Evaluation of Reservoir Quality and Forecasted Production Variability along a Multi-Fractured Horizontal Well. Part 1: Reservoir Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wireline- and Drilling-Derived Rock Properties

2.1.1. Petrophysical Properties

2.1.2. Geomechanical Properties

2.2. Laboratory Characterization of Drill Cuttings

3. Results

3.1. Log- and Drilling-Derived Rock Properties

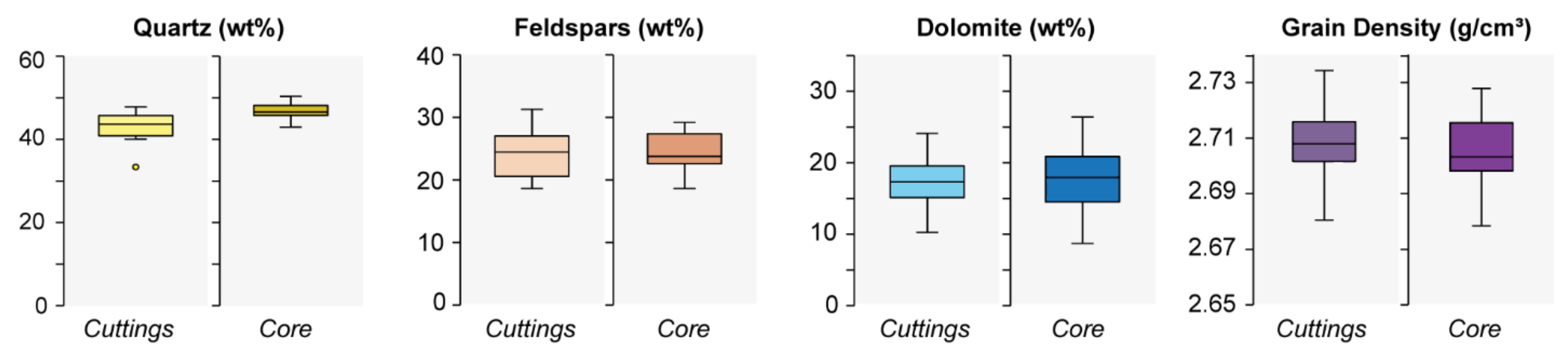

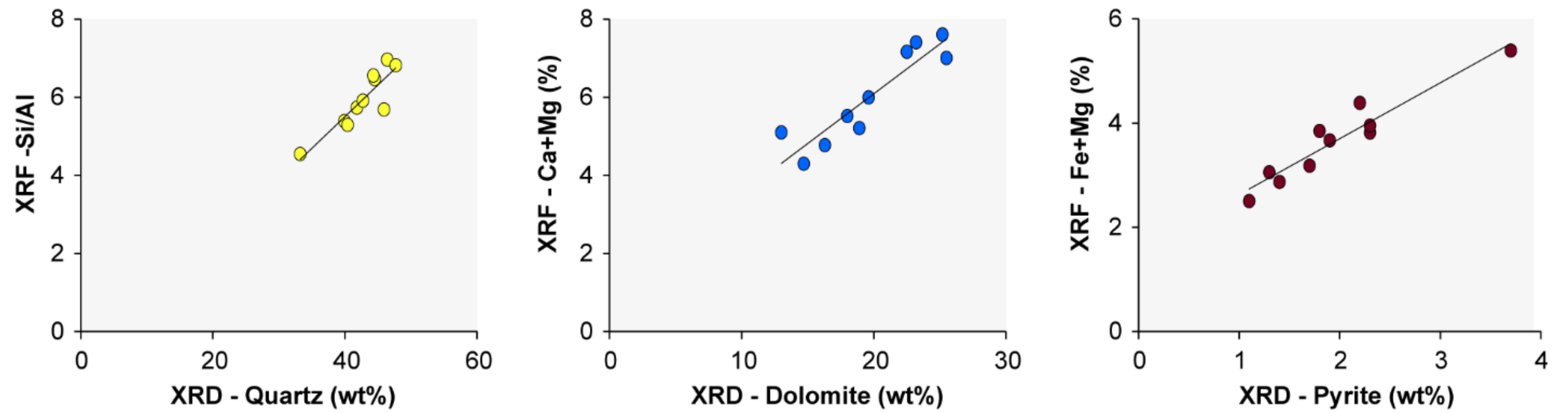

3.2. Reservoir Characteristics from Drill Cuttings

4. Discussion

4.1. Well Log and Drill Cuttings Analysis Integration

4.2. Evaluation of Reservoir Quality and Completion Quality

4.3. Challenges and Additional Considerations

4.3.1. Well Logs

4.3.2. Drill Cuttings

5. Conclusions

- Petrophysical and geomechanical properties calculated from well logs served to identify and group “similar-rock” intervals along the well. Based on the observed heterogeneity in reservoir properties, the lateral length of the well was subdivided into nine segments, which displayed variable RQ and CQ.

- For the identification of “sweet spots” for stimulation, a set of RQ and CQ cutoff-based values were determined by considering the overall variations of petrophysical and geomechanical properties along the lateral (2524 m). Superior RQ and CQ intervals were found to be associated with predominantly massive-porous siltstone facies; these intervals are regarded as the primary targets for stimulation. In contrast, relatively inferior RQ and CQ intervals were found to be associated with either dolomite-cemented facies or laminated siltstones.

- The potential of drill cuttings to produce reliable reservoir data that can be tied to core-measured rock properties, including rock composition, petrophysical properties, and even rock types, has been demonstrated.

- Contrary to other unconventional plays, in the Montney, the gamma ray log is not representative of the log-calculated petrophysical or geomechanical properties. This fact underscores the need to combine multiple well logs or integrate additional datasets, such as drill cuttings and drilling-derived properties, to improve the along-well characterization.

- The evaluation and quantification of lithological and rock fabric variations on drill cutting samples—while drilling—could be of great importance to the optimization of hydraulic fracture stimulation treatments, particularly in formations where the mineralogy is not strongly indicative of RQ as in the Montney.

