A Novel Hybrid Life Cycle Assessment Approach to Air Emissions and Human Health Impacts of Liquefied Natural Gas Supply Chain

Abstract

:1. Introduction

1.1. LNG Industry and Supply Chain

1.2. Socio-Environmental Impacts of LNG Chain

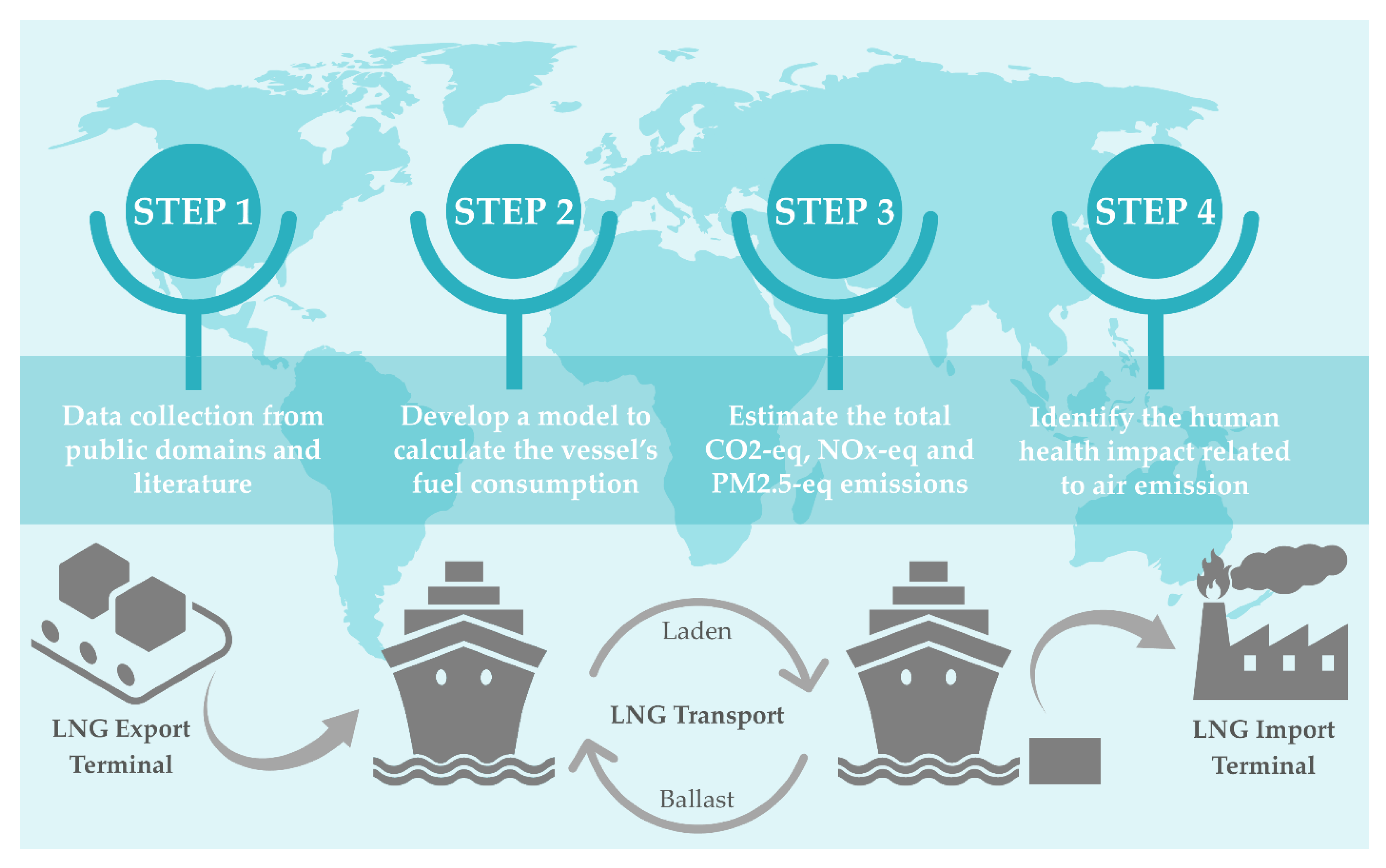

1.3. Novelty and Research Objectives

- Presenting a framework for measuring the footprint of air pollution and human health from LNG manufacturing and maritime transportation.

- Formulating and building a hybrid life cycle assessment (LCA) model combining both process-LCA and MRIO models.

- Establishing a high accurate simulation model for the optimized LNG process using the Aspen HYSYS tool.

- Proposing an accurate and effective human health impact accounting tool that various gas and oil process-related disciplines can use.

- Implementing further analysis helps to identify critical parameters that influence the LNG process and shipping air pollution footprints.

1.4. Organization of the Research

2. Literature Review

2.1. Environmental LCA for Energy Production Sectors

2.2. Social LCA of Human Health Impact for Energy Sectors

- While all of the towns or cities were required to increase their gross domestic product (GDP), the efficiency of the environment was rising further in a lot of the cities.

- The health efficiency directory implied that the illness efficiency had heightened in a lot of the cities but decreased in one-third of them. This finding means that it is essential to strengthen the efficiency of medication.

- The efficiency of the treatment of respiratory disease in the majority of towns increased, and the chance for development reduced substantially.

- The mortality rate improved in 15 towns; however, the medication effectiveness of the mortality rate decreased in 11 towns.

2.3. LNG Process Chain

3. Research Method

3.1. Scope and LCI Data

3.2. MRIO Analysis

3.3. Aspen HYSYS Model

- LNG process simulation while plant normal operations only.

- Minimum flaring is anticipated.

- BOG flaring while holding and loading modes is reliquefied and reused to the maximum extent.

- Seawater cooling water intake and outfall differential temperature are assumed to be within 3 °C for heating/cooling purposes.

- Point sources stack emissions shall not exceed the limits set by the authorities.

- Zero liquid discharges of treated industrial water to the sea.

- LNG product holding mode was assumed in this research. However, another assumption is that all LNG products are loaded and distributed to customers throughout the year by LNG carriers.

