1. Introduction

Lately, the EU has set goals and developed a legislative framework centered on clean energy, minimizing energy use and lowering CO

2 emissions, which are supported by directives and laws [

1]. The most recent energy-related goals are the following three: (a) 20-20-20 (a 20% increase in energy efficiency, a 20% reduction in greenhouse gas emissions compared to 1990 and a 20% contribution to the energy utilized from renewable energy sources/RES, which were to be achieved by 2020) [

1]; (b) more ambitious energy targets for 2030 (27–30% improvement in energy efficiency, 40% reduction in greenhouse gas emissions compared to 1990, at least 27% contribution from renewable energy sources and a 15% electricity interconnection target) [

2]; and (c) a 2050 far-reaching energy goal (greenhouse gas emissions reduction of 80–95% compared to 1990), aiming at an almost carbon neutral energy mixture [

3]. As a result, the adopted energy policy aims to direct the European economy towards cleaner energy and lower greenhouse gas emissions or towards a decarbonized society. Other than the pressure applied by legislature and the regulatory framework, a holistic decarbonization strategy has significant and quantifiable benefits, which should make it appealing [

4]. The need and the benefits of decarbonizing the energy sector are highlighted in a long-term strategy towards modern competitiveness and climate neutrality [

5]. As a result, decarbonization technologies are driven, articulated and explained by the technical character of the process [

6].

Despite the evident relevance of decarbonizing the energy sector, few frameworks for decarbonization and optimization of renewable energy systems (RES) in residential grids and micro-grids have been created up till now. Still, the development of optimization models in the field of energy production and planning has received a lot of attention lately. Other than the requirement for decreasing cost in RES applications, integrating storage systems in their operation is also noteworthy, since, in contrast to fossil fuels and specific renewable sources such as geothermal energy and biomass, the yield from wind and solar energy is directly linked to weather conditions, making energy output less predictable and non-dispatchable.

As a result, energy storage is critical in addressing energy accessibility challenges, as well as better energy management, cost reduction and environmental impact reduction. Despite the existing barriers for regulating energy storage systems (ESS), particularly for batteries used in residential applications, the importance of battery integration is crucial. Following the significant improvements in battery technology, their costs are expected to fall by 50–66% by 2030 [

7]. As a result, auxiliary services, such as battery capacity alignment and demand response that maintains the required frequency, are expected to be supported by batteries due to their lower investment cost compared to further power generation units.

Technological advances, when paired with algorithms and mathematical programming, enable considerable improvements in integrated system dimensioning, as well as the less imaginable environmental effects of carbon dioxide emissions reduction and energy availability for demand response. In this vein, the research is focused on creating a framework that can manage electricity from home-based photovoltaic panels and store it, considering various types of batteries, with a dimensioning set of limitations as a result, to achieve the least environmental impact.

Given the importance of RES, batteries and their integration in energy production systems, their dimensioning and proper usage plays a decisive role in minimizing the environmental impact of a system. This dimensioning process contains technical components and parameters, such as the battery power, which determines the system’s capacity. The components included in the design and the production process also affect the environmental profile of the system analyzed: the environmental emission factors based on production, usage and disposal define the environmental impact of the different stages and prioritize the system’s parameters regarding the consumption, the energy storage or the possibility of selling the electricity generated to the grid. Finally, the functioning of energy storage systems is governed by regulatory concerns. The study focuses on developing a decision-support tool for battery dimensioning in an existing system by using environmental criteria. The tool is adaptive to possible system modifications and can also be used for other systems. The developed tool has, as a main advantage, the ability to combine the input data and provide optimum solutions regarding the battery type and capacity which minimize the system’s environmental impact.

As a result, developing and evaluating energy policies for countries and regions has become a complicated task [

8]. A similar statement may be made regarding the challenge of evaluating individual activities in the domain of energy source type and placement [

8]. The stated competing objectives (economic, social, technological and environmental) offer the context for utilizing multi-criteria decision analysis (MCDA) methodologies [

9].

Solving RES decision-making challenges, MCDA approaches are commonly utilized. MCDA methods have demonstrated to be a profitable inquiry not only regarding the evaluation and positioning of alternatives [

10] but, moreover, for suggesting how to alter procedures and activities in an arrangement to optimize the expressed objective of choice [

11].

Most of the published data, as they will be presented in the literature review, focus on the implementation of the life cycle analysis (LCA) methodology for ESS, but there is still a lack of a framework specifically for dimensioning the storage system, aligned with the system’s energy management, and considering the materials used to produce various battery types under the scope of low environmental impact. In this sense, the adaptive decision-making tool developed is capable of illustrating an integrated assessment covering the gap mentioned about the decision-making process. The tool is not confined to a single type of battery, but it is flexible enough to compute the system’s total emission based on the batteries’ materials, as met in various battery kinds. The battery capacity emission sensitivity analysis can be undertaken using this framework, yielding clear results for energy storage on a residential level. Finally, the data needed to properly formulate the framework, namely of the specific battery materials and the respective contribution of each material depending on their capacity, can develop a clear drive to any future battery selection for residential applications, taking into consideration the environmental impact.

2. Materials and Methods

2.1. State of the Art

Significant research effort has been made to develop mathematical frameworks and respective software tools for either planning of production or management of energy. Some of the mathematical programming techniques that can be utilized in order to solve such problems are mixed integer programming (MIP) and linear (or non-linear) programming (LP or NLP).

Table 1 presents some of the most prominent battery optimization studies, with an emphasis on residential applications, either using optimization techniques or focusing on the environmental impact calculation based on batteries.

