Feasibility Analysis of a DC Distribution System for a 6 kW Photovoltaic Installation in Ireland

Abstract

:1. Introduction

2. System-Level Model

2.1. AC System

2.2. DC System

3. System Loss Analysis

3.1. AC Analysis

3.1.1. DC/AC Inverter Losses

3.1.2. MPPT Losses

3.1.3. Battery Charging/Discharging Losses

3.1.4. Rectifier Losses

3.2. DC Analysis

3.2.1. MPPT Losses

3.2.2. Battery Charging/Discharging Losses

3.2.3. Bidirectional Inverter Losses

4. Results and Discussion

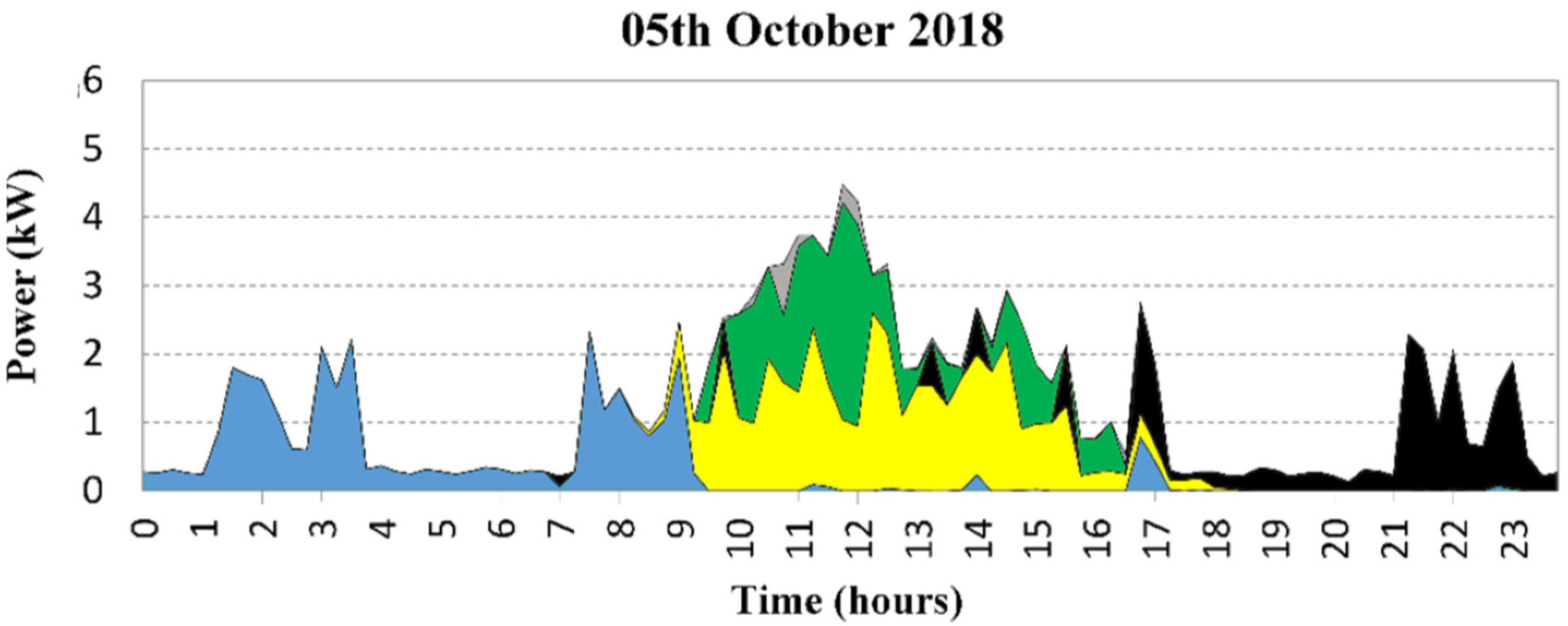

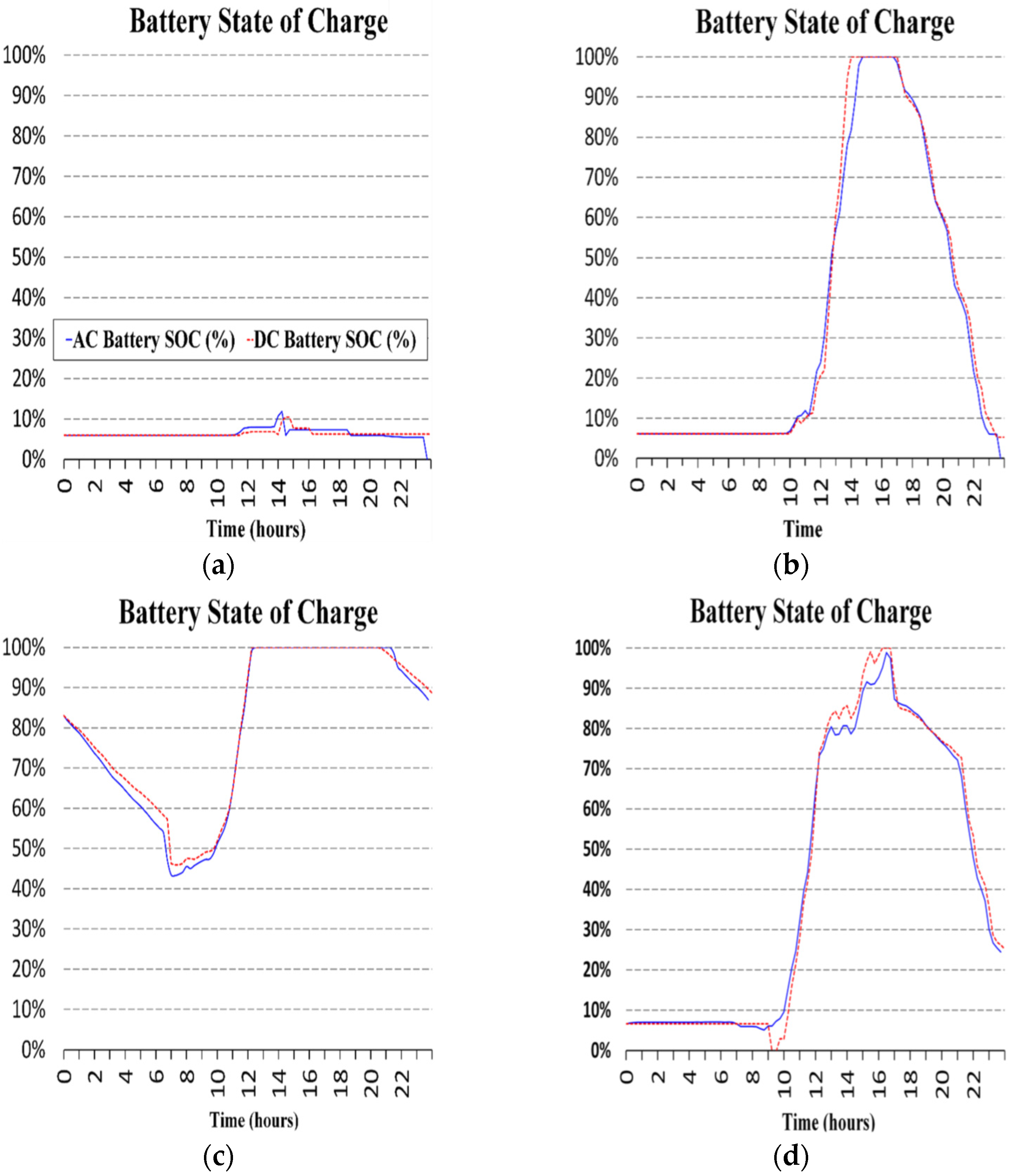

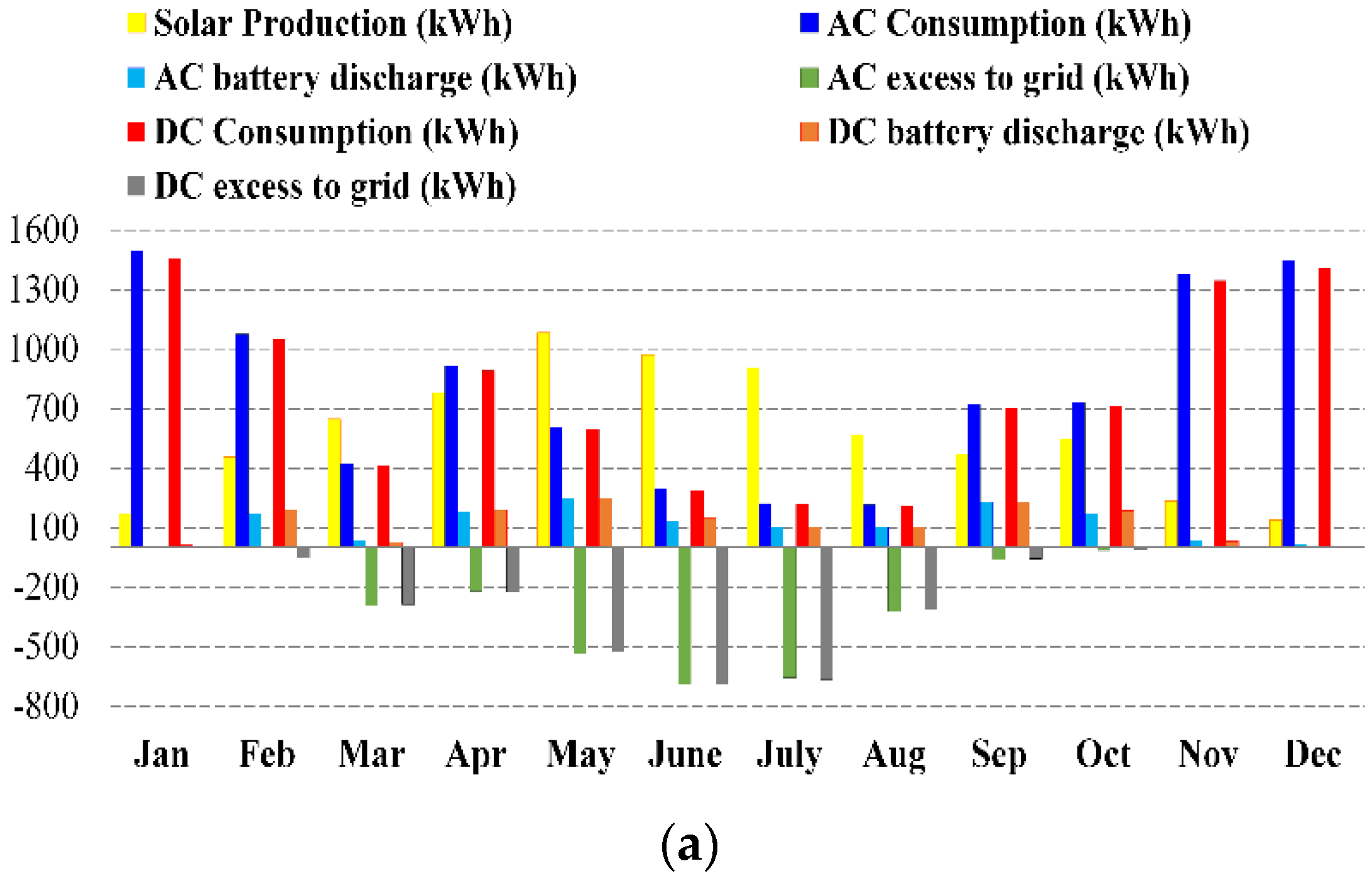

4.1. Grid Power and Battery Usage Levels

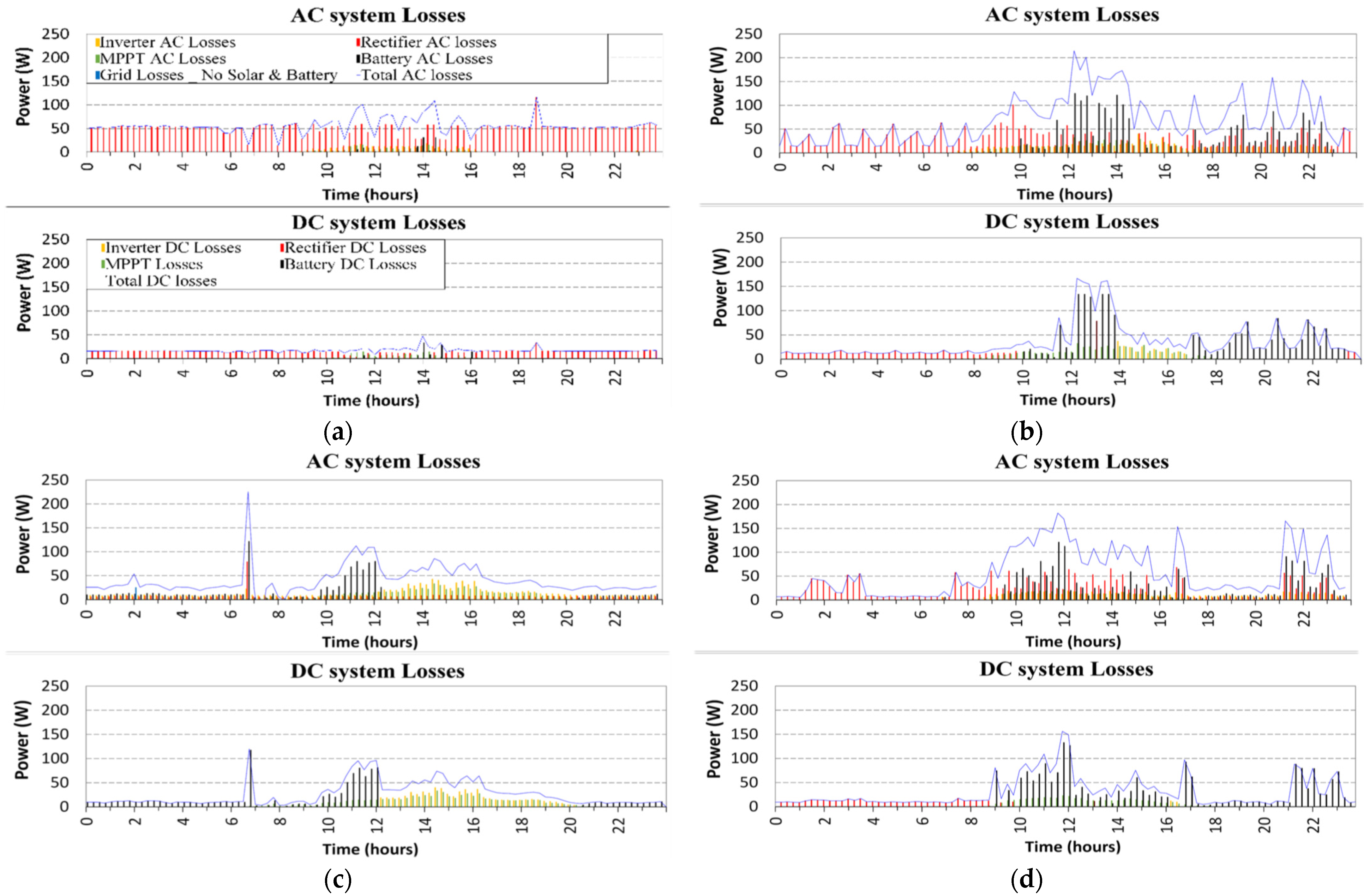