3.4. LNG Maritime Transport Emission Quantification Tool

3.5. Hybrid Life Cycle Air Emission Assessment Model

3.6. Midpoint and Endpoint Human Health Impact with RECIPE

4. Results and Discussion

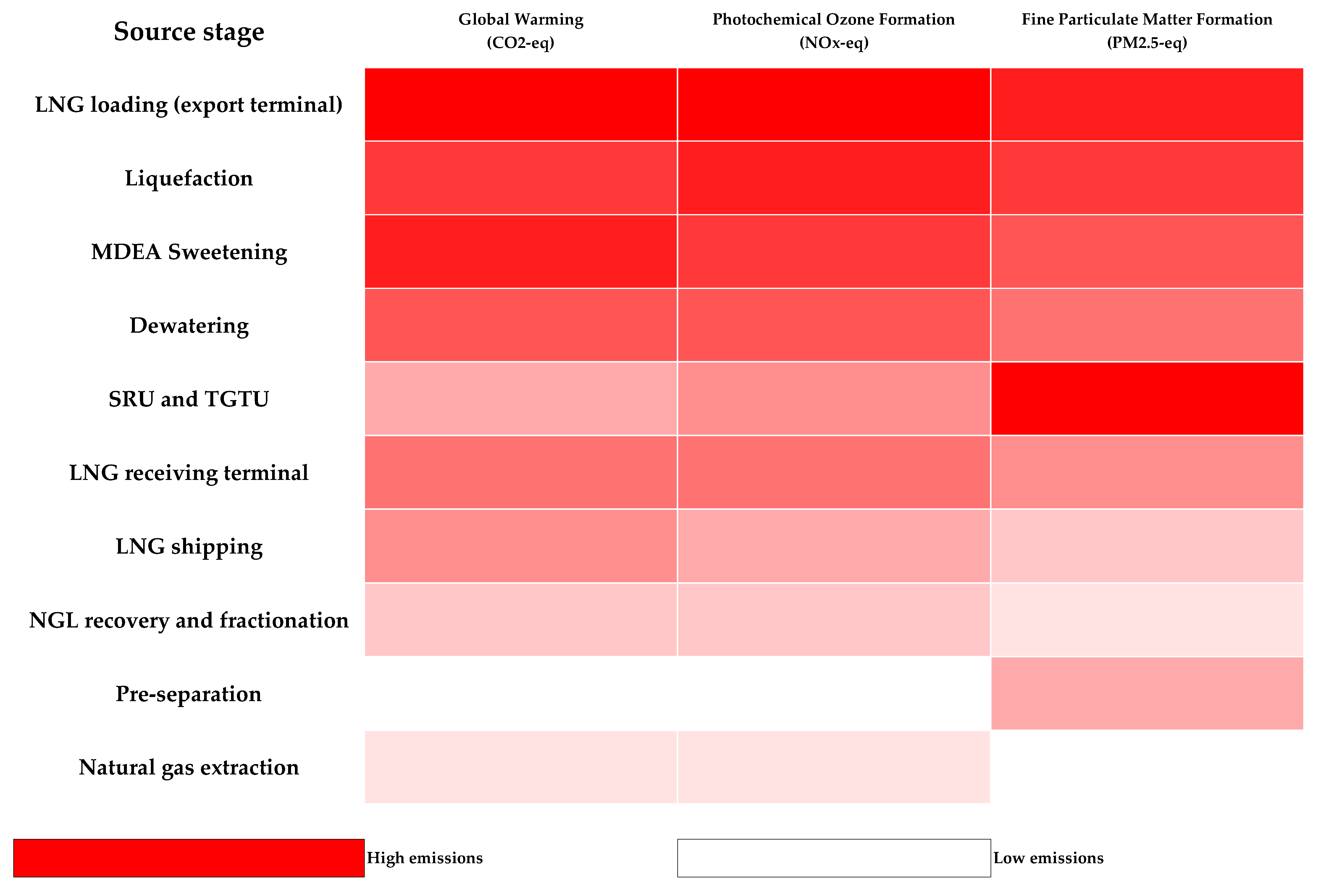

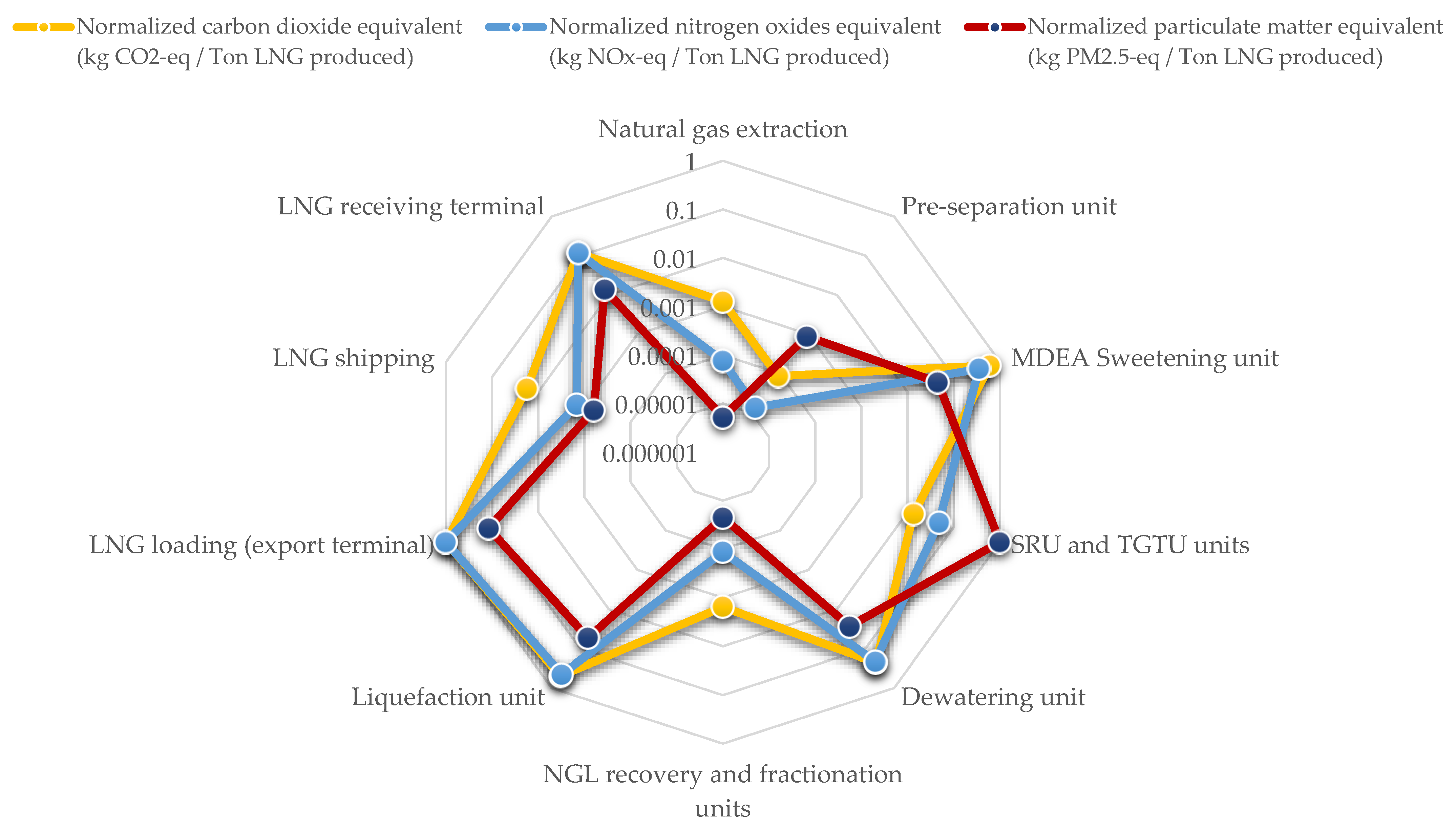

4.1. Sources and Midpoint Emissions Clustering in the LNG Supply Chain

4.2. Midpoint Emission Results for LNG Supply Chain Stages

4.3. Midpoint Air Emissions Analysis

4.4. Endpoint Social Human Health Impact Analysis

4.5. Social Human Health Implications

5. Conclusions and Recommendations

5.1. Discussion of Key Findings

5.2. Limitations of the Current Research

5.3. Recommendations, Future Work and Policy Making

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EIA. Annual Energy Review 2009; Office of Energy Markets and Use, U.S. Deptment of Energy: Washington, DC, USA, 2010.

- IEA. World Energy Outlook 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 1 August 2021).