- Drill cuttings are naturally an imperfect dataset; the impact of several factors (e.g., particle size, DBM, etc.) on the different laboratory analyses should be recognized and accounted for.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baihly, J.D.; Malpani, R.; Edwards, C.; Han, S.Y.; Kok, J.C.L.; Tollefsen, E.M.; Wheeler, C.W. Unlocking the shale mystery: How lateral measurements and well placement impact completions and resultant production. In Proceedings of the SPE Tight Gas Completions Conference, San Antonio, TX, USA, 2–3 November 2010. [Google Scholar]

- Miller, C.; Waters, G.; Rylander, E. Evaluation of production log data from horizontal wells drilled in organic shales. In Proceedings of the SPE Americas Unconventional Gas Conference, The Woodlands, TX, USA, 14–16 June 2011. [Google Scholar]

- Chorn, L.; Stegent, N.; Yarus, J. Optimizing lateral lengths in horizontal wells for a heterogeneous shale play. In Proceedings of the SPE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 25–27 February 2014. [Google Scholar]

- Salahshoor, S.; Maity, D.; Ciezobka, J. Stage-level data integration to evaluate the fracturing behavior of horizontal wells at the hydraulic fracturing test site (HFTS): An insight into the production performance. In Proceedings of the SPE Unconventional Resources Technology Conference, Austin, TX, USA, 20–22 July 2020. [Google Scholar]

- Cipolla, C.; Weng, X.; Onda, H.; Nadaraja, T.; Ganguly, U.; Malpani, R. New algorithms and integrated workflow for tight gas and shale completions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Walker, K.; Wutherich, K.; Terry, J.; Shreves, J.; Caplan, J. Improving production in the Marcellus Shale using an engineered completion design: A case study. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Ajisafe, F.; Pope, T.; Azike, O.; Reischman, R.; Herman, D.; Burkhardt, C.; Helmreich, A.; Phelps, M. Engineered completion workflow increases reservoir contact and production in the Wolfcamp Shale, West Texas. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Logan, W.D. Engineered shale completions based on common drilling data. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Buller, D.; Scheibe, C.; Stringer, C.; Carpenter, G. A new mineralogy cuttings analysis workflow for optimized horizontal fracture-stage placement in organic shale reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Stolyarov, S.; Gadzhimirzaev, D.; Sadykhov, S.; Ackley, B.; Lipp, C. Lateral wellbore rock characterization and hydraulic fracture optimization utilizing drilling cuttings and mud log in Cleveland Sand, a case study. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, OK, USA, 27–31 March 2017. [Google Scholar]

