Abstract

Sorption thermochemical storage systems can store thermal energy for the long-term with minimum amount of losses. Their flexibility in working with sustainable energy sources further increases their importance vis-à-vis high levels of pollution from carbon-based energy forms. These storage systems can be utilized for cooling and heating purposes or shifting the peak load. This review provides a basic understanding of the technologies and critical factors involved in the performance of thermal energy storage (TES) systems. It is divided into four sections, namely materials for different sorption storage systems, recent advances in the absorption cycle, system configuration, and some prototypes and systems developed for sorption heat storage systems. Energy storage materials play a vital role in the system design, owing to their thermal and chemical properties. Materials for sorption storage systems are discussed in detail, with a new class of absorption materials, namely ionic liquids. It can be a potential candidate for thermal energy storage due to its substantial thermophysical properties which have not been utilized much. Recent developments in the absorption cycle and integration of the same within the storage systems are summarized. In addition, open and closed systems are discussed in the context of recent reactor designs and their critical issues. Finally, the last section summarizes some prototypes developed for sorption heat storage systems.

1. Introduction

The substantial rise in global temperature over the last few decades owing to increased energy consumption is alarming and has negative global ramifications. Reports on future energy demand forecast an increase of 18% for developed countries and 71% for developing countries until 2040, which is a great concern. Long-term utilization of fossil fuels for energy production threatens human life and the ecosystem. These factors have motivated the stakeholders to reduce their dependence on traditional non-renewable energy sources [1,2]. The cognizance of people’s role in climate change is the primary driver of environmentally friendly energy production and utilization [3]. Eco-friendly energy resources are abundant and are safe for the future. Therefore, it is essential to explore sustainable sources, such as wind energy, solar energy, and biomass energy, which have sufficient potential to fulfill the energy demands [4]. Solar energy is reliable and is available in abundance in nature compared to other energy resources. Its ecological nature has attracted the attention of researchers as a potential source of energy. Solar energy can be harnessed into thermal energy using photothermal conversion systems or electrical energy with photovoltaic cells [5,6].

Photothermal conversion systems are based on the photothermal effect, which produces thermal energy by photoexcitation of the material used. However, the optical and thermophysical properties of the materials utilized are critical for the overall efficiency of the system. Recent advances in nanoscale materials have attracted the attention of researchers. Boldoo et al. [7] reviewed the performances of different nanofluids and their recent developments in photothermal conversion. It was concluded that their preparation method and enhancement of their optical properties could increase the solar photothermal conversion efficiency.

Furthermore, the magnetic field and good dispersion stability of the working fluid helps improve efficiency. Different types of collectors have been reported in the literature for solar energy conversion, and their selection criteria depend on the output temperature of the system. Consumption of thermal energy from the sun is accepted worldwide, and intense research has been conducted on the same. Solar thermal energy has numerous applications, including distillation and desalination, domestic water heating systems, industrial process heat, and drying [8]. The main challenge in working with solar energy is its intermittent nature, which is a significant barrier to its mass implementation. The conversion of solar energy to thermal energy is limited because of a mismatch between the supply and demand; this situation can be mitigated if a storage system is used, which results in minimizing the gap [9]. Coupling the energy resources with a storage system enhances the system performance and offers high-grade energy throughout the year, regardless of seasonal limitations. The solar thermal energy collected during summers or peak hours can be consumed during subsequent months. Some of the globally operational concentrating solar power plants with TES systems are listed in Table 1.

Table 1.

Globally operational concentrated solar plants with energy storage systems [10].

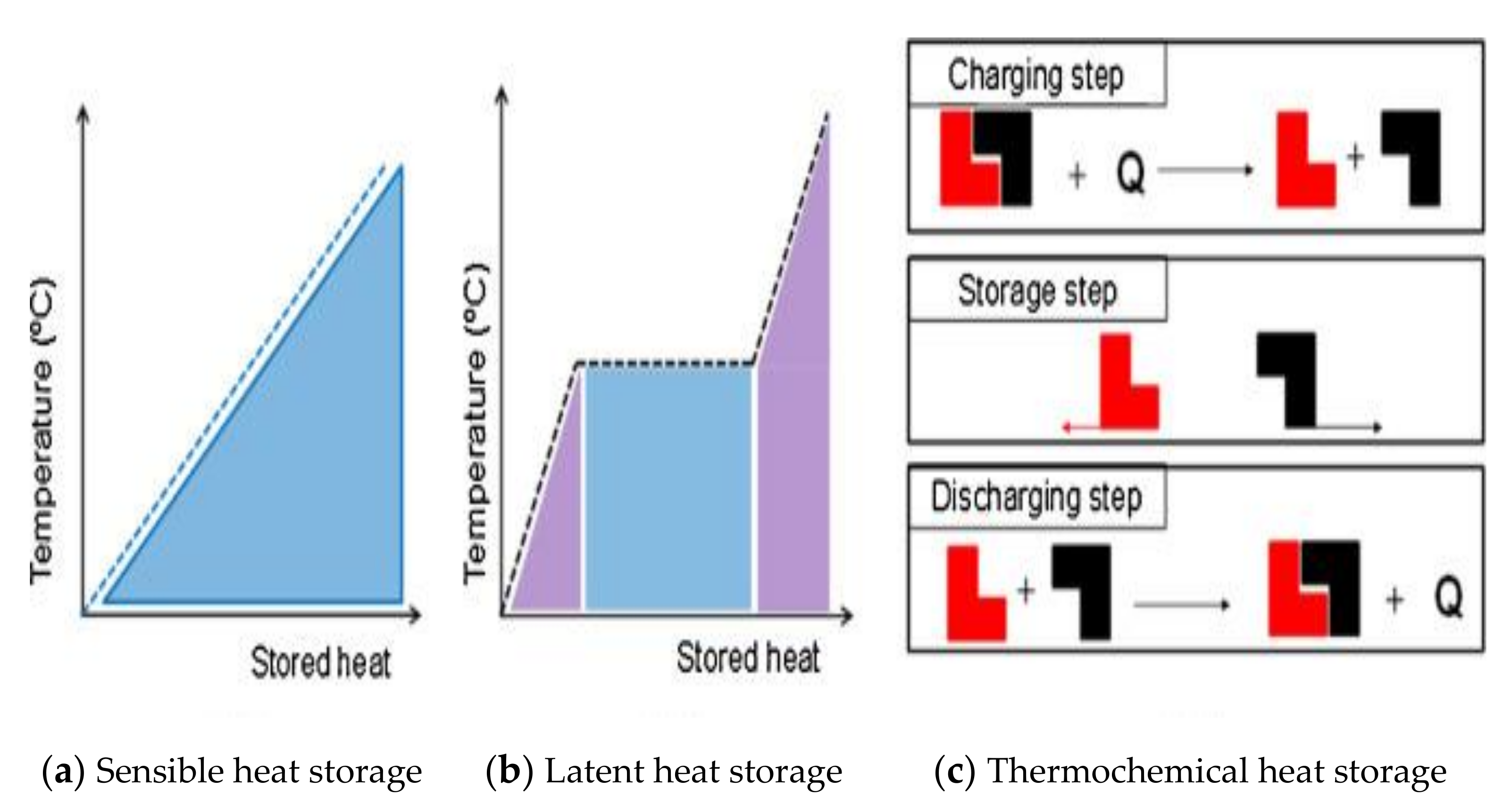

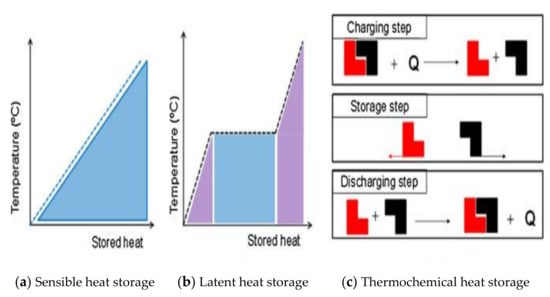

The primary mechanism of all TES systems is the same. The steps involved in utilizing thermal energy include charging, storing, and discharging, which together are termed a cycle. During charging, energy is supplied to the system to be stored and retrieved during the discharging. The main variations involve the amount of energy stored and the selection of storage methods utilized. Another aspect related to the thermal storage system is the temperature output. Storage systems are categorized as low- and medium-to-high-temperature storage systems. The type of storage system is selected based on its temperature output. The low-temperature thermal energy storage temperature range is defined by different authors, which varies considering < 120 °C, whereas others considered temperature < 200 °C as thermal energy storage for low-temperature applications. In this study, the temperature range considered for low-temperature applications is <200 °C [11,12]. Based on the TES mechanism, three different techniques are commonly used, namely sensible heat storage, latent heat storage, and thermochemical heat storage [13,14]. These are depicted in Figure 1. The thermochemical heat storage represented in Figure 1c shows the different steps involved in storing the heat energy. This includes a charging step where the molecular blocks in the pictorial view when absorbing the heat will split the blocks and can be stored separately throughout the storage duration; during the discharging step, the molecular blocks are reunited and the absorption heat is retrieved from the system.

Figure 1.

Different approaches for TES [15]: (a) Sensible heat storage; (b) Latent heat storage; (c) Thermochemical heat storage. The red and black blocks represent molecular blocks with Q as absorption heat.

Sensible heat storage works by stepping up the temperature of a material without any phase change, as shown in Figure 1a. Thermal energy can be accumulated via an exchange of heat in a thermodynamic system, and results in an increase in the temperature of the material, and a subsequent release of the energy by decreasing the temperature of the material. Sensible heat storage is dependent on the thermophysical properties of the material used [16]. The material used for sensible heat storage can be in a liquid or solid state. Some of the low-temperature sensible heat storage projects and potential materials are summarized in Table 2 and Table 3, respectively. Equation (1) gives the amount of heat stored as sensible heat in a storage system.

where Q is the amount of sensible heat energy stored (J), m mass of the storage material (kg), cp specific heat capacity (kJ/kg K), dT temperature difference (°C), Tf final temperature (°C), and Ti is the initial temperature (°C).

Table 2.

Commercial projects for sensible heat storage.

Table 3.

Sensible heat storage materials [13].

Latent heat storage employs a phase transition at a constant temperature to accumulate or retrieve thermal energy by the latent heat of fusion of the storage medium, as shown in Figure 1b. Phase change materials (PCMs) have a high energy density and they can increase the energy storage capacity of the system; however, they have a low thermal conductivity. The latent heat of fusion, melting point, and chemical stability of the material are essential properties [24,25,26]. These mechanisms have been extensively researched, and some common materials used for latent heat storage are presented in Table 4. The amount of heat stored in such a storage system can be calculated using Equation (2).

Table 4.

Commonly used materials for latent heat storage [27].

Where Q is the amount of latent heat energy stored (J), m mass of the storage material (kg), cp specific heat capacity (kJ/kg K), dT temperature difference (°C), am amount of fraction melted (kg), Tf final temperature (°C), Ti initial temperature (°C), Tm melting temperature (°C), and Tf is the freezing temperature (°C).

A thermochemical energy storage (TCES) system uses sorption, which is a term collectively used for absorption, adsorption, and reversible chemical reactions. The energy is stored depending on the formation and splitting of the molecular bonds. During the charging phase, heat can be directed to a working pair, which absorbs energy and splits the sorbate and sorbent to store the energy, and is kept separately until the discharging phase is initiated. The energy is retrieved in an exothermic reaction during the discharging phase by integrating some reactant substances [28]. The output temperature and heat capacity of the system depends on the thermal and chemical properties of the reactant. The working mechanism of a TCES system is illustrated in Figure 1c. The amount of energy stored in a TCES system can be calculated using Equation (3). As the aforementioned thermal storage methods have both advantages and disadvantages, they are typically selected according to the application.

where Q is the amount of thermochemical energy stored (J), m mass of the storage material (kg), ar is the amount of the fraction reacted (kg), and Δhr is the heat of reaction (kJ/kg).