- IGU. Global Gas Report 2020; International Gas Union (IGU), BloombergNEF (BNEF) and Snam: Milan, Italy, 2020. [Google Scholar]

- Oliver, M.E. Economies of scale and scope in expansion of the US natural gas pipeline network. Energy Econ. 2015, 52, 265–276. [Google Scholar] [CrossRef]

- Whitmore, W.D.; Baxter, V.K.; Laska, S.L. A critique of offshore liquefied natural gas (LNG) terminal policy. Ocean. Coast. Manag. 2009, 52, 10–16. [Google Scholar] [CrossRef]

- Agnolucci, P.; Arvanitopoulos, T. Industrial characteristics and air emissions: Long-term determinants in the UK manufacturing sector. Energy Econ. 2019, 78, 546–566. [Google Scholar] [CrossRef]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A Review. Front. Public Health 2020, 8, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kampa, M.; Castanas, E. Human health effects of air pollution. Environ. Pollut. 2008, 151, 362–367. [Google Scholar] [CrossRef]

- Shah, A.S.V.; Langrish, J.P.; Nair, H.; McAllister, D.A.; Hunter, A.L.; Donaldson, K.; Newby, D.E.; Mills, N.L. Global association of air pollution and heart failure: A systematic review and meta-analysis. Lancet 2013, 382, 1039–1048. [Google Scholar] [CrossRef] [Green Version]

- OECD. Economic Consequences of Outdoor Air Pollution; Organisation for Economic Co-operation and Development: Paris, France, 2016. [Google Scholar]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.M.; van Zelm, R. A taste of the new ReCiPe for life cycle assessment: Consequences of the updated impact assessment method on food product LCAs. Int. J. Life Cycle Assess. 2020, 25, 2315–2324. [Google Scholar] [CrossRef] [Green Version]

- Van Caneghem, J.; Block, C.; Van Hooste, H.; Vandecasteele, C. Eco-efficiency trends of the Flemish industry: Decoupling of environmental impact from economic growth. J. Clean. Prod. 2010, 18, 1349–1357. [Google Scholar] [CrossRef]

- Kucukvar, M.; Onat, N.C.; Haider, M.A. Material dependence of national energy development plans: The case for Turkey and United Kingdom. J. Clean. Prod. 2018, 200, 490–500. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Conventional, hybrid, plug-in hybrid or electric vehicles? State-based comparative carbon and energy footprint analysis in the United States. Appl. Energy 2015, 150, 36–49. [Google Scholar] [CrossRef]

- Kucukvar, M.; Tatari, O. Ecologically based hybrid life cycle analysis of continuously reinforced concrete and hot-mix asphalt pavements. Transp. Res. Part D Transp. Environ. 2012, 17, 86–90. [Google Scholar] [CrossRef]

- Aberilla, J.M.; Gallego-Schmid, A.; Stamford, L.; Azapagic, A. Synergistic generation of energy and water in remote communities: Economic and environmental assessment of current situation and future scenarios. Energy Convers. Manag. 2020, 207, 112543. [Google Scholar] [CrossRef]

- Tamura, I.; Tanaka, T.; Kagajo, T.; Kuwabara, S.; Yoshioka, T.; Nagata, T.; Kurahashi, K.; Ishitani, H. Life cycle CO2 analysis of LNG and city gas. Appl. Energy 2001, 68, 301–319. [Google Scholar] [CrossRef]

- Korre, A.; Nie, Z.; Durucan, S. Life Cycle Assessment of the natural gas supply chain and power generation options with CO2 capture and storage: Assessment of Qatar natural gas production, LNG transport and power generation in the UK. Sustain. Technol. Syst. Policies 2012, 11. [Google Scholar] [CrossRef]

- Biswas, W.; Engelbrecht, D.; John, M. Carbon footprint assessment of Western Australian LNG production and export to the Chinese market. Int. J. Prod. Lifecycle Manag. 2013, 6, 339–356. [Google Scholar] [CrossRef]

- Jaramillo, P.; Griffin, W.M.; Matthews, H.S. Comparative life-cycle air emissions of coal, domestic natural gas, LNG, and SNG for electricity generation. Environ. Sci. Technol. 2007, 41, 6290–6296. [Google Scholar] [CrossRef] [PubMed]

- Raj, R.; Ghandehariun, S.; Kumar, A.; Linwei, M. A well-to-wire life cycle assessment of Canadian shale gas for electricity generation in China. Energy 2016, 111, 642–652. [Google Scholar] [CrossRef]

- Sapkota, K.; Oni, A.O.; Kumar, A. Techno-economic and life cycle assessments of the natural gas supply chain from production sites in Canada to north and southwest Europe. J. Nat. Gas Sci. Eng. 2018, 52, 401–409. [Google Scholar] [CrossRef]

- Al-Haidous, S.; Al-Ansari, T. Sustainable Liquefied Natural Gas Supply Chain Management: A Review of Quantitative Models. Sustainability 2020, 12, 243. Available online: https://www.mdpi.com/2071-1050/12/1/243 (accessed on 2 August 2021). [CrossRef] [Green Version]

- Al-Haidous, S.; Govindan, R.; Al-Ansari, T. Swarm Optimisation for Shipping Fleet Scheduling, Routing and Delivery in Sustainable Liquified Natural Gas (LNG) Supply Chain Models. In Computer Aided Chemical Engineering; Pierucci, S., Manenti, F., Bozzano, G.L., Manca, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; Volume 48, pp. 1225–1230. [Google Scholar] [CrossRef]

- Onat, N.C.; Aboushaqrah, N.N.M.; Kucukvar, M.; Tarlochan, F.; Hamouda, A.M. From sustainability assessment to sustainability management for policy development: The case for electric vehicles. Energy Convers. Manag. 2020, 216, 112937. [Google Scholar] [CrossRef]

- Ghorani-Azam, A.; Riahi-Zanjani, B.; Balali-Mood, M. Effects of air pollution on human health and practical measures for prevention in Iran. J. Res. Med. Sci. 2016, 21, 65. [Google Scholar] [CrossRef]

- Sivarethinamohan, R.; Sujatha, S.; Priya, S.; Sankaran; Gafoor, A.; Rahman, Z. Impact of air pollution in health and socio-economic aspects: Review on future approach. Mater. Today Proc. 2021, 37, 2725–2729. [Google Scholar] [CrossRef]

- Rocha, C.A.; Lima, J.L.R.; Mendonça, K.V.; Marques, E.V.; Zanella, M.E.; Ribeiro, J.P.; Bertoncini, B.V.; Castelo Branco, V.T.F.; Cavalcante, R.M. Health impact assessment of air pollution in the metropolitan region of Fortaleza, Ceará, Brazil. Atmos. Environ. 2020, 241, 117751. [Google Scholar] [CrossRef]

- Li, Y.; Chiu, Y.-H.; Lin, T.-Y. The Impact of Economic Growth and Air Pollution on Public Health in 31 Chinese Cities. Int. J. Environ. Res. Public Health 2019, 16, 393. Available online: https://www.mdpi.com/1660-4601/16/3/393 (accessed on 4 August 2021). [CrossRef] [Green Version]

- Bergstra, A.D.; Brunekreef, B.; Burdorf, A. The effect of industry-related air pollution on lung function and respiratory symptoms in school children. Env. Health 2018, 17, 30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, K.-H.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Katebah, M.A.; Hussein, M.M.; Shazed, A.; Bouabidi, Z.; Al-musleh, E.I. Rigorous simulation, energy and environmental analysis of an actual baseload LNG supply chain. Comput. Chem. Eng. 2020, 141, 106993. [Google Scholar] [CrossRef]

