Effect of Accumulative Recycling of Aqueous Phase on the Properties of Hydrothermal Degradation of Dry Biomass and Bio-Crude Oil Formation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Analytical Methods

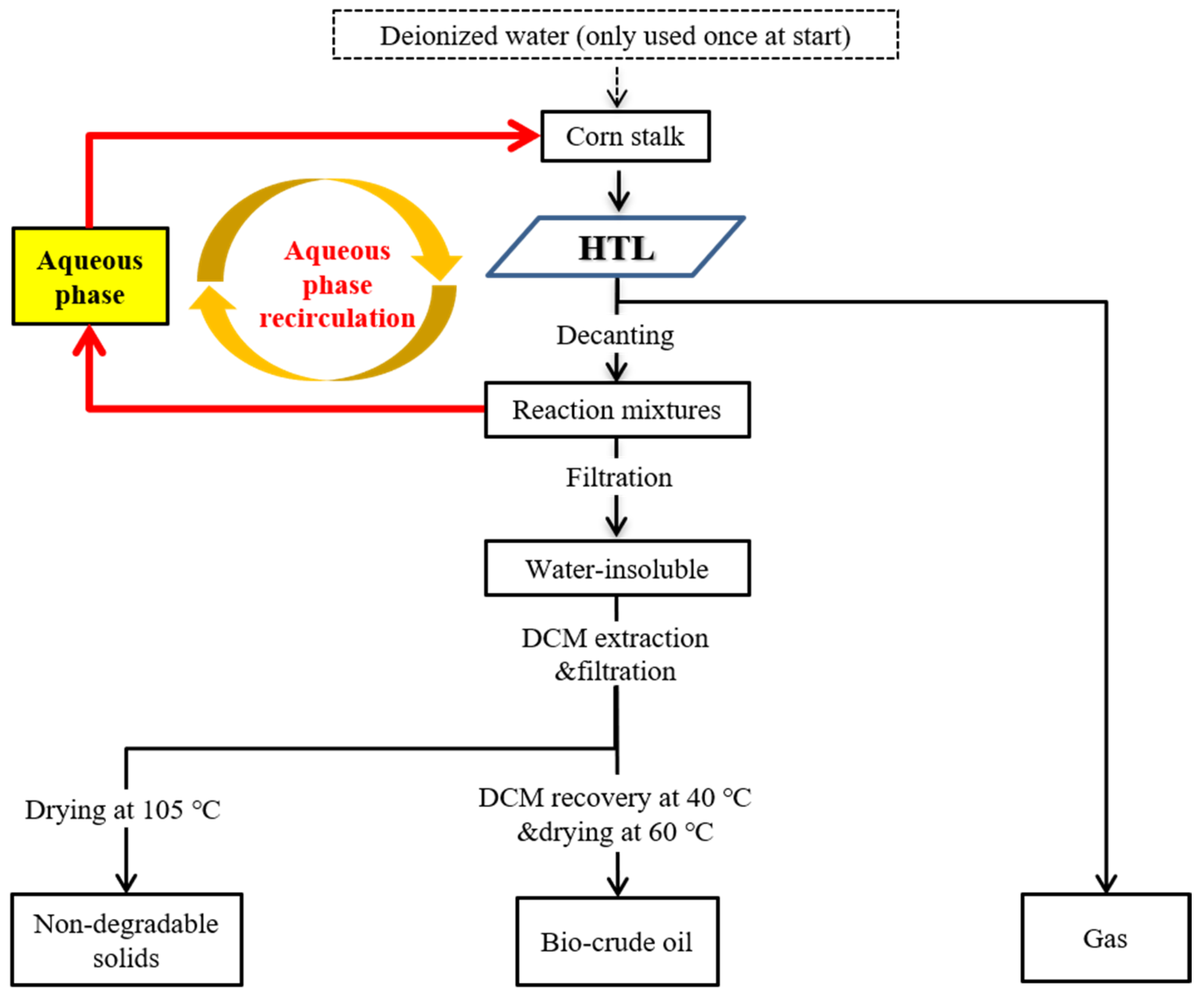

2.2. HTL Experimental Methods

2.3. Analysis and Calculation Methods

2.3.1. Analysis of HTL Products

2.3.2. Calculation Methods of Evaluation Indicators

- Calculation of the evaluation indicator for hydrothermal degradation:

- Calculation and indicators for the characterization of NDS:

- Calculation of the deposition rates of NDS:

3. Results and Discussion

3.1. Characteristics of Raw Materials

3.1.1. Characteristics of Corn Stalk

3.1.2. Characteristics of Aqueous Phase

3.2. Significance Analysis

3.3. Effect of Aqueous Phase Recycling on Degradation Based on NDS Characteristics

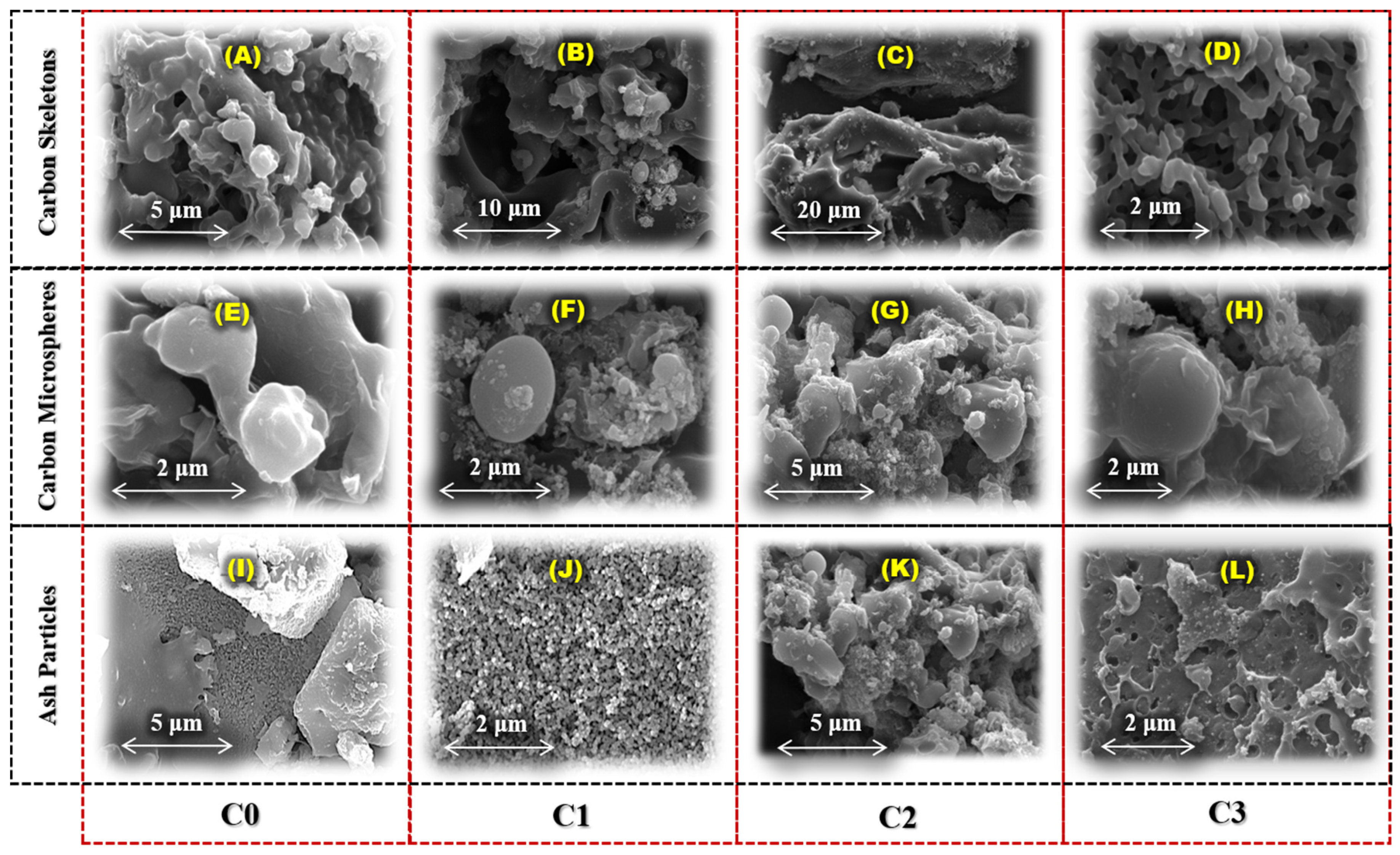

3.3.1. Changes of NDS Microstructure

3.3.2. Changes of Major Ash–Forming Metals in NDS

3.3.3. Changes of Internal Structure in NDS

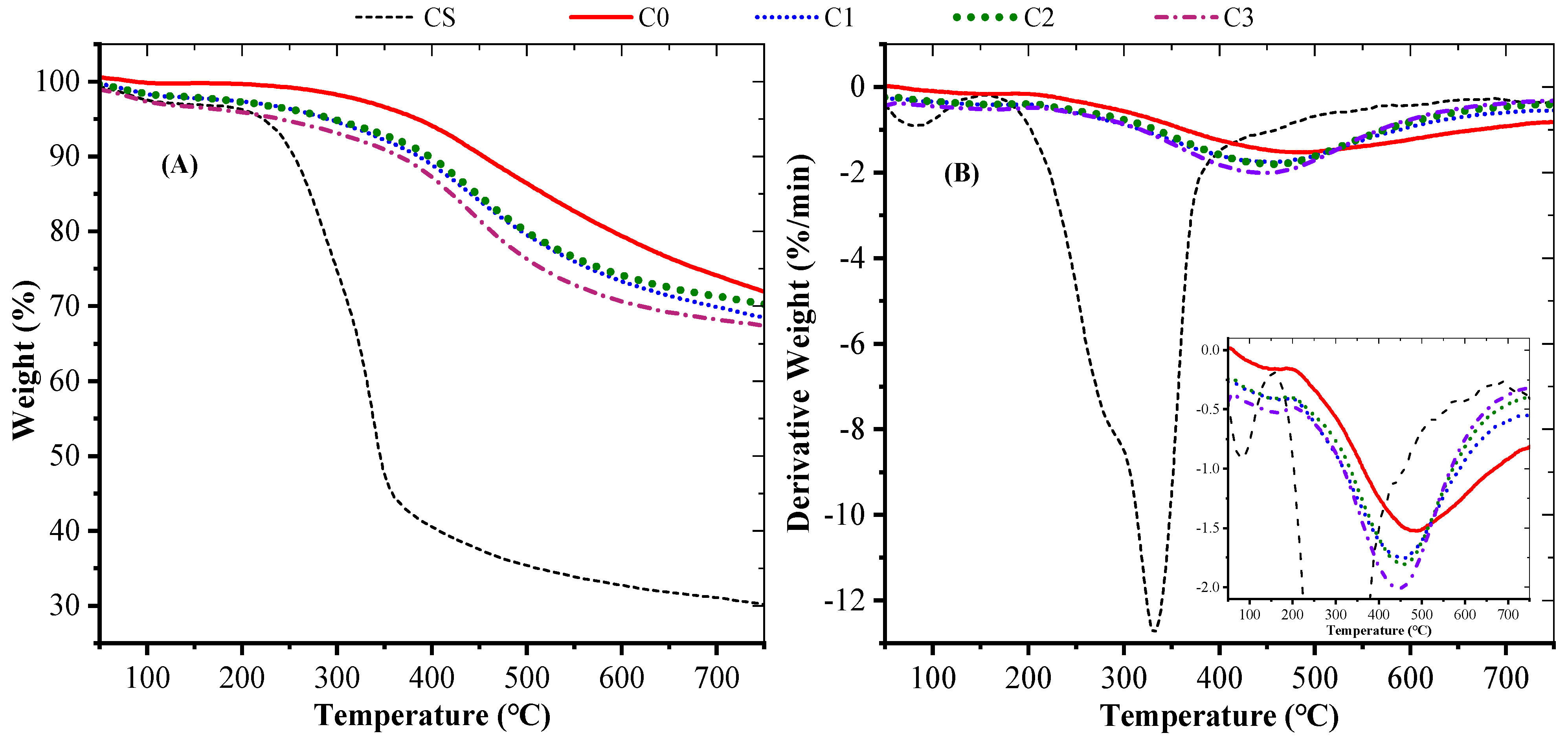

3.3.4. Thermal Stability of NDS

3.4. Effect of Aqueous Phase Recycling on Bio-Crude Oil Characteristics

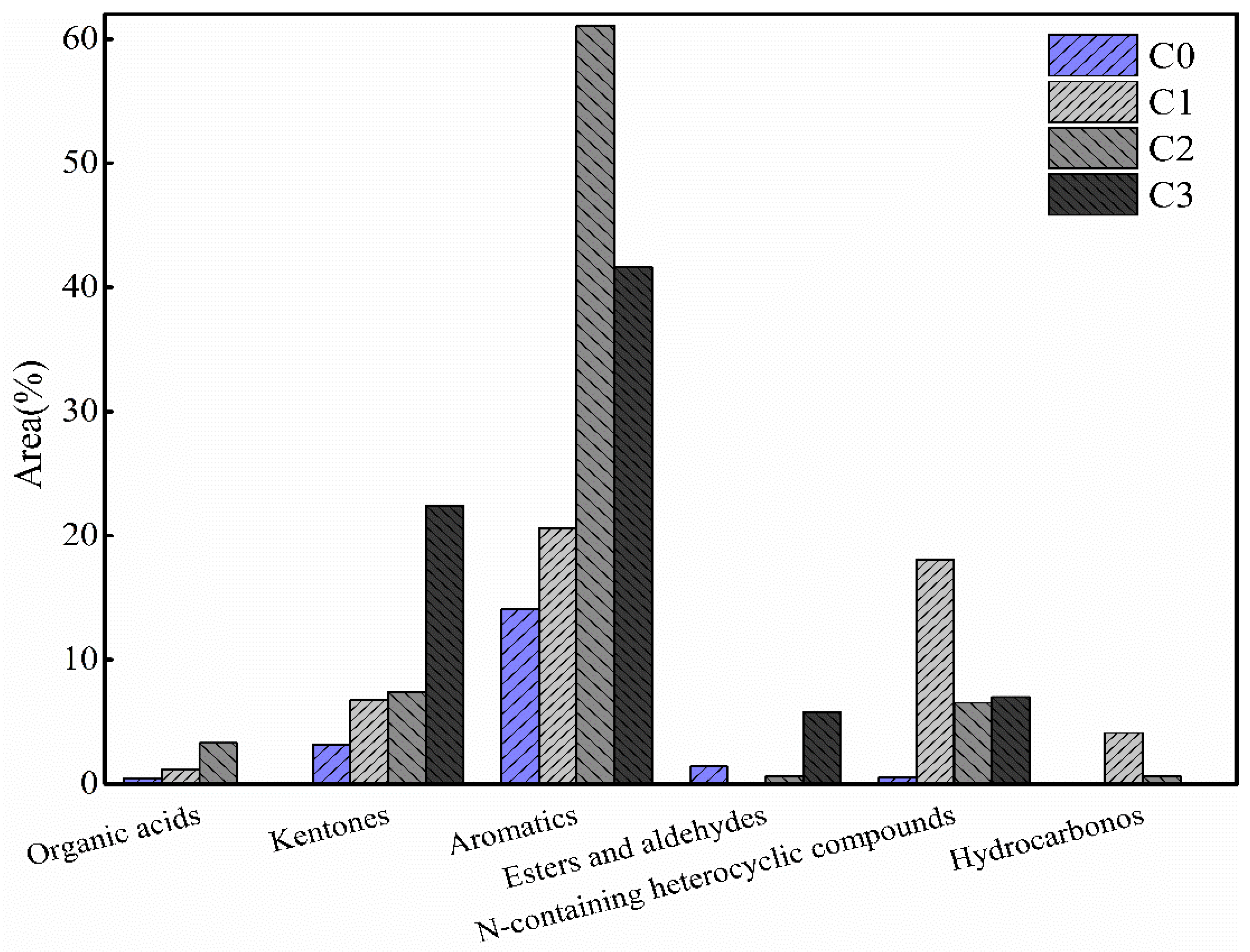

3.4.1. Compound Composition

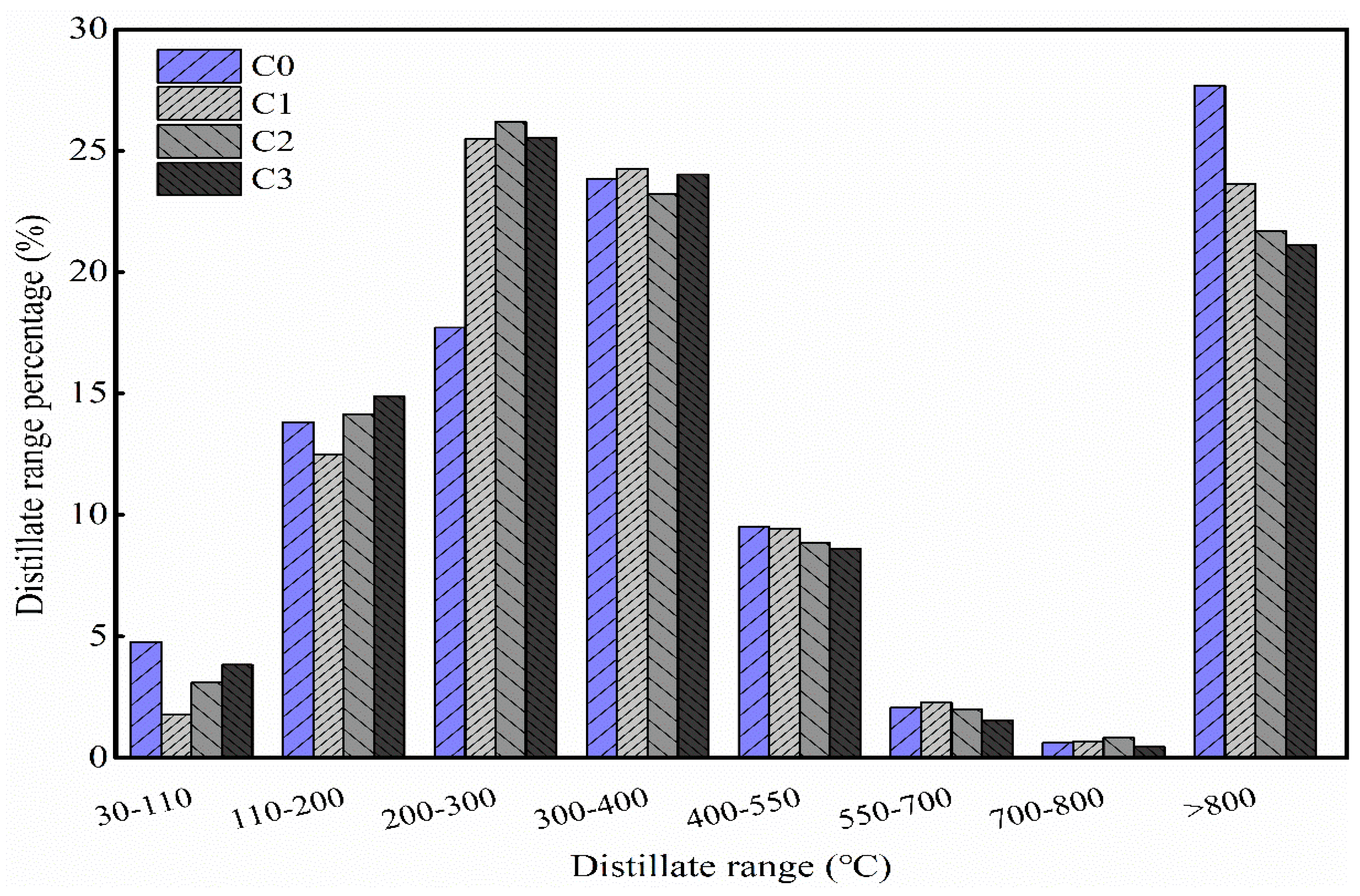

3.4.2. Boiling Point Distribution

3.4.3. Ultimate Analysis

