1. Introduction

Electric control of combustion may optimize energy efficiency, emission control, and fuel flexibility. The hydrocarbon combustion flame contains a large number of ions and electrons with a number density of 10

9–10

12/cm

3 due to chemi-ionization in the reaction zone, which, in turn, affects the combustion behavior. Hence, by the application of the electric field, the flame combustion dynamics including combustion stability, combustion efficiency, and exhaust emissions can be modified. The dominant ions in the flame of hydrocarbon fuels are cations such as CHO

+, C

3H

3+, and C

2H

3O

+. The concentration of electrons or negative ions such as O

2− and OH

− depends on the mixing ratio with air. [

1,

2,

3,

4].

During the combustion process, nitrogen (N

2) in a high-temperature zone of a flame flow tends to react with oxygen (O

2) forming NO and NO

2. In general, NO

x can be formed in three ways. Firstly, thermal NO

x is formed during the combustion of gases and fuels (oils) at a high temperature in a flame, when dissociated oxygen reacts with atmospheric nitrogen [

5,

6]. Secondly, NO

x is generated by the reaction between hydrocarbon radicals and nitrogen contained in the fuel. Lastly, prompt NO

x is produced rapidly when fuel is exposed to a higher temperature than 1000 ℃ in a high concentration state of fuel before it is completely mixed with air. Clean combustion control techniques include methods of low excess air firing, combustion of low nitrogen fuel oil, different modifications of burner construction, etc. The simplest method of reducing NO

x is to use a water injection into the combustion zone of a flame and H

2O

2 injection into a hot flue gas stream [

7].

The factor that greatly influences NO

x production is the length of the flame. In the case of burning the same amount of fuel, the instability of the flame increases as the length of the flame increases, which affects the soot and NO

x generation [

8,

9,

10,

11]. The longer the flame length is, the longer the survival time of the flame will be. The longer the flame survival time is, the longer the reaction time with nitrogen in the air will be; therefore, the probability of generating thermal NO

x increases.

This concept of combustion through using the electric fields is a promising technique in achieving clean combustion through a reduction of emissions such as NO

x and other pollutants from combustion. Electric field effects depend on the electric field configuration and polarity, while it can be regulated by varying high voltage DC/AC power supply. Through electrically controlled combustion, a variation of flame temperature can be achieved, affecting the mass fraction distribution in the flame by improving the fuel mixing with oxygen and can cause the change in flame dynamics [

12,

13,

14,

15,

16]. In addition, the ionic wind effect present in the combustion process by application of an electric field improves flame efficiency. Therefore, the electric field effect shows a very promising effect to improve the combustion stability and efficiency of the flame [

17,

18]. Equation (1) gives the general relation between the diffusion coefficient and the length of the flame [

8,

9,

19], where

H is the length of the flame,

T0 is the ambient temperature,

Tf is the flame temperature,

s is the air-fuel ratio,

Q is the volumetric flow rate of fuel, and

D is the diffusion coefficient; that is, as the diffusion coefficient increases, the length of the flame becomes shorter.

The change in the diffusion coefficient of gaseous ions due to the electric field can be inferred from the Einstein relation (Equation (2)).

In the equations above,

e is the charge number of ion,

kB is the Boltzmann constant,

T is the absolute temperature,

N is the number density,

μ is the mobility of the ion (m

2/sV), and

E is the electric field strength (V/m). Equation (3) is the diffusion coefficient in the direction parallel to the electric field, and Equation (4) is the diffusion coefficient in the direction perpendicular to the electric field. The energy increases, as shown in Equations (5) and (6) below, due to collisions among ions and molecules and an increase in flow velocity due to the electric field [

20,

21].

where

m is the mass of the ion,

M is the mass of the molecule, and

A* is the collision rate between the ion and the molecule; that is, the diffusion coefficient increases in proportion to the kinetic energy of moving molecules due to collision with ions.

A study on the change in diffusion flame characteristics in an electric field has been conducted until recently; Kim [

22] and Chien [

23] studied both the shape of the flame and the effect on heat transfer. Additionally, Farraj [

24] and Pu [

25] successfully simulated the shape change of the flame by applying the body force term of the ionic wind to the momentum equation.

The interaction between the electric field and the flame also worked in the premixed flame. Li [

26] and Fang [

27] investigated the effect of electric field on methane-air mixture premix flame experimentally. The deformation process of the spherically expanding premixed flame was observed, and the application of an electric field commonly promotes flame propagation and increases the heat release rate.