- Anderson, T.N.; Ehrhardt, M.E.; Foglesong, R.E.; Bolton, T.; Jones, D.; Richardson, A. Shipboard Reliquefaction for Large LNG Carriers. In Proceedings of the 1st Annual Gas Processing Symposium; Alfadala, H.E., Rex Reklaitis, G.V., El-Halwagi, M.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2009; Volume 1, pp. 317–324. [Google Scholar] [CrossRef]

- Gómez, M.R.; García, R.; Gómez, J.; Catoira, A. Cold exergy recovery during LNG regasification through a closed Brayton cycle. Int. J. Energy 2014, 14, 484–504. [Google Scholar] [CrossRef]

- Kucukvar, M.; Onat, N.C.; Abdella, G.M.; Tatari, O. Assessing regional and global environmental footprints and value added of the largest food producers in the world. Resour. Conserv. Recycl. 2019, 144, 187–197. [Google Scholar] [CrossRef]

- Stadler, K.; Wood, R.; Bulavskaya, T.; Södersten, C.-J.; Simas, M.; Schmidt, S.; Usubiaga, A.; Acosta-Fernández, J.; Kuenen, J.; Bruckner, M.; et al. EXIOBASE 3: Developing a Time Series of Detailed Environmentally Extended Multi-Regional Input-Output Tables. J. Ind. Ecol. 2018, 22, 502–515. [Google Scholar] [CrossRef] [Green Version]

- Aseel, S.; Al-Yafei, H.; Kucukvar, M.; Onat, N.C.; Turkay, M.; Kazancoglu, Y.; Al-Sulaiti, A.; Al-Hajri, A. A Model for Estimating the Carbon Footprint of Maritime Transportation of Liquefied Natural Gas under Uncertainty. Sustain. Prod. Consum. 2021, 27, 1602–1613. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A.; Schepelmann, P.; Ritthoff, M. Options for broadening and deepening the LCA approaches. J. Clean. Prod. 2010, 18, 120–127. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Integrating triple bottom line input–output analysis into life cycle sustainability assessment framework: The case for US buildings. Int. J. Life Cycle Assess. 2014, 19, 1488–1505. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Scope-based carbon footprint analysis of U.S. residential and commercial buildings: An input–output hybrid life cycle assessment approach. Build. Environ. 2014, 72, 53–62. [Google Scholar] [CrossRef]

- Kucukvar, M.; Tatari, O. Towards a triple bottom-line sustainability assessment of the U.S. construction industry. Int. J. Life Cycle Assess. 2013, 18, 958–972. [Google Scholar] [CrossRef]

- Zhao, Y.; Onat, N.C.; Kucukvar, M.; Tatari, O. Carbon and energy footprints of electric delivery trucks: A hybrid multi-regional input-output life cycle assessment. Transp. Res. Part D Transp. Environ. 2016, 47, 195–207. [Google Scholar] [CrossRef]

- Kucukvar, M.; Haider, M.A.; Onat, N.C. Exploring the material footprints of national electricity production scenarios until 2050: The case for Turkey and UK. Resour. Conserv. Recycl. 2017, 125, 251–263. [Google Scholar] [CrossRef]

- Tukker, A.; Dietzenbacher, E. Global multiregional input–output frameworks: An introduction and outlook. Econ. Syst. Res. 2013, 25, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Galli, A.; Weinzettel, J.; Cranston, G.; Ercin, E. A Footprint Family extended MRIO model to support Europe’s transition to a One Planet Economy. Sci. Total. Environ. 2013, 461–462, 813–818. [Google Scholar] [CrossRef]

- Kucukvar, M.; Cansev, B.; Egilmez, G.; Onat, N.C.; Samadi, H. Energy-climate-manufacturing nexus: New insights from the regional and global supply chains of manufacturing industries. Appl. Energy 2016, 184, 889–904. [Google Scholar] [CrossRef] [Green Version]

- Abdella, G.M.; Kucukvar, M.; Onat, N.C.; Al-Yafay, H.M.; Bulak, M.E. Sustainability assessment and modeling based on supervised machine learning techniques: The case for food consumption. J. Clean. Prod. 2020, 251, 119661. [Google Scholar] [CrossRef]

- Andrew, R.M.; Peters, G.P. A Multi-Region Input–Output Table Based on the Global Trade Analysis Project Database (Gtap-Mrio). Econ. Syst. Res. 2013, 25, 99–121. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Peters, G.P. Carbon Footprint of Nations: A Global, Trade-Linked Analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Ingwersen, W.W.; Hawkins, T.R.; Srocka, M.; Meyer, D.E. USEEIO: A new and transparent United States environmentally-extended input-output model. J. Clean. Prod. 2017, 158, 308–318. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, D.; Vita, G.; Steen-Olsen, K.; Stadler, K.; Melo, P.C.; Wood, R.; Hertwich, E.G. Mapping the carbon footprint of EU regions. Environ. Res. Lett. 2017, 12, 054013. [Google Scholar] [CrossRef]

- Steinmann, Z.J.N.; Schipper, A.M.; Stadler, K.; Wood, R.; de Koning, A.; Tukker, A.; Huijbregts, M.A.J. Headline Environmental Indicators Revisited with the Global Multi-Regional Input-Output Database EXIOBASE. J. Ind. Ecol. 2018, 22, 565–573. [Google Scholar] [CrossRef] [Green Version]

- Wood, R.; Stadler, K.; Bulavskaya, T.; Lutter, S.; Giljum, S.; De Koning, A.; Kuenen, J.; Schütz, H.; Acosta-Fernández, J.; Usubiaga, A.; et al. Global Sustainability Accounting—Developing EXIOBASE for Multi-Regional Footprint Analysis. Sustainability 2015, 7, 138–163. Available online: https://www.mdpi.com/2071-1050/7/1/138 (accessed on 20 July 2021). [CrossRef] [Green Version]

- Foss, M.M. The Outlook for US Gas Prices in 2020: Henry hub at $3 or $10? Oxford Institute for Energy Studies: Oxford, UK, 2011. [Google Scholar]

- Chapter 1—LNG Fundamentals. In Handbook of Liquefied Natural Gas; Mokhatab, S.; Mak, J.Y.; Valappil, J.V.; Wood, D.A. (Eds.) Gulf Professional Publishing: Boston, MA, USA, 2014; pp. 1–106. [Google Scholar] [CrossRef]

- Aspen Technology Inc., Aspen HYSYS. In aspentech.com. 2021. Available online: https://www.aspentech.com/en/products/engineering/aspen-hysys (accessed on 6 August 2021).

- Perdu, G.; Normand, L.; Laborie, G.; Alhatou, O. Acid gas treatment upgrade for Qatargas. In International Petroleum Technology Conference; Society of Petroleum Engineers: Doha, Qatar, 2016; Available online: www.eptq.com (accessed on 1 August 2021).

