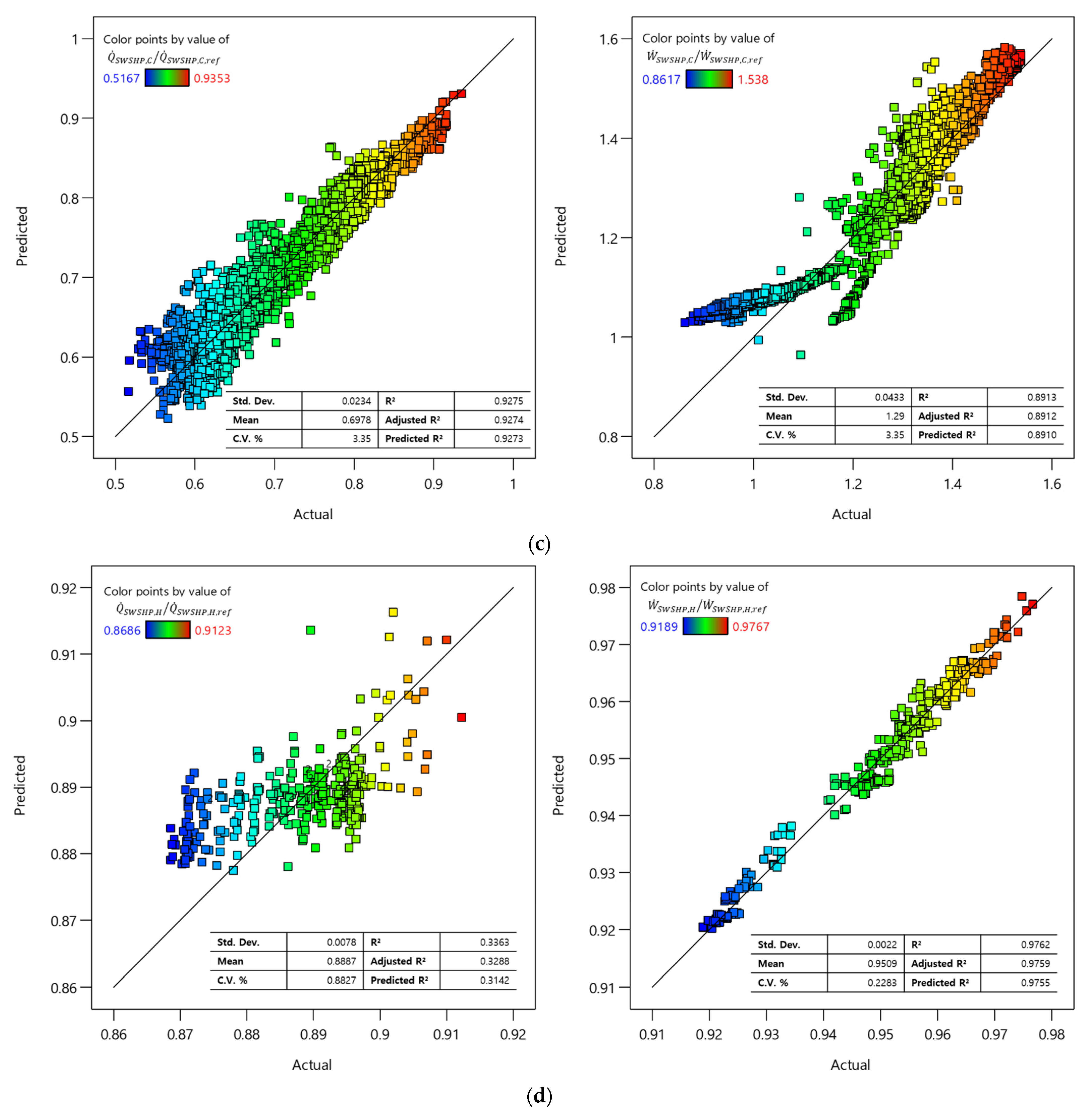

3.3. Heat Pump Models

3.4. Discussion

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A Key Review of Wastewater Source Heat Pump (WWSHP) Systems. Energy Convers. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Robinson, Z.P.; Wang, X.; Wu, J.; Li, F. The Feasibility and Challenges of Energy Self-Sufficient Wastewater Treatment Plants. Appl. Energy 2017, 204, 1463–1475. [Google Scholar] [CrossRef] [Green Version]

- Culha, O.; Gunerhan, H.; Biyik, E.; Ekren, O.; Hepbasli, A. Heat Exchanger Applications in Wastewater Source Heat Pumps for Buildings: A Key Review. Energy Build. 2015, 104, 215–232. [Google Scholar] [CrossRef]

- Mazhar, A.R.; Liu, S.; Shukla, A. A State of Art Review on the District Heating Systems. Renew. Sustain. Energy Rev. 2018, 96, 420–439. [Google Scholar] [CrossRef]

