Improving the Electrical Efficiency of the PV Panel via Geothermal Heat Exchanger: Mathematical Model, Validation and Parametric Analysis

Abstract

:1. Introduction

2. Methodology

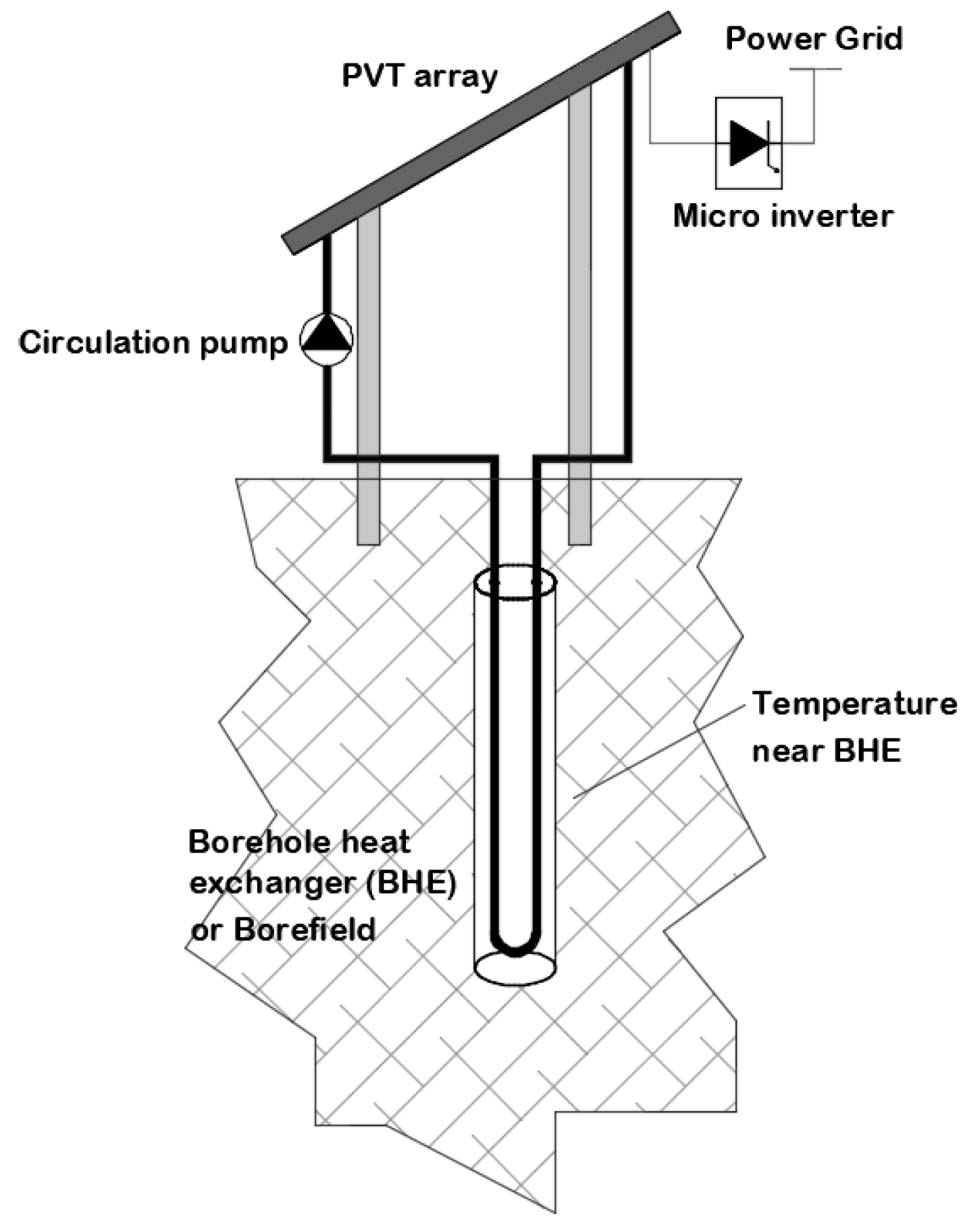

2.1. Set Up of the Assessment

2.2. Experimental Array

2.3. Mathematical Models

PV and PVT

3. Results and Discussion

3.1. Model Validation

3.2. Comparison of the Energy Performance

- The PV and PVT are scaled up by 3, with the aim to achieve more realistic results. The widely used PV panels have area of about 1.6 m2 and this used for the experiment has 0.537 m2, about three times smaller. Thus, the used nominal power is set to be 229.8 W, the area (Ac) at 1.611 m2 and the MC to be 16,800 J K−1 for the PVT and 11,520 J K−1 for the PV accordingly. The remain parameters are set equal to these listed in Table 1.

