Experimental Analysis of Bi-Directional Heat Trading Operation Integrated with Heat Prosumers in Thermal Networks

Abstract

:1. Introduction

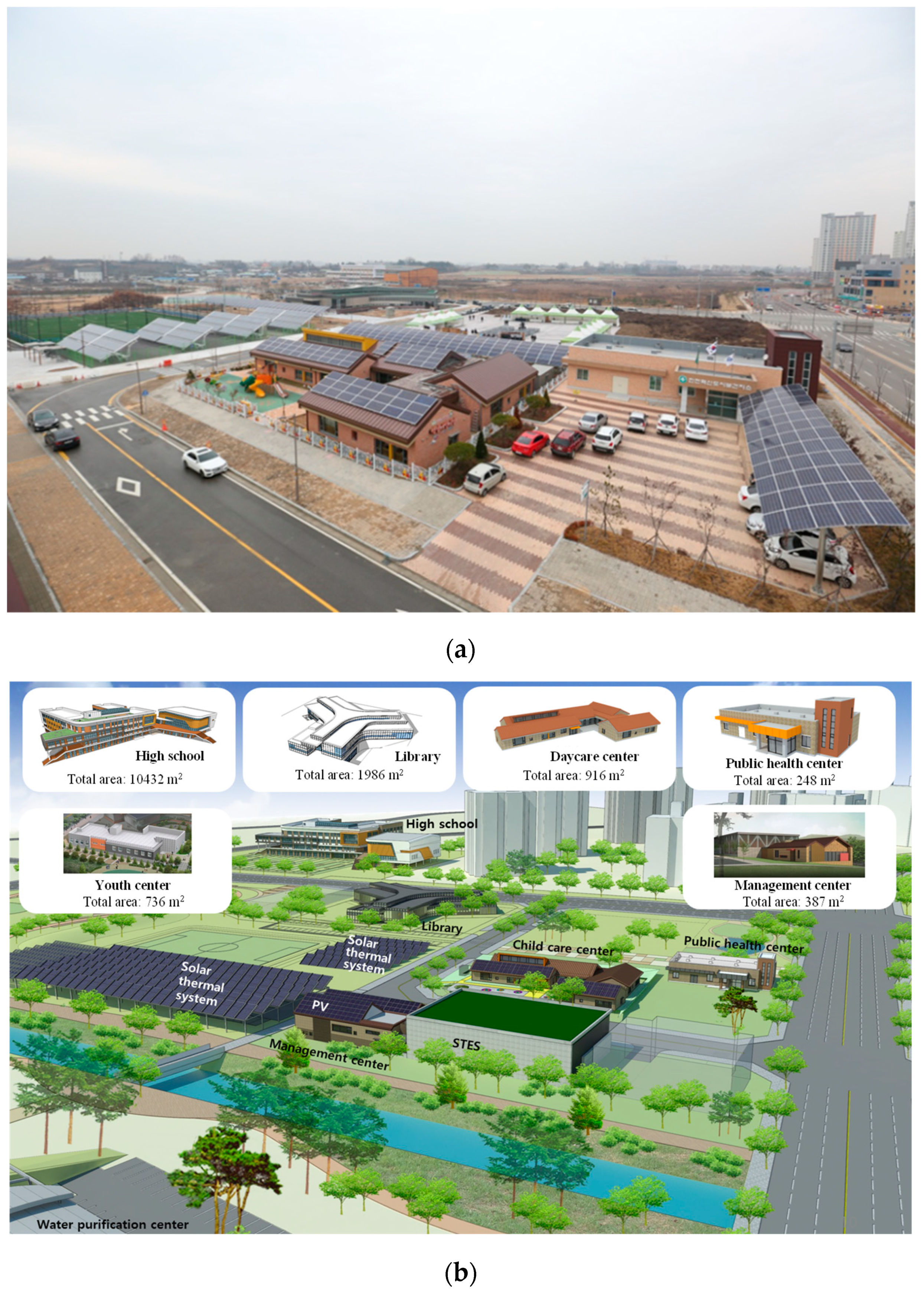

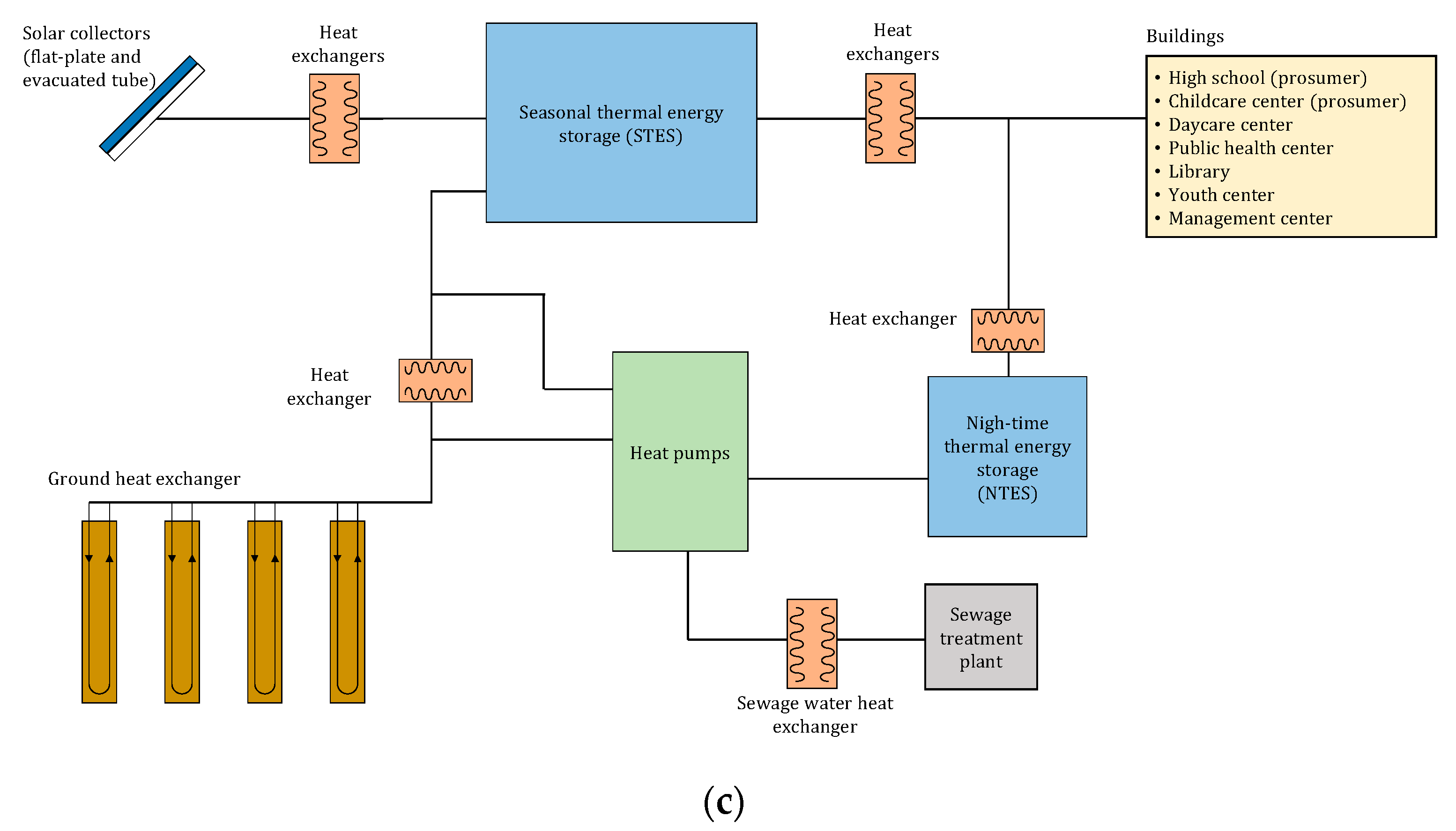

2. Overview of Field Test Site

2.1. Jincheon Eco-Friendly Energy Town

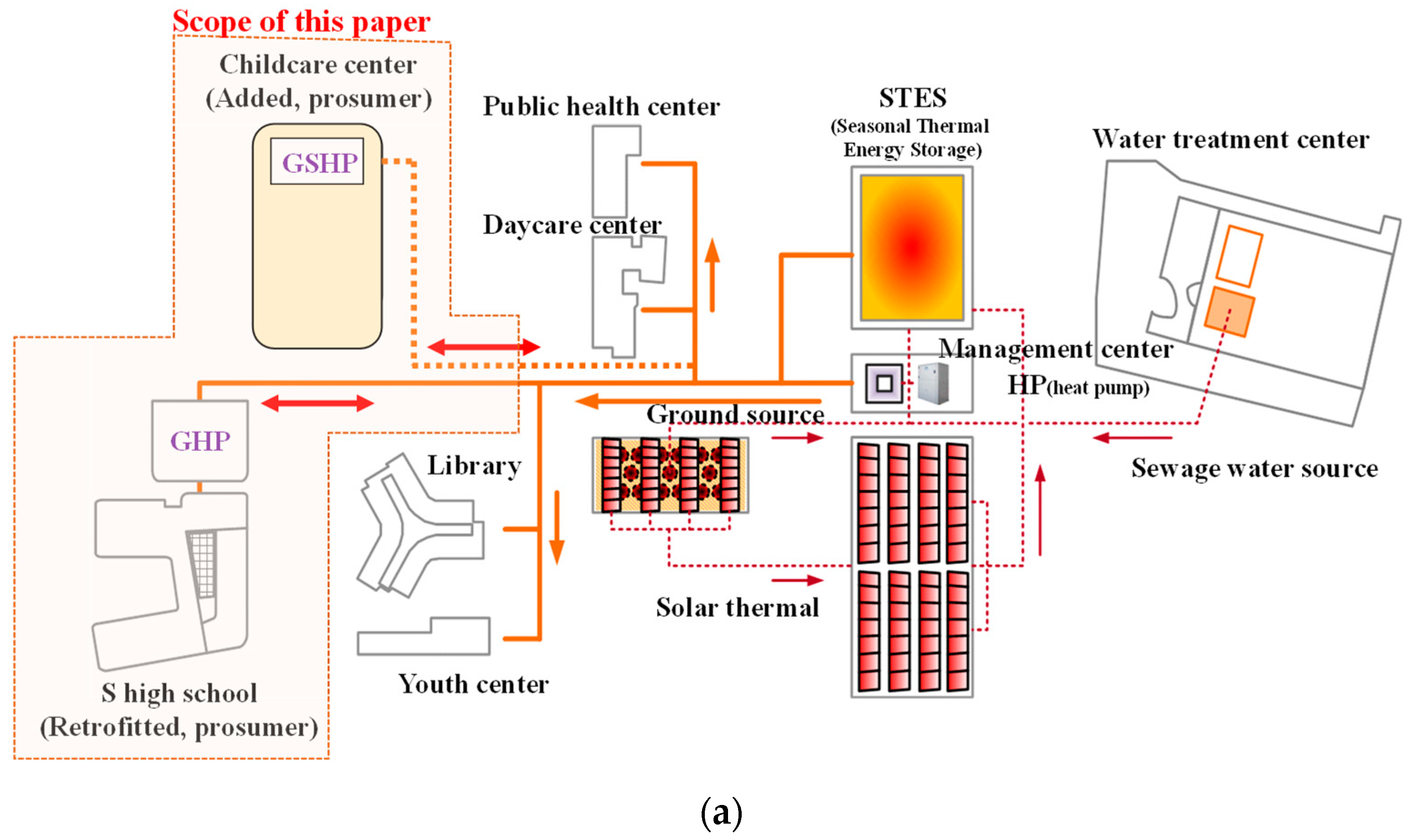

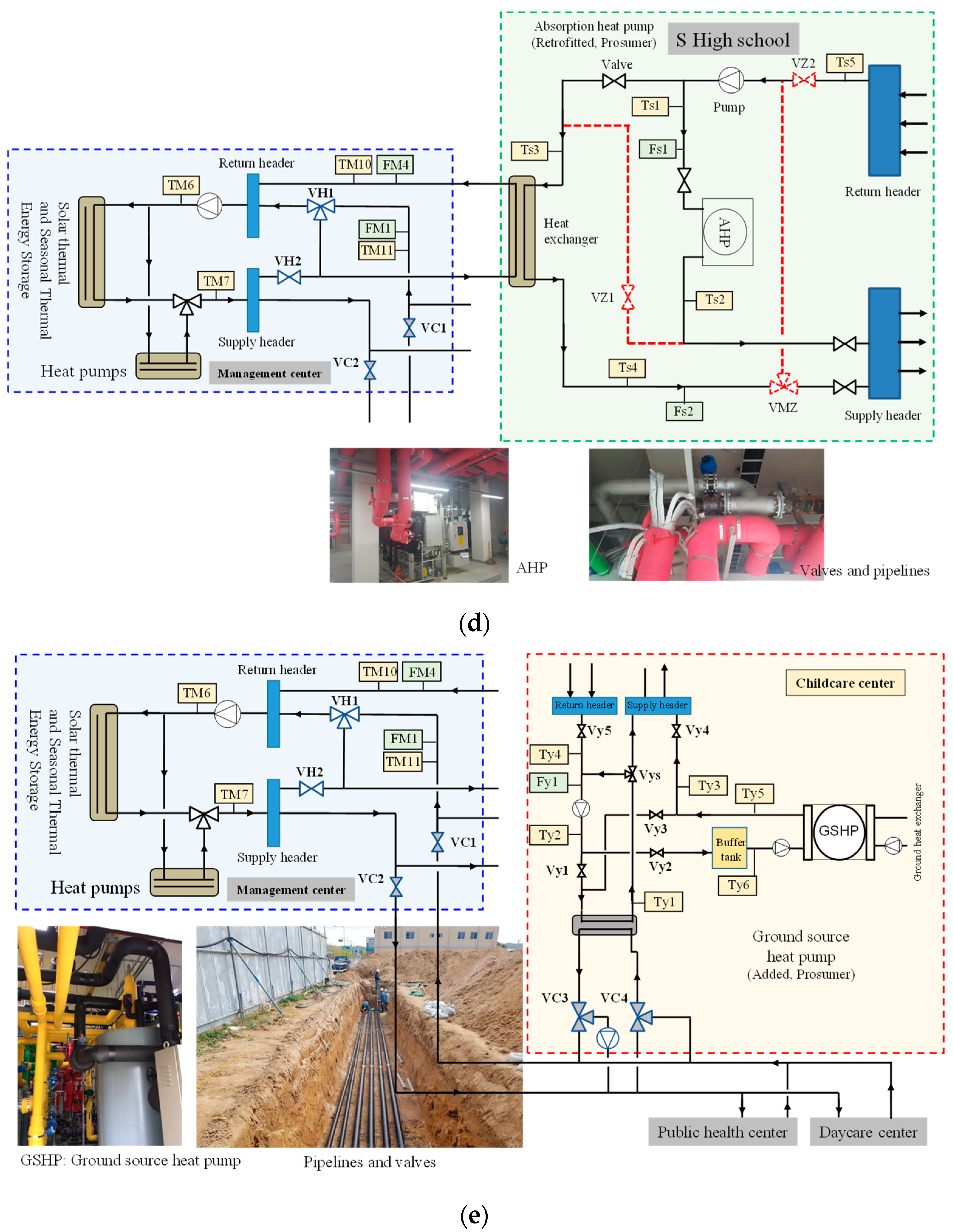

2.2. Thermal Network Retrofitting for Heat Trading

3. Methods

3.1. Overview of Experiments and Monitoring Systems

3.2. Energy Balance Equations

3.3. Simulation Overview

4. Results and Discussion

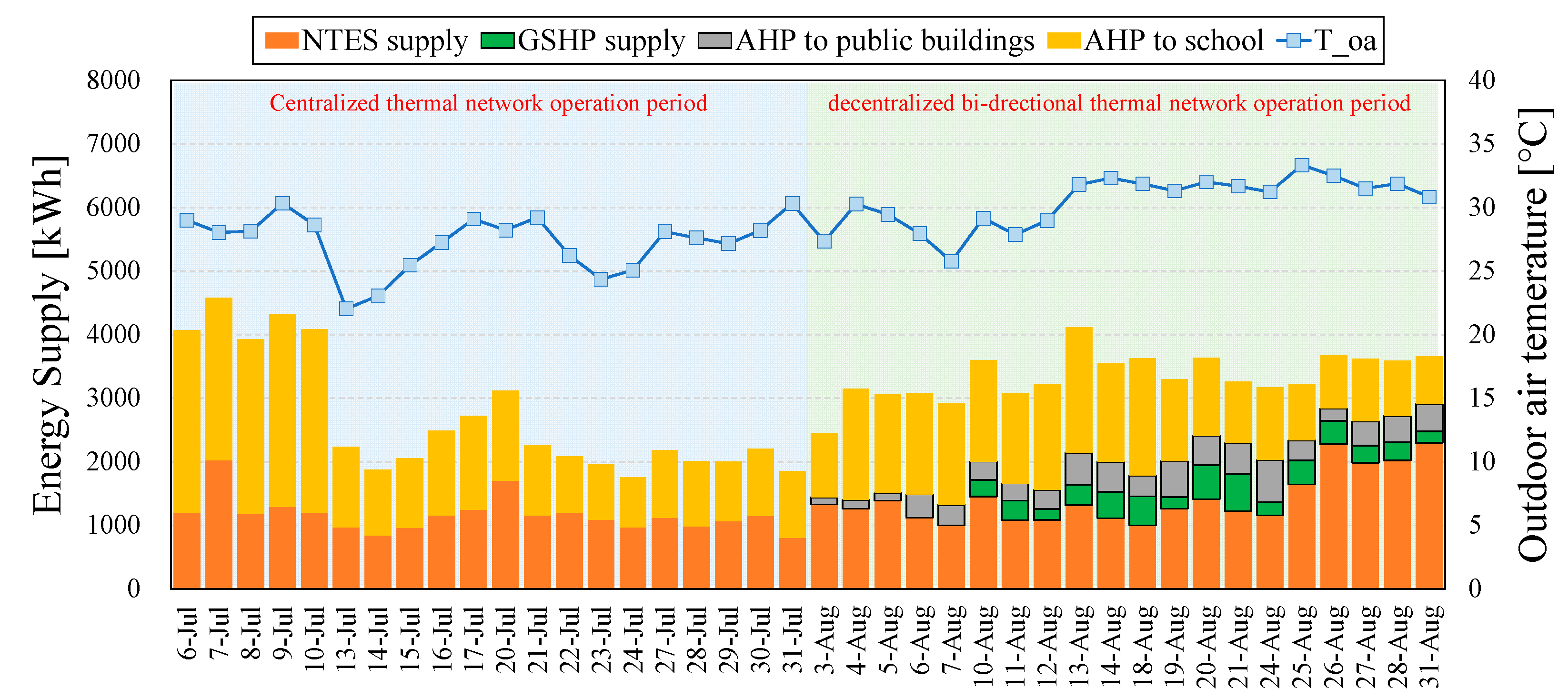

4.1. Outdoor Air Conditions and Thermal Loads

4.2. Experimental Results of the Thermal Network

