Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings

Abstract

:1. Introduction

2. Materials and Methods

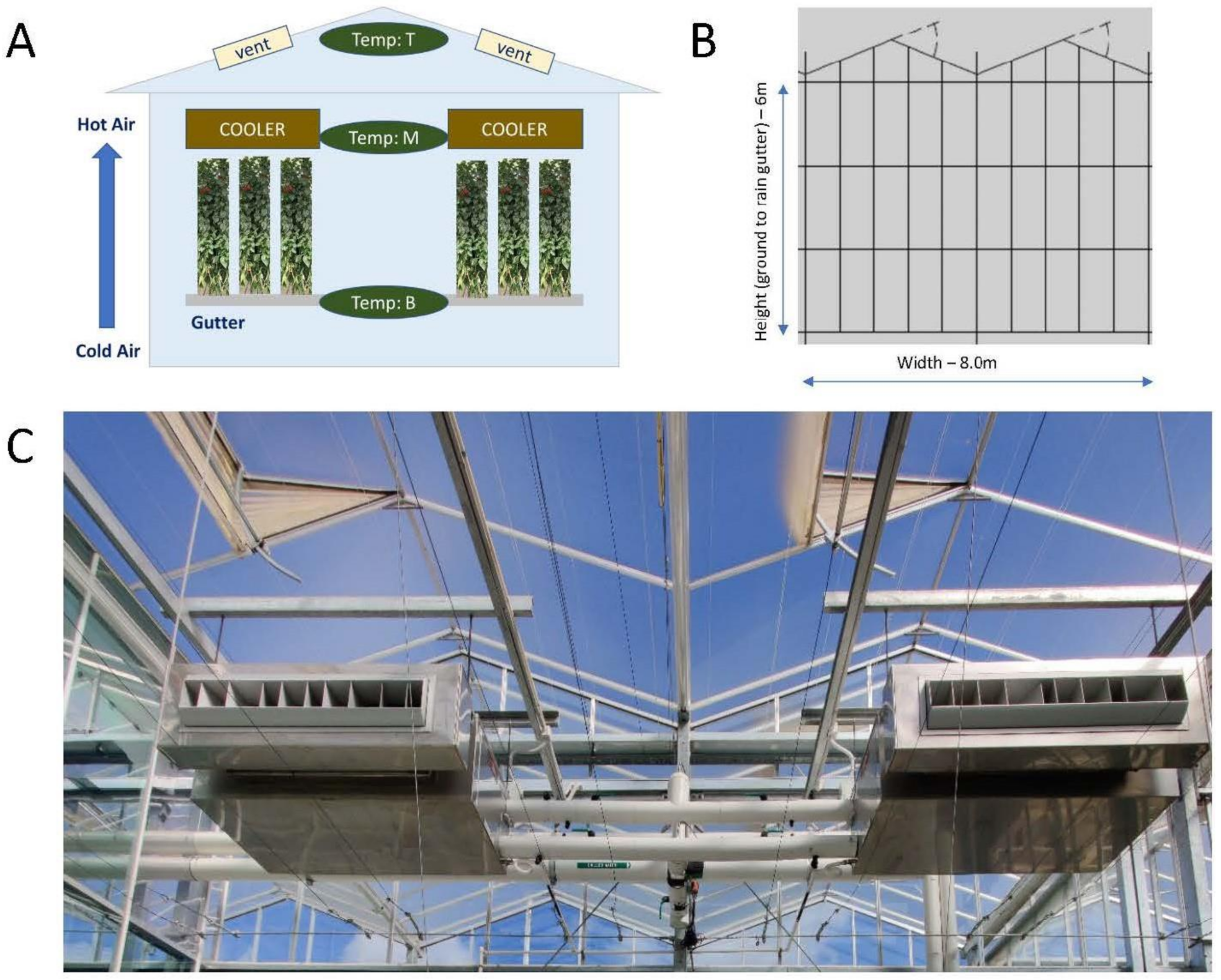

2.1. Greenhouse Hardware and Software

2.2. Research Design

2.3. Experimental Configuration

2.4. Research Compartment Parameters, Settings, and Climate Strategy

3. Results

3.1. Analysis of Overall Energy Consumption under four Different Vent/Shade Screen Configurations

3.2. Analysis of Temperature and Energy during Period 1

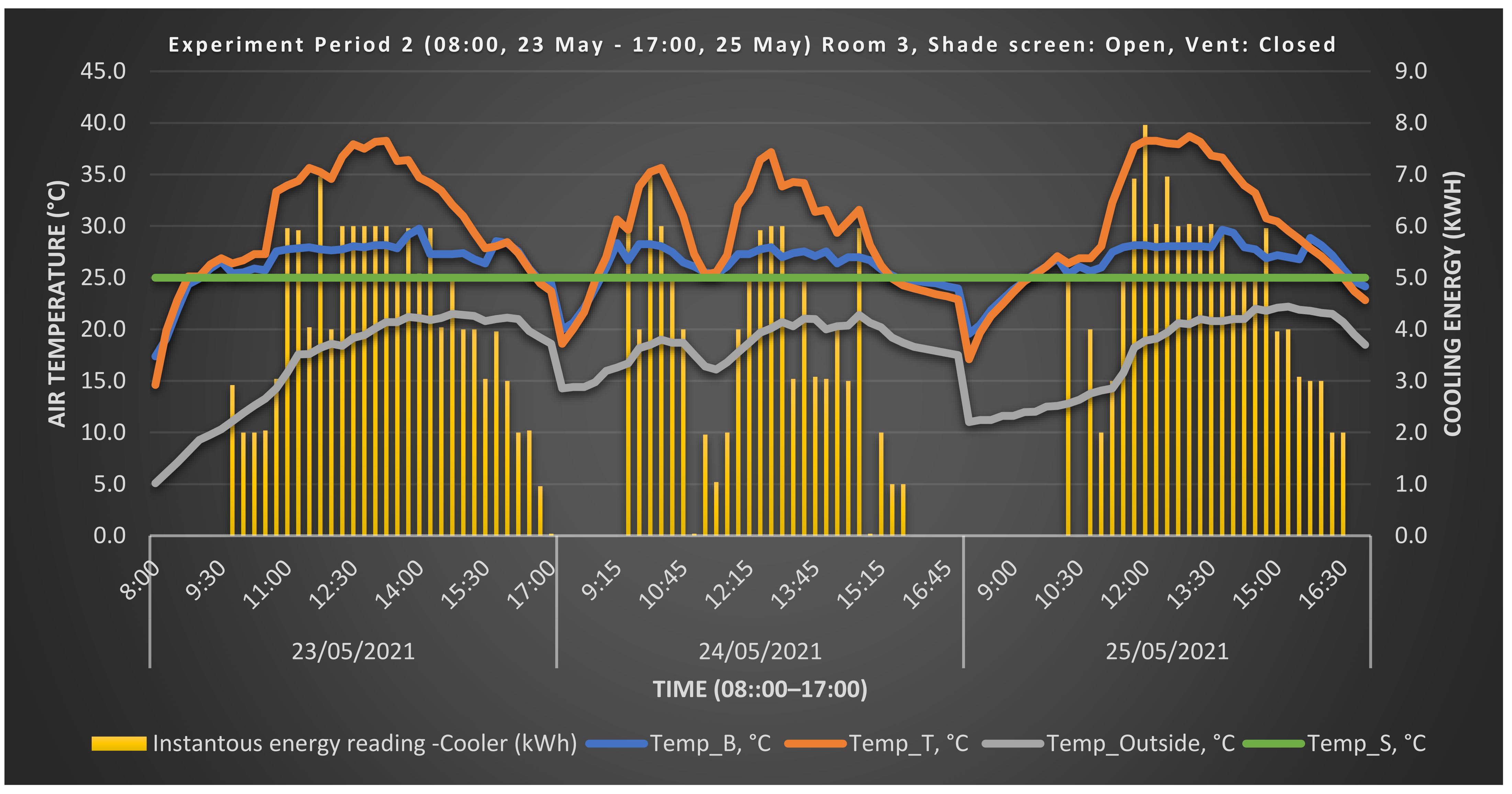

3.3. Analysis of Temperature and Energy during Period 2

3.4. Analysis of Temperature and Energy during Period 3

3.5. Analysis of Temperature and Energy during Period 4

3.6. Comparative Analysis of Energy Consumption and Potential Savings

3.7. Energy Consumption Benchmarking with Temperature Profile

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Priva Variable Name |

|---|---|

| Timestamp | Timestamp (dd/mm/yy hh:mm:ss) |

| Measured Air Temperature | Meas grh temp (°C) Des setpoint temp (°C) |

| Shade Screen | Act shade screen func. (0, 1, 2) Meas shade screen (%) |

| CO2 | Meas CO2 conc (ppm) Set conc (ppm) |