- The thermal insulation at the rear side of the PVT is removed and the heat losses due to convection heat losses is estimated via the same Equation (11) and coefficient C as this of the PV (C at 8.8 instead 26 which is for the PVT in Equation (11)). This choice was made in order to maximize the heat losses of PVT by exposing the absorber directly to the ambient conditions, as it applied for the PV panel. It is worth remembering that the convection heat transfer coefficient is related to the temperature difference between the absorber and the adjacent to the absorber air temperature. Thus, the insulated absorber (external side) has low temperature difference from the adjacent air and therefore low heat transfer coefficient. Though the naked PVT with the copper made absorber has higher temperature difference with the adjacent air, thus higher heat transfer coefficient. In reality, the naked absorber may have higher heat transfer coefficient even from the PV, which has at its rear side EVA, but for the current study we can set these values to be equal.

3.2.1. Parametric Analysis of a Single PVT Collector

3.2.2. Balance of the Soil Temperature

3.2.3. Influence of the BHE Length and Size

3.2.4. PVT Array and Borefield Size Parametric Analysis

3.2.5. Variation of the Soil Temperature near BHEs

3.2.6. Comparison of the Results with the Existing Literature

3.2.7. Capital Cost of the Investigated System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Nomenclature | Acronyms and Subscripts | ||

| Ac | PV panel area, m2 | BHE | borehole heat exchanger |

| bo | incidence angle modifier coefficient, - | cell | PV cell |

| E | electrical energy, kWh | cond | conduction, - |

| FI | percentage fractional improvement, % | conv | convection, - |

| GT | total incidence irradiance, W m−2 | GHE | geothermal heat exchanger |

| h | heat loss coefficient, W m−2 K−1 | PV | photovoltaic panel |

| m | mass flowrate, kg h−1 | PVT | photovoltaic and thermal collector |

| MC | sensible heat capacity, J K−1 | rad | radiation, - |

| n | number of collectors, - | ||

| P | power, W | ||

| Q | thermal energy, kWh | ||

| S | absorbed irradiance, W m−2 | ||

| SP | annual Specific productivity, kWh m−2 | ||

| SPPVT_el | PVT’s annual electric specific productivity, kWh m−2 | Greek letters | |

| SPPVT_th | system’s annual heat specific productivity, kWh m−2 | βcell | temperature power coefficient, K−1 |

| Ta | ambient temperature, K | ηe | PV cell efficiency, - |

| Tpm | effective plate mean temperature, K | ηn | PV cell nominal efficiency, - |

| Tsky | effective sky temperature, K | θi | solar incident angle, degrees |

| Tpm_PVT | PVT effective plate mean temperature, K | Kθ | incident angle modifier, - |

| Tpm_PV | PV effective plate mean temperature, K | ||

| UL | overall Heat loss coefficient, W m−2 K−1 | ||

| VW | wind speed, m s−1 | ||

References

- Wolf, M. Performance analyses of combined heating and photovoltaic power systems for residences. Energy Convers 1976, 16, 79–90. [Google Scholar] [CrossRef]

- Florschuetz, L. Extension of the Hottel-Whillier Model to the Analysis of Combined Photovoltaic/Thermal Flat Plate Collectors. Sol. Energy 1979, 22, 361–366. [Google Scholar] [CrossRef]

- Chow, T.T. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Ibrahim, A.; Othman, M.Y.; Ruslan, M.H.; Mat, S.; Sopian, K. Recent advances in flat plate photovoltaic/thermal (PV/T) solar collectors. Renew. Sustain. Energy Rev. 2011, 15, 352–365. [Google Scholar] [CrossRef]

