A Study on the Numerical Performances of Diffuse Interface Methods for Simulation of Melting and Their Practical Consequences

Abstract

:1. Introduction

2. Problem Statement

2.1. Flow Modeling

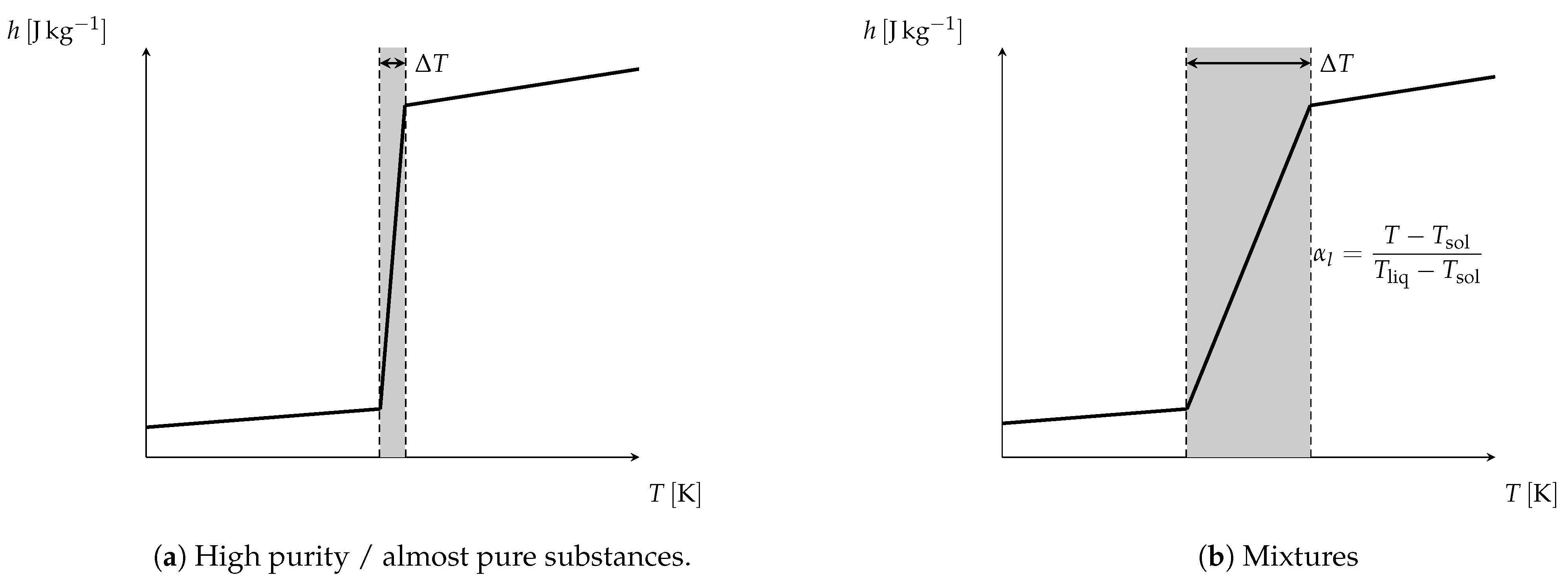

2.2. Thermal Modeling

2.3. Numerical Implementation

2.4. Threshold and Evaluation

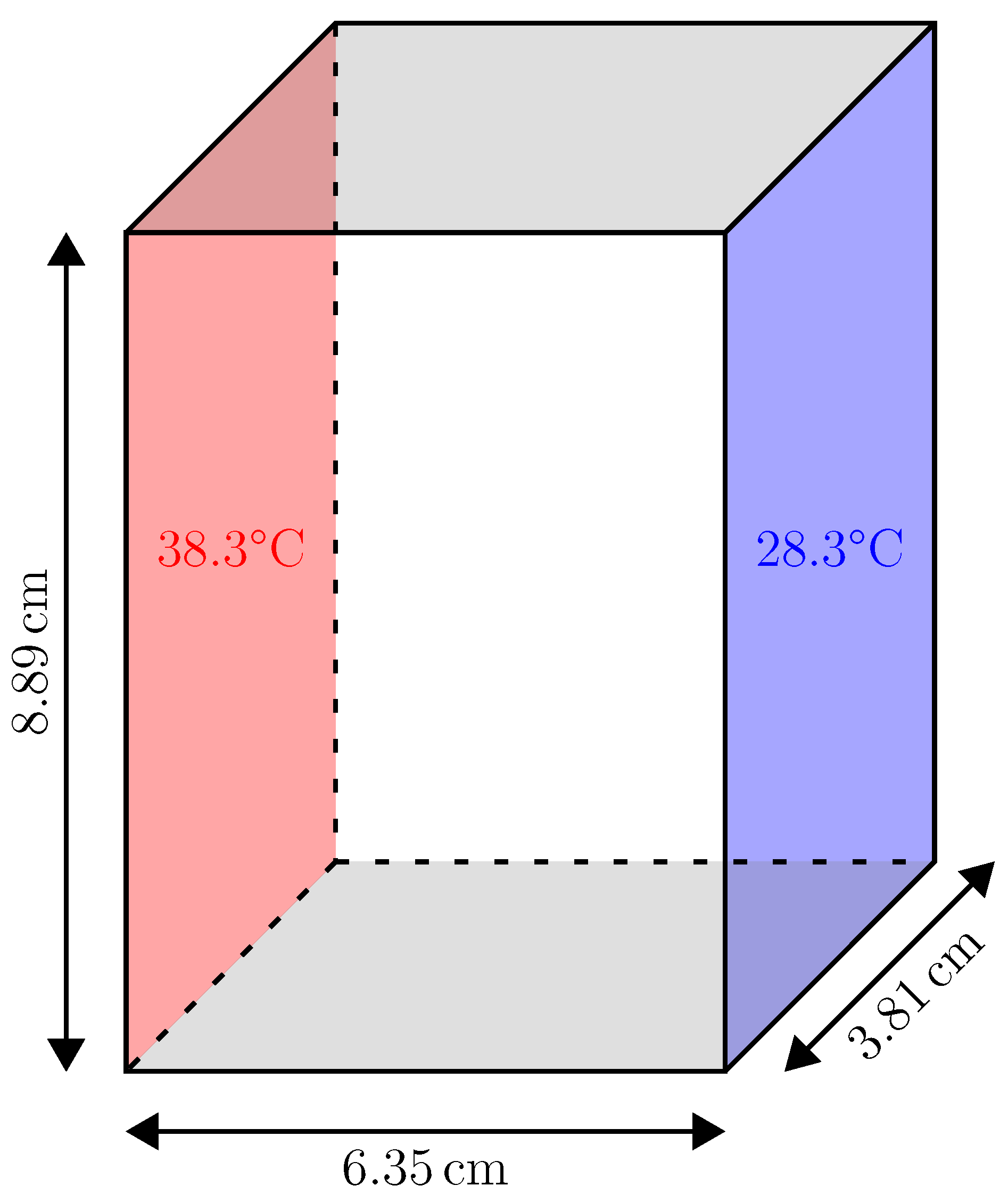