- Ghanizadeh, A.; Rashidi, B.; Clarkson, C.R.; Sidhu, N.; Hobbs, J.J.; Yang, Z.; Song, C.; Hazell, S.; Bustin, R.M. Characterization of reservoir qualityin tight rocks using drill cuttings: Examples from the Montney Formation Alberta, Canada. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar]

- Shi, X.; Jiang, S.; Wang, Z.; Xiao, D.; Sun, X. The application of drill cuttings to evaluate the fracability in unconventional shale gas resources. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar]

- Esatyana, E.; Sakhaee-Pour, A.; Sadooni, F.N.; Al-Saad Al-Kuwari, H. Nanoindentation of shale cuttings and its application to core measurements. Petrophys.—SPWLA J. Form. Eval. Reserv. Descr. 2020, 61, 404–416. [Google Scholar] [CrossRef]

- Tahmeen, M.; Hareland, G.; Hayes, J.P. A convenient technology to calculate geomechanical properties from drilling data. In Proceedings of the ASME 39th International Conference on Ocean, Offshore and Arctic Engineering; American Society of Mechanical Engineers, Virtual, Online, 3–7 August 2020. [Google Scholar]

- Trivedi, A.S.; Clarkson, C.R.; Shor, R.J. Accounting for hydraulics and vibration in MSE calculations to estimate formation properties. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 3–5 March 2020. [Google Scholar]

- Akihisa, K.; Knapp, L.J.; Sekine, K.; Akai, T.; Uchida, S.; Wood, J.M.; Ardakani, O.H.; Sanei, H. Integrating mud gas and cuttings analyses to understand local CGR variation in the Montney tight gas reservoir. Int. J. Coal Geol. 2018, 197, 42–52. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Zhang, Z.; Tabasinejad, F.; Becerra, D.; Ghanizadeh, A. Evaluation of reservoir quality and forecasted production variability along a multi-fractured horizontal well. Part 2: Selected stage forecasting. Energies 2021, 14, 6007. [Google Scholar] [CrossRef]

- National Energy Board; British Columbia Oil & Gas Commission; Alberta Energy Regulator; British Columbia Ministry of Natural Gas Development The Ultimate Potential for Unconventional Petroleum from the Montney Formation of British Columbia and Alberta. Energy Brief. Note 2013, 1–23.

- Kuppe, F.; Haysom, S.; Nevokshonoff, G. Liquids rich unconventional Montney: The geology and the forecast. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar]

- Davies, G.R.; Watson, N.; Moslow, T.F.; Maceachern, J.A. Regional subdivisions, sequences, correlations and facies relationships of the lower triassic Montney Formation, west-central Alberta to northeastern British Columbia, Canada—With emphasis on role of paleostructure. Bull. Can. Pet. Geol. 2018, 66, 23–92. [Google Scholar]

- Davis, D.H. Estimating porosity of sedimentary rocks from bulk density. J. Geol. 1954, 62, 102–107. [Google Scholar] [CrossRef]

- Wood, J.M. Water distribution in the Montney Tight Gas Play of the Western Canadian Sedimentary Basin: Significance for resource evaluation. SPE Reserv. Eval. Eng. 2013, 16, 290–302. [Google Scholar] [CrossRef]

- Kowalski, J. Formation strength parameters from well logs. In Proceedings of the SPWLA 16th Annual Logging Symposium, New Orleans, LA, USA, 4–7 June 1975. [Google Scholar]

- McNally, G.H. Estimation of coal measures rock strength using sonic and neutron logs. Geoexploration 1987, 24, 381–395. [Google Scholar] [CrossRef]

- Rigaku. Integrated X-ray powder diffraction software PDXL. Rigaku J. 2010, 26, 23–27. [Google Scholar]

- Becerra, D.; Pires De Lima, R.; Galvis-Portilla, H.; Clarkson, C.R. Generating a labeled dataset to train machine learning algorithms for lithological classification of drill cuttings. 2021; In Preparation. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Core Lab. Shale Matrix Permeameter (SMP), operations manual. 2013, 1–22.

