Stabilization of Rock Roadway under Obliquely Straddle Working Face

Abstract

:1. Introduction

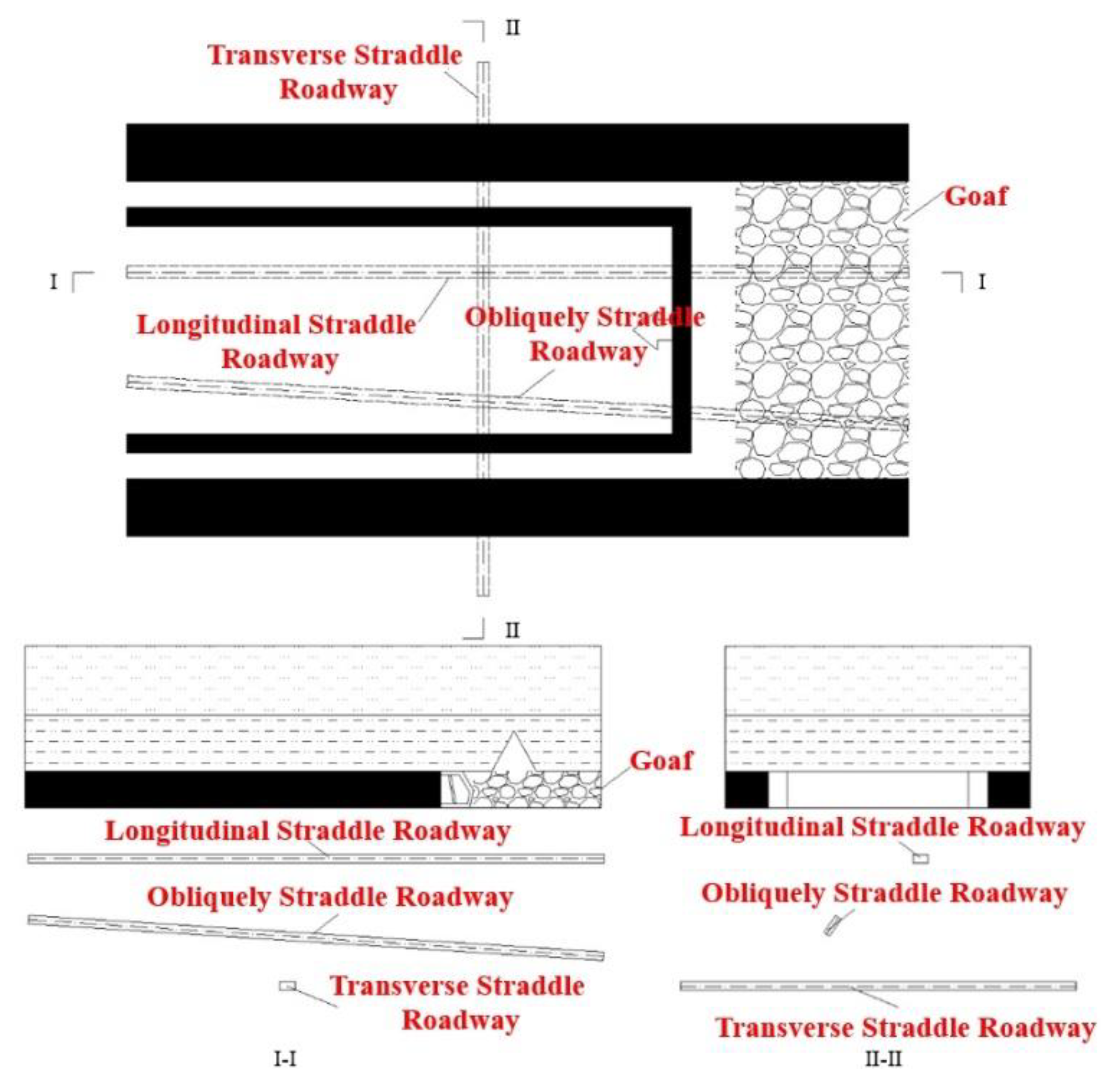

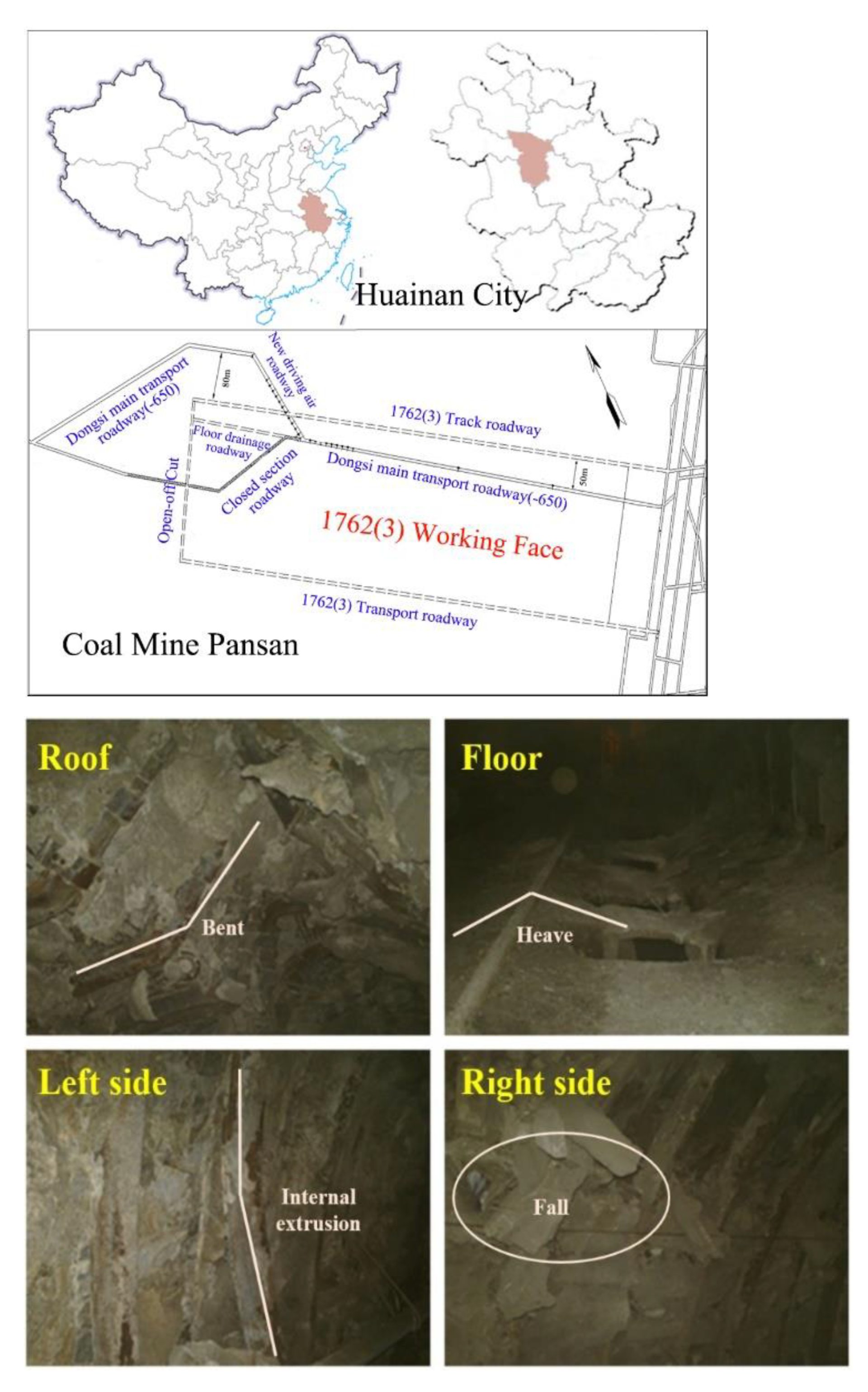

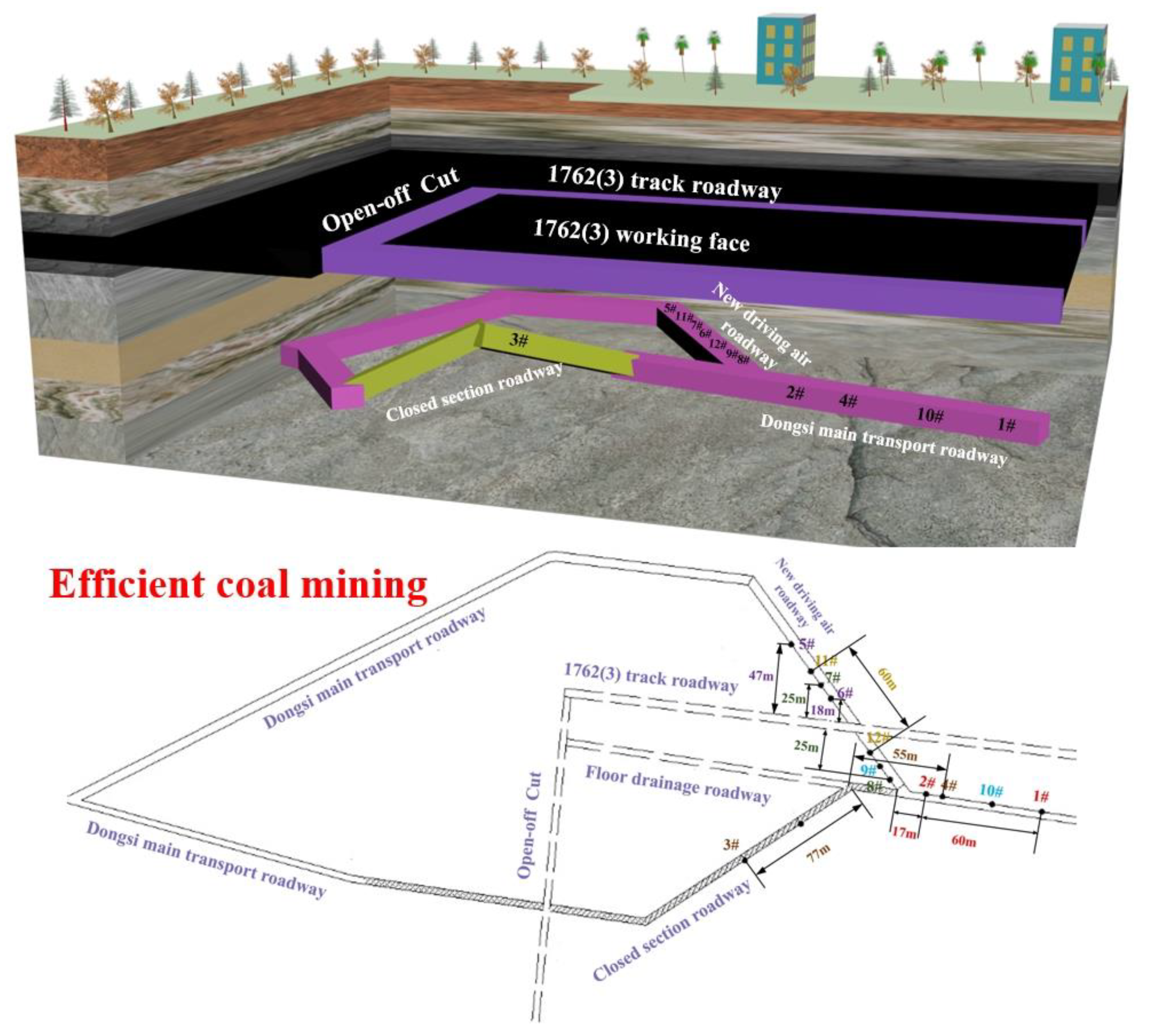

2. Engineering Background and Methods

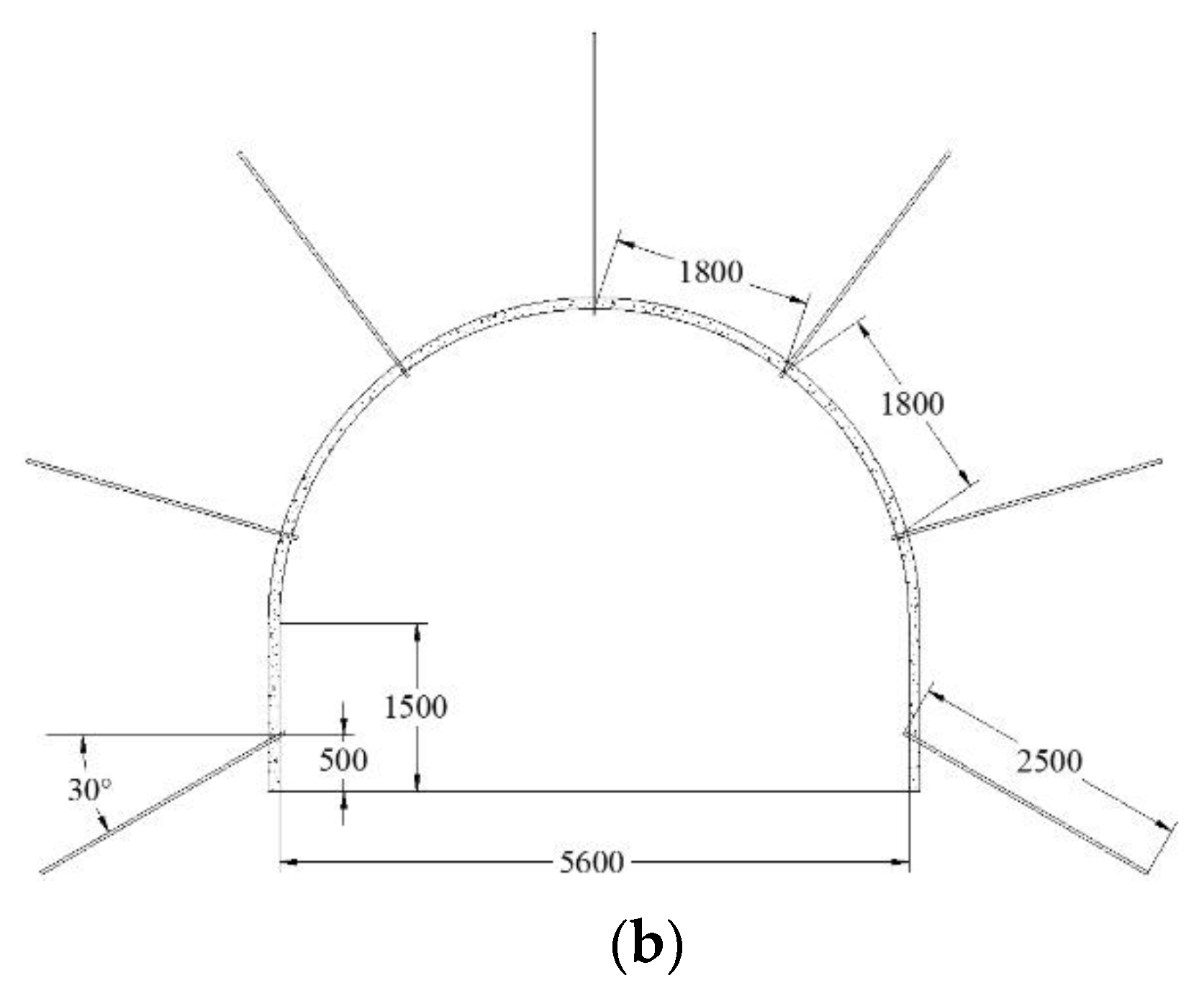

2.1. Engineering Background