3. Test Case

4. Results

4.1. Summary of the Liquid Fraction Evaluation

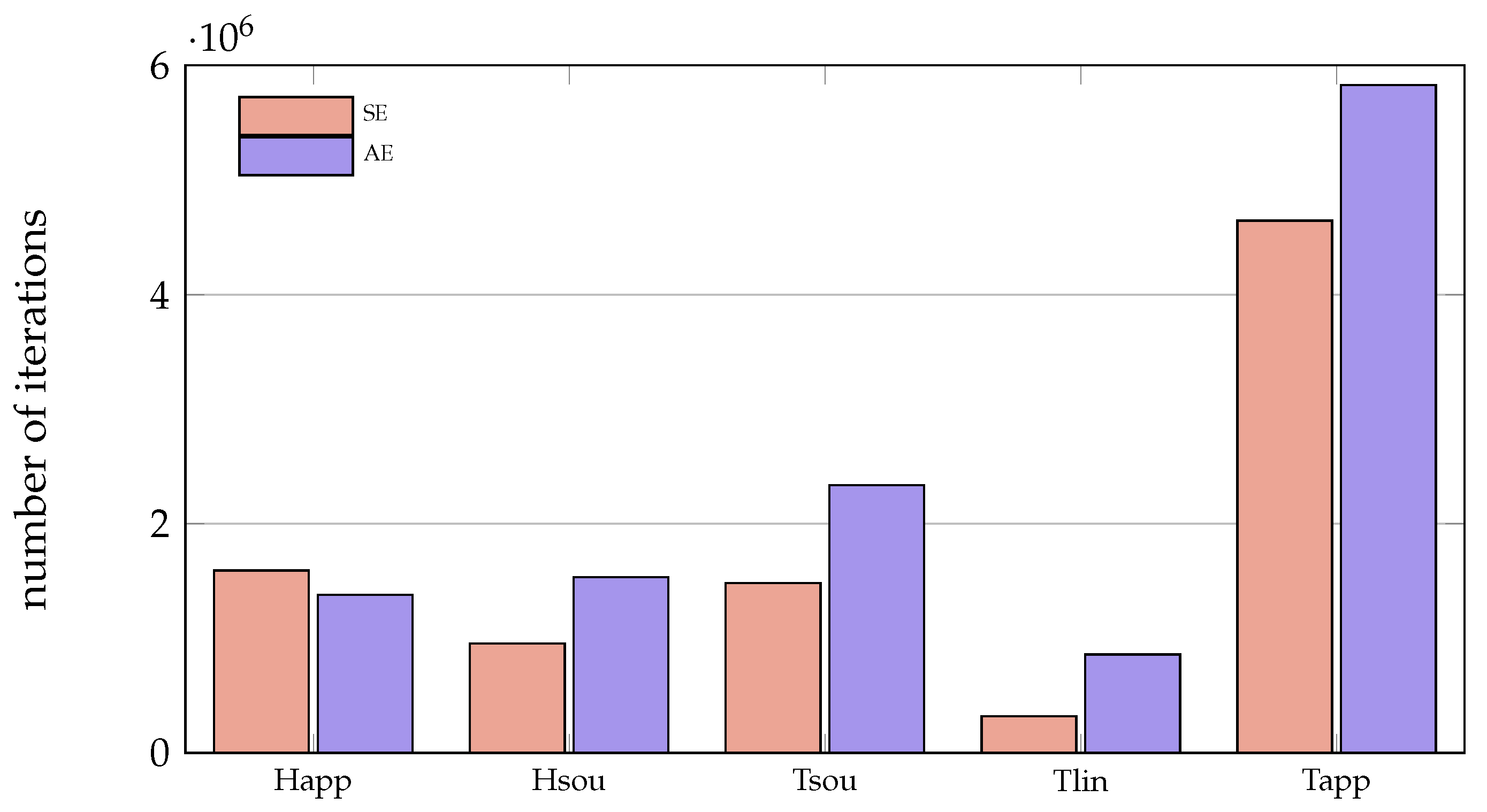

4.2. Total Iterations

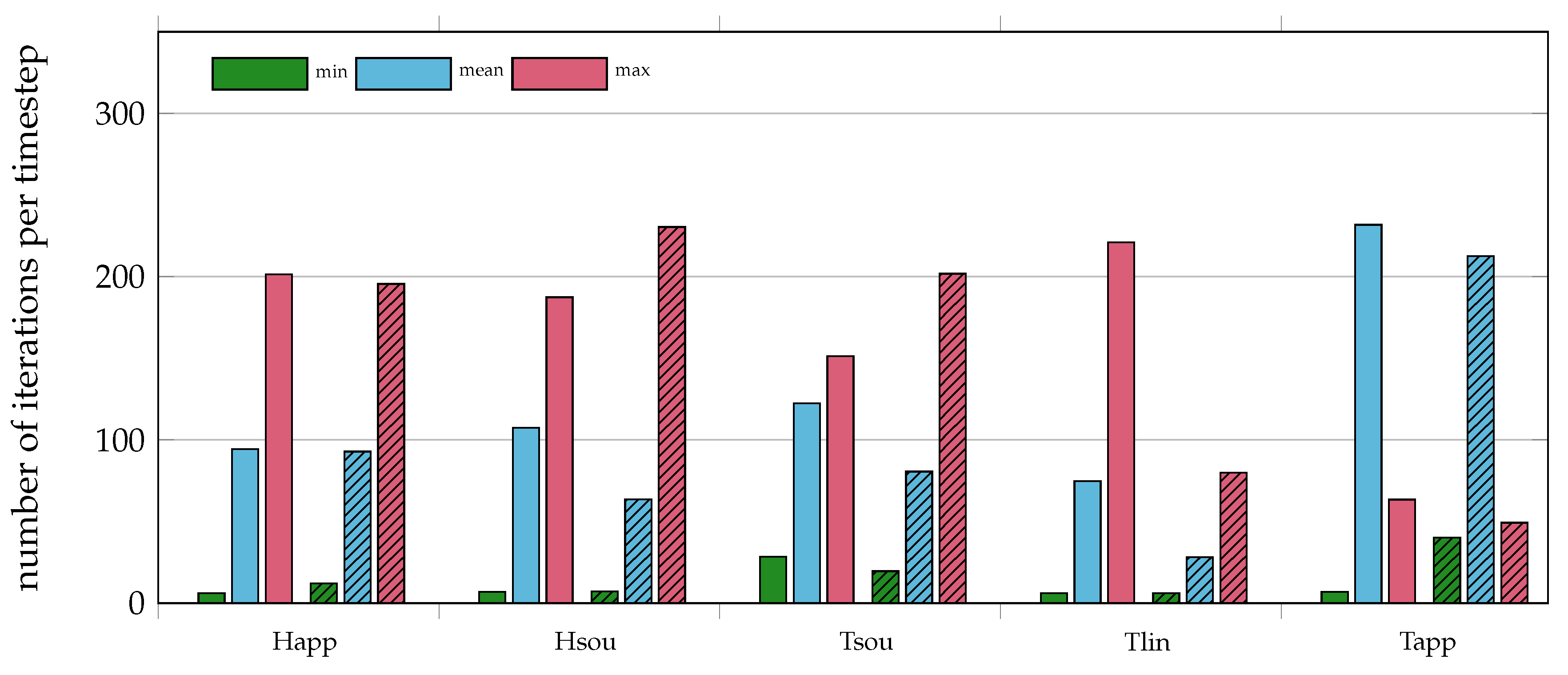

- On average, SE needs fewer iterations than AE except for Happarent where AE needs slightly fewer than SE.

- The differences between the minimum and the maximum number of iterations within one solver, but for different parameter combinations are between one and two orders of magnitude.

- For SE, the ranking is in ascending order: Tlinear, Hsource, Tsource, Happarent, Tapparentlinear.

- For AE, the ranking is in ascending order: Tlinear, Happarent, Hsource, Tsource, Tapparentlinear.