- Vishkai, M.; Wang, J.; Wong, R.C.K.; Clarkson, C.R.; Gates, I.D. Modeling geomechanical properties in the Montney Formation, Alberta, Canada. Int. J. Rock Mech. Min. Sci. 2017, 96, 94–105. [Google Scholar] [CrossRef]

- Ghanizadeh, A.; Clarkson, C.R.; Vahedian, A.; Ardakani, O.H.; Wood, J.M.; Sanei, H. Laboratory-based characterization of pore network and matrix permeability in the Montney Formation: Insights from methodology comparisons. Bull. Can. Pet. Geol. 2018, 66, 472–498. [Google Scholar]

- Teale, R. The concept of specific energy in rock drilling. Int. J. Rock Mech. Min. Sci. 1965, 2, 57–73. [Google Scholar] [CrossRef]

- Dupriest, F.E.; Koederitz, W.L. Maximizing drill rates with real-time surveillance of mechanical specific energy. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 23–25 February 2005. [Google Scholar]

- Zeuch, D.H.; Finger, J.T. Rock breakage mechanisms with a PDC cutter. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–25 September 1985. [Google Scholar]

- Ghanizadeh, A.; Clarkson, C.R.; Aquino, S.; Ardakani, O.H.; Sanei, H. Petrophysical and geomechanical characteristics of Canadian tight oil and liquid rich gas reservoirs: II. Geomechanical property estimation. Fuel 2015, 153, 682–691. [Google Scholar] [CrossRef]

- Heller, R.; Vermylen, J.; Zoback, M. Experimental investigation of matrix permeability of gas shales. Am. Assoc. Pet. Geol. Bull. 2014, 98, 975–995. [Google Scholar] [CrossRef]

- Peng, S.; Loucks, B. Permeability measurements in mudrocks using gas-expansion methods on plug and crushed-rock samples. Mar. Pet. Geol. 2016, 73, 299–310. [Google Scholar] [CrossRef] [Green Version]

- Clarkson, C.R.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.D.; Riazi, N.; Debuhr, C.; Deglint, H.J. Nanopores to megafractures: Current challenges and methods for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Vaisblat, N.; Harris, N.B.; Ayranci, K.; Power, M.; DeBhur, C.; Bish, D.L.; Chalaturnyk, R.; Krause, F.; Crombez, V.; Euzen, T.; et al. Compositional and diagenetic evolution of a siltstone, with implications for reservoir quality; an example from the Lower Triassic Montney Formation in western Canada. Mar. Pet. Geol. 2021, 129, 105066. [Google Scholar] [CrossRef]

- Vocke, C.P.; Deglint, H.J.; Clarkson, C.R.; Debuhr, C.; Ghanizadeh, A.; Hazell, S.; Bustin, M. Estimation of petrophysical properties of tight rocks from drill cuttings using image analysis: An integrated laboratory-based approach. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar]

- Landry, C.J.; Hart, B.S.; Prodanović, M. Comparison of wireline log and SEM image-based measurements of porosity in overburden shales. In Proceedings of the SPE Unconventional Resources Technology Conference, Austin, TX, USA, 20–22 July 2020. [Google Scholar]

- Buckman, J.; Aboussou, A.; Esegbue, O.; Wagner, T.; Gambacorta, G. Fine-scale heterogeneity of pyrite and organics within mudrocks: Scanning electron microscopy and image analysis at the large scale. Minerals 2020, 10, 354. [Google Scholar] [CrossRef]

- Kennedy, L.A.; Spray, J.G. Frictional melting of sedimentary rock during high-speed diamond drilling: An analytical SEM and TEM investigation. Tectonophysics 1992, 204, 323–337. [Google Scholar] [CrossRef]

- Davies, G.R.; Moslow, T.F.; Sherwin, M.D. The Lower Triassic Montney Formation, west-central Alberta. Bull. Can. Pet. Geol. 1997, 45, 474–505. [Google Scholar] [CrossRef]