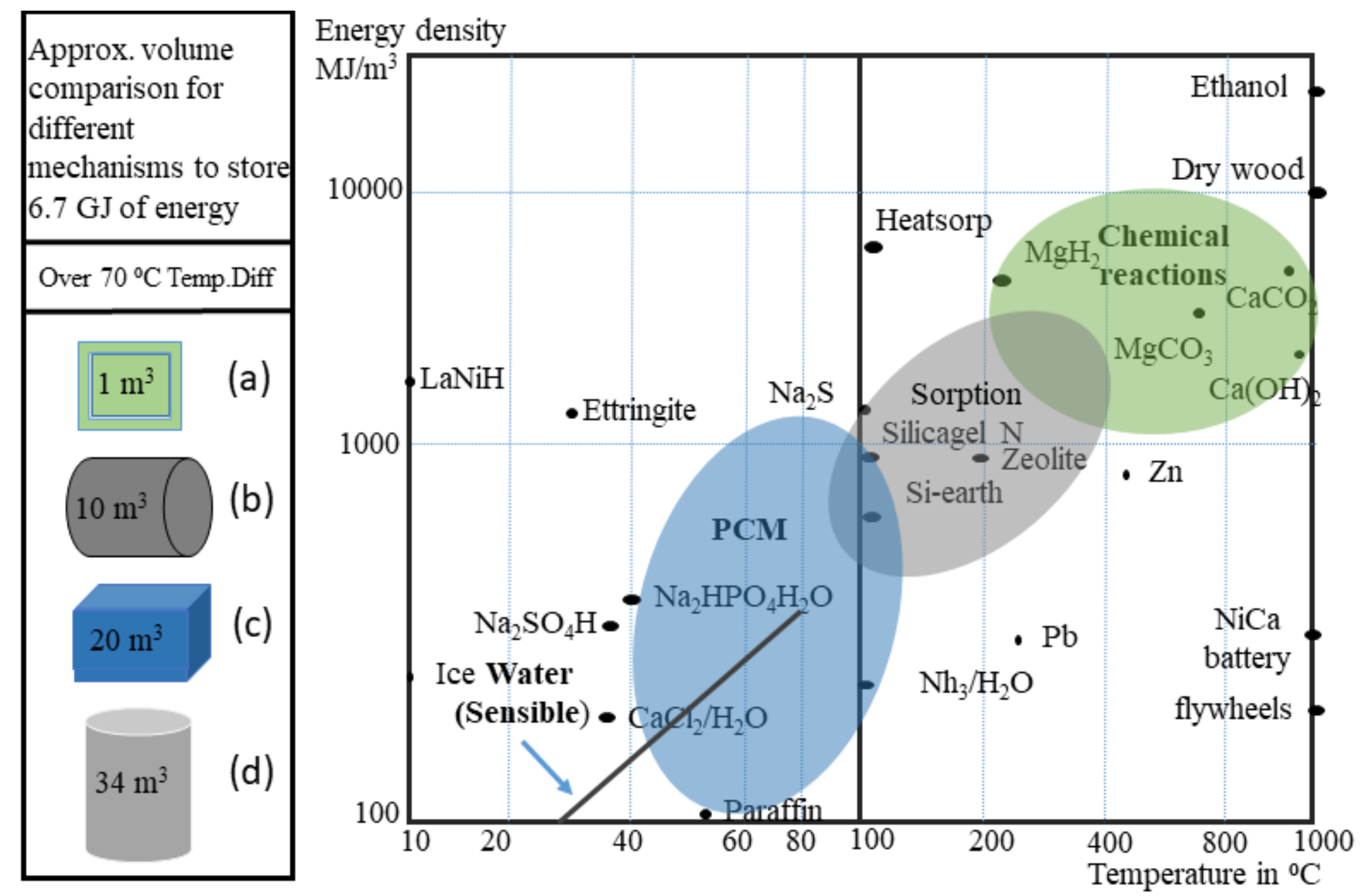

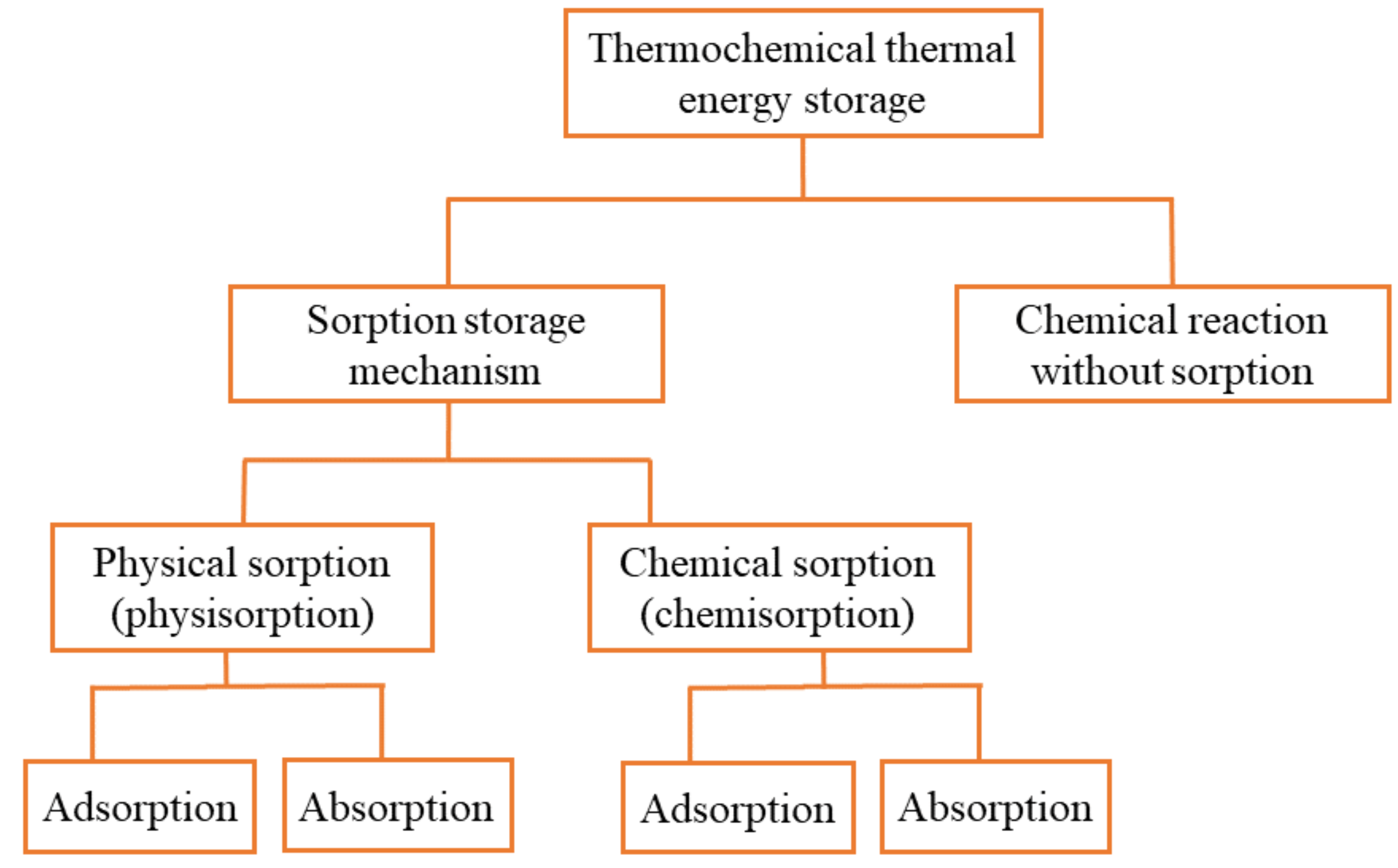

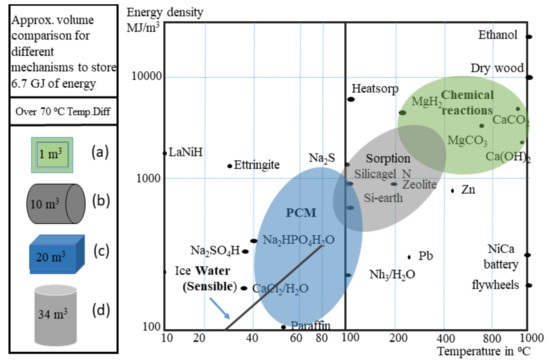

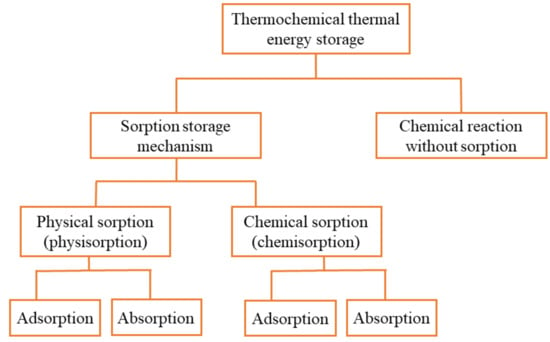

Table 5 presents a brief overview of the salient features of the technologies mentioned for different storage systems [29]. TCES appears to be most favorable and reliable for TES in the existing technologies with high energy densities, as it can preserve energy for a long time with minimum energy losses. Figure 2 illustrates the energy densities for the different TES mechanisms, among which the TCES has the highest energy density, followed by the latent heat storage system [30]. With a high energy density, the volume required to store the energy should be reduced. To store a 6.7 MJ of energy, TCES required the minimum volume. The TCES systems are categorized into those with chemical reactions with and without sorption mechanisms, as shown in Figure 3 [31]. Chemical reactions without sorption are generally utilized in high-temperature applications [29]. The sorption heat storage mechanism offers both low- and medium-temperature outputs; therefore, it allows researchers to create efficient systems [32]. The terminology structure of a sorption heat storage system was defined by Yu et al. [33], and this terminology was used in this study. Sorption involves various phenomena that are imperative for a chemical process arbitrated by the surface. The sorption mechanism is divided into four types: adsorption, absorption, chemical reactions, and composite materials.

Table 5.

Brief overview of storage systems [29].

Figure 2.

Energy densities of different thermal storage systems [30]: (a) Chemical reaction TES; (b) Sorption TES; (c) Latent heat TES; (d) Sensible TES.

Figure 3.

Different mechanisms of thermochemical heat storage systems.

Adsorption is a surface phenomenon that occurs at the interfacial layer between two phases. At least two substances—an adsorbate and an adsorbent—are required to initiate adsorption. The substance that adsorbs is referred to as the adsorbent, whereas the material in the adsorbed state is called an adsorbate. As a result, it forms a thin layer on the surface of the adsorbent with atoms or molecules influenced by cohesive forces without changing its structure. Different phases of the adsorbent and adsorbate are categorized into four groups: solid/liquid, solid/gas, liquid/liquid, and liquid/gas. Adsorption can also be divided into physical and chemical adsorption based on the cohesive forces between the adsorbate and adsorbent. Physical adsorption is due to Van der Waals forces, which require a low activation energy. Chemical adsorption is due to covalent bonds, which require a high activation energy to initiate adsorption [34]. In general, adsorbents have the potential to store large amounts of heat owing to their porous structure. Many studies have been performed to study different adsorbents and adsorbates to develop an efficient adsorption system. Different adsorbents include silica gels, zeolites, activated carbon, and alumina, which can be treated with adsorbates, such as H2O, NH3, and hydrocarbons. The energy retrieved from the adsorption system depends on the adsorbate and adsorbent interactivity, temperature, pressure, and pore structure [35].

Absorption occurs at the molecular level by penetration of the absorbate into a bulk solid/liquid, altering its morphology and composition. The absorption process requires a relatively high activation energy compared to the adsorption process. This energy is linked to the covalent bonds of the molecules or atoms. The absorbate can be in a liquid or gaseous phase, resulting in different amounts of binding energy as heat of reaction. Commonly used materials include LiBr/H2O and NH3/H2O [36]. The thermophysical properties of absorption materials play a vital role in the performance of absorption systems; however, the thermodynamic cycle and system design cannot be neglected. Therefore, thorough research is required to develop an efficient thermodynamic cycle for the absorption system. With the recent advances in absorption cycles, systems working with three-phase solutions yield a high energy capacity compared to two-phase solutions.

The chemical reaction related to the sorption process implies a coordination reaction between ammoniates or salt hydrate with a water hydration reaction. These reactions can be considered coordination reactions because the metal ions attract water vapor or ammonia to form coordinate bonds. There is still ambiguity about whether the coordination reaction is classified as solid adsorption or solid absorption because of the surface contribution. Some authors refer to it as solid/gas absorption because of the bulk phase change, and the word of a chemical reaction is generally used for it [37]. Salt hydrate has a high energy storage capacity compared to adsorption and absorption processes.

Although the chemical reaction for the sorption process has a high energy density, there are still some drawbacks at the material level. The main issues include over-hydration and deliquescence, low energy output in prototypes, low thermal conductivity, and reduced material performance after multiple cycles. For this reason, a new class of sorbents known as composite materials was introduced [38]. The composite material was a porous structure impregnated with an inorganic salt. In addition, selective water sorbate is generally used, involving the chemical reaction between salt hydrate and water and the liquid absorption phenomenon [39].

Although sorption energy storage systems have many advantages, there are still some critical shortcomings that need to be overcome to successfully utilize it. This review mainly focuses on various aspects of the low-temperature sorption heat storage system, along with its limitations. It also reviews the various working pairs, component designs, thermodynamic cycles, and system configurations that are necessary for the effective operation of the sorption thermal storage system. Firstly, materials play a critical role in the design and enactment of the energy capacity of the system. Proper screening should be performed on materials prior to their use in real systems. A novel family of porous materials is discussed in the thermal storage system, emphasizing the use of composite materials for sorption heat storage systems. Secondly, the thermodynamic cycle is a vital factor in determining the coefficient of performance (COP) of the system. Recent advancements in the absorption thermodynamic cycle are presented, and an integrated storage system with an absorption cycle is presented. However, open and closed system concepts have technical limitations related to reactor design. Different approaches have been discussed to enhance heat and mass transfer in reactor design. In the last section, the developed prototypes are discussed in detail. However, this technology is still at the lab scale and requires intense research for commercialization and mass implementation. This review introduces and discusses previously mentioned information on low-temperature sorption thermal storage systems. In the next section, recent research on various storage materials for different sorption mechanisms and technologies is introduced and reviewed.

2. Materials for Low-Temperature Sorption Heat Storage Systems

In designing a heat storage system for sorption technology, the role of materials is significant. The structure, size, and thermal properties of material play a crucial role in the development of sorption heat storage systems. Certain key characteristics are especially important while selecting the storage materials [40,41,42]. The sorption material selection parameters are briefly described below.

- Products with small molar volumes for compact design

- High sorption properties

- Maximum energy density at operating temperatures

- Small volume changes during reactions

- High thermal conductivity

- Low regeneration time

- High heat and mass transport of the sorbent/sorbate

- Non-corrosive and non-flammable nature

- High reaction output during charging and discharging

- Non-irritating environment

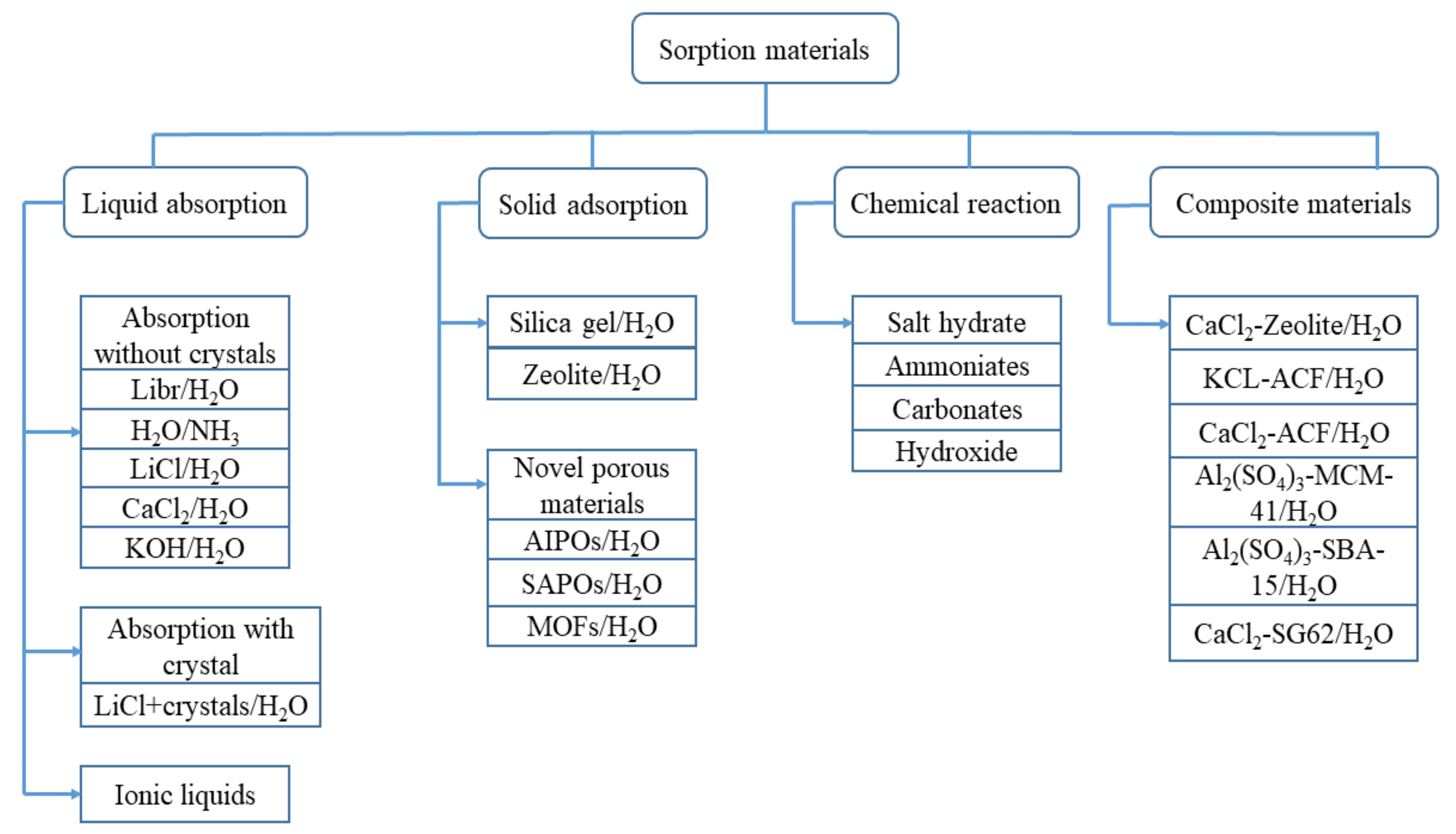

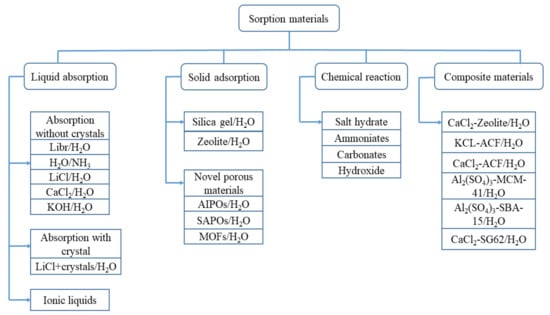

Various sorption heat storage materials have been categorized from a compilation of the previous works, and are presented in Figure 4 [33]. The sorption materials are divided into liquid absorption, solid adsorption, chemical reaction, and composite materials. It is difficult to find a material that possesses all the aforementioned properties. Among these properties, sorption properties and energy density are key parameters in selecting materials for heat storage systems. In this section, various sorption materials, shown in Figure 4, are introduced, and their advantages and disadvantages are presented, along with their applicability to heat storage systems.

Figure 4.

Categorization of sorption materials [33].

2.1. Liquid Absorption Materials

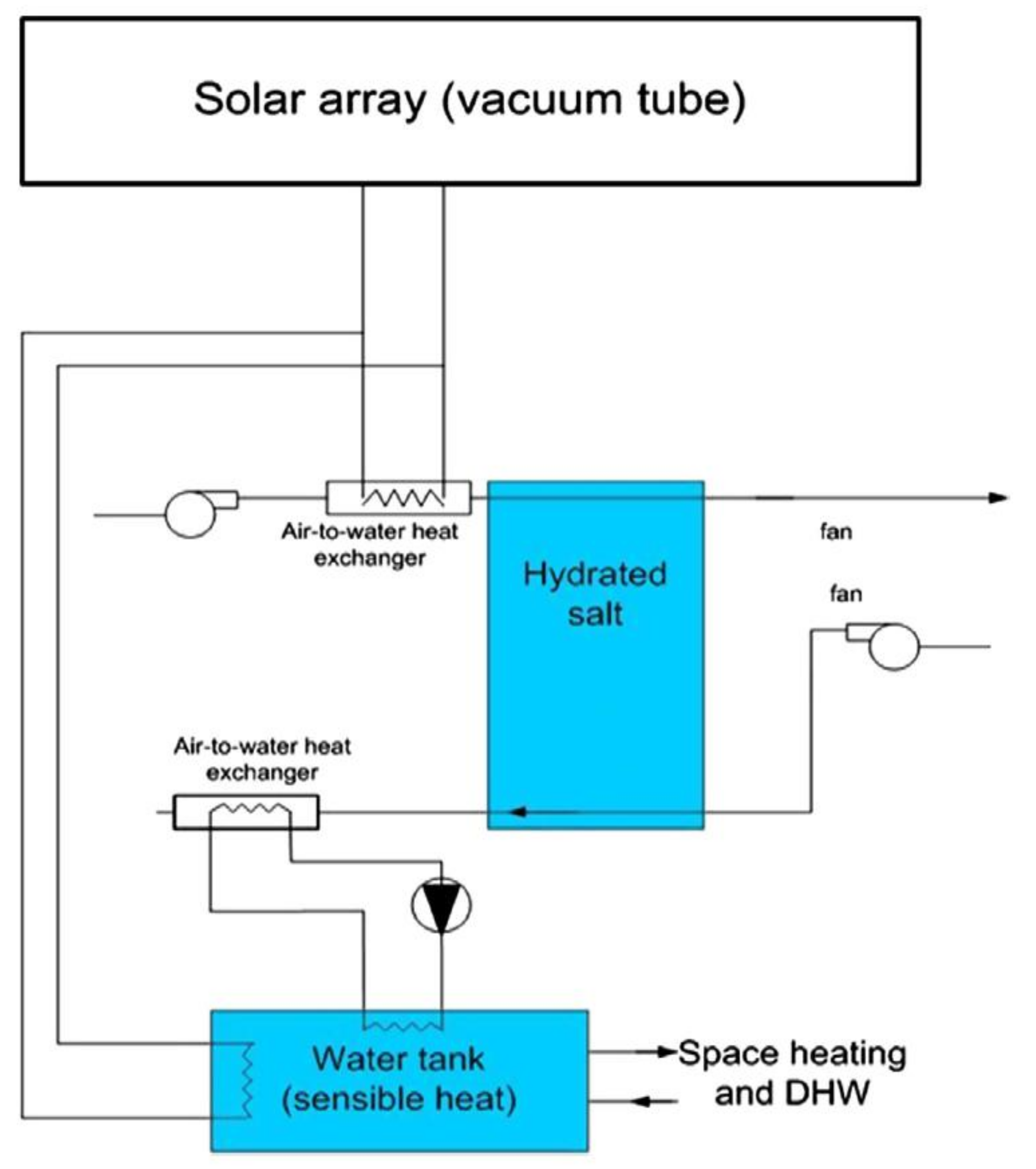

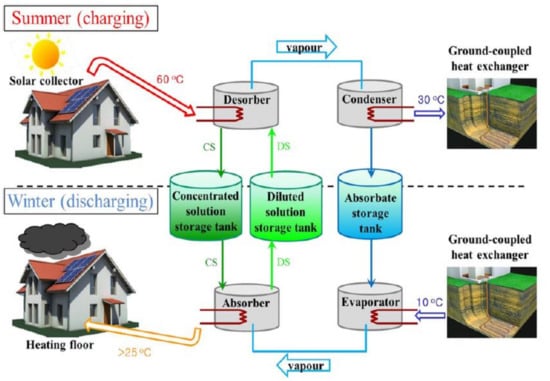

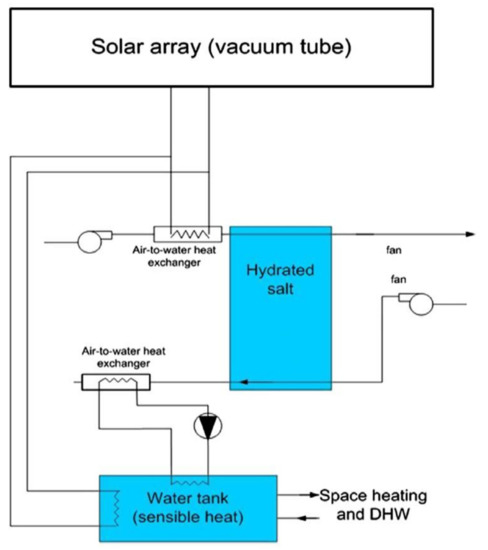

The working principle of a liquid absorption TES system is shown in Figure 5. Heat is stored as the chemical potential of the solution. Different absorption working pairs have been proposed for various applications; these store energy as a liquid solution potential. Unfortunately, no absorption material possesses all the properties mentioned above, which have been a driving force for researchers to find optimal absorption working pairs. For a sorption TES system, the absorption working pairs are divided based on the absorbent, namely, salts, salt hydrates, ammonia-water, and ionic liquid-based. Water-based working pairs are widely used in sorption energy storage systems because of their eco-friendly nature, easy availability, cost-effectiveness, and high heat of mixing [43].