2.2. Theoritical Backround on Batteries’ Materials

The current section gives an outline of the many types of batteries that may be utilized in renewable energy systems. Key benefits and disadvantages of every type are discussed, as part of the determining the most suitable choice for residential PV systems.

2.3. Lithium-Ion

Lithium-ion batteries are readily available on the market, primarily for small scale storage applications. They are a comparatively new technology, rapidly gaining market shares in a variety of fields. Even though their initial cost is high, it is gradually decreasing, fostering their propagation in the market. Most have a cathode of lithium oxide (LiMO

2, LiCoO

2, LiNiO

2), a graphite pure carbon anode and lithium salt electrolyte organic solvent (LiPF6). When compared to other types of batteries, lithium-ion batteries have a longer life cycle (500–2000 cycles) and are more energy efficient (99–100%) [

25]. Lithium is the lightest compared to all metals, with the highest electrochemical potential and the highest energy density in battery designs (up to 250 Wh/kg) [

22]. Furthermore, they do not need maintenance as the self-discharge rate is low (5%), and they are not influenced by the memory phenomenon; therefore, no scheduled full discharges are required to keep them in excellent shape. Shorter life cycle at high temperatures, limited stress resistance and the requirement for a safety circuit are some of the drawbacks. Each array contains a circuit that keeps the peak voltage of each element from dropping during charging and prevents it from dropping during discharge. Maximum charge and discharge currents and temperature are all regulated to prevent lithium metal plating due to overload [

22].

A cathode combination of nickel, manganese and cobalt is one of the most successful Li-ion systems (NMC). These systems, similar to Li-manganese, can be modified to serve as energy cells or power cells. NMC in an 18,650 cell for moderate load conditions, for example, has a capacity of about 2800 mAh and can produce 4A to 5A [

26]. The capacity of a silicon-based anode can be increased to 4000 mAh and beyond, but at the cost of reduced loading capability and shorter cycle life. The disadvantage of silicon added to graphite is that the anode expands and contracts with charge and discharge, making the cell mechanically unstable [

26]. The cathode material for lithium-ion batteries is lithium nickel–cobalt–aluminum oxide (NCA), which is mostly used in electric vehicles. The capacity of batteries can be improved due to the high nickel content of lithium nickel–cobalt–aluminum oxide (NCA), which leads to a greater distance that can be traveled with a single charge [

26]. NCA has a usable charge storage capacity of 180 to 200 mAh/g [

27]. The two materials, NCA and NMC, have similar structures, electrochemical behavior and performance, with comparably high energy densities and performance. The NCA battery is projected to hold 4.5 to 9.5 kg of cobalt and 11.6 kg of lithium [

27].

2.4. Lead–Acid

These are the most used batteries that are rechargeable; they are a safe and reliable technology with a decreased purchase rate. Their cathode is made of lead dioxide (PbO

2), the anode is made of lead (Pb) and the electrolyte is made of sulphuric acid (H

2SO

4) [

28]. Some of the technology’s advantages include the low rate of discharge (5%) and the battery’s ability to function over a wide range of temperatures [

27]. On the other hand, they have some disadvantages, including decreased energy density (30–50 Wh/kg), increased maintenance requirements, decreased life cycle (200–300 cycles with 80% DOD), low efficiency (90%), slow charging (8–16 h) and, in particular, the use of toxic construction materials, which make these batteries difficult to recycle, hence making them less sustainable than other types [

29,

30]. Still, they are met in cars, hoisting and lifting machinery, shipping and uninterruptible power supply (UPS) systems. They are also, at least until now, the most frequently used storage system for PVs [

31].

2.5. Nickel–Metal Hydride (NiMH)

Nickel–cadmium and nickel–metal hydride batteries are both classified as alkaline batteries and share similar properties. The second type of battery has a 30–40% higher energy density than the first one (60–120 Wh/kg) [

28,

29,

32]. The life cycle is lowered to 300–500 cycles, while the charging duration is increased to 2–4 h. They are, on the other hand, less influenced by the memory phenomenon, which is a concern with many battery types since it decreases availability and usability. Finally, non-toxic, mostly recyclable materials are used in this type [

26]. They are rechargeable disposable batteries of various sizes that are used to replace non-rechargeable batteries in computers, medical equipment and other uses. They can also be used in applications using renewable energy [

28].

2.6. Nickel–Cadmium (NiCd)

The present version of this battery has a nickel hydroxide positive electrode and a cadmium hydroxide negative electrode, with an electrolyte made from an aqueous solution of potassium hydroxide and lithium hydroxide [

22]. Although they have a higher energy density than lead–acid batteries, they nevertheless have a low energy density (45–80 Wh/kg). Increased discharge (about 20%) is one of their drawbacks, which is accompanied by low voltage in each cell. Finally, one of the inherent disadvantages of this battery type is the use of harmful components [

30]. Communication equipment, medical devices and power tools are among the most common applications for this battery type. Although they are well suited for renewable energy systems, they are rarely used due to their high initial cost, since they are more expensive—up to four times more than lead–acid and two times more than lithium-ion batteries [

25].