3.5. Comprehensive Analysis on Hydrothermal Degradation and Bio-Crude Oil Formation

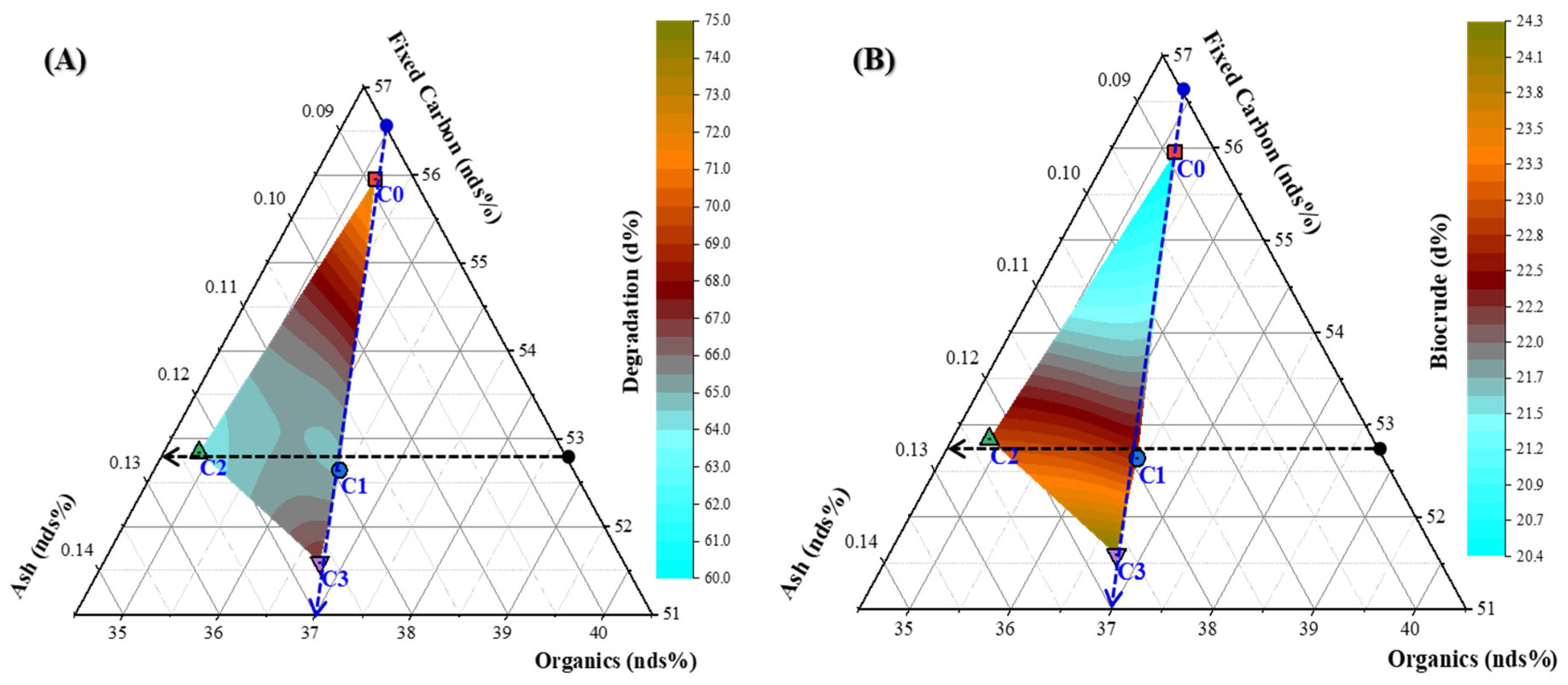

3.5.1. Effect of the Compositional Characteristics of NDS

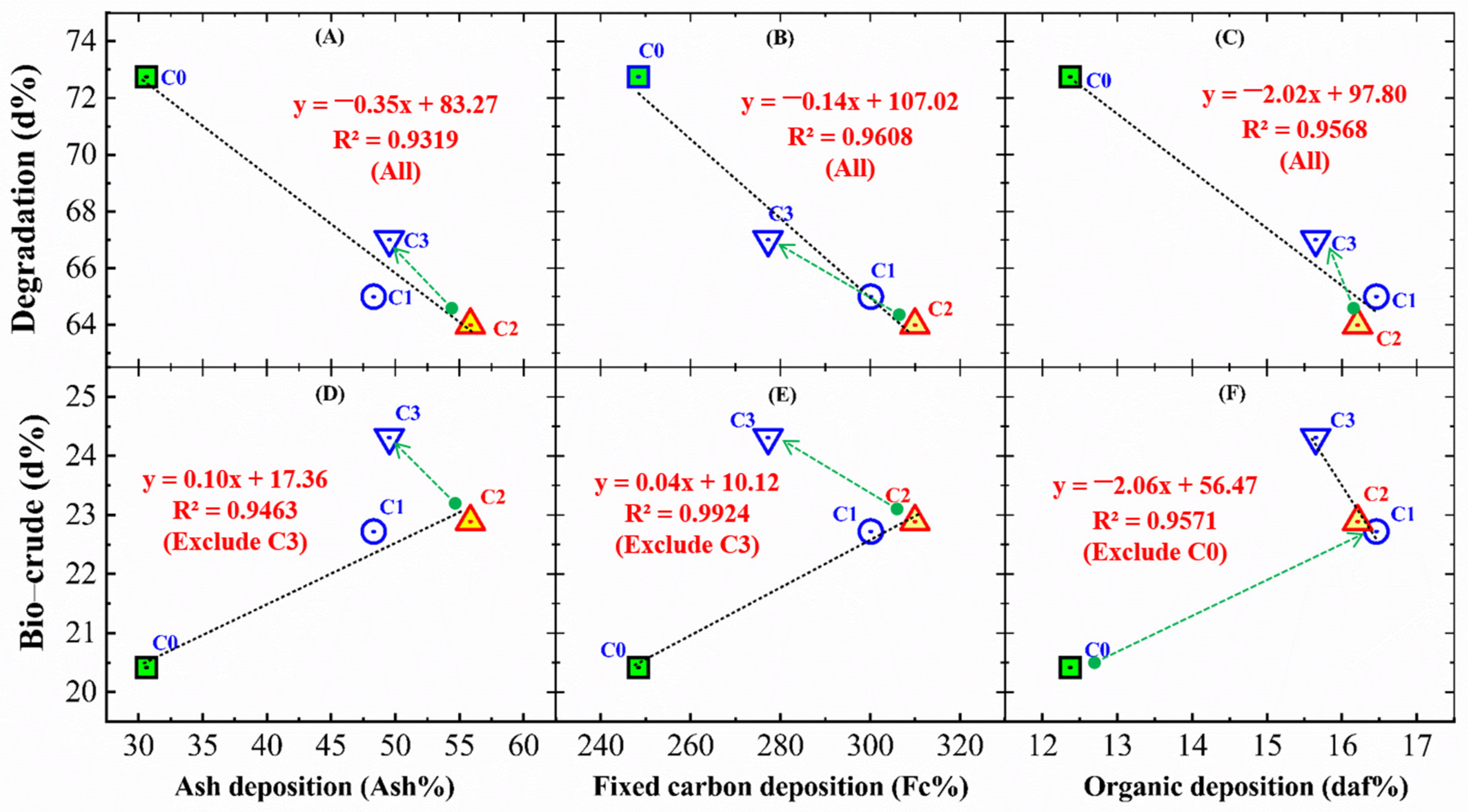

3.5.2. Effect of the Deposition Characteristics of NDS

3.5.3. Summary

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HTL | Hydrothermal liquefaction |

| FPL | Fast pyrolysis liquefaction |

| HTD | Hydrothermal degradation |

| DCM | Dichloromethane |

| BO | Bio-crude oil |

| NDS | Nondegradable solids |

| AP | Aqueous phase |

| daf | Dry ash free basis |

| d | Dry basis |

| GC–MS | Gas chromatography–mass spectrometry |

| ICP–OES | Inductively coupled plasma optic emission spectrometer |

| FT–IR | Fourier transform infrared spectroscopy |