Figure 5.

Liquid absorption TES systems [44].

2.1.1. Salts, Salt Hydrates, and Ammonia-Water Based Working Pairs

Water has been extensively investigated because of its good thermodynamic properties and low cost for absorption systems. Different water-based working pairs, including LiBr-H2O, LiCl-H2O, NaOH-H2O, CaCl2-H2O, and KOH-H2O [45,46], were reported in previous studies. Yang [47] studied a LiBr-H2O solution for a single-effect absorption system, integrated with a storage system for cooling applications. The absorption system was operated for cooling in summer conditions at an ambient temperature of 35 °C. Their results showed that the COP and energy densities were 0.7453 and 0.169 GJ/m3, respectively.

The high performance of LiBr-H2O at low temperature for a single-effect absorption machine makes it the best fit for solar cooling applications. Fumey et al. [48] investigated a closed sorption heat storage prototype with a NaOH-H2O working pair in an absorption TES system. The data reported by them showed that 1 kW of thermal power output was achieved. Berlitz et al. [49] compared different thermal storage techniques, such as external driving heat storage with oil, internal heat storage with LiBr-H2O, and external cold storage with sensible water heat. The absorption chiller cooling capacity was 20 kW; the stored cold was 3.3 kWh with a COP of 1.2, and the required driving heat was 2.8 kWh. To achieve the aforementioned parameters for a double-effect LiBr-H2O absorption system, the required concentration of H2O and strong LiBr were 4.8 and 42 L, respectively, which were 10 times less than the external cold storage and 11.5 times less than the external driving heat storage. As a result, this comparison showed that the internal storage was more efficient than the external storage. A numerical analysis was performed by Xu et al. [50] for solar-powered absorption refrigeration with LiBr-H2O; they demonstrated an energy storage density of 0.3685 GJ m3.

CaCl2 and LiCl are widely utilized in dehumidification and storage systems in metal chloride solutions for absorption cycles. LiCl-H2O has performed excellently in the storage of thermal energy with a compact system design [51,52]. Zhao et al. [53] studied a sorption TES system with a three-phase absorption process. LiCl-H2O was mixed with expanded graphite to enhance its thermal conductivity. The results showed that the charging/discharging temperatures and solution flow rate significantly influenced the performance of the system. The sorption heat storage was compared with a hot water tank storage, and it was concluded that the volume required for the hot water was twice that of the sorption storage system. The energy densities reported for the sorption energy storage and hot water tank were 0.235, and 0.155 GJ/m3, respectively. The absorption system working with H2O-NH3 was operated at very high pressure. System sealing is a crucial aspect of the system design because the airflow can seriously affect absorption and desorption. The driving temperature of the absorption cycles is low; hence, concentrated solar collectors can be used for desorption. In thermal absorption storage, H2O-NH3 was used to transfer electricity load from peak load to off-peak load [54,55]; however, the result showed a low energy density. Hui et al. [56] reported the energy capacity and efficiency of seven absorption working pairs, including KOH-H2O, LiCl-H2O, LiBr-H2O, NaOH-H2O, CaCl2-H2O, Glycerin-H2O, and H2O-NH3 for seasonal storage systems. The crystals that appeared in the solution enhanced the energy capacity owing to the significant mass difference of the absorbent between the weak and strong solutions, which resulted in greater absorption of the absorbate during the heating phase. It was concluded that KOH-H2O was the most economical considering its price and energy capacity; however, it is hazardous to health and is chemically active. CaCl2-H2O could be a possible fit for solar collector applications because of its operating temperature; however, the solution tanks for this option are comparatively expensive. In addition, LiCl/H2O has good energy capacity and efficiency; however, its only drawback is its high cost.

2.1.2. Ionic Liquids for Absorption TES System

Ionic liquids (ILs) are a class of molten salts that remain in a liquid state below room temperature and are a combination of organic cations and inorganic anions. They have been used in different industries because of their chemical and physical properties, such as negligible vapor pressure, low volatility, low melting point, and good solubility. In addition, ILs can be good substitutes for some of the toxic working pairs used in the absorption cycle to remove the metal compatibility problem [57,58,59]. ILs, such as imidazolium working pairs, were analyzed for absorption TES owing to their excellent thermophysical properties and stability. Adequate mixing of the refrigerant and an IL can create new working pairs with properties particularly favorable for energy storage systems. However, IL working pairs still have some deficiencies, such as a high circulation ratio and low energy-harvesting efficiency [60].

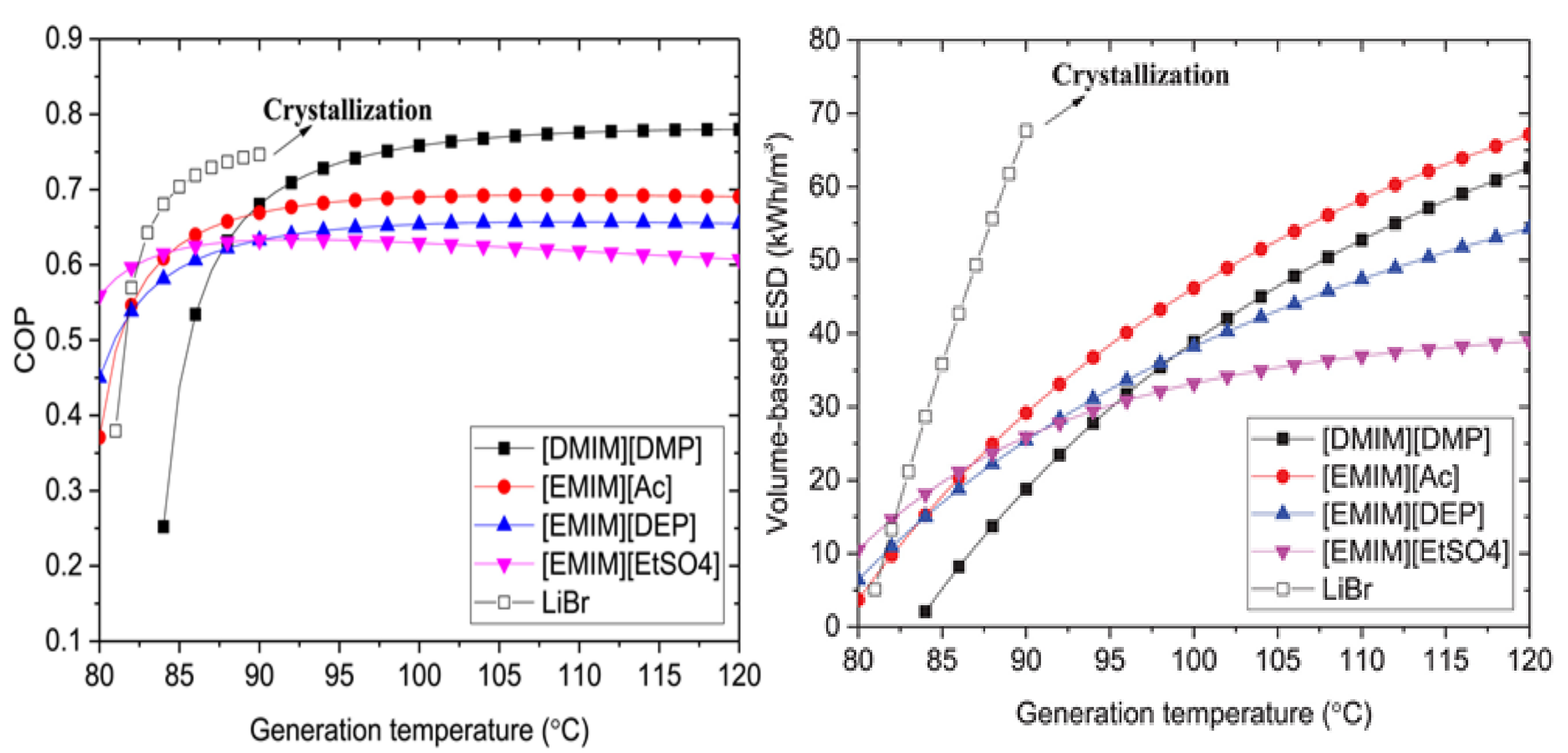

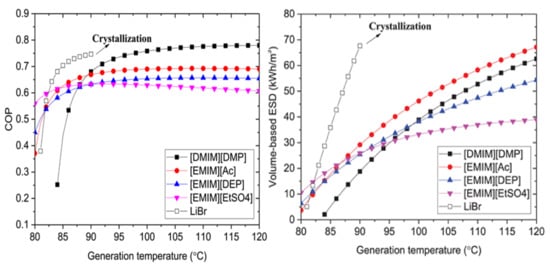

Thermodynamic analysis of an absorption refrigeration system with an IL-refrigerant was theoretically performed by Kim et al. [61] The IL used was imidazolium 1-ethyl-3-methylimidazolium tetrafluoroborate [EMIM][BF4]-H2O, and the system was driven by waste heat for electronics cooling. The results yielded a COP of 0.9 for the system. Liang et al. [62] compared 1-ethyl-3-methylimidazolium dimethyl phosphate [EMIM][DMP]-H2O and H2O-LiBr under the same working conditions in an absorption chiller. The results showed that H2O-[EMIM][DMP] had a lower COP than H2O-LiBr; however, it was as high as 0.7. Furthermore, the regeneration temperature of H2O-[EMIM][DMP] was low, indicating that it could be the best choice for low-grade energy-driven absorption chillers. Wu et al. [63] studied seven different ILs for absorption TES systems based on a preliminary screening. Among various ILs-H2O working pairs, [DMIM][DMP]-H2O, [EMIM][Ac]-H2O, [EMIM][DEP]-H2O, and [EMIM][EtSO4]-H2O were selected for a detailed study. In addition, the COP and energy density of IL-H2O were compared to those of H2O-LiBr. The performance analysis of ILs/H2O mixtures in absorption thermal energy storage for different generation temperatures is shown in Figure 6. Their results showed that H2O-LiBr was affected by crystallization, which constrained its COP and energy storage density (ESD). By varying the generation temperature, [DMIM][DMP]-H2O achieved a high COP above 95 °C, and [EMIM][Ac]-H2O had a higher energy density of 67.1 kWh/m3 at 120 °C. The UNIQAC functional-group activity coefficients (UNIFAC) model provides a numerical method to correlate and predict the activity coefficient without experimental data. This model is suitable for a molecule mixture, but not for ionic components because it interacts with a short span [64]. The working pairs with hydrofluorocarbons (HFC)/IL have comparatively low COPs, ranging from 0.12 to 0.39; however, they can be utilized in a hybrid cycle, such as an absorption/compression cycle. The COP for the NH3/IL working pair was 0.48–0.59, which was lower than that of conventional ammoniate working pairs [65].

Figure 6.

Performance analysis of ILs/H2O mixtures in absorption thermal energy storage for different generation temperatures [63].

2.2. Solid Adsorption Materials

In the development of solid adsorption materials, the role of the adsorbate is vital to the TES system. Owing to a weak cohesive force, it has a low energy density; however, it has other advantages. Using zeolites, the heat and mass transfer are enhanced compared to salt hydrates because of their hydrothermal strength. In addition, solid adsorption materials have good mechanical strength and large pore volumes [66]. In this section, representative research related to solid adsorption materials is introduced and summarized.

2.2.1. Zeolites/H2O

Zeolites are aluminosilicates that form hollow structures and channels, inside which cations, water, and small molecules reside. Zeolites are naturally available; however, they are also synthesized using commercial processes. Synthetic zeolites are molecular sieves because of their uniform pore size distribution, with a tetrahedral structure, and are composed of silicon and aluminum. Different morphological materials can be synthesized for commercial processes; however, the low regeneration temperature makes it feasible for low-temperature applications. Some well-known types of zeolites include 4A, 5A, 10X, 13X, and Y [33,67]. Janchen et al. [68] studied the ion-exchange of NaA, NaX, and NaY zeolites with water adsorption, which enhanced its storage properties. Different ion sizes and charges achieved enhancement in the thermochemical properties. Sheigeishi et al. [69] compared different adsorbents (4A, 5A, and 13X) in terms of water uptake and heat of adsorption. It was concluded that zeolite 13X exhibited better performance for the energy storage system. Mette et al. [70] performed an experimental investigation with binderless zeolite 13X and found a maximum sorption temperature of 85 °C, with an inlet hydrated temperature of 50 °C at 15 mbar. Fasano et al. [71] studied zeolite adsorbents with different adsorbates, such as distilled water, ethanol, and ethanol–water mixture. The results showed that the ethanol mixture and ethanol dehydrated faster at lower temperatures than water. However, the water pair had the highest energy storage density among all the adsorbates considered. Ristic et al. [72] compared different post-synthesis treatments to enhance the performance of NaY zeolite. The hydrophilic properties of the parent NaY zeolite were modified with inorganic HCL treatment, chemical treatment with H4EDTA, and sequential ion-exchange acid treatment. The results showed a desorption temperature drop ranging from 10–30 °C with a mild HCL treatment and chemical treatment with H4EDTA. The Mg-exchanged ion treatment resulted in an augmented sorption potential and charging temperature. The large pore size of the synthetic zeolite makes it a good fit for sorption energy storage systems.

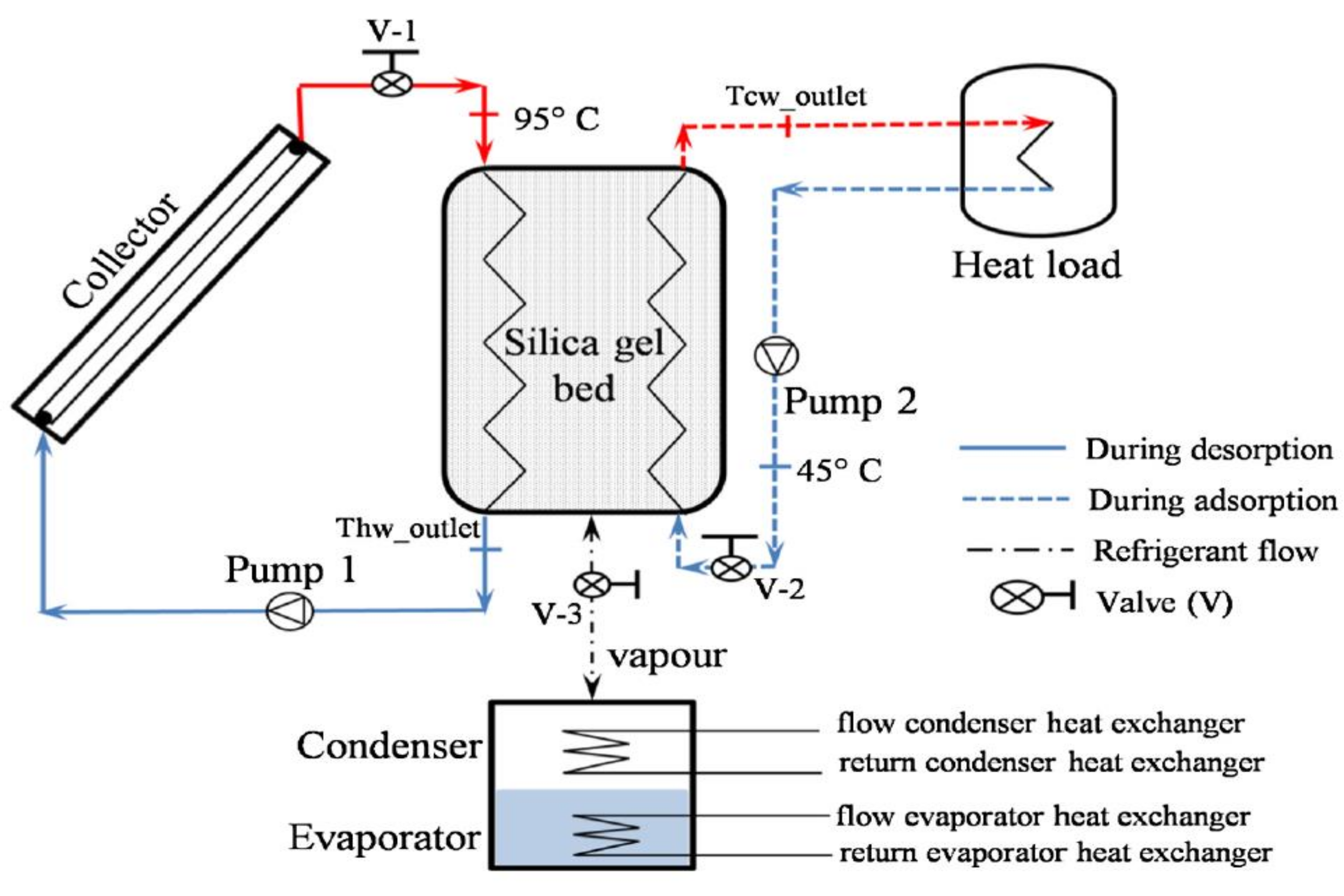

2.2.2. Silica Gel/H2O

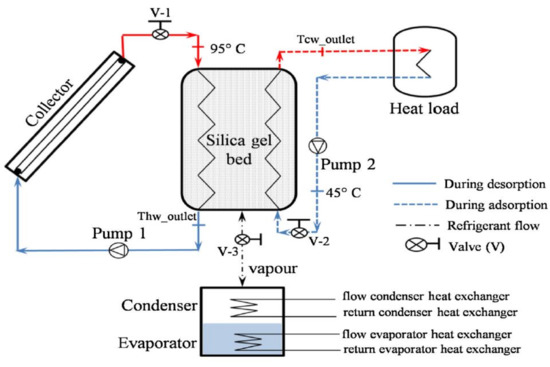

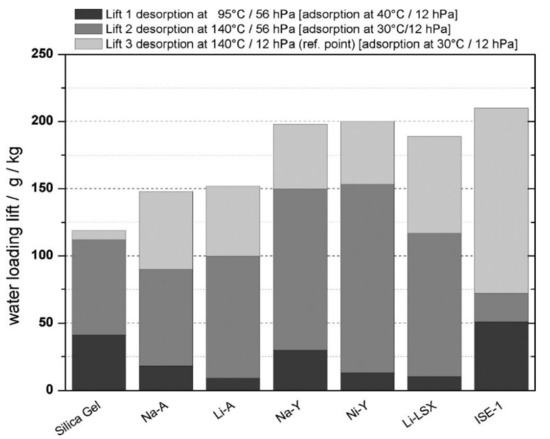

Silica gel is a widely used desiccant owing to its high adsorption capacity and low regeneration temperature. The charge temperature for the silica gel is less than 100 °C, which makes it a good fit for low-temperature applications. Close et al. [73] proposed storing adsorption energy in the bed of adsorption material. Their results revealed that the mass of silica gel was 16.4–40.3 times that of gravel for different desorption temperatures. This amount decreased as the temperature increased. Deshmukh et al. [74] performed a thermal analysis of a solar collector adsorption heat storage system with a silica gel bed. The Solar-assisted adsorption system utilizing silica gel is shown in Figure 7. The heat storage system could store 18 kWh of heat supplied at 3 kW for 6 h. The desired heat capacity was possible with a 350-kg silica gel bed with a parametric heat transfer of 400 W/K. The main drawback of using silica gel is its low temperature-lift beyond a specific adsorption capacity, as shown in Figure 8.