2.7. Flow Batteries

This battery type is an electrochemical cell generating chemical energy by flowing two chemical components dissolved in liquids on opposing sides of a membrane across the system. While both liquids circulate in their own region, ion exchange (followed by the flow of electric current) occurs via the membrane. The Nernst equation verifies cell voltage, which can vary from 1.0 to 2.43 volts in real-world applications. With wasted fuel collected and new fuel pumped into the system, a flow battery can be utilized either as a fuel cell or as a rechargeable battery, where an electric power source drives the fuel regeneration [

30,

31]. While this offers certain technological benefits over traditional rechargeable batteries, such as the possibility of separate liquid tanks and nearly infinite battery life, current implementations are less powerful and need more complicated circuitry. Flow cells of many types have been built, including redox, hybrid and membraneless flow cells. The main difference between regular batteries and flow cells is that in traditional batteries, energy is stored in the electrode material, but in flow cells, it is stored in the electrolyte. Their advantages include long life cycles, increased safety owing to non-flammable materials, a customizable architecture and rapid response to energy needs [

32]. They also produce less pollution. The low charge and discharge rate, as well as the poor energy density, are also drawbacks that boost the battery’s operational cost. Nonetheless, they fulfill the specifications for usage in RES systems, stand-alone systems, electric automobiles and power conversion technologies [

33].

2.8. Selection of Battery Type for Residential Applications

When considering which battery type to use for an energy system in residential applications, it is important to consider its life cycle cost, with the two major contributing factors being investment and the disposal cost. The cost effectiveness of a battery is eventually determined by parameters including its efficiency, safety, reliability and its environmental impact [

31]. The energy density and power the systems provide, as well as their fast-charging capability and energy efficiency, are other characteristics crucial for the battery’s use.

As already mentioned, lead–acid batteries are the most common type used in residential PV applications because of their low discharge rate, reliability and decreased total cost. Nevertheless, due to the short lifetime resulting from the combination of a limited number of life cycles and the need for continuous loading and discharges within the limits, not all requirements are satisfied [

27].

Lithium-ion batteries appear to fulfil the fundamental requirements for increased energy density, increased efficiency, extended life cycle and constant partial discharge capability. Furthermore, they do not contain harmful ingredients and may achieve the required reliability with careful control [

30]. Since their cost has been decreasing in the last few years, they are steadily becoming a viable choice, expected to dominate the field soon. For all these reasons, either lithium-ion or lead–acid batteries should be considered for a PV-based micro-grid system.

With respect to their environmental impact, the main batteries’ construction features and the materials used for their production have been gathered and reviewed for three main types, namely lead–acid, lithium-ion NCM and lithium-ion NCA. All the needed details were collected, considering the energy density (Wh/kg), the active materials and wt% corresponding to every type of battery, the emission factor during the production stage and the open loop (kg CO

2eq/kg). The main reference used for the emission factors were the Defra [

33], Ecoinvent [

34] and IPCC [

35] databases. Regarding the batteries’ materials, the results of the literature research are presented in

Table 2 based on the wt% of the material found in every battery type and calculating the material used for the package of the battery (cathode, anode, electrolyte, separator, electronics, casing) [

10,

11,

12,

13,

14,

15,

16,

17,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57,

58]. Based on the objective function of [

59], the embodied carbon indicator is related to the different type of the materials used, as well as the energy and fuel consumption at the different life cycle stages (production, use, end-of-life).

3. Results of Mathematical Model Analysis for the Battery Dimensioning

The mathematical model developed for the calculation of the battery dimensioning decision support system is presented in this section, considering the total environmental impact during the battery’s life cycle in a micro-grid. The life cycle assessment is a methodology defined by ISO 14040-44. Therefore, the terminology and the implementation processes are based on ISO standards. The model was developed using the AIMMS software [

60] using a non-linear programming approach (NLP). An algebraic modeling language, an integrated development environment for both modifying models and building a graphical user interface around these models and a graphical end-user environment make up the AIMMS Prescriptive Analytics Platform. The AIMMS Open Solver Interface connects AIMMS to a variety of solvers. CPLEX, FICO Xpress, MOSEK, CBC, MINOS, Conopt, KNITRO, IPOPT, SNOPT and CP optimizer are among the solvers supported [

61]. For the aforementioned reasons, AIMMS is selected as the software for both optimizing the problem and offering the results through a graphical user interface. Total environmental impact is calculated considering both the carbon dioxide equivalent during the operation as well as the production of the battery.

3.1. Total Emission Objective Function

The objective function of the system is developed so as to minimize the total emissions (TE), taking into consideration the battery usage. The (TE) value is a result of the total emissions during the production of the batteries (TEP) as well as the emissions of the system during its operation (TEO):

3.2. Total Emissions during Production Process

The emissions during the production process have been calculated based on the materials (MP(mt)) used to produce each battery type (lead–acid, lithium-ion NCM, lithium-ion NCA) multiplied by the carbon dioxide equivalent emission factor for each material (EmP(mt)), for the needed battery capacity (BC), the energy density (END) based on the battery type and the times the battery is changed (BCT) during the years of study:

3.3. Total Emissions during Operation Process

The emissions during operation have been calculated by taking into account the carbon dioxide equivalent of the total electricity purchased from the main grid for every month of the year (Eimp(m,t)) for the years of study (y) and the grid electricity carbon dioxide emission factor (Eel):

3.4. Energy Balance

The energy used for demand response (ED(m,t) can either be (a) the energy produced by the PV panels (N) of the micro-grid for a given solar radiation (rad(m,t))), and hence for every month and time of the year (Epv(m,t)), the area of the panel (apv) and the losses of the panel (ns,np) of each house (H), or (b) the energy bought by the main grid (Egrid). As such, the energy that has either not been covered by the PV panel production (E(m,t)) or the energy excess that could be stored in the battery can be calculated based on Equation (5):

