Life Cycle Assessment of Municipal Wastewater Treatment Processes Regarding Energy Production from the Sludge Line

Abstract

:1. Introduction

2. Materials and Methods

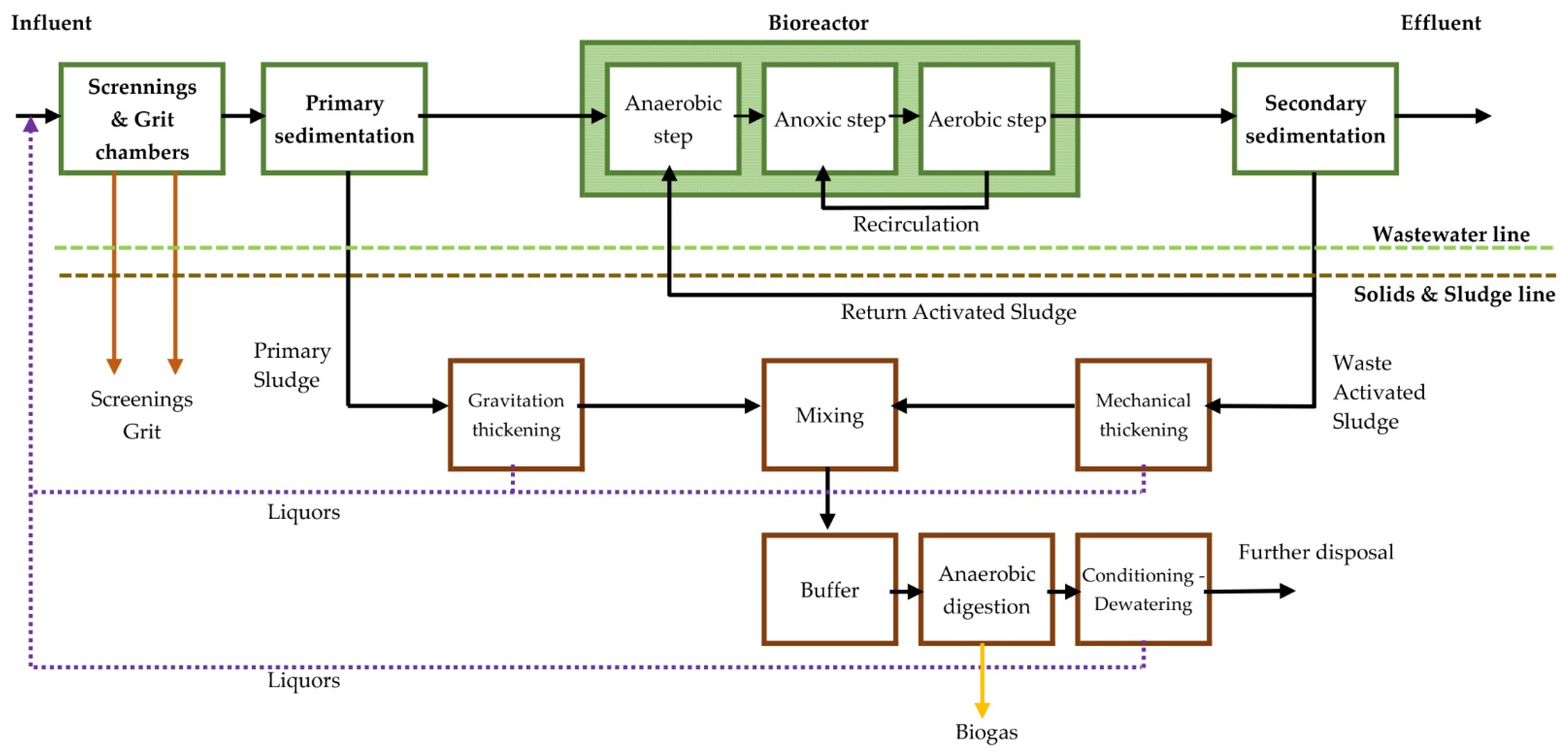

2.1. WWTP Description

2.2. Methods

2.2.1. Background

- Selection and definition of impact categories: The purpose of this step is to select the impact categories that will be considered as part of the overall LCA. It should be completed as part of the initial goal and scope definition phase to guide the LCI (Life Cycle Inventory) data collection process and requires reconsideration following the data collection phase. The items identified in the LCI have potential human health and environmental impacts;