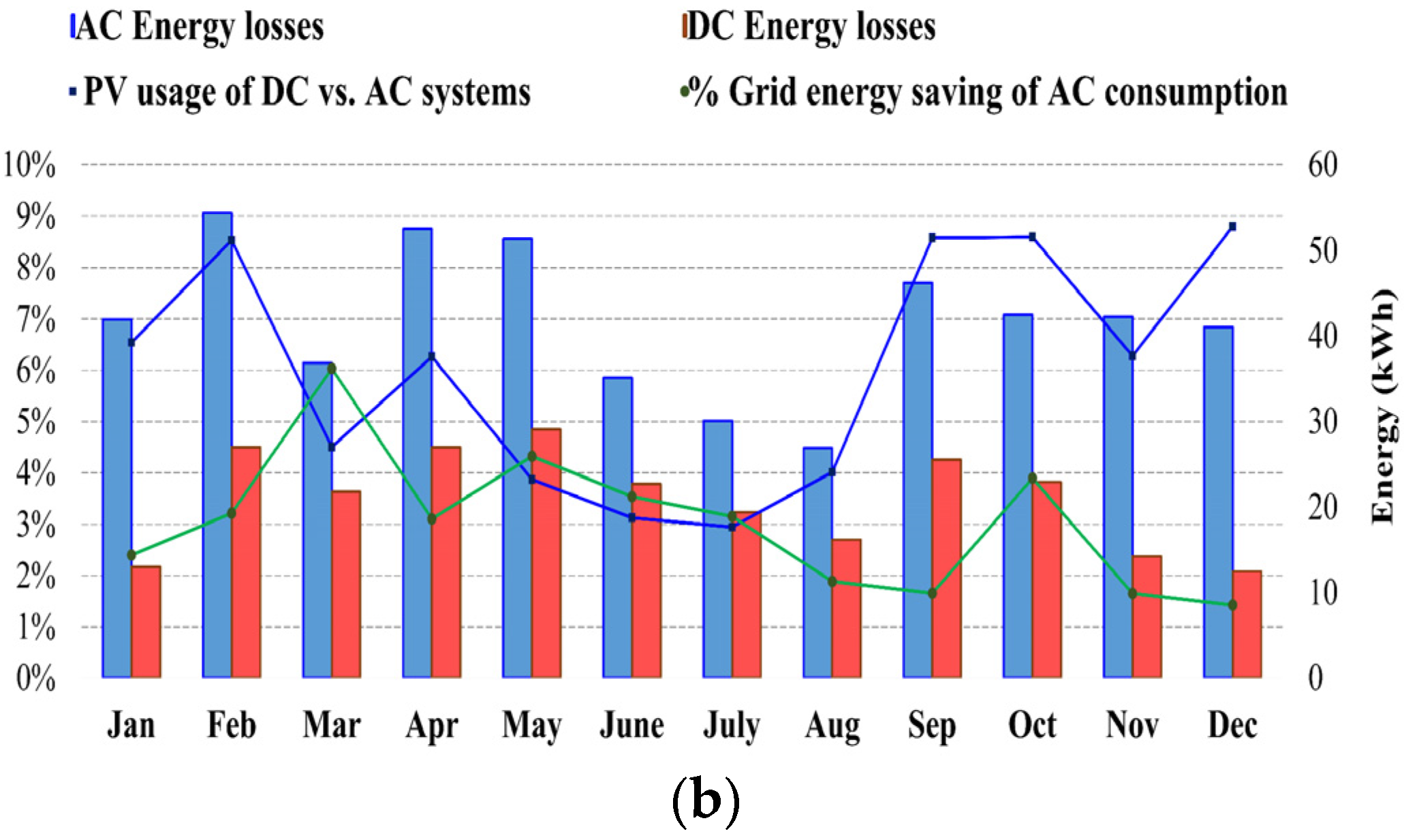

4.2. Loss Breakdown

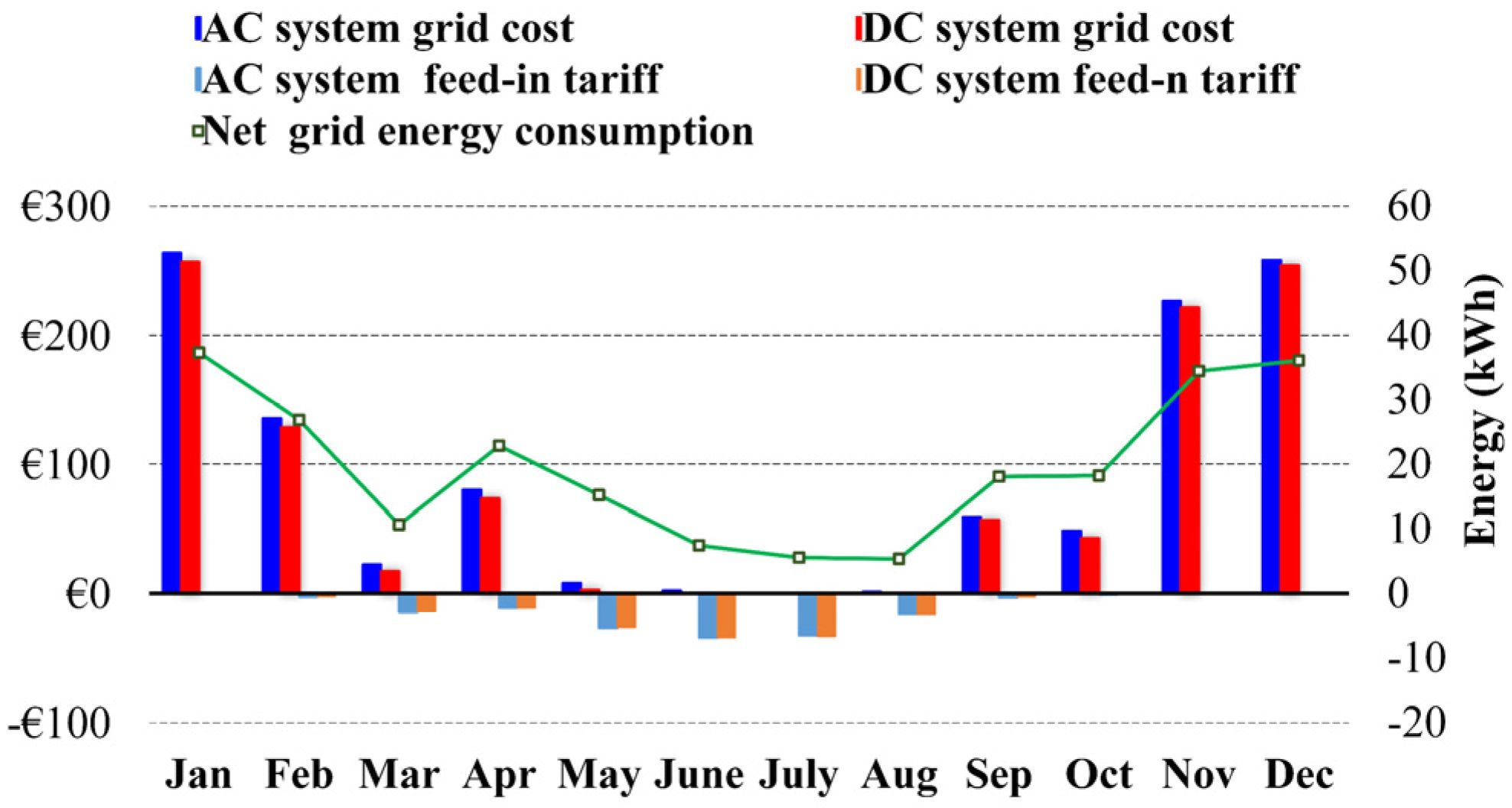

4.3. Summary Analysis

5. Conclusions

- In both systems, losses are dominated by battery charging/discharging processes, and there is scope to improve this by demand side management.

- There is scope for further improvement in terms of sizing the energy source to better match the load demand and to reduce the need for energy storage.