3.5. Energy Flow in Batteries

The energy that can be stored in the batteries for each hour of a month’s representative day (ES(m,t)) can be calculated by comparing the energy excess (E(m,t)), the energy purchased by the main grid (Egrid(m,t)) or the energy sold to the main grid (Esell(m,t)), the energy that has already been stored in the batteries the previous time (t-1) (ES(m,t-1)) and the battery capacity (BC), taking into account the maximum and minimum state of charge of the battery (CHmax, CHmin), the current state of charge (CH(m,t)) and the batteries’ efficiencies of charging and discharging and of the total battery energy (nc, nd, nt) [

62]. It should be noted that the times the battery has to be changed (BCT) can be calculated for the years of study (y) and charging cycles of the battery based on its type (c), assuming that one full charge is being achieved during every day [

41,

63,

64]. Three main cases are examined. When there is an energy excess, the battery charging and following the battery capacity are calculated based on the size needed to reach the maximum state of charge. On the other hand, when the energy excess is less than zero, the calculation is made considering the minimum state of charge. That way, both the maximum and the minimum limits for capacity are evaluated, and the final capacity of battery is calculated.

4. Results Analysis of Representative Case Studies

The optimization framework elaborated was used to solve the following case studies, in order to assess the framework and obtain valuable data on battery optimization. Thessaloniki, Greece (Csa on the Koeppen Scale [

65]), was chosen as a location for the case study. It is a densely populated urban area, with buildings that feature mostly flat roofs that are ideally suited for the installation of PVs. Furthermore, due to the Mediterranean climate and the increased use of air conditioning for cooling, the buildings present high peak demand values during midday in the cooling period. A load profile generator [

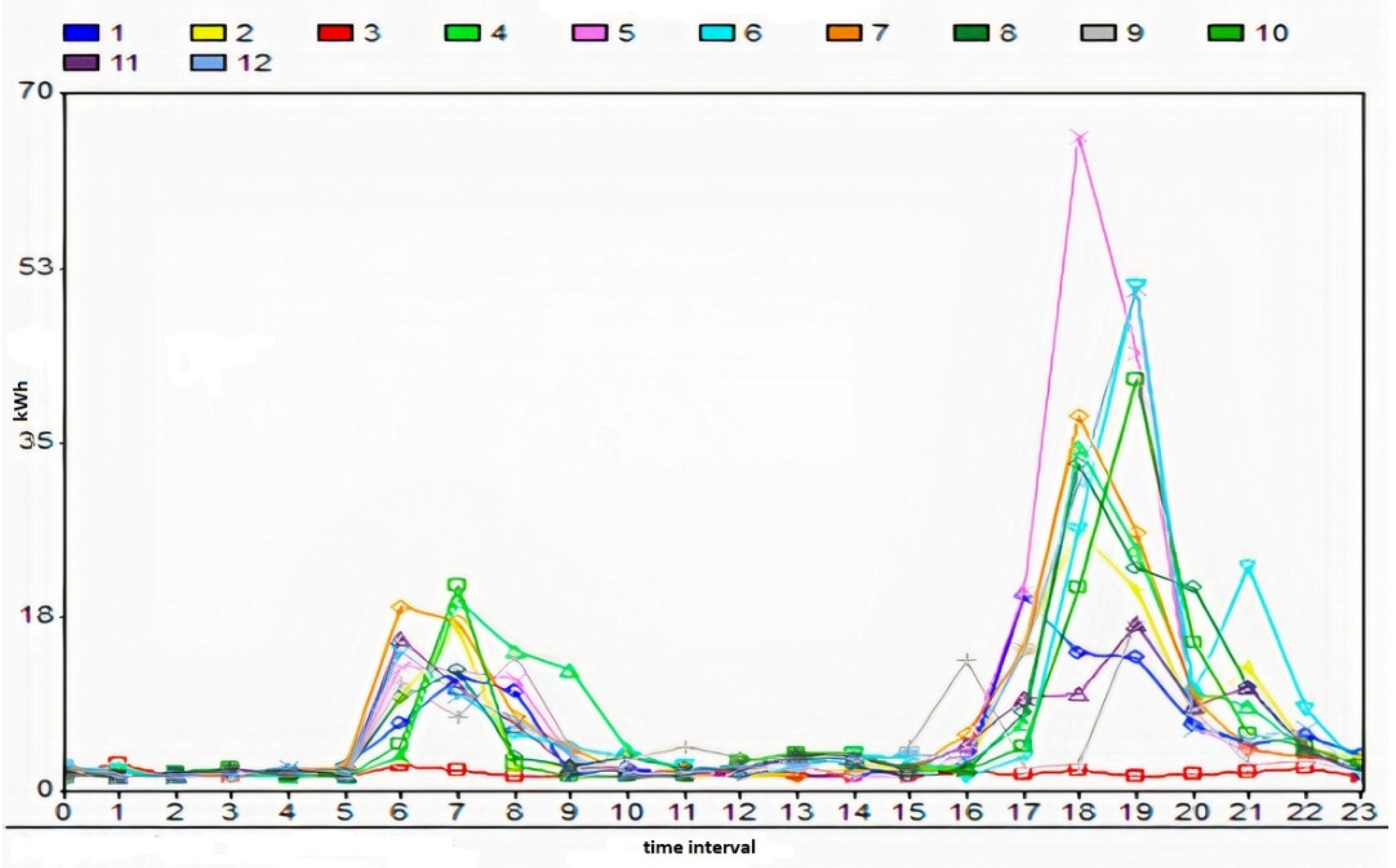

66] was used to compute the electricity demand of each household for a typical four-person family, as shown in

Figure 1. The European database Photovoltaic Geographical Information System (PVGIS) [

67] was used to acquire solar irradiance for power production. In addition, the carbon indicator for energy purchased from the Greek main grid was calculated to be 0.628 (kg CO

2eq/kg) [

68,

69]. Finally, the photovoltaic panels used were monocrystalline, and the batteries utilized were either lithium-ion batteries (NCA, NCM) with a 95% efficiency for 6000 charging cycles [

70] or lead–acid batteries with an efficiency of 80% for 1450 charging cycles [

71].

