An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications

Abstract

:1. Introduction

2. Biofuel as a Renewable Fuel

- Biofuels are renewable and are carbon- and CO2/GHG-neutral during the progression of the life cycle [17].

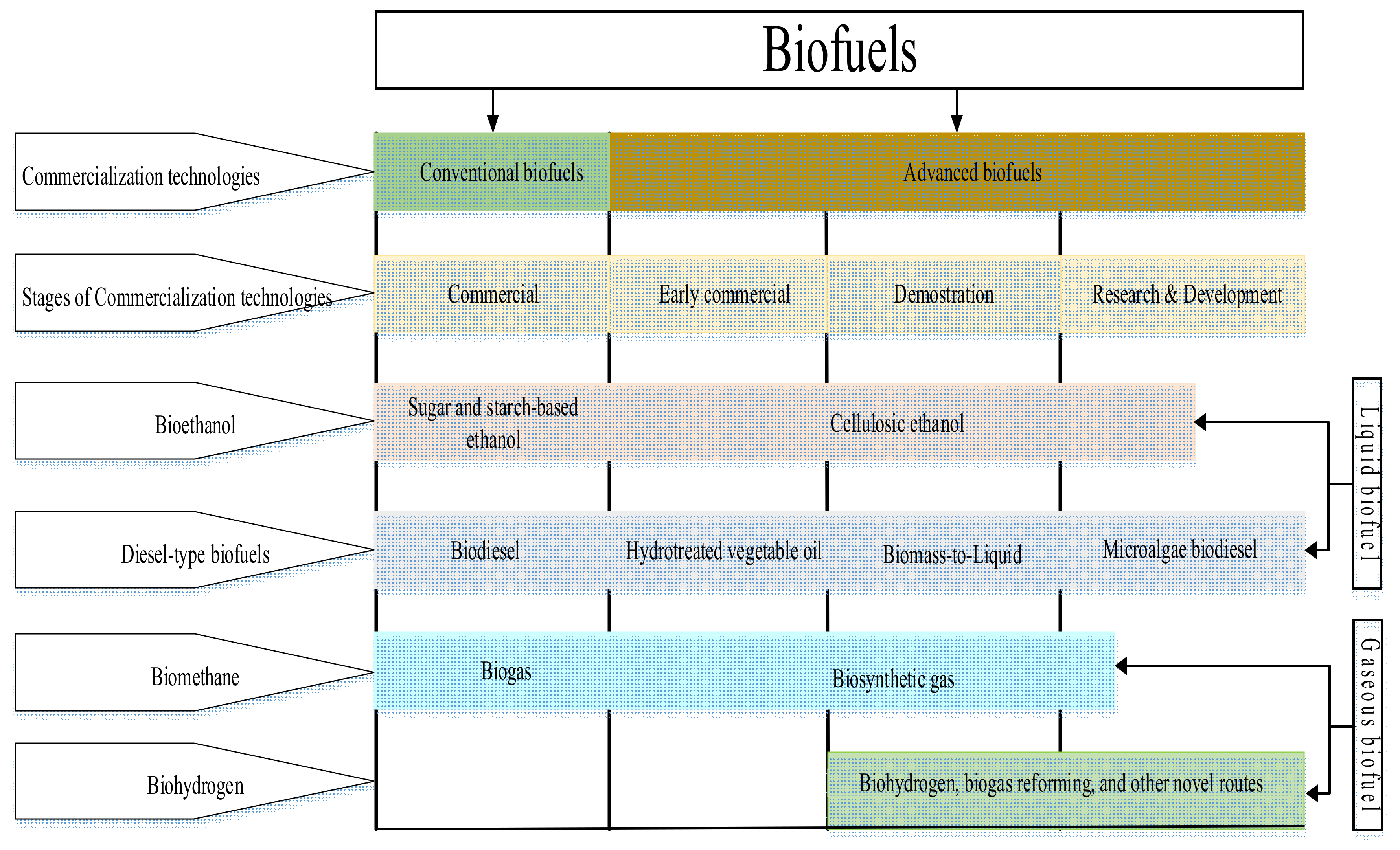

2.1. Classification of Biofuels

2.1.1. Classification Based on the Physical State

Solid Biofuels

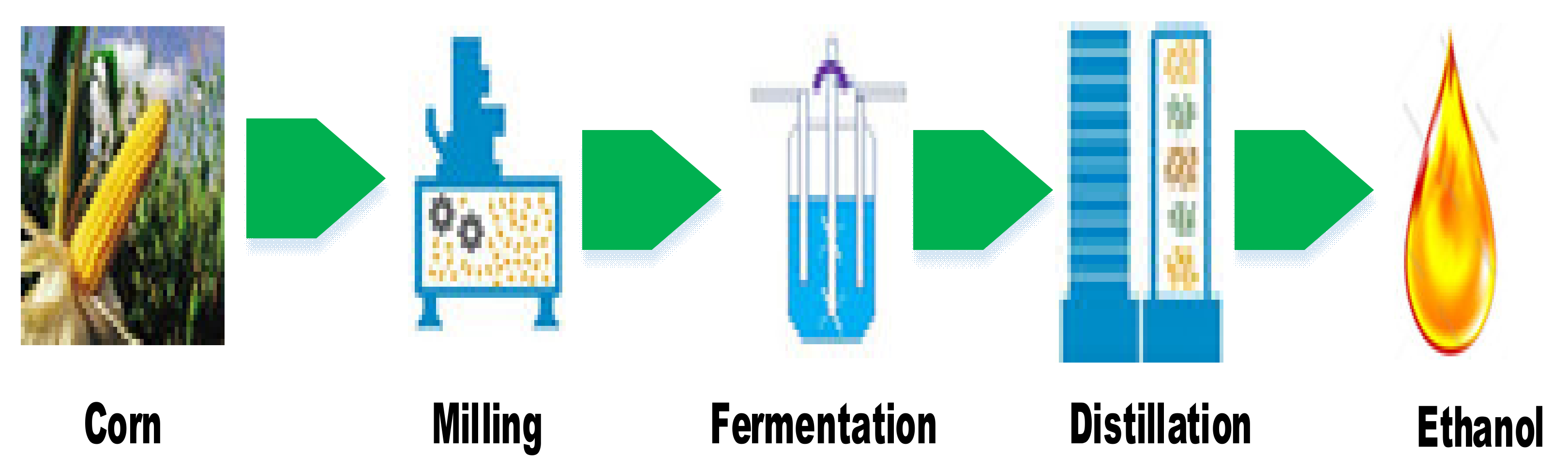

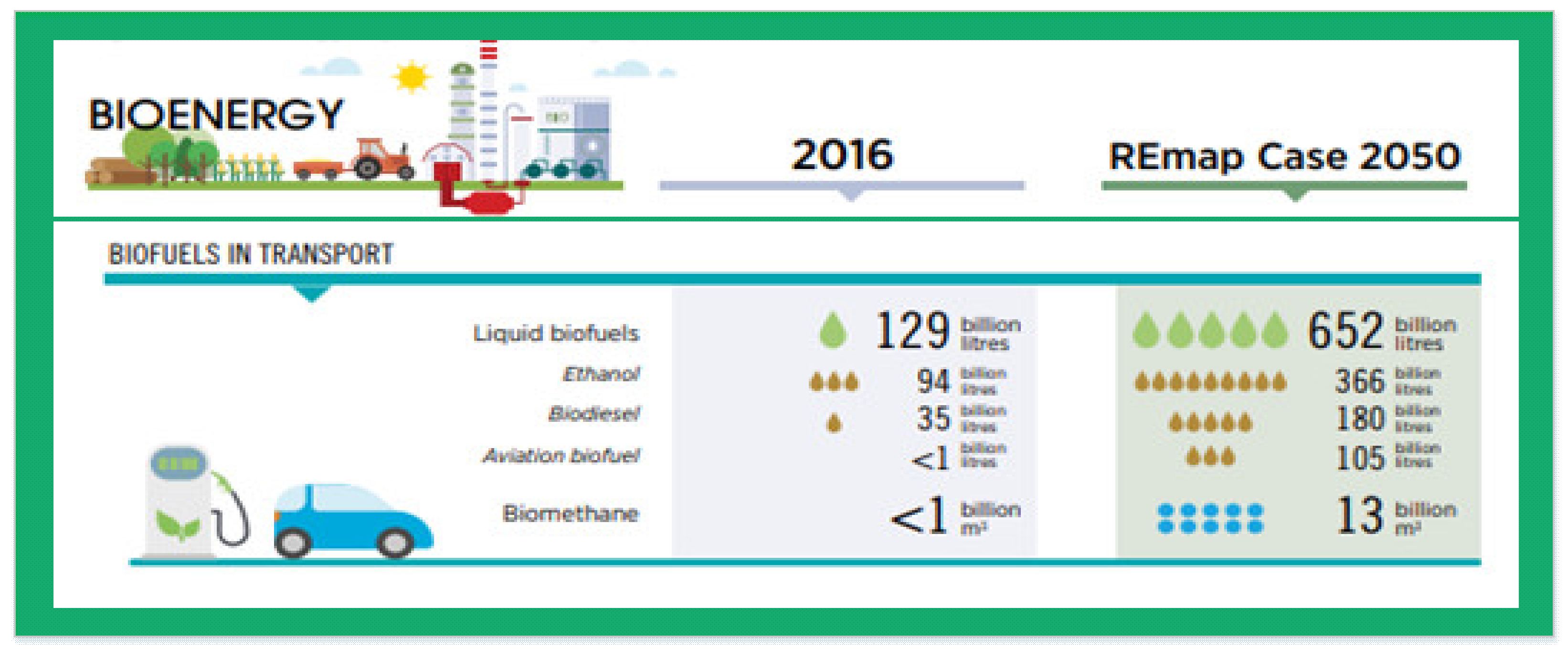

Liquid Biofuels

Gaseous Biofuels

2.1.2. Classification Based on Technology Maturity

Conventional Biofuels

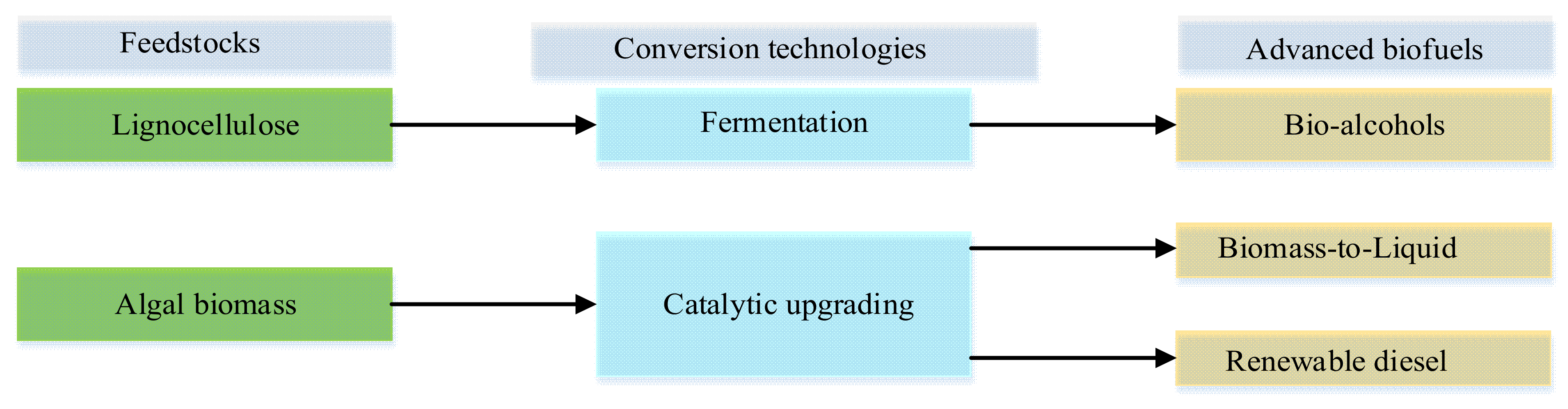

Advanced Biofuels

2.1.3. Classification Based on the Generation of Feedstock

First-Generation Feedstock

Second-Generation Feedstock

Third-Generation Feedstock

| Basis | Macroalgae | Microalgae |

|---|---|---|

| Cell | Multicellular plant | Unicellular plant |

| Growth habitat | Saline and freshwater | Saline and freshwater |

| Growth rate | Low | Fast |

| Size | 60 m in length | Small size (1 µm) |

| Nutrient storage capacity | High | More |

| Uses | For food and extraction of hydrocolloids | For food, fuel, and medical supplements |

- The cultivation of algae consumes CO2, ensures carbon mitigation, and contributes to a carbon-neutral environment. The generation of 1 g algal biomass consumes 1.83 g CO2 [73];

- Conversion of CO2 to algae-based biofuel; a ton of CO2 can be converted to between 55 and 70 gallons of ethanol [74];

- No competition with food security; eliminates the food vs. fuel debate [78];

- Algae biomass has high oil content and produces between 10 and 100 times more oil per acre compared with other traditional oil crops [83];

- Cultivation of algae does not involve the application of herbicides or pesticides [84];

- Microalgae allow wastewater bioremediation by removing NH4, NO3, and PO4 from municipal wastewater [85];

- Microalgal biomass can be utilized as food, animal feed, and fertilizer [70].