2.2. Methods

2.2.1. On-Site In Situ Mine Pressure Monitoring

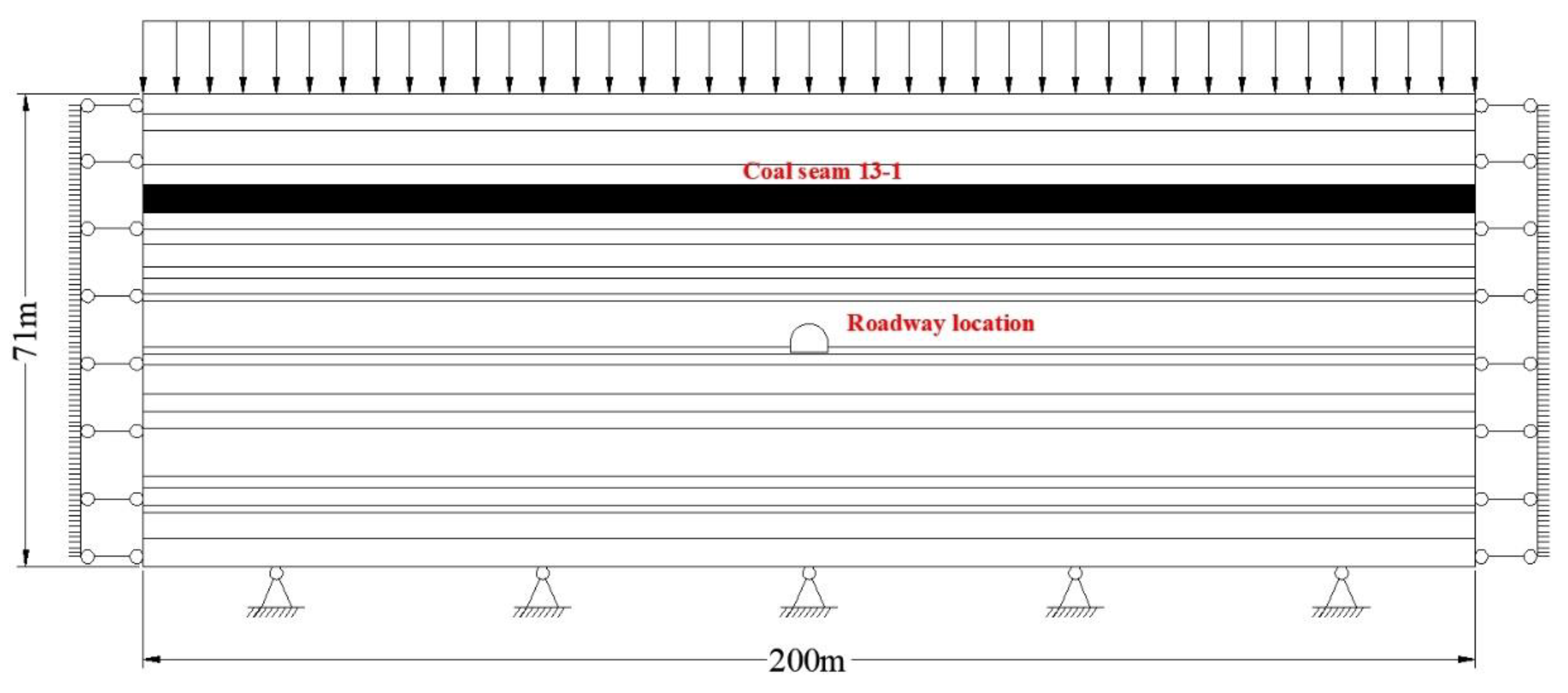

2.2.2. Numerical Simulation Software and Model

3. Results and Analysis

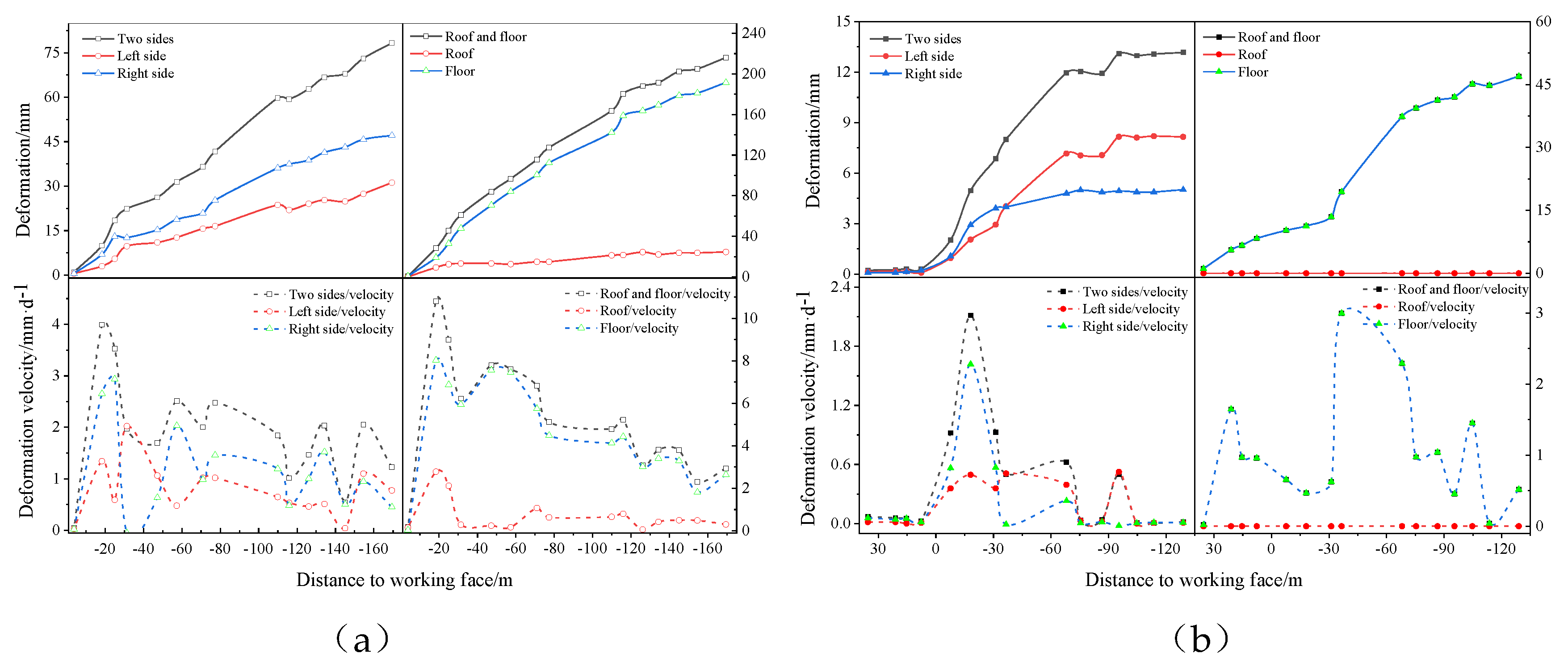

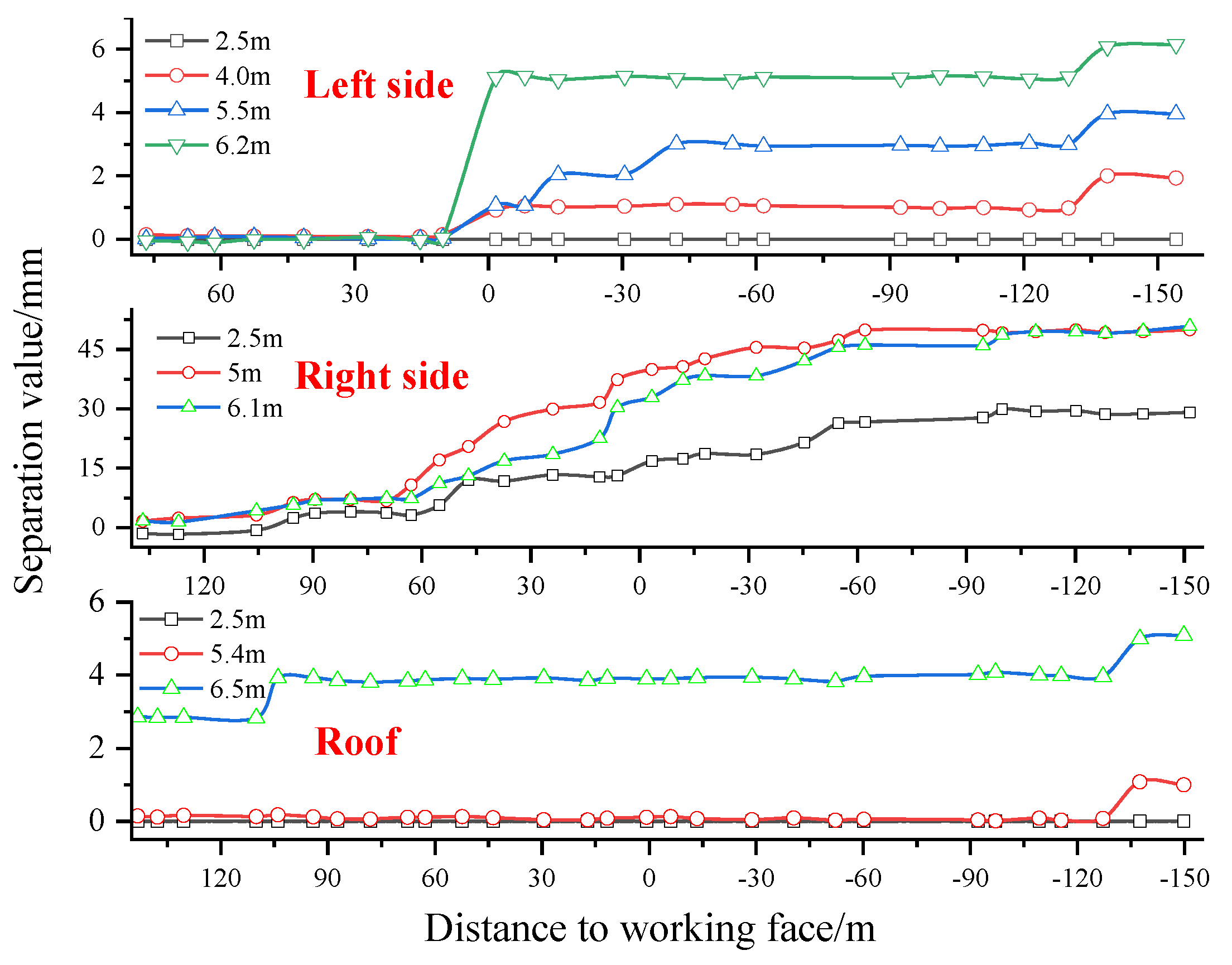

3.1. In Situ Test for Surrounding Rock Stability