- Cooper, D.; Gustafsson, T. Methodology for Calculating Emissions from Ships: 1. Update of Emission Factors; Swedish Meteorological and Hydrological Institute: Norrköping, Sweden, 2004. [Google Scholar]

- Aboushaqrah, N.N.M.; Onat, N.C.; Kucukvar, M.; Hamouda, A.M.S.; Kusakci, A.O.; Ayvaz, B. Selection of alternative fuel taxis: A hybridized approach of life cycle sustainability assessment and multi-criteria decision making with neutrosophic sets. Int. J. Sustain. Transp. 2021, 1–14. [Google Scholar] [CrossRef]

- Kucukvar, M.; Samadi, H. Linking national food production to global supply chain impacts for the energy-climate challenge: The cases of the EU-27 and Turkey. J. Clean. Prod. 2015, 108, 395–408. [Google Scholar] [CrossRef]

- Huang, Y.A.; Lenzen, M.; Weber, C.L.; Murray, J.; Matthews, H.S. The Role of Input—Output Analysis for the Screening of Corporate Carbon FootprINTS. Econ. Syst. Res. 2009, 21, 217–242. [Google Scholar] [CrossRef]

- Van Caneghem, J.; Block, C.; Vandecasteele, C. Assessment of the impact on human health of industrial emissions to air: Does the result depend on the applied method? J. Hazard. Mater. 2010, 184, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability 2017, 9, 706. Available online: https://www.mdpi.com/2071-1050/9/5/706 (accessed on 1 August 2021). [CrossRef] [Green Version]

- Onat, N.; Kucukvar, M.; Aboushaqrah, N.; Jabbar, R. How sustainable is electric mobility? A comprehensive sustainability assessment approach for the case of Qatar. Appl. Energy 2019, 250, 461–477. [Google Scholar] [CrossRef]

- Kucukvar, M.; Kutty, A.A.; Al-Hamrani, A.; Kim, D.; Nofal, N.; Onat, N.C.; Ermolaeva, P.; Al-Ansari, T.; Al-Thani, S.K.; Al-Jurf, N.M.; et al. How circular design can contribute to social sustainability and legacy of the FIFA World Cup Qatar 2022™? The case of innovative shipping container stadium. Environ. Impact Assess. Rev. 2021, 91, 106665. [Google Scholar] [CrossRef]

- Al-Hamrani, A.; Kim, D.; Kucukvar, M.; Onat, N.C. Circular economy application for a Green Stadium construction towards sustainable FIFA world cup Qatar 2022™. Environ. Impact Assess. Rev. 2021, 87, 106543. [Google Scholar] [CrossRef]

| Impact Area | Impact/Indicator | Unit | Description |

|---|---|---|---|

| Environmental | Global Warming Potential (GWP) | kg CO2-eq. | Total GHG emissions based on IPCC’s factors for GWP100 according to Assessment Report 5 (AR5) |

| Particulate Matter Formation Potential (PMFP) | kg PM2.5-eq. | Total criteria air pollutant emissions | |

| Photochemical Oxidant Formation Potential (POFP) | kg NOx-eq. | Amount of airborne substances able to form atmospheric oxidants |

| NG Feed Parameters | Specifications |

|---|---|

| Temperature (°C) | 27 |

| Pressure (bar) | 84.5 |

| Flowrate (MMSCFD) | 18,146 |

| Composition (mol%) | |

| N2 | 3.78 |

| H2S | 0.80 |

| CO2 | 2.43 |

| C1 | 81.3 |

| C2 | 4.84 |

| C3 | 1.84 |

| C4 | 1.03 |

| C5+ | 2.93 |

| BTX | 0.24 |

| Mercaptans | 0.04 |

| H2O | 0.74 |

| He | 0.04 |

| LNG Product Parameters | Specifications |

| Temperature (°C) | −161 |

| Higher heating value (BTU/SCF) | 1040 |

| Flowrate (MMTA) | 126 |

| Composition (mol%) | |

| N2 | 0.70 |

| C1 | 93.4 |

| C2 | 5.90 |

| C3 | 0.03 |

| H2S (ppm) | ≤4 |

| CO2 (ppm) | ≤59.2 |

| Specification\Stream | Feed from Off-Shore | Sour NG to AGRU | Condensate | Sour Water |

|---|---|---|---|---|

| Temperature (°C) | 27.00 | 34.50 | 40.24 | 28.64 |

| Pressure (bar) | 84.50 | 74.66 | 74.66 | 28.00 |

| Flowrate (MMSCFD) | 18,145.67 | 17,658.50 | 368.79 | 135.21 |

| Composition (mol%) | ||||

| N2 | 3.78 | 3.88 | ||

| H2S | 0.80 | 0.82 | 0.01 | 0.05 |

| CO2 | 2.43 | 2.49 | 0.06 | |

| C1 | 81.30 | 83.32 | ||

| C2 | 4.84 | 4.96 | 0.02 | |

| C3 | 1.84 | 1.87 | 0.50 | |

| C4 | 1.03 | 0.96 | 9.13 | |

| C5+ | 2.93 | 1.47 | 82.46 | |

| BTX | 0.24 | 0.10 | 7.80 | |

| Mercaptans | 0.04 | 0.04 | 0.08 | |

| H2O | 0.74 | 0.07 | ||

| He | 0.04 | 0.04 | 99.89 |

| Specification\Stream | Sweet Gas to Dehydration | Acid Gas to TGT | Acid Gas to SRU | Wastewater |

|---|---|---|---|---|

| Temperature (°C) | 47.00 | 58.91 | 113.80 | 127.60 |

| Pressure (bar) | 68.59 | 5.00 | 1.90 | 2.30 |

| Flowrate (MMSCFD) | 16,994.18 | 237.51 | 428.96 | 1.16 |

| Composition (mol%) | ||||

| N2 | 4.01 | 0.57 | 0.04 | 0.00 |

| H2S | 0.00 | 6.50 | 32.89 | 27.56 |

| CO2 | 0.01 | 84.27 | 66.27 | 4.51 |

| C1 | 86.19 | 6.16 | 0.38 | 0.02 |

| C2 | 5.14 | 0.04 | 0.00 | 0.01 |

| C3 | 1.93 | 0.42 | 0.03 | 0.01 |

| C4 | 0.98 | 0.32 | 0.02 | 0.01 |

| C5+ | 1.50 | 0.94 | 0.05 | 0.01 |

| BTX | 0.09 | 0.48 | 0.26 | 0.05 |

| Mercaptans | 0.04 | 0.31 | 0.06 | 0.03 |

| H2O | 0.07 | 0.00 | 0.00 | 67.79 |

| He | 0.04 | 0.00 | 0.00 | 0.00 |

| Specification\Stream | Steam | Fuel | Air | Sour Water | Water Out | Absorber Top | Sulfur |