This article focused on studying the behavior of propane-air diffusion flame when subjected to DC electric field over the voltage range of −5 to +5 kV. In particular, efforts were made to investigate the flame dynamics when different applied voltage and polarity were applied at different fuel-air flow rates. Based on previous research, this study aimed to understand and investigate the application of DC voltage and polarity through a radial electrode, generating an electric field in the same or opposite direction of the flame flow, on propane diffusion flame dynamics in terms of flame shape, lowest hot region of flame, flame reaction zone width, flame hot temperature region, and finally, the NOx generation.

The difference from the previous studies about the interaction between e-field and flame is that in this study, a ring-type electrode was used so that it made e-field concentrate on the diffusion flame’s reaction zone. Additionally, based on this difference, correlations were derived between the changes in flame length by e-field and EINOx.

2. Experimental Setup

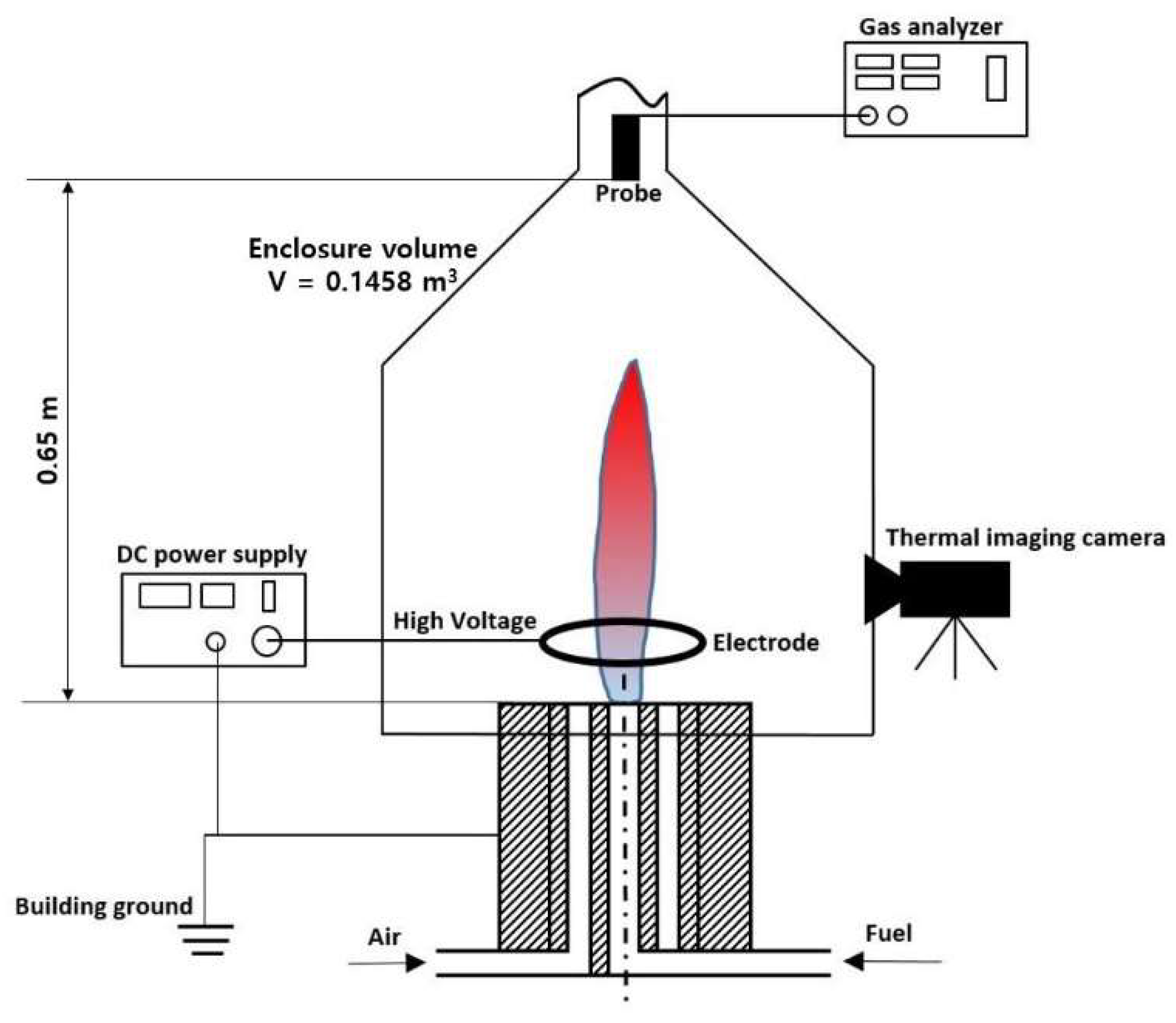

In this paper,

Figure 1 illustrates a schematic diagram of the experimental setup for propane diffusion flame combustion tests by application of electrostatic voltage. The closed chamber used in the experiment has dimensions of 0.5 m × 0.5 m and 0.75 m in height. A grounded burner with a diameter of 42 mm for establishing diffusion flame was made of stainless steel. The outlet of the burner was divided into three parts in the direction of the concentric circle. Pure propane was supplied at the central outlet with a diameter of 6 mm. A mass flow controller (Line Tech M3100V) supplied the fuel at a rate of 0.25, 0.5, and 1 L/min. At the second outlet from the center, the dry air was supplied by the mass flow controller at 12 L/min. At the burner exit, the Reynolds number of this flow is about 900, which is the laminar flow region. Fuel-lean (equivalence ratio: 0.5), stoichiometry (equivalence ratio: 1), and fuel-rich (equivalence ratio: 2) flame were formed depending on the fuel supply. All cases of the experiment can be seen in

Table 1.

High-resolution IR camera set to capture the temperature distribution data within the propane diffusion flame. Changes in the temperature profile and flame dynamics were observed by thermal imaging (infrared) camera (Fluke Ti400). The IR camera had an infrared spectral band from 7.5 μm to 14 μm. The range of wavelength emitted varied as an object’s temperature changed, and the sensor detected its wavelength emitted. Then, based on the strength of the wavelength, the appropriate colors were displayed on a screen. The IR emissivity of the flame surface was set to 1. The purpose of this research is to focus on the flame length change more than obtaining precisely measured flame temperature. Therefore, slight errors did not affect the results of this study.

A high voltage power supply (GLASSMAN HIGH VOLTAGE INC. EK series) with a ring-type electrode (

Figure 2) of 26.5 mm in inner diameter and 3.25 mm in thickness was adjusted at 25 mm height from burner exit to generate electric field and polarity of −5 to +5 kV. The high voltage power source was able to supply direct-current voltage from 0 to 5 kV.

The NO

x was measured by installing a gas analyzer probe (EUROTRON Greenline) on the exhaust portion of the combustion chamber (