Fourth-Generation Feedstock

2.1.4. Classification Based on the Generation of Products

Primary Biofuels

First-Generation Biofuels

Second-Generation Biofuels

Third-Generation Biofuels

Fourth-Generation Biofuels

| Types of Biofuels | Benefits | Drawbacks | Ref. |

|---|---|---|---|

| Primary |

|

| [137] |

| First generation |

|

| [138,139] |

| Second generation |

|

| [140,141] |

| Third generation |

|

| [142,143] |

| Fourth generation |

|

| [144,145] |

3. Transesterification as the Biofuel Conversion Technique

4. Biofuel Production from Waste

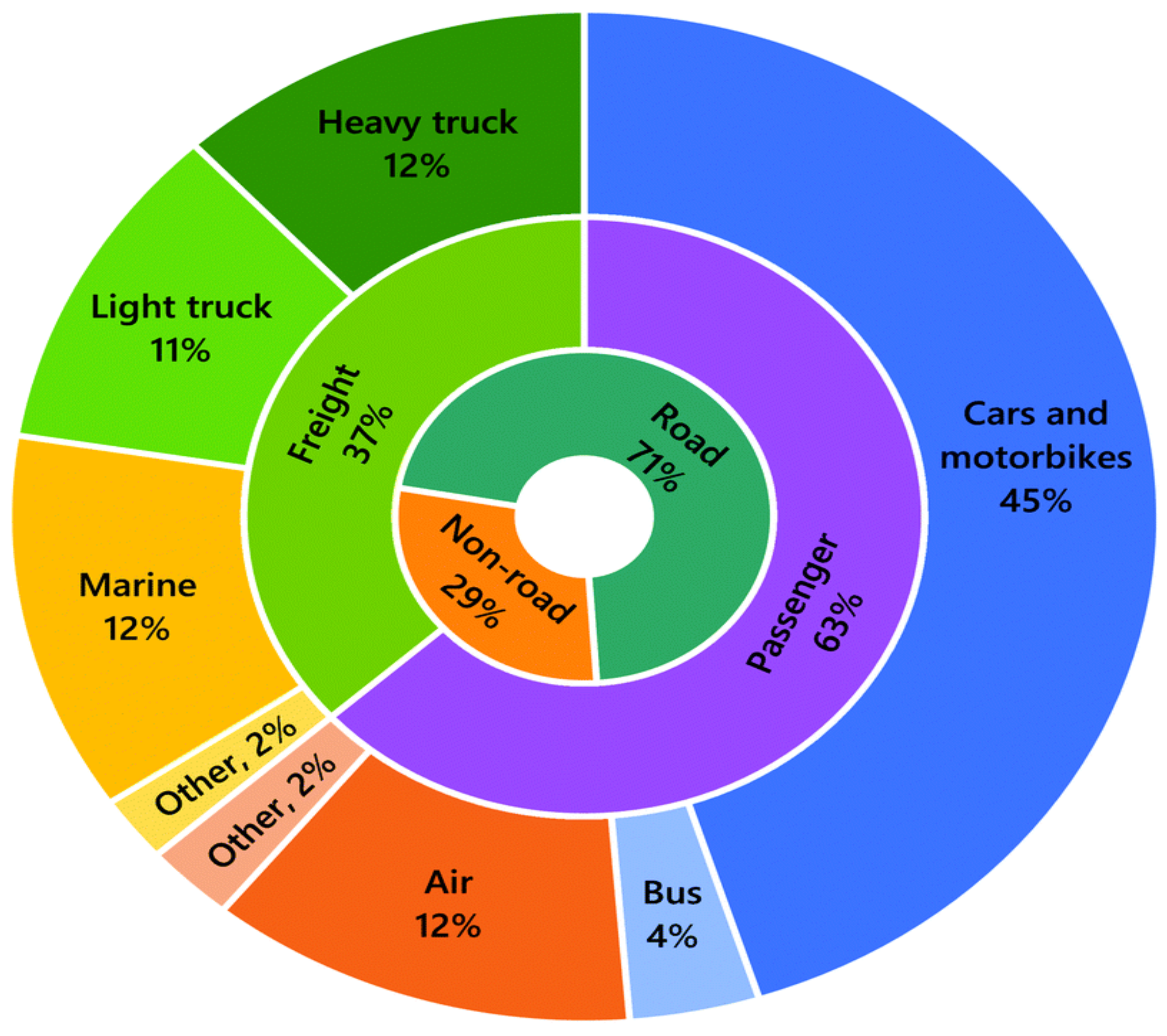

5. Biofuel as Internal Combustion Engine Fuels

| Property | PBG | PBD | Methanol | Ethanol | DME | Biogas | Hydrogen | Biodiesel | F-T Diesel |

|---|---|---|---|---|---|---|---|---|---|

| Chemical formula | CnH1.87n | CnH1.8n | CH3OH | C2H5OH | CH3OCH3 | CH4 | H2 | C15H31CO2CH3 | C9 to C20 |

| Density (kg/m3) | 720–780 | 820–870 | 800 | 790 | 667 | - | 70 | 850–885 | 774–782 |

| Kinetic viscosity at 40 °C (cSt) | 0.7 | 2.0–3.5 | 0.75 | 1.5 | 0.18 | - | - | 4.43 | 2-4.5 |

| Cetane number | 13–17 | 45–55 | 5 | 8 | 55–60 | - | - | 45-65 | 72 |

| Self-ignition temperature (°C) | 260a | 210 a | 470 | 365 | 320 | 580 | 500 | 220 | 315 |

| Lower heating value (MJ/kg) | 44 | 43 | 19.7 | 28.6 | 28.2 | 24 | 120 | 37 | 43.5 a |

| Lower heating value (liquid) (MJ/L) | 33 | 36 | 16 | 21 | 19 | - | 8.5 | 33 | - |

| Higher heating value (mixture) (kJ/kg) | 3.8 | 3.9 | 3.5 | - | 3.4 | 3.1 | 2.0 | - | - |

| Adiabatic temperature (°C) | 1995 | - | 1950 | 1965 | 2020 | 1954 | 2510 | 2000 | - |

| Boiling temperature (°C) | 25–210 | 180–360 | 65 | 78 | −25 | −162 | −253 | 250–350 | 157.6 |

| Reid vapor pressure at 38 °C (kPa) | 55–100 | <1.5 | 32 | 16 | 800 | - | - | - | - |

| Stoichiometric A/F ratio | 14.5 a | 14 a | 6.4 | 9.0 | 9.0 | 17 | 34.1 | 13 a | 15 |

| Research octane number | 98 | - | 115 | 110 | - | 120 | 106 | - | - |

| Enthalpy of vaporization (kJ/kg) | 350 a | 270 a | 1100 | 900 | 375 | 510 | 455 | - | - |

| Flammability limit (% vol.) | 1.3–8 | 0.6–8 | 7–36 | 4.3–19 | 3.4–19 | - | 4–75 | - | - |

| Flash point (°C) | -40 | 60–80 | 11 | 12 | −41 | - | - | 62 | 500 |

| Oxygen content (wt.%) | - | - | 50 | 35 | 34.8 | - | - | 10.7 | - |

| Carbon content (wt.%) | - | - | - | - | 52.2 | - | - | 76.9 | 86.44 |

| Hydrogen content (wt.%) | - | - | - | - | 13 | - | - | 12.4 | 13.56 |

5.1. Utilization of Biofuels in Spark Ignition Engines

5.2. Utilization of Biofuels in Compression Ignition Engines

6. Prospects for Biofuel Conversion Techniques

7. Implications

8. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Nguyen, K.H.; Kakinaka, M. Renewable energy consumption, carbon emissions, and development stages: Some evidence from panel cointegration analysis. Renew. Energy 2019, 132, 1049–1057. [Google Scholar] [CrossRef]

- BP. Statistical Review of World Energy. 2016. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/downloads.html (accessed on 2 June 2020).

- Ritchie, H.; Roser, M. Fossil Fuels. Our World in Data. 2017. Available online: https://ourworldindata.org/fossil-fuels (accessed on 2 June 2020).

- World Oil Final Consumption by Sector. 2018. Available online: https://www.iea.org/data-and-statistics/charts/world-oil-final-consumption-by-sector-2018 (accessed on 25 June 2021).

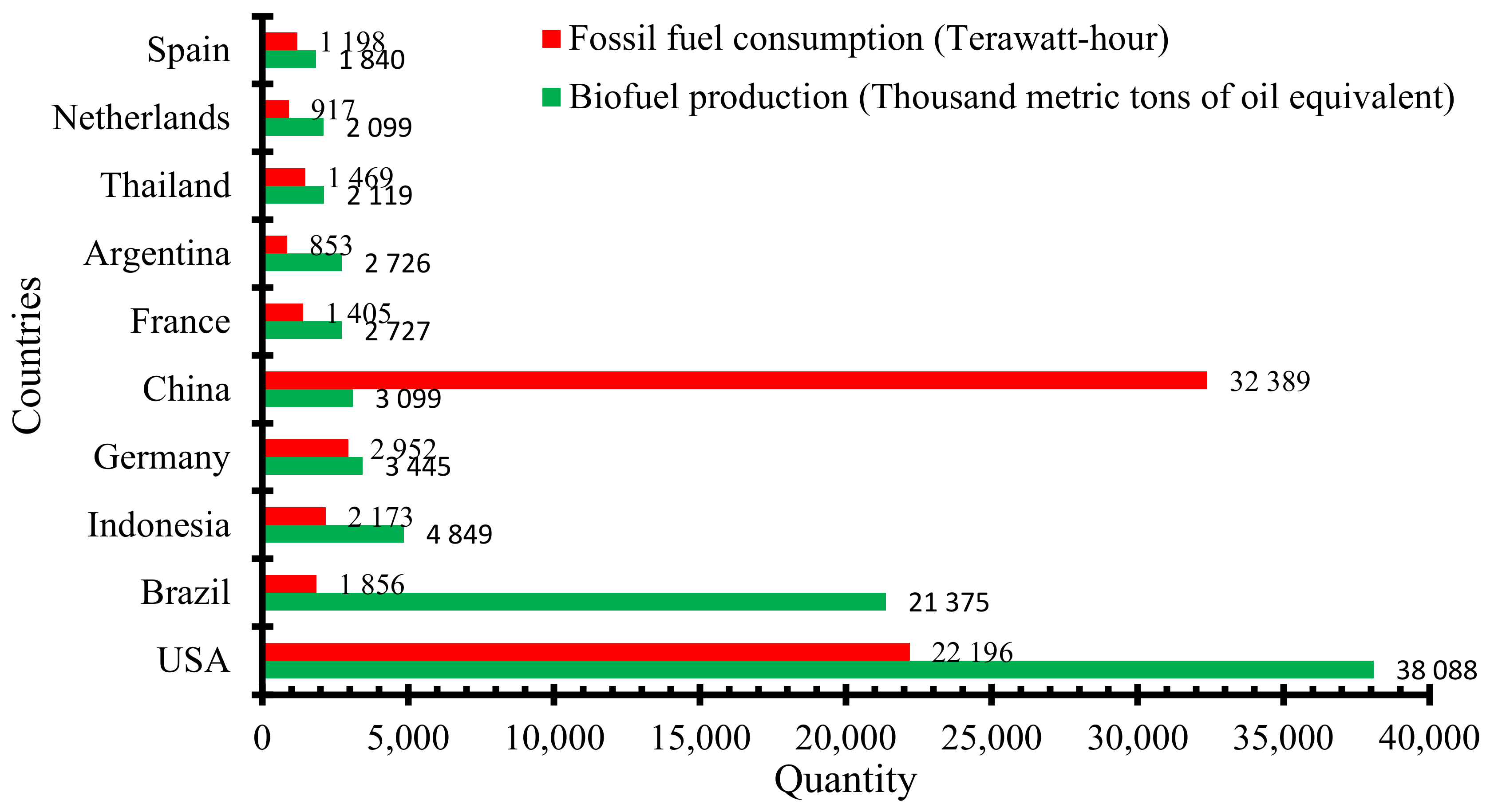

- Fossil Fuel Consumption. Available online: https://ourworldindata.org/fossil-fuels (accessed on 25 June 2021).

- Statista. Global Biofuel Production from 2000 to 2018. Available online: https://www.statista.com/statistics/274163/global-biofuel-production-in-oil-equivalent/ (accessed on 5 June 2020).

- Statista. Leading Countries Based on Biofuel Production in 2018. Available online: https://www.statista.com/statistics/274168/biofuel-production-in-leading-countries-in-oil-equivalent/ (accessed on 5 June 2020).