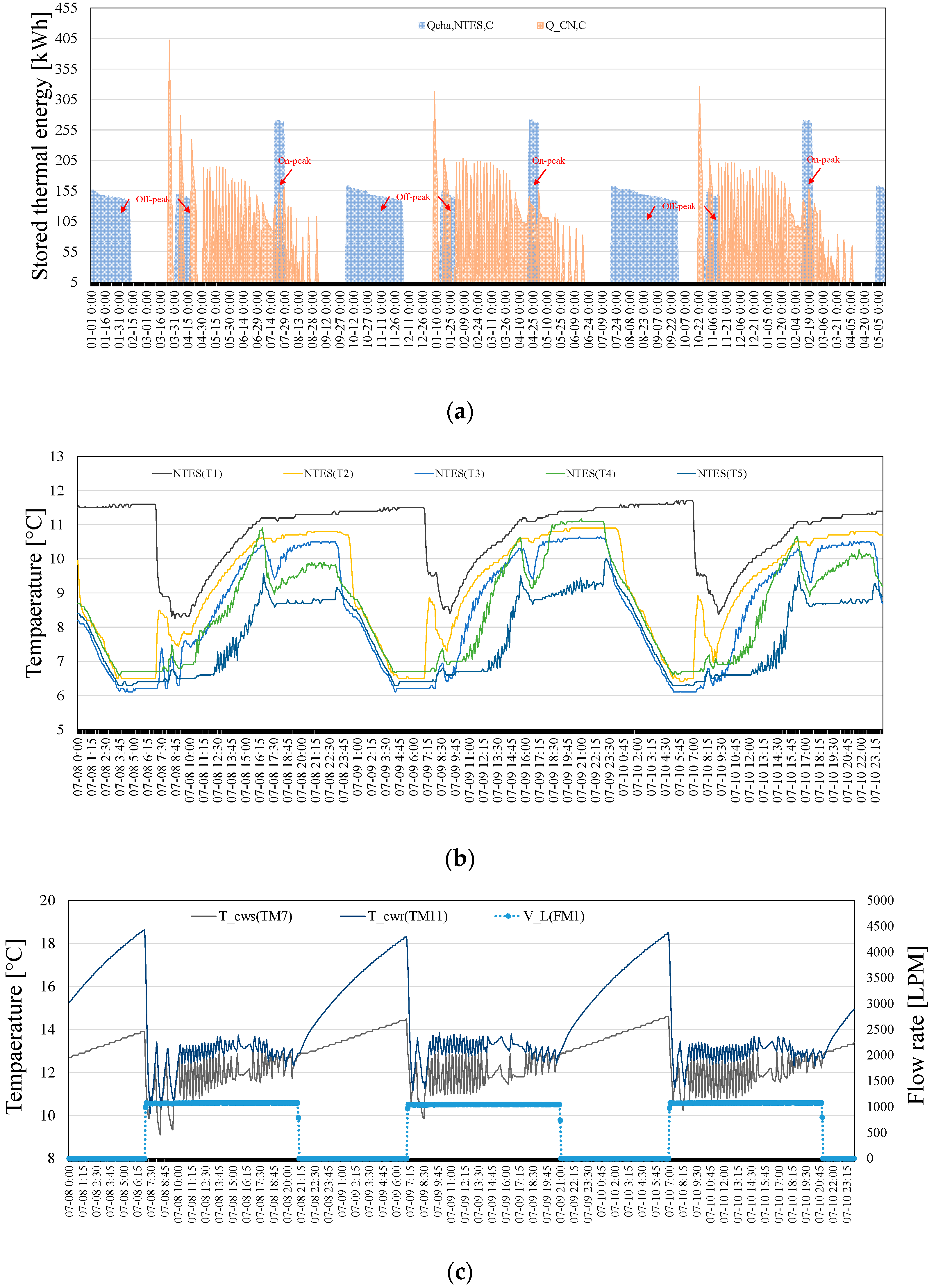

4.2.1. Conventional Centralized Thermal Network Operation

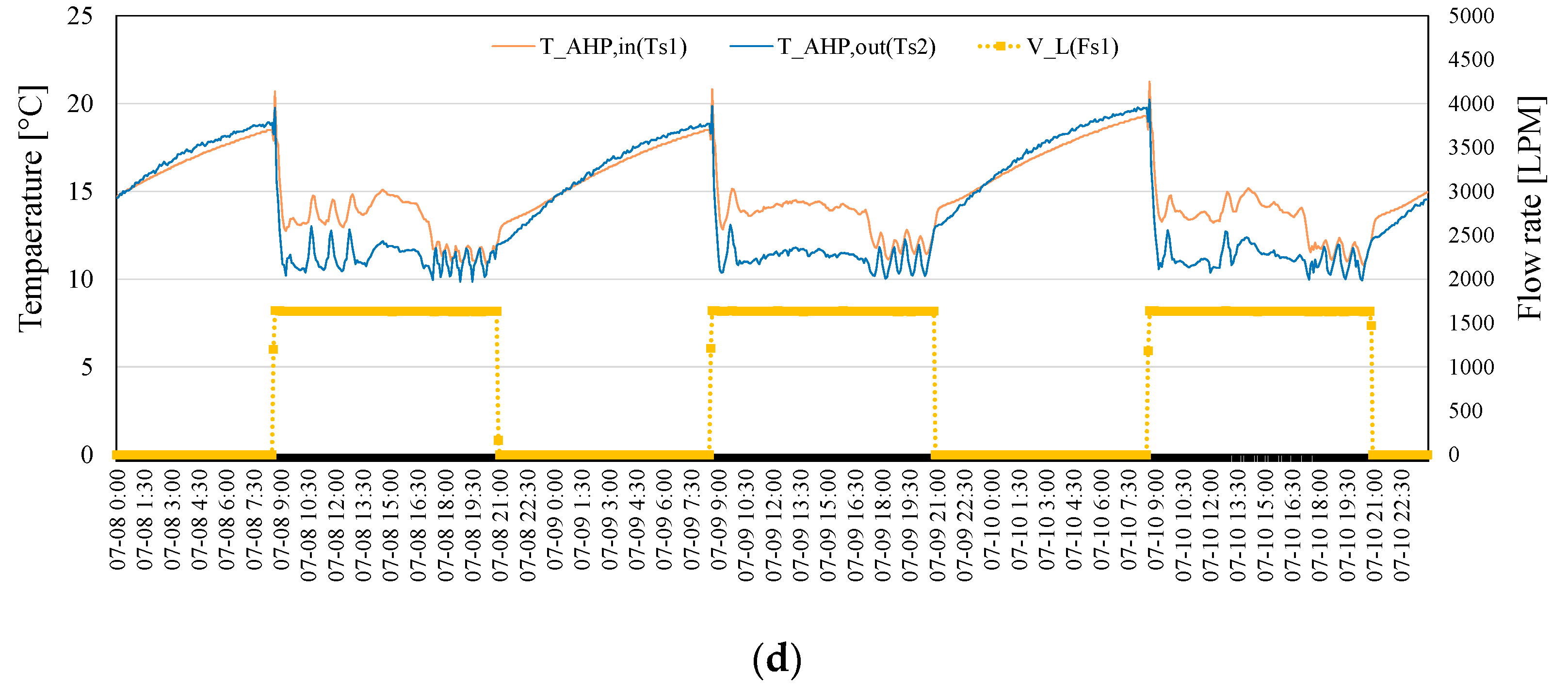

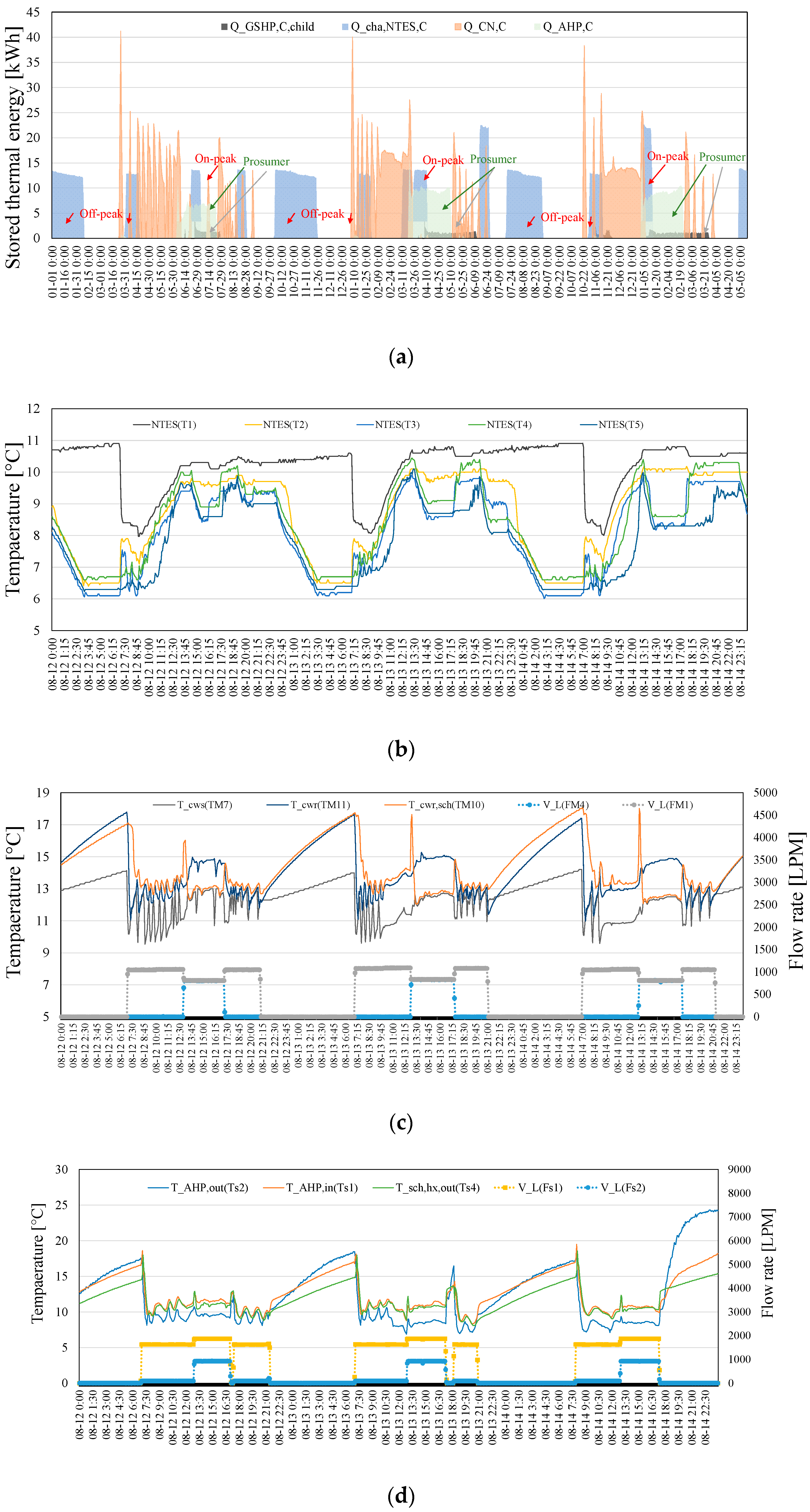

4.2.2. Bi-Didirectional Decentralized Thermal Network Operation

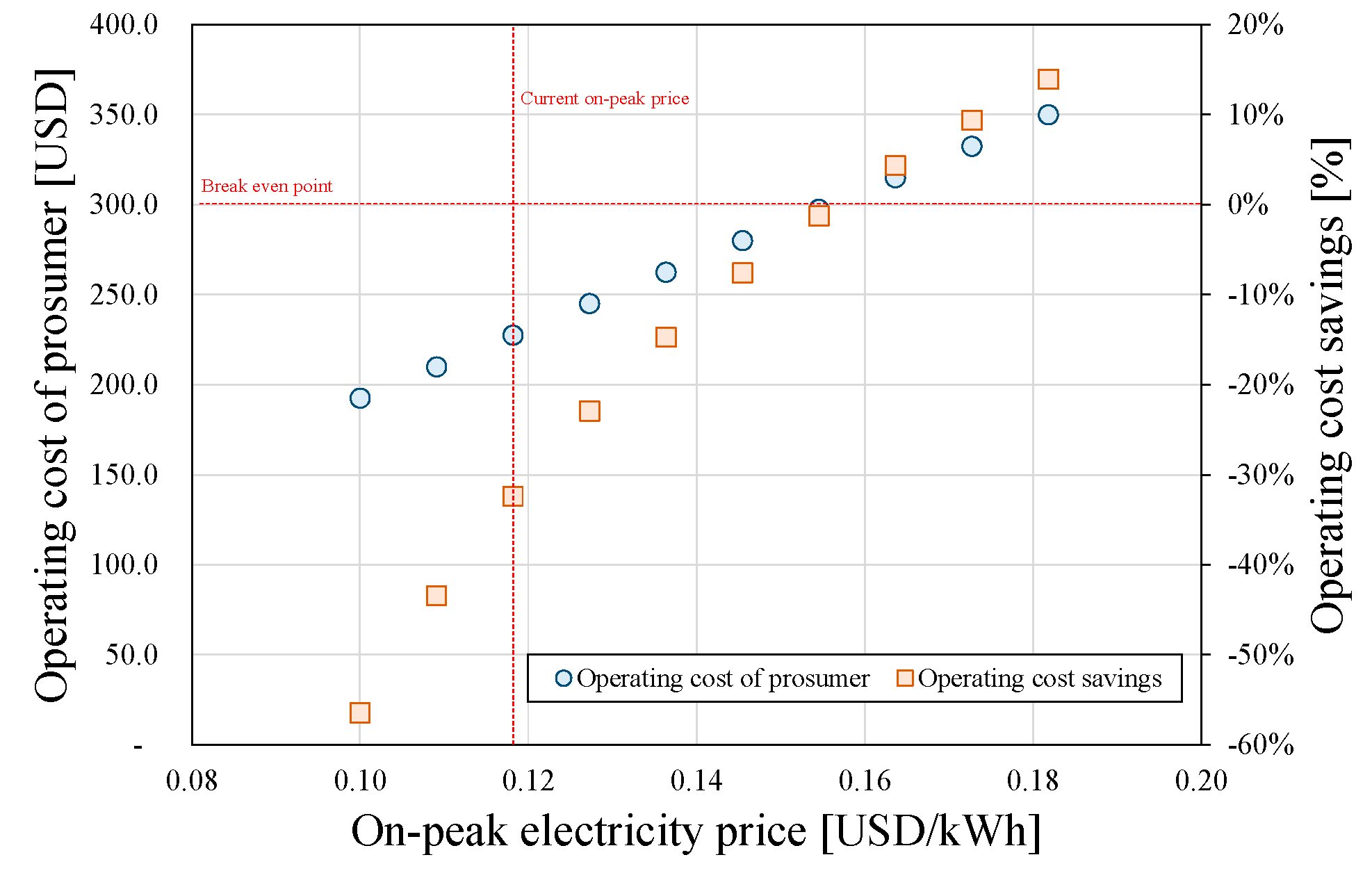

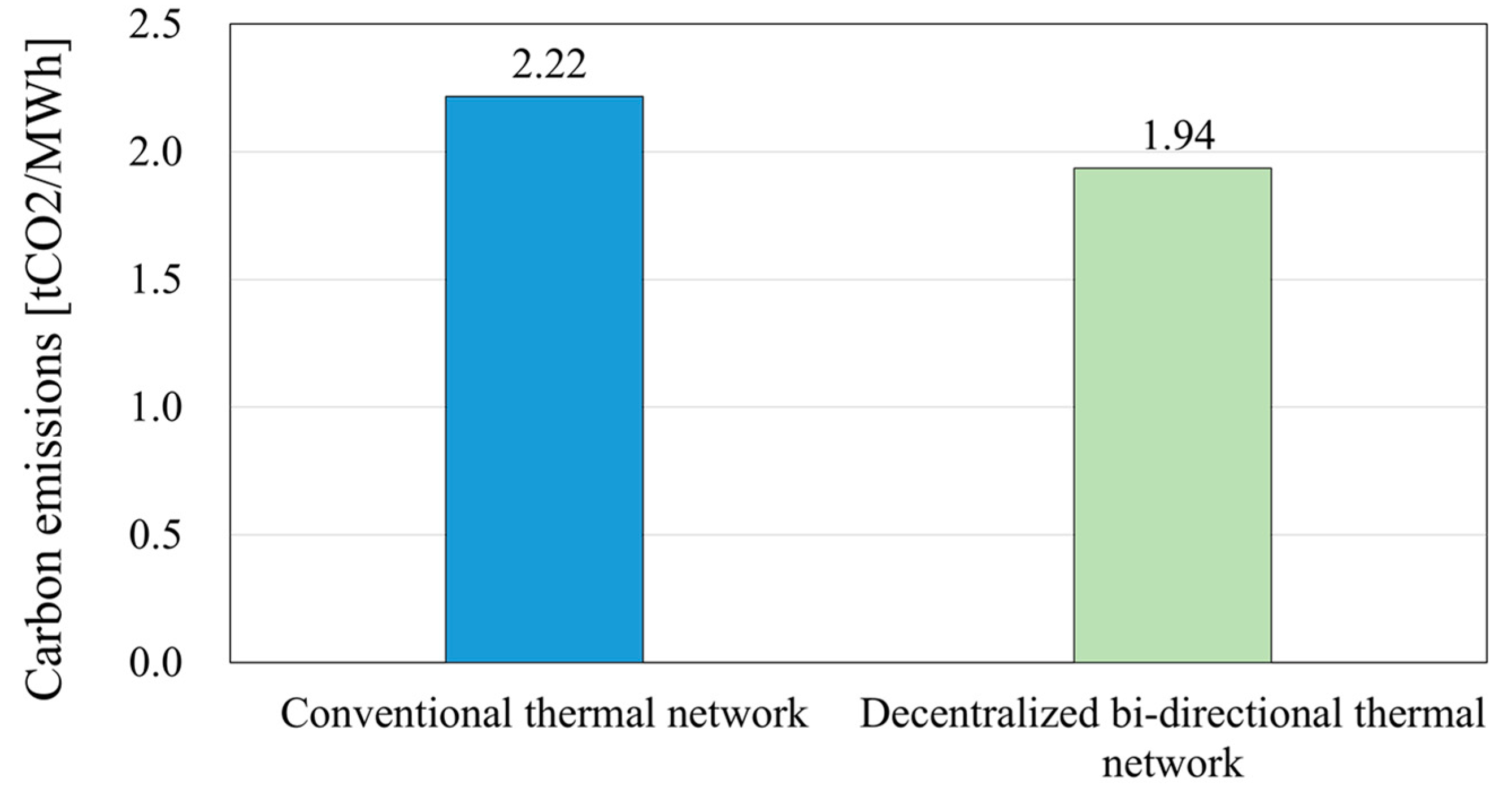

4.3. Operating Cost and Environmental Impact of the Bi-Directional Thermal Network

4.4. Discussion and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Connolly, D.; Lund, H.; Mathiesen, B.V. Smart Energy Europe: The technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew. Sustain. Energy Rev. 2016, 60, 1634–1653. [Google Scholar] [CrossRef]