|---|---|---|---|---|---|---|---|

| Temperature (°C) | 148.04 | 14.95 | 34.99 | 25.00 | 100.01 | 35.00 | 135.00 |

| Pressure (bar) | 4.51 | 3.77 | 1.70 | 1.01 | 1.01 | 1.06 | 1.43 |

| Flowrate (MMSCFD) | 7.53 | 8.04 | 68.14 | 0.58 | 437.34 | 577.56 | 118.43 |

| Composition (mol%) | |||||||

| O2 | 20.95 | ||||||

| N2 | 79.02 | 77.64 | |||||

| H2S | 0.02 | ||||||

| CO2 | 0.03 | 10.28 | |||||

| C1 | 95.00 | ||||||

| C2 | 4.00 | ||||||

| C3 | 1.00 | ||||||

| H2O | 100.00 | 100.00 | 100.00 | 5.28 | |||

| H2 | 6.78 | ||||||

| S | 100.00 |

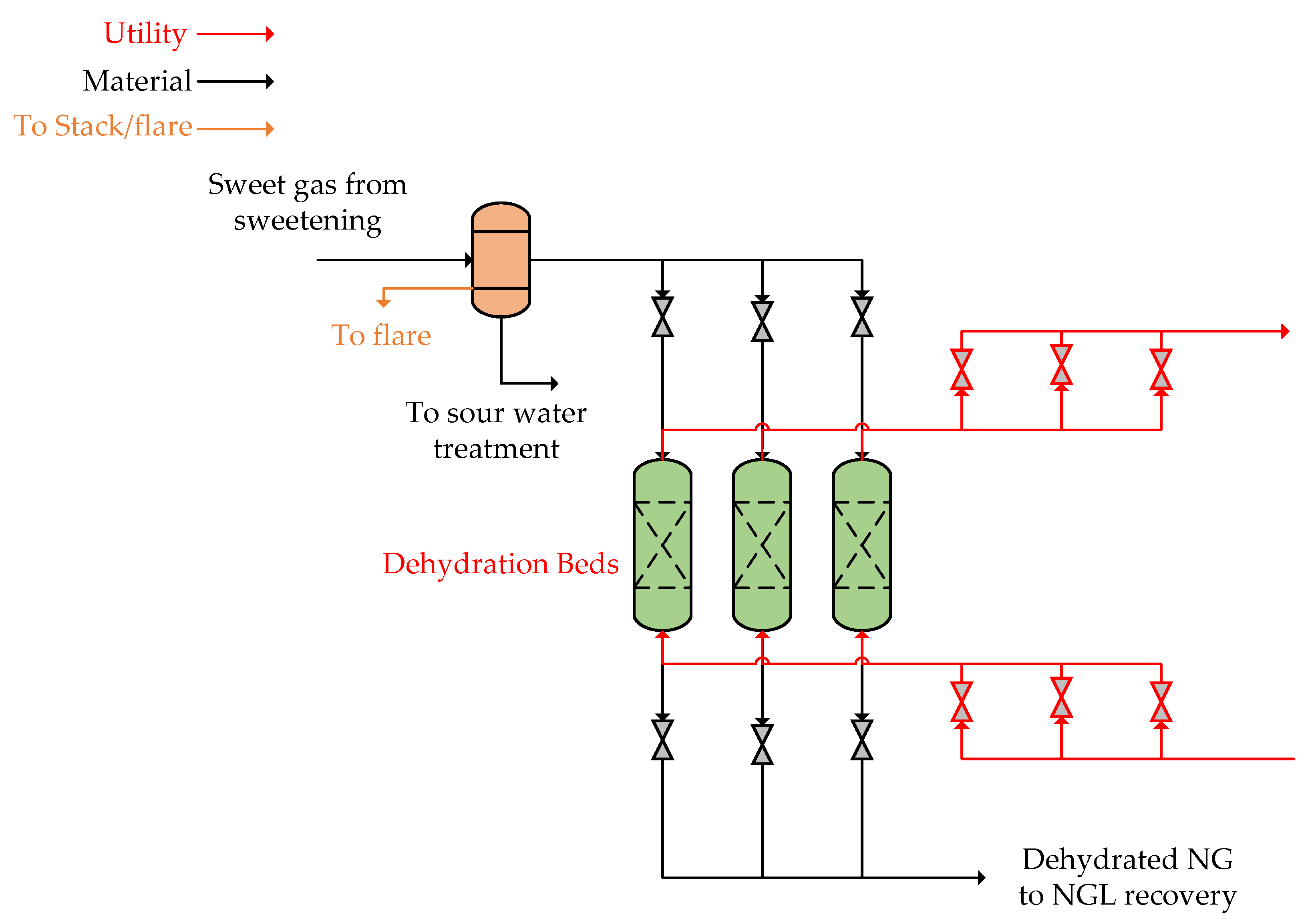

| Specification\Stream | Sour Water | Dehydrated NG |

|---|---|---|

| Temperature (°C) | 24.96 | 24.08 |

| Pressure (bar) | 67.54 | 66.81 |

| Flowrate (MMSCFD) | 1.00 | 16,817.03 |

| Composition (mol%) | ||

| N2 | 4.04 | |

| CO2 | 0.01 | |

| C1 | 86.80 | |

| C2 | 5.12 | |

| C3 | 1.90 | |

| C4 | 0.92 | |

| C5+ | 1.14 | |

| BTX | 0.03 | |

| H2O | 100.00 | |

| He | 0.04 |

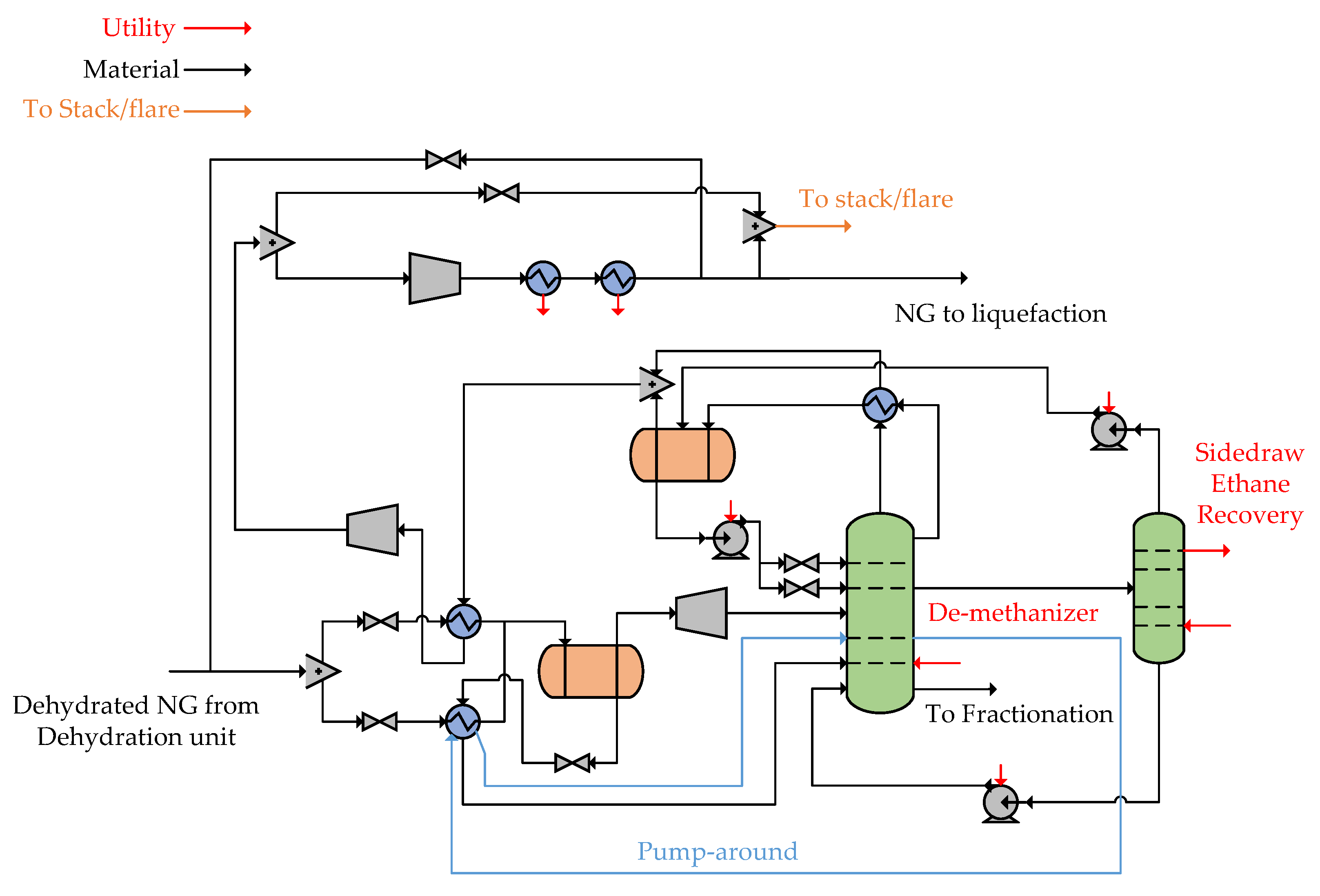

| Specification\Stream | NG to Liquefaction | NGL |

|---|---|---|

| Temperature (°C) | 36.42 | 123.60 |

| Pressure (bar) | 66.83 | 32.20 |

| Flowrate (MMSCFD) | 14,640.59 | 723.79 |

| Composition (mol%) | ||

| N2 | 4.20 | |

| CO2 | 0.01 | |

| C1 | 90.39 | |

| C2 | 5.33 | 1.05 |

| C3 | 0.03 | 46.48 |

| C4 | 23.14 | |

| C5+ | 28.49 | |

| BTX | 0.85 | |

| He | 0.04 |

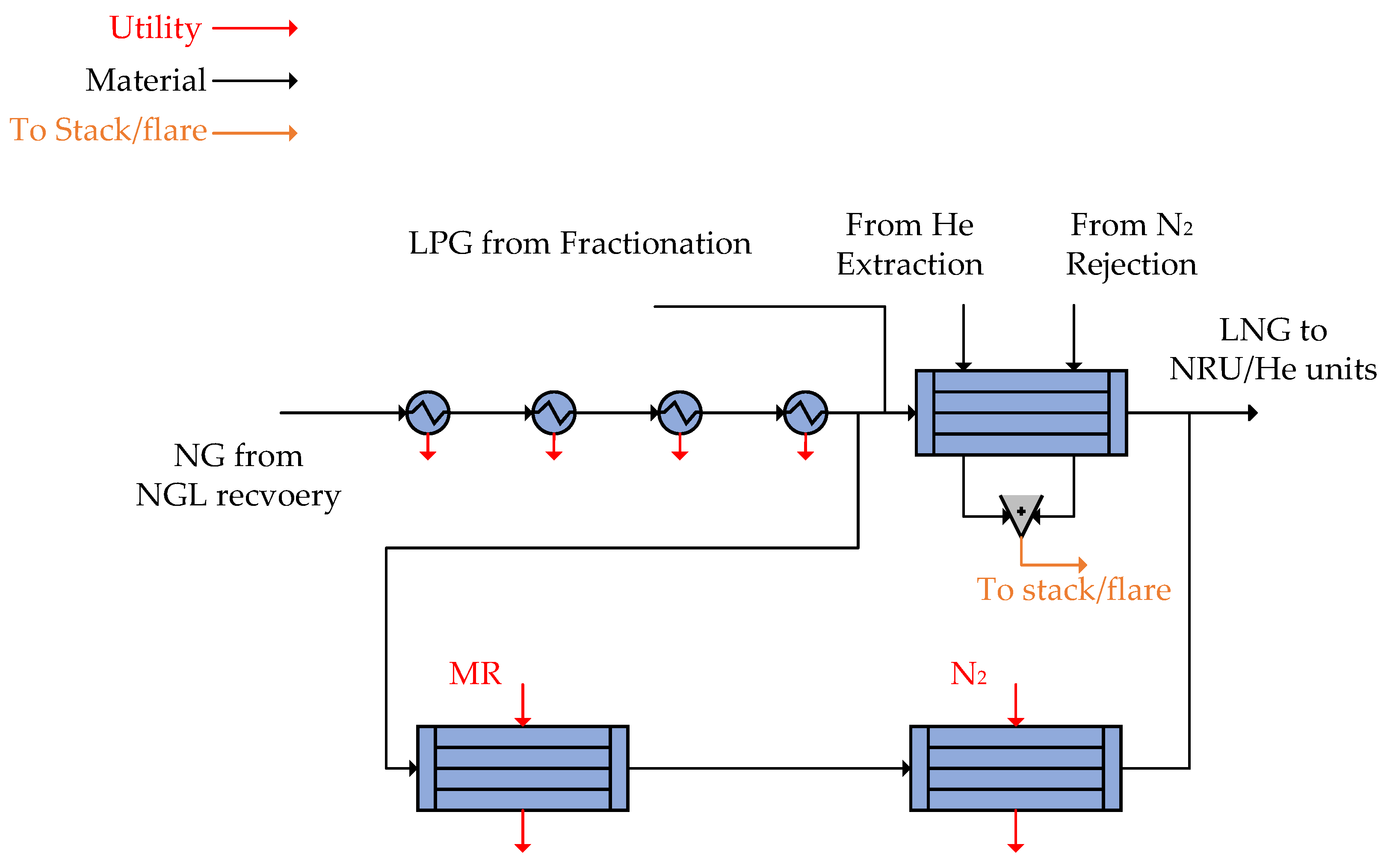

| Specification\Stream | From He | From N2 | LNG |

|---|---|---|---|

| Temperature (°C) | −155.30 | −161.90 | −148.40 |

| Pressure (bar) | 3.18 | 1.20 | 43.35 |

| Flowrate (MMSCFD) | 13.51 | 1547.55 | 16,487.81 |

| Composition (mol%) | |||

| N2 | 49.94 | 37.61 | 4.20 |

| CO2 | 0.01 | ||

| C1 | 2.00 | 62.35 | 90.39 |

| C2 | 0.01 | 5.33 | |

| C3 | 0.03 | ||

| He | 48.06 | 0.03 | 0.04 |

| Specification\Stream | Crude He | LNG Product |

|---|---|---|

