Fault Propagation Inference Based on a Graph Neural Network for Steam Turbine Systems

Abstract

:1. Introduction

- (1)

- A graph is introduced for the first time to characterize the relationships between process variables and faults.

- (2)

- A hierarchical framework is, for the first time, established to model the fault propagation paths.

- (3)

- Score function is, for the first time, applied to evaluate the propagation paths quantitatively.

2. Problem Formulation

3. Preliminaries

4. Numerical Examples

5. Conclusion Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HP | High Pressure Casing |

| ESV | Emergency Shut Valve |

| CV | Control Valve |

| IP | Intermediate Pressure Casing |

| LP | Low Pressure Casing |

| RH | Reheater |

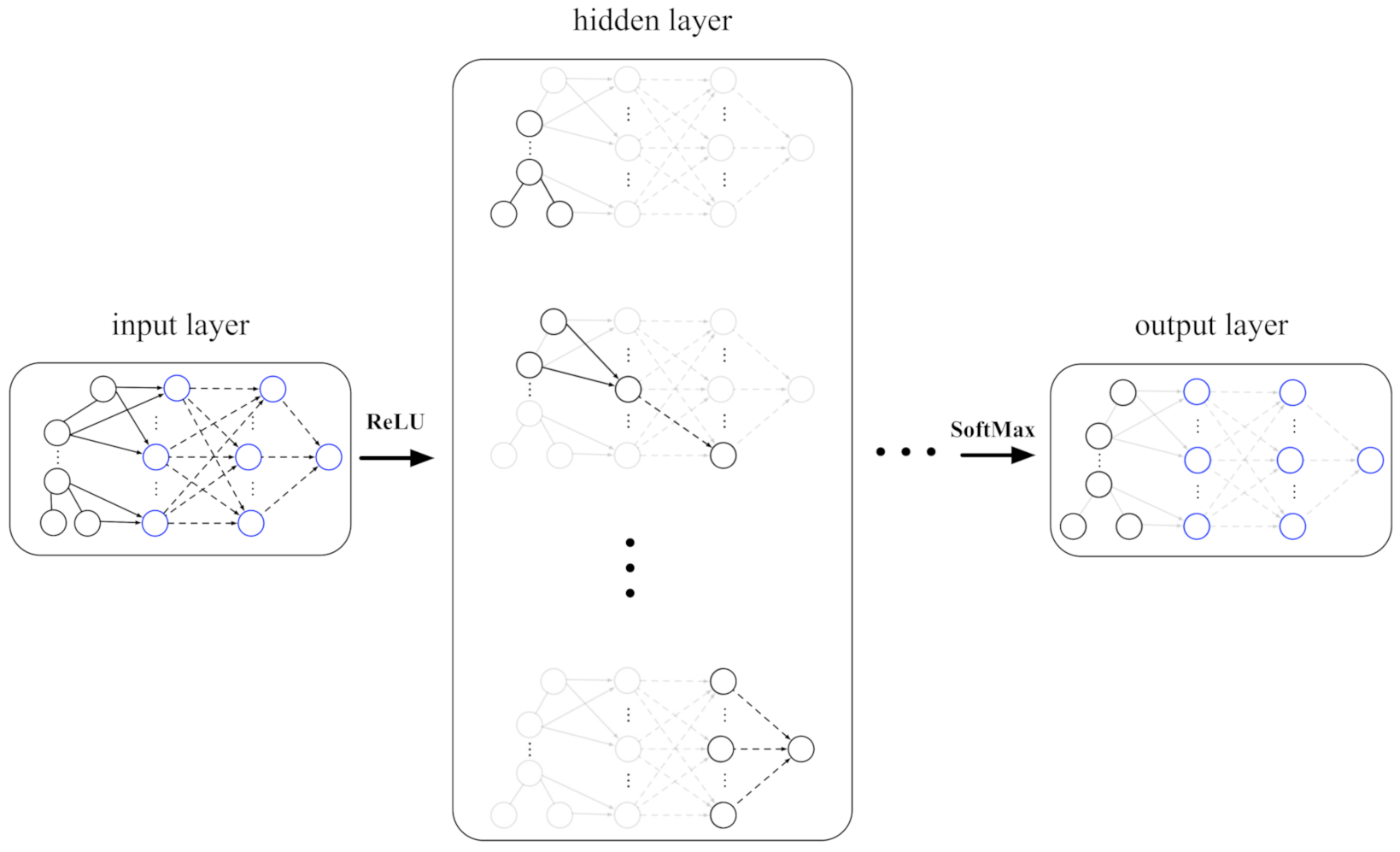

| MLP | multi-layer perceptron |

| PCA | principle component analysis |

References

- Yang, F.; Xiao, D. Progress in root cause and fault propagation analysis of large-scale industrial processes. J. Control Sci. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Dibowski, H.; Holub, O.; Rojícek, J. Knowledge-based fault propagation in building automation systems. In Proceedings of the 2016 International Conference on Systems Informatics, Modelling and Simulation (SIMS), Riga, Latvia, 1–3 June 2016; pp. 124–132. [Google Scholar]

- Pearl, J. Causality; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Bollen, K.A.; Long, J.S. Testing Structural Equation Models; Sage: New York, NY, USA, 1993; Volume 154. [Google Scholar]

- Robbins, M.W.; Fisher, T.J. Cross-correlation matrices for tests of independence and causality between two multivariate time series. J. Bus. Econ. Stat. 2015, 33, 459–473. [Google Scholar] [CrossRef]

- Friston, K.J.; Bastos, A.M.; Oswal, A.; van Wijk, B.; Richter, C.; Litvak, V. Granger causality revisited. NeuroImage 2014, 101, 796–808. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bahmani-Oskooee, M.; Chang, T.; Ranjbar, O. Asymmetric causality using frequency domain and time-frequency domain (wavelet) approaches. Econ. Model. 2016, 56, 66–78. [Google Scholar] [CrossRef]

- Murari, A.; Peluso, E.; Gelfusa, M.; Garzotti, L.; Frigione, D.; Lungaroni, M.; Pisano, F.; Gaudio, P.; Contributors, J. Application of transfer entropy to causality detection and synchronization experiments in tokamaks. Nucl. Fusion 2015, 56, 026006. [Google Scholar] [CrossRef]