| Venting Temperature | Set vent temp (°C) Vent temp (°C) Meas vent t (°C) Base vent t (°C) |

| Vent Aperture | Min lee (%) Min wind (%) Max lee (%) Max wind (%) Meas lee (%) Meas wind (%) Act vent pos. (%) |

| Heating System (Gas Heater With Pipes) | Heat temp (°C) Set heat temp (°C) Current (A) Meter reading (kW) Total (kWh) Pump active (1, 2) |

| Cooling System (Mechanical Cooler With Pipes) | Current (A) Meter reading (kW) Total (kWh) ATS active strat (1, 2) |

| Humidity Deficit | Used HD meas. (g m−3) Des HD (g m−3) |

| Relative Humidity | Used RH meas. (%) Des RH (%) |

| Photosynthetically-active Radiation | PAR Control (μmol s−1 m−2) Used PAR (μmol s−1 m−2) PAR sum (mol m−2) |

| Irrigation/Fertigation | 24 h dose (L m−2) 24 h drain (L m−2) Meas EC drain (mS cm−2) |

Appendix B

| Descriptive Statistics | ||||||

|---|---|---|---|---|---|---|

| Variable | Count | Sum | Average | Variance | ||

| Temp_B, °C | 27 | 710 | 26.28 | 4.51 | ||

| Temp_T, °C | 27 | 809 | 29.95 | 29.33 | ||

| Temp_Outside, °C | 27 | 469.6 | 17.39 | 16.44 | ||

| ANOVA—BetweenTemp_B and Temp_T | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 181.66 | 1 | 181.66 | 10.734 | 0.0018 | 4.03 |