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.; Show, P.-L. Waste to bioenergy: A review on the recent conversion technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Tsita, K.G.; Kiartzis, S.J.; Ntavos, N.K.; Pilavachi, P.A. Next generation biofuels derived from thermal and chemical conversion of the Greek transport sector. Sci. Eng. Prog. 2020, 17, 100387. [Google Scholar] [CrossRef]

- Dung, T.N.B.; Sen, B.; Chen, C.C.; Kumar, G.; Lin, C.Y. Food waste to bioenergy via anaerobic processes. Energy Procedia 2014, 61, 307–312. [Google Scholar] [CrossRef] [Green Version]

- Alaswad, A.; Dassisti, M.; Prescott, T.; Olabi, A.G. Technologies and developments of third generation biofuel production. Renew. Sustain. Energy Rev. 2015, 51, 1446–1460. [Google Scholar] [CrossRef]

- Saladini, F.; Patrizi, N.; Pulselli, F.M.; Marchettini, N.; Bastianoni, S. Guidelines for emergy evaluation of first, second and third generation biofuels. Renew. Sustain. Energy Rev. 2016, 66, 221–227. [Google Scholar] [CrossRef]

- Schulte, L.A.; Ontl, T.A.; Larsen, G.L. Biofuels and biodiversity, wildlife habitat restoration. In Encyclopedia of Biodiversity, 2nd ed.; Levin, S.A., Ed.; Academic Press: Waltham, MA, USA, 2013; pp. 540–551. [Google Scholar]

- Cruz, C.H.B.; Souza, G.M.; Cortez, L.A.B. Biofuels for Transport. In Future Energy; Letcher, T.M., Ed.; Elsevier: London, UK, 2014; pp. 215–244. [Google Scholar]

- Ruan, R.; Zhang, Y.; Chen, P.; Liu, S.; Fan, L.; Zhou, N.; Ding, K.; Peng, P.; Addy, M.; Cheng, Y.; et al. Biofuels: Introduction. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels, 2nd ed.; Pandey, A., Larroche, C., Dussap, C.G., Gnansounou, E., Khanal, S.K., Ricke, S., Eds.; Academic Press: Waltham, MA, USA, 2019; pp. 3–43. [Google Scholar]

- Janampelli, S.; Darbha, S. Hydrodeoxygenation of vegetable oils and fatty acids over different group VIII metal catalysts for producing biofuels. Catal. Surv. Asia 2019, 23, 90–101. [Google Scholar] [CrossRef]

- Wu, B.; Bai, X.; Liu, W.; Lin, S.; Liu, S.; Luo, L.; Guo, Z.; Zhao, S.; Lv, Y.; Zhu, C.; et al. Non-negligible stack emissions of non-criteria air pollutants from coal-fired power plants in China: Condensable particulate matter and sulfur trioxide. Environ. Sci. Technol. 2020, 54, 6540–6550. [Google Scholar] [CrossRef] [PubMed]

- Appavu, P.; Ramanan, M.V.; Jayaraman, J.; Venu, H. NOx emission reduction techniques in biodiesel-fuelled CI engine: A review. Aust. J. Mech. Eng. 2021, 18, 210–220. [Google Scholar] [CrossRef]

- Navas, M.B.; Ruggera, J.F.; Lick, I.D.; Casella, M.L. A sustainable process for biodiesel production using Zn/Mg oxidic species as active, selective and reusable heterogeneous catalysts. Bioresour. Bioprocess. 2020, 7, 4. [Google Scholar] [CrossRef]

- Pugazhendhi, A.; Alagumalai, A.; Mathimani, T.; Atabani, A. Optimization, kinetic and thermodynamic studies on sustainable biodiesel production from waste cooking oil: An Indian perspective. Fuel 2020, 273, 117725. [Google Scholar] [CrossRef]

- Darby, H.M.; Callahan, C.W. On-farm oil-based biodiesel production. In Bioenergy; Elsevier: London, UK, 2020; pp. 157–184. [Google Scholar] [CrossRef]

- Smith, N. The Creation of an Inclusive and Safe Biofuel Production Method; Research Paper; Savannah State University: Sannah, GA, USA, 2019. [Google Scholar]

- Yaghoubi, J.; Yazdanpanah, M.; Komendantova, N. Iranian agriculture advisors’ perception and intention toward biofuel: Green way toward energy security, rural development and climate change mitigation. Renew. Energy 2019, 130, 452–459. [Google Scholar] [CrossRef] [Green Version]

- Szabó, Z. Can biofuel policies reduce uncertainty and increase agricultural yields through stimulating investments? Biofuels Bioprod. Biorefining 2019, 13, 1224–1233. [Google Scholar] [CrossRef]

- Chintala, V. Coal versus biofuels: A social and economic assessment. In Second and Third Generation of Feedstocks; Elsevier: London, UK, 2019; pp. 513–529. [Google Scholar]

- Oyewole, S.O.; Ishola, B.; Oyewole, A.L. Socioeconomic issues associated with campaign for large scale jatropha production to meet the anticipated biofuel demand. Int. J. For. Plant 2019, 2, 19–25. [Google Scholar]

- Topcu, M.; Tugcu, C.T. The impact of renewable energy consumption on income inequality: Evidence from developed countries. Renew. Energy 2020, 151, 1134–1140. [Google Scholar] [CrossRef]

- Schuenemann, F.; Kerr, W.A. European union non-tariff barriers to imports of African biofuels. Agrekon 2019, 58, 407–425. [Google Scholar] [CrossRef] [Green Version]

- Mattioda, R.A.; Tavares, D.R.; Casela, J.L.; Junior, O.C. Social life cycle assessment of biofuel production. In Biofuels for a More Sustainable Future; Ren, J., Scipioni, A., Manzardo, A., Liang, H., Eds.; Elsevier: London, UK, 2020; pp. 255–271. [Google Scholar] [CrossRef]

- Siddiqui, M.R.; Miranda, A.; Mouradov, A. Microalgae as bio-converters of wastewater into biofuel and food. In Water Scarcity and Ways to Reduce the Impact; Pannirselvam, M., Shu, L., Griffin, G., Philip, L., Natarajan, A., Hussain, S., Eds.; Springer: New York, NY, USA, 2019; pp. 75–94. [Google Scholar] [CrossRef]

- Ingle, A.P.; Ingle, P.; Gupta, I.; Rai, M. Socioeconomic impacts of biofuel production from lignocellulosic biomass. In Sustainable Bioenergy; Rais, M., Ingle, A., Eds.; Elsevier: London, UK, 2019; pp. 347–366. [Google Scholar]

- Vassilev, S.V.; Vassileva, C.G. Composition, properties and challenges of algae biomass for biofuel application: An overview. Fuel 2016, 181, 1–33. [Google Scholar] [CrossRef]

- Meyer, K.; Newman, P. A quota for agricultural GHG emissions (methane and nitrous oxide). In Planetary Accounting; Meyer, K., Newman, P., Eds.; Springer: Singapore, 2020; pp. 137–145. [Google Scholar] [CrossRef]

- Patidar, S.K.; Raheman, H. Performance and durability analysis of a single-cylinder direct injection diesel engine operated with water emulsified biodiesel-diesel fuel blend. Fuel 2020, 273, 117779. [Google Scholar] [CrossRef]

- Adewuyi, A. Challenges and prospects of renewable energy in Nigeria: A case of bioethanol and biodiesel production. Energy Rep. 2020, 6, 77–88. [Google Scholar] [CrossRef]

- Mandley, S.; Daioglou, V.; Junginger, H.; van Vuuren, D.; Wicke, B. EU bioenergy development to 2050. Renew. Sustain. Energy Rev. 2020, 127, 109858. [Google Scholar] [CrossRef]

- Knapczyk, A.; Francik, S.; Fraczek, J.; Slipek, Z. Analysis of research trends in production of solid biofuels. In Proceedings of the 18th International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 22–24 May 2019; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2019; pp. 1503–1509. [Google Scholar]

- Chua, S.Y.; Goh, C.M.H.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Walvekar, R.; Abdullah, E. Biodiesel synthesis using natural solid catalyst derived from biomass waste—A review. J. Ind. Eng. Chem. 2020, 81, 41–60. [Google Scholar] [CrossRef]

- Morato, T.; Vaezi, M.; Kumar, A. Assessment of energy production potential from agricultural residues in Bolivia. Renew. Sustain. Energy Rev. 2019, 102, 14–23. [Google Scholar] [CrossRef]

- Islas, J.; Manzini, F.; Masera, O.; Vargas, V. Solid biomass to heat and power. In The Role of Bioenergy in the Bioeconomy; Lago, C., Caldés, N., Lechón, Y., Eds.; Elsevier: London, UK, 2019; pp. 145–177. [Google Scholar]

- Carrasco-Diaz, G.; Perez-Verdin, G.; Escobar-Flores, J.; Marquez-Linares, M.A. A technical and socioeconomic approach to estimate forest residues as a feedstock for bioenergy in northern Mexico. Ecosyst 2019, 6, 45. [Google Scholar] [CrossRef] [Green Version]

- Rupp, S.P.; Ribic, C.A. Second-generation feedstocks from dedicated energy crops. In Renewable Energy and Wildlife Conservation; Moorman, C.E., Grodsky, S.M., Rupp, S.P., Eds.; Baltimore University Press: Baltimore, MD, USA, 2019; pp. 64–66. [Google Scholar]

- Ho, D.P.; Ngo, H.H.; Guo, W. A mini review on renewable sources for biofuel. Bioresour. Technol. 2014, 169, 742–749. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IEA. Tracking Transport 2019, Paris. Available online: https://www.iea.org/reports/tracking-transport-2019 (accessed on 21 June 2020).

- Moriarty, P.; Yan, X.; Wang, S.J. Liquid biofuels: Not a long-term transport solution. Energy Procedia 2019, 158, 3265–3270. [Google Scholar] [CrossRef]

- Jacobson, M.Z. Why Not Liquid Biofuels for Transportation as Part of a 100% Wind-Water-Solar (WWS) and Storage Solution to Global Warming, Air Pollution, and Energy Security. 2020. Available online: https://web.stanford.edu/group/efmh/jacobson/Articles/I/BiofuelVsWWS.pdf (accessed on 21 June 2020).

- Huang, H.; Jin, Q. Industrial waste valorization: Applications to the case of liquid biofuels. green energy to sustainability: Strategies for global industries. In Green Energy to Sustainability: Strategies for Global Industries; Vertès, A.A., Qureshi, N., Blaschek, H.P., Yukawa, H., Eds.; John Wiley & Sons: New York, NY, USA, 2020; pp. 515–537. [Google Scholar] [CrossRef]

- Guo, M. The global scenario of biofuel production and development. In Practices and Perspectives in Sustainable Bioenergy; Mitra, M., Nagchaudhuri, A., Eds.; Springer: New Delhi, India, 2020; pp. 29–56. [Google Scholar]

- Demain, A.L.; Báez-Vásquez, M.A. Biofuels of the present and the future. In New and Future Developments in Catalysis; Suib, S.L., Ed.; Elsevier: Oxford, UK, 2013; pp. 325–364. [Google Scholar]

- Bharathiraja, B.; Jayamuthunagai, J.; Chakravarthy, M.; Kumar, R.P. Bioprocessing of biofuels for green and clean environment. In Bioprocess Engineering for a Green Environment; Sivasubramanian, V., Ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 237–249. [Google Scholar]

- IEA. Technology Roadmap. Biofuels for Transport. Available online: https://www.ieabioenergy.com/wp-content/uploads/2013/10/IEA-Biofuel-Roadmap.pdf (accessed on 9 June 2020).

- Doshi, A.; Pascoe, S.; Coglan, L.; Rainey, T.J. Economic and policy issues in the production of algae-based biofuels: A review. Renew. Sustain. Energy Rev. 2016, 64, 329–337. [Google Scholar] [CrossRef] [Green Version]

- Oh, Y.K.; Hwang, K.R.; Kim, C.; Kim, J.R.; Lee, J.S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour. Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Iulianelli, A.; Di Paola, L.; Basile, M.; Basile, A. Ethanol from biomass: Future and perspectives. In Ethanol; Basile, A., Iulianelli, A., Dalena, F., Veziroğlu, T.N., Eds.; Elsevier: London, UK, 2019; pp. 25–59. [Google Scholar]

- Rulli, M.C.; Bellomi, D.; Cazzoli, A.; De Carolis, G.; D’Odorico, P. The water-land-food nexus of first-generation biofuels. Sci. Rep. 2016, 6, 22521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senatore, A.; Dalena, F.; Sola, A.; Marino, A.; Valletta, V.; Basile, A. First-generation feedstock for bioenergy production. In Second and Third Generation of Feedstocks; Basile, A., Dalena, F., Eds.; Elsevier: London, UK, 2019; pp. 35–57. [Google Scholar]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Binod, P.; Gnansounou, E.; Sindhu, R.; Pandey, A. Enzymes for second generation biofuels: Recent developments and future perspectives. Bioresour. Technol. Rep. 2019, 5, 317–325. [Google Scholar] [CrossRef]

- Akhtar, A.; Jiricek, I.; Krepl, V.; Mehrabadi, A. Improving the Stability of Wastewater Derived Microalgae Carbon Materials: Products Characterization, and Kinetic Modelling. Available online: https://chemrxiv.org/articles/preprint/Improving_the_Stability_of_Wastewater_Derived_Microalgae_Carbon_Materials_Products_Characterization_and_Kinetic_Modelling/11301896/2 (accessed on 21 June 2020).