- Lund, H.; Werner, S.; Wiltshire, R.; Svendsen, S.; Thorsen, J.E.; Hvelplund, F.; Mathiesen, B.V. 4th Generation District Heating (4GDH). Energy 2014, 68, 1–11. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Connolly, D.; Wenzel, H.; Ostergaard, P.A.; Möller, B.; Nielsen, S.; Ridjan, I.; KarnOe, P.; Sperling, K.; et al. Smart ennergy systems for coherent 100% renewable energy and transport solutions. Appl. Energy 2015, 145, 139–154. [Google Scholar] [CrossRef]

- Suh, H.S.; Kim, D.D. Energy performance assessment towards nearly zero energy community buildings in South Korea. Sustain. Cities Soc. 2019, 44, 488–498. [Google Scholar] [CrossRef]

- Radl, J.; Fleischhacker, A.; Revheim, F.H.; Lettner, G.; Auer, H. Comparison of Profitability of PV Electricity Sharing in Renewable Energy Communities in Selected European Countries. Energies 2020, 13, 5007. [Google Scholar] [CrossRef]

- Lopes, R.A.; Martins, J.; Aelenei, D.; Lima, C.P. A cooperative net zero energy community to improve load matching. Renew. Energy 2016, 93, 1–13. [Google Scholar] [CrossRef]

- Bloess, A.; Schill, W.-P.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Revesz, A.; Jones, P.; Dunham, C.; Davies, G.; Marques, C.; Matabuena, R.; Scott, J.; Maidment, G. Developing novel 5th generation district energy networks. Energy 2020, 201, 117389. [Google Scholar] [CrossRef]

- Buffa, S.; Cozzini, M.; D’Antoni, M.; Baratieri, M.; Fedrizzi, R. 5th generation district heating and cooling systems: A review of existing cases in Europe. Renew. Sustain. Energy Rev. 2019, 104, 504–522. [Google Scholar] [CrossRef]