- Vesely, W.E.; Goldberg, F.F.; Roberts, N.H.; Haasl, D.F. Fault Tree Handbook; Technical Report; Nuclear Regulatory Commission: Washington, DC, USA, 1981. [Google Scholar]

- McDermott, R.; Mikulak, R.J.; Beauregard, M. The Basics of FMEA; SteinerBooks: Hudson, NY, USA, 1996. [Google Scholar]

- Ruijters, E.; Stoelinga, M. Fault tree analysis: A survey of the state-of-the-art in modeling, analysis and tools. Comput. Sci. Rev. 2015, 15, 29–62. [Google Scholar] [CrossRef] [Green Version]

- Kabir, S. An overview of fault tree analysis and its application in model based dependability analysis. Expert Syst. Appl. 2017, 77, 114–135. [Google Scholar] [CrossRef] [Green Version]

- Feili, H.R.; Akar, N.; Lotfizadeh, H.; Bairampour, M.; Nasiri, S. Risk analysis of geothermal power plants using Failure Modes and Effects Analysis (FMEA) technique. Energy Convers. Manag. 2013, 72, 69–76. [Google Scholar] [CrossRef]

- Safari, H.; Faraji, Z.; Majidian, S. Identifying and evaluating enterprise architecture risks using FMEA and fuzzy VIKOR. J. Intell. Manuf. 2016, 27, 475–486. [Google Scholar] [CrossRef]

- Kumru, M.; Kumru, P.Y. Fuzzy FMEA application to improve purchasing process in a public hospital. Appl. Soft Comput. 2013, 13, 721–733. [Google Scholar] [CrossRef]

- Andrews, J.; Moss, T. Risk and Reliability Assessment; John Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Meshkat, L. Probabilistic risk assessment for decision making during spacecraft operations. In Proceedings of the 2009 Annual Reliability and Maintainability Symposium, Forth Worth, TX, USA, 26–29 January 2009; pp. 140–145. [Google Scholar]

- Darbra, R.; Palacios, A.; Casal, J. Domino effect in chemical accidents: Main features and accident sequences. J. Hazard. Mater. 2010, 183, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Shah, S.; Xiao, D. Signed directed graph based modeling and its validation from process knowledge and process data. Int. J. Appl. Math. Comput. Sci. 2012, 22, 41–53. [Google Scholar] [CrossRef] [Green Version]

- Gawthrop, P.J.; Bevan, G.P. Bond-graph modeling. IEEE Control Syst. Mag. 2007, 27, 24–45. [Google Scholar]