- Wüst, R.A.J.; Nassichuk, B.R.; Bustin, R.M. Porosity characterization of various organic-rich shales from the western Canadian sedimentary basin, Alberta and British Columbia, Canada. AAPG Mem. 2013, 81–100. [Google Scholar] [CrossRef]

- Cipolla, C.; Lewis, R.; Maxwell, S.; Mack, M. Appraising unconventional resource plays: Separating reservoir quality from completion effectiveness. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 7–9 February 2012. [Google Scholar]

- Mullen, J.; Lowry, J.C.; Nwabuoku, K.C. Lessons learned developing the Eagle Ford Shale. In Proceedings of the SPE Tight Gas Completions Conference, San Antonio, TX, USA, 2–3 November 2010. [Google Scholar]

- Anifowoshe, O.; Yates, M.; Xu, L.; Dickenson, P.; Akin, J.; Carney, B.J.; Hewitt, J.; Costello, I.; Arnold, Z. Improving wellbore stimulation coverage in the Marcellus: Integrating lateral measurements with enhanced engineered completion design and fiber optic evaluation. In Proceedings of the SPE Eastern Regional Meeting, Canton, OH, USA, 13–15 September 2016. [Google Scholar]

- Slocombe, R.; Acock, A.; Chadwick, C.; Wigger, E.; Viswanathan, A.; Fisher, K.; Reischman, R. Eagle Ford completion optimization strategies using horizontal logging data. In Proceedings of the SPE Unconventional Resources Technology Conference, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- El Sgher, M.; Aminian, K.; Ameri, S. Contribution of hydraulic fracture stage on the gas recovery from the Marcellus Shale. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 7–11 October 2018. [Google Scholar]

- Wutherich, K.D.; Walker, K.J. Designing completions in horizontal shale gas wells - Perforation strategies. In Proceedings of the SPE Americas Unconventional Resources, Pittsburgh, PA, USA, 5–7 June 2012. [Google Scholar]

- Glaser, K.S.; Miller, C.K.; Johnson, G.M.; Toelle, B.; Kleinberg, R.L.; Miller, P.; Pennington, W.D. Seeking the sweet spot: Reservoir and completion quality in organic shales. Oilf. Rev. 2013, 25, 16–29. [Google Scholar]

- Worthington, P.F.; Cosentino, L. The application of cutoffs in integrated reservoir studies. SPE Reserv. Eval. Eng. 2008, 11, 968–975. [Google Scholar] [CrossRef]

- Shahri, M.P.; Chok, H.; Safari, R.; Huang, J.; Amorocho, C.; Mejia, C.; Mutlu, U. Automated hydraulic fracturing stage design based on integrated fracture potential. In Proceedings of the SPE Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Laronga, R.; Mosse, L.; Velez, E.; Haddad, E.; Gonzalez-Iglesias, J. Improving unconventional reservoir performance with geoscience-based development strategies. World Oil 2021, 242, 2–5. [Google Scholar]

- Venieri, M.; Weir, R.; McKean, S.H.; Pedersen, P.K.; Eaton, D.W. Determining elastic properties of organic-rich shales from core, wireline logs and 3-D seismic: A comparative study from the Duvernay play, Alberta, Canada. J. Nat. Gas Sci. Eng. 2020, 84, 103637. [Google Scholar] [CrossRef]

- Lili, X.; Yates, M.; Anifowoshe, O.; Uschner-Arroyo, N.; Yang, Y.; MacPhail, K. Comparing strategies for optimizing horizontal shale completions by projecting pilot well measurements across laterals. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, WV, USA, 13–15 October 2015. [Google Scholar]

- Krause, F.F.; Wiesman, A.C.; Williscroft, K.R.; Solano, N.; Morris, N.J.; Meyer, R.; Marr, R. InSight CWLS Magazine; Canadian Well Logging Society: Calgary, AB, Canada, 2012; pp. 1–4. [Google Scholar]

- Mavko, G.; Mukerji, T.; Dvorkin, J. The Rock Physics Handbook; Cambridge University Press: Cambridge, UK, 2009; ISBN 9780511626753. [Google Scholar]