| Temperature (°C) | −155.30 | −161.60 |

| Pressure (bar) | 3.18 | 1.20 |

| Flowrate (MMSCFD) | 13.51 | 14,931.41 |

| Composition (mol%) | ||

| N2 | 49.94 | 0.70 |

| H2S (ppm) | ≤4 | |

| CO2 (ppm) | ≤59.2 | |

| C1 | 2.00 | 93.38 |

| C2 | 5.88 | |

| C3 | 0.03 | |

| He | 48.06 |

| Specification\Stream | LPG | Ethane | Propane | Pentane Plus |

|---|---|---|---|---|

| Temperature (°C) | 16.40 | 35 | 45 | 130.63 |

| Pressure (bar) | 32.00 | 27.5 | 30.09 | 8.30 |

| Flowrate (MMSCFD) | 1,847.23 | 7.09 | 4.61 | 170.27 |

| Composition (mol%) | ||||

| C2 | 67.21 | 98.02 | 1.61 | |

| C3 | 20.36 | 1.98 | 96.44 | |

| C4 | 12.35 | 1.95 | 0.34 | |

| C5+ | 0.08 | 97.49 | ||

| BTX | 2.17 |

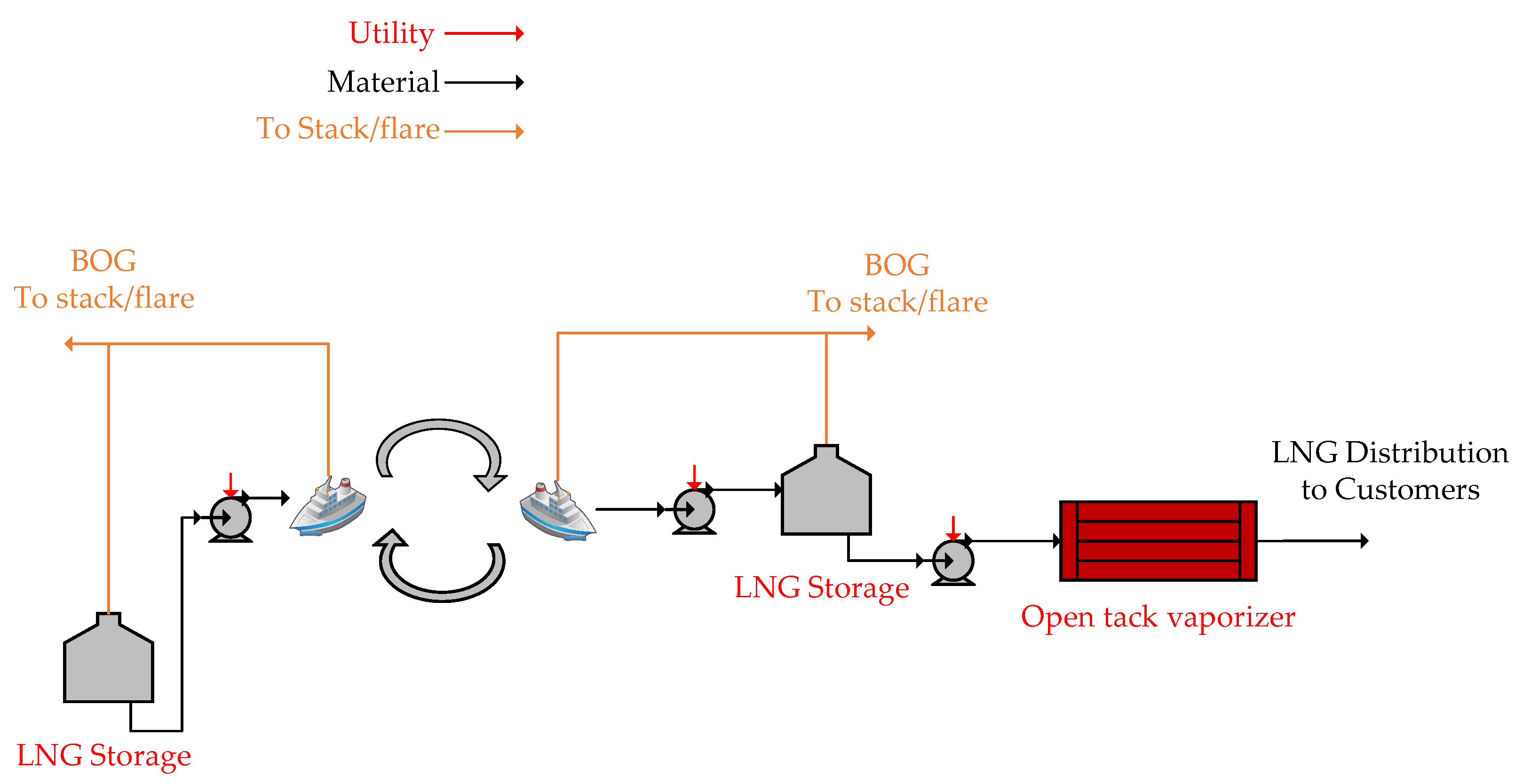

| Specification\Stream | LNG out from Tank | LNG to Customers |

|---|---|---|

| Temperature (°C) | −160.6 | 25 |

| Pressure (bar) | 3.0 | 81 |

| Flowrate (MMSCFD) | 14,931.41 | 14,931.41 |

| Composition (mol%) | ||

| N2 | 0.70 | 0.70 |

| H2S (ppm) | ≤4 | ≤4 |

| CO2 (ppm) | ≤59.2 | ≤59.2 |

| C1 | 93.38 | 93.38 |

| C2 | 5.88 | 5.88 |

| C3 | 0.03 | 0.03 |

| Midpoint to the Endpoint CF Human Health | Midpoint Emission Considered | Midpoint Unit | Midpoint Impact CF (Hierarchic) | Endpoint Unit | Endpoint Impact CF (Hierarchic) |

|---|---|---|---|---|---|

| Global Warming Potential (GWP) | CO2 | kg CO2-eq./kg midpoint emission | 1.00 | DALY/kg CO2-eq. | 9.28 × 10-7 |

| CH4 | 28.00 | ||||

| N2O | 265.00 | ||||

| Photochemical ozone formation | NOx | kg NOx-eq./kg midpoint emission | 1.00 | DALY/kg NOx-eq. | 9.10 × 10-7 |

| Fine particulate matter formation | SO2 | kg PM2.5-eq./kg midpoint emission | 0.29 | DALY/kg PM2.5-eq. | 6.29 × 10-4 |

| NH3 | 0.24 | ||||

| NO | 0.17 | ||||

| NO2 | 0.11 | ||||

| SO3 | 0.23 | ||||

| PM2.5 | 1.00 |

| Emission Source | Global Warming (kg CO2-eq) | Photochemical Ozone Formation (kg NOx-eq) | Fine Particulate Matter Formation (kg PM2.5-eq) |