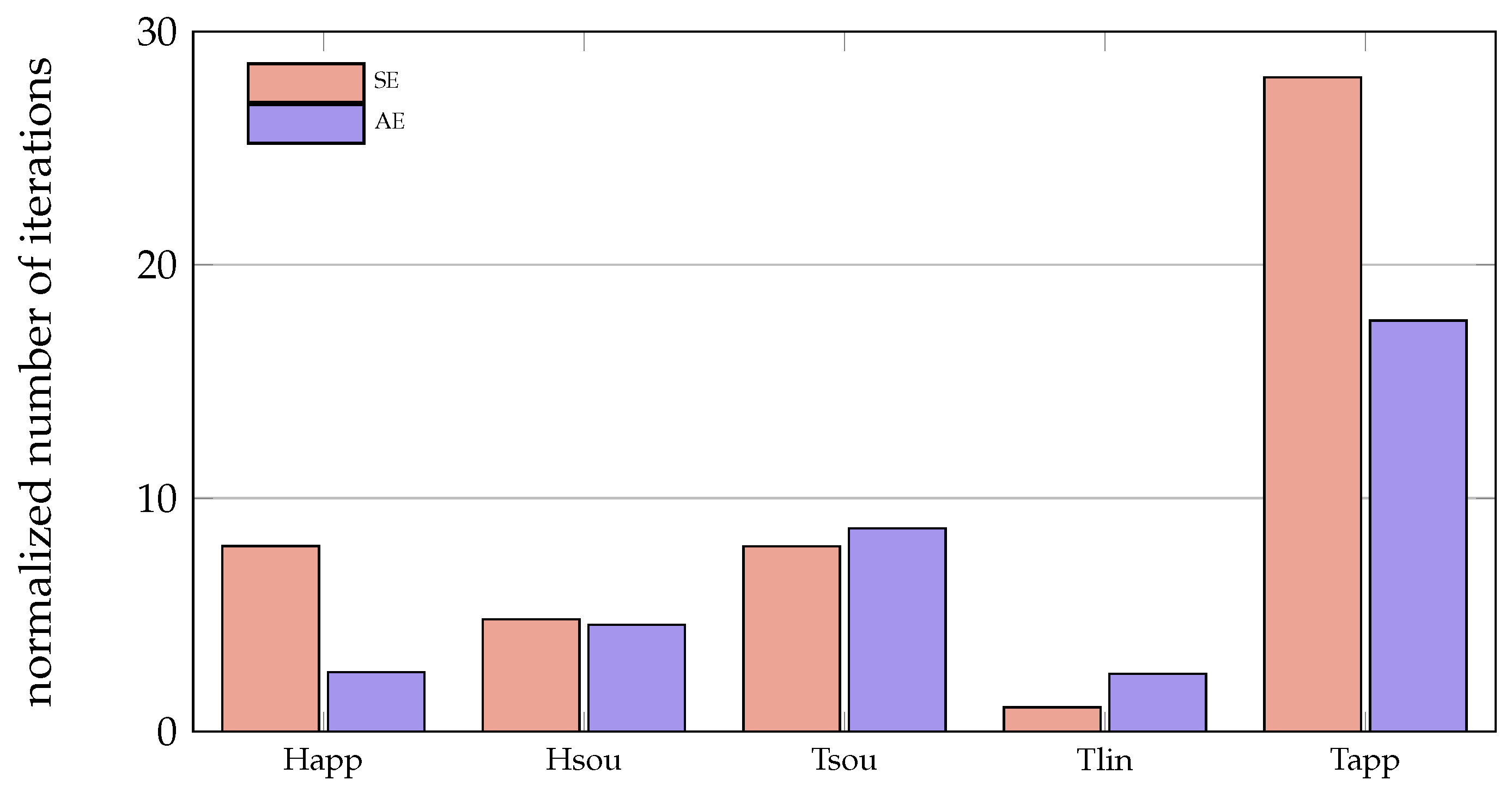

4.3. Iterations per Time Step

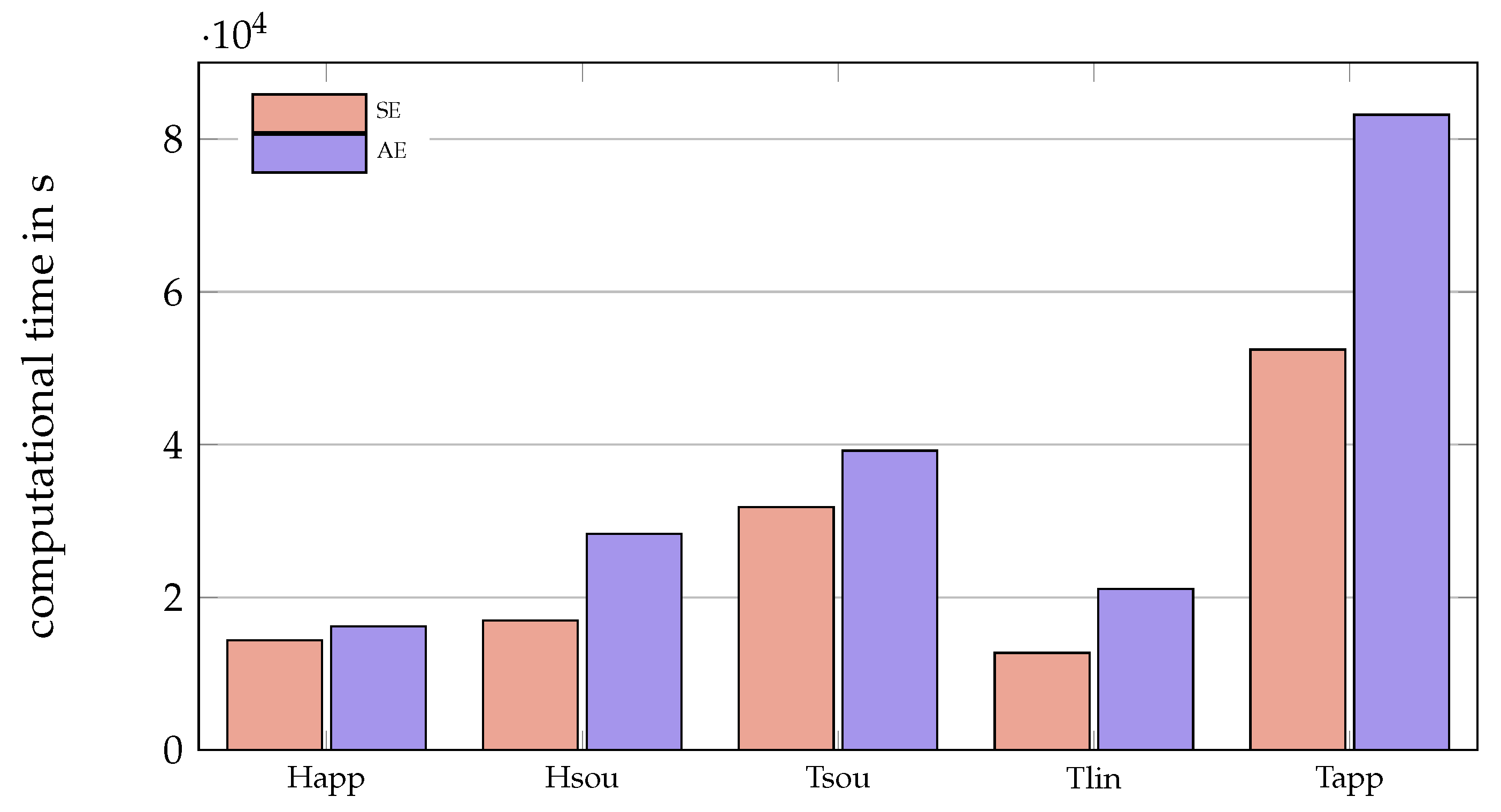

4.4. Computational Time

4.5. Computational Time per Iteration

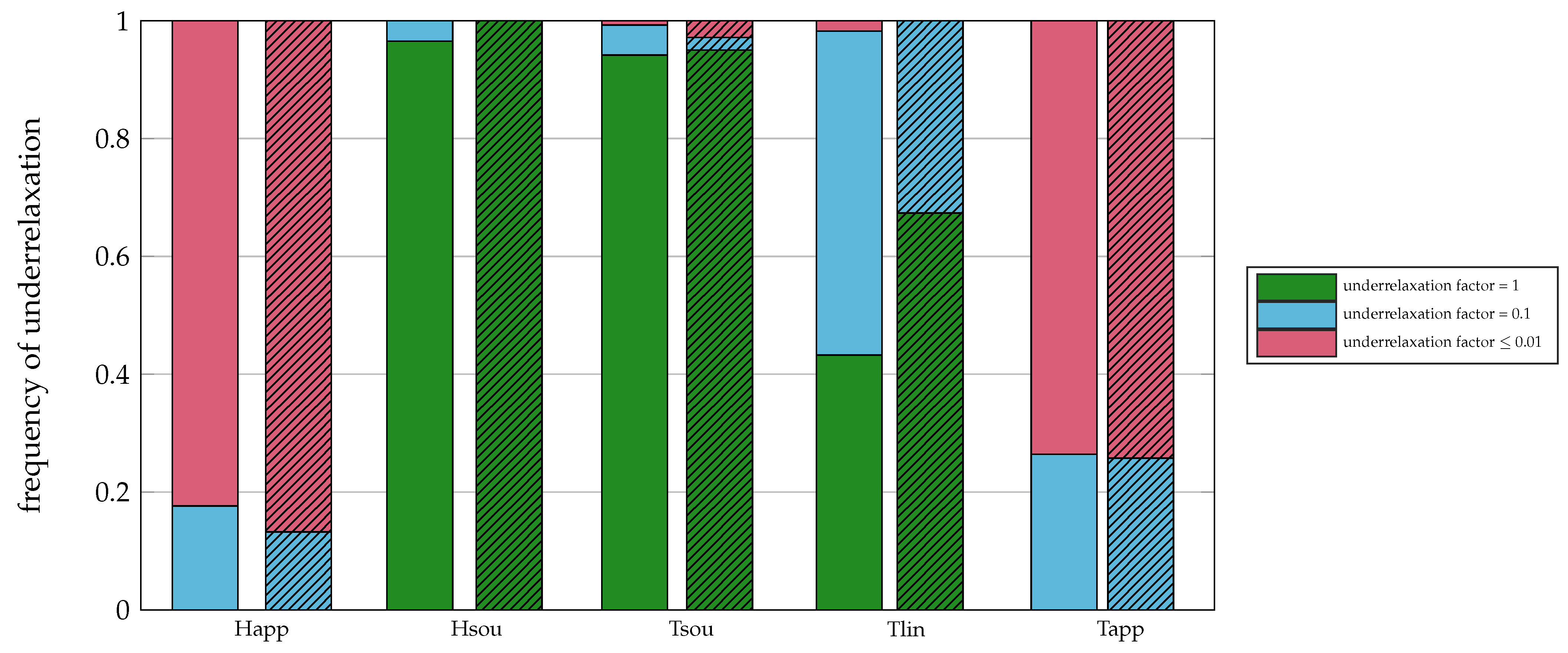

4.6. Underrelaxation

5. Discussion

5.1. General Results

5.2. Solver Specific Analysis

- Happarent was resilient for AE as well as SE for a broad range of parameters. Although it needed the strongest underrelaxation, it required one of the fewest iterations for AE and was in midfield of needed iterations for SE. The SE formulation of Happarent is the only solver not relying on the solving of a matrix equation system for the energy equation—resulting in the shortest mean simulation time per iteration. The implementation of Happarent is very simple so that it is the easiest solver to program.

- Hsource was the most resilient solver for the tested conditions; for both formulations, no simulations gave results outside the chosen thresholds of a final liquid fraction from 60% to 70%. It is also the solver that was the least dependent on underrelaxation—only the AE formulation needs underrelaxation in very few cases. In terms of simulation time and required iterations, Hsource is within the average of the resilient solvers. The implementation of Hsource is moderately complex.

- Tsource has proven to be resilient for a wide range of parameters and only in very few cases underrelaxation was needed. Tsource is within the average of the resilient solvers concerning the simulation time and required iterations. In addition, the implementation of Tsource is moderately complex.

- Tlinear AE was resilient and Tlinear SE was the most resilient together with Hsource—no simulation gave results that were outside the chosen threshold of a final liquid fraction from 60% to 70%. It should be mentioned that a parallel study [30] indicates that an additional linearization of the convection term in the case of the AE formulation would increase its resilience. Underrelaxation was necessary in roughly 50% of the cases. Tlinear SE needed clearly the fewest iterations of all solvers followed by Tlinear AE. The fact that Tlinear needs fewer iterations than other solvers confirms results in the literature [26]. On the other hand, the calculation time for one iteration was long compared to the other solvers. The implementation of Tlinear is the most complex one of all solvers tested.