- Bharadwaj, S.V.; Ram, S.; Pancha, I.; Mishra, S. Recent trends in strain improvement for production of biofuels from microalgae. In Microalgae Cultivation for Biofuels Production; Yousuf, A., Ed.; Elsevier: London, UK, 2020; pp. 211–225. [Google Scholar]

- Mathimani, T.; Pugazhendhi, A. Utilization of algae for biofuel, bio-products and bio-remediation. Biocatal. Agric. Biotechnol. 2019, 17, 326–330. [Google Scholar] [CrossRef]

- Rajak, R.C.; Jacob, S.; Kim, B.S. A holistic zero waste biorefinery approach for macroalgal biomass utilization: A review. Sci. Total Environ. 2020, 716, 137067. [Google Scholar] [CrossRef] [PubMed]

- Aparicio, E.; Rodríguez-Jasso, R.M.; Lara, A.; Loredo-Treviño, A.; Aguilar, C.N.; Kostas, E.T.; Ruiz, H.A. Biofuels production of third generation biorefinery from macroalgal biomass in the Mexican context: An overview. In Sustainable Seaweed Technologies; Torres, M.D., Kraan, S., Dominguez, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 393–446. [Google Scholar]

- Vo, H.N.P.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Chen, Z.; Wang, X.C.; Chen, R.; Zhang, X. Microalgae for saline wastewater treatment: A critical review. Crit. Rev. Environ. Sci. Technol. 2019, 50, 1224–1265. [Google Scholar] [CrossRef]

- Chen, C.Y.; Kuo, E.W.; Nagarajan, D.; Ho, S.H.; Dong, C.D.; Lee, D.G.; Chang, J.-S. Cultivating Chlorella sorokiniana AK-1 with swine wastewater for simultaneous wastewater treatment and algal biomass production. Bioresour. Technol. 2020, 302, 122814. [Google Scholar] [CrossRef]

- Zhu, C.; Zhai, X.; Xi, Y.; Wang, J.; Kong, F.; Zhao, Y.; Chi, Z. Progress on the development of floating photobioreactor for microalgae cultivation and its application potential. World J. Microb. Biotechnol. 2019, 35, 190. [Google Scholar] [CrossRef]

- IEA. State of Technology Review—Algae Bioenergy an IEA Bioenergy Inter-Task Strategic Project. Available online: https://www.ieabioenergy.com/wp-content/uploads/2017/02/IEA-Bioenergy-Algae-report-update-Final-template-20170131.pdf (accessed on 26 June 2020).

- Raheem, A.; Wan Azlina, W.A.K.G.; Taufiq Yap, Y.H.; Danquah, M.K.; Harun, R. Thermochemical conversion of microalgal biomass for biofuel production. Renew. Sustain. Energy Rev. 2015, 49, 990–999. [Google Scholar] [CrossRef]

- Kumar, K.; Ghosh, S.; Angelidaki, I.; Holdt, S.L.; Karakashev, D.B.; Morales, M.A.; Das, D. Recent developments on biofuels production from microalgae and macroalgae. Renew. Sustain. Energy Rev. 2016, 65, 235–249. [Google Scholar] [CrossRef]

- Sillanpää, M.; Ncibi, M.C. A Sustainable Bioeconomy: The Green Industrial Revolution; Springer: Cham, Switzerland, 2017; pp. 120–136. [Google Scholar]

- Rosenberg, J.N.; Mathias, A.; Korth, K.; Betenbaugh, M.J.; Oyler, G.A. Microalgal biomass production and carbon dioxide sequestration from an integrated ethanol biorefinery in Iowa: A technical appraisal and economic feasibility evaluation. Biomass Bioenerg. 2011, 35, 3865–3876. [Google Scholar] [CrossRef]

- Nandan, S. Biofuel Production Technology from bioenergy crop-algae biofuel. SSRN Electron. J. 2020, 1–12. [Google Scholar] [CrossRef]

- Marella, T.K.; Datta, A.; Patil, M.D.; Dixit, S.; Tiwari, A. Biodiesel production through algal cultivation in urban wastewater using algal floway. Bioresour. Technol. 2019, 280, 222–228. [Google Scholar] [CrossRef]

- Bleakley, S.; Hayes, M. Algal proteins: Extraction, application, and challenges concerning production. Foods 2017, 6, 33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Agrawal, K.; Bhatt, A.; Bhardwaj, N.; Kumar, B.; Verma, P. Algal biomass: Potential renewable feedstock for biofuels production–Part I. In Biofuel Production Technologies. Critical Analysis for Sustainability; Srivastava, N., Srivastava, M., Mishra, P.K., Gupta, V.K., Eds.; Springer: Cham, Switzerland, 2020; pp. 203–237. [Google Scholar]

- Sander, K.; Murthy, G.S. Life cycle analysis of algae biodiesel. Int. J. Life Cycle Assess. 2010, 15, 704–714. [Google Scholar] [CrossRef]

- Bibi, R.; Ahmad, Z.; Imran, M.; Hussain, S.; Ditta, A.; Mahmood, S.; Khalid, A. Algal bioethanol production technology: A trend towards sustainable development. Renew. Sustain. Energy Rev. 2017, 71, 976–985. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Periyasamy, M.; Prathima, A.; Sabariswaran, K. Performance analysis of diesel engine fueled with S. marginatum Macro algae biofuel-diesel blends. Mater. Today 2020, 33, 3464–3469. [Google Scholar] [CrossRef]

- Dharmaprabhakaran, T.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Algal biodiesel-promising source to power CI engines. Mater. Today 2020, 33, 2870–2873. [Google Scholar] [CrossRef]

- Laurens, L.M. Whole algal biomass in situ transesterification to fatty acid methyl esters as biofuel feedstocks. In Bioenergy; Dahiya, A., Ed.; Elsevier: London, UK, 2020; pp. 525–537. [Google Scholar] [CrossRef]

- Sulieman, A.M.E.; Rahman, E.H.A.; Ahmed, W.A. Capabilities of algae to be utilized as a renewable energy source. Acad. J. Life Sci. 2020, 6, 18–26. [Google Scholar] [CrossRef]

- Alam, F.; Date, A.; Rasjidin, R.; Mobin, S.; Moria, H.; Baqui, A. Biofuel from algae-is it a viable alternative? Procedia Eng. 2012, 49, 221–227. [Google Scholar] [CrossRef] [Green Version]

- Chalivendra, S. Bioremediation of Wastewater Using Microalgae. Doctoral Thesis, University of Dayton, Dayton, OH, USA, 2014. Available online: https://ecommons.udayton.edu/graduate_theses/779/ (accessed on 21 June 2020).

- Behera, S.; Singh, R.; Arora, R.; Sharma, N.K.; Shukla, M.; Kumar, S. Scope of algae as third generation biofuels. Front. Bioeng. Biotechnol. 2015, 2, 90. [Google Scholar] [CrossRef]

- Moravvej, Z.; Makarem, M.A.; Rahimpour, M.R. The fourth generation of biofuel. In Second and Third Generation of Feedstocks; Basile, A., Dalena, F., Eds.; Elsevier: London, UK, 2019; pp. 557–597. [Google Scholar]

- Naghshbandi, M.P.; Tabatabaei, N.; Aghbashlo, M.; Aftab, M.N.; Iqbal, I. Metabolic engineering of microalgae for biofuel production. In Biofuels from Algae; Spilling, K., Ed.; Springer: Cham, Switzerland, 2019; pp. 153–172. [Google Scholar]

- Ghag, S.B.; Vavilala, S.L.; D’Souza, J.S. Metabolic engineering and genetic manipulation of novel biomass species for biofuel production. In Advanced Bioprocessing for Alternative Fuels, Biobased Chemicals, and Bioproducts; Hosseini, M., Ed.; Elsevier: London, UK, 2019; pp. 13–34. [Google Scholar]

- Pereira, A.G.; Jimenez-Lopez, C.; Fraga, M.; Lourenço-Lopes, C.; García-Oliveira, P.; Lorenzo, J.M.; Perez-Lamela, C.; Prieto, M.A.; Simal-Gandara, J. Extraction, properties, and applications of bioactive compounds obtained from microalgae. Curr. Pharm. Des. 2020, 26, 1929–1950. [Google Scholar] [CrossRef]

- Al Hattab, M.; Ghaly, A. Production of biodiesel from marine and freshwater microalgae: A review. Adv. Res. 2015, 3, 107–155. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Introduction to biofuels and potentials of nanotechnology. In Green Nanotechnology for Biofuel Production; Biofuel and Biorefinery Technologies; Srivastava, N., Srivastava, M., Pandey, H., Mishra, P.K., Ramteke, P.W., Eds.; Springer: Cham, Switzerland, 2018; pp. 1–15. [Google Scholar] [CrossRef]

- Merugu, R. Green Synthesis approach to fabricate nanomaterials. In Nanomaterials in Biofuels Research; Clean Energy Production Technologies; Srivastava, M., Srivastava, N., Mishra, P., Gupta, V., Eds.; Springer: Singapore, 2020; pp. 75–113. [Google Scholar] [CrossRef]

- Barker, J.; Richard, P.; Snape, C.; Meredith, W. Diesel injector deposits—An issue that has evolved with engine technology. SAE Tech. Pap. 2011, 148, 7191. [Google Scholar]

- Karikalan, L.; Chandrasekaran, M.; Sudhagar, K. Comparative studies on vegetable oil usage in CI engines as an alternative to diesel fuel. IREME J. 2013, 7, 705–715. [Google Scholar]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Akhlaghi, S.; Gedde, U.W.; Hedenqvist, M.S.; Braña, M.T.C.; Bellander, M. Deterioration of automotive rubbers in liquid biofuels: A review. Renew. Sustain. Energy Rev. 2015, 43, 1238–1248. [Google Scholar] [CrossRef]

- Jamwal, V.L.; Kapoor, N.; Gandhi, S.G. Biotechnology of biofuels: Historical overview, business outlook and future perspectives. In Biotechnology Business—Concept to Delivery; Saxena, A., Ed.; Springer: Cham, Switzerland, 2020; pp. 109–127. [Google Scholar] [CrossRef]

- Lesun, A.; Kazak, A.; Bankovskaya, I. Biofuels. 2019. Available online: https://rep.bntu.by/bitstream/handle/data/60791/64-67.pdf?sequence=1 (accessed on 9 June 2020).

- Neto, J.M.; Komesu, A.; da Silva Martins, L.H.; Gonçalves, V.O.; de Oliveira, J.A.R.; Rai, M. Third generation biofuels: An overview. In Sustainable Bioenergy; Rai, M., Avinash, P.I., Eds.; Elsevier: London, UK, 2019; pp. 283–298. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P.; Yusaf, T.; Hamawand, I. Production and application of ABE as a biofuel. Renew. Sustain. Energy Rev. 2018, 82, 1195–1214. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Poudyal, R.S.; Tiwari, I.; Voloshin, R.A.; Zharmukhamedov, S.K.; Nam, H.G.; Zayadan, B.; Bruce, B.; Hou, H.; Allakhverdiev, S. Biofuel production: Challenges and opportunities. Int. J. Hydrog. Energy 2017, 42, 8450–8461. [Google Scholar] [CrossRef]

- Noraini, M.; Ong, H.C.; Badrul, M.J.; Chong, W. A review on potential enzymatic reaction for biofuel production from algae. Renew. Sustain. Energy Rev. 2014, 39, 24–34. [Google Scholar] [CrossRef]

- Mahjoub, N.; Sahebi, H.; Mazdeh, M.; Teymouri, A. Optimal design of the second and third generation biofuel supply network by a multi-objective model. J. Clean Prod. 2020, 256, 120355. [Google Scholar] [CrossRef]

- Chowdhury, H.; Loganathan, B. Third-generation biofuels from microalgae: A review. Curr. Opin. Green Sustain. Chem. 2019, 20, 39–44. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Biofuels technologies: An overview of feedstocks, processes, and technologies. In Biofuels for a More Sustainable Future; Jingzheng, R., Antonio, S., Alessandro, M., Hanwei, L., Eds.; Elsevier: London, UK, 2020; pp. 1–19. [Google Scholar]

- Fasahati, P.; Liu, J.J.; Ohlrogge, J.B.; Saffron, C.M. Process design and economics for production of advanced biofuels from genetically modified lipid-producing sorghum. Appl. Energy 2019, 239, 1459–1470. [Google Scholar] [CrossRef]

- Hao, H.; Liu, Z.; Zhao, F.; Ren, J.; Chang, S.; Rong, K.; Du, J. Biofuel for vehicle use in China: Current status, future potential and policy implications. Renew. Sustain. Energy Rev. 2018, 82, 645–653. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Pham, V.V. Pathway of sustainable fuel development with novel generation biofuels. AIP Conf. Proc. 2020, 2235, 020012. [Google Scholar] [CrossRef]

- Barry, T.; Crisby, C.; LaBossiere, M.; Luft, R.; Peterson, D.; Thompson, D.; Yeske, R. Biofuels: The Potential Opportunities and the Realistic Limitations; University of Victoria: Victoria, BC, Canada, 2020; pp. 2–16. Available online: https://web.uvic.ca/~djberg/Chem300A/GroupGH_Biofuels_Proj1.pdf (accessed on 9 June 2020).