of Obliquely Straddle Roadway under Different Influencing Factors

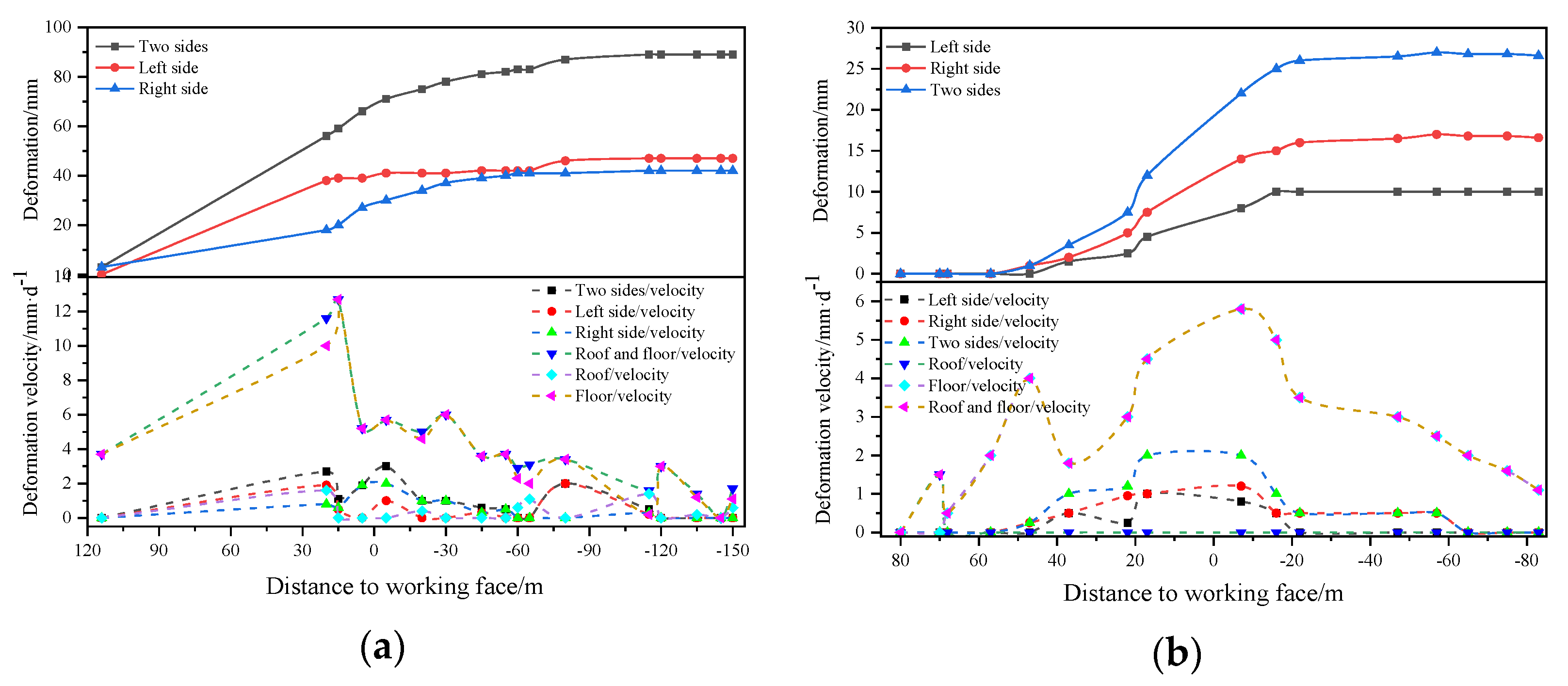

3.1.1. Influence of Different Lithology on Stability of Surrounding Rock

3.1.2. Influence of Vertical Distance and Horizontal Distance between Roadway and Overlying Working Face End on Surrounding Rock Stability