- Brange, L.; Englund, J.; Lauenburg, P. Prosumers in district heating networks–A Swedish case study. Appl. Energy 2016, 164, 492–500. [Google Scholar] [CrossRef]

- Ancona, M.; Branchini, L.; De Pascale, A.; Melino, F. Smart District Heating: Distributed Generation Systems’ Effects on the Network. Energy Procedia 2015, 75, 1208–1213. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, V.F.; Uriarte, A.; Barreiro, E.; Porta, M. Smart dual thermal network. Int. J. Energy Prod. Manag. 2017, 2, 315–326. [Google Scholar] [CrossRef] [Green Version]

- Brand, L.; Calvén, A.; Englund, J.; Landersjö, H.; Lauenburg, P. Smart district heating networks–A simulation study of prosumers’ impact on technical parameters in distribution networks. Appl. Energy 2014, 129, 39–48. [Google Scholar] [CrossRef]

- Li, Y.; Fu, L.; Zhang, S.; Zhao, X. A new type of district heating system based on distributed absorption heat pumps. Energy 2011, 36, 4570–4576. [Google Scholar] [CrossRef]

- Pipiciello, M.; Caldera, M.; Cozzini, M.; Ancona, M.A.; Melino, F.; Di Pietra, B. Experimental characterization of a prototype of bidirectional substation for district heating with thermal prosumers. Energy 2021, 223, 120036. [Google Scholar] [CrossRef]

- Wirtz, M.; Kivilip, L.; Remmen, P.; Müller, D. Quantifying Demand Balancing in Bidirectional Low Temperature Networks. Energy Build. 2020, 224, 110245. [Google Scholar] [CrossRef]

- Lorenzen, P.; Janßen, P.; Winkel, M.; Klose, D.; Kernstock, P.; Schrage, J.; Schubert, F. Design of a Smart Thermal Grid in the Wilhelmsburg district of Hamburg: Challenges and approaches. Energy Procedia 2018, 149, 499–508. [Google Scholar] [CrossRef]

- Rosemann, T.; Löser, J.; Rühling, K. A New DH Control Algorithm for a Combined Supply and Feed-In Substation and Testing Through Hardware-In-The-Loop. Energy Procedia 2017, 116, 416–425. [Google Scholar] [CrossRef]

- Heymann, M.; Rosemann, T.; Rühling, K.; Tietze, T.; Hafner, B. Concept and Measurement Results of Two Decentralized Solar Thermal Feed-in Substations. Energy Procedia 2018, 149, 363–372. [Google Scholar] [CrossRef]