- Aste, N.; del Pero, C.; Leonforte, F. Water flat plate PV-thermal collectors: A review. Sol. Energy 2014, 102, 98–115. [Google Scholar] [CrossRef]

- Debbarma, M.; Sudhakar, K.; Baredar, P. Comparison of BIPV and BIPVT: A review. Resour. Technol. 2017, 3, 263–271. [Google Scholar] [CrossRef]

- Sommerfeldt, N.; Madani, H. Review of Solar PV/Thermal Plus Ground Source Heat Pump Systems for European Multi-Family Houses. In Proceedings of the EuroSun Conference, Palma de Mallorca, Spain, 11–14 October 2016; pp. 1–12. [Google Scholar]

- Nouri, G.; Noorollahi, Y.; Yousefi, H. Solar assisted ground source heat pump systems—A review. Appl. Therm. Eng. 2019, 163. [Google Scholar] [CrossRef]

- Sakellariou, E.I.; Wright, A.J.; Axaopoulos, P.; Oyinlola, M.A. PVT based solar assisted ground source heat pump system: Modelling approach and sensitivity analyses. Sol. Energy 2019, 193, 37–50. [Google Scholar] [CrossRef]

- De Soto, W.; Klein, S.A.; Beckman, W.A. Improvement and validation of a model for photovoltaic array performance. Sol. Energy 2006, 80, 78–88. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature dependent photovoltaic (PV) efficiency and its effect on PV production in the world—A review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Zondag, H. Flat-plate PV-Thermal collectors and systems: A review. Renew. Sustain. Energy Rev. 2008, 12, 891–959. [Google Scholar] [CrossRef] [Green Version]

- Maleki, A.; Haghighi, A.; El Haj Assad, M.; Mahariq, I.; Alhuyi Nazari, M. A review on the approaches employed for cooling PV cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Good, C.; Andresen, I.; Hestnes, A.G. Solar energy for net zero energy buildings—A comparison between solar thermal, PV and photovoltaic-thermal (PV/T) systems. Sol. Energy 2015, 122, 986–996. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, M.; Vivar, M.; de la Casa, J.; Aguilera, J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for BIPV. Renew. Sustain. Energy Rev. 2018, 93, 110–120. [Google Scholar] [CrossRef]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Bambrook, S.M.; Sproul, A.B. Maximising the energy output of a PVT air system. Sol. Energy 2012, 86, 1857–1871. [Google Scholar] [CrossRef]

- Krauter, S. Increased electrical yield via water flow over the front of photovoltaic panels. Sol. Energy Mater. Sol. Cells 2004, 82, 131–137. [Google Scholar] [CrossRef]

- Kordzadeh, A. The effects of nominal power of array and system head on the operation of photovoltaic water pumping set with array surface covered by a film of water. Renew. Energy 2010, 35, 1098–1102. [Google Scholar] [CrossRef]

- Bahaidarah, H.; Subhan, A.; Gandhidasan, P.; Rehman, S. Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 2013, 59, 445–453. [Google Scholar] [CrossRef]

- Sakellariou, E.; Axaopoulos, P. Simulation and experimental performance analysis of a modified PV panel to a PVT collector. Sol. Energy 2017, 155, 715–726. [Google Scholar] [CrossRef]

- Jakhar, S.; Soni, M.S.; Gakkhar, N. An integrated photovoltaic thermal solar (IPVTS) system with earth water heat exchanger cooling: Energy and exergy analysis. Sol. Energy 2017, 157, 81–93. [Google Scholar] [CrossRef]

- Elminshawy, N.A.S.; El Ghandour, M.; Gad, H.M.; El-Damhogi, D.G.; El-Nahhas, K.; Addas, M.F. The performance of a buried heat exchanger system for PV panel cooling under elevated air temperatures. Geothermics 2019, 82, 7–15. [Google Scholar] [CrossRef]

- Ariff, W.; Bin, F.; Abdullah, W.; Ping, C.S.; Binti, R.N. The Improvement on the Efficiency of Photovoltaic Module using Water Cooling. OP Conf. Ser. Earth Environ. Sci. 2021, 721, 012001. [Google Scholar] [CrossRef]