- Kuster, R.R.; Prinzing, M.; Matthias, B.; Eschmann, M.; Bertsch, S.S. Field Performance Of Domestic Heat Pumps For Heating And Hot Field Performance Of Domestic Heat Pumps For Heating And Hot Water In Switzerland Part I: Technology, Methods And State Of The Art Of The Field Studies. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 24–28 May 2021; p. 2083. [Google Scholar]

- Cho, Y.; Yun, R. A Raw Water Source Heat Pump Air-Conditioning System. Energy Build. 2011, 43, 3068–3073. [Google Scholar] [CrossRef]

- Qin, N.; Hao, P.Z. The Operation Characteristics of Sewage Source Heat Pump System and the Analysis of Its Thermal Economic Benefits. Appl. Therm. Eng. 2017, 124, 1083–1089. [Google Scholar] [CrossRef]

- Shen, C.; Yang, L.; Wang, X.; Jiang, Y.; Yao, Y. An Experimental and Numerical Study of a De-Fouling Evaporator Used in a Wastewater Source Heat Pump. Appl. Therm. Eng. 2014, 70, 501–509. [Google Scholar] [CrossRef]

- Shen, C.; Lei, Z.; Lv, G.; Ni, L.; Deng, S. Experimental Performance Evaluation of a Novel Anti-Fouling Wastewater Source Heat Pump System with a Wastewater Tower. Appl. Energy 2019, 236, 690–699. [Google Scholar] [CrossRef]

- Ni, L.; Tian, J.; Shen, C.; Zhao, J. Experimental Study of the Separation Performance of a Novel Sewage Hydrocyclone Used in Sewage Source Heat Pump. Appl. Therm. Eng. 2016, 106, 1300–1310. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Yin, C.; Liu, F.; Wang, G. Experimental Evaluation of Heat Transfer Performance of Falling Film Evaporator for Wastewater Source Heat Pump with Backwash System. Int. J. Refrig. 2020, 113, 80–93. [Google Scholar] [CrossRef]

- Kim, D.; Lee, D.; Heo, J.; Kim, M. Empirical Results and Operational Cost Analysis of Geothermal Heat Pump System Using Thermal Energy Storage in Cooling Season. Korean J. Air-Cond. Refrig. Eng. 2018, 30, 167–174. [Google Scholar] [CrossRef]

- EnergyPlus Development Team. EnergyPlus Version 9.2 Engineering Reference: The Reference to EnergyPlus; EnergyPlus Development Team: Washington, DC, USA, 2019. [Google Scholar]

- Taylor, B.N.; Kuyatt, C.E. Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results—1994 Edition; National Institute of Standards and Technology: Gaithersburg, MA, USA, 1994. [Google Scholar]

- Stat-Ease, Inc. Design-Expert 2021. Available online: www.statease.com (accessed on 9 August 2021).

- You, T.; Wu, W.; Shi, W.; Wang, B.; Li, X. An Overview of the Problems and Solutions of Soil Thermal Imbalance of Ground-Coupled Heat Pumps in Cold Regions. Appl. Energy 2016, 177, 515–536. [Google Scholar] [CrossRef]

- Bai, X.; Luo, T.; Cheng, K.; Chai, F. Experimental Study on Fouling in the Heat Exchangers of Surface Water Heat Pumps. Appl. Therm. Eng. 2014, 70, 892–895. [Google Scholar] [CrossRef]

- Zubair, S.M.; Sheikh, A.K.; Younas, M.; Budair, M.O. A Risk Based Heat Exchanger Analysis Subject to Fouling: Part I: Performance Evaluation. Energy 2000, 25, 427–443. [Google Scholar] [CrossRef]

- Lalot, S.; Lecoeuche, S. Online Fouling Detection in Electrical Circulation Heaters Using Neural Networks. Int. J. Heat Mass Transf. 2003, 46, 2445–2457. [Google Scholar] [CrossRef]

- Zhang, B.; You, S.; Wang, S.; Ding, X.; Wang, C.; Gao, Y. From Laboratory to On-Site Operation: Reevaluation of Empirically Based Electric Water Chiller Models. Build. Simul. 2021. [Google Scholar] [CrossRef]

- Lu, Q.; Narsilio, G.A.; Aditya, G.R.; Johnston, I.W. Economic Analysis of Vertical Ground Source Heat Pump Systems in Melbourne. Energy 2017, 125, 107–117. [Google Scholar] [CrossRef]