| Within Groups | 879.99 | 52 | 16.92 | |||

| ANOVA—Between Temp_B and Temp_Outside | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 1066 | 1 | 1066 | 101.77 | 0.00000 | 4.03 |

| Within Groups | 544.73 | 52 | 10.48 | |||

| Descriptive Statistics | ||||||

| Variable | Count | Sum | Average | Variance | ||

| Temp_B, °C | 27 | 700 | 25.92 | 4.71 | ||

| Temp_T, °C | 27 | 755 | 27.97 | 30.56 | ||

| Temp_Outside, °C | 27 | 459.4 | 17.01 | 11.50 | ||

| ANOVA—Between Temp_B and Temp_T | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 56.65 | 1 | 56.67 | 3.21 | 0.08 | 4.03 |

| Within Groups | 917.07 | 52 | 17.64 | |||

| ANOVA—Between Temp_B and Temp_Outside | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 1070.63 | 1 | 1070.63 | 132.04 | 0.0000 | 4.03 |

| Within Groups | 421.64 | 52 | 8.11 | |||

| Descriptive Statistics | ||||||

|---|---|---|---|---|---|---|

| Variable | Count | Sum | Average | Variance | ||

| Hourly Energy Consumption (kWh)—Period 2 | 27 | 337 | 12.48 | 80.13594 | ||

| Hourly Energy Consumption (kWh)—Period 3 | 27 | 203 | 7.52 | 22.28928 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