Figure 7.

Solar-assisted adsorption system utilizing silica gel [74].

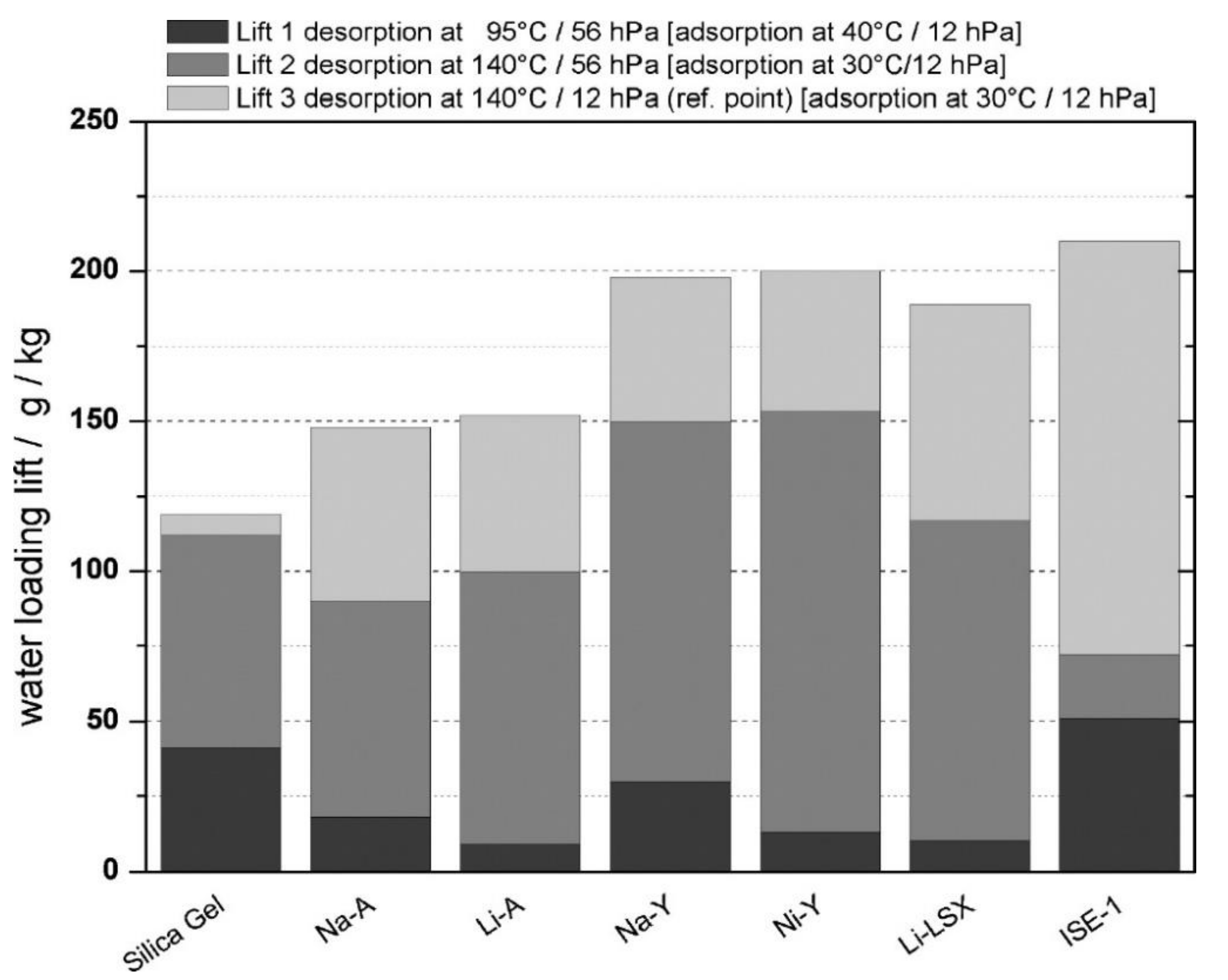

Figure 8.

Water loading spread for different adsorbents [75].

2.2.3. Novel Porous Materials

With the recent advances in material science, a new family of porous materials, with good sorption properties, has been introduced as a potential candidate for adsorption TES. This new class of materials for adsorption includes aluminophosphates (AlPOs), silico-aluminophosphates (SAPOs), and metal-organic frameworks (MOFs) [76,77,78]. Ristic et al. [79] performed thermal analysis on three different aluminophosphate materials, namely SAPO-34, ALPO4-18, and APO-Tric, to show the correlation between the structure and sorption behavior. Materials with different crystal sizes were selected, which were referred to as SAPO-34 (5 μm), ALPO4-18 (3 μm), and APO-Tric (10 μm). The results showed that APO-Tric demonstrated better capacity and could be used for sorption storage; it had a heat of adsorption of 53.6 kJ/mol and water uptake 318 g/kg. Li et al. [80] analyzed an energy storage system with SAPO-34, which was considered a potential material from the SAPO-sorbent, and reported an energy density of 230 Wh/kg.

Presently, MOFs are receiving increasing attention for heating, cooling, and storage applications because of their high specific area, structural alteration, and large pore volume. Ehrenmann et al. [81] studied the sorption properties of MIL-101 for heat transformation applications. It was concluded that MOFs were favorable for heat storage, as they adsorbed 1 g of water per g of adsorbent and demonstrated good hydrothermal stability. The water lift for the charging phase at 90 °C and discharging temperature at 40 °C was 0.939 g/g, which was reduced owing to adsorption hysteresis. Elsayed et al. [82] characterized a new MOF material for energy storage CPO-27(Ni), which is also known as MOF-74(Ni). They reported that the energy density of the material was 170 Wh/kg, with a desorption temperature of 100 °C, over a half-cycle duration of 3600 s. Henninger et al. [75] compared silica gel with five zeolites and MOFs (ISE-1) for heat transformation applications, as shown in Figure 8. The MOFs showed better efficiency than the other materials with a water uptake of 210 g/kg. These novel porous materials can be used for the synthesis of composite materials owing to their high porosity and good adsorption properties. Despite the good sorption capacity of porous materials, many potential large-scale projects have not been established because of the high cost and low durability of these materials. The adsorption materials reviewed in this section are summarized in Table 6.

Table 6.

Summary of the adsorption materials for thermal heat storage.

2.3. Chemical Reaction Materials

The chemical reaction linked to the sorption mechanism consists of a reversible reaction, including mainly a hydration reaction between inorganic salts and water vapor, and a coordination reaction between ammoniates. Chemical sorption has a high reaction enthalpy compared to physical sorption because of the intermolecular forces involved. Many studies have been conducted on chemical sorbents that can be used for low-temperature applications and have the capacity to store energy for long durations with minimum losses. Numerous analyses have been performed on salt hydrates from a lab-scale to practical implementation. An open thermochemical heat storage system utilized for salt hydrates is shown in Figure 9. [83] The reversible reaction can occur at different charging temperatures, resulting in an anhydrous salt. Van Essen et al. [84] investigated the charging/discharging of heptahydrate magnesium sulfate for low-temperature sorption TES with an energy density of 2.2 GJ/m3. The results showed that the temperature required for charging the material was below 150 °C, which could be achieved using a vacuum tube solar collector. However, retrieving the stored energy at the atmospheric pressure is difficult because of the dependence of the discharging phase on the vapor pressure and system pressure. Heat retrieval was difficult above 40 °C at the atmospheric pressure. However, it could easily release the heat at 25 °C of temperature and a water vapor pressure of 2.1 kPa, thus making it a good fit for space heating. Stengler et al. [85] performed a lab-scale experiment and reported the SrBr2 hydration reaction. It was concluded that the SrBr2·H2O pair could provide a discharging temperature of 250 °C if the water vapor was provided at a temperature of 110 °C. Molenda et al. [86] characterized CaCl2 as a potential material for a sorption storage system for a wide range of vapor pressures of 5 to 96.5 kPa. The reaction of CaCl2 with water vapor could provide discharging temperatures of up to 180 °C. A cyclability study was performed by Donkers et al. [87] for four different salts, including CuCl2, CuSO4, MgCl2, and MgSO4 for 7–13 cycles. Nuclear magnetic resonance (NMR) was used to determine the location and quantity of water. The results indicated that CuCl2 had good hydrothermal stability for heat storage because of the kinetics of the drop in other reactions in a subsequent run.

Figure 9.

Open thermochemical heat storage for salt hydrates [83].

Al-zareer et al. [88] proposed TES for heating and cooling applications with SrCl2·NH3 as a working pair. The maximum heating exergy was 50.8% when the desorption temperature was 87 °C. Yan et al. [89] developed a prototype with MnCl2/NH3, with a maximum heat storage density of 1391 kJ/kg desorption and sorption temperatures of 174 and 50 °C, respectively. This material class has a high sorption capacity; however, they have some limitations, such as agglomeration, deliquescence, and low mass transfer. Some of the salt hydrates are summarized in Table 7.

Table 7.

Characteristics of salt hydrates.

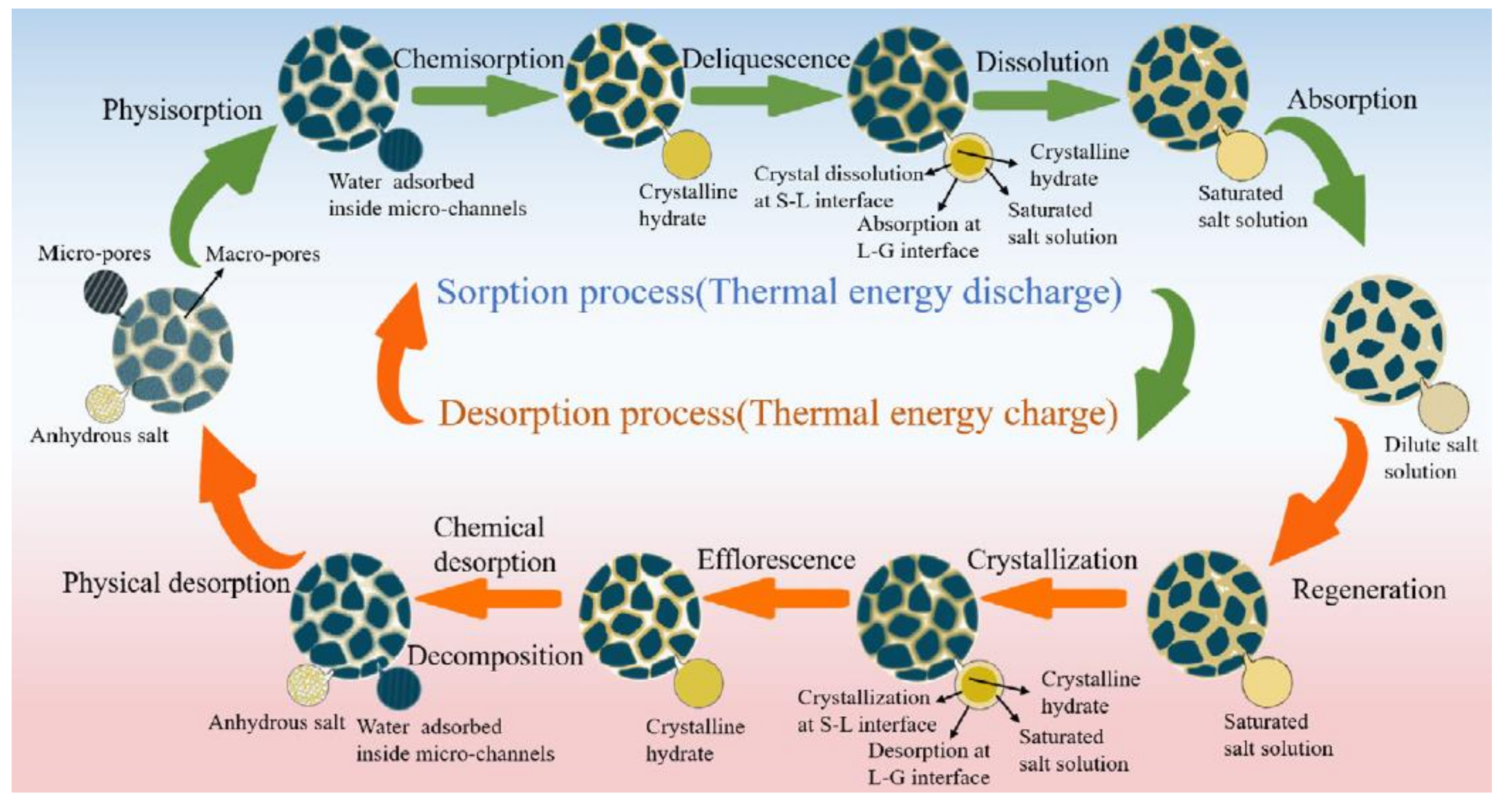

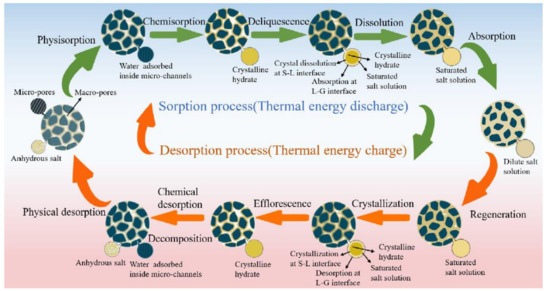

2.4. Composite Materials

Salt hydrates have high water uptake kinetics; however, some drawbacks limit their performance, as adsorption materials are hydrothermally stable with low sorption capacities. Aristov et al. [90] proposed a new material class by fusing salt hydrate into the pores of an adsorption material with open pores. Impregnating the salt hydrate helped control the water uptake by varying the pore size and chemical nature of the salt hydrate. It was concluded that the sorption behaviors involved in these composite materials were liquid absorption, solid adsorption, and chemical reaction, which could also overcome some of the drawbacks of the base materials [91,92]. The host matrix should have a high porosity to accumulate more active materials. The secondary function of the host matrix is to increase the thermal conductivity and immovability [41]. The charging/discharging of multiple steps involved in the composite material is shown in Figure 10. Casey et al. [93] characterized eight salt-impregnated matrices (SIM), with matrices such as silica gel, vermiculite, activated carbon, and zeolite 13X. The salts utilized were CaCl2, MgSO4, Ca(NO3)2, Li(NO3)2, and LiBr. The prepared microstructure pore networks of the raw and SIM were examined. The raw adsorbent followed a type I isotherm, whereas, in the case of SIM, the isotherm was type IV. Zeolite 13X experienced an increase in the pore size, resulting from micro-pore network damage caused by the fusion of salts. This increase in the pore size was comparatively low in the silica gel and activated carbon matrices. The vermiculite structure did not exhibit any structural distortion. In the non-vermiculite samples, the mesopore volume was reduced, which affected the accessibility of moisture vapor. Among all the samples, CaCl2 and LiBr, fused into vermiculite matrices and appeared to be potential candidates for thermal storage systems with high energy density.

Figure 10.

Working principle of composite materials depicting numerous steps involved in charging/discharging [98].

Druske et al. [91] synthesized composite materials with expanded natural graphite (ENG) and activated carbon foam (ACF) with calcium chloride and potassium chloride salts to improve their performance. The results showed that the thermal conductivity and water absorption were improved with impregnation. Jabbari-Hichri et al. [94] studied aluminum sulfate salt hydrate with mesoporous Mobil catalyst material (MCM-41) and Santa Barbara amorphous (SBA-15) to form a composite material. Six composite materials were prepared with different salt contents of 3, 5, and 7 wt%. The results revealed high sorption capacity and dehydration heat compared to pure materials. The maximum sorption capacity and dehydration heat were achieved for MCM-41 with 7 wt% of salt; these were 4.25 and 1.6 times higher than those of the pure material. The performance of magnesium sulfate-impregnated zeolite 13X and alumina in a closed storage system was studied by Xu et al. [95] Extended natural graphite treated with sulfuric acid (ENG-TSA) was used to fill the gaps in the host matrices and fused salt hydrate to increase the thermal conductivity of the composite material. The fusion of magnesium sulfate enhanced the overall performance of the thermal storage system by achieving a higher energy density. The temperature lift rate was increased by three times for zeolite 13X and 32.5% for the alumina composite material. The energy storage densities for the zeolite composite material and alumina were 123.4 and 82.6 kWh/m3, respectively. A novel synthesis protocol was proposed for composite materials to accommodate a high salt content with good stability, which is a primary requirement for seasonal storage applications. Courbon et al. [96] synthesized aluminophosphate (SG62) with 43 wt% CaCl2, which showed better performance than previously reported composite materials with low energy storage density at high desorption temperatures. The achieved energy density for this composite material was 211 kWh/m3, with a high water absorption of 0.40 g/g. Shkatulov et al. [97] prepared 69 wt% K2CO3 with expanded vermiculite matrices as a potential material for energy storage systems. They reported that the energy density was 0.7–0.9 GJ/m3 with a water uptake of 0.4–1.5 g/g. Salt fusion increased the hydration/dehydration rate and stabilized the salt in the subsequent run. Table 8 presents a summary of the composite materials discussed in this section.

Table 8.

Summary of composite materials.

In this section, various potential materials for low-temperature and long-duration sorption storage systems have been discussed. In general, liquid sorbent materials have been investigated for domestic hot water and space heating applications. This class of materials has some limitations in achieving a high discharging temperature with a high energy density; if domestic hot water requires a high temperature, it is difficult to achieve the same with an absorption thermal storage system. An alternative material for the absorption system is an IL, which has not been extensively explored; however, it has been investigated on a lab-scale for a thermal storage system. The physical and chemical properties of ILs make them a good fit for absorption thermal storage systems. The solid sorbent for adsorption is hydrothermally stable, even though it has a low sorption capacity. However, the cost of these materials is relatively high, which limits their applications. Novel porous materials show good sorption properties, enhance the adsorption phenomena, and are utilized as supporting matrices for composite materials. A new class of sorption composite materials is very important because the sorption properties can be varied, and both materials are stable and have good sorption properties. On the other hand, salt hydrates show good sorption capacity; however, they face agglomeration and deliquescence, which limit the thermal storage system performance. Therefore, further research is required to develop cost-effective composite materials. The sorption materials have a significant impact on the system performance; however, an equal contribution is made by the thermodynamic cycle. The following section presents recent advances in the absorption cycle and integration with the storage system to enhance system performance.