- Tavizón-Pozos, J.A.; Ibarra, I.S.; Guevara-Lara, A.; Galán-Vidal, C.A. Application of design of experiments in biofuel production: A review. In Design of Experiments for Chemical, Pharmaceutical, Food, and Industrial Applications; Rodríguez-Ávila, J.A., Arredondo-Soto, K.C., Cornejo-Bravo, J.M., Eds.; IGI Global: Hershey PA, USA, 2020; pp. 77–103. [Google Scholar]

- Alalwan, H.A.; Alminshid, H.A.; Aljaafari, H.A. Promising evolution of biofuel generations. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar] [CrossRef]

- Li, X.; Luo, X.; Jin, Y.; Li, J.; Zhang, H.; Zhang, A.; Xie, J. Heterogeneous sulfur-free hydrodeoxygenation catalysts for selectively upgrading the renewable bio-oils to second generation biofuels. Renew. Sustain. Energy Rev. 2018, 82, 3762–3797. [Google Scholar] [CrossRef]

- Joshi, G.; Pandey, J.K.; Rana, S.; Rawat, D.S. Challenges and opportunities for the application of biofuel. Renew. Sustain. Energy Rev. 2017, 79, 850–866. [Google Scholar] [CrossRef]

- Du, C.; Zhao, X.; Liu, D.; Lin, C.S.K.; Wilson, K.; Luque, R.; Clark, J. Introduction: An overview of biofuels and production technologies. In Handbook of Biofuels Production; Luque, R., Ki Lin, C.S., Wilson, K., Clark, J., Eds.; Elsevier: London, UK, 2016; pp. 3–12. [Google Scholar]

- Gupta, V.K.; Potumarthi, R.; O’Donovan, A.; Kubicek, C.P.; Sharma, G.D.; Tuohy, M.G. Bioenergy research: An overview on technological developments and bioresources. In Bioenergy Research: Advances and Applications; Gupta, V.K., Tuohy, M.G., Kubicek, C.P., Saddler, J., Xu, F., Eds.; Elsevier: London, UK, 2014; pp. 23–47. [Google Scholar]

- Fokaides, P.; Christoforou, E. Life cycle sustainability assessment of biofuels. In Handbook of Biofuels Production; Luque, R., Ki Lin, C.S., Wilson, K., Clark, J., Eds.; Elsevier: London, UK, 2016; pp. 41–60. [Google Scholar]

- Knapczyk, A.; Francik, S.; Wójcik, A.; Ślipek, Z. Application of methods for scheduling tasks in the production of biofuels. In Renewable Energy Sources: Engineering, Technology, Innovation; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 863–873. [Google Scholar]

- Isah, S.; Ozbay, G. Valorization of food loss and wastes: Feedstocks for biofuels and valuable chemicals. Front. Sustain. Food Syst. 2020, 4, 82. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. Effect of emission from ethylic biodiesel of edible and non-edible vegetable oil, animal fats, waste oil and alcohol in CI engine. Energy Convers. Manag. 2018, 166, 704–718. [Google Scholar] [CrossRef]

- Ahamed, M.; Dash, S.; Kumar, A.; Lingfa, P. A critical review on the production of biodiesel from Jatropha, Karanja and Castor feedstocks. In Bioresource Utilization and Bioprocess; Ghosh, S., Sen, R., Chanakya, H., Pariatamby, A., Eds.; Springer: Singapore, 2020; pp. 107–115. [Google Scholar]

- Hadin, A.; Eriksson, O. Horse manure as feedstock for anaerobic digestion. Waste Manag. 2016, 56, 506–518. [Google Scholar] [CrossRef]

- Ajanovic, A. Biofuels versus food production: Does biofuels production increase food prices? Energy 2011, 36, 2070–2076. [Google Scholar] [CrossRef]

- Callegari, A.; Bolognesi, S.; Cecconet, D.; Capodaglio, A.G. Production technologies, current role, and future prospects of biofuels feedstocks: A state-of-the-art review. Crit. Rev. Environ. Sci. Technol. 2020, 50, 384–436. [Google Scholar] [CrossRef]

- Al Hatrooshi, A.S.; Eze, V.C.; Harvey, A.P. Production of biodiesel from waste shark liver oil for biofuel applications. Renew. Energy 2020, 145, 99–105. [Google Scholar] [CrossRef]

- Patel, A.; Sartaj, K.; Pruthi, P.A.; Pruthi, V.; Matsakas, L. Utilization of clarified butter sediment waste as a feedstock for cost-effective production of biodiesel. Foods 2019, 8, 234. [Google Scholar] [CrossRef] [Green Version]

- Ekeoma, M.; Okoye, P.; Ajiwe, V.; Hameed, B. Modified coconut shell as active heterogeneous catalyst for the transesterification of waste cooking oil. J. Chem. Soc. Niger. 2020, 45, 107. [Google Scholar]

- Ndiaye, M.; Arhaliass, A.; Legrand, J.; Roelens, G.; Kerihuel, A. Reuse of waste animal fat in biodiesel: Biorefining heavily-degraded contaminant-rich waste animal fat and formulation as diesel fuel additive. Renew. Energy 2020, 145, 1073–1079. [Google Scholar] [CrossRef]

- Nikhom, R.; Mueanmas, C.; Suppalakpanya, K.; Tongurai, C. Utilization of oil recovered from biodiesel wastewater as an alternative feedstock for biodiesel production. Environ. Prog. Sustain. Energy 2020, 39, 13365. [Google Scholar] [CrossRef]

- Hess, J.R.; Ray, A.E.; Rials, T.G. Advancements in biomass feedstock preprocessing: Conversion ready feedstocks. Front. Energy Res. 2019, 7, 140. [Google Scholar] [CrossRef] [Green Version]

- Puettmann, M.; Sahoo, K.; Wilson, K.; Oneil, E. Life cycle assessment of biochar produced from forest residues using portable systems. J. Clean. Prod. 2020, 250, 119564. [Google Scholar] [CrossRef]

- Abdulkareem-Alsultan, G.; Asikin-Mijan, N.; Lee, H.; Taufiq-Yap, Y. Biofuels: Past, Present, Future. In Innovations in Sustainable Energy and Cleaner Environment; Springer: Berlin/Heidelberg, Germany, 2020; pp. 489–504. [Google Scholar]

- Sindhu, R.; Binod, P.; Pandey, A.; Ankaram, S.; Duan, Y.; Awasthi, M.K. Biofuel production from biomass: Toward sustainable development. In Current Developments in Biotechnology and Bioengineering; Larroche, C., Sanroman, M., Du, G., Pandey, A., Eds.; Elsevier: London, UK, 2019; pp. 79–92. [Google Scholar]

- Nwoba, E.G.; Vadiveloo, A.; Ogbonna, C.N.; Ubi, B.E.; Ogbonna, J.C.; Moheimani, N.R. Algal cultivation for treating wastewater in African developing countries: A review. Clean Soil Air Water 2020, 48, 2000052. [Google Scholar] [CrossRef]

- Veeramuthu, A.; Ngamcharussrivichai, C. Potential of microalgal biodiesel: Challenges and applications. IntechOpen 2020, 9, 51–60. [Google Scholar] [CrossRef]

- Chew, B.; Shen, X.; Ansell, J.; Hamid, S.; Oh, Y. Review a decade of BP’s Technology roadmap on the next generation biofuels development. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012009. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, K.P.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Soriano, A.; Kostrinsky, S.; Gikonyo, B. Alfalfa Hay as Non-Human Feedstock for Second Generation Biofuels: Hope or Hoax? Part II; SUNY Geneseo: Geneseo, NY, USA, 2020; Available online: https://knightscholar.geneseo.edu/cgi/viewcontent.cgi?article=1027&context=great-day-symposium (accessed on 6 June 2020).

- Saini, S.; Chandel, A.K.; Sharma, K.K. Past practices and current trends in recovery and purification of first generation ethanol: A learning curve for lignocellulosic ethanol. J. Clean. Prod. 2020, 268, 122357. [Google Scholar] [CrossRef]

- Chen, W.H.; Chen, Y.C.; Lin, J.G. Evaluation of biobutanol production from non-pretreated rice straw hydrolysate under non-sterile environmental conditions. Bioresour. Technol. 2013, 135, 262–268. [Google Scholar] [CrossRef]

- Santos, F.; Eichler, P.; de Queiroz, J.H.; Gomes, F. Production of second-generation ethanol from sugarcane. In Sugarcane Biorefinery, Technology and Perspectives; Santos, F., Rabelo, S., De Matos, M., Eichler, P., Eds.; Elsevier: London, UK, 2020; pp. 195–228. [Google Scholar]

- Molinuevo-Salces, B.; Riaño, B.; Hernández, D.; García-González, M.C. Microalgae and wastewater treatment: Advantages and disadvantages. In Microalgae Biotechnology for Development of Biofuel and Wastewater Treatment; Alam, M.A., Wang, Z., Eds.; Springer: Cham, Switzerland, 2019; pp. 505–533. [Google Scholar]

- Voloshin, R.A.; Rodionova, M.V.; Zharmukhamedov, S.K.; Nejat Veziroglu, T.; Allakhverdiev, S.I. Review: Biofuel production from plant and algal biomass. Int. J. Hydrog. Energy 2016, 41, 17257–17273. [Google Scholar] [CrossRef]

- Bhan, C.; Verma, L.; Singh, J. Alternative fuels for sustainable development. In Environmental Concerns and Sustainable Development; Shukla, V., Kumar, N., Eds.; Springer: Singapore, 2020; pp. 317–331. [Google Scholar]

- Gupta, V. Catalyst in biorefineries: Solution to promote environment sustainability in India. In Advanced Catalysis Processes in Petrochemicals and Petroleum Refining: Emerging Research and Opportunities; Al-Kinany, M., Aldrees, S.A., Eds.; IGI Global: Hershey, PA, USA, 2020; pp. 139–171. [Google Scholar]

- Biodiesel Production and Consumption. Available online: https://knoema.com/atlas/topics/Energy/Renewables/Biodiesel-production (accessed on 26 June 2021).

- Dutta, K.; Daverey, A.; Lin, J.G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Abdullah, B.; Syed, M.; Syed, A.F.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P. Review of process parameters for biodiesel production from different feedstocks. Renew. Sustain. Energy Rev. 2016, 62, 1063–1071. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; Torrestiana-Sánchez, B.; Dal Magro, L.; Virgen-Ortíz, J.J.; Suárez-Ruíz, F.J.; Rodrigues, R.C.; Fernandez-Lafuente, R. Comparison of acid, basic and enzymatic catalysis on the production of biodiesel after RSM optimization. Renew. Energy 2019, 135, 1–9. [Google Scholar] [CrossRef]

- Baskar, G.; Aiswarya, R. Trends in catalytic production of biodiesel from various feedstocks. Renew. Sustain. Energy Rev. 2016, 57, 496–504. [Google Scholar] [CrossRef]

- Veljković, V.B.; Banković-Ilić, I.B.; Stamenković, O.S. Purification of crude biodiesel obtained by heterogeneously-catalyzed transesterification. Renew. Sustain. Energy Rev. 2015, 49, 500–516. [Google Scholar] [CrossRef]

- Musa, I.A. The effects of alcohol to oil molar ratios and the type of alcohol on biodiesel production using transesterification process. Egypt. J. Pet. 2016, 25, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Navas, M.B.; Lick, I.D.; Bolla, P.A.; Casella, M.L.; Ruggera, J.F. Transesterification of soybean and castor oil with methanol and butanol using heterogeneous basic catalysts to obtain biodiesel. Chem. Eng. Sci. 2018, 187, 444–454. [Google Scholar] [CrossRef] [Green Version]

- Avagyan, A.B.; Singh, B. Biodiesel from Plant Oil and Waste Cooking Oil. In Biodiesel: Feedstocks, Technologies, Economics and Barrier; Avagyan, A.B., Singh, B., Eds.; Springer: Cham, Switzerland, 2019; pp. 15–75. [Google Scholar]

- Borton, J.; Lopez, F.D.N.; Doan, L.; Holmes, W.E.; Benson, T.J. Conversion of high free fatty acid lipid feedstocks to biofuel using triazabicyclodecene catalyst (homogeneous and heterogeneous). Energy Fuels 2019. [Google Scholar] [CrossRef]