- Tapparentlinear in its present implementation (using the approach of Morgan et al. [25] with additional iterative correction of the apparent heat capacity) performed by far the worst and cannot be recommended. It was found that the apparent heat capacity correction can be trapped in between several points for this formulation [14]. However, it should be mentioned that many different apparent heat capacity methods exist and it is conceivable that others work better.

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Latin letters | |

| porosity function () | |

| c | specific capacity () |

| C | Darcy constant () |

| g | gravity acceleration () |

| h | specific enthalpy () |

| L | latent heat () |

| P | pressure (}) |

| q | small Darcy constant (–) |

| T | temperature (}) |

| velocity () | |

| t | time (s) |

| Greek letters | |

| volume fraction (–) | |

| volumetric coefficient of thermal expansion () | |

| tolerance (–) | |

| thermal conductivity () | |

| density () | |

| dynamic viscosity () | |

| kinematic viscosity () | |

| Exponents and subscripts | |

| app | apparent |

| l | liquid |

| liq | liquidus |

| M | melting |

| ref | reference |

| s | solid |

| sol | solidus |

| Acronyms | |

| AE | all enthalpy convection |

| CFL | Courant–Friedrichs–Lewy |

| DIM | diffuse interface method |

| FGM | fixed grid method |

| Happ | Happarent |

| Hsou | Hsource |

| SE | sensible enthalpy convection |

| Tapp | Tapparentlinear |

| Tlin | Tlinear |

| Tsou | Tsource |

References

- Stadler, I.; Hauer, A.; Bauer, T. Thermal Energy Storage. In Handbook of Energy Storage; Springer Vieweg: Berlin/Heidelberg, Germany, 2019; pp. 563–609. [Google Scholar]

- Fukusako, S.; Seki, N. Fundamental aspects of analytical and numerical methods on freezing and melting heat-transfer problems. In Annual Review of Heat Transfer; Begell: New York, NY, USA, 1987; Volume 1, pp. 351–402. [Google Scholar]

- Basu, B.; Date, A. Numerical modelling of melting and solidification problems—A review. Sadhana 1988, 13, 169–213. [Google Scholar] [CrossRef]

- Voller, V.R.; Swaminathan, C.R.; Thomas, B.G. Fixed grid techniques for phase change problems: A review. Int. J. Numer. Methods Eng. 1990, 30, 875–898. [Google Scholar] [CrossRef]

- Hu, H.; Argyropoulos, S.A. Mathematical modelling of solidification and melting: A review. Model. Simul. Mater. Sci. Eng. 1996, 4, 317. [Google Scholar] [CrossRef] [Green Version]

- König-Haagen, A.; Franquet, E.; Pernot, E.; Brüggemann, D. A comprehensive benchmark of fixed-grid methods for the modeling of melting. Int. J. Therm. Sci. 2017, 118, 69–103. [Google Scholar] [CrossRef]

- Gobin, D.; Le Quéré, P. Melting from an isothermal vertical wall. Synthesis of a numerical comparison exercise. Comput. Assist. Mech. Eng. Sci. 2000, 7, 289–306. [Google Scholar]

- Combeau, H.; Bellet, M.; Fautrelle, Y.; Gobin, D.; Arquis, E.; Budenkova, O.; Dussoubs, B.; Terrail, Y.D.; Kumar, A.; Gandin, C.A.; et al. Analysis of a numerical benchmark for columnar solidification of binary alloys. IOP Conf. Ser. Mater. Sci. Eng. 2012, 33, 012086. [Google Scholar] [CrossRef]

- Lacroix, M.; Voller, V.R. Finite difference solutions of solidification phase change problems: Transformed versus fixed grids. Numer. Heat Transf. Part B Fundam. 1990, 17, 25–41. [Google Scholar] [CrossRef]

- Viswanath, R.; Jaluria, Y. A comparison of different solution methodologies for melting and solidification problems in enclosures. Numer. Heat Transf. Part B Fundam. 1993, 24, 77–105. [Google Scholar] [CrossRef]

- Bertrand, O.; Binet, B.; Combeau, H.; Couturier, S.; Delannoy, Y.; Gobin, D.; Lacroix, M.; Quéré, P.L.; Médale, M.; Mencinger, J.; et al. Melting driven by natural convection A comparison exercise: First results. Int. J. Therm. Sci. 1999, 38, 5–26. [Google Scholar] [CrossRef]

- Ahmad, N.; Rappaz, J.; Desbiolles, J.L.; Jalanti, T.; Rappaz, M.; Combeau, H.; Lesoult, G.; Stomp, C. Numerical simulation of macrosegregation: A comparison between finite volume method and finite element method predictions and a confrontation with experiments. Metall. Mater. Trans. A 1998, 29, 617–630. [Google Scholar] [CrossRef]

- Kosec, G.; Založnik, M.; Šarler, B.; Combeau, H. A Meshless Approach Towards Solution of Macrosegregation Phenomena. Comput. Mater. Contin. 2011, 22, 169–195. [Google Scholar]

- König-Haagen, A.; Franquet, E.; Faden, M.; Brüggemann, D. Influence of the convective energy formulation for melting problems with enthalpy methods. Int. J. Therm. Sci. 2020, 106477. [Google Scholar] [CrossRef]

- Swaminathan, C.R.; Voller, V.R. On the enthalpy method. Int. J. Numer. Methods Heat Fluid Flow 1993, 3, 233–244. [Google Scholar] [CrossRef]

- Pointner, H.; de Gracia, A.; Vogel, J.; Tay, N.; Liu, M.; Johnson, M.; Cabeza, L.F. Computational efficiency in numerical modeling of high temperature latent heat storage: Comparison of selected software tools based on experimental data. Appl. Energy 2016, 161, 337–348. [Google Scholar] [CrossRef] [Green Version]