|---|---|---|---|

| Natural gas extraction | 53,648,395.34 | 78,932.64 | 7740.91 |

| Preseparation unit | 3,630,834.41 | 14,129.75 | 1,308,947.10 |

| MDEA Sweetening unit | 25,414,306,084.39 | 367,511,207.61 | 67,015,269.55 |

| SRU and TGTU units | 569,820,482.48 | 50,239,730.24 | 1,483,250,846.87 |

| Dewatering unit | 9,591,964,940.34 | 226,246,569.61 | 40,551,701.60 |

| NGL recovery and fractionation units | 65,316,380.97 | 118,701.79 | 33,094.41 |

| Liquefaction unit | 21,012,275,442.69 | 469,812,499.27 | 79,849,788.70 |

| LNG loading (export terminal) | 42,201,635,518.84 | 1,043,728,533.51 | 177,395,647.88 |

| LNG shipping | 742,164,478.68 | 1,522,491.68 | 925,655.30 |

| LNG receiving terminal | 4,933,090,400.29 | 122,400,674.00 | 20,803,647.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Yafei, H.; Kucukvar, M.; AlNouss, A.; Aseel, S.; Onat, N.C. A Novel Hybrid Life Cycle Assessment Approach to Air Emissions and Human Health Impacts of Liquefied Natural Gas Supply Chain. Energies 2021, 14, 6278. https://doi.org/10.3390/en14196278

Al-Yafei H, Kucukvar M, AlNouss A, Aseel S, Onat NC. A Novel Hybrid Life Cycle Assessment Approach to Air Emissions and Human Health Impacts of Liquefied Natural Gas Supply Chain. Energies. 2021; 14(19):6278. https://doi.org/10.3390/en14196278

Chicago/Turabian StyleAl-Yafei, Hussein, Murat Kucukvar, Ahmed AlNouss, Saleh Aseel, and Nuri C. Onat. 2021. "A Novel Hybrid Life Cycle Assessment Approach to Air Emissions and Human Health Impacts of Liquefied Natural Gas Supply Chain" Energies 14, no. 19: 6278. https://doi.org/10.3390/en14196278

APA StyleAl-Yafei, H., Kucukvar, M., AlNouss, A., Aseel, S., & Onat, N. C. (2021). A Novel Hybrid Life Cycle Assessment Approach to Air Emissions and Human Health Impacts of Liquefied Natural Gas Supply Chain. Energies, 14(19), 6278. https://doi.org/10.3390/en14196278