- Sandoval, G.; Casas-Godoy, L.; Bonet-Ragel, K.; Rodrigues, J.; Ferreira-Dias, S.; Valero, F. Enzyme-catalyzed production of biodiesel as alternative to chemical-catalyzed processes: Advantages and constraints. Curr. Biochem. Eng. 2017, 4, 109–141. [Google Scholar] [CrossRef]

- Yin, X.; Ma, H.; You, Q.; Wang, Z.; Chang, J. Comparison of four different enhancing methods for preparing biodiesel through transesterification of sunflower oil. Appl. Energy 2012, 91, 320–325. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Rashid, U.; Saiman, M.I.; Tan, Y.P.; Alsultan, G.A.; Taufiq-Yap, Y.H. Modified waste egg shell derived bifunctional catalyst for biodiesel production from high FFA waste cooking oil. a review. Renew. Sustain. Energy Rev. 2018, 82, 3645–3655. [Google Scholar] [CrossRef]

- Littlewood, J.; Murphy, R.J.; Wang, L. Importance of policy support and feedstock prices on economic feasibility of bioethanol production from wheat straw in the UK. Renew. Sustain. Energy Rev. 2013, 17, 291–300. [Google Scholar] [CrossRef]

- Gissén, C.T.; Prade, E.; Kreuger, I.A.; Nges, H.; Rosenqvist, S.; Svensson, S.-E.; Lantz, M.; Mattsson, J.E.; Börjesson, P.; Björnsson, L. Comparing energy crops for biogas production—Yields, energy input and costs in cultivation using digestate and mineral fertilisation. Biomass Bioenergy 2014, 64, 199–210. [Google Scholar] [CrossRef]

- Mohadesi, M.; Aghel, B.; Maleki, M.; Ansari, A. The use of KOH/Clinoptilolite catalyst in pilot of microreactor for biodiesel production from waste cooking oil. Fuel 2020, 263, 116659. [Google Scholar] [CrossRef]

- Naeem, A.; Wali Khan, I.; Farooq, M.; Mahmood, T.; Ud Din, I.; Ali Ghazi, Z.; Saeed, T. Kinetic and optimization study of sustainable biodiesel production from waste cooking oil using novel heterogeneous solid base catalyst. Bioresour. Technol. 2021, 328, 124831. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Palani, S.; Munir, M.; Saeed, M.; Thangavelu, L.; Mohanam, A.; Jambulingam, R. Engine characteristics study on beef tallow biodiesel produced by ethanol based co-solvent transesterification. Energy Source Part A 2020, 1–21. [Google Scholar] [CrossRef]

- Odetoye, T.E.; Agu, J.O.; Ajala, E.O. Biodiesel production from poultry wastes: Waste chicken fat and eggshell. J. Environ. Chem. Eng. 2021, 9, 105654. [Google Scholar] [CrossRef]

- He, C.; Mei, Y.; Zhang, Y.; Liu, L.; Li, P.; Zhang, Z.; Jing, Y.; Li, G.; Jiao, Y. Enhanced biodiesel production from diseased swine fat by ultrasound-assisted two-step catalyzed process. Bioresour. Technol. 2020, 304, 123017. [Google Scholar] [CrossRef]

- Karimi, S.; Karimi, K. Efficient ethanol production from kitchen and garden wastes and biogas from the residues. J. Clean. Prod. 2018, 187, 37–45. [Google Scholar] [CrossRef]

- Casabar, J.T.; Unpaprom, Y.; Ramaraj, R. Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers. Biorefinery 2019, 9, 761–765. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.; Chi, M.; Sun, Y.; Zhang, J.; Jiang, S.; Cui, Z. Effects of co-digestion of cucumber residues to corn stover and pig manure ratio on methane production in solid state anaerobic digestion. Bioresour. Technol. 2018, 250, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Shamurad, B.; Sallis, P.; Petropoulos, E.; Tabraiz, S.; Ospina, C.; Leary, P.; Dolfing, J.; Gray, N. Stable biogas production from single-stage anaerobic digestion of food waste. Appl. Energy 2020, 263, 114609. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Liu, X.; Xu, Q.; Yang, Q.; Li, X.; Zhang, Y.; Liu, Y.; Wang, Q.; Ni, B.-J.; et al. Heat pretreatment assists free ammonia to enhance hydrogen production from waste activated sludge. Bioresour. Technol. 2019, 283, 316–325. [Google Scholar] [CrossRef]

- Argun, H.; Dao, S. Bio-hydrogen production from waste peach pulp by dark fermentation: Effect of inoculum addition. Int. J. Hydrog. Energy 2017, 42, 2569–2574. [Google Scholar] [CrossRef]

- Hasan, A.; Dincer, I. Comparative assessment of various gasification fuels with waste tires for hydrogen production. Int. J. Hydrog. Energy 2019, 44, 18818–18826. [Google Scholar] [CrossRef]

- Subramanian, K.A. Biofueled Reciprocating Internal Combustion Engines; CRC Press: Boca Raton, FL, USA, 2017; p. 15. [Google Scholar]

- IEA. Key World Energy Statistics. 2018. Available online: https://webstore.iea.org/key-world-energy-statistics-2018 (accessed on 12 July 2020).

- TERM. Transport Indicators Tracking Progress towards Environmental Targets in Europe; No 7/2015; European Environment Agency: Copenhagen, Denmark, 2015; Available online: https://www.eea.europa.eu/publications/term-report-2015 (accessed on 12 July 2020).

- EIA—Energy Information Administration. International Energy Outlook. 2017. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 4 August 2020).

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef] [Green Version]

- IRENA. Global Energy Transformation: The REmap Transition Pathway (Background Report to 2019 Edition); International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; Available online: https://www.irena.org/publications/2019/Apr/Global-energy-transformation-The-REmap-transition-pathway (accessed on 4 August 2020).

- Gis, W. Electromobility and hydrogenization of the motor transport in Poland now and in the future. J. KONES 2018, 25, 95–101. [Google Scholar] [CrossRef]

- Green Car. 2014. Available online: https://www.greencarreports.com/news/1093560_1-2-billion-vehicles-on-worlds-roads-now-2-billion-by-2035-report (accessed on 4 August 2020).

- Lamb, J.J.; Austbø, B. Current Use of Bioenergy. In Hydrogen, Biomass and Bioenergy; Jacob, J., Pollet, B.G., Eds.; Academic Press: Trondheim, Norway; Elsevier: London, UK, 2020; pp. 9–20. [Google Scholar]

- Martins, J.; Brito, F. Alternative fuels for internal combustion engines. Energies 2020, 13, 4086. [Google Scholar] [CrossRef]

- Lisý, M.; Lisá, H.; Jecha, D.; Baláš, M.; Križan, P. Characteristic properties of alternative biomass fuels. Energies 2020, 13, 1448. [Google Scholar] [CrossRef] [Green Version]

- Aladejare, A.E.; Onifade, M.; Lawal, A.I. Application of metaheuristic based artificial neural network and multilinear regression for the prediction of higher heating values of fuels. Int. J. Coal Prep. Util. 2020, 1–22. [Google Scholar] [CrossRef]

- Noushabadi, A.S.; Dashti, A.; Raji, M.; Zarei, A.; Mohammadi, A.H. Estimation of cetane numbers of biodiesel and diesel oils using regression and PSO-ANFIS models. Renew. Energy 2020, 4, 146. [Google Scholar] [CrossRef]

- Huang, Y.; Li, F.; Bao, G.; Wang, W.; Wang, H. Estimation of kinematic viscosity of biodiesel fuels from fatty acid methyl ester composition and temperature. J. Chem. Eng. Data 2020, 65, 2476–2485. [Google Scholar] [CrossRef]

- SAE International Hybrid-EV Committee. J2841: Utility Factor Definitions for Plug-In Hybrid Electric Vehicles Using Travel Survey Data; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Arat, H.T.; Baltacioglu, M.K.; Özcanli, M.; Aydin, K. Effect of using Hydroxy–CNG fuel mixtures in a non-modified diesel engine by substitution of diesel fuel. Int. J. Hydrog. Energy 2016, 41, 8354–8363. [Google Scholar] [CrossRef]

- McCormick, R.L.; Fioroni, G.; Fouts, L.; Christensen, E.; Yanowitz, J.; Polikarpov, E.; Albrecht, K.; Gaspar, D.; Gladden, J.; George, A. Selection criteria and screening of potential biomass-derived streams as fuel blendstocks for advanced spark-ignition engines. SAE Int. J. Fuels Lubr. 2017, 10, 442–460. [Google Scholar] [CrossRef]

- Mustafa, A.; Lougou, B.G.; Shuai, Y.; Wang, Z.; Tan, H. Current technology development for CO2 utilization into solar fuels and chemicals: A review. J. Energy Chem. 2020, 49, 96–123. [Google Scholar] [CrossRef]

- Chintala, V. Production, upgradation and utilization of solar assisted pyrolysis fuels from biomass–a technical review. Renew. Sustain. Energy Rev. 2018, 90, 120–130. [Google Scholar] [CrossRef]

- Jiao, Y.; Liu, R.; Zhang, Z.; Yang, C.; Zhou, G.; Dong, S.; Liu, W. Comparison of combustion and emission characteristics of a diesel engine fueled with diesel and methanol-Fischer-Tropsch diesel-biodiesel-diesel blends at various altitudes. Fuel 2019, 243, 52–59. [Google Scholar] [CrossRef]

- Bongartz, D.; Doré, L.; Eichler, K.; Grube, T.; Heuser, B.; Hombach, L.E.; Robinius, M.; Pischinger, S.; Stolten, D.; Walther, G.; et al. Comparison of light-duty transportation fuels produced from renewable hydrogen and green carbon dioxide. Appl. Energy 2018, 231, 757–767. [Google Scholar] [CrossRef]

- Bae, C.J.; Kim, J. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Ileleji, K.E.; Martin, C.; Jones, D. Basics of energy production through anaerobic digestion of livestock manure. In Bioenergy; Dahiya, A., Ed.; Academic Press: Boston, MA, USA, 2015; pp. 287–295. [Google Scholar]

- Dykstra, C.M.; Pavlostathis, S.G. Bioelectrochemical Enhancement and Intensification of Methane Production from Anaerobic Digestion. In Microbial Electrochemical Technologies; Tiquia-Arashiro, S.M., Pan, D., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 260–275. [Google Scholar]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.k. The anaerobic digestion process of biogas production from food waste: Prospects and constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Dupnock, T.L. Development of a High Performance, Biological Trickling Filter to Upgrade Raw Biogas to Renewable Natural Gas Standards. Master’s Thesis, Duke University, Durham, NC, USA, 2019. [Google Scholar]

- Bora, D.; Barbora, L.; Borah, A.J.; Mahanta, P. A Comparative Assessment of Biogas Upgradation Techniques and Its Utilization as an Alternative Fuel in Internal Combustion Engines. In Alternative Fuels and Advanced Combustion Techniques as Sustainable Solutions for Internal Combustion Engines. Energy, Environment, and Sustainability; Singh, A.P., Kumar, D., Agarwal, A.K., Eds.; Springer: Singapore, 2021; pp. 95–115. [Google Scholar]

- Baena-Moreno, F.M.; Rodríguez-Galán, M.; Vega, F.; Vilches, L.F.; Navarrete, B. Recent advances in biogas purifying technologies. Int. J. Green Energy 2019, 16, 401–412. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; le Saché, E.; Pastor-Pérez, L.; Reina, T. Biogas as a renewable energy source: Focusing on principles and recent advances of membrane-based technologies for biogas upgrading. In Membranes for Environmental Applications; Zhang, Z., Zhang, W., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2020; pp. 95–120. [Google Scholar]

- Saboor, A.; Khan, S.; Ali Shah, A.; Hasan, F.; Khan, H.; Badshah, M. Enhancement of biomethane production from cattle manure with codigestion of dilute acid pretreated lignocellulosic biomass. Int. J. Hydrog. Energy 2017, 14, 632–637. [Google Scholar] [CrossRef]

- Musthafa, M. Production of biogas from multiple feedstocks and its application as a fuel for spark ignition engines-a review. Eur. J. Sustain. Dev. Res. 2020, 4, 35–43. [Google Scholar] [CrossRef] [Green Version]

- IRENA. Biogas for Road Vehicles: Technology Brief; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2017/Mar/IRENA_Biogas_for_Road_Vehicles_2017.pdf (accessed on 12 August 2020).