- Mehrabian, R.; Keane, M.; Flemings, M. Interdendritic fluid flow and macrosegregation; influence of gravity. Metall. Mater. Trans. A 1970, 1, 1209–1220. [Google Scholar] [CrossRef]

- Bennon, W.; Incropera, F. A continuum model for momentum, heat and species transport in binary solid-liquid phase change systems—I. Model formulation. Int. J. Heat Mass Transf. 1987, 30, 2161–2170. [Google Scholar] [CrossRef]

- Voller, V.R.; Cross, M.; Markatos, N.C. An enthalpy method for convection/diffusion phase change. Int. J. Numer. Methods Eng. 1987, 24, 271–284. [Google Scholar] [CrossRef]

- Voller, V.R.; Prakash, C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Brent, A.D.; Voller, V.R.; Reid, K.J. Enthalpy-porosity technique for modeling convection-diffusion phase change: Application to the melting of a pure metal. Numer. Heat Transf. Part A Appl. 1988, 13, 297–318. [Google Scholar]

- Eyres, N.R.; Hartree, D.R.; Ingham, J.; Jackson, R.; Sarjant, R.J.; Wagstaff, J.B. The Calculation of Variable Heat Flow in Solids. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1946, 240, 1–57. [Google Scholar]

- Rose, M.E. A Method for Calculating Solutions of Parabolic Equations with a Free Boundary. Math. Comput. 1960, 14, 249–256. [Google Scholar] [CrossRef]

- Cao, Y.; Faghri, A.; Chang, W. A numerical analysis of Stefan problems for generalized multi-dimensional phase-change structures using the enthalpy transforming model. Int. J. Heat Mass Transf. 1989, 32, 1289–1298. [Google Scholar] [CrossRef]

- Morgan, K.; Lewis, R.W.; Zienkiewicz, O.C. An improved algrorithm for heat conduction problems with phase change. Int. J. Numer. Methods Eng. 1978, 12, 1191–1195. [Google Scholar] [CrossRef]

- Swaminathan, C.; Voller, V. A general enthalpy method for modeling solidification processes. Metall. Trans. B 1992, 23, 651–664. [Google Scholar] [CrossRef]

- Rolph, W.D.; Bathe, K.J. An efficient algorithm for analysis of nonlinear heat transfer with phase changes. Int. J. Numer. Methods Eng. 1982, 18, 119–134. [Google Scholar] [CrossRef] [Green Version]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Gau, C.; Viskanta, R. Melting and solidification of a pure metal on a vertical wall. ASME J. Heat Transf. 1986, 108, 174–181. [Google Scholar] [CrossRef]

- Faden, M.; König-Haagen, A.; Brüggemann, D. An Optimum Enthalpy Approach for Melting and Solidification with Volume Change. Energies 2019, 12, 868. [Google Scholar] [CrossRef] [Green Version]

| Property | Value | Unit |

|---|---|---|

| 6093 | kg m−3 | |

| 6093 | kg m−3 | |

| 381.5 | J K−1 kg−1 | |

| 381.5 | J K−1 kg−1 | |

| 32 | W K−1 m−1 | |

| 32 | W K−1 m−1 | |

| 29.78 | °C | |

| L | 80 160 | J kg−1 |

| kg m−1 s−1 | ||

| m2 s−1 | ||

| K−1 |

| Variable | Remarks | Variation | Unit |

|---|---|---|---|

| Tlinear, Tapparentlinear | |||

| Tsource | |||

| Happarent, Hsource | |||

| number of cells | 50 × 50, 100 × 100, 150 × 150, 200 × 200 | − | |

| time step | 0.1, 1 | ||

| 1, 4, 8 | − | ||

| tolerance for the energy equation | , | − | |

| formulation of the convective term | AE, SE | − |

| Parameter | AE | SE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variation | Happ | Hsou | Tsou | Tlin | Tapp | Happ | Hsou | Tsou | Tlin | Tapp | |

| 50 × 50 | 1.000 | 1.000 | 1.000 | 1.000 | 0.306 | 1.000 | 1.000 | 1.000 | 1.000 | 0.597 | |

| 100 × 100 | 1.000 | 1.000 | 1.000 | 1.000 | 0.375 | 1.000 | 1.000 | 1.000 | 1.000 | 0.569 | |

| 150 × 150 | 1.000 | 1.000 | 0.944 | 0.972 | 0.347 | 1.000 | 1.000 | 0.972 | 1.000 | 0.431 | |

| 200 × 200 | 0.778 | 1.000 | 0.861 | 0.944 | 0.181 | 0.778 | 1.000 | 0.917 | 1.000 | 0.236 | |

| 1 s | 0.889 | 1.000 | 0.931 | 0.972 | 0.264 | 0.889 | 1.000 | 0.944 | 1.000 | 0.403 | |

| 0.1 s | 1.000 | 1.000 | 0.972 | 0.986 | 0.340 | 1.000 | 1.000 | 1.000 | 1.000 | 0.514 | |

| 0.944 | 1.000 | 0.917 | 0.958 | 0.257 | 0.944 | 1.000 | 0.944 | 1.000 | 0.396 | ||

| 0.944 | 1.000 | 0.986 | 1.000 | 0.347 | 0.944 | 1.000 | 1.000 | 1.000 | 0.521 | ||

| CFL | 1 | 1.000 | 1.000 | 1.000 | 1.000 | 0.438 | 1.000 | 1.000 | 1.000 | 1.000 | 0.542 |

| 4 | 0.917 | 1.000 | 1.000 | 0.969 | 0.250 | 0.917 | 1.000 | 1.000 | 1.000 | 0.427 | |