Table 3 indicates the different case studies solved. It should be noted that the following figures represent a yearly average of the values met for the micro-grid within the system’s life cycle.

Table 4 presents the main outcomes obtained by the optimization (obtained by the optimization tool) regarding both the battery dimensioning and the carbon emissions that occurred (a) at the production stage of a battery or (b) from the energy obtained by the main grid.

Figure 1,

Figure 2,

Figure 3 and

Figure 4 have been made using AIMMS software after optimizing the total emissions of the system for each case study.

Figure 2 illustrates the comparison between the total carbon emissions due to the purchase of energy from the main grid.

Finally,

Figure 3 and

Figure 4 depict the daily energy exchange within the micro-grid, so that the energy demand can be covered properly, as well as the specific energy amount purchased from the main grid for every month of the year, helping to achieve the best possible energy management within the micro-grid using battery storage systems.

5. Discussion

Sizing a micro-grid and a battery system for a residential application is not a straightforward exercise, especially if environmental criteria are considered over the system’s lifecycle. As it became apparent from this study, from the results obtained, it can be concluded that the total carbon emissions may vary significantly, depending on the battery type used.

Regarding case study I, it is noticed that the total system’s carbon emissions over its lifetime are 4,809,008.95 (kg). The carbon emissions are increased mainly because of the short lifetime and the greater number of replacements of the lead–acid batteries. In fact, it is necessary to replace them about seven times within the 30 years of the system’s lifecycle, which contributes quite drastically to carbon emissions. For that reason, and mainly due to increased carbon emissions at the batteries’ production stage, this option is not a preferrable one, compared to alternative battery types. Additionally, it is worth noticing that even if the increased carbon emissions are ignored, the lead–acid battery capacity is not as effective as that of the lithium-ion batteries (83.13 compared to 100.36 kWh). This leads to a daily exchange of energy within the micro-grid reaching a maximum of 40 (kWh) compared to almost 80 (kWh) in the case of lithium-ion batteries.

Moreover, in cases II and III, it can be concluded that the optimization results in almost the same emissions and the same battery capacity for the system. A slight difference is observed (369.84 kg) between NCA and NCM battery production emissions, due to the different structure of materials used in the battery. Additionally, even if the energy demand cannot be covered fully by the photovoltaics’ production, it is worth mentioning that the energy imported is not increased significantly. This is a result of the batteries’ important role in the energy management.

Additionally, it is of great importance to analyze the total emissions of a micro-grid system without any kind of ESS whatsoever (case study IV) to compare it with the aforementioned cases. As it can be concluded by case study IV, the total carbon emissions of the system would be 871,069.82 (kg) in the case that no battery system was used. As a result, the selection of lead–acid batteries seems to present very high carbon emissions, not only compared to NCA and NCM batteries but also compared to the case in which no battery at all is used in the system. Lithium-ion batteries seem to be the most feasible option, as they result in a reduction of almost 60%, compared to the base case of energy purchase from the main grid.

Finally, as it has been shown by the optimization, sizing a micro-grid’s energy storage system can be supported by a tool such as the one presented. Simultaneously, by managing the energy flow within the micro-grid and minimizing the total emissions related to different battery types of materials, the results regarding the batteries’ capacity can be obtained.

6. Conclusions

The goal of this paper was to present and discuss the battery types most suitable for RES systems such as PVs in residential applications, especially when storage is integrated in micro-grids. The most suitable types of batteries were presented, namely lead–acid, lithium-ion NCA and lithium-ion NMC batteries, with emphasis being given not only to energy consumption and technical effectiveness but also to environmental aspects.

A decision-making tool was presented which supports the dimensioning of batteries in micro-grid systems. The tool optimizes the carbon indicator along with the energy consumption, taking into consideration the energy policies applied, the upcoming technology of micro-grids and the state-of-the-art ESS technologies. The model tool is designed to be flexible so as to consider the coverage of the electricity demand whilst simultaneously optimizing battery dimensioning and type selection, taking into consideration the CO2 emissions over the system’s life cycle.

A case study was analyzed to demonstrate the tool’s applicability to small communities. The results of the case study demonstrated that not all batteries lead to environmentally acceptable solutions when storing PV produced electricity, since the need to replace batteries frequently (in the case of lead–acid batteries) leads to an environmental impact that offsets the benefits or renewable energy generation over the grid’s lifetime. On the other hand, the types of lithium-ion batteries (NCA, NCM) are feasible choices.

From the analysis of the case study, it can also be concluded that the dimensioning tool designed has achieved its goal. It can support the selection of the appropriate type of batteries and the sizing, avoiding over dimensioning, which can lead to cost-ineffective solutions, whilst minimizing carbon emissions. Furthermore, electricity sharing between residences may result in the avoidance of electricity purchased from the main grid, because the interchange at peak demand periods can be fulfilled by electricity stored within the micro-grid. Additionally, further research is needed in order to develop the proposed tool so it can be used to increase the number of residential and non-residential buildings, taking into consideration more parameters in the decision-making process such as climate conditions, cost indicators and other emissions besides CO2. Future research could also deal with different types of renewable energy fed into the micro-grid. Additionally, different structures of grids could be added, extending the community to that of a mini-grid. Finally, it would be worth researching the optimization’s results by altering both the electricity selling and purchase prices.