Figure 1). The probe is located at a height of 65 cm from the burner surface. It is possible that the exhaust gas is diluted by the fresh air in the container. Therefore, we used values that were measured after ignition, and we waited until the inside of the enclosure became stable and uniform case by case.

The intensity and direction of the electric field generated by the electrode were demonstrated by using the Ansys Maxwell 2D program (

Figure 3).

3. Results

The main focus of this research was to understand the effect of applied voltage and polarity on the flame dynamics of the propane diffusion flame. To understand this phenomenon, the following experimentation was performed, as discussed in subsequent sections.

3.1. Flame Shape and Length

Efforts were made to understand the electric field within the flame due to the application of the applied voltage and polarity (negative or positive) (

Figure 3).

Figure 3 shows that there is a different direction of the electric field within the flame for the applied positive and negative voltage.

For the negative polarity case, the direction of the electric field is upward from the burner exit, while for the positive polarity, the direction of the electric field is toward the burner exit. Among charged ions inside the flame, the positive ions move in the same direction as the electric field. The cations generated from the pyrolysis of fuel are dense in the blue region, which is why this area is most affected by electric fields. With an increase in the applied negative polarity, the positive ions move away from the burner exit. It is also observed that the blue region (reaction zone) of the applied negative polarity is stretched with an increase in voltage through the electrode, as seen in

Figure 4, whereas in the blue region of the positive polarity, the blue region becomes shorter but thicker.

Figure 5 is an image taken with an infrared thermal imaging camera of the shape of the flame that changes when a positive voltage is applied to the electrode. When no electric field is applied, it can be seen that the flame length is shorter in the fuel-lean case (c) than in cases (a) and (b). The length of the coaxial diffusion flame is proportional to the fuel flow rate and inversely proportional to the diffusion coefficient and air-fuel ratio, as was discussed in Equation (1) in the Introduction Section.

In the reaction zone between the electrode and the burner surface, an electric field acting in the opposite direction to the direction of the flame is formed, and the turbulence increases as the voltage increases due to the conflict between the body force of the ionic wind that presses the flame downward and the fuel ejected upward.

Figure 6 shows the shape of the flame that changes when a negative voltage is applied to the electrode. In all cases (a), (b), and (c), the flame length became shorter as the voltage applied to the electrode increased. In all cases under the same voltage, as the amount of fuel supplied increased, the length of the flame was longer. As in the case where the electrode was positively charged, the diffusion coefficient of the flame increased due to the electric field acting in the direction parallel to the direction of the flame in the reaction zone of the flame, and thus, the length of the flame was reduced (Equations (1)–(6)). However, it showed a stable appearance without increasing turbulence, compared to when a positive electric field was applied in all areas and the reaction zone of the flame.