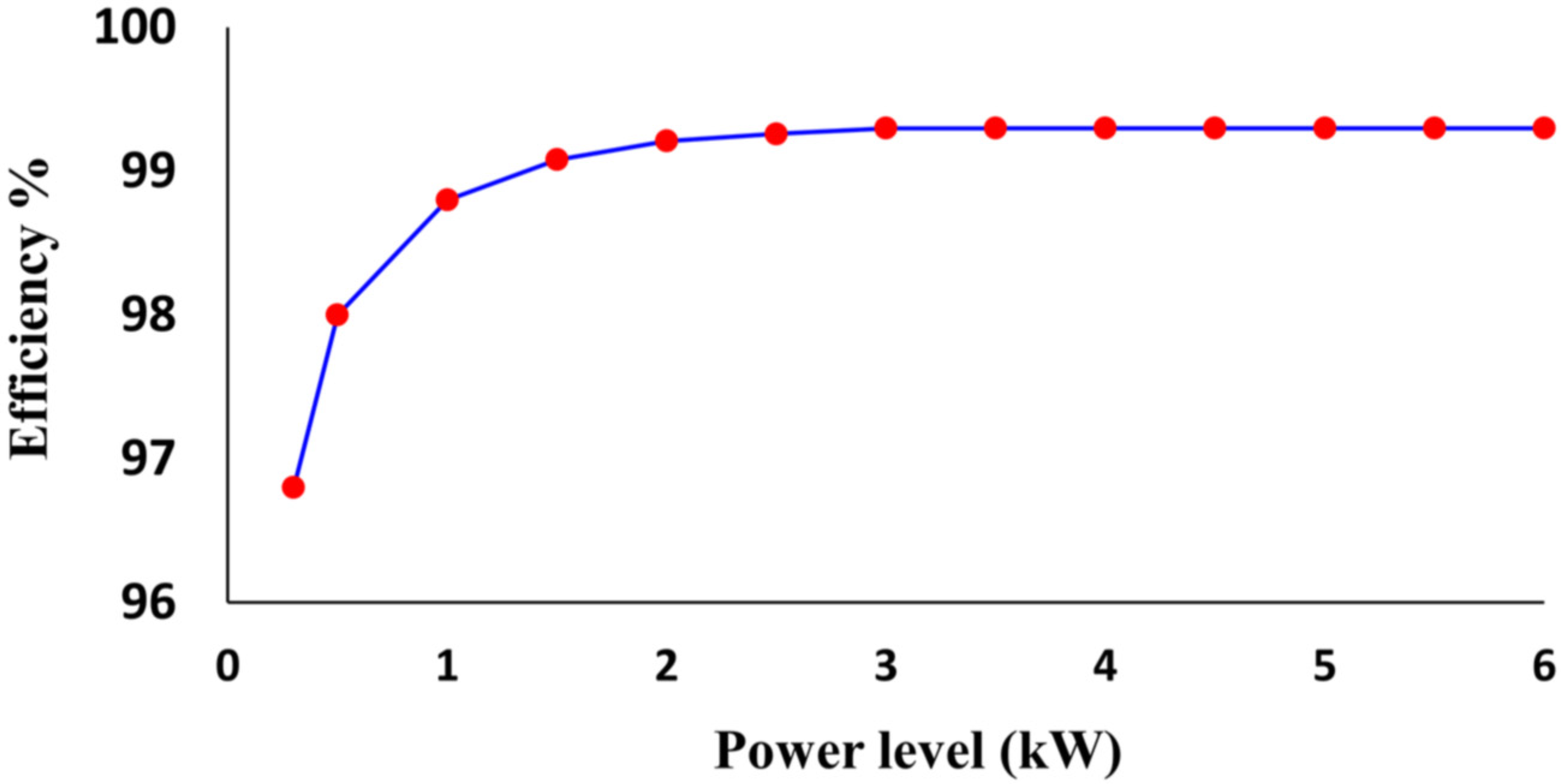

- There is also scope to improve the efficiency of power conversion stages, particularly bidirectional inverters for battery charging and grid connection, which have optimal efficiency when there is a high power level, but operate under reduced capacity most of the time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | Alternative current |

| DC | Direct current |

| LED | Light-emitting diode |

| MPPT | Maximum power point tracking |

| PV | Photovoltaic |

References

- Khoury, J.; Mbayed, R.; Salloum, G.; Monmasson, E.; Guerrero, J. Review on the integration of photovoltaic renewable energy in developing countries—Special attention to the Lebanese case. Renew. Sustain. Energy Rev. 2016, 57, 562–575. [Google Scholar] [CrossRef]

- Virupaksha, V.; Harty, M.; McDonnell, K. Microgeneration of electricity using a solar photovoltaic system in Ireland. Energies 2019, 12, 4600. [Google Scholar] [CrossRef] [Green Version]

- Murphy, F.; McDonnell, K. A feasibility assessment of photovoltaic power systems in Ireland; a case study for the Dublin region. Sustainability 2017, 9, 302. [Google Scholar] [CrossRef] [Green Version]

- Mishra, A.; Rajeev, K.K.; Garg, V. Assessment of 48 volts DC for homes. In Proceedings of the 2018 IEEMA Engineer Infinite Conference (eTechNxT), New Delhi, India, 13–14 March 2018; pp. 1–6. [Google Scholar]

- Rodriguez-Diaz, E.; Vasquez, J.C.; Guerrero, J.M. Potential energy savings by using direct current for residential applications: A Danish household study case. In Proceedings of the 2017 IEEE Second International Conference DC Microgrids (ICDCM), Bamberg, Germany, 27–29 June 2017; pp. 547–552. [Google Scholar]

- Rodriguez-Diaz, E.; Savaghebi, M.; Vasquez, J.C.; Guerrero, J.M. An overview of low voltage DC distribution systems for residential applications. In Proceedings of the 5th IEEE International Conference on Consumer Electronics-Berlin (ICCE-Berlin), Berlin, Germany, 6–9 September 2015; pp. 318–322. [Google Scholar]

- Ahn, J.; Koo, K.; Kim, D.; Lee, B.; Jin, H. Comparative analysis and safety standard guideline of AC and DC supplied home appliances. In Proceedings of the 8th International Conference on Power Electronics—ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 1118–1125. [Google Scholar]

- Park, J.S.; Choi, J.H.; Gu, B.G.; Jung, I.S. Feasibility study of DC electrical distribution system. In Proceedings of the 8th International Conference on Power Electronics-ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 2935–2938. [Google Scholar]