- Jung, Y.; Kim, J.; Kim, H.; Yun, R.; Park, C.; Nam, Y.; Cho, H.; Lee, H. Comprehensive Feasibility Investigation of River Source Heat Pump Systems in Terms of Life Cycle. Appl. Therm. Eng. 2021, 188, 116655. [Google Scholar] [CrossRef]

| Category | Specification |

|---|---|

| Solar thermal collector | Flat plate type: 399 EA (798 m2) Evacuated tube type: 198 EA (808 m2) |

| Heat pumps | Seasonal thermal energy storage source heat pump (STHP): 181 kW (R134a) Ground source heat pump (GSHP): 175 kW (R410a) Sewage water source heat pump (SWSHP): 181 kW (R134a) |

| Seasonal thermal energy storage | Double wall structure, stainless lining 4000 m3 (24.7 m × 16.7 m × 10.3 m) |

| Night-time thermal energy storage | Concrete wall, 200 m3 |

| Ground source heat exchanger | HDPE pipe (30 A, SDR-11) U-Bend 30 A Grout: volclay Casing: 150 A 150 m depth × 24 holes |

| Category | Model | Specification | Quantity |

|---|---|---|---|

| Temperature (T) | RTD PT100 transmitter | −10–100 °C Accuracy ± 0.106 °C Resolution 0.001 °C | 57 |

| RTD 3 wire | 11 | ||

| RTD pt1000 | 5 | ||

| Pressure | Sensys PSCH0006K | 0–6 bar Accuracy ± 0.25% FS | 21 |

| Solar irradiation | Kippen & Zonen | CMP11 Accuracy 0.2% (1000 W/m2) | 2 |

| Flow () | Toshiba LF620 | Accuracy Vs > 0.5 m/s ± 0.3% of rate Vs < 0.5 m/s ± 0.4% of rate | 17 |

| Outdoor air temperature | GOTH-1420/PT1000 | −36~80 °C ±(0.2~0.4) °C @25 °C | 1 |

| Category | Parameters | Values |

|---|---|---|

| Ground source heat pump (GSHP) | 175,436 W | |

| 177,980 W | ||

| 580 LPM | ||

| 580 LPM | ||

| 37,469 W | ||

| 47,733 W | ||

| Sewage water source heat pump (SWSHP) | 141,000 W | |

| 186,900 W | ||

| 580 LPM | ||

| 580 LPM | ||

| 29,800 W | ||

| 53,900 W |

| GSHP for Cooling | ||||||

[°C] | [°C] | [LPM] | [LPM] | [kW] | [kW] | Dataset |

| 7.0–18.5 | 26.7–35.5 | 617.3–658.1 | 704.6–891.0 | 140.0–198.9 | 40.0–44.5 | 5092 |

| GSHP for Heating | ||||||

[°C] | [°C] | [LPM] | [LPM] | [kW] | [kW] | Dataset |

| 26.7–46.8 | 7.1–18.5 | 514.4–704.6 | 693.0–879.4 | 177.3–245.1 | 42.2–60.5 | 11,358 |

| SWSHP for Cooling | ||||||

[°C] | [°C] | [LPM] | [LPM] | [kW] | [kW] | Dataset |

| 5.84–12.8 | 24.2–38.3 | 611.5–663.9 | 555.6–733.8 | 72.47–131.9 | 25.68–45.83 | 5897 |

| SWSHP for Heating | ||||||

[°C] | [°C] | [LPM] | [LPM] | [kW] | [kW] | Dataset |

| 49.6–52.5 | 9.8–12.8 | 663.9–669.7 | 578.7–582.4 | 162.3–170.5 | 49.5–52.6 | 361 |

| −1.26713 | +6.37042 | −3.53001 | −0.336208 | −0.030342 |

| −0.359476 | −2.79622 | +4.49128 | +0.007381 | +0.053795 |

| −4.92172 | +9.04453 | −4.52053 | +0.995621 | +0.344876 |

| −3.03365 | +0.272381 | +2.44377 | +1.01202 | +0.001317 |

| −5.62857 | +1.36093 | +4.99586 | −0.001842 | −0.014707 |

| −5.45878 | +5.31541 | +0.764227 | −0.062415 | +0.001011 |

| −12.05627 | +3.91437 | +11.30657 | −2.45730 | −0.015136 |

| −5.69276 | +5.17011 | +1.20514 | −0.136563 | −0.325128 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-H.; Kim, D.-W.; Han, G.; Heo, J.; Lee, D.-W. Ground Source and Sewage Water Source Heat Pump Systems for Block Heating and Cooling Network. Energies 2021, 14, 5640. https://doi.org/10.3390/en14185640

Kim M-H, Kim D-W, Han G, Heo J, Lee D-W. Ground Source and Sewage Water Source Heat Pump Systems for Block Heating and Cooling Network. Energies. 2021; 14(18):5640. https://doi.org/10.3390/en14185640

Chicago/Turabian StyleKim, Min-Hwi, Deuk-Won Kim, Gwangwoo Han, Jaehyeok Heo, and Dong-Won Lee. 2021. "Ground Source and Sewage Water Source Heat Pump Systems for Block Heating and Cooling Network" Energies 14, no. 18: 5640. https://doi.org/10.3390/en14185640

APA StyleKim, M.-H., Kim, D.-W., Han, G., Heo, J., & Lee, D.-W. (2021). Ground Source and Sewage Water Source Heat Pump Systems for Block Heating and Cooling Network. Energies, 14(18), 5640. https://doi.org/10.3390/en14185640