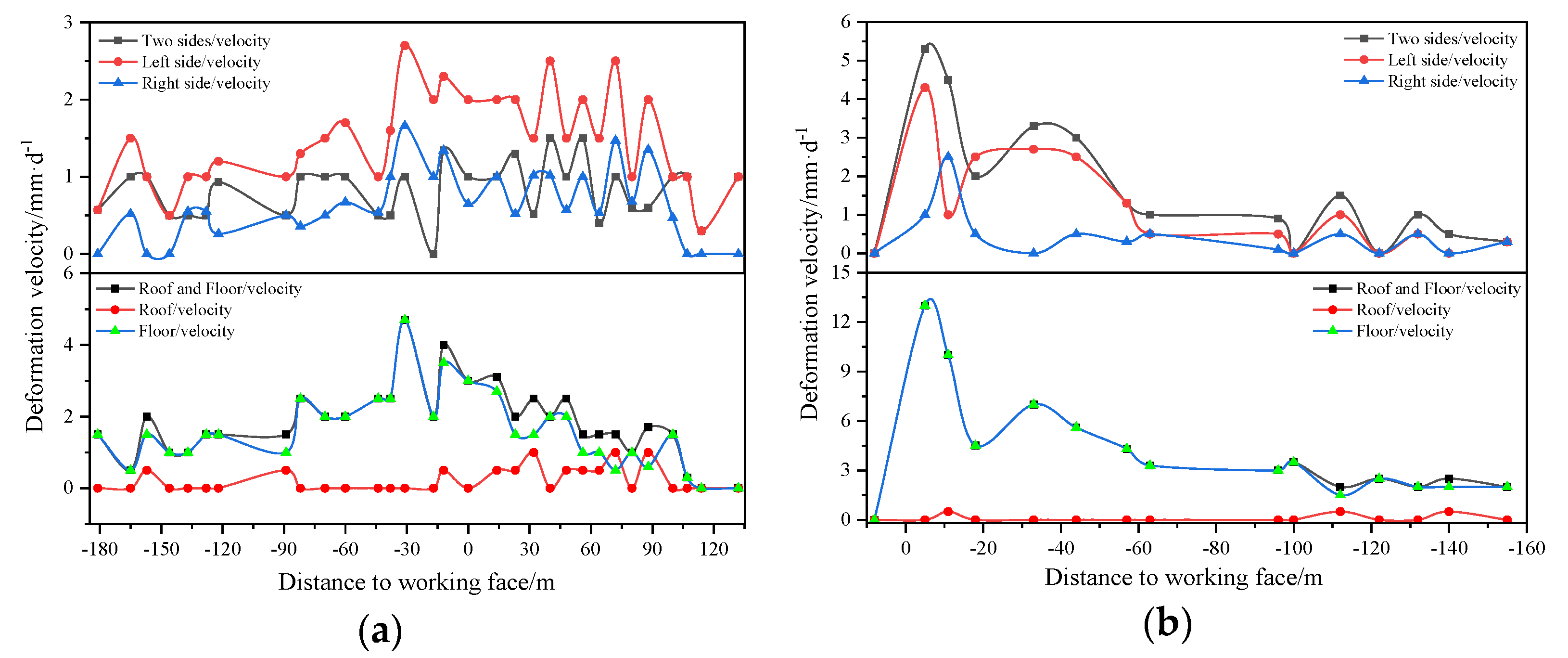

3.1.3. Influence of Position Relationship between Roadway and Overlying Working Face on Surrounding Rock Stability

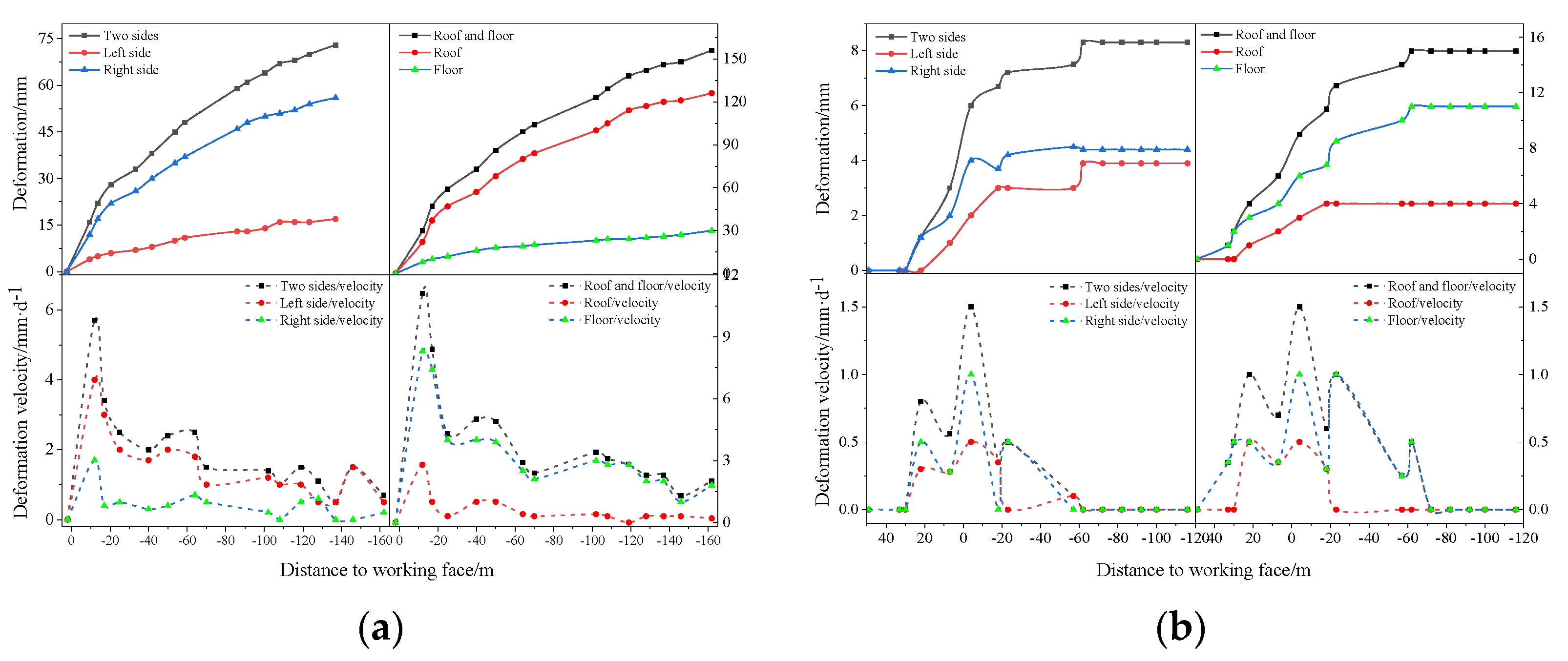

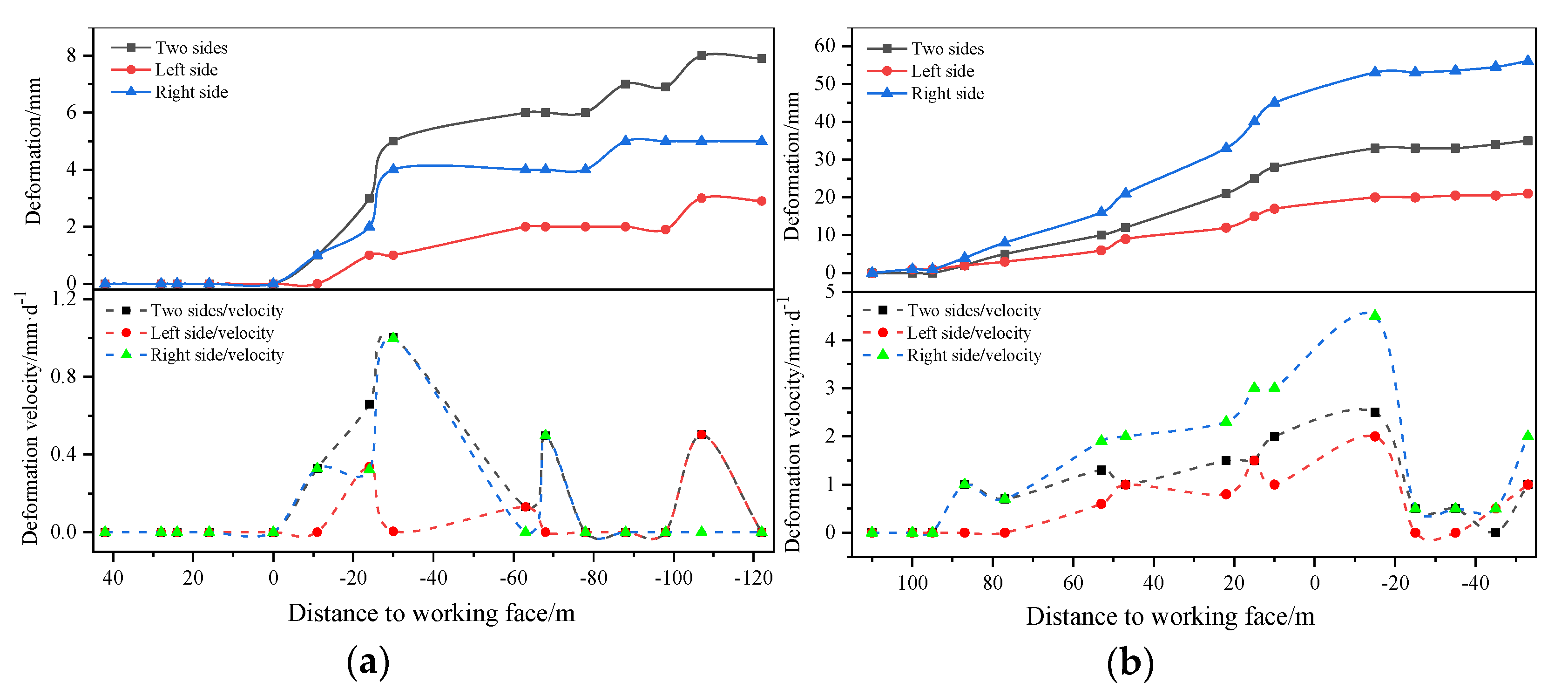

3.1.4. Influence of Support Form and Strength on Surrounding Rock Stability

3.2. Simulation of Surrounding Rock Stability for Inclined Span Roadway under Different Support Conditions

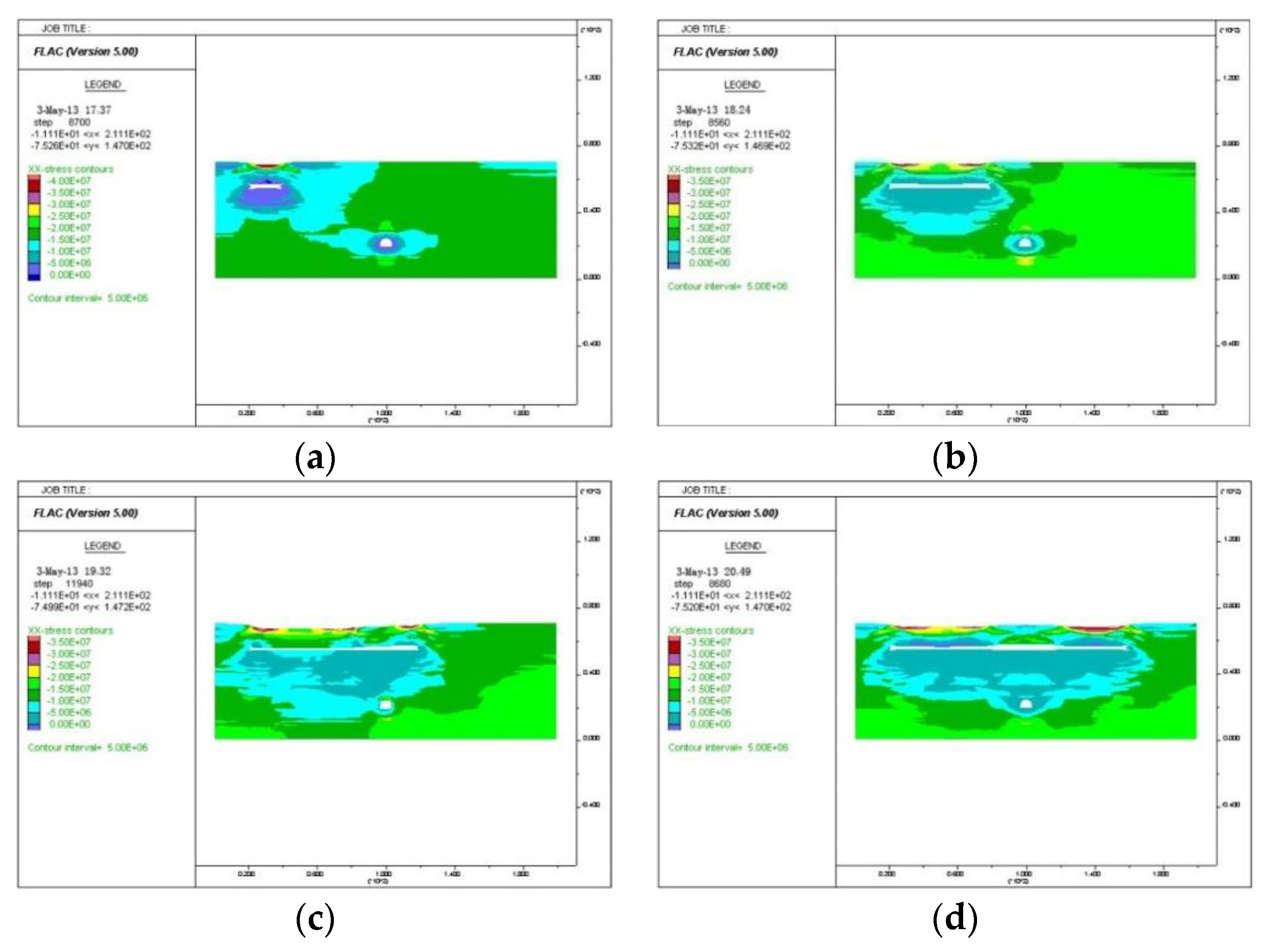