Appendix C

| Period 2 (23–25 May 2021) | Period 3 (26–28 May 2021) | |||||

|---|---|---|---|---|---|---|

| Time | Temp_B, °C | Temp_T, °C | Hourly Cooling Energy Consumption (kWh) | Temp_B, °C | Temp_T, °C | Hourly Cooling Energy Consumption (kWh) |

| 08:00 | 20.67 | 20.60 | 0.00 | 21.52 | 23.54 | 0.00 |

| 09:00 | 25.71 | 26.17 | 2.92 | 25.61 | 26.98 | 1.89 |

| 10:00 | 26.17 | 28.64 | 9.08 | 25.83 | 31.77 | 9 |

| 11:00 | 27.84 | 34.80 | 22.88 | 26.46 | 34.90 | 13 |

| 12:00 | 27.86 | 36.69 | 22 | 26.78 | 34.72 | 13.06 |

| 13:00 | 28.33 | 37.28 | 23 | 27.45 | 33.72 | 14 |

| 14:00 | 27.89 | 33.59 | 20.08 | 27.64 | 30.57 | 13 |

| 15:00 | 27.27 | 29.06 | 15 | 27.86 | 25.03 | 9.05 |

| 16:00 | 26.20 | 25.95 | 8.04 | 26.03 | 20.46 | 7 |

| 08:00 | 21.64 | 21.27 | 0 | 20.14 | 20.09 | 0 |

| 09:00 | 27.32 | 30.28 | 9.96 | 25.18 | 25.84 | 0 |

| 10:00 | 27.57 | 33.82 | 22 | 25.23 | 31.94 | 8.95 |

| 11:00 | 25.76 | 34.28 | 5.04 | 26.29 | 35.04 | 7.05 |

| 12:00 | 27.57 | 34.75 | 20.88 | 26.90 | 36.46 | 11 |

| 13:00 | 27.25 | 33.41 | 17.08 | 28.19 | 35.60 | 13.84 |

| 14:00 | 26.98 | 30.74 | 16 | 27.77 | 32.25 | 9.11 |

| 15:00 | 25.61 | 25.89 | 4.04 | 27.59 | 25.21 | 8 |

| 16:00 | 24.37 | 23.43 | 0 | 25.42 | 19.80 | 4.05 |

| 08:00 | 21.19 | 20.12 | 0 | 20.14 | 20.00 | 0 |

| 09:00 | 25.01 | 24.91 | 0 | 25.25 | 25.26 | 0 |

| 10:00 | 25.98 | 26.81 | 9 | 25.13 | 28.11 | 9 |

| 11:00 | 27.40 | 33.27 | 16.92 | 26.24 | 29.55 | 7 |

| 12:00 | 28.06 | 38.13 | 26.96 | 26.49 | 30.51 | 12.95 |

| 13:00 | 28.43 | 37.58 | 24.04 | 28.24 | 29.73 | 11.96 |

| 14:00 | 27.99 | 33.29 | 21.04 | 27.47 | 27.06 | 8.09 |

| 15:00 | 27.45 | 29.16 | 14.04 | 27.62 | 22.79 | 6.95 |

| 16:00 | 25.99 | 24.94 | 7 | 25.34 | 18.22 | 5.05 |

References

- Torrellas, M.; Antón, A.; Ruijs, M.; Victoria, N.G.; Stanghellini, C.; Montero, J.I. Environmental and economic assessment of protected crops in four European scenarios. J. Clean. Prod. 2012, 28, 45–55. [Google Scholar] [CrossRef]