3. Advances in Absorption TES Systems

A system operating with liquid absorption TES is based on a developed technology and reliable techniques to use low-grade thermal energy. Liquid absorption working fluids are binary mixtures that incorporate absorbents and refrigerants. The thermal absorption storage system consists of two processes: charging and discharging. The transition time between the charging and discharging depends on the application. In this section, advances in absorption TES systems are introduced and discussed.

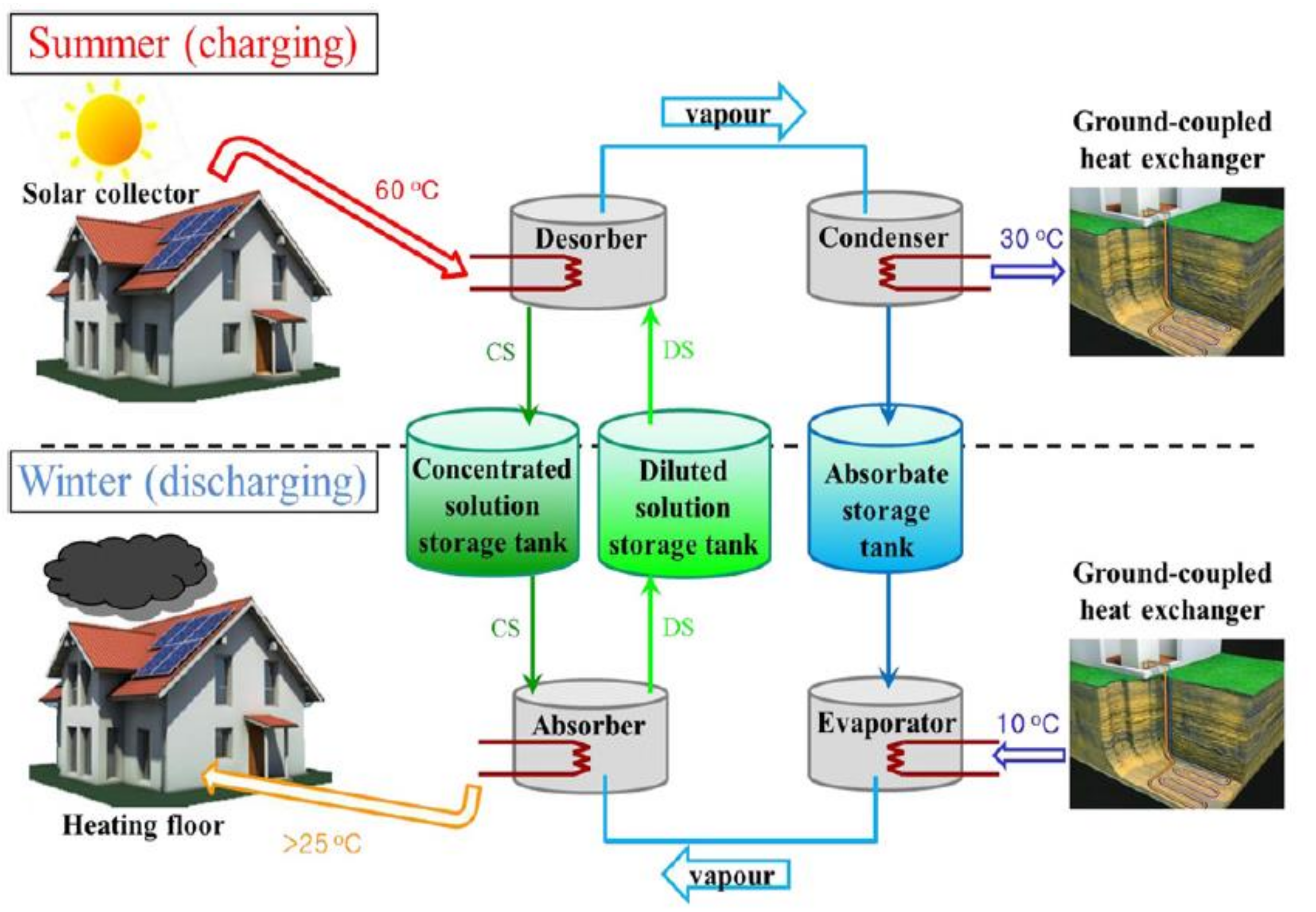

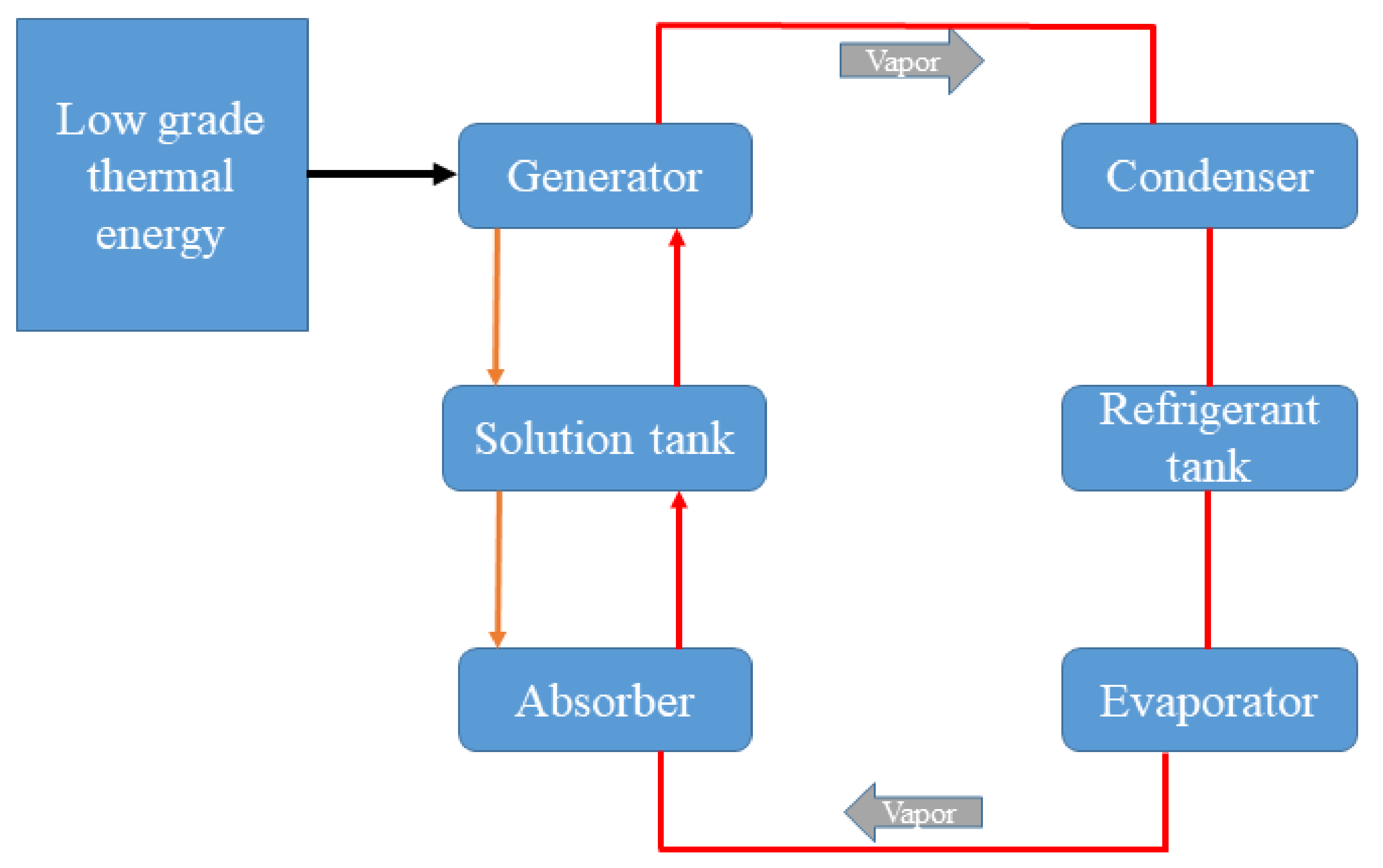

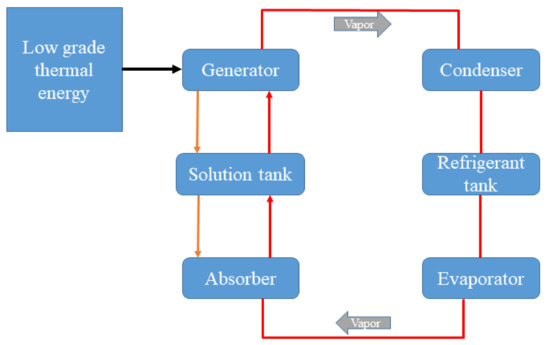

3.1. Long-Term Cycles for Absorption TES Systems

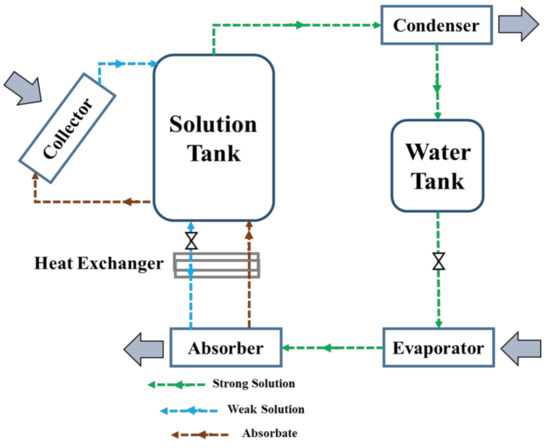

The long-term single-stage cycle is a simple type of absorption refrigeration configuration and its working principle can be explained by a thermodynamic cycle. The absorption TES system consists of a generator, condenser, evaporator, absorber, and storage compartments for the absorbent and refrigerant. The generator and condensers are maintained at high pressure, whereas the evaporator and absorber are kept at low pressure. During the charging process, thermal energy is supplied to the generator from an external heat source. As a result, the refrigerant is vaporized from the absorbent in the generator; the condenser attracts the refrigerant vapor, and heat is rejected at an intermediate temperature to the ambient. The condensate is stored in the refrigerant, and the strong solution is transferred to a solution tank until the discharge process. In the discharging process, the counter process occurs at a low pressure by ambient heat to vaporize the refrigerant in the evaporator. The refrigerant is attracted by the strong solution in the absorber chamber until it becomes saturated. The heat rejected from the system presents its energy density, which is the main factor for measuring the system performance.

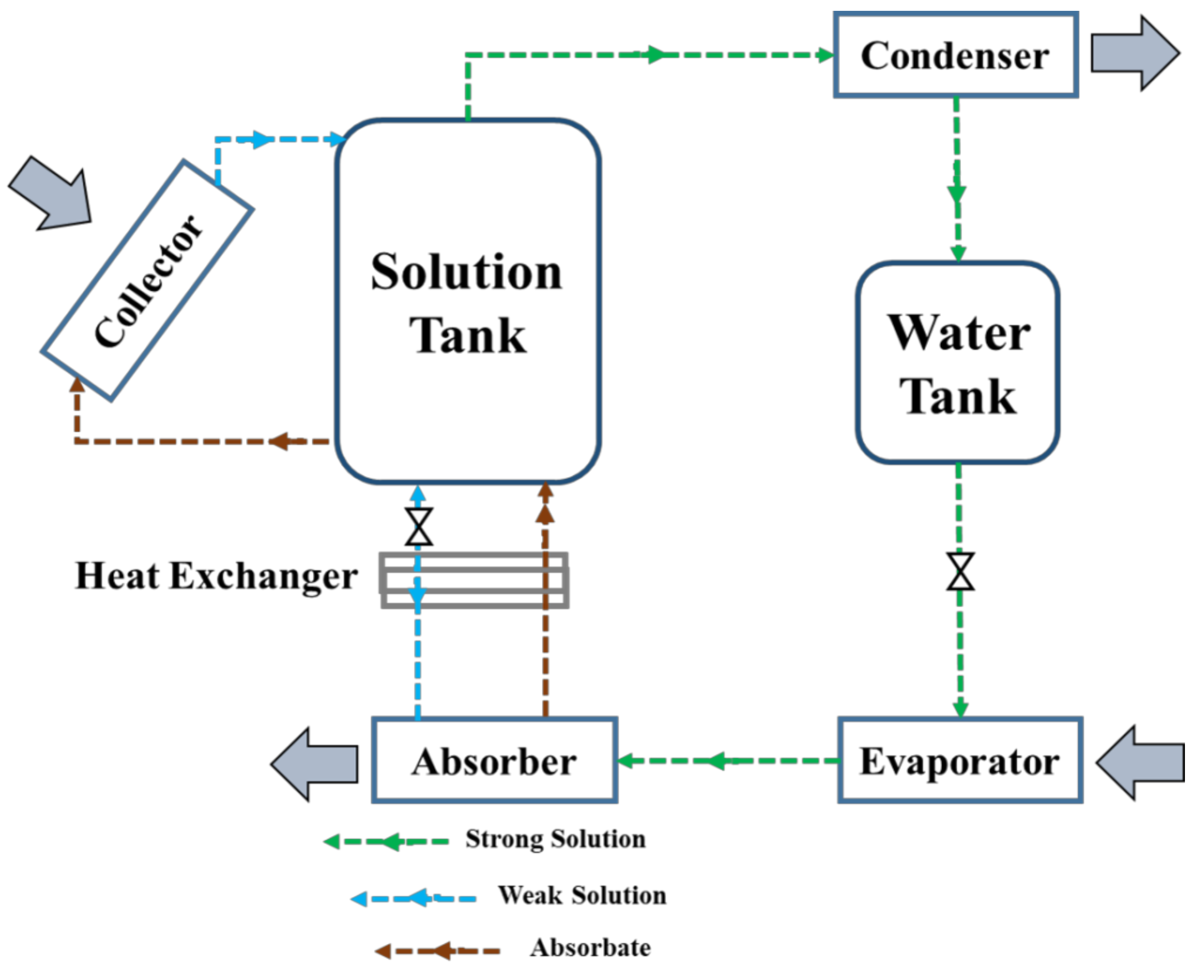

This system is more flexible than a conventional TES, as it can be used for cold and hot energy storage. The system performance is analyzed by the energy density, which is linked to the design of storage materials and components. The compact system ensures a high energy density. The difference in the charging temperature to the discharging temperature can result in a difference in the system efficiency [99,100]. The efficiency of the cycle has been evaluated in numerous analytical, experimental, and numerical studies, performed at various operating temperatures, for different working fluids. Generally, the COP of this system depends on the thermal properties of the working fluids [101,102,103]. These researchers investigated absorption storage for long durations with NaOH by adopting a single-stage absorption cycle. The simple working mechanism of the single-stage absorption thermal storage system is shown in Figure 11. It had two solution reservoirs (weak and strong solutions), a refrigerant reservoir, absorber, generator, evaporator, and condenser. The two solution reservoirs were positioned in parallel as the flow was influenced by gravity. It was concluded that the storage capacity was significantly influenced by the absorption temperature and the solubility of the refrigerant. The results showed that the heat storage was six times in the case of space heating and three times in the case of hot water, compared to a sensible storage system [104]. A similar technique was employed to develop a prototype for seasonal thermal storage. The system operated on a hybrid absorption storage system with sensible heat storage. Sensible heat storage stored the energy for a short duration and absorption storage system for a long duration. The authors concluded that this system could be used for long-term storage, but was not feasible for short-term storage because of substantial losses linked to heat and mass transfer units for charging and discharging. A water tank was attached to the prototypes for daily TES.

Figure 11.

Single-stage absorption TES system.

The valuable output power was 1 kW, which was significantly less than the theoretically estimated power of 8 kW [48,105,106]. The heat exchanger equipped with the developed prototype was a tube buddle array chosen for its high heat transfer, low price, and simple design. Poor wettability and low residence time were two problems associated with the tube buddle array [107,108]. In addition, two alternative solutions were suggested. Porous silicon carbide foams were engraved into the tubes to enhance the wettability and exposure time; however, the absorbate was infused into the holes, resulting in a decrease in the extended surface for heat transfer [109]. A spiral finned tube heat exchanger was designed to augment the heat transfer and energy capacity of the system. The results showed a large surface area, good wettability, thin film, and sufficient exposure time; however, the output thermal power was not significantly enhanced [110].