| TGA | Thermogravimetric analysis |

| SEM | Scanning electron microscope |

| TOC | Total organic carbon |

| EC | Electrical conductance |

| TDS | Total dissolved solids |

| SAL | Salinity |

| V | Volatile/Hard–to–degrade organics |

| FC | Fixed carbon |

References

- Cao, L.; Zhang, C.; Chen, H.; Tsang, D.C.; Luo, G.; Zhang, S.; Chen, J. Hydrothermal liquefaction of agricultural and forestry wastes: State-of-the-art review and future prospects. Bioresour. Technol. 2017, 245, 1184–1193. [Google Scholar] [CrossRef]

- Chen, H.; Hao, S.; Chen, Z.; Sompong, O.; Fan, J.; Clark, J.; Luo, G.; Zhang, S. Mesophilic and thermophilic anaerobic digestion of aqueous phase generated from hydrothermal liquefaction of cornstalk: Molecular and metabolic insights. Water Res. 2020, 168, 115199. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Liu, S.; Du, J.; Wang, Z.; Wang, H.; Zhao, T. Conversion and extracting bio-oils from rod-shaped cornstalk by sub-critical water. J. Anal. Appl. Pyrolysis 2015, 115, 316–325. [Google Scholar] [CrossRef]

- Panisko, E.; Wietsma, T.; Lemmon, T.; Albrecht, K.; Howe, D. Characterization of the aqueous fractions from hydrotreatment and hydrothermal liquefaction of lignocellulosic feedstocks. Biomass Bioenergy 2015, 74, 162–171. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; He, Z.; Zhang, B.; Feng, H.; Kandasamy, S.; Wang, B. Effects of the aqueous phase recycling on bio-oil yield in hydrothermal liquefaction of Spirulina Platensis, α-cellulose, and lignin. Energy 2019, 179, 1103–1113. [Google Scholar] [CrossRef]