- Zhang, Q.; Geng, S. Dynamic uncertain causality graph applied to dynamic fault diagnoses of large and complex systems. IEEE Trans. Reliab. 2015, 64, 910–927. [Google Scholar] [CrossRef]

- Liu, Y.K.; Wu, G.H.; Xie, C.L.; Duan, Z.Y.; Peng, M.J.; Li, M.K. A fault diagnosis method based on signed directed graph and matrix for nuclear power plants. Nucl. Eng. Des. 2016, 297, 166–174. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, L.; Tong, J. Online Fault Diagnosis of Nuclear Power Plants Using Signed Directed Graph and Fuzzy Theory. In Proceedings of the 2017 25th International Conference on Nuclear Engineering, Shanghai, China, 2–6 July 2017; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2017. [Google Scholar]

- Wu, G.; Liu, Y.; Peng, M.; Duan, Z.; Xie, C. Research on fault diagnosis based on SDG-QTA in nuclear power plant. At. Energy Sci. Technol. 2016, 50, 1467–1473. [Google Scholar]

- Yang, Z.; Zhang, C.; Liu, M.Z.; Yu, Y.; Qiao, L.; Peng, X. Fault propagation characteristics analysis for large-scale electronic system by hierarchical signed directed graph. In Proceedings of the 2015 IEEE Autotestcon, National Harbor, MD, USA, 2–5 November 2015; pp. 219–226. [Google Scholar]

- Smaili, R.; El Harabi, R.; Abdelkrim, M. Design of fault monitoring framework for multi-energy systems using Signed Directed Graph. IFAC-PapersOnLine 2017, 50, 15734–15739. [Google Scholar] [CrossRef]

- Borutzky, W. Bond Graphs for Modelling, Control and Fault Diagnosis of Engineering Systems; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Dong, C.; Zhao, Y.; Zhang, Q. Assessing the influence of an individual event in complex fault spreading network based on dynamic uncertain causality graph. IEEE Trans. Neural Netw. Learn. Syst. 2016, 27, 1615–1630. [Google Scholar] [CrossRef]

- Dong, J.; Wang, M.; Zhang, X.; Ma, L.; Peng, K. Joint data-driven fault diagnosis integrating causality graph with statistical process monitoring for complex industrial processes. IEEE Access 2017, 5, 25217–25225. [Google Scholar] [CrossRef]

- Scarselli, F.; Gori, M.; Tsoi, A.C.; Hagenbuchner, M.; Monfardini, G. The graph neural network model. IEEE Trans. Neural Networks 2008, 20, 61–80. [Google Scholar] [CrossRef] [Green Version]

- Kipf, T.N.; Welling, M. Semi-supervised classification with graph convolutional networks. arXiv 2016, arXiv:1609.02907. [Google Scholar]

- Kipf, T.N.; Welling, M. Variational graph auto-encoders. arXiv 2016, arXiv:1611.07308. [Google Scholar]

- Battaglia, P.; Pascanu, R.; Lai, M.; Rezende, D.J.; Kavukcuoglu, K. Interaction networks for learning about objects, relations and physics. In Proceedings of the Advances in Neural Information Processing Systems, Barcelona, Spain, 5–10 December 2016; pp. 4502–4510. [Google Scholar]

- Duvenaud, D.K.; Maclaurin, D.; Iparraguirre, J.; Bombarell, R.; Hirzel, T.; Aspuru-Guzik, A.; Adams, R.P. Convolutional networks on graphs for learning molecular fingerprints. In Proceedings of the Advances in Neural Information Processing Systems, Montreal, QC, Canada, 7–12 December 2015; pp. 2224–2232. [Google Scholar]

- Wu, Z.; Pan, S.; Chen, F.; Long, G.; Zhang, C.; Yu, P.S. A comprehensive survey on graph neural networks. arXiv 2019, arXiv:1901.00596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, J.; Cui, G.; Zhang, Z.; Yang, C.; Liu, Z.; Wang, L.; Li, C.; Sun, M. Graph neural networks: A review of methods and applications. arXiv 2018, arXiv:1812.08434. [Google Scholar]

- Kurtoglu, T.; Tumer, I.Y. A graph-based fault identification and propagation framework for functional design of complex systems. J. Mech. Des. 2008, 130. [Google Scholar] [CrossRef]