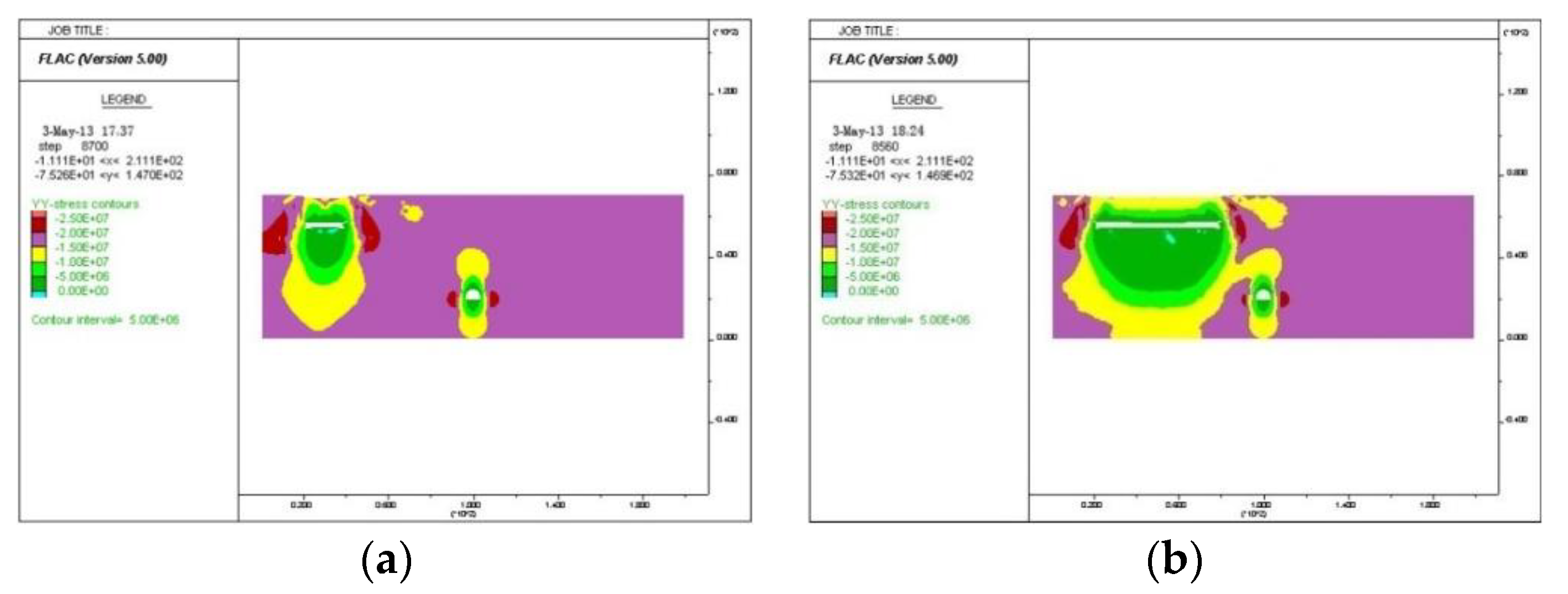

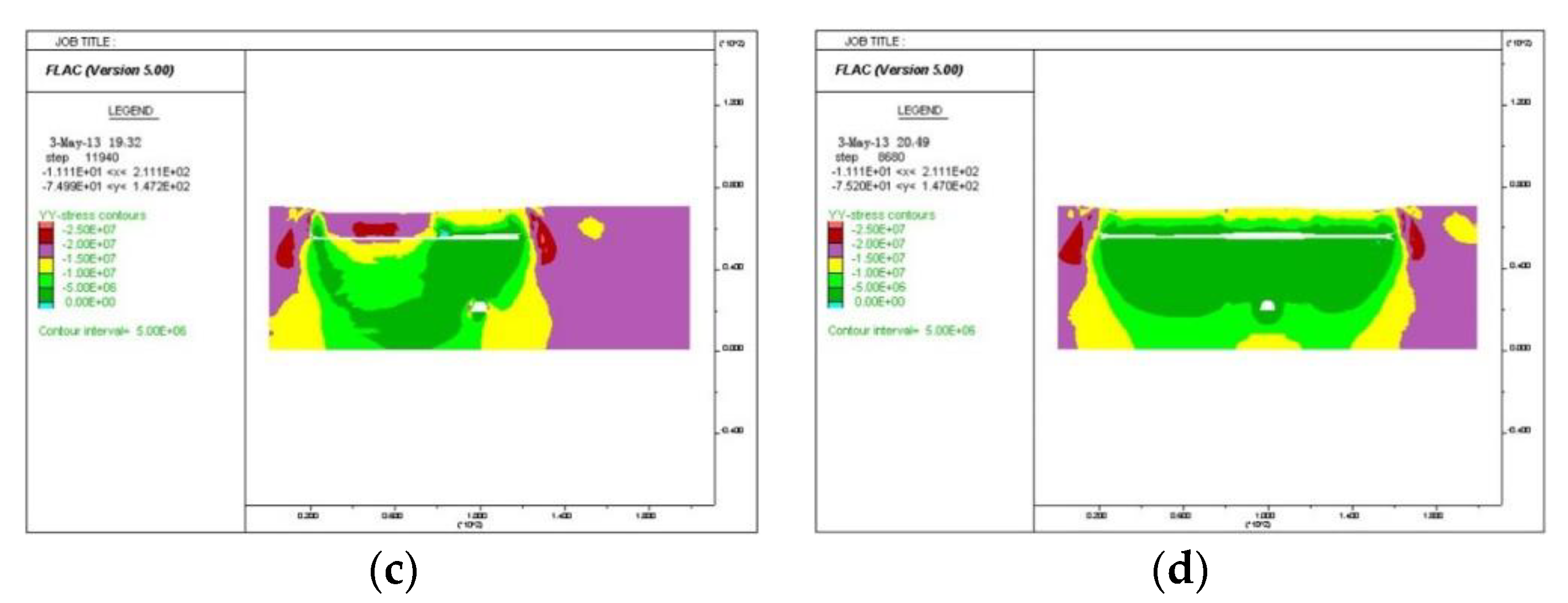

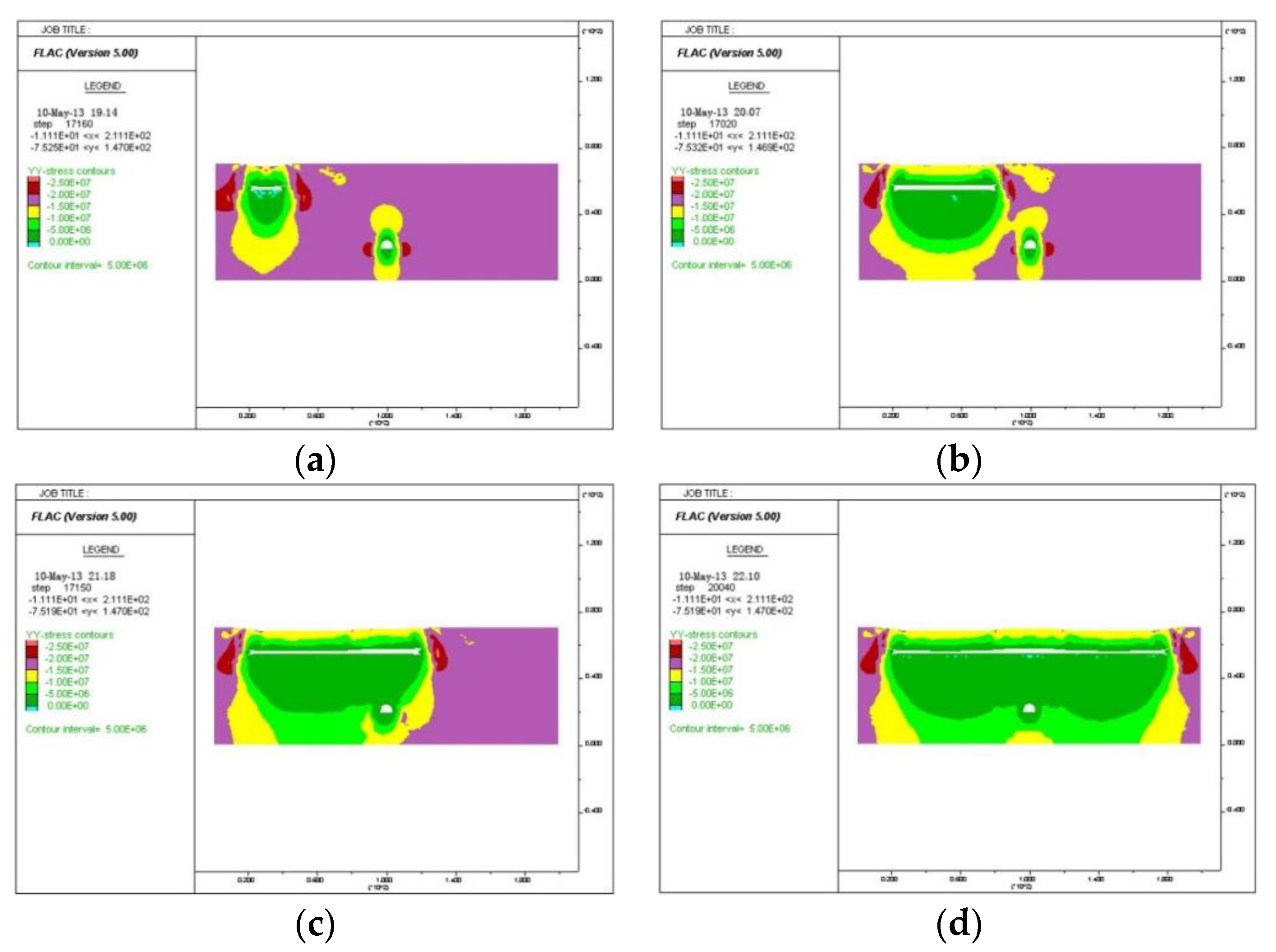

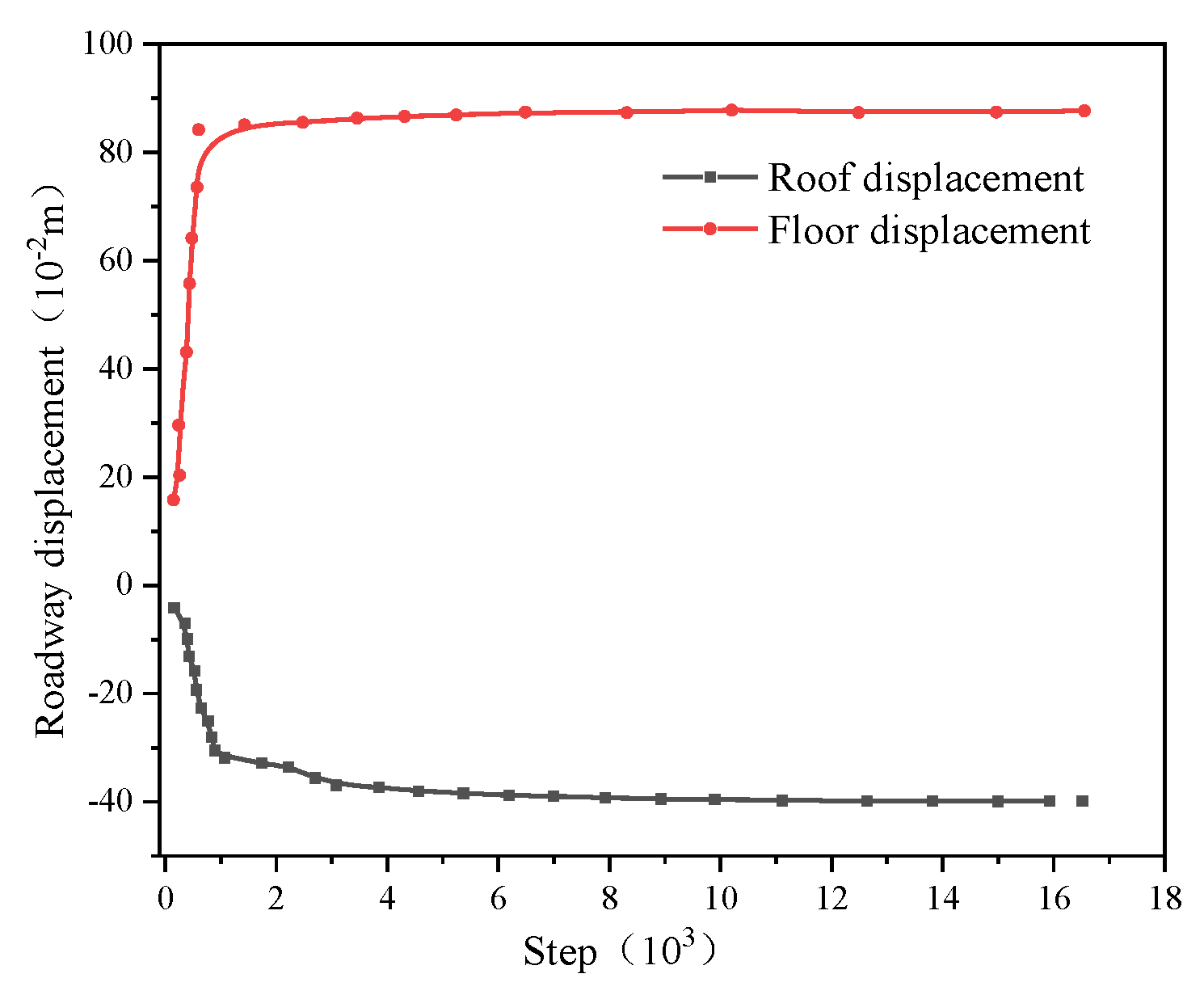

3.2.1. Stress and Deformation of Rock Surrounding the Roadway Supported by Original Bolt under Mining Influence

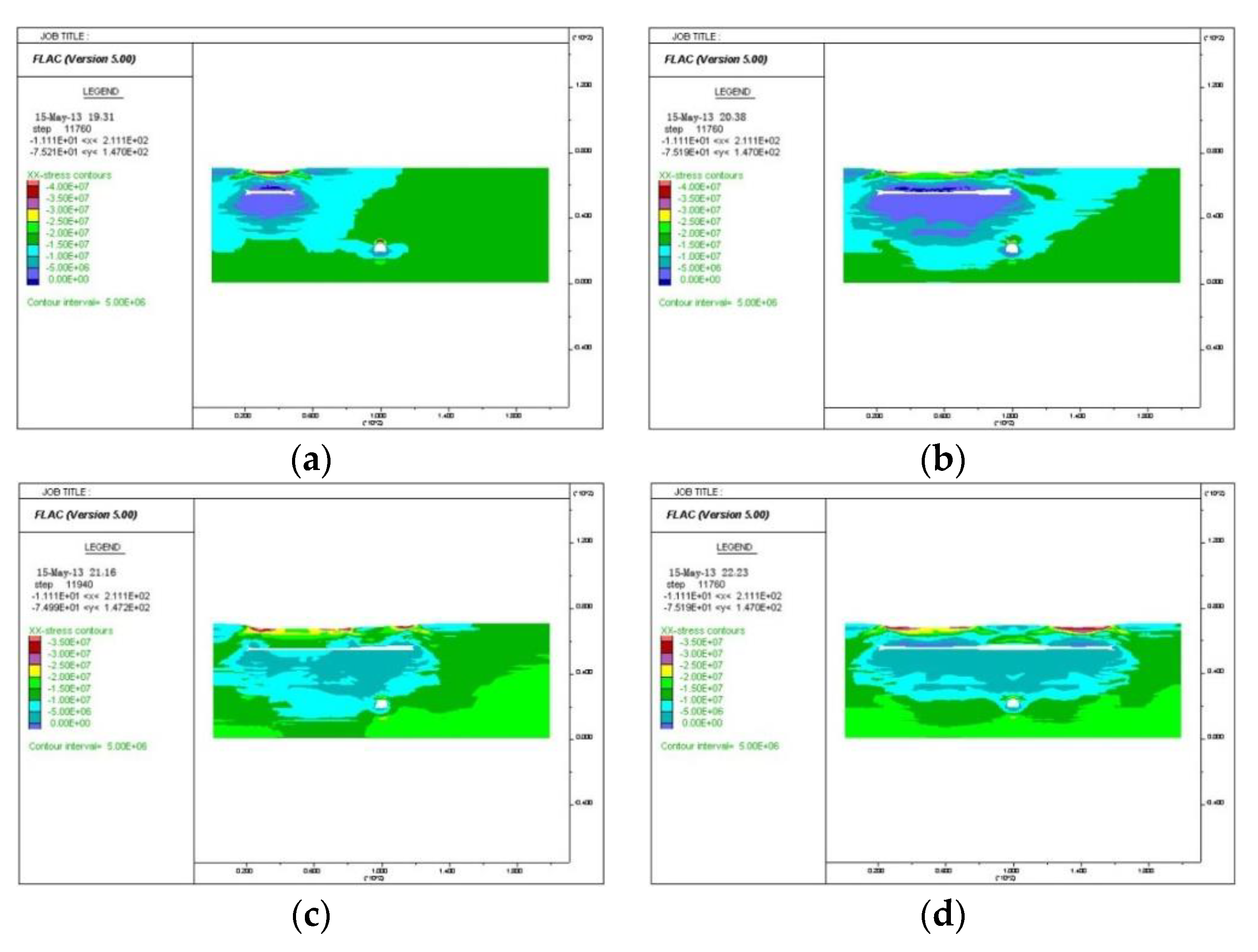

3.2.2. Stress and Deformation of Rock Surrounding the Lower Roadway under Different Optimized Support Schemes

- (1)

- Simulation results and analysis of combined bolt and shed support.