- Vossos, V.; Garbesi, K.; Shen, H. Energy savings from direct-DC in U.S. residential buildings. Energy Build. 2014, 68, 223–231. [Google Scholar] [CrossRef]

- Noritake, M.; Yuasa, K.; Takeda, T.; Shimomachi, K.; Hara, R.; Kita, H.; Matsumura, T. Experimental study of a 400 v class DC microgrid for commercial buildings. In Proceedings of the 9th International Conference on Power Electronics andECCE Asia (ICPE-ECCE Asia), Seoul, Korea, 1–5 June 2015; pp. 1730–1735. [Google Scholar]

- Zhang, F.; Meng, C.; Yang, Y.; Sun, C.; Ji, C.; Chen, Y.; Wei, W.; Qiu, H.; Yang, G. Advantages and challenges of DC microgrid for commercial building a case study from Xiamen university DC microgrid. In Proceedings of the 2015 IEEE First International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 355–358. [Google Scholar]

- Iyer, S.; Dunford, W.G.; Ordonez, M. DC distribution systems for homes. In Proceedings of the IEEE Power Energy Society General Meeting, Denver, CO, USA, 26–30 July 2015; pp. 1–5. [Google Scholar]

- Baek, J.W.; Ryu, M.H.; Kim, J.H.; Kim, T.J. A Study on the DC Distribution System for Small Scale Residential Buildings. In Proceedings of the 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Korea, 1–5 June 2015; pp. 2527–2531. [Google Scholar]

- Das, J.P.; Fatema, R.J.; Anower, M.S. Feasibility study of low voltage DC distribution system for residential buildings in Bangladesh & hybrid home appliance design for tropical climate. In Proceedings of the 2nd International Conference on Electrical, Computer and Telecommunication Engineering (ICECTE), Rajshahi, Bangladesh, 8–10 December 2017; pp. 1–4. [Google Scholar]

- Dastgeer, F.; Gelani, H.E.; Anees, H.M.; Paracha, Z.J.; Kalam, A. Analyses of efficiency/energy-savings of DC power distribution systems/microgrids: Past, present and future. Int. J. Electr. Power Energy Syst. 2019, 104, 89–100. [Google Scholar] [CrossRef]

- Gelani, H.E.; Dastgeer, F.; Nasir, M.; Khan, S.; Guerrero, J.M. AC vs. DC distribution efficiency: Are we on the right path? Energies 2021, 14, 4039. [Google Scholar] [CrossRef]

- Lo Franco, F.; Morandi, A.; Raboni, P.; Grandi, G. Efficiency Comparison of DC and AC Coupling Solutions for Large-Scale PV+BESS Power Plants. Energies 2021, 14, 4823. [Google Scholar] [CrossRef]

- Gerber, D.L.; Vossos, V.; Feng, W.; Khandekar, A.; Marnay, C.; Nordman, B. A simulation based comparison of AC and DC power distribution networks in buildings. In Proceedings of the IEEE 2nd International Conference Direct Current Microgrids (ICDCM), Nuremburg, Germany, 27–29 June 2017; pp. 588–595. [Google Scholar]

- Vossos, V.; Gerber, D.; Bennani, Y.; Brown, R.; Marnay, C. Techno-economic analysis of DC power distribution in commercial buildings. Appl. Energy 2018, 230, 663–678. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, R.K.; Rajpurohit, B.S. DC Distribution System for Energy Efficient Buildings. In Proceedings of the 2014 Eighteenth National Power System Conference (NPSC), Guwahati, India, 18–20 December 2014; pp. 1–6. [Google Scholar]

- Hofer, J.; Svetozarevic, B.; Schlueter, A. Hybrid AC/DC building microgrid for solar PV and battery storage integration. In Proceedings of the 2017 IEEE 2nd International Conference Direct Current Microgrids (ICDCM), Nuremburg, Germany, 27–29 June 2017; pp. 188–191. [Google Scholar]

- Kakigano, H.; Nomura, M.; Ise, T. Loss evaluation of dc distribution for residential houses compared with ac system. In Proceedings of the 2010 International Power Electronics Conference—ECCE Asia, Sapporo, Japan, 21–24 June 2010; pp. 480–486. [Google Scholar]

- Amin, M.; Arafat, Y.; Lundberg, S.; Mangold, S. Low voltage DC distribution system compared with 230 V AC. In Proceedings of the 2011 IEEE Electrical Power and Energy Conference, Winnipeg, MB, Canada, 3–5 October 2011; pp. 340–345. [Google Scholar]

- Weiss, R.; Ott, L.; Boeke, U. Energy efficient low-voltage DC-grids for commercial buildings. In Proceedings of the 2015 IEEE 1st International Conference Direct Current Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 154–158. [Google Scholar]

- Fregosi, D.; Ravula, S.; Brhlik, D.; Saussele, J.; Frank, S.; Bonnema, E.; Scheib, J.; Wilson, E. A comparative study of DC and AC microgrids in commercial buildings across different climates and operating profiles. In Proceedings of the 2015 IEEE 1st International Conference Direct Current Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 159–164. [Google Scholar]