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [Green Version]

- Stepanenko, D.; Kneba, Z. DME as alternative fuel for compression ignition engines-a review. Combust. Eng. 2019, 177, 172–179. [Google Scholar] [CrossRef]

- Inayat, A.; Ghenai, C.; Naqvi, M.; Ammar, M.; Ayoub, M.; Hussin, M.N.B. Parametric Study for Production of Dimethyl Ether (DME) As a Fuel from Palm Wastes. Energy Procedia 2017, 105, 1242–1249. [Google Scholar] [CrossRef]

- Evans, C.; Smith, C. Biomass to Liquids Technology. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; Volume 5, pp. 155–204. [Google Scholar]

- Zang, G.; Sun, P.; Elgowainy, A.A.; Bafana, A.; Wang, M. Performance and cost analysis of liquid fuel production from H2 and CO2 based on the Fischer-Tropsch process. J. CO2 Util. 2021, 46, 101459. [Google Scholar] [CrossRef]

- IRENA. Hydrogen: A Renewable Energy Perspective; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Hydrogen_2019.pdf (accessed on 5 June 2021).

- Qureshy, A.M.M.I.; Dincer, I. A new integrated renewable energy system for clean electricity and hydrogen fuel production. Int. J. Hydrog. Energy 2020, 45, 20944–20955. [Google Scholar] [CrossRef]

- Karagöz, Y.; Balcı, Ö.; Köten, H. Investigation of hydrogen usage on combustion characteristics and emissions of a spark ignition engine. Int. J. Hydrog. Energy 2019, 44, 14243–14256. [Google Scholar] [CrossRef]

- Ortiz-Imedio, R.; Ortiz, A.; Urroz, J.C.; Diéguez, P.M.; Gorri, D.; Gandía, L.M.; Ortiz, I. Comparative performance of coke oven gas, hydrogen and methane in a spark ignition engine. Int. J. Hydrog. Energy 2021, 46, 17572–17586. [Google Scholar] [CrossRef]

- Akhlaghi, N.; Najafpour-Darzi, G. A comprehensive review on biological hydrogen production. Int. J. Hydrog. Energy 2020, 45, 22492–22512. [Google Scholar] [CrossRef]

- Sharma, S.; Ghoshal, S.K. Hydrogen the future transportation fuel: From production to applications. Renew. Sustain. Energy Rev. 2015, 43, 1151–1158. [Google Scholar] [CrossRef]

- Afanasiev, A.; Pavlov, D.; Epishkin, V.; Gapchenko, U. Application of hydrogen and hydrogen-containing gases in internal combustion engines. IOP Conf. Ser. Mater. Sci. Eng. 2020, 734, 012198. [Google Scholar] [CrossRef]

- Asoyan, A.R.; Danilov, I.K.; Asoyan, I.A.; Polishchuk, G.M. Hydrogen application in internal combustion engines. RUDN J. Eng. Res. 2020, 21, 14–19. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vladut, V.; Biris, S.S. Capitalization of wastewater-grown algae in bioethanol production. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 20–22 May 2020; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2020; pp. 20–22. [Google Scholar] [CrossRef]

- Loupatty, V.; Radiena, M. Properties Activity of Yeast Against Seaweed Bioethanol Fermentation Time and Its Functional Group. J. Phys. 2020, 1463, 012018. [Google Scholar] [CrossRef]

- Salvi, B.L.; Subramanian, K.A. Experimental investigation on effects of compression ratio and exhaust gas recirculation on backfire, performance and emission characteristics in a hydrogen fuelled spark ignition engine. Int. J. Hydrog. Energy 2016, 41, 5842–5855. [Google Scholar] [CrossRef]

- Ceviz, M.A.; Sen, A.K.; Küleri, A.K.; Öner, I.V. Engine performance, exhaust emissions, and cyclic variations in a lean-burn SI engine fueled by gasoline–hydrogen blends. Appl. Therm Eng. 2012, 36, 314–324. [Google Scholar] [CrossRef]

- Duan, X.; Li, Y.; Liu, J.; Guo, G.; Fu, J.; Zhang, Q.; Zhang, S.; Liu, W. Experimental study the effects of various compression ratios and spark timing on performance and emission of a lean-burn heavy-duty spark ignition engine fueled with methane gas and hydrogen blends. Energy 2019, 169, 558–571. [Google Scholar] [CrossRef]

- Krishnaiah, R.; Kumar, S.; Devunuri, S.; Alexander, J.; Nimmakayala, M.R.; Vora, K.; Wu, Z.; Sumathy, S. Experimental investigations on lean burn spark ignition engine using methanol-gasoline blends. SAE Tech. Pap. 2019, 9. [Google Scholar] [CrossRef]

- Gu, X.; Huang, Z.; Cai, J.; Gong, J.; Wu, X.; Lee, C.F. Emission characteristics of a spark-ignition engine fuelled with gasoline-n-butanol blends in combination with EGR. Fuel 2012, 93, 611–617. [Google Scholar] [CrossRef]

- Turner, D.; Xu, H.; Cracknell, R.F.; Natarajan, V.; Chen, X. Combustion performance of bio-ethanol at various blend ratios in a gasoline direct injection engine. Fuel 2011, 90, 1999–2006. [Google Scholar] [CrossRef]

- Broustail, G.; Halter, F.; Seers, P.; Moréac, G.; Mounaim-Rousselle, C. Comparison of regulated and non-regulated pollutants with iso-octane/butanol and iso-octane/ethanol blends in a port-fuel injection spark-ignition engine. Fuel 2012, 94, 251–261. [Google Scholar] [CrossRef]

- Rosdi, S.; Mamat, R.; Alias, A.; Hamzah, H.; Sudhakar, K.; Hagos, F. Performance and emission of turbocharger engine using gasoline and ethanol blends. IOP Conf. Ser. Mater. Sci. Eng. 2020, 863, 012034. [Google Scholar] [CrossRef]

- Badrawada, I.; Susastriawan, A. Influence of ethanol–gasoline blend on performance and emission of four-stroke spark ignition motorcycle. Clean. Technol. Environ. Policy 2019, 21, 1891–1896. [Google Scholar] [CrossRef]

- Sakthivel, P.; Subramanian, K.A.; Mathai, R. Comparative studies on combustion, performance and emission characteristics of a two-wheeler with gasoline and 30% ethanol-gasoline blend using chassis dynamometer. Appl. Eng. 2019, 146, 726–737. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K. Comparative assessment of a spark ignition engine fueled with gasoline and raw biogas. Renew. Energy 2019, 134, 1307–1319. [Google Scholar] [CrossRef]

- de Faria, M.M.N.; Bueno, J.P.V.M.; Ayad, S.M.E.; Belchior, C.R.P. Thermodynamic simulation model for predicting the performance of spark ignition engines using biogas as fuel. Energy Convers. Manag. 2017, 149, 1096–1108. [Google Scholar] [CrossRef]

- Kim, Y.; Kawahara, N.; Tsuboi, K.; Tomita, E. Combustion characteristics and NOX emissions of biogas fuels with various CO2 contents in a micro co-generation spark-ignition engine. Appl. Energy 2016, 182, 539–547. [Google Scholar] [CrossRef]

- Muhajir, K.; Badrawada, I.; Susastriawan, A. Utilization of biogas for generator set fuel: Performance and emission characteristics. Biomass Convers. Biorefinery 2019, 9, 695–698. [Google Scholar] [CrossRef]

- Kan, X.; Zhou, D.; Yang, W.; Zhai, X.; Wang, C.H. An investigation on utilization of biogas and syngas produced from biomass waste in premixed spark ignition engine. Appl. Energy 2018, 212, 210–222. [Google Scholar] [CrossRef]

- Chandran, D. Compatibility of diesel engine materials with biodiesel fuel. Renew. Energy 2020, 147, 89–99. [Google Scholar] [CrossRef]

- Méndez, C.I.; Ancheyta, J. Kinetic models for Fischer-Tropsch synthesis for the production of clean fuels. Catal. Today 2020, 335, 3–16. [Google Scholar] [CrossRef]

- Dimethyl Ether (DME) Market. Available online: https://www.globenewswire.com/news-release/2018/09/09/1568236/0/en/Global-Dimethyl-Ether-Market-Will-Reach-USD-9-100-Million-By-2024-Zion-Market-Research.html (accessed on 31 July 2020).

- Farsi, M.; Fekri Lari, M.; Rahimpour, M.R. Development of a green process for DME production based on the methane tri-reforming. J. Taiwan Inst. Chem. Eng. 2020, 106, 9–19. [Google Scholar] [CrossRef]

- Mondal, U.; Yadav, G.D. Perspective of dimethyl ether as fuel: Part I. Catalysis. J. CO2 Util. 2019, 32, 299–320. [Google Scholar] [CrossRef]

- Simsek, S. Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel 2020, 265, 117026. [Google Scholar] [CrossRef]

- Hirner, F.S.; Hwang, J.; Bae, C.; Patel, C.; Gupta, T.; Agarwal, A.K. Performance and emission evaluation of a small-bore biodiesel compression-ignition engine. Energy 2019, 183, 971–982. [Google Scholar] [CrossRef]

- Rosha, P.; Mohapatra, S.K.; Mahla, S.K.; Cho, H.; Chauhan, B.S.; Dhir, A. Effect of compression ratio on combustion, performance, and emission characteristics of compression ignition engine fueled with palm (B20) biodiesel blend. Energy 2019, 178, 676–684. [Google Scholar] [CrossRef]

- Srikanth, H.; Venkatesh, J.; Godiganur, S.; Manne, B.; Bharath Kumar, S.; Spurthy, S. Combustion, performance, and emission characteristics of dairy-washed milk scum biodiesel in a dual cylinder compression ignition engine. Energy Source Part A 2019, 42, 1–18. [Google Scholar] [CrossRef]

- Nirmala, N.; Dawn, S.S.; Harindra, C. Analysis of performance and emission characteristics of waste cooking oil and Chlorella variabilis MK039712.1 biodiesel blends in a single cylinder, four strokes diesel engine. Renew. Energy 2020, 147, 284–292. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Combustion performance and emission reduction characteristics of automotive DME engine system. Prog. Energy Combust. Sci. 2013, 39, 147–168. [Google Scholar] [CrossRef]

- Yang, S.; Lee, C. Exhaust gas characteristics according to the injection conditions in diesel and DME engines. Appl. Sci. 2019, 9, 647. [Google Scholar] [CrossRef] [Green Version]

- Raza, M.; Chen, L.; Ruiz, R.; Chu, H. Influence of pentanol and dimethyl ether blending with diesel on the combustion performance and emission characteristics in a compression ignition engine under low temperature combustion mode. J. Energy Inst. 2019, 92, 1658–1669. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Zhang, J.; Wang, J.; Shuai, S. Study on combustion and emission characteristics of Polyoxymethylene Dimethyl Ethers/diesel blends in light-duty and heavy-duty diesel engines. Appl. Energy 2017, 185, 1393–1402. [Google Scholar] [CrossRef]

- Yongcheng, H.; Longbao, Z.; Shangxue, W.; Shenghua, L. Study on the performance and emissions of a compression ignition engine fuelled with Fischer-Tropsch diesel fuel. Proc. Inst. Mech. Eng. Part D 2006, 220, 827–835. [Google Scholar] [CrossRef]

- Alotri, B. Comprehensive Cost Assessment of Present and Future Energy Conversion Technologies. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2020. Available online: http://dspace.library.uu.nl/handle/1874/397259 (accessed on 21 August 2020).

- Ramasamy, S.; Arun, S.; Pakshirajan, K. An overview of algal photobioreactors for resource recovery from waste. In Bioreactors; Singh, L., Yousuf, A., Mahapatra, D.M., Eds.; Elsevier: London, UK, 2020; pp. 215–248. [Google Scholar]

- Gani, P.; Sunar, N.M.; Matias-Peralta, H.M. Cultivation system and harvesting techniques in Microalgae Biomass production. Quantum J. Eng. Sci. Technol. 2020, 1, 33–44. [Google Scholar]

- Reynoso, A.; Iriarte-Velasco, U.; Gutiérrez-Ortiz, M.; Ayastuy, J. Highly stable Pt/CoAl2O4 catalysts in aqueous-phase reforming of glycerol. Catal. Today 2020, 367, 278–289. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Gruber, H.; Weber, G.; Reichhold, A.; Pirone, R.; Bensaid, S. Aqueous phase reforming of pilot-scale Fischer-Tropsch water effluent for sustainable hydrogen production. Catal. Today 2020, 367, 239–247. [Google Scholar] [CrossRef]

- Bullis, K. Amyris Announces Commercial Production of Biochemicals. MIT Technology Review, 29 April 2011. Available online: https://www.technologyreview.com/2011/04/29/195019/amyris-announces-commercial-production-of-biochemicals/ (accessed on 21 August 2020).