- Jafari, R.; Erkılıç, K.T.; Uğurer, D.; Kanbur, Y.; Yıldız, M.; Ayhan, E.B. Enhanced photovoltaic panel energy by minichannel cooler and natural geothermal system. Int. J. Energy Res. 2021, 1–11. [Google Scholar] [CrossRef]

- Awasthi, A.; Shukla, A.K.; Murali Manohar, S.R.; Dondariya, C.; Shukla, K.N.; Porwal, D.; Richhariya, G. Review on sun tracking technology in solar PV system. Energy Rep. 2020, 6, 392–405. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Chen, S.G.; Hu, L.; Chen, X. Recent advancements and challenges in Solar Tracking Systems (STS): A review. Renew. Sustain. Energy Rev. 2018, 81, 250–279. [Google Scholar] [CrossRef]

- Fernández-Ahumada, L.M.; Casares, F.J.; Ramírez-Faz, J.; López-Luque, R. Mathematical study of the movement of solar tracking systems based on rational models. Sol. Energy 2017, 150, 20–29. [Google Scholar] [CrossRef]

- Racharla, S.; Rajan, K. Solar tracking system–a review. Int. J. Sustain. Eng. 2017, 10, 72–81. [Google Scholar] [CrossRef]

- Solar Energy Laboratory University of Wisconsin-Madison, GmbH—TRANSSOLAR Energietechnik, CSTB—Centre Scientifique et Technique du Bâtiment, TESS—Thermal Energy Systems Specialists. TRNSYS 17—a TRaNsientSYstem. Simulation Program. Simulation, 2009.

- Meteonorm. Irradiation Data for Every Place on Earth; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2016. [Google Scholar]

- ASHRAE. Methods of Testing to Determine the Thermal Performance of Solar Collectors; ASHRAE: Peachtree Corners, GA, USA, 1977; pp. 93–97. [Google Scholar]

- Zhang, H.F.; Lavan, Z. Thermal Performance of a Serpentine Absorber Plate. Proc. Annu. Meet. Am. Sect. Int. Sol. Energy Soc. 1983, 34, 471–476. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Heat and mass transfer—Incropera 6e. Fundam. Heat. Mass. Transf. 2007, 997. [Google Scholar] [CrossRef]

- Dolara, A.; Leva, S.; Manzolini, G. Comparison of different physical models for PV power output prediction. Sol. Energy 2015, 119, 83–99. [Google Scholar] [CrossRef] [Green Version]

- Ventura, C.; Tina, G.M.; Gagliano, A.; Aneli, S. Enhanced models for the evaluation of electrical efficiency of PV/T modules. Sol. Energy 2021, 224, 531–544. [Google Scholar] [CrossRef]

- El Fouas, C.; Hajji, B.; Gagliano, A.; Tina, G.M.; Aneli, S. Numerical model and experimental validation of the electrical and thermal performances of photovoltaic/thermal plant. Energy Convers. Manag. 2020, 220, 112939. [Google Scholar] [CrossRef]

- Maadi, S.R.; Khatibi, M.; Ebrahimnia-Bajestan, E.; Wood, D. Coupled thermal-optical numerical modeling of PV/T module—Combining CFD approach and two-band radiation DO model. Energy Convers. Manag. 2019, 198, 111781. [Google Scholar] [CrossRef]

- Hellström, G. Duct Ground Heat Storage Model, Manual for Computer Code. Energy 1989. [Google Scholar]

- Technical Chamber of Greece. Technical Directive 20701-1: National Specifications of Parameters for Calculating the Energy Performance of Buildings and the Issue of the Energy Performance Certificate 2017; Technical Chamber of Greece: Athens, Greece, 2017. [Google Scholar]

- Badache, M.; Eslami-Nejad, P.; Ouzzane, M.; Aidoun, Z.; Lamarche, L. A new modeling approach for improved ground temperature profile determination. Renew. Energy 2016, 85, 436–444. [Google Scholar] [CrossRef]