Author Contributions

Conceptualization, M.M.S., E.G., A.M.P.; methodology, M.M.S., E.G., A.M.P.; software, M.M.S.; validation, M.M.S., E.G., A.M.P.; formal analysis, M.M.S.; investigation, M.M.S.; resources, M.M.S., E.G.; data curation, M.M.S., E.G., A.M.P.; writing—original draft preparation, M.M.S., E.G., A.M.P.; writing—review and editing, M.M.S., E.G., A.M.P.; visualization, M.M.S., E.G., A.M.P.; supervision, M.M.S., E.G., A.M.P.; project administration, M.M.S., E.G., A.M.P.; funding acquisition, E.G., A.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 2020 Energy Strategy|Energy. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/2020-energy-strategy (accessed on 14 March 2019).

- 2030 Energy Strategy|Energy. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/2030-energy-strategy (accessed on 14 March 2019).

- 2050 Energy Strategy|Energy. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/2050-energy-strategy (accessed on 14 March 2019).

- Acha, S.; Mariaud, A.; Shah, N.; Markides, C.N. Optimal design and operation of distributed low-carbon energy technologies in commercial buildings. Energy 2018, 142, 578–591. [Google Scholar] [CrossRef]

- Com, C.C.; Planet, C.; For, D. In-Depth Analysis in Support of the Commission Communication Com (2018) 773 A Clean Planet for All—A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; This Document Provi, Supplementary Information; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Giama, E.; Kyriaki, E.; Fokaides, P.; Papadopoulos, A.M. Energy policy towards nZEB: The Hellenic and Cypriot case. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1–14. [Google Scholar] [CrossRef]

- IRENA. Battery Storage for Renewables: Market Status and Technology Outlook; IRENA: Abu Dhabi, United Arab Emirates, 2015; p. 60. [Google Scholar]

- Wang, Q.; Zhan, L. Assessing the sustainability of renewable energy: An empirical analysis of selected 18 European countries. Sci. Total Environ. 2019, 692, 529–545. [Google Scholar] [CrossRef] [PubMed]

- Ilbahar, E.; Cebi, S.; Kahraman, C. A state-of-the-art review on multi-attribute renewable energy decision making. Energy Strateg. Rev. 2019, 25, 18–33. [Google Scholar] [CrossRef]

- Stojčić, M.; Zavadskas, E.K.; Pamučar, D.; Stević, Ž.; Mardani, A. Application of MCDM methods in sustainability engineering: A literature review 2008–2018. Symmetry 2019, 11, 350. [Google Scholar] [CrossRef] [Green Version]

- Kizielewicz, B.; Watróbski, J.; Sałabun, W. Identification of relevant criteria set in the mcda process—Wind farm location case study. Energies 2020, 13, 6548. [Google Scholar] [CrossRef]

- Nair, N.K.C.; Garimella, N. Battery energy storage systems: Assessment for small-scale renewable energy integration. Energy Build. 2010, 42, 2124–2130. [Google Scholar] [CrossRef]

- Chatzisideris, M.D.; Ohms, P.K.; Espinosa, N.; Krebs, F.C.; Laurent, A. Economic and environmental performances of organic photovoltaics with battery storage for residential self-consumption. Appl. Energy 2019, 256, 13. [Google Scholar] [CrossRef]

- McManus, M.C. Environmental consequences of the use of batteries in low carbon systems: The impact of battery production. Appl. Energy 2012, 93, 288–295. [Google Scholar] [CrossRef] [Green Version]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Longo, S.; Antonucci, V.; Cellura, M.; Ferraro, M. Life cycle assessment of storage systems: The case study of a sodium/nickel chloride battery. J. Clean. Prod. 2014, 85, 337–346. [Google Scholar] [CrossRef]

- Aberilla, J.M.; Gallego-Schmid, A.; Stamford, L.; Azapagic, A. Design and environmental sustainability assessment of small-scale off-grid energy systems for remote rural communities. Appl. Energy 2019, 258, 114004. [Google Scholar] [CrossRef]

- Wang, L.; Hu, J.; Yu, Y.; Huang, K.; Hu, Y. Lithium-air, lithium-sulfur, and sodium-ion, which secondary battery category is more environmentally friendly and promising based on footprint family indicators? J. Clean. Prod. 2020, 276, 124244. [Google Scholar] [CrossRef]

- Zubi, G.; Adhikari, R.S.; Sánchez, N.E.; Acuña-Bravo, W. Lithium-ion battery-packs for solar home systems: Layout, cost and implementation perspectives. J. Energy Storage 2020, 32, 101985. [Google Scholar] [CrossRef]

- Hiremath, M.; Derendorf, K.; Vogt, T. Comparative life cycle assessment of battery storage systems for stationary applications. Environ. Sci. Technol. 2015, 49, 4825–4833. [Google Scholar] [CrossRef] [PubMed]

- Raugei, M.; Leccisi, E.; Fthenakis, V.M. What Are the Energy and Environmental Impacts of Adding Battery Storage to Photovoltaics? A Generalized Life Cycle Assessment. Energy Technol. 2020, 8, 1901146. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Brutsch, E.; Jamis, A.; Reyes, W.; Strutner, M.; Sinha, P.; Geyer, R. Environmental Impacts of Utility-Scale Battery Storage in California. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 2472–2474. [Google Scholar] [CrossRef]

- Elzein, H.; Dandres, T.; Levasseur, A.; Samson, R. How can an optimized life cycle assessment method help evaluate the use phase of energy storage systems? J. Clean. Prod. 2019, 209, 1624–1636. [Google Scholar] [CrossRef]