- Schlichtkrull, M.; Kipf, T.N.; Bloem, P.; Van Den Berg, R.; Titov, I.; Welling, M. Modeling relational data with graph convolutional networks. In Proceedings of the European Semantic Web Conference, Crete, Greece, 3–7 June 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 593–607. [Google Scholar]

- Yang, B.; Yih, W.t.; He, X.; Gao, J.; Deng, L. Embedding entities and relations for learning and inference in knowledge bases. arXiv 2014, arXiv:1412.6575. [Google Scholar]

- Golinkin, S.; Lipski, M.; Luker, J.; Al-Jaafari, R. Modernization of Steam Turbine Diaphragms for the Saudi Aramco Gas Plants. In Proceedings of the Middle East Turbomachinery Symposia, Doha, Qatar, Texas A&M Engineering Experiment Station, College Station, TX, USA, 13–16 February 2013. Turbomachinery Laboratory. [Google Scholar]

- Kirk, R.; Gao, R. Analysis of rotordynamic forces for high inlet pre-swirl rate labyrinth seals. In Proceedings of the 10th International Conference on Vibrations in Rotating Machinery, London, UK, 11–13 September 2012; Woodhead Publishing: Cambridge, UK, 2012; pp. 467–476. [Google Scholar] [CrossRef]

- Xu, J. Effects of Operating Damage of Labyrinth Seal on Seal Leakage and Wheelspace Hot Gas Ingress. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2007. [Google Scholar]

- Xia, B. On Modeling and Safety Analysis of Large Size Ultra Supercritial Steam Turbines. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2015. [Google Scholar]

| Path | HP Interstage Gland | HP Shaft Gland | HP Steam Leakage |

|---|---|---|---|

| →HP Steam Leakage | →HP Steam Leakage | →Steam Consumption Increase | |

| Accuracy/% | 88.46 | 86.96 | 97.91 |

| Miss alarm rate/% | 11.54 | 13.04 | 2.09 |

| False alarm rate/% | 13.04 | 11.54 | 2.08 |

| Path | HP Interstage Gland | HP Shaft Gland | HP Steam Leakage |

|---|---|---|---|

| →HP Steam Leakage | →HP Steam Leakage | →Steam Consumption Increase | |

| Accuracy/% | 97.62 | 97.62 | 99.49 |

| Miss alarm rate/% | 2.38 | 0 | 0.51 |

| False alarm rate/% | 0 | 2.38 | 3.26 |

| Path | lP Interstage Gland | LP Shaft Gland | LP Steam Leakage |

|---|---|---|---|

| →LP Steam Leakage | →LP Steam Leakage | →Steam Consumption Increase | |

| Accuracy/% | 96.08 | 96.08 | 99.47 |

| Miss alarm rate/% | 0 | 3.92 | 0.53 |

| False alarm rate/% | 3.92 | 0 | 1.01 |

| Fault Root Cause of Steam Consumption Increasing | HP Interstage Gland | HP Shaft Gland | IP Interstage Gland | IP Shaft Gland | LP Interstage Gland | LP Shaft Gland |

|---|---|---|---|---|---|---|

| HP steam leakage→ Steam consumption increasing | 0.87 | 0.92 | 0.10 | 0.10 | 0.11 | 0.01 |

| IP steam leakage→ Steam consumption increasing | 0.08 | 0.04 | 0.88 | 0.85 | 0.12 | 0.05 |

| LP steam leakage→ Steam consumption increasing | 0.15 | 0.04 | 0.02 | 0.05 | 0.77 | 0.94 |

| Interstage gland→ steam leakage | 0.98 | 0.16 | 0.93 | 0.01 | 0.89 | 0.17 |

| Shaft gland→ steam leakage | 0.02 | 0.84 | 0.07 | 0.99 | 0.11 | 0.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-J.; Hu, L.-S. Fault Propagation Inference Based on a Graph Neural Network for Steam Turbine Systems. Energies 2021, 14, 309. https://doi.org/10.3390/en14020309

Zhang Y-J, Hu L-S. Fault Propagation Inference Based on a Graph Neural Network for Steam Turbine Systems. Energies. 2021; 14(2):309. https://doi.org/10.3390/en14020309

Chicago/Turabian StyleZhang, Yi-Jing, and Li-Sheng Hu. 2021. "Fault Propagation Inference Based on a Graph Neural Network for Steam Turbine Systems" Energies 14, no. 2: 309. https://doi.org/10.3390/en14020309