- Biller, P.; Madsen, R.B.; Klemmer, M.; Becker, J.; Iversen, B.B.; Glasius, M. Effect of hydrothermal liquefaction aqueous phase recycling on bio-crude yields and composition. Bioresour. Technol. 2016, 220, 190–199. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Hognon, C.; Delrue, F.; Texier, J.; Grateau, M.; Thiery, S.; Miller, H.; Roubaud, A. Comparison of pyrolysis and hydrothermal liquefaction of Chlamydomonas reinhardtii. Growth studies on the recovered hydrothermal aqueous phase. Biomass Bioenergy 2015, 73, 23–31. [Google Scholar] [CrossRef]

- Matayeva, A.; Basile, F.; Cavani, F.; Bianchi, D.; Chiaberge, S. Development of Upgraded Bio-Oil Via Liquefaction and Pyrolysis. Stud. Surf. Sci. Catal. 2019, 178, 231–256. [Google Scholar] [CrossRef]

- Elliott, D.C.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal liquefaction of biomass: Developments from batch to continuous process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Feng, S.; Yuan, Z.; Xu, C.C.; Bassi, A. Investigation of aqueous phase recycling for improving Bio-crude oil yield in hydrothermal liquefaction of algae. Bioresour. Technol. 2017, 239, 151–159. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, S.; Nam, H.; Chakraborty, J.P. Conversion of Solid Wastes to Fuels and Chemicals through Pyrolysis. Waste Biorefin. 2018, 239–263. [Google Scholar] [CrossRef]

- Zhu, Z.; Rosendahl, L.A.; Toor, S.S.; Yu, D.; Chen, G. Hydrothermal liquefaction of barley straw to bio-crude oil: Effects of reaction temperature and aqueous phase recirculation. Appl. Energy 2015, 137, 183–192. [Google Scholar] [CrossRef]

- Stemann, J.; Putschew, A.; Ziegler, F. Hydrothermal carbonization: Process water characterization and effects of water recirculation. Bioresour. Technol. 2013, 143, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, T.; Grigoras, I.; Hoffmann, J.; Toor, S.; Daraban, I.; Jensen, C.; Iversen, S.; Madsen, R.; Glasius, M.; Arturi, K.; et al. Continuous hydrothermal co-liquefaction of aspen wood and glycerol with water phase recirculation. Appl. Energy 2016, 162, 1034–1041. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, J.A.; Brown, R.J.; Rainey, T.J. A Review of Hydrothermal Liquefaction Bio-crude Properties and Prospects for Upgrading to Transportation Fuels. Energies 2015, 8, 6765–6794. [Google Scholar] [CrossRef] [Green Version]

- Valdez, P.J.; Savage, P.E. A reaction network for the hydrothermal liquefaction of Nannochloropsis sp. Algal Res. 2013, 2, 416–425. [Google Scholar] [CrossRef]

- Valdez, P.J.; Tocco, V.J.; Savage, P. A general kinetic model for the hydrothermal liquefaction of microalgae. Bioresour. Technol. 2014, 163, 123–127. [Google Scholar] [CrossRef]

- Zhuang, X.; Zhan, H.; Song, Y.; Huang, Y.; Yin, X.; Wu, C. Reutilization potential of antibiotic wastes via hydrothermal liquefaction (HTL): Bio–oil and aqueous phase characteristics. J. Energy Inst. 2019, 92, 1537–1547. [Google Scholar] [CrossRef]

- Watson, J.; Wang, T.; Si, B.-C.; Chen, W.-T.; Aierzhati, A.; Zhang, Y. Valorization of hydrothermal liquefaction aqueous phase: Pathways towards commercial viability. Prog. Energy Combust. Sci. 2020, 77, 100819. [Google Scholar] [CrossRef]

- Usman, M.; Chen, H.; Chen, K.; Ren, S.; Clark, J.H.; Fan, J.; Luo, G.; Zhang, S. Characterization and utilization of aqueous products from hydrothermal conversion of biomass for bio-oil and hydro–char production: A review. Green Chem. 2019, 21, 1553–1572. [Google Scholar] [CrossRef]

- Yin, S.; Tan, Z. Hydrothermal liquefaction of cellulose to bio–oil under acidic, neutral and alkaline conditions. Appl. Energy 2012, 92, 234–239. [Google Scholar] [CrossRef]

- Zhu, Z.; Toor, S.S.; Rosendahl, L.; Yu, D.; Chen, G. Influence of alkali catalyst on product yield and properties via hydrothermal liquefaction of barley straw. Energy 2015, 80, 284–292. [Google Scholar] [CrossRef]

- Déniel, M.; Haarlemmer, G.; Roubaud, A.; Weiss–Hortala, E.; Fages, J. Energy valorisation of food processing residues and model compounds by hydrothermal liquefaction. Renew. Sustain. Energy Rev. 2016, 54, 1632–1652. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Si, B.-C.; Lu, J.; Watson, J.; Zhang, Y.; Liu, Z. Elemental migration and characterization of products during hydrothermal liquefaction of cornstalk. Bioresour. Technol. 2017, 243, 9–16. [Google Scholar] [CrossRef]

- Kalderis, D.; Kotti, M.S.; Méndez, A.; Gascó, G. Characterization of hydrochars produced by hydrothermal carbonization of rice husk. Solid Earth 2014, 5, 477–483. [Google Scholar] [CrossRef] [Green Version]

- Sevilla, M.; Fuertes, A.B. The production of carbon materials by hydrothermal carbonization of cellulose. Carbon 2009, 47, 2281–2289. [Google Scholar] [CrossRef] [Green Version]

- Luan, C.; You, C.; Zhang, D. An experimental investigation into the characteristics and deposition mechanism of high–viscosity coal ash. Fuel 2014, 119, 14–20. [Google Scholar] [CrossRef]