| 8 | 0.917 | 1.000 | 0.854 | 0.969 | 0.219 | 0.917 | 1.000 | 0.917 | 1.000 | 0.406 | |

| 2 K | 1.000 | 1.000 | 0.958 | 1.000 | 0.688 | 1.000 | 1.000 | 0.958 | 1.000 | 0.708 | |

| 1 K | - | - | - | 1.000 | 0.521 | - | - | - | 1.000 | 0.458 | |

| 0.5 K | - | - | - | 1.000 | 0.521 | - | - | - | 1.000 | 0.604 | |

| 0.2 K | 0.917 | 1.000 | 0.958 | 1.000 | 0.083 | 0.917 | 1.000 | 0.979 | 1.000 | 0.646 | |

| 0.1 K | - | - | - | 1.000 | 0.000 | - | - | - | 1.000 | 0.333 | |

| 0 K | 0.917 | 1.000 | 0.938 | 0.875 | 0.000 | 0.917 | 1.000 | 0.979 | 1.000 | 0.000 | |

| Parameter | AE | SE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variation | Happ | Hsou | Tsou | Tlin | Tapp | Happ | Hsou | Tsou | Tlin | Tapp | |

| 50 × 50 | 1.878 | 2.418 | 4.262 | 1.638 | 32.011 | 2.897 | 2.403 | 3.745 | 1.067 | 27.470 | |

| 100 × 100 | 2.936 | 3.968 | 8.191 | 2.808 | 10.977 | 6.360 | 4.034 | 6.518 | 1.048 | 27.007 | |

| 150 × 150 | 2.558 | 6.532 | 12.141 | 3.527 | 9.497 | 12.228 | 6.005 | 9.509 | 1.016 | 23.352 | |

| 200 × 200 | 2.789 | 5.401 | 10.372 | 1.708 | 16.653 | 10.583 | 6.808 | 12.049 | 1.012 | 30.389 | |

| 1 s | 2.596 | 4.018 | 7.152 | 1.966 | 14.728 | 8.808 | 4.010 | 6.782 | 1.069 | 17.906 | |

| 0.1 s | 2.484 | 5.141 | 10.137 | 2.921 | 19.174 | 7.040 | 5.615 | 8.909 | 1.002 | 34.894 | |

| 1.370 | 6.139 | 14.863 | 4.319 | 30.659 | 8.672 | 3.189 | 9.428 | 1.068 | 34.982 | ||

| 3.713 | 3.020 | 3.014 | 1.014 | 10.717 | 7.220 | 6.436 | 6.502 | 1.003 | 25.128 | ||

| CFL | 1 | 3.556 | 3.720 | 8.948 | 1.009 | 31.252 | 7.971 | 3.654 | 6.450 | 1.000 | 40.446 |

| 4 | 2.123 | 4.964 | 9.869 | 3.404 | 8.329 | 11.317 | 7.736 | 12.519 | 1.070 | 25.253 | |

| 8 | 1.945 | 5.055 | 7.290 | 2.998 | 8.696 | 4.550 | 3.048 | 4.826 | 1.038 | 18.398 | |

| 2 K | 2.726 | 2.816 | 5.908 | 2.713 | 11.819 | 6.834 | 3.497 | 6.380 | 1.150 | 6.775 | |

| 1 K | - | - | - | 1.007 | 16.747 | - | - | - | 1.000 | 30.995 | |

| 0.5 K | - | - | - | 1.000 | 17.355 | - | - | - | 1.000 | 35.913 | |

| 0.2 K | 2.274 | 5.324 | 9.572 | 4.178 | 38.320 | 7.061 | 5.152 | 7.833 | 1.039 | 35.391 | |

| 0.1 K | - | - | - | 1.000 | NaN | - | - | - | 1.000 | 31.088 | |

| 0 K | 2.625 | 5.599 | 10.626 | 4.923 | NaN | 9.943 | 5.789 | 9.581 | 1.025 | NaN | |

| AE | SE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Happ | Hsou | Tsou | Tlin | Tapp | Happ | Hsou | Tsou | Tlin | Tapp | |

| resilience | + | ++ | + | + | -- | + | ++ | + | ++ | -- |

| iterations | o | o | - | + | -- | o | + | o | ++ | -- |

| time per iteration | - | o | o | - | o | + | o | o | - | o |

| numerical implementation | + | o | o | - | o | + | o | o | - | o |

| underrelaxation | -- | + | + | o | -- | -- | ++ | + | o | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

König-Haagen, A.; Franquet, E.; Faden, M.; Brüggemann, D. A Study on the Numerical Performances of Diffuse Interface Methods for Simulation of Melting and Their Practical Consequences. Energies 2021, 14, 354. https://doi.org/10.3390/en14020354

König-Haagen A, Franquet E, Faden M, Brüggemann D. A Study on the Numerical Performances of Diffuse Interface Methods for Simulation of Melting and Their Practical Consequences. Energies. 2021; 14(2):354. https://doi.org/10.3390/en14020354

Chicago/Turabian StyleKönig-Haagen, Andreas, Erwin Franquet, Moritz Faden, and Dieter Brüggemann. 2021. "A Study on the Numerical Performances of Diffuse Interface Methods for Simulation of Melting and Their Practical Consequences" Energies 14, no. 2: 354. https://doi.org/10.3390/en14020354

APA StyleKönig-Haagen, A., Franquet, E., Faden, M., & Brüggemann, D. (2021). A Study on the Numerical Performances of Diffuse Interface Methods for Simulation of Melting and Their Practical Consequences. Energies, 14(2), 354. https://doi.org/10.3390/en14020354