- Bambara, J.; Athienitis, A.K. Energy and economic analysis for the design of greenhouses with semi-transparent photovoltaic cladding. Renew. Energy 2019, 131, 1274–1287. [Google Scholar] [CrossRef]

- Geilfus, C.-M. Protected Cropping in Horticulture. In Controlled Environment Horticulture; Springer: Cham, Switzerland, 2019; pp. 7–17. [Google Scholar]

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- Del Borghi, A.; Gallo, M.; Strazza, C.; Del Borghi, M. An evaluation of environmental sustainability in the food industry through Life Cycle Assessment: The case study of tomato products supply chain. J. Clean. Prod. 2014, 78, 121–130. [Google Scholar] [CrossRef]

- Islam, M.S.; Wong, A.T. Climate change and food in/security: A critical nexus. Environments 2017, 4, 38. [Google Scholar] [CrossRef] [Green Version]

- Castilla, N.; Montero, J.I. Environmental control and crop production in Mediterranean greenhouses. In Proceedings of the International Workshop on Greenhouse Environmental Control and Crop Production in Semi-Arid Regions 797, Tucson, AZ, USA, 20–24 October 2008; pp. 25–36. [Google Scholar]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a tomato crop in a multi-tunnel greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Flores, H.; Villalobos, J.R.; Ahumada, O.; Uchanski, M.; Meneses, C.; Sanchez, O. Use of supply chain planning tools for efficiently placing small farmers into high-value, vegetable markets. Comput. Electron. Agric. 2019, 157, 205–217. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life cycle assessment of open field and greenhouse cultivation of lettuce and barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef] [Green Version]

- Rabbi, B.; Chen, Z.H.; Sethuvenkatraman, S. Protected cropping in warm climates: A review of humidity control and cooling methods. Energies 2019, 12, 2737. [Google Scholar] [CrossRef] [Green Version]

- Stanhill, G. The energy cost of protected cropping: A comparison of six systems of tomato production. J. Agric. Eng. Res. 1980, 25, 145–154. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

- Yildizhan, H. Energy, exergy utilization and CO2 emission of strawberry production in greenhouse and open field. Energy 2018, 143, 417–423. [Google Scholar] [CrossRef]

- Golzar, F.; Heeren, N.; Hellweg, S.; Roshandel, R. A novel integrated framework to evaluate greenhouse energy demand and crop yield production. Renew. Sustain. Energy Rev. 2018, 96, 487–501. [Google Scholar] [CrossRef]

- Chavan, S.G.; Maier, C.; Alagoz, Y.; Filipe, J.C.; Warren, C.R.; Lin, H.; Jia, B.; Loik, M.E.; Cazzonelli, C.I.; Chen, Z.H.; et al. Light-limited photosynthesis under energy-saving film decreases eggplant yield. Food Energy Secur. 2020, 9, e245. [Google Scholar] [CrossRef]

- He, X.; Maier, C.; Chavan, S.G.; Zhao, C.-C.; Alagoz, Y.; Cazzonelli, C.; Ghannoum, O.; Tissue, D.T.; Chen, Z.-H. Light-altering cover materials and sustainable greenhouse production of vegetables: A review. Plant Growth Regul. 2021, 95, 1–17. [Google Scholar] [CrossRef]

- Zhao, C.; Chavan, S.; He, X.; Zhou, M.; Cazzonelli, C.I.; Chen, Z.-H.; Tissue, D.T.; Ghannoum, O. Smart glass impacts stomatal sensitivity of greenhouse Capsicum through altered light. J. Exp. Bot. 2021, 72, 3235–3248. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.-H.; Woo, B.-K.; Son, W.-T.; Park, K.-S. A study on the energy efficiency improvement of greenhouses—with a focus on the theoretical and experimental analyses. J. Mech. Sci. Technol. 2012, 26, 3331–3338. [Google Scholar] [CrossRef]