- Beier, R.A.; Smith, M.D.; Spitler, J.D. Reference data sets for vertical borehole ground heat exchanger models and thermal response test analysis. Geothermics 2011, 40, 79–85. [Google Scholar] [CrossRef]

- Sakellariou, E.I.; Axaopoulos, P.J.; Wright, A.J. Energy and economic evaluation of a solar assisted ground source heat pump system for a north Mediterranean city. Energy Build. 2020, 231, 110640. [Google Scholar] [CrossRef]

| PV Panel | |

|---|---|

| Nominal power | 76.6 Wp |

| Nominal efficiency (STC) | 14.25% |

| PV apparatuses area | 0.57 m2 |

| Temperature coefficient | 0.0046 K−1 |

| Cell type | Polycrystalline (p-Si) |

| Transmittance Absorptance at normal (τα)n | 0.875 |

| Absorber | |

| Type | Serpentine |

| Material (sheet and tube) | Copper |

| Distance between pipes (W) | 0.064 m |

| Outer diameter of the tube (Do) | 6.35 × 10−3 m |

| Inter diameter of the tube (Di) | 5.35 × 10−3 m |

| Thickness of the sheet (δ) | 3 × 10−4 m |

| Rear side thermal insulation thickness | 1 × 10−2 m |

| Thermal conductivity the insulation (polyurethane) | 4 × 10−2 W m−1 K−1 |

| Bound conductance (Cb) | 2 W m−1 K−1 |

| Parameter | Nomenclature | Uncertainty |

|---|---|---|

| PVT inlet temperature | Tin (°C) | ±0.15 °C |

| PVT outlet temperature | Tout (°C) | |

| PVT absorber temperature (center) | Tpm_PVT (°C) | |

| PV panel temperature (center) | Tpm_PV (°C) | |

| Ambient temperature | Ta (°C) | |

| Incident solar irradiance at tilted surface | GT (W m−2) | ±10 W m−2 |

| Wind speed | VW (m s−1) | ±0.025 m s−1 |

| PVT and PV power | P (W) | ±0.25 W |

| Flow-rate | m (kg s−1) | ±0.001 kg s−1 |

| Parameter | Value |

|---|---|

| Specific heat capacity of the heat transfer fluid, water. (cp) | 4185 J kg−1 K−1 |

| Dynamic viscosity of the water (μ) | 0.00086 Ns m−2 |

| Water thermal conductivity (λ) | 0.56 W m−1 k−1 |

| Parameter | Value |

|---|---|

| Header depth | 0.4 m |

| Soil thermal conductivity [41] | 1.5 W m−1 K−1 |

| Soil (clay) specific heat capacity [41] | 2400 kJ m−3 K−1 |

| Soil diffusivity | 0.054 m2 day−1 |

| Soil undisturbed temperature [42] | 17.2 °C |

| Grout thermal conductivity (backfill) | 1.6 W m−1 K−1 |

| Borehole radius | 0.075 m |

| Outer Radius of Pipe | 0.015 m |

| Inner Radius of Pipe | 0.014 m |

| Pipes center-to-center half distance | 0.045 m |

| Pipe Thermal Conductivity | 0.33 W m−1 K−1 |

| Flowrate (kg/h) | Fractional Improvement, FI (%) | Soil Temperature near BHEs (°C) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 BHE | 2 BHE | 3 BHE | 4 BHE | 1 BHE | 2 BHE | 3 BHE | 4 BHE | |