- (2)

- Simulation results and analysis for anchor–shotcreting–grouting support.

3.3. Discussion

4. Industrial Tests

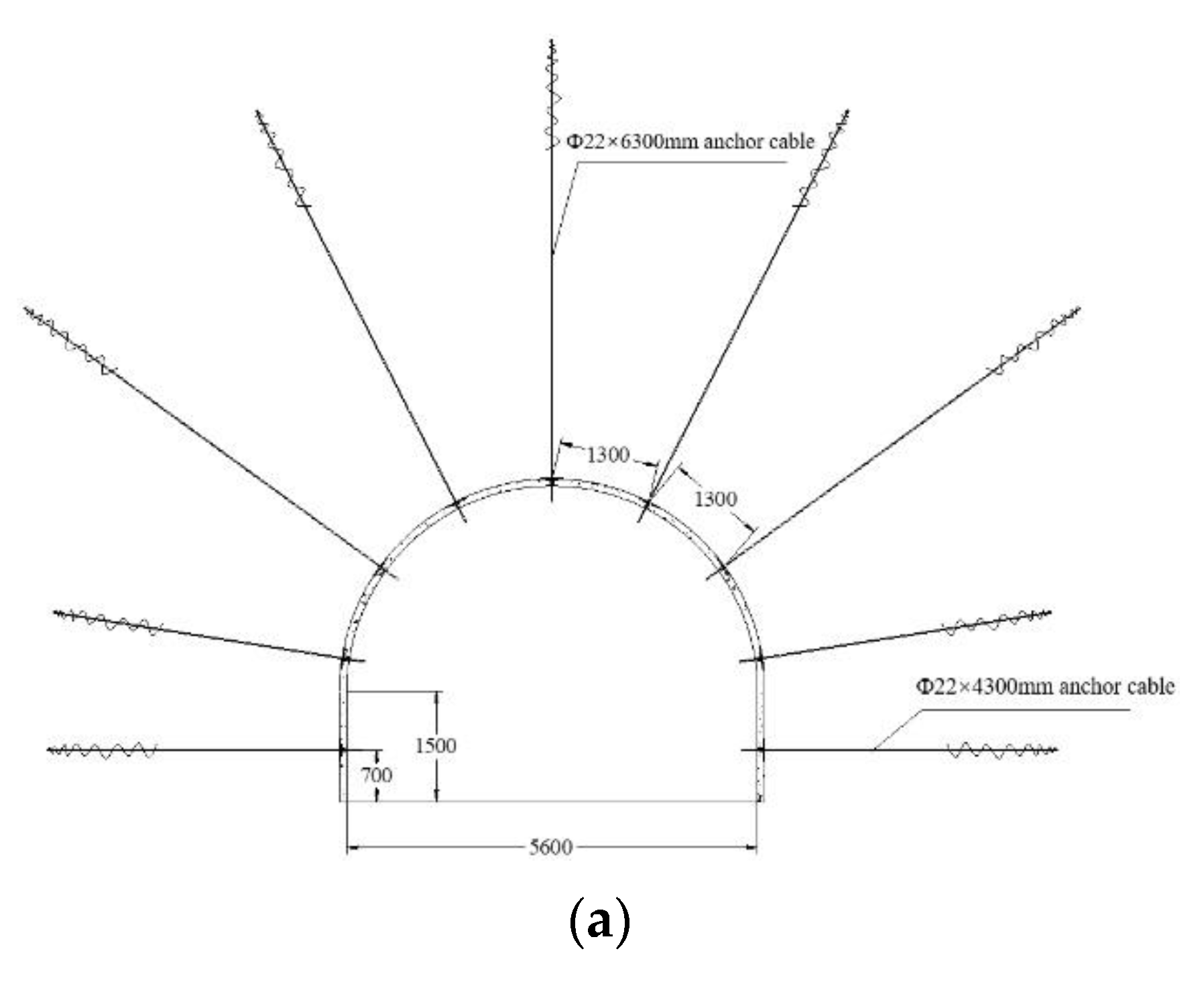

4.1. Support Scheme Design

4.2. Monitoring Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, H.P. Support technologies for deep and complex roadways in underground coal mines: A review. Int. J. Coal Sci. Technol. 2014, 1, 261–277. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Xue, F.; Zhang, N.C.; Feng, X.W. Patterns and security technologies for co-extraction of coal and gas in deep mines without entry pillars. Int. J. Coal Sci. Technol. 2015, 2, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.F.; Pang, Y.H. Surrounding rock control theory and longwall mining technology innovation. Energy Sci. Eng. 2017, 4, 301–309. [Google Scholar] [CrossRef] [Green Version]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 1, 28–38. [Google Scholar] [CrossRef]