- Manandhar, U.; Keng, T.; Jonathan, K. Efficiency Comparison of DC and AC Microgrid. In Proceedings of the 2015 IEEE Innovative Smart Grid Technolgies—Asia (ISGT ASIA), Bangkok, Thailand, 3–6 November 2015; pp. 1–6. [Google Scholar]

- Liu, Z.; Li, M. Research on Energy Efficiency of DC Distribution System. AASRI Procedia 2014, 7, 68–74. [Google Scholar] [CrossRef]

- Al-Subhi, A.; El-Amin, I. Experimental performance analysis of existing conventional AC air conditioner and corresponding new pure DC air conditioner. In Proceedings of the 2017 IEEE 2nd International Conference Direct Current Microgrids (ICDCM), Nuremburg, Germany, 27–29 June 2017; pp. 330–336. [Google Scholar]

- Sahoo, N.C.; Mohapatro, S.; Sahu, A.K.; Mohapatro, B.S. Loss and cost evaluation of typical DC distribution for residential house. In Proceedings of the IEEE 6th International Conference Power Energy (PECon), Melaka, Malaysia, 28–29 November 2017; pp. 668–673. [Google Scholar]

- Glasgo, B.; Azevedo, I.L.; Hendrickson, C. How much electricity can we save by using direct current circuits in homes? Understanding the potential for electricity savings and assessing feasibility of a transition towards DC powered buildings. Appl. Energy 2016, 180, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Alshammari, M.; Duffy, M. Comparative analysis between AC and DC distribution systems in a photovoltaic system: A case study of a school in Ireland. In Proceedings of the PCIM Europe 2019, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 7–9 May 2019; pp. 1–8. [Google Scholar]

- America, N. SolarEdge Single Phase Inverters. Change 5–6. Available online: https://cutt.ly/LcIPu9f (accessed on 1 May 2018).

- Solaredge Efficiency of P Series Power Optimizers. 2018, pp. 1–5. Available online: https://cutt.ly/DcIAcKT (accessed on 1 May 2018).

- Northern Ireland Residential Electricity Customers Price Schedule—Simpler Living 24 Hour BillPay. 2019. Available online: https://cutt.ly/3cIAYKm. (accessed on 1 October 2018).

- Action, C.; Stanley, T.D. ESB’s Role The EU Clean Energy Package Provides a Regulatory Framework for Microgeneration. 2021, pp. 1–5. Available online: https://cutt.ly/TcIABdo (accessed on 1 October 2018).

| Building Type | Ref. | Energy Sources | Efficiency Improvement |

|---|---|---|---|

| Residential | [20] | 0.9 kW PV, Grid, Energy storage 500 Ah | 50.1% |

| Residential | [21] | 7.4 kW PV, Grid, Energy storage 10 kWh | 20–30% |

| Residential complex | [22] | 30 kW PV, 6.6 kW Gas engine | 15% |

| Residential | [23] | PV, Micro turbine, and Fuel cell | Low for 48 V DC |

| Commercial | [24] | PV | 5.5% |

| Commercial | [25] | 41 kW PV | 8% |

| Residential | [26] | Grid | - |

| Office | [27] | Grid | 14.9% |

| Residential | [28] | Grid | 25.3% |

| Residential | [29] | PV, Energy storage | 6.4% |

| Residential | [30] | PV, Energy storage | 16% |

| Power Parameter | Measurement Quantity (W) |

|---|---|

| PAC1 | Battery charging and discharging (W) |

| PAC2 | System production (W) |

| PAC3 | Self-consumption (W) |

| PAC4 | Total consumption (W) |

| PAC5 | Power from grid (W) |

| PAC6 | Excess power from solar (W) |

| Component | Systems | Model |

|---|---|---|

| Power optimizer (MPPT) | AC & DC | SolarEdge |

| Inverter | AC | SolarEdge |

| Battery charge controller | AC & DC | Tesla |

| Rectifier | AC | [25] |

| Bidirectional Inverter | DC | SolarEdge |

| Appliances | Quantity | Power (W) |

|---|---|---|

| Heat pump | 1 | 14 k |

| Smart whiteboards | 5 | 800 |

| LED lights | 25 | 15/38 |

| PC | 7 | 120 |

| Others | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshammari, M.; Duffy, M. Feasibility Analysis of a DC Distribution System for a 6 kW Photovoltaic Installation in Ireland. Energies 2021, 14, 6265. https://doi.org/10.3390/en14196265

Alshammari M, Duffy M. Feasibility Analysis of a DC Distribution System for a 6 kW Photovoltaic Installation in Ireland. Energies. 2021; 14(19):6265. https://doi.org/10.3390/en14196265

Chicago/Turabian StyleAlshammari, Meshari, and Maeve Duffy. 2021. "Feasibility Analysis of a DC Distribution System for a 6 kW Photovoltaic Installation in Ireland" Energies 14, no. 19: 6265. https://doi.org/10.3390/en14196265