Figure 7 graphically presents the results of the flame length. As for the length of the flame presented numerically in this result, the maximum length from the burner surface to the part of the flame at 600 °C or higher was defined as the length of the flame. The length of 20 thermal images of the flame was measured, and the average was presented as a result.

As shown, (a) is the result when the electrode is positively charged, and (b) is the result when the electrode is negatively charged. In the fuel-rich case, where the flow rate (Q) of the supplied fuel was double, and the air-fuel ratio (s) was small, the flame length was the longest in all cases under all voltages (Equation (1)). Additionally, the flame length of the fuel-lean case with a large air-fuel ratio was the shortest in all cases under all voltages.

In the electric field to which a positive voltage was applied, the flame length of the stoichiometry and the fuel-rich case decreased steadily as the voltage increased, and in the fuel-lean case, the flame length started to decrease sharply above 2 kV. In the fuel-lean case, it can be seen that the decrease in flame length due to the low equivalence ratio (φ = 0.5) is more dominant than the increase in the diffusion coefficient by the electric field at a low voltage of 2 kV or less.

The length of the flame continued to decrease as the voltage increased also in the electric field to which the negative voltage was applied, but the decrease was small, compared to the positive case.

Flames contain a high concentration of free electrons and charged ions. The rate of ion generation depends on the mixture composition. When the DC electric field is applied on the propane diffusion flame through the electrode, a large number of ions and electrons are moved. This ionic wind affects flame dynamics, which enhances the heat and mass transfer between the flame front and the unburned area, thereby increasing the rate of combustion. As a result, the length of the flame is reduced.

In all cases, the fuel-rich case has the longest flame length, and the fuel-lean case has the shortest. When the electrode is negatively charged, the flame length decreases by 35 to 65% at −5 kV, and by 53 to 70% at +5 kV, when positively charged.

3.2. NOx Formation

The amount of NOx generated from the flame was measured by inserting the suction tube of the gas analyzer into the exhaust duct for the propane diffusion flame. Here, the amount of NOx means the sum of the amounts of NO and NO2.

In a coaxial diffusion flame, when the same amount of fuel is burned, flame instability increases as the length of the flame increases, and soot and NO

x generation are also affected [

8,

9,

10,

11].

When the electrode is charged with positive polarity (

Figure 8a) up to 2 kV at all air-fuel ratios, the amount of NO

x reduction is not noticeable. However, as the voltage continues to increase, the amount of NOx rapidly decreases up to 3.5 kV. After that, the amount of generated NO

x is almost constant even when the voltage is increased.

When the negative electric field is applied to the flame (

Figure 8b), it is shown that the amount of NO

x production decreases steadily at all air-fuel ratios.

In both results, the main reason for the decrease in the amount of NOx generation is that the length of the flame is decreased by the electric field, and the residential time of the flame is decreased. Thus, the chance of thermal NOx formation is reduced.

Through this study, it is noticed that the maximum reduction in NOx with the applied voltage and polarity is within the range of 55% to 78%. It is also noticed that the NOx emission is gradually decreased with an increase in the applied voltage (0 to 5 kV) for both polarities (positive and negative).

3.3. EINOx Scaling

Peters and Donnerhack [

10] derived theoretical equations for emission index of NOx (EINOx), grams of nitrogen oxides produced per kilogram of fuel), and the length of diffusion flame (Equation (7)), Chen [

28] and Driscoll [

29] derived a relational expression shown in Equation (8), after revising it in Equation (7), considering the effect of the turbulence of the flame. After that, Equations (7) and (8) were experimentally verified by the researchers in models of several diffusion flames [

11,

30,

31,

32,

33].

In Equations (7) and (8), Lf is the length of the flame, df is the diameter of the fuel nozzle, and Uf is the fuel outlet velocity. As seen in the equations, EINOx scales the length of the flame to the power of three; that is, the amount of NOx generated is most affected by the length of the flame. In each case of this experimental study, Uf and df are fixed, and only Lf changes by the electric field. Therefore, in Equation (8), is regarded as constant.

Figure 9 is a graph drawn by substituting the

EINOx result according to the flame length into Equation (7) when the electric field is used. In the graph, the slope of the average line is 0.35. This can be expressed as follows:

Compared to Equation (7), Equation (9) shows that EINOx is smaller by 0.35 power, which indicates that a smaller amount of NOx is generated in the flame with the electric field.