- Kauko, H.; Kvalsvik, K.H.; Rohde, D.; Nord, N.; Utne, Å. Dynamic modeling of local district heating grids with prosumers: A case study for Norway. Energy 2018, 151, 261–271. [Google Scholar] [CrossRef]

- Postnikov, I.; Stennikov, V.; Penkovskii, A. Prosumer in the District Heating Systems: Operating and Reliability Modeling. Energy Procedia 2019, 158, 2530–2535. [Google Scholar] [CrossRef]

- Kim, M.-H.; Lee, D.-W.; Kim, D.-W.; An, Y.-S.; Yun, J.-H. Energy Performance Investigation of Bi-Directional Convergence Energy Prosumers for an Energy Sharing Community. Energies 2021, 14, 5544. [Google Scholar] [CrossRef]

- Huang, P.; Copertaro, B.; Zhang, X.; Shen, J.; Löfgren, I.; Rönnelid, M.; Fahlen, J.; Andersson, D.; Svanfeldt, M. A review of data centers as prosumers in district energy systems: Renewable energy integration and waste heat reuse for district heating. Appl. Energy 2020, 258, 114109. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Wang, Y.; Zhao, J.; Zhu, J.; Zhong, S.; Li, Y. Energy, exergy, and economic analysis of a data center energy system driven by the CO2 ground source heat pump: Prosumer perspective. Energy Convers. Manag. 2021, 232, 113877. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, H.; Liu, R.; Wang, M.; Li, C. Configuration Optimization Model for Data-Center-Park-Integrated Energy Systems under Economic, Reliability, and Environmental Considerations. Energies 2020, 13, 448. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, S.; Hansen, K.; Lund, R.; Moreno, D. Unconventional Excess Heat Sources for District Heating in a National Energy System Context. Energies 2020, 13, 5068. [Google Scholar] [CrossRef]

- Amiri, L.; Madadian, E.; Bahrani, N.; Ghoreishi-Madiseh, S. Techno-Economic Analysis of Waste Heat Utilization in Data Centers: Application of Absorption Chiller Systems. Energies 2021, 14, 2433. [Google Scholar] [CrossRef]

- Kim, M.-H.; Lee, D.-W.; Kim, D.-W.; Heo, J. Feasibility Study of Bi-Directional Heat Supply in a Small Thermal Network. Korean J. Air-Cond. Refrig. Eng. 2021, 33, 31–41. [Google Scholar] [CrossRef]

- Kim, M.-H.; Kim, D.; Heo, J.; Lee, D.-W. Energy performance investigation of net plus energy town: Energy balance of the Jincheon Eco-Friendly energy town. Renew. Energy 2020, 147, 1784–1800. [Google Scholar] [CrossRef]

- Lim, S.-Y.; Kim, H.-J.; Yoo, S.-H. South Korean Household’s Willingness to Pay for Replacing Coal with Natural Gas? A View from CO2 Emissions Reduction. Energies 2017, 10, 2031. [Google Scholar] [CrossRef] [Green Version]

| Operation Mode | Return Valve | Closed Valve | Conventional Valve | Valve for Prosumer | |||||

|---|---|---|---|---|---|---|---|---|---|

| VH1 | VMZ | VH2 | GV1 | GV2 | GV3 | GV4 | VZ1 | VZ2 | |

| Heating mode (consumer) | Close | Close | Open | Open | Close | Open | Open | Close | Open |

| Cooling mode (consumer) | Close | Close | Close | Close | Open | Open | Close | Close | Open |

| Prosumer mode | Open | Open | Close | Close | Open | Open | Close | Open | Open |

| Operation Mode | Network Separate Valve | Closed Valve | Conventional Valve | Valve for Prosumer | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VC1 | VC2 | Vys | Vy1 | Vy2 | Vy3 | Vy4 | Vy5 | VC3 | VC4 | |

| Cooling and heating mode (consumer) | Open | Open | Close | Open | Close | Close | Close | Open | Close | Close |

| Prosumer mode | Close | Close | Open | Close | Open | Open | Open | Open | Open | Open |

| Category | Model | Specifications |

|---|---|---|

| Temperature | RTD PT100 transmitter | −10–100 °C Accuracy ±0.106 °C Resolution 0.001 °C |

| Pressure | Sensys PSCH0006K | 0–6 bar Accuracy ±0.25% FS |

| Solar radiation | Kippen & Zonen | CMP11 Accuracy 0.2% (1000 W/m2) |

| Water flow | Toshiba LF620 | Accuracy vs. > 0.5 m/s ±0.3% of rate vs. < 0.5 m/s ±0.4% of rate |

| Gas flow | RMG 132 (rotary meter) | Accuracy ±1.0% @ (0.6–65) m3/h |

| SF 2200 (gas volume corrector) | Accuracy Pressure 0.25% Temperature 0.5 °C | |

| Outdoor air temperature | GOTH-1420/PT1000 | (–36–80) °C ±(0.2–0.4) °C @ 25 °C |

| Season | Price (USD/kWh) |

|---|---|

| Heating season (i.e., October–February) | |

| Off-peak | 0.06 |

| Mid-peak | 0.09 |

| On-peak | 0.10 |

| Intermediate season (i.e., March–May, September–November) and cooling season (i.e., June–August) | |

| Off-peak | 0.05 |

| Mid-peak | 0.10 |

| On-peak | 0.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-H.; Kim, D.-W.; Lee, D.-W.; Heo, J. Experimental Analysis of Bi-Directional Heat Trading Operation Integrated with Heat Prosumers in Thermal Networks. Energies 2021, 14, 5881. https://doi.org/10.3390/en14185881

Kim M-H, Kim D-W, Lee D-W, Heo J. Experimental Analysis of Bi-Directional Heat Trading Operation Integrated with Heat Prosumers in Thermal Networks. Energies. 2021; 14(18):5881. https://doi.org/10.3390/en14185881

Chicago/Turabian StyleKim, Min-Hwi, Deuk-Won Kim, Dong-Won Lee, and Jaehyeok Heo. 2021. "Experimental Analysis of Bi-Directional Heat Trading Operation Integrated with Heat Prosumers in Thermal Networks" Energies 14, no. 18: 5881. https://doi.org/10.3390/en14185881