| 20 | 0.49 | 0.95 | 1.34 | 1.71 | 24.03 | 23.92 | 23.67 | 23.53 |

| 40 | 0.45 | 0.85 | 1.22 | 1.55 | 23.96 | 23.74 | 23.35 | 23.14 |

| 60 | 0.54 | 0.88 | 1.21 | 1.48 | 23.84 | 23.57 | 23.15 | 22.89 |

| 80 | 0.80 | 1.17 | 1.43 | 1.67 | 23.61 | 23.32 | 22.90 | 22.65 |

| 100 | 1.19 | 1.48 | 1.69 | 1.89 | 23.16 | 22.90 | 22.52 | 22.29 |

| 120 | 1.70 | 1.82 | 1.98 | 2.17 | 22.38 | 22.23 | 21.94 | 21.75 |

| 140 | 2.11 | 2.23 | 2.36 | 2.42 | 21.41 | 21.34 | 21.11 | 21.04 |

| 160 | 2.37 | 2.47 | 2.52 | 2.62 | 20.49 | 20.46 | 20.38 | 20.28 |

| 180 | 2.53 | 2.59 | 2.61 | 2.66 | 19.93 | 19.91 | 19.90 | 19.80 |

| 200 | 2.50 | 2.58 | 2.59 | 2.67 | 19.86 | 19.72 | 19.72 | 19.58 |

| Length of BHE (m) | SPPV_el (kWh m−2) | SPPVT_el (kWh m−2) | SPPVT_th (kWh m−2) | Pump Consumption (kWh) | FI (%) | Tpm_PV * (°C) | Tpm_PVT * (°C) | Tsoil ** (°C) |

|---|---|---|---|---|---|---|---|---|

| 1 | 201.7 | 210.7 | 43.6 | 12.4 | 0.61 | 23.9 | 21.7 | 23.8 |

| 2 | 201.7 | 211.2 | 91.1 | 12.6 | 0.80 | 23.9 | 21.5 | 23.6 |

| 4 | 201.7 | 212.2 | 187.3 | 13.2 | 1.12 | 23.9 | 21.2 | 23.2 |

| 6 | 201.7 | 213.1 | 281.8 | 13.9 | 1.36 | 23.9 | 20.8 | 22.7 |

| 10 | 201.7 | 214.6 | 452.0 | 14.9 | 1.80 | 23.9 | 20.3 | 21.8 |

| 15 | 201.7 | 216.1 | 627.5 | 16.3 | 2.15 | 23.9 | 19.7 | 20.9 |

| 20 | 201.7 | 217.3 | 774.6 | 17.1 | 2.47 | 23.9 | 19.2 | 20.1 |

| 25 | 201.7 | 218.3 | 891.7 | 17.9 | 2.74 | 23.9 | 18.8 | 19.4 |

| 30 | 201.7 | 219.0 | 989.0 | 18.3 | 2.93 | 23.9 | 18.4 | 18.9 |

| 40 | 201.7 | 220.1 | 1138.2 | 18.9 | 3.30 | 23.9 | 17.9 | 18.0 |

| Work | System | FI (%) |

|---|---|---|

| Experiment [16] | Open loop air-based PVT systems (Singapore) | 12–14 |

| Experiment [17] | Open loop air-based PVT systems (Sydney, Australia) | 10.6–12.2 |

| Experiment andSimulations [22] | Water based PVT with horizontal GHE of 80 m buried 3 m (North-West India) | 1.02–1.41 |

| Experiment (Indoor) [24] | Water based PVT system with serpentine shaped absorber (Indoor) | 3 |

| Experiment [25] | Water based PVT with microchannel pair with a spiral shaped GHE (3 depth) (Ankara, Turkey) | 10 |

| Experiment and imulations [20] | Water bases PVT system with water tank (Dhahran, Saudi Arabia) | 9 |

| Experiment [21] | Water bases PVT system with water tank (Athens, Greece) | 0.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sakellariou, E.I.; Axaopoulos, P.J.; Sarris, I.E.; Abdullaev, N. Improving the Electrical Efficiency of the PV Panel via Geothermal Heat Exchanger: Mathematical Model, Validation and Parametric Analysis. Energies 2021, 14, 6415. https://doi.org/10.3390/en14196415

Sakellariou EI, Axaopoulos PJ, Sarris IE, Abdullaev N. Improving the Electrical Efficiency of the PV Panel via Geothermal Heat Exchanger: Mathematical Model, Validation and Parametric Analysis. Energies. 2021; 14(19):6415. https://doi.org/10.3390/en14196415

Chicago/Turabian StyleSakellariou, Evangelos I., Petros J. Axaopoulos, Ioannis E. Sarris, and Nodirbek Abdullaev. 2021. "Improving the Electrical Efficiency of the PV Panel via Geothermal Heat Exchanger: Mathematical Model, Validation and Parametric Analysis" Energies 14, no. 19: 6415. https://doi.org/10.3390/en14196415