- Shen, Y.; Wei, R.; Xu, L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Høgh-Jensen, H.; Egelyng, H.; Langer, V. Energy efficiency of organic pear production in greenhouses in China. Renew. Agric. Food Syst. 2010, 25, 196–203. [Google Scholar] [CrossRef]

- Moghaddam, P.R.; Feizi, H.; Mondani, F. Evaluation of Tomato Production Systems in Terms of Energy Use Efficiency and Economical Analysis in Iran. Not. Sci. Biol. 2011, 3, 58–65. [Google Scholar] [CrossRef] [Green Version]

- Samaranayake, P.; Liang, W.; Chen, Z.-H.; Tissue, D.; Lan, Y.-C. Sustainable Protected Cropping: A Case Study of Seasonal Impacts on Greenhouse Energy Consumption during Capsicum Production. Energies 2020, 13, 4468. [Google Scholar] [CrossRef]

- Almeida, J.; Achten, W.; Verbist, B.; Heuts, R.F.; Schrevens, E.; Muys, B. Carbon and water footprints and energy use of greenhouse tomato production in Northern Italy. J. Ind. Ecol. 2014, 18, 898–908. [Google Scholar] [CrossRef]

- Zarei, M.J.; Navab, K.; Afshin, M. Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agric. Sci. 2017, 18, 249–255. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of control strategies for improving energy efficiency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. E_cacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Su, Y.; Xu, L.; Goodman, E.D. Greenhouse climate fuzzy adaptive control considering energy saving. Int. J. Control Autom. Syst. 2017, 15, 1936–1948. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Khosla, S.; Van Acker, R.; Young, S.B.; Whitney, S.; Hendricks, P. Life cycle perspectives on the sustainability of Ontario greenhouse tomato production: Benchmarking and improvement opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Payen, S.; Basset-Mens, C.; Perret, S. LCA of local and imported tomato: An energy and water trade-off. J. Clean. Prod. 2015, 87, 139–148. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Muñoz, P.; Antón, A.; Rieradevall, J. Assessment of tomato Mediterranean production in open-field and standard multi-tunnel greenhouse, with compost or mineral fertilizers, from an agricultural and environmental standpoint. J. Clean. Prod. 2011, 19, 985–997. [Google Scholar] [CrossRef]

- Bojacá, C.R.; Wyckhuys, K.; Schrevens, E. Life cycle assessment of Colombian greenhouse tomato production based on farmer-level survey data. J. Clean. Prod. 2014, 69, 26–33. [Google Scholar] [CrossRef]

- Cellura, M.; Ardente, F.; Longo, S. From the LCA of food products to the environmental assessment of protected crops districts: A case-study in the south of Italy. J. Environ. Manag. 2012, 93, 194–208. [Google Scholar] [CrossRef]

- Blengini, G.A.; Busto, M. The life cycle of rice: LCA of alternative agri-food chain management systems in Vercelli (Italy). J. Environ. Manag. 2009, 90, 1512–1522. [Google Scholar] [CrossRef] [PubMed]

| Period 1: May 20 (08:00)–22 (17:00) | Period 2: May 23 (08:00)–25 (17:00) | Period 3: May 26 (08:00)–28 (17:00) | Period 4: May 29 (08:00)–31 (17:00) | ||||

|---|---|---|---|---|---|---|---|

| Shade screen Status | Vent Status | Shade screen Status | Vent Status | Shade screen Status | Vent Status | Shade screen Status | Vent Status |

| Open | Open | Open | Closed | Closed | Open | Closed | Closed |

| Experiment Variable | Description |

|---|---|

| Date | Experiment period from 20 May to 31 May 2021 |

| Time | 15 min interval from 08:00 to 17:00 each day |

| Temp_B (°C) | Temperature captured at the gutter level |

| Temp_M (°C) | Temperature captured at the mechanical cooler level |

| Temp_T (°C) | Temperature captured at the rooftop level |

| Temp_S (°C) | Set Temperature at the facility as the desired temperature |

| Temp_Outside (°C) | Outdoor temperature captured from the weather station installed above the northwestern corner of the facility |