- Reza, M.T.; Lynam, J.G.; Uddin, M.H.; Coronella, C.J. Hydrothermal carbonization: Fate of inorganics. Biomass Bioenergy 2013, 49, 86–94. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.-C.; Li, W.-Y.; Feng, J. Ash contents and ash–forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, L.; Zhang, S.; Fu, H.; Chen, J. Hydrothermal Liquefaction of Macroalgae Enteromorpha prolifera to Bio-oil. Energy Fuels 2010, 24, 4054–4061. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Y.; Yang, H.; Gentili, F.G.; Söderlind, U.; Wang, X.; Zhang, W.; Chen, H. Conversion of high-ash microalgae through hydrothermal liquefaction. Sustain. Energy Fuels 2020, 4, 2782–2791. [Google Scholar] [CrossRef]

- Li, C.; Yang, X.; Zhang, Z.; Zhou, D.; Zhang, L.; Zhang, S.; Chen, J. Hydrothermal Liquefaction of Desert Shrub Salix psammophila to High Value-added Chemicals and Hydrochar with Recycled Processing Water. BioResources 2013, 8, 2981–2997. [Google Scholar] [CrossRef]

- Hu, J.; Shen, D.; Wu, S.; Zhang, H.; Xiao, R. Effect of temperature on structure evolution in char from hydrothermal degradation of lignin. J. Anal. Appl. Pyrolysis 2014, 106, 118–124. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, F.; Djandja, J.O.; Zhang, S.-L.; Xu, Y.-P.; Duan, P.-G. Hydrothermal liquefaction of crop straws: Effect of feedstock composition. Fuel 2020, 265, 116946. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, W.-T.; Zhang, P.; Luo, Z.; Zhang, Y. Hydrothermal liquefaction of Chlorella pyrenoidosa in sub- and supercritical ethanol with heterogeneous catalysts. Bioresour. Technol. 2013, 133, 389–397. [Google Scholar] [CrossRef]

- Chen, W.-T.; Zhang, Y.; Zhang, J.; Schideman, L.; Yu, G.; Zhang, P.; Minarick, M. Co-liquefaction of swine manure and mixed-culture algal biomass from a wastewater treatment system to produce Bio-crude oil. Appl. Energy 2014, 128, 209–216. [Google Scholar] [CrossRef]

- Ross, A.B.; Biller, P.; Kubacki, M.; Li, H.; Lea-Langton, A.; Jones, J. Hydrothermal processing of microalgae using alkali and organic acids. Fuel 2010, 89, 2234–2243. [Google Scholar] [CrossRef]

- Ross, A.B.; Jones, J.M.; Kubacki, M.L.; Bridgeman, T. Classification of macroalgae as fuel and its thermochemical behaviour. Bioresour. Technol. 2008, 99, 6494–6504. [Google Scholar] [CrossRef]

- Tian, C.; Li, B.; Liu, Z.; Zhang, Y.; Lu, H. Hydrothermal liquefaction for algal biorefinery: A critical review. Renew. Sustain. Energy Rev. 2014, 38, 933–950. [Google Scholar] [CrossRef]

| Components | Content |

|---|---|

| Proximate analysis (d%) | |

| Fixed carbon | 6.14 ± 0.20 |

| Volatile matter | 77.48 ± 0.30 |

| Ash content | 7.92 ± 0.22 |

| Ultimate analysis (d%) | |

| Carbon | 44.17 ± 0.09 |

| Hydrogen | 5.65 ± 0.07 |

| Nitrogen | 0.92 ± 0.06 |

| Sulfur | 0.19 ± 0.05 |

| Oxygen * | 49.07 ± 0.14 |

| Chemical composition (daf%) | |

| Hemicellulose | 31.31 ± 0.69 |

| Cellulose | 40.13 ± 0.40 |

| Lignin | 4.74 ± 0.87 |

| Water Quality Analysis | C0 | C1 | C2 | C3 |

|---|---|---|---|---|

| pH | 3.77 ± 0.10 | 3.62 ± 0.20 | 3.85 ± 0.04 | 3.91 ± 0.03 |

| EC (μs/cm) | 913.15 ± 19.55 | 1973.75 ± 149.08 | 2250.50 ± 89.80 | 2739.50 ±21.92 |

| TDS (ppm) | 473.55 ± 29.92 | 986.78 ± 173.82 | 1125.50 ± 44.55 | 1402.00 ± 56.57 |

| Salinity (psu) | 0.46 ± 0.03 | 1.00 ± 0.19 | 1.16 ± 0.05 | 1.46 ± 0.06 |

| TOC (g/L) | 26.90 ± 0.64 | 43.88 ± 0.53 | 52.07 ± 0.46 | 60.30 ± 0.54 |

| Componentsidentification of aqueous phase | ||||

| Acids | 40.89 | 55.02 | 55.96 | 59.93 |

| Ketones | 14.43 | 10.24 | 9.90 | 8.27 |

| Phenols | 26.21 | 19.77 | 15.58 | 9.38 |

| Esters, alcohols, and aldehydes | ND | 2.79 | 3.53 | 4.32 |

| N–containing compounds | ND | 3.28 | 3.29 | 4.17 |

| Heterocyclic compounds | ND | ND | 0.57 | 1.55 |

| Dependent Variables | Sum of Squares | dif | Mean Square | F | Sig. | |

|---|---|---|---|---|---|---|

| Between Groups | 15.505 | 3 | 5.168 | 7.201 | 0.043 * | |

| Within Groups | 2.871 | 4 | 0.718 | |||

| Total | 18.376 | 7 | ||||

| Between Groups | 92.012 | 3 | 30.671 | 15.413 | 0.012 * | |

| Within Groups | 7.960 | 4 | 1.990 | |||

| Total | 99.971 | 7 | ||||

| Between Groups | 92.012 | 3 | 30.671 | 15.413 | 0.012 * | |

| Within Groups | 7.960 | 4 | 1.990 | |||

| Total | 99.971 | 7 | ||||

| Between Groups | 703.852 | 3 | 234.617 | 47.523 | 0.001 ** | |

| Within Groups | 19.748 | 4 | 4.937 | |||

| Total | 723.600 | 7 | ||||

| Between Groups | 4485.412 | 3 | 1495.137 | 9.853 | 0.026 * | |

| Within Groups | 606.819 | 4 | 151.705 | |||

| Total | 5092.230 | 7 | ||||

| Between Groups | 21.632 | 3 | 7.211 | 17.440 | 0.009 ** | |

| Within Groups | 1.654 | 4 | 0.413 | |||

| Total | 23.286 | 7 |

| Number of Recycling | 0 | 1 | 2 | 3 |

|---|---|---|---|---|

| Hydrothermal degradation efficiency index (d%) | ||||

| Nondegradable solid yield ( d%) | 27.26 ± 1.31 | 35.01 ± 1.19 | 36.02 ± 2.17 | 33.00 ± 0.35 |