- Classification: Its purpose is to organize and possibly combine the LCI results into impact categories. For LCI items that contribute to only one impact category, the procedure is a straightforward assignment. For example, carbon dioxide emissions can be classified into the global warming category;

- Characterization: This step uses science-based conversion factors, called characterization factors, to convert and combine the LCI results into representative indicators of impacts on human and ecological health. Characterization factors are also commonly referred to as equivalency factors. Characterization provides a way to directly compare the LCI results within each impact category. In other words, characterization factors translate different inventory inputs into directly comparable impact indicators;

- Normalization: This is an LCIA (Life Cycle Impact Assessment) tool used to express impact indicator data in a way that can be compared between impact categories. This procedure normalizes the indicator results by dividing by a selected reference value;

- Grouping: This step assigns impact categories into one or more sets to better facilitate the interpretation of the results into specific areas of concern;

- Weighting: This is sometimes also referred to as valuation of an LCIA, and it assigns weights or relative values to the different impact categories based on their perceived importance or relevance. Weighting is important because the impact categories should also reflect study goals and stakeholder values.

- Climate change—unit: kg CO2 eq;

- Ozone depletion—unit: kg CFC-11 eq;

- Terrestrial acidification—unit: kg SO2 eq;

- Freshwater eutrophication—unit: kg P eq;

- Marine eutrophication—unit: kg N eq;

- Human toxicity—unit: kg 1,4-DB eq;

- Photochemical oxidant formation—unit: kg NMVOC eq;

- Particulate matter formation—unit: kg PM10 eq;

- Terrestrial ecotoxicity—unit: kg 1,4-DB eq;

- Freshwater ecotoxicity—unit: kg 1,4-DB eq;

- Marine ecotoxicity—unit: kg 1,4-DB eq;

- Ionizing radiation—unit: kBq U235 eq;

- Agricultural land occupation—unit: m2a;

- Urban land occupation—unit: m2a;

- Natural land transformation—unit: m2;

- Water depletion—unit: m3;

- Metal depletion—unit: kg Fe eq;

- Fossil fuel depletion—unit: kg oil eq.