- Wang, H.W.; Jiang, Y.D.; Xue, S.; Shen, B.T.; Wang, C.; Lv, J.G.; Yang, T. Assessment of excavation damaged zone around roadways under dynamic pressure induced by an active mining process. Int. J. Rock Mech. Min. Sci. 2015, 77, 265–277. [Google Scholar] [CrossRef]

- Qin, D.D.; Wang, X.F.; Zhang, D.S.; Chen, X.Y. Study on Surrounding Rock-Bearing Structure and Associated Control Mechanism of Deep Soft Rock Roadway Under Dynamic Pressure. Sustainability 2019, 11, 1892. [Google Scholar] [CrossRef] [Green Version]

- Prusek, S.; Masny, W. Analysis of damage to underground workings and their supports caused by dynamic phenomena. J. Min. Sci. 2015, 1, 63–72. [Google Scholar] [CrossRef]

- Yao, Q.L.; Zhou, J.; Li, Y.N.; Tan, Y.M.; Jiang, Z.G. Distribution of Side Abutment Stress in Roadway Subjected to Dynamic Pressure and Its Engineering Application. Shock Vib. 2015, 2015, 929836. [Google Scholar]

- Lu, S.L.; Sun, Y.L.; Jiang, Y.D. Position of floor rock roadway and adjacent coal seam roadway and cross mining pressure behavior law. Coal Sci. Technol. 1994, 22, 27–31. [Google Scholar]

- Mo, S.; Sheffield, P.; Corbett, P.; Ramandi, H.L.; Oh, J.; Canbulat, I.; Saydam, S. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 2020, 103, 103497. [Google Scholar] [CrossRef]

- Zhang, X.C.; Li, D.Y.; Chen, S.H.; Li, D.S.; Fan, D.W. Stability Prediction and Control of Surrounding Rocks for Roadway Affected by Overhead Mining. J. Min. Eng. 2008, 25, 361–365. [Google Scholar]

- Zhang, P.S.; Lin, D.C.; Yang, J.; Wang, M.H. Numerical Simulation of Deep Varied Interval Riding Mining Roadway Stability Based on Time-effect of Rock. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2012, 31, 10–14. [Google Scholar]

- Hebblewhite, B.K.; Lu, T. Geomechanical behaviour of laminated, weak coal mine roof strata and the implications for a ground reinforcement strategy. Int. J. Rock Mech. Min. Sci. 2004, 1, 147–157. [Google Scholar] [CrossRef]

- Lu, X.; Zheng, Y.S.; Yan, M.C.; Li, W.; Cao, S.L. Study on ground pressure behavior and support technology of short distance over mining roadway. Coal Technol. 2019, 38, 47–50. [Google Scholar]

- Malkowski, P.; Ostrowski, L.; Bachanek, P. Modelling the small throw fault effect on the stability of a mining roadway and its verification by in situ investigation. Energies 2017, 12, 2082. [Google Scholar]

- Sun, Z.H.; Xie, W.B.; Zhang, J.W.; Cheng, X.J. Surrounding rock deformation regularity and control technology of soft rock roadway in floor during across mining. Coal Technol. 2016, 35, 65–67. [Google Scholar]

- Gabet, T.; Malecot, Y.; Daudeville, L. Triaxial behaviour of concrete under high stresses: Influence of the loading path on compaction and limit states. Cem. Concr. Res. 2008, 38, 403–412. [Google Scholar] [CrossRef]

- Okubo, S.; Fukui, K.; Hashiba, K. Development of a transparent triaxial cell and observation of rock deformation in compression and creep tests. Int. J. Rock Mech. Min. Sci. 2008, 45, 351–361. [Google Scholar] [CrossRef]

- Chang, C.; Haimson, B. Waveform analysis in mitigation of blast-induced vibrations. J. Geophys. Res.-Solid Earth 2000, 105, 18999–19013. [Google Scholar] [CrossRef]

- Haimson, B.C.; Chang, C.D. True triaxial strength of the KTB amphibolite under borehole wall conditions and its use to estimate the maximum horizontal in situ stress. J. Geophys. Res.-Solid Earth 2002, 107, 2257. [Google Scholar] [CrossRef]

- Ning, S. Research on Surrounding Rock Deformation and Sectional Control Technology of Roadway Crossing through Passage. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2019. [Google Scholar]

- Zha, W.H.; Fu, X.M.; Yu, J.Y. Dynamic stepping and segmenting control and reinforcement technology of deep longitudinal spanning roadway. Saf. Coal Mines 2013, 44, 100–103. [Google Scholar]

- Xu, B.G.; Wang, K. Study on pre—reinforcement technology of roadway affected by contugous overhead mining. Coal Sci. Technol. 2020, 48, 194–199. [Google Scholar]

- Zhang, Z.Y. Study on the Support Law of the Right-Angle Trapezoidal Plate Breakage and Stress Propagation to the Floor. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2017. [Google Scholar]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Xiong, L.J. Control Technical Research on the Stability of Wall Rock under the Deep Lose Continuous Roadway Passed by Working Face. Master’s Thesis, AnHui University of Science and Technology, Huainan, China, 2013. [Google Scholar]

- Li, X.H.; Yao, Q.L.; Zhang, N.; Wang, D.Y.; Zheng, X.G.; Ding, X.L. Numerical Simulation of Stability of Surrounding Rock in High Horizontal Stress Roadw ay Under Overhead Mining. J. Min. Saf. Eng. 2008, 25, 420–425. [Google Scholar]

- Majdi, A.; Hassani, F.P.; Nasiri, M.Y. Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar] [CrossRef]

- Hu, X.Y.; Zhang, H.L.; Zhang, L.G. Analysis on Stress Concentration Factors of Roadway Surrounding Rock Affected by Cross Mining. Chin. J. Undergr. Space Eng. 2015, 11, 658–664. [Google Scholar]

- Li, Y.Y. Study on the Technology of Surrounding Rock Control in Floor Roadway under Repeated Overhead Mining. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Jiang, J.Q.; Han, J.S.; Feng, Z.Q. Sub classification of surrounding rock structure stability of cross mining roadway and its application. J. Eng. Geol. 1999, 7, 321–326. [Google Scholar]

- Zhang, J.C.; Liu, T.Q. On the depth and distribution characteristics of coal seam floor mining fracture zone. J. China Coal Soc. 1990, 15, 46–55. [Google Scholar]

- Liu, T.Q. Influence and control engineering of mining rock mass and its application. J. China Coal Soc. 1995, 20, 1–5. [Google Scholar]

- Li, G.C.; Ma, C.Q.; Zhang, N.; Wang, P.P.; Ma, R. Research on failure characteristics and control measures of roadways affected by multiple overhead mining in Huaibei mining area. J. Min. Saf. Eng. 2013, 30, 181–187. [Google Scholar]

- Yuan, A.Y.; Yang, Z.Y.; Yang, Y.M. Across Mechanical Analysis and Control Technology of Surrounding Rock of Roadway Under the Influence of Dynamic Pressure. Met. Mine 2016, 2, 47–50. [Google Scholar]

- Guo, Y.; Zheng, X.G.; Guo, G.Y.; Zhao, Q.F.; Zhou, W.; An, T.L. Study on deformation failure and control of surrounding rock in soft rock roadway in close range coal seam with overhead mining. J. Min. Saf. Eng. 2018, 35, 56–63. [Google Scholar]

- Zhang, H.L.; Wang, L.G. Computation of Mining Induced Floor Additional Stress and Its Application. J. Min. Saf. Eng. 2011, 28, 288–292. [Google Scholar]

- Xie, W.B.; Shi, Z.F.; Yin, S.J. Stability Analysis of Surrounding Rock Masses of Roadway Under Overhead Mining. Chin. J. Rock Mech. Eng. 2004, 23, 1986–1991. [Google Scholar]

- Zhu, Q.H. Mechanics Analysis of Surrounding Rock Deformation of Roadway Affected by Deep Riding Mining and Its Stability Control. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2012. [Google Scholar]

- Zhang, C.; Zhang, L.Y.; Li, K.; Li, M. Numerical Simulation of Rock Mass Stability in Mining Dynamic Pressure Straddling. J. Xuzhou Inst. Technol. (Nat. Sci. Ed.) 2011, 26, 40–46. [Google Scholar]

- Ma, X.Z. Application of large rigidity coupling support technology in high stress cross mining roadway. Energy Technol. Manag. 2011, 2, 62–64. [Google Scholar]

| Name | Bulk Modulus (GPa) | Shear Modulus (GPa) | Density (kg/m3) | Cohesion (MPa) | Friction Angle (°) |

|---|---|---|---|---|---|

| Sandstone | 7.3 | 4.2 | 2400 | 2 | 35 |

| Siltstone | 8.1 | 5.1 | 2500 | 2.1 | 29 |

| Mudstone | 3.2 | 2.74 | 2400 | 1.2 | 25 |

| Coal seam | 2.4 | 1.37 | 1350 | 0.8 | 23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zhang, N.; Kan, J.; Wang, B.; Xu, X. Stabilization of Rock Roadway under Obliquely Straddle Working Face. Energies 2021, 14, 5759. https://doi.org/10.3390/en14185759

Wang P, Zhang N, Kan J, Wang B, Xu X. Stabilization of Rock Roadway under Obliquely Straddle Working Face. Energies. 2021; 14(18):5759. https://doi.org/10.3390/en14185759

Chicago/Turabian StyleWang, Peng, Nong Zhang, Jiaguang Kan, Bin Wang, and Xingliang Xu. 2021. "Stabilization of Rock Roadway under Obliquely Straddle Working Face" Energies 14, no. 18: 5759. https://doi.org/10.3390/en14185759