- Oliveira, L.; Messagie, M.; Mertens, J.; Laget, H.; Coosemans, T.; van Mierlo, J. Environmental performance of electricity storage systems for grid applications, a life cycle approach. Energy Convers. Manag. 2015, 101, 326–335. [Google Scholar] [CrossRef]

- Nousdilis, A.I.; Kontis, E.O.; Kryonidis, G.C.; Christoforidis, G.C.; Papagiannis, G.K. Economic assessment of lithium-ion battery storage systems in the nearly zero energy building environment. In Proceedings of the 2018 20th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 3–6 June 2018. [Google Scholar] [CrossRef]

- Types of Lithium-ion Batteries—Battery University. Available online: https://batteryuniversity.com/learn/article/types_of_lithium_ion (accessed on 8 June 2021).

- Doeff, M.M. Battery Cathodes. In Batteries for Sustainability; Springer: New York, NY, USA, 2013; pp. 5–49. [Google Scholar]

- Akimoto, Y.; Takezawa, H.; Iijima, Y.; Suzuki, S.-n.; Okajima, K. Comparative analysis of fuel cell and battery energy systems for Internet of Things devices. Energy Rep. 2020, 6, 29–35. [Google Scholar] [CrossRef]

- Battery Information Table of Contents, Basic to Advanced. Available online: https://batteryuniversity.com/learn/ (accessed on 13 February 2021).

- Nazarko, Ł. Future-Oriented Technology Assessment. Procedia Eng. 2017, 182, 504–509. [Google Scholar] [CrossRef]

- Akinyele, D.; Belikov, J.; Levron, Y. Battery storage technologies for electrical applications: Impact in stand-alone photovoltaic systems. Energies 2017, 10, 1760. [Google Scholar] [CrossRef] [Green Version]

- Nousdilis, A.I.; Kryonidis, G.C.; Kontis, E.O.; Papagiannis, G.K.; Christoforidis, G.C.; Bouhouras, A.S.; Georghiou, G.; Afxentis, S.; Papageorgiou, I.; Veleva, S.; et al. Enhancing storage integration in buildings with photovoltaics (PV-ESTIA project). In Proceedings of the 2018 IEEE International Energy Conference (ENERGYCON), Limassol, Cyprus, 3–7 June 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Government Conversion Factors for Company Reporting of Greenhouse Gas Emissions—GOV.UK. Available online: https://www.gov.uk/government/collections/government-conversion-factors-for-company-reporting (accessed on 7 June 2021).

- Ecoinvent. Available online: https://www.ecoinvent.org/ (accessed on 7 June 2021).

- IPCC—Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch/ (accessed on 7 June 2021).

- Hall, D.; Lutsey, N. Effects of Battery Manufacturing on Electric Vehicle Life-Cycle Greenhouse Gas Emissions; ICCT Briefing: Washington, DC, USA, 2018; p. 12. Available online: https://www.theicct.org/sites/default/files/publications/EV-life-cycle-GHG_ICCT-Briefing_09022018_vF.pdf (accessed on 14 March 2019).

- Kelly, J.C.; Dai, Q.; Wang, M. Globally regional life cycle analysis of automotive lithium-ion nickel manganese cobalt batteries. Mitig. Adapt. Strateg. Glob. Chang. 2019, 25, 371–396. [Google Scholar] [CrossRef]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A critical review of lithium-ion battery recycling processes from a circular economy perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef] [Green Version]

- Goedkoop, M.J.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A Life Cycle Impact Assessment Method which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, Report 1: Characterisation, 1st ed.; VROM: Den Haag, The Netherlands, 2009.

- Romare, M.; Dahllöf, L. The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries: A Study with Focus on Current Technology and Batteries for Light-Duty Vehicles; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2017. [Google Scholar]

- MEV Team. A Guide to Understanding Battery Specifications; MIT Electric Vehicle Team: Cambridge, MA, USA, 2008. [Google Scholar]

- Battery Information Table of Contents, Basic to Advanced. Available online: https://batteryuniversity.com/learn/?__cf_chl_jschl_tk__=960f23bc91ae65092d3348db9f2e7d77ad6e6d42-1608572006-0-AQSgmbqxPCKr0s1eC_0Tlposg1VZQosduJeRZsL8AYxcNy21xUWGdxRof2vzPHYAL4VcbYUQJOwDlsHud66S_KPqD9JtGQnx14_9-jj7kUl6H_uRIgUGYcl5ujr_zh5fPYcN7VzdYq-3NSVe-iBD_rrk3eGHRRhbL0ktJ69UQ3154OCsbvJjCWVMtPjqggozkSH9HfVpVPR0AKAkasI7AO0OIZPKBkxbtFzuvsUXjCeMyslP7_w0IygH9TnFsN24rtwGsgPKraCQf6tW3_YWR5LVJ_0lSZUw7P1m4Ob2PnOZFKONdq0n53ig0ms30nQVSw (accessed on 21 December 2020).

- Battery Comparison of Energy Density—Cylindrical and Prismatic Cells. Available online: https://www.epectec.com/batteries/cell-comparison.html (accessed on 7 June 2021).