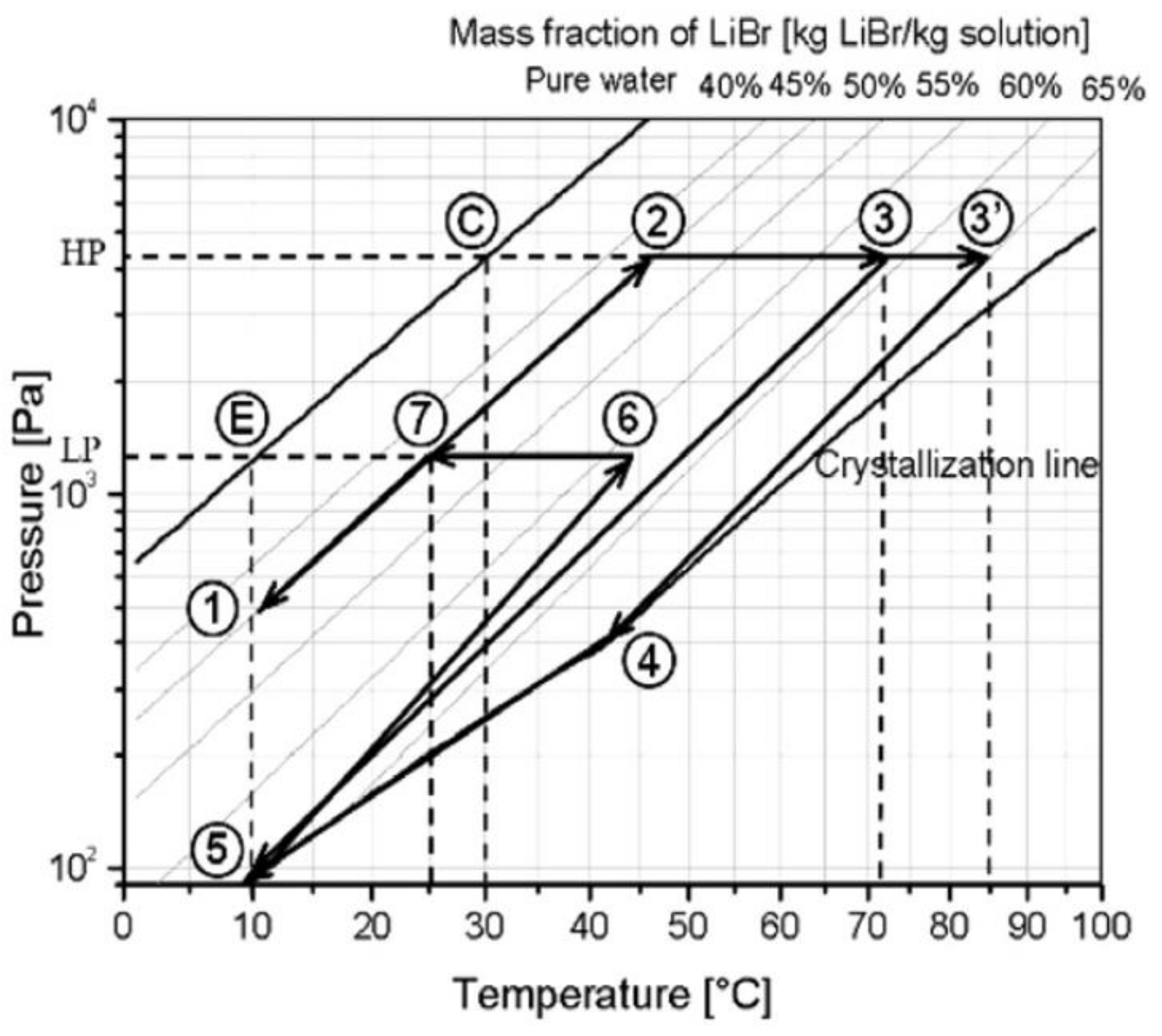

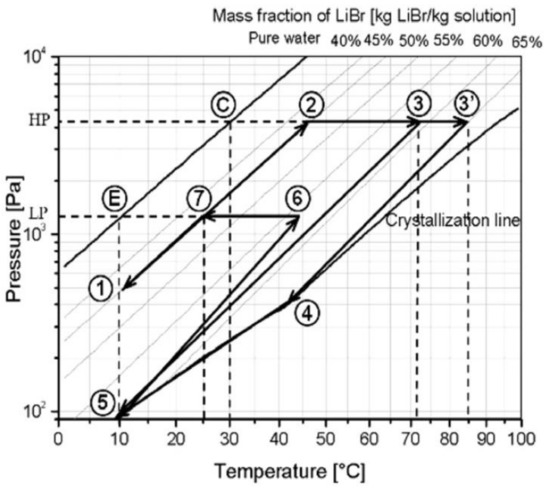

The concept of a triple-stage absorption storage system was introduced to have a high energy storage capacity and long-term storage for house-heating applications. The working principle can be explained by considering the LiBr/H2O system, as shown in Figure 12. The absorption cycle allows the solution to reach the crystallization point in the storage tank. The operation principle is the same as that of a conventional absorption TES cycle. The mass fraction of the absorbent for cycle 1–2–3–5–6–7–1 is selected so that at point 3, no crystals are formed. For cycle 1–2–3–4–5–6–7–1, in LiBr/H2O, the mass fraction of the absorption solution is higher at 3′ than that at point 3. During the transition period of charging and discharging, the isosteric line crosses the crystallization at point 4, which results in a crystal formation. From point 4 to point 5, continuous crystals are formed in the solution tank. In this process, a high-concentration glide can result in a maximum energy density. However, proper handling of the crystals is required, as they can affect the process by clogging the pipeline [56]. An experiment was conducted to investigate the behavior of crystals formed using LiBr/H2O [111]. A systematic dynamic simulation was performed to evaluate the influence of different parameters, such as heat exchanger size, solution flow rate, and absorption percentage, and operating conditions, such as heat supply temperature to the building, crystallization ratio, and heat need on the system performance. It was concluded that the solution flow rate played a vital role in the process performance. With crystallization, the energy density was enhanced by three times compared to that of a single-stage absorption cycle [112].

Figure 12.

Working principle of LiBr/H2O with a conventional crystallization cycle [56].

3.2. Solar-Driven Absorption Cycle-Integrated Thermal Storage

Solar absorption chiller/heat pumps, integrated with thermal storage systems, are used to run chiller/heat pumps when solar energy is insufficient. Utilizing solar power can enhance the COP of the system, which ranges between 0.27 and 1.20 [113]. The chiller/heat pump can accommodate single or multiple-storage tanks. In the case of a single tank, it only holds the absorbate and must be placed parallel to the condenser at the mutual height [114,115]. The integrated system can operate continuously for 24 h. During the daytime, desorption occurs, and some strong solution and refrigerant are stored, while another refrigerant is circulated in the cycle for cooling and heating processes. When external heat is not available, the stored heat energy is utilized. Grassie et al. [116] numerically analyzed a solar air conditioner dynamic model using LiBr/H2O. Some advantages were observed when TES was employed in the absorption cycle. Among the known working liquids, water demonstrated the highest enthalpy, and the design of the storage container was not considered as critical, as the storage pressure was low. Their simulation results did not contain any data on the energy density of the solution. However, the system was concluded to be thermodynamically feasible and a crucial player for cooling applications. Xu et al. [50] studied a direct solar-powered absorption refrigeration (SPAR) system and storage tanks. An advanced technology, called a variable mass-energy transformation system, minimized the fluctuation between solar radiation and air conditioner load. The solution used was LiBr/H2O, and the operating cycle is shown in Figure 13. The cycle consisted of two storage tanks and a solar collector, in contrast to the conventional cycle, wherein the collector acts as a generator. Solar radiation increased the temperature of the collector. As a result, the solution vapor would enter the solution tank, where the vapor was separated and condensed in the condenser. In addition, the condensate was collected by the refrigerant tank. The simulation showed that the energy density was 368.5 MJ/m3 and a COP of 0.7555 was achieved with air cooling at the condenser.

Figure 13.

SPAR integrated with the storage system [50].

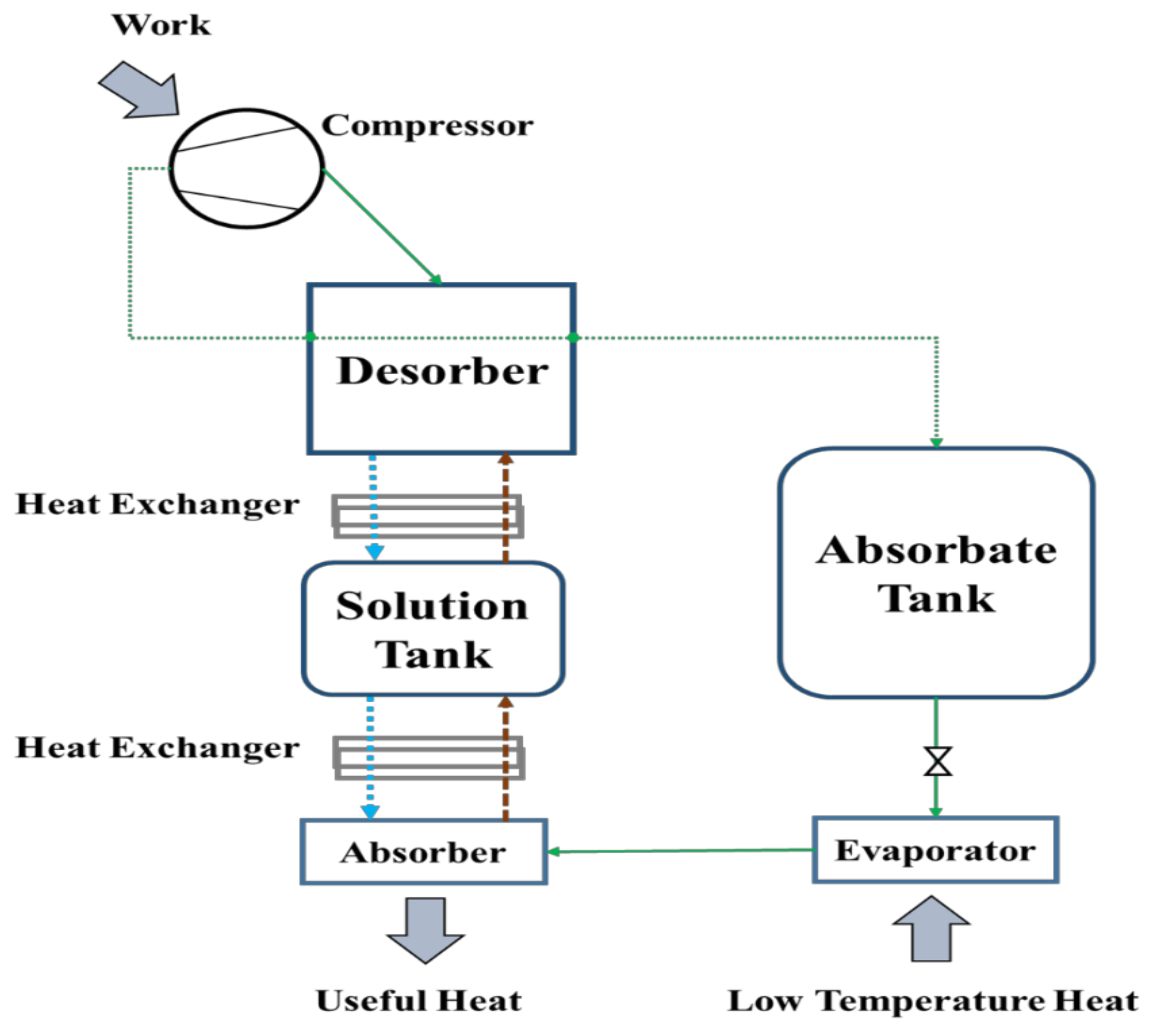

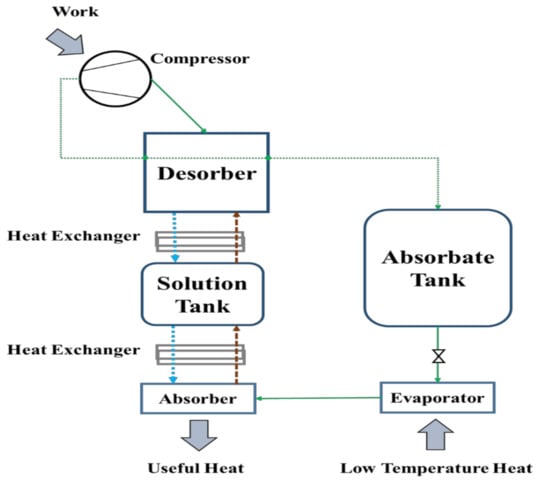

3.3. Compression-Driven Absorption Cycle Integrated Thermal Storage

When low-grade energy is unavailable to transfer electricity from peak-loads to off-peak loads, high-grade energy is utilized to drive the absorption integrated cycle. A high-grade energy-driven absorption cycle consists of a compressor that is linked to a conventional absorption cycle. The compressor can be attached either internally or externally. In a high-grade absorption integrated cycle, the energy is stored as a phase-transition latent heat. The operating principle of the compression-assisted absorption cycle for thermal storage is shown in Figure 14 [117,118]. This concept was proposed by Voigt et al. [119], whereby the storage system was attached to the compressor-assisted absorption cycle. In the charging process, vapor was evaporated from a strong solution when it was heated by the pressurized vapor from the compressor in the desorber. The compressor controlled the generated vapor; when the pressure was increased the vapor was sent back to the desorber for condensation. The condensed vapor and strong solution were stored in respective tanks. Condensation heat and compressor waste heat were again used for weak solution generation.

Figure 14.

Compression-driven absorption cycle integrated with thermal storage [119].

External heating depends on the characteristics of the working pairs. Ammonia-based working pairs with high operating pressures do not require external heating [119]. In contrast, water-based working pairs require external heating to pressurize the solution [120]. Ammonia-based and water-based working pairs have been investigated by several researchers [54,121,122] for cooling, heating, and hot water for maximum and partial storage for 24 h. The compressor would run simultaneously during the charging process for maximum storage, whereas it runs continuously for partial storage. The results showed the system COPs were 3.90 and 3.64, respectively, and energy densities were 125.2 and 118.1 MJ/m3, respectively, when NH3-H2O was run with full and partial loads. For LiBr-H2O, the total load COP was 3.0917 and the energy density was 402.2 MJ/m3; for partial storage, the COP was 3.2606, and the energy density was 394 MJ/m3.

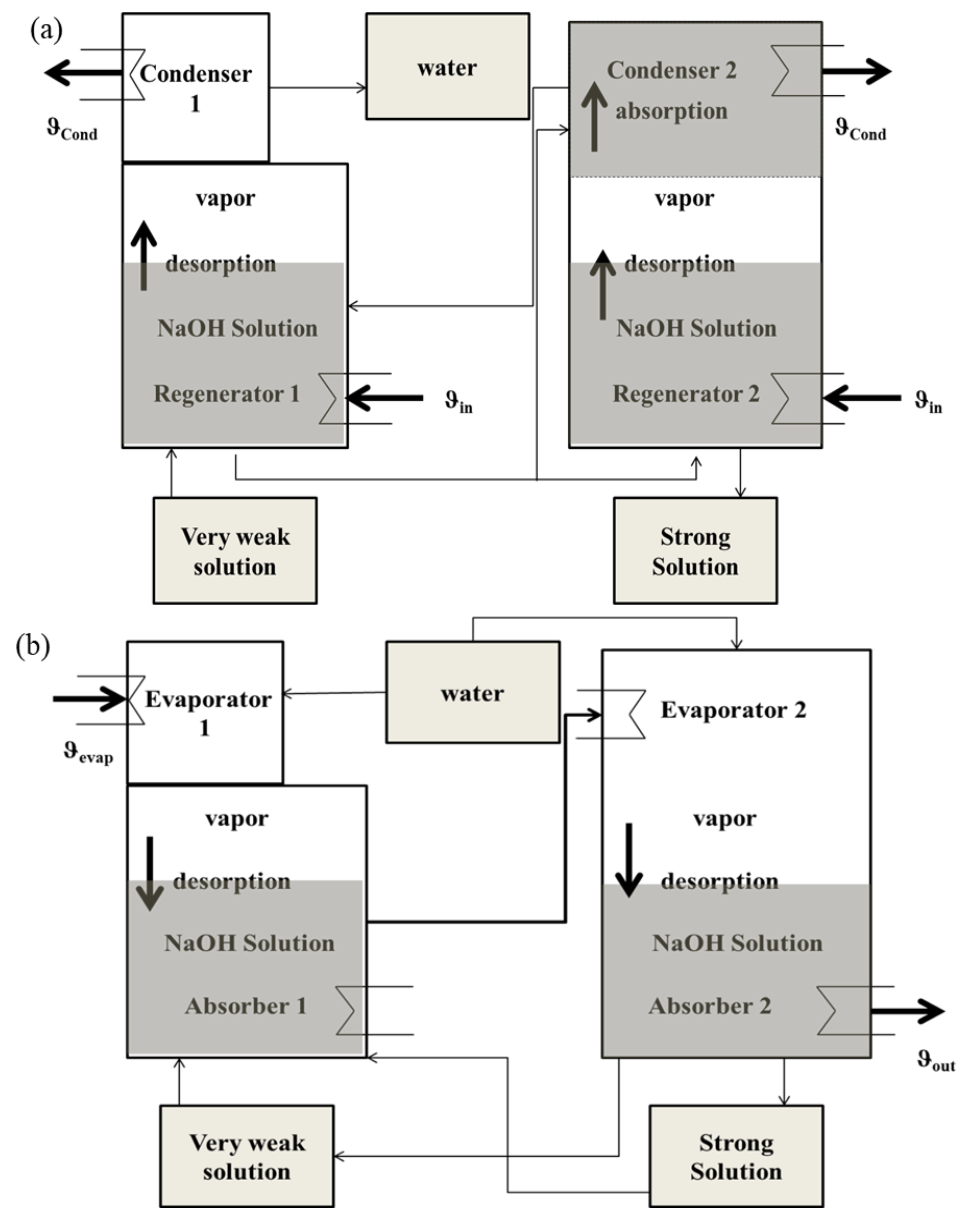

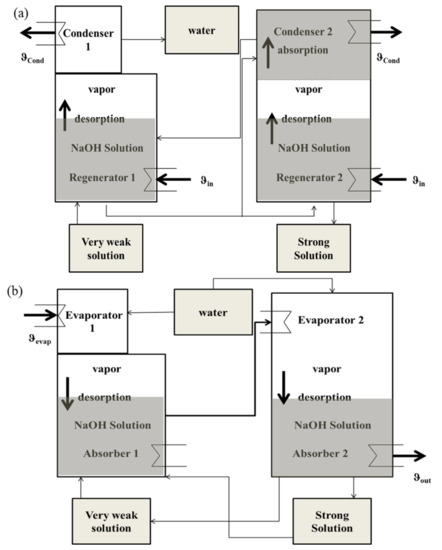

3.4. Double-Stage Absorption Cycle

To increase the temperature of condensation or to reduce the desorption temperature in the charging process, or aim for a high discharging temperature, multiple advanced cycles have been explored recently. The goal of developing advanced cycles is to make the system more flexible and efficient [123,124]. Weber et al. [104] proposed a double-stage absorption cycle. Its operating principle is similar to that of the single-stage absorption cycle, but with an additional condenser/evaporator and desorber/absorber, as depicted in Figure 15a,b. The solution in regenerator 1 splits into two during the charging process and flows to regenerator 2 and condenser 2. In regenerator 2, the generated vapor goes to condenser 2 and a strong solution flows to the storage tank. To move the vapor to the condenser, a vapor pressure difference is needed, which should be less than the pressure of regenerator 1. As a result, a high concentration of glide can be achieved with a lower thermal source temperature. During the discharging process, the heat energy from absorber 2 can be utilized for heating purposes, while that from absorber 1 is used to raise the temperature of evaporator 2. The heat is rejected at low concentrations because of the high vapor pressure in absorber 2. Xu et al. [125] studied the performance of a multi-stage absorption cycle. The performances of the double- and triple-stage absorption cycles were compared to that of the single-stage absorption cycle. It was concluded that the heat losses were 75.4% and 82.3% less for the double- and triple-stage absorption cycles, respectively. The energy densities were 7.32 and 6.78 times higher for the double- and triple-stage absorption cycles, respectively, compared to that of the single-stage absorption cycle.

Figure 15.

Double-stage absorption cycle: (a) Charging; (b) Discharging [104].

Absorption TES systems have the potential to store energy from renewable energy sources. To present a clear view, this section has provided detailed information on systems based on the absorption storage mechanism, including the thermodynamic absorption cycles and an integrated framework. Some of the critical factors related to absorption storage systems were identified through the literature review. The thermodynamic cycle design influences the energy storage density, thermal power output, and system design, which can be improved by switching from the conventional absorption cycle to a novel absorption cycle. The triple-stage absorption cycle is a novel approach to enhance the energy density of the system; it outperforms the conventional absorption cycle. The absorption system linked with the storage system provides more flexibility to be run by solar energy or a compressor, which has better performance than a system with only energy storage and retrieval. The different working pairs for an absorption storage system, working pairs with water as an absorbate, are extensively utilized because of their stability and physical properties. Open and closed systems, different reactor designs, and critical issues in reactor design are presented in the following section.