- Eissa, E.A.; Kazi, A. Relation between static and dynamic Young’s moduli of rocks. Int. J. Rock Mech. Min. Sci. 1988, 25, 479–482. [Google Scholar] [CrossRef]

- Najibi, A.R.; Ghafoori, M.; Lashkaripour, G.R.; Asef, M.R. Empirical relations between strength and static and dynamic elastic properties of Asmari and Sarvak limestones, two main oil reservoirs in Iran. J. Pet. Sci. Eng. 2015, 126, 78–82. [Google Scholar] [CrossRef]

- Elkatatny, S.; Tariq, Z.; Mahmoud, M.; Abdulraheem, A.; Mohamed, I. An integrated approach for estimating static Young’s modulus using artificial intelligence tools. Neural Comput. Appl. 2019, 31, 4123–4135. [Google Scholar] [CrossRef]

- Barree, R.D.; Conway, M.W.; Miskimins, J.L. Use of conventional well logs in selective completion designs for unconventional reservoirs. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Atashnezhad, A.; Cedola, A.E.; Hareland, G. An empirical model to estimate a critical stimulation design parameter using drilling data. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23 April 2017. [Google Scholar]

- Cedola, A.E.; Atashnezhad, A.; Hareland, G. Evaluating multiple methods to determine porosity from drilling data. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, OK, USA, 27–31 March 2017. [Google Scholar]

- Cui, X.; Bustin, A.M.M.M.M.; Bustin, R.M. Measurements of gas permeability and diffusivity of tight reservoir rocks: Different approaches and their applications. Geofluids 2009, 9, 208–223. [Google Scholar] [CrossRef]

- Achang, M.; Pashin, J.C.; Cui, X. The influence of particle size, microfractures, and pressure decay on measuring the permeability of crushed shale samples. Int. J. Coal Geol. 2017, 183, 174–187. [Google Scholar] [CrossRef]

- Glowka, D. The thermal response of rock to friction in the drag cutting process. J. Struct. Geol. 1989, 11. [Google Scholar] [CrossRef]

- Taylor, J.C.M. Bit-metamorphism, illustrated by lithological data from german north sea wells. Geol. Mijnb. 1982, 62, 211–219. [Google Scholar] [CrossRef]

- Wenger, L.M.; Pottorf, R.J.; MacLeod, G.; Otten, G.; Dreyfus, S.; Justwan, H.; Wood, E.S. Drill-bit metamorphism: Recognition and impact on show evaluation. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Ashton, T.; Ly, C.V.; Graham, S.; Oliver, G. Portable technology puts real-time automated mineralogy on the well site. In Proceedings of the SPE Unconventional Resources Conference and Exhibition-Asia Pacific, Brisbane, Australia, 11–13 November 2013. [Google Scholar]

| Sample | Grain Density (g/cm3) | Porosity (%) | Permeability (mD) | Water Saturation (%) | Quartz (wt%) | Feldspars (wt%) | Dolomite (wt%) | Pyrite (wt%) | Clays (wt%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.68 | - | - | 8.5 | 45.4 | 24.0 | 22.8 | 0.8 | 7.0 |