- Ballesteros, M.; Manzanares, P. Liquid Biofuels. In The Role of Bioenergy in the Bioeconomy; Lago, C., Caldés, N., Lechón, Y., Eds.; Academic Press: Madrid, Spain; Elsevier: London, UK, 2019; pp. 113–144. [Google Scholar]

- Malode, S.J.; Prabhu, K.K.; Mascarenhas, R.J.; Shetti, N.P.; Aminabhavi, T.M. Recent advances and viability in biofuel production. Energy Convers. Manag. 2021, 10, 100070. [Google Scholar] [CrossRef]

- Adegboye, M.F.; Ojuederie, O.B.; Talia, P.M.; Babalola, O.O. Bioprospecting of microbial strains for biofuel production: Metabolic engineering, applications, and challenges. Biotechnol. Biofuels 2021, 14, 5. [Google Scholar] [CrossRef]

- Lin, C.Y.; Lu, C. Development perspectives of promising lignocellulose feedstocks for production of advanced generation biofuels: A review. Renew. Sustain. Energy Rev. 2021, 136, 110445. [Google Scholar] [CrossRef]

| Lignocellulosic Biomass | Solid Waste | ||

|---|---|---|---|

| Agricultural Residues | Forest Residues | Energy Crops | |

| Rice straw Rice husk Wheat straw Sorghum straw Corn stover Sugarcane bagasse Sugarcane peel Barley straw Olive pulp Grapeseed | Firewoods Wood chips Wood branches Sawdust Fruit bunch Willow chips Black locust Pine Spruce Eucalyptus Softwood Hardwood Hybrid poplar | Switchgrass Miscanthus Energy cane grass Hybrid Pennisetum Triarrhena lutarioriparia Energy cane leaf Energy cane stem Grass leaf Grass stem | Municipal solid waste Processed paper Plastics Wastewater sludge Food waste Dried animal manure Poultry waste |

| The Classifications | Description | Ref. | |

|---|---|---|---|

| Feedstocks | Examples | ||

| 2 GB | Bioethanol, biodiesel, biogas | [96,97] | |

| 2 GB | Vegetable oil, animal fats | ||

| 1 GB | Edible food crops | NA | [98,99,100,114,115,116] |

| 2 GB | Inedible feedstocks | ||

| 3 GB | Cultivated feedstocks | ||

| Primary biofuels | Grass, wood, wood chips | NA | [101,102] |

| Secondary biofuels | |||

| 1 GB | Grains, sugar | ||

| 2 GB | Lignocellulosic biomass | ||

| 3 GB | Algae, microbes | ||

| Primary biofuels | Firewood, animal waste, landfill gas | NA | [103,104,105] |

| 1 GB | Edible feedstock | ||

| 2 GB | Lignocellulosic feedstock | ||

| 3 GB | Algae feedstock | ||

| Conventional biofuels (1 GB) | High-sugar-content crops, high-oleic plants, animal fats | Ethanol, biodiesel | [106,107] |

| Cellulosic ethanol (2 GB) | Energy crops, forest/park residues, seed pods, leaves, stems, corn stovers | Bioethanol, isopropanol, butanol, isobutanol, farnesol | |

| Algae biofuel (3 GB) | Algae | Biodiesel | |

| Next generation biofuel (4 GB) | Genetically and metabolically engineered algae | Biosyngas | |

| 1 GB | Food crops | NA | [108] |

| 1.5 GB | Non-food crops, oil-bearing crops | ||

| 2 GB | Agricultural and forest residues, waste cooking oil | ||

| 3 GB | Algae | ||

| 1 GB | Animal waste, vegetable oil | Bioalcohols, vegetable oil, biodiesel, biomethanol, biosyngas, biogas | [109,110,111,112,113,117] |

| 2 GB | NA | Bioalcohols, bio-oil, bioDMF, bioFT, biodiesel, biohydrogen, biomethanol | |

| 3 GB | Algal biomass, waste vegetable oil | Vegetable oil biodiesel, bioethanol, bioethanol, biomethanol, jet fuels | |

| 4 GB | Green biodiesel, biogasoline, green aviation fuels | ||

| Primary biofuel | Grass, wood, wood chips, wood dust, rice mill dust | Wood chips, sawdust, firewood, animal waste, forest and crop residues, landfill gas | The authors |

| 1 GB | Animal waste, edible oil, fats, and oil | Bioalcohols, vegetable oil, biodiesel, biomethanol, biosyngas, biogas | |

| 2 GB | Wood and woody products, waste fats, waste cooking oil, energy crops | Bioalcohols, biooil, biodimethylfuran, bioFT, biodiesel, biohydrogen, biomethanol | |

| 3 GB | Algae, high-sugar content crops, high oleic plants, animal fats | Vegetable oil biodiesel, bioethanol, bioethanol, biomethanol, jet fuels | |

| 4 GB | Waste cooking oil, algal biomass | Hydrogenated renewable diesel, biogasoline, green aviation fuel, vegetable oil, biodiesel | |

| Production Techniques | Advantages | Disadvantages |

|---|---|---|

| Pyrolysis |

|

|

| Micro-emulsion |

|

|

| Dilution |

|

|

| Transesterification |

|

|

| Superfluid methods |

|

|

| Biodiesel Production (Thousand Barrels per Day) | Biodiesel Consumption (Thousand Barrels per Day) | ||

|---|---|---|---|

| Countries | Volume | Countries | Volume |

| Indonesia | 137.86 | US | 118.25 |

| US | 112.49 | Indonesia | 106.84 |

| Brazil | 99.95 | Brazil | 99.84 |

| Germany | 62.29 | Thailand | 30.02 |

| Argentina | 43.08 | China | 22.4 |

| Generation of Biodiesel | Feedstock | Processing Technique | Benefits | Problems |

|---|---|---|---|---|

| First | Palm oil, sunflower oil, soybean oil, corn oil, canola oil | Esterification and transesterification of oils, purification |

|

|

| Second | Non-edible oil, waste cooking oil, waste and recovered animal fats | Pre-treatment of feedstock, esterification and transesterification of feedstock, purification |

|

|

| Third | Microalgae, Macroalgae | Algae cultivation, harvesting, oil extraction, transesterification |

|

|

| Fourth | Microalgae, Microbes | Metabolic engineering of algae, cultivation, harvesting, transesterification |

|

|

| Type of Catalyst | Example | Pros | Cons |

|---|---|---|---|

| Homogeneous | NaOH, KOH, CH3ONa, H2SO4 |

|

|

| Heterogeneous | CaO, Mg/Zr, Mg-Al hydrotalcite, ZnO/KF, ZnO/Ba, Na/BaO, K2CO3-supported MgO, Al2O3/ZrO2/WO3, Al2O3/KNO3, solid vanadium phosphate, Fe-Zn double metal cyanide complex |

|

|

| Bio-based (enzyme) | Lipase, Candida antaractia |

|

|

| Feedstock | Process | Product | Reasons for the Adoption | Remarks | Ref. |

|---|---|---|---|---|---|

| WCO | Transesterification | Biodiesel |

|

| [21] |

| WCO | Transesterification | Biodiesel |

|

| [162] |

| WCO | Transesterification | Biodiesel |

|

| [163] |

| Waste soybean oil | Transesterification | Biodiesel |

|

| [164] |

| Waste beef tallow | Transesterification | Biodiesel |

|

| [164] |

| Waste chicken fat | Transesterification | Biodiesel |

|

| [165] |

| Swine fat | Transesterification | Biodiesel |

|

| [166] |

| Kitchen and garden waste | Fermentation | Ethanol |

|

| [167] |

| Kitchen and garden waste residue | Anaerobic digestion | Biogas |

|

| [167] |

| Pineapple fruit peel waste | Fermentation | Bioethanol |

|

| [168] |

| Cucumber residue | Anaerobic digestion | Methane |

|

| [169] |

| Food waste | Anaerobic digestion | Methane |

|

| [170] |

| Waste activated sludge | Fermentation | Hydrogen |

|

| [171] |

| Waste peach pulp | Fermentation | Biohydrogen |

|

| [172] |

| Waste tires | Gasification | Hydrogen |

|

| [173] |

| Fuel | Stored Energy (MJ) |

|---|---|

| Diesel | 36 |

| Gasoline | 33 |

| Biodiesel | 33 |

| Methanol | 16 |

| Ethanol | 21 |

| Liquid H2 (at −253 °C) | 8.5 |

| Compressed H2 (at 250 bar) | 2.5 |

| Steps and pH | Process | Reaction Equations | Microorganisms |

|---|---|---|---|

| Step 1: Hydrolysis pH = 5.5–6.0 | Breakdown of large organic polymers (carbohydrates, fats, and proteins) in biomass into smaller molecules (amino acids, fatty acids, and simple sugars) to produce hydrogen and acetate | Clostridium, Proteus, Vibrio, Bacillus, Peptococcus, Bacteroides, Staphylococcus | |

| Step 2: Acidogenesis pH = 6.0–7.0 | Acidogenic microorganisms further break down the organic matter in the biomass into smaller molecules to generate an acidic environment. The fermentative bacteria generate NH3, H2, CO2, H2S, shorter volatile fatty acids, carbonic acids, alcohols, and other byproducts | Lactobacillus, Escherichia, Bacillus, Staphylococcus, Pseudomonas, Sarcina, Desulfovibro, Selenomonas, Streptococcus, Veollonella Desulfobacter, Deslforomonas, Clostridium, Eubacterium | |

| Step 3: Acetogenesis pH = 6.0–7.0 | Acetogens catabolize the products of acidogenesis into acetic acid, CO2, and H2, which are later converted to methane (CH4) by methanogens | Clostridium, Syntrophomonas | |

| Step 4: Methanogenesis pH = 6.5–7.5 | Methanogens generate CH4 and other byproducts from acetic acid created during acetogenesis via two routes | Methanobacterium, Methanobrevibacter, Methanoplanus, Methanospirillum |

| Biofuel Used | Engine Details | Effect | Ref. | |

|---|---|---|---|---|

| Performance | Emission | |||

| Hydrogen | 1C, 4S, NA, air-cooled, r = 8.5 |

|

| [213] |

| Hydrogen | 1C, 4S, N = 3600 rpm generator set |

|

| [221] |

| Hydrogen | 4C, water-cooled, r = 10 |

|

| [222] |

| Hydrogen | 6C, 4S in line, turbocharged, intercooler |

|

| [223] |

| Methanol | 1C, 4S, air-cooled, N = 1500 rpm, r = 10.5 |

|

| [224] |

| n-Butanol | 3C, port fuel injection, N = 3000 rpm | NA |

| [225] |

| Ethanol | 1C, N = 1500 rpm, IMEP = 3.4 bar, ST = 24° bTDC, Vs = 565.6cc | NA |

| [226] |

| Ethanol | 1C, N = 1500 rpm, IMEP = 5 bar, r = 9.5, Vs = 499 cc | NA |

| [227] |

| Butanol | 1C, N = 1500 rpm, IMEP = 5 bar, r = 9.5, Vs = 499 cc | NA |

| [227] |

| Ethanol | 4C, 4S, turbocharged, r = 9.5 |

|

| [228] |

| Ethanol | 1C, 4S, r = 9.2 |

|

| [229] |

| Ethanol | 1C, air-cooled, r = 9.35 |

|

| [230] |

| Biogas | 1C, N = 1450 to 1700 rpm |

|

| [231] |

| Biogas | 1C, constant speed |

|

| [232] |

| Biogas | 3C, 4S, r = 12, Vs = 1642 cc |

|

| [233] |

| Biogas | Generator set TL3000 |

|

| [234] |

| Biogas | 4C, 4S, NA, N = 1500 rpm |

|

| [235] |

| Biofuel Used | Engine Details | Effects | Ref. | |

|---|---|---|---|---|

| Performance | Emissions | |||

| Biodiesel | 1C, 4S, NA, DI, air-cooled |

|

| [241] |

| Biodiesel | 1C, common-rail DI, r = 16 |

|

| [242] |

| Biodiesel | 1C, 4S, DI, VCR, water-cooled |

|

| [243] |

| Biodiesel | 2C, water-cooled, r = 17.5, N = 1500 rpm |

|

| [244] |

| Biodiesel | 1C, 4S, constant speed, water-cooled |

|

| [245] |

| DME | 1S, common-rail injection |

|

| [246] |

| DME | 1S, 4S, DI, water-cooled, r = 18, N = 2200 rpm | NA |

| [247] |

| DME | 4C, NA, in-line, common rail, r = 18.5 |

|

| [248] |

| DME | 1S, common rail, r = 16.7 |

|

| [249] |

| F-T | 1S, 4S, NA, DI, water-cooled, r = 18 |

|

| [250] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awogbemi, O.; Kallon, D.V.V.; Onuh, E.I.; Aigbodion, V.S. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies 2021, 14, 5687. https://doi.org/10.3390/en14185687

Awogbemi O, Kallon DVV, Onuh EI, Aigbodion VS. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies. 2021; 14(18):5687. https://doi.org/10.3390/en14185687

Chicago/Turabian StyleAwogbemi, Omojola, Daramy Vandi Von Kallon, Emmanuel Idoko Onuh, and Victor Sunday Aigbodion. 2021. "An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications" Energies 14, no. 18: 5687. https://doi.org/10.3390/en14185687

APA StyleAwogbemi, O., Kallon, D. V. V., Onuh, E. I., & Aigbodion, V. S. (2021). An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies, 14(18), 5687. https://doi.org/10.3390/en14185687