4. Designs for Low-Temperature TES Systems

In designing a low-temperature sorption heat storage system, the material examination is a crucial factor, as well as one of the main obstacles to be carefully addressed. The material properties should be satisfied at the system-scale. In addition, it is necessary to configure a system suitable for an optimal material, and an optimal design must be arrived at to achieve optimum efficiency. This section introduces and discusses the main system layouts, reactor arrangements, and system parameters for low-temperature TES systems.

4.1. Open and Closed Systems

Sorption heat storage systems can be classified into open and closed systems. An open system allows the charging and discharging interactions with ambient conditions. Hazardous refrigerants cannot be used for open sorption heat storage systems because of the mass transfer to the environment; therefore, mostly, water can be utilized. During the charging process, a hot air stream is blown and heated by an external heat source to the reactor, where water is adsorbed or absorbed by the sorbent. The water is removed by hot air, and as a result, the hot air becomes cool and wet, while leaving the reactor. In the discharging process, cool and humid air enters directly into the reactor, and the sorbent attracts water vapor from the air, thus generating the heat necessary to increase the air temperature. At this time, hot air can be used for heating purposes. Air dehumidification is also required in liquid absorption systems [126,127].

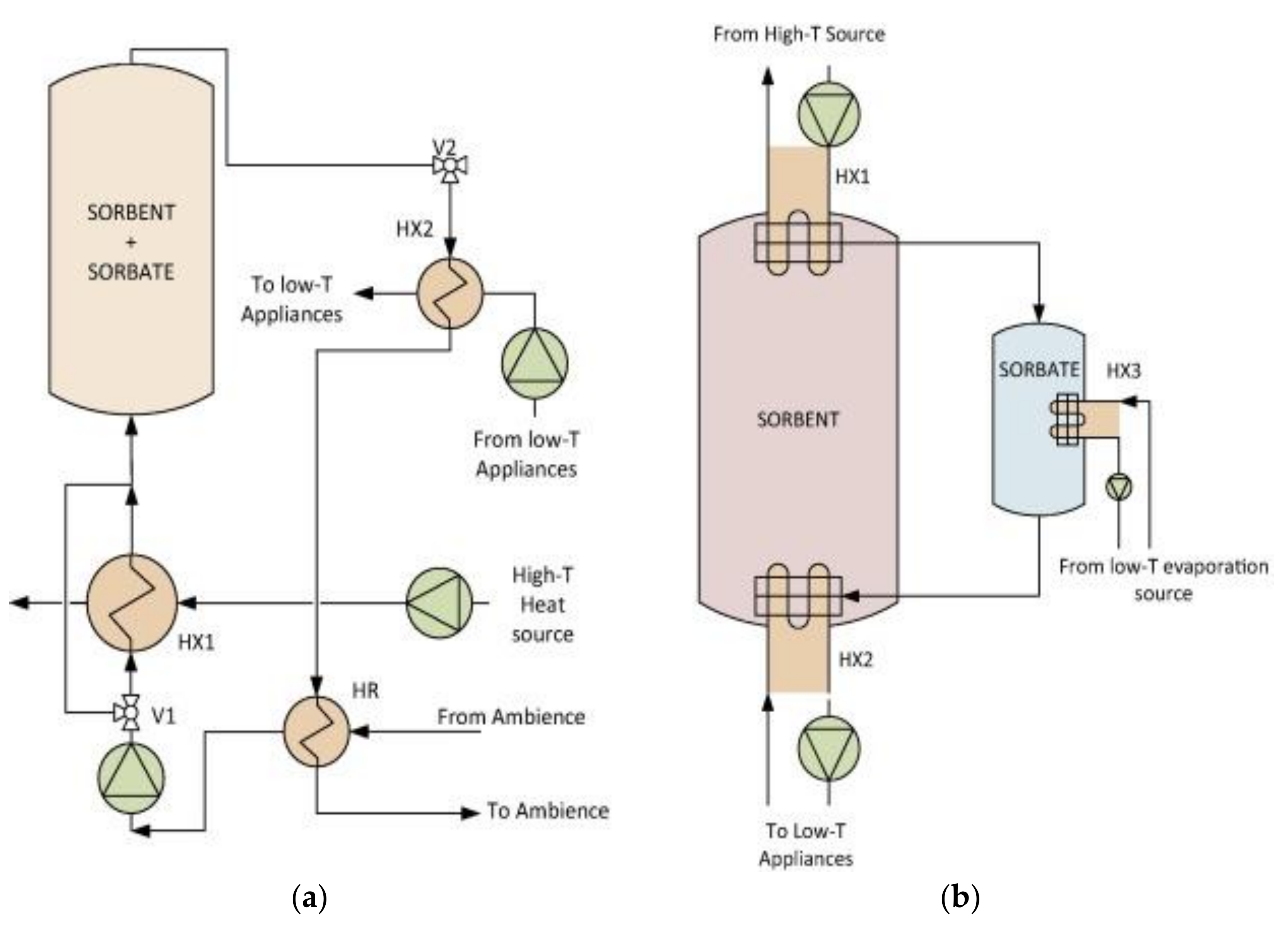

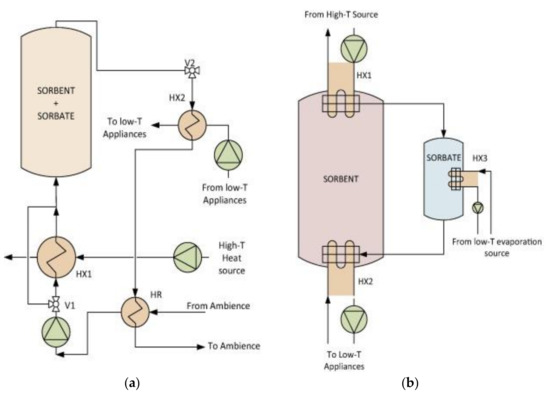

In contrast to an open system, a closed system only transfers energy to the environment. It does not undergo mass transfer with the environment. The open system has many advantages over the closed system, such as enhanced heat and mass transfer by increasing the circulation ratio, a simple mechanism, and the ability to work at low pressure. However, it has some disadvantages, such as high-pressure drop, extra fan, humidifier, and safety of the sorbate. The dominant features of a closed system include high discharge temperature and no requirement of a fan for sorbate circulation. A limitation of the closed systems is that more components are required, such as a condenser and an evaporator, a sorbate storage reservoir, and evaporation energy for the sorbate. Figure 16 illustrates open and closed sorption heat storage systems for the long-term [128]. Abedin et al. [129] performed energy and exergy analyses for the open and closed sorption heat storage systems. Their results showed that the energy and exergy efficiencies for the closed system were 50% and 9%, respectively, while they were 69% and 23% for the open system, respectively.

Figure 16.

Sorption heat storage systems for long-term [128]: (a) Open sorption system; (b) Closed sorption system.

4.2. Reactor Design

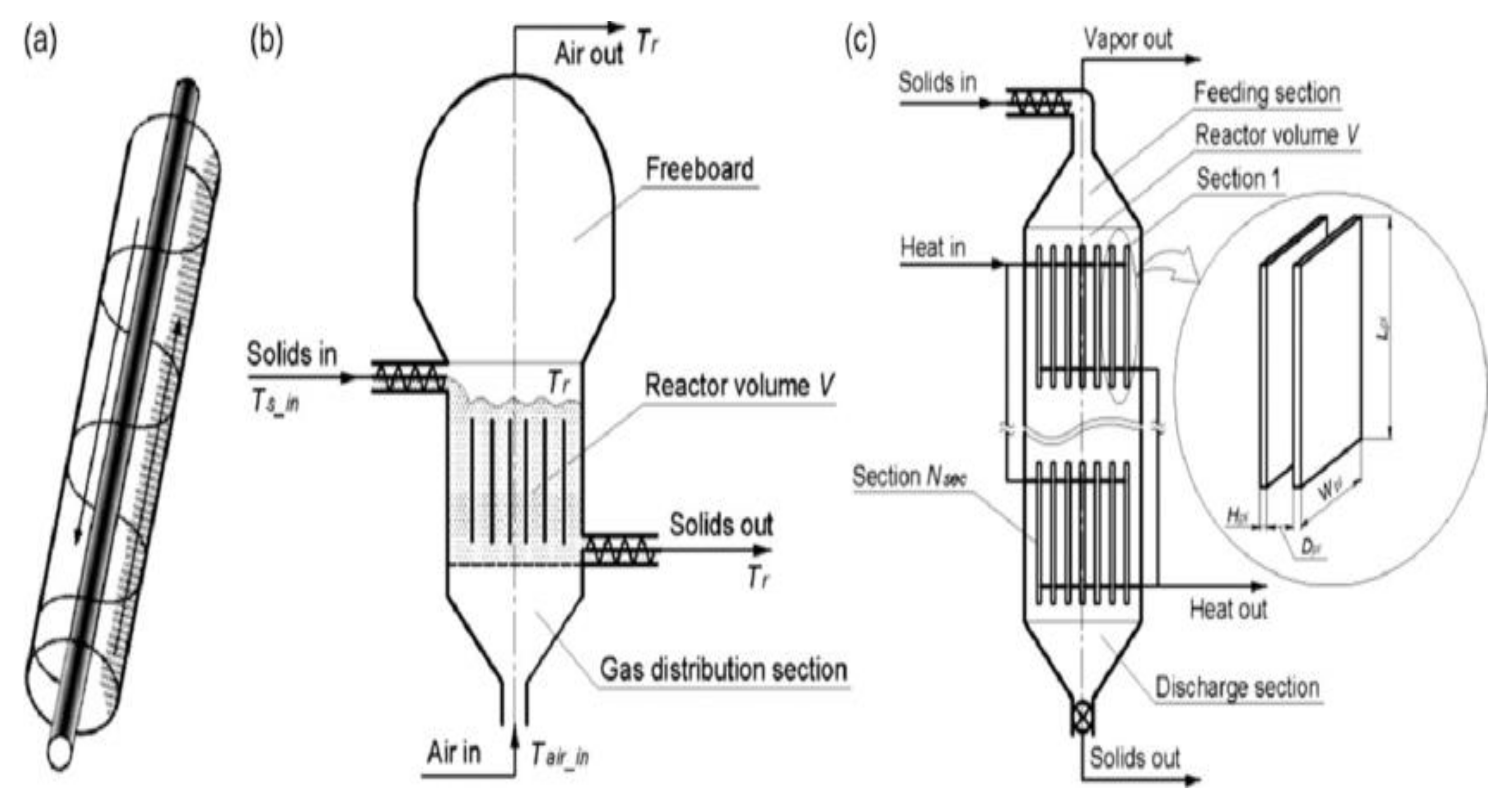

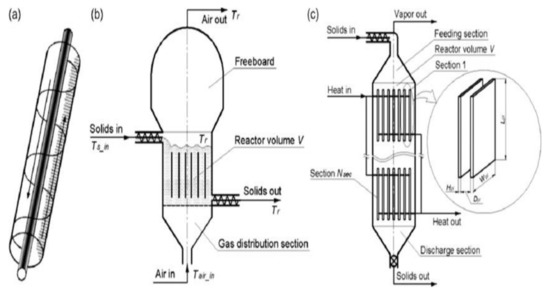

Sorption materials have a high theoretical energy density, which is not reflected in the actual prototype for sorption heat storage systems; therefore, it is of great concern to the system design. After an in-depth screening of the storage systems, it was concluded that the reactor design plays an essential role in delivering the energy, and it directly affects the system capacity and efficiency. Some previous studies have revealed that some critical issues related to reactor design should be addressed to develop an efficient reactor design. Reducing the heat losses, and improving heat and mass transfer of the system can enhance its performance. The general configuration of a solid reactor includes separate and integrated reactors [30]. Schuitema et al. [130] examined three different layouts of separate reactors, namely a screw reactor, a fluidized bed reactor, and a gravity-assisted bulk flow reactor, as shown in Figure 17. The authors concluded that the agitated reactor performed well because the active material assisted in the stirring and increased the system performance. The main issue related to the agitator reactor was the physical stirring of the system, as it could damage the active materials.

Figure 17.

Types of reactors: (a) Screw reactor; (b) Fluidized bed reactor [131]; (c) Gravity-assisted bulk flow reactor [130].

4.3. Thermal Conductivity and Mass Transfer in the Reactor

In an open sorption heat storage system, mass transfer is a critical issue, whereas in a closed system, heat transfer is very limited. These problems occur because of unfavorable material selection and system parameters. Coagulation of materials can occur because of mixing water, and local deliquescence material pulverization by continuous expansion and shrinking [132]. N’Tsoukpoe et al. [133] reviewed how heat and mass transfers are linked to the material size in the system. They reported that the particle size affected the adsorption capacity until it achieved a regime insensitive to the grain size. The ratio of the heat transfer surface to that of the absorbent was investigated, which is a critical factor for system optimization. Broader surfaces can also enhance heat transfer, for example, finned tubes [134], plate-fin heat exchangers [32], and coated spiro-tubes [135]. This arrangement is feasible if the wall heat transfer rate is high, and if no material shrinkage or expansion occurs [136].

This section has discussed different storage system configurations along with the pros and cons of open and closed sorption heat storage systems. In an open sorption heat storage system, a hazardous sorbate cannot be utilized because of its direct interaction with the environment. In addition, heat and mass transfer are critical for the overall efficiency of the system. In addition, in this section, different separate reactors have been presented, among which the agitator reactor outperforms the others because of the agitation of the active material. Heat transfer is another issue related to the system design, which requires a high-end heat exchanger to enhance it. A heat exchanger with extended surfaces performs well in a closed sorption heat storage system to increase the heat transfer in the system. Based on the component design for a highly efficient sorption heat storage system, numerous attempts have been made to investigate the system performance through actual experiments. In the following section, some developed prototypes will be presented and discussed in terms of their energy density and working mechanisms.

5. Developed Prototypes and Systems for Thermal Energy Storage

In this section, representative prototypes based on open and closed sorption systems for low-temperature applications are presented. After tentative research on sorption materials and system design, numerous efforts were made to develop a highly efficient sorption heat storage system. Thus, some previously established prototypes are discussed in this section; Table 9 provides more information on some of the established prototypes.

Table 9.

Summary of developed prototypes of thermal storage systems.

Kroanauer et al. [137] recently developed one of the largest sorption heat storage systems. This system had a mobile heat storage system that was operated by waste heat from industries and distributed this energy in rural areas. This sorption heat storage system consisted of two tanks with 14 t of zeolite that uses waste heat from an incineration plant to charge the adsorption material at 130 °C. The sorption heat storage system was carried away over 7 km to deliver the stored energy at 60 °C to assist a gas burner in a drying process, thus saving the burning of fuel. The stored energy delivered to the discharge station is shown in Figure 18. The storage heat capacity was 2.3 MWh with 0.09 kg/kg of water absorption, and it could save 616 kg of carbon emissions per cycle. However, the storage handling system needed special attention to improving its efficiency. For example, maldistribution of flow in the heat storage system and humidity variation owing to weather fluctuations were observed. The estimated energy cost was 73 €/MWh, which is not practical and economical compared to oil or gas. The authors suggested that it could be lowered to 36 €/MWh by installing an optimized handling storage system and by increasing the sorption material quantity by over 50 tonnes.

Figure 18.

Stored energy delivering system at a discharge station [137].

Fumey et al. [48] developed a closed sorption heat storage system under the COMTES project. Sodium hydroxide was utilized as the adsorbent, with water as an adsorbate. The solar collector field was installed on a 7 m-long container, which provided the heat for efficient operation. The outside solar collectors connected to the container and inside the experimental setup of the closed sorption storage system are shown in Figure 19. A hybrid storage technique was employed based on sensible heat storage for short-term storage and sorption storage systems to store heat over the long-term, simultaneously. The hybrid technique produced a low charging/discharging temperature for sensible heat storage and minimum losses while storing heat during the sorption heat storage. The thermal output of the sorption heat storage was estimated to be 8 kW. An absorption test was performed with 1000 kg of NaOH at 50% concentration in water, and 700 kg of deionized water was charged into the prototype. Two bundles of falling heat and mass exchangers were used, one for the de/absorber AC unit, and another for the evaporation/condensation EC unit. Both units were equipped with dripping nozzles, which helped distribute the sorbent over the tube bundles, and the heat was transferred to the heat transfer fluid flowing inside the tubes heated by a solar collector. The heat was transferred at a low temperature to the sorbent, which was evaporated to form water vapor. The results showed that the solar collector increased the temperature of the heat transfer fluid by 2.16 °C, with a final temperature of 26.03 °C. However, the temperature output was estimated to be 56 °C without any losses in the AC unit, which was not achieved. The absorption process was slower than the actual process, which resulted in a low thermal output of 1 kW from the system. The authors suggested increasing the thermal output and optimization of the absorption process by finding an efficient heat and mass exchanger design.

Figure 19.

Prototype of closed sorption storage system [48].

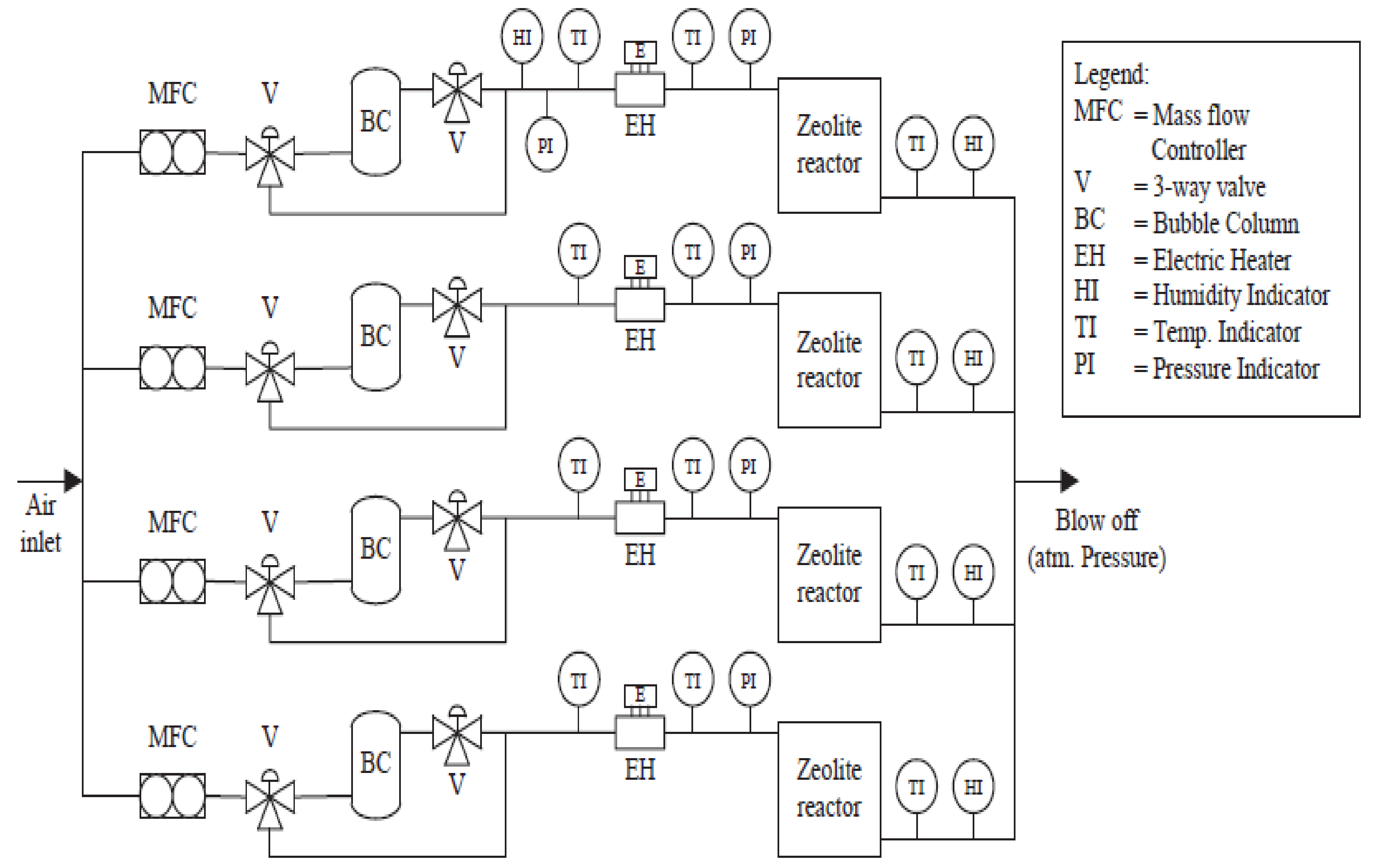

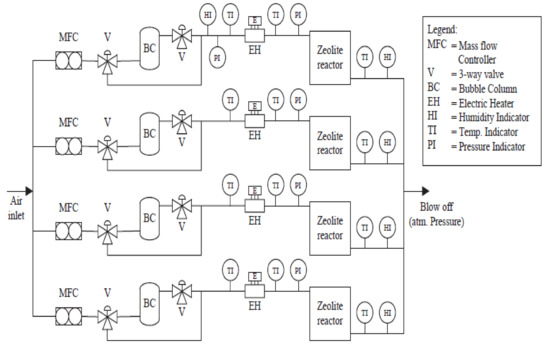

Van Alebeek et al. [138] investigated the performance of a sorption heat storage system with zeolite 13X for space heating at a house scale. Several factors that were reported in the literature to have a negative effect on the overall performance were addressed while designing the storage system. The designed sorption heat storage system was modular with segregated reactors, resulting in a low-pressure drop and increased overall efficiency. The total amount of adsorbent was 250 L, which was equally divided into four segments in each reactor. The zeolite bed was held between two perforated plates to keep the grains compact. A schematic layout of the experimental setup for the sorption TES system is shown in Figure 20. The pressurized air was fed into the system, where a mass flow meter controlled the flow. After the controlled airflow, a three-way valve directed the air into the bubble column for hydration and bypassed the dehydration process. The level of the bubble column was adjusted according to the desired humidity value. Electric heaters were placed in the pathway to control the air temperature and to allow it to enter the reactor. After the sorption process in the reactor, the air was released to the environment. The system could store 54 kWh of thermal energy and deliver a power output of 4 kW. The reported storage capacity was lower than the desired value because of the lower air humidity and the higher pressure in the humidifier. Reducing the pressure drop in the system enhanced its performance. The calculated efficiency of the system was 76%, and the authors suggested that it could be increased to 91% by recovering the sensible heat losses from the solid material in the reactor. The authors concluded that the flow distribution in the zeolite bed was a critical issue that should be addressed appropriately for better system performance.

Figure 20.

Schematic layout of the sorption TES system [138].

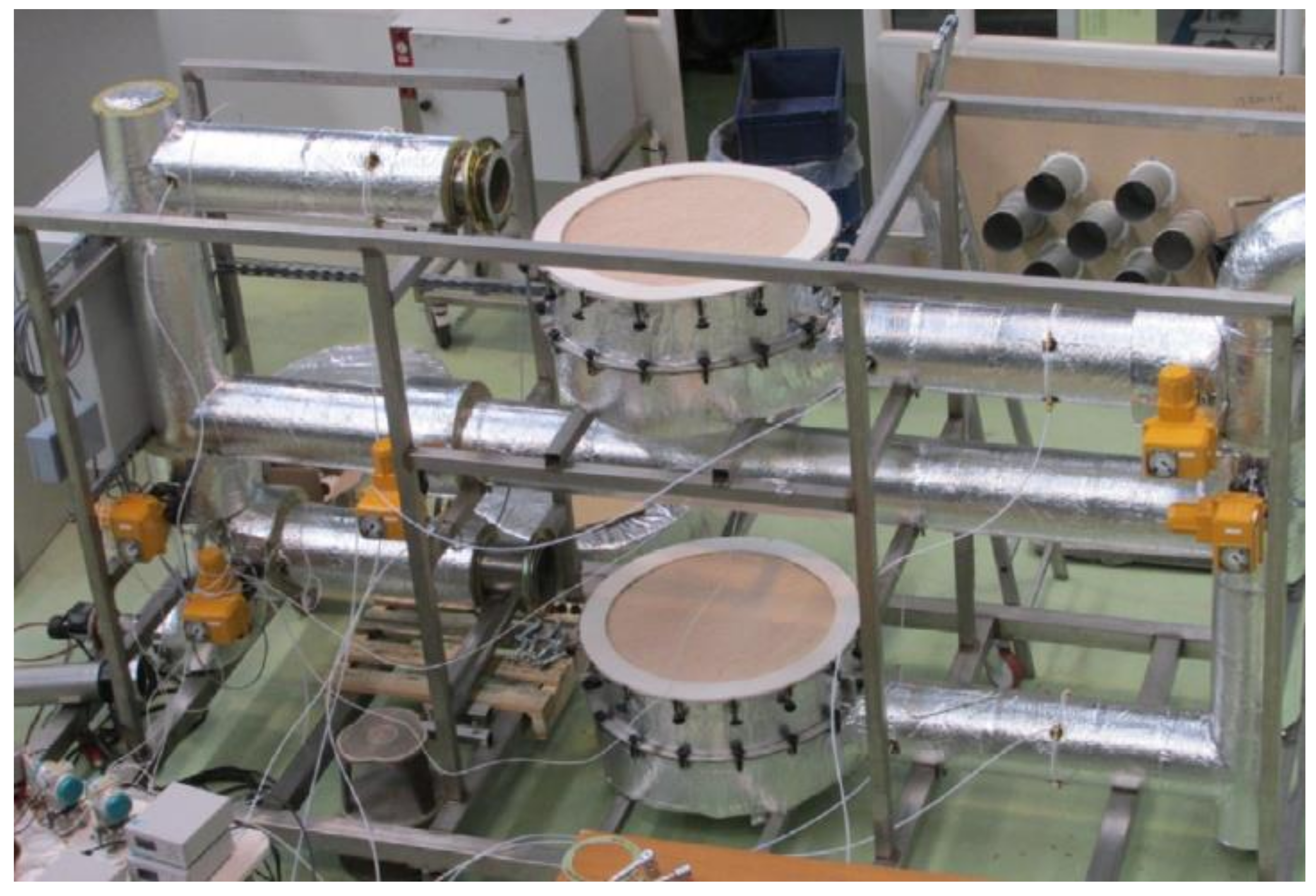

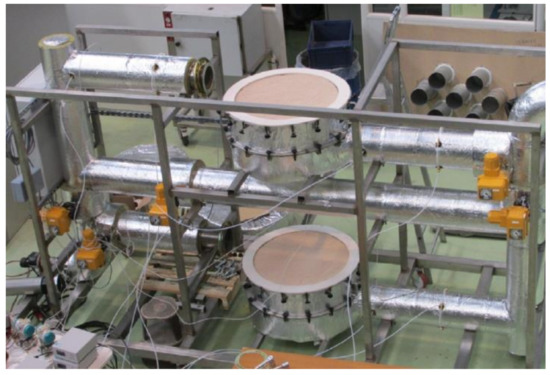

Johannes et al. [139] developed a sorption heat storage system integrated with a building ventilation system to contribute to peak-load times, which lasted for 2 h. An open sorption heat storage system was designed to accumulate air from the building and heat it with a solar air collector panel or heater; the air was utilized for dehydration in the charging process. For the discharging process, moist air from the building was used to hydrate the material. The selected material for this prototype was zeolite 13X, with a particulate diameter of 2 mm and a spherical shape. The bed porosity, which was the driving factor in the air diffusion into the bed, was approximately 0.36 for the compactly packed spherical material. The experimental setup consisted of two reactors and a duct to drive the air into the de/hydration zone. The developed sorption heat storage system is shown in Figure 21. The experimental data revealed that the system thermal energy output was 2.25 kW for 6 h with 27.5 W/kg of the material. The authors mentioned that making the reactor design more compact could limit the system power output duration to 2 h. It was concluded that the system’s power output decreased with a lower dehydration temperature, and with lower humidity in the reactor chamber during the hydration. In addition, they reported that a decreased airflow rate affected the heat storage capacity and the maximum power output.

Figure 21.

Developed sorption heat storage system [139].

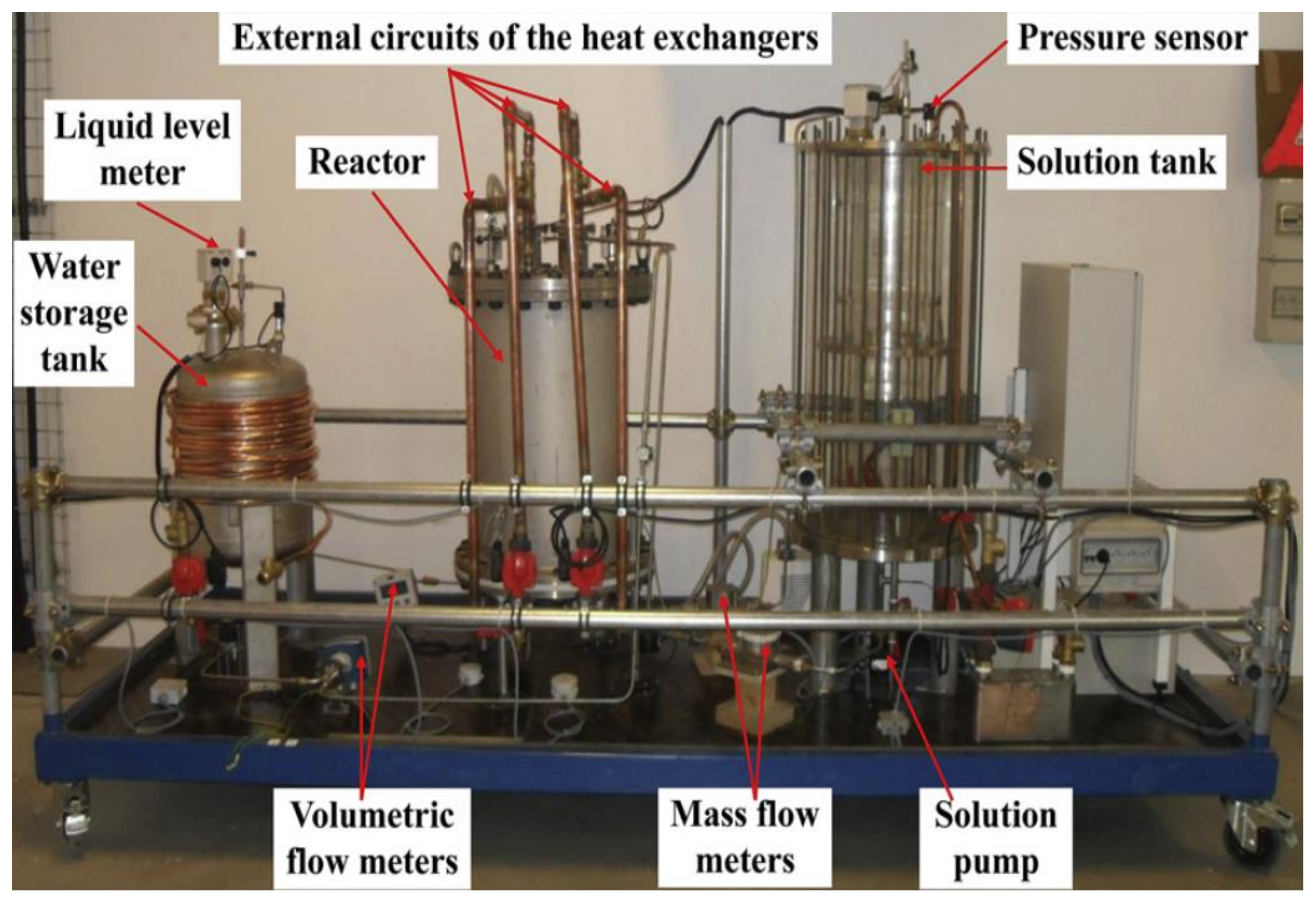

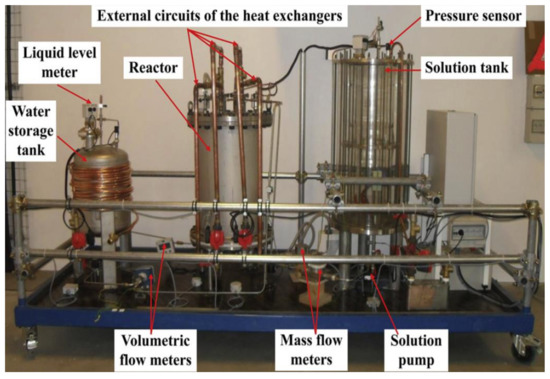

N’Tsoukpoe et al. [44] investigated a long-term absorption TES system with a storage capacity of 8 kW and delivered a thermal output power of 1 kW. An optimal number of components was selected for the prototype because they impacted the overall cost and storage capacity. A single solution tank was considered for this experiment, instead of two appropriate storage tanks for the solar energy. Two storage tanks working with variable input energy into the desorber resulted in solutions with different concentrations, which needed to be recirculated. There was one outlet from the desorber for the concentrated solution, which was inadequate to recirculate the solution from the desorber. With one storage tank, it was easy to recirculate the solution from the desorber. The prototype consisted of two storage tanks, one for the absorbate and the other for the absorbent. A reactor with two heat exchangers was utilized. A one-unit separate reactor design was proposed for the long-term absorption thermal storage system, as shown in Figure 22. In more than twenty tests that were carried out, the prototype was charged under practical conditions of 10–95 °C in the desorber, and 10–30 °C in the condenser. The heat transfer rate in the desorber was less than expected owing to the hydraulic limitations. The charging process had a charging power of 2–5 kW, with a storage capacity of 13 kWh. The solution flow rate was a complex factor related to the heat transfer rate in the desorber. The solution flow rate was increased by a factor of two, resulting in twice the heat transfer rate. However, crystallization was observed in several cycles. The discharging process was confirmed to be a failure, which was attributed to the inappropriate design of the absorber. Various methods, including heat and mass transfer additives, and reverse flow direction of fluids, were employed; however, none of these strategies were able to resolve the issue. The authors suggested a new design for the absorber to eliminate the limitations of this work.

Figure 22.

Long-term absorption thermal energy storage [44].

Numerous attempts have been made to develop effective thermal storage systems in various countries. Table 8 shows the representative prototypes of thermal storage systems for short- and long-term energy storage. Most of them were designed for long-term TES, and various TES materials were also used. In addition, the systems in Table 8 are presented for various heat capacities from small to large, even though their COP was not very high.

Ongoing research on sorption heat storage prototypes has been primarily on open and closed systems. Different reactor designs were utilized in the prototypes; however, the layout with a separate and modular reactor was of great interest because it enhanced the mass transfer. Modular reactors were used in an open system, resulting in lower pressure drops and good mass transport; however, only a few studies have been performed on separate reactor designs. The charging/discharging, energy density and prototype layout are also presented. The energy efficiency of the open sorption heat storage system was higher than that of the closed sorption system.

6. Conclusions

In this study, a comprehensive review of sorption thermochemical storage systems in light of experimental and numerical data, as well as previous literature, has been introduced and summarized. Sorption technology is a promising approach for effectively storing thermal energy and can be used for a wide range of operations. Furthermore, its advantageous properties of being able to store thermal energy with a high energy density and minimum heat losses make it the best choice among various storage mechanisms. This review provides a clear path for future research in this field and highlights some key issues that degrade the system performance. The following conclusions were drawn from this literature review.

Regarding the working pairs, the search for suitable materials with good sorption properties, hydrothermal stability, and good cyclability performance under the system operating conditions should be continued. The ionic liquids utilized for absorption thermal energy storage outperforms in some aspects compared to the conventional absorption materials. It has not been used much for absorption thermal energy storage, and a limited number of materials are reported. To fill the gap, a detailed study would be helpful to search for more potential candidates. Among different sorption materials, it is difficult to identify an ideal material for sorption heat storage systems. Although composite materials are quite promising, further studies are needed to find a host matrix with good thermophysical properties, high porosity, and cost-effectiveness. Sorption materials play a vital role in the overall efficiency of sorption heat storage systems; however, the thermodynamic cycle and reactor design cannot be ignored either.

The innovative thermodynamic absorption cycle-integrated storage system provides excellent reliability and enhances its effectiveness. Different system designs and layouts have been discussed for the sorption heat storage system. The open sorption storage system has high efficiency and is more reliable in terms of its components. Reactor design is the key factor in reducing the heat losses from the system and enhancing the overall system performance. A separate reactor-type design for a closed sorption system can increase the system performance by decreasing the thermal mass of the reactor. This technology requires intense research to design an efficient thermal storage system. Many attempts have been made to develop effective thermal storage systems in various countries. However, there are still many problems in sorption heat storage systems, including low energy density, low COP, complex components, and crystallization. Various methods, including heat and mass transfer additives, and reverse flow direction of fluids, have been employed; however, none of these methods have solved the problem perfectly. Therefore, continuing research is needed to develop a stable and high-efficiency thermal storage system using low-temperature energy sources. In addition, system design technology with a simple structure and high energy density is required.

7. Future Outlook

Sorption thermochemical storage systems, which store thermal energy, were introduced to minimize the supply versus demand gap, and assist during the peak load durations. The sorption heat storage system has high theoretical energy storage capacity and efficiency; however, in a real prototype, the developed system exhibited low performance and efficiency, which was a significant concern for the mass implementation of this technology. The reasons for the same include inappropriate material selection, incomplete component design, and insufficient system optimization. Thus, some limitations still exist that should be addressed in future studies.