| Instantaneous energy reading—Cooler (kWh) | Energy usage measured in kilowatt-hour for cooling units (>0 active; 0 = inactive) for each time period (15 min) |

| Day of the Period | Period 1 Shade Screen/Vent (Open/Open) | Period 2 Shade Screen/Vent (Open/Closed) | Period 3 Shade Screen/Vent (Closed/Open) | Period 4 Shade Screen/Vent (Closed/Closed) |

|---|---|---|---|---|

| Day 1 | 79 | 123 | 80 | 78 |

| Day 2 | 0 | 95 | 62 | 41 |

| Day 3 | 79 | 119 | 61 | 92 |

| Average energy consumption | 52.67 | 112.33 | 67.67 | 70.33 |

| Average (Day 1 and Day 3) | 79 | 121 | 70.5 | 85 |

| Standard Error | 26.33 | 8.74 | 6.17 | 15.21 |

| Period | The Temperature at Gutter Level (°C) | Cooling Energy Consumption (kWh) | |||||

|---|---|---|---|---|---|---|---|

| Average Temp_B | Min Temp_B | Max Temp_B | Hourly Average | Hourly Minimum | Hourly Maximum | Per 1 °C Cooling (kWh) | |

| Period 2 | 27.12 | 25.61 | 28.43 | 15.32 | 2.92 | 26.96 | 7.23 |

| Period 3 | 26.71 | 25.13 | 28.24 | 9.23 | 1.89 | 14.00 | 5.40 |

| Day 1 (Periods 2 and 3) | Day 2 (Periods 2 and 3) | Day 3 (Periods 2 and 3) | |||

|---|---|---|---|---|---|

| Time-HRS | Temp_B, °C | Time-HRS | Temp_B, °C | Time-HRS | Temp_B, °C |

| 08:00 | 21.1 | 8:00 | 20.89 | 08:00 | 20.67 |

| 09:00 | 25.66 | 10:00 | 26.4 | 10:00 | 25.55 |

| 08:51 | 25.0 | 9:29 | 25.0 | 09:47 | 25.0 |

| State | Wholesale Price per MWh (2020) * | Estimated Energy Savings in the WSU Greenhouse, $ °C−1 | Estimated Energy Savings in a 10-Ha High-Tech Greenhouse, $ °C−1 |

|---|---|---|---|

| VIC | $40 | $19.76 | $17,967 |

| NSW | $71 | $35.08 | $31,892 |

| QLD | $48 | $23.72 | $21,561 |

| SA | $35 | $17.29 | $15,721 |

| TAS | $46 | $22.73 | $20,662 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samaranayake, P.; Maier, C.; Chavan, S.; Liang, W.; Chen, Z.-H.; Tissue, D.T.; Lan, Y.-C. Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings. Energies 2021, 14, 6014. https://doi.org/10.3390/en14196014

Samaranayake P, Maier C, Chavan S, Liang W, Chen Z-H, Tissue DT, Lan Y-C. Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings. Energies. 2021; 14(19):6014. https://doi.org/10.3390/en14196014

Chicago/Turabian StyleSamaranayake, Premaratne, Chelsea Maier, Sachin Chavan, Weiguang Liang, Zhong-Hua Chen, David T. Tissue, and Yi-Chen Lan. 2021. "Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings" Energies 14, no. 19: 6014. https://doi.org/10.3390/en14196014

APA StyleSamaranayake, P., Maier, C., Chavan, S., Liang, W., Chen, Z.-H., Tissue, D. T., & Lan, Y.-C. (2021). Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings. Energies, 14(19), 6014. https://doi.org/10.3390/en14196014