2.2.2. Goal and Scope of Analysis

Definition of the Analysis Goal

Functional Unit

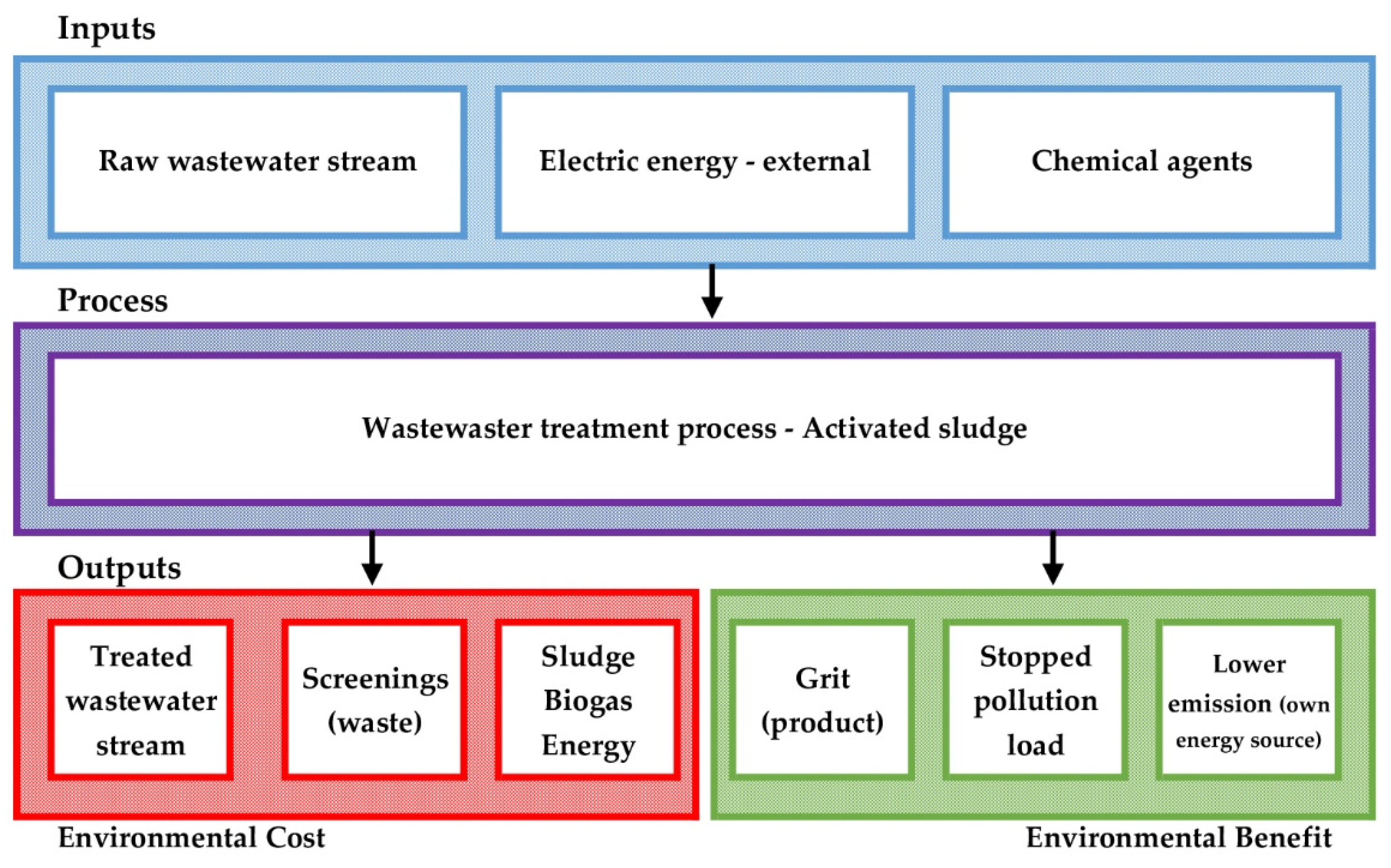

System Boundaries, Assumptions and Limitations

- As sources of environmental loads adopted: (a) A treated wastewater stream that, although characterized by significantly lower values of the analyzed parameters determining the harmfulness of the wastewater (concentrations), still contains substances that have a negative impact on the environment; (b) The so-called “screenings”, i.e., macro-pollutants separated by means of mechanical separators (screens), which were not taken into account at all in the preliminary analysis and at this stage were treated as waste to be treated; and (c) Sewage sludge, which is then directed to anaerobic digesters and serves to produce the methane-rich biogas, which is next used to produce the energy used in the process of wastewater treatment; this way of generating energy and its use in the process of wastewater treatment also has a negative environmental impact (e.g., emissions during biogas combustion, etc.),

- As sources of the indirect environmental benefits: (a) Grit (mineral by-products that consists mostly of sand collected from the streets), recovered from the mechanical separation processes and treated as a product for later release and use; (b) The avoided impacts resulting from differences in the values of standardized parameters characterizing wastewater streams, raw and treated; and (c) the amount of avoided environmental impacts resulting from the production of energy from the plant’s own sources, which in turn allows for the avoidance of consumption of an equivalent amount of energy from external sources.

- COD;

- BOD5;

- total suspended solids (TTS);

- total nitrogen (TN);

- total phosphorus (TP);

- arsenic;

- chromium;

- zinc;

- cadmium;

- copper;

- nickel;

- lead;

- mercury;

- silver;

- vanadium;

- total organic carbon;

- anionic surfactants;

- substances extracted with petroleum ether;

- phenolic index;

- mineral oil index (C10-C40);

- chlorides;

- sulfates;

- silicon.

2.2.3. Life Cycle Inventory (LCI)

Process Inputs

Process Outputs

- Electricity produced from ADs taking into account the environmental costs (emissions during production and combustion);

- Electricity, whose consumption from the grid has been avoided, together with the environmental loads associated with its generation in accordance with the Polish electricity mix, as shown in Figure 4.

3. Results—Life Cycle Impact Assessment (LCIA)