- Xie, Z.; Du, L.; Lv, X.; Wang, Q.; Huang, J.; Fu, T.; Li, S. Evaluation and Analysis of Battery Technologies Applied to Grid-Level Energy Storage Systems Based on Rough Set Theory. Trans. Tianjin Univ. 2020, 26, 228–235. [Google Scholar] [CrossRef] [Green Version]

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 15, 145–157. [Google Scholar] [CrossRef]

- Ishihara, K.; Kihira, N.; Terada, N.; Iwahori, T. Environmental Burdens of Large Lithium-ion Batteries Developed in a Japanese National Project. Renew. Energy 2008, 33, 366–382. [Google Scholar]

- Wen, J.; Zhao, D.; Zhang, C. An overview of electricity powered vehicles: Lithium-ion battery energy storage density and energy conversion efficiency. Renew. Energy 2020, 162, 1629–1648. [Google Scholar] [CrossRef]

- Yasin, G.; Arif, M.; Mehtab, T.; Lu, X.; Yu, D.; Muhammad, N.; Nazir, M.T.; Songe, H. Understanding and suppression strategies toward stable Li metal anode for safe lithium batteries. Energy Storage Mater. 2020, 25, 644–678. [Google Scholar] [CrossRef]

- Gomes, I.S.F.; Perez, Y.; Suomalainen, E. Coupling small batteries and PV generation: A review. Renew. Sustain. Energy Rev. 2020, 126, 109835. [Google Scholar] [CrossRef]

- Base Metals Commodities|Prices, Charts, Forecasts, News. Available online: https://www.focus-economics.com/commodities/base-metals (accessed on 23 June 2020).

- Ali, T.; Ma, H.; Nahian, A.J. A Multi-Criteria Decision-Making Approach to Determine the Optimal Hybrid Energy System in Coastal Off-Grid Areas: A Case Study of Bangladesh. Process Integr. Optim. Sustain. 2020, 4, 265–277. [Google Scholar] [CrossRef]

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef]

- Yang, C.; Xin, S.; Mai, L.; You, Y. Materials Design for High-Safety Sodium-Ion Battery. Adv. Energy Mater. 2020, 11, 2000974. [Google Scholar] [CrossRef]

- Krawczyk, P.; Sliwi, A. Eco-Efficiency Assessment of the Application of Large-Scale Rechargeable Batteries in a Coal-Fired Power Plant. Energies 2020, 13, 1384. [Google Scholar] [CrossRef] [Green Version]

- Quartarone, E.; Mustarelli, P. Review—Emerging Trends in the Design of Electrolytes for Lithium and Post-Lithium Batteries. J. Electrochem. Soc. 2020, 167, 050508. [Google Scholar] [CrossRef]

- Voltage, L.; Voltage, M.; Stacks, M. Product Specifications Guide; European Commission Joint Research Centre Institute for Energy: Ispra, Italy, 2003; pp. 18–19. [Google Scholar]

- Olabi, A.G.; Onumaegbu, C.; Wilberforce, T.; Ramadan, M.; Abdelkareem, M.A.; Al-Alami, A.H. Critical review of energy storage systems. Energy 2021, 214, 118987. [Google Scholar] [CrossRef]

- Pender, J.P.; Jha, G.; Youn, D.H.; Ziegler, J.M.; Andoni, I.; Choi, E.J.; Heller, A.; Dunn, B.S.; Weiss, P.S.; Penner, R.M.; et al. Electrode Degradation in Lithium-Ion Batteries. ACS Nano 2020, 14, 1243–1295. [Google Scholar] [CrossRef] [Green Version]

- Giama, E.; Papadopoulos, A.M. Benchmarking carbon footprint and circularity in production processes: The case of stonewool and extruded polysterene. J. Clean. Prod. 2020, 257, 120559. [Google Scholar] [CrossRef]

- Prescriptive Analytics and Supply Chain Management|AIMMS. Available online: https://aimms.com/ (accessed on 13 March 2019).

- How to Set up a Supply Chain Analytics Center of Excellence. Available online: https://www.aimms.com/story/a-practical-guide-to-setting-up-a-supply-chain-analytics-center-of-excellence/ (accessed on 15 September 2021).

- Sharma, V.; Haque, M.H.; Aziz, S.M. Energy cost minimization for net zero energy homes through optimal sizing of battery storage system. Renew. Energy 2019, 141, 278–286. [Google Scholar] [CrossRef]

- Petinrin, J.O.; Shaabanb, M. Impact of renewable generation on voltage control in distribution systems. Renew. Sustain. Energy Rev. 2016, 65, 770–783. [Google Scholar] [CrossRef]

- Gamage, V.; Withana, N.; Silva, C.; Samarasinghe, R. Battery Energy Storage based Approach for Grid Voltage Regulation in Renewable Rich Distribution Networks. In Proceedings of the 2nd IEEE International Conference on Industrial Electronics for Sustainable Energy Systems (IESES), Cagliari, Italy, 1–3 September 2020; pp. 163–168. [Google Scholar] [CrossRef]

- World Maps of Köppen-Geiger Climate Classification. Available online: http://koeppen-geiger.vu-wien.ac.at/ (accessed on 26 June 2019).

- LoadProfileGenerator. Available online: https://www.loadprofilegenerator.de (accessed on 14 March 2019).

- European Commission. JRC Photovoltaic Geographical Information System (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html (accessed on 14 March 2019).

- DEDDIE. Available online: https://www.deddie.gr/ (accessed on 13 March 2019).

- Greenhouse Gas Reporting: Conversion Factors 2018—GOV.UK. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2018 (accessed on 13 March 2019).

- LG. LG Chem RESU 10H-400V Lithium-Ion Storage Battery. Available online: https://www.europe-solarstore.com (accessed on 14 March 2019).

- Rolls. S12 24|Rolls Battery. Available online: https://www.rollsbattery.com (accessed on 15 March 2020).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).