| Hydrothermal degradation rate (HTD, d%) | 72.75 ± 1.31 | 64.99 ± 1.19 | 63.99 ± 2.17 | 67.00 ± 0.35 |

| Bio-crude oil yield ( d%) | 20.42 ± 0.32 | 22.72 ± 1.61 | 22.89 ± 0.20 | 24.31 ± 1.64 |

| Composition characteristics of nondegradable solids (NDS%) | ||||

| Hard–to–degrade organics content of NDS ( SR%) | 35.15 ± 0.65 | 36.43 ± 0.78 | 34.87 ± 0.21 | 36.75 ± 2.01 |

| Ash content of NDS ( NDS%) | 8.90 ± 1.73 | 10.93 ± 0.74 | 12.29 ± 1.73 | 11.66 ± 0.65 |

| Fixed carbon content of NDS ( NDS%) | 55.96 ± 1.09 | 52.64 ± 1.51 | 52.85 ± 1.95 | 51.59 ± 1.36 |

| Deposition characteristics of nondegradable solids components (%) | ||||

| Fixed carbon deposition rate ( FC%) | 248.41± 11.92 | 300.14 ± 10.20 | 309.97 ± 18.68 | 277.28 ± 2.97 |

| Hard–to–degrade organics deposition rate ( daf%) | 12.37 ± 0.59 | 16.46 ± 0.56 | 16.21 ± 0.98 | 15.65 ± 0.17 |

| Ash deposition rate ( Ash%) | 30.61 ± 1.47 | 48.31 ± 1.64 | 55.86 ± 3.37 | 49.55 ± 1.89 |

| Metals | C0 | C1 | C2 | C3 |

|---|---|---|---|---|

| Ca | 0.692 | 0.356 | 0.699 | 0.465 |

| K | 0.359 | 0.629 | 0.643 | 0.389 |

| Mg | 0.345 | 0.156 | 0.569 | 0.246 |

| Al | 0.284 | 0.455 | 0.164 | 0.139 |

| Fe | 0.177 | 0.137 | 0.119 | 0.068 |

| Ni | 0.048 | 0.122 | 0.082 | 0.035 |

| Ti | 0.017 | 0.010 | 0.010 | 0.002 |

| Cr | 0.007 | 0.020 | 0.019 | 0.006 |

| Mn | 0.006 | 0.005 | 0.006 | 0.004 |

| Ba | 0.006 | 0.008 | 0.006 | 0.003 |

| Mo | 0.005 | 0.004 | 0.097 | 0.026 |

| Number of Recycling | Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Size (nm) |

|---|---|---|---|

| 0 | 12.20 | 0.06 | 18.25 |

| 1 | 4.64 | 0.04 | 36.15 |

| 2 | 6.69 | 0.03 | 20.29 |

| 3 | 4.08 | 0.02 | 17.74 |

| Number of Recycling | Ultimate Analysis (d%) | H/C | O/C | N/O | Carbon Recovery (CR%) | Hydrogen Recovery (HR%) | Nitrogen Recovery (NR%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | |||||||

| 0 | 69.80 ± 0.06 | 6.78 ± 0.13 | 13.34 ± 0.20 | 1.19 ± 0.14 | 0.00 ± 0.00 | 1.17 | 0.14 | 0.10 | 32.28 ± 0.50 | 24.51 ± 0.38 | 26.42 ± 0.41 |

| 1 | 68.08 ± 0.16 | 7.10 ± 0.17 | 12.56 ± 0.40 | 1.25 ± 0.03 | 0.08 ± 0.04 | 1.25 | 0.14 | 0.11 | 35.01 ± 2.47 | 28.54 ± 2.02 | 30.86 ± 2.18 |

| 2 | 68.61 ± 0.04 | 6.86 ± 0.02 | 10.75 ± 0.03 | 1.49 ± 0.01 | 0.00 ± 0.00 | 1.20 | 0.12 | 0.16 | 35.55 ± 0.31 | 27.80 ± 0.24 | 37.07 ± 0.32 |

| 3 | 69.84 ± 0.12 | 7.08 ± 0.07 | 9.92 ± 0.01 | 1.49 ± 0.01 | 0.02 ± 0.03 | 1.22 | 0.23 | 0.17 | 38.44 ± 2.59 | 30.45 ± 2.05 | 39.37 ± 2.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Zhang, N.; Tian, C.; Yi, W.; Yuan, Q.; Fu, P.; Zhang, Y.; Li, Z. Effect of Accumulative Recycling of Aqueous Phase on the Properties of Hydrothermal Degradation of Dry Biomass and Bio-Crude Oil Formation. Energies 2021, 14, 285. https://doi.org/10.3390/en14020285

Yin S, Zhang N, Tian C, Yi W, Yuan Q, Fu P, Zhang Y, Li Z. Effect of Accumulative Recycling of Aqueous Phase on the Properties of Hydrothermal Degradation of Dry Biomass and Bio-Crude Oil Formation. Energies. 2021; 14(2):285. https://doi.org/10.3390/en14020285

Chicago/Turabian StyleYin, Siyuan, Nianze Zhang, Chunyan Tian, Weiming Yi, Qiaoxia Yuan, Peng Fu, Yuchun Zhang, and Zhiyu Li. 2021. "Effect of Accumulative Recycling of Aqueous Phase on the Properties of Hydrothermal Degradation of Dry Biomass and Bio-Crude Oil Formation" Energies 14, no. 2: 285. https://doi.org/10.3390/en14020285