| 2 | 2.73 | 7.04 | 0.0178 | 9.6 | 47.2 | 18.5 | 29.3 | 1.1 | 3.9 |

| 3 | 2.69 | 2.07 | 0.0005 | 7.9 | 45.8 | 29.2 | 10.6 | 2.3 | 12.0 |

| 4 | 2.73 | 3.81 | 0.0015 | 13.1 | 42.1 | 22.3 | 26.1 | 1.4 | 8.2 |

| 5 | 2.70 | 1.86 | 0.0003 | 9.1 | 46.3 | 24.5 | 17.7 | 1.2 | 10.3 |

| 6 | 2.70 | - | - | 11.4 | 49.6 | 23.2 | 18.2 | 1.5 | 7.4 |

| 7 | 2.70 | 4.09 | 0.0018 | 7.2 | 45.4 | 28.3 | 14.3 | 2.4 | 9.7 |

| 8 | 2.71 | 4.98 | 0.0029 | 10.5 | 46.1 | 23.4 | 22.7 | 1.2 | 6.7 |

| Min | 2.68 | 1.86 | 0.0003 | 7.2 | 42.1 | 18.5 | 10.6 | 0.8 | 3.9 |

| Max | 2.73 | 7.04 | 0.0178 | 13.1 | 49.6 | 29.2 | 29.3 | 2.4 | 12.0 |

| Average | 2.71 | 3.98 | 0.0041 | 9.7 | 46.0 | 24.2 | 20.2 | 1.5 | 8.2 |

| Well Segment | Gamma Ray (API) | Porosity (%) | Permeability (mD) | Water Saturation (%) | Young’s Modulus (GPa) | Poisson’s Ratio | UCS (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | (88–130) 115 | (0.9–4.5) 2.6 | (0.00012–0.00165) 0.00036 | (10–30) 21 | (62.4–68.9) 66.3 | (0.24–0.28) 0.26 | (155–174) 164 |

| 2 | (81–125) 102 | (3.0–7.2) 5.3 | (0.00061–0.00568) 0.00248 | (7–17) 9 | (61.6–66.2) 64.0 | (0.23–0.27) 0.25 | (152–165) 158 |

| 3 | (85–145) 114 | (1.0–7.4) 3.6 | (0.00018–0.00617) 0.00086 | (6–26) 15 | (56.3–68.0) 61.3 | (0.25–0.29) 0.27 | (151–173) 157 |

| 4 | (77–148) 106 | (3.5–7.8) 5.4 | (0.00097–0.00715) 0.00262 | (7–15) 10 | (60.3–67.7) 64.0 | (0.21–0.27) 0.24 | (147–166) 155 |

| 5 | (83–128) 106 | (0.9–6.8) 3.3 | (0.00013–0.00491) 0.00067 | (9–30) 18 | (63.1–70.1) 66.3 | (0.20–0.28) 0.25 | (150–172) 163 |

| 6 | (80–119) 105 | (0.4–7.5) 3.9 | (0.00012–0.00648) 0.00112 | (7–30) 14 | (64.2–72.1) 68.2 | (0.22–0.30) 0.25 | (156–178) 169 |

| 7 | (81–128) 111 | (0.4–6.6) 4.2 | (0.00027–0.00464) 0.00136 | (8–25) 14 | (63.4–71.4) 66.8 | (0.23–0.28) 0.25 | (158–180) 166 |

| 8 | (88–133) 113 | (2.4–9.0) 6.3 | (0.00042–0.01054) 0.00496 | (7–24) 11 | (59.7–66.7) 64.2 | (0.23–0.27) 0.25 | (148–170) 158 |

| 9 | (94–146) 113 | (2.7–6.1) 4.3 | (0.00039–0.00361) 0.00142 | (11–24) 18 | (60.3–68.2) 64.0 | (0.22–0.27) 0.24 | (150–163) 156 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Becerra, D.; Clarkson, C.R.; Ghanizadeh, A.; Pires de Lima, R.; Tabasinejad, F.; Zhang, Z.; Trivedi, A.; Shor, R. Evaluation of Reservoir Quality and Forecasted Production Variability along a Multi-Fractured Horizontal Well. Part 1: Reservoir Characterization. Energies 2021, 14, 6154. https://doi.org/10.3390/en14196154

Becerra D, Clarkson CR, Ghanizadeh A, Pires de Lima R, Tabasinejad F, Zhang Z, Trivedi A, Shor R. Evaluation of Reservoir Quality and Forecasted Production Variability along a Multi-Fractured Horizontal Well. Part 1: Reservoir Characterization. Energies. 2021; 14(19):6154. https://doi.org/10.3390/en14196154

Chicago/Turabian StyleBecerra, Daniela, Christopher R. Clarkson, Amin Ghanizadeh, Rafael Pires de Lima, Farshad Tabasinejad, Zhenzihao Zhang, Ajesh Trivedi, and Roman Shor. 2021. "Evaluation of Reservoir Quality and Forecasted Production Variability along a Multi-Fractured Horizontal Well. Part 1: Reservoir Characterization" Energies 14, no. 19: 6154. https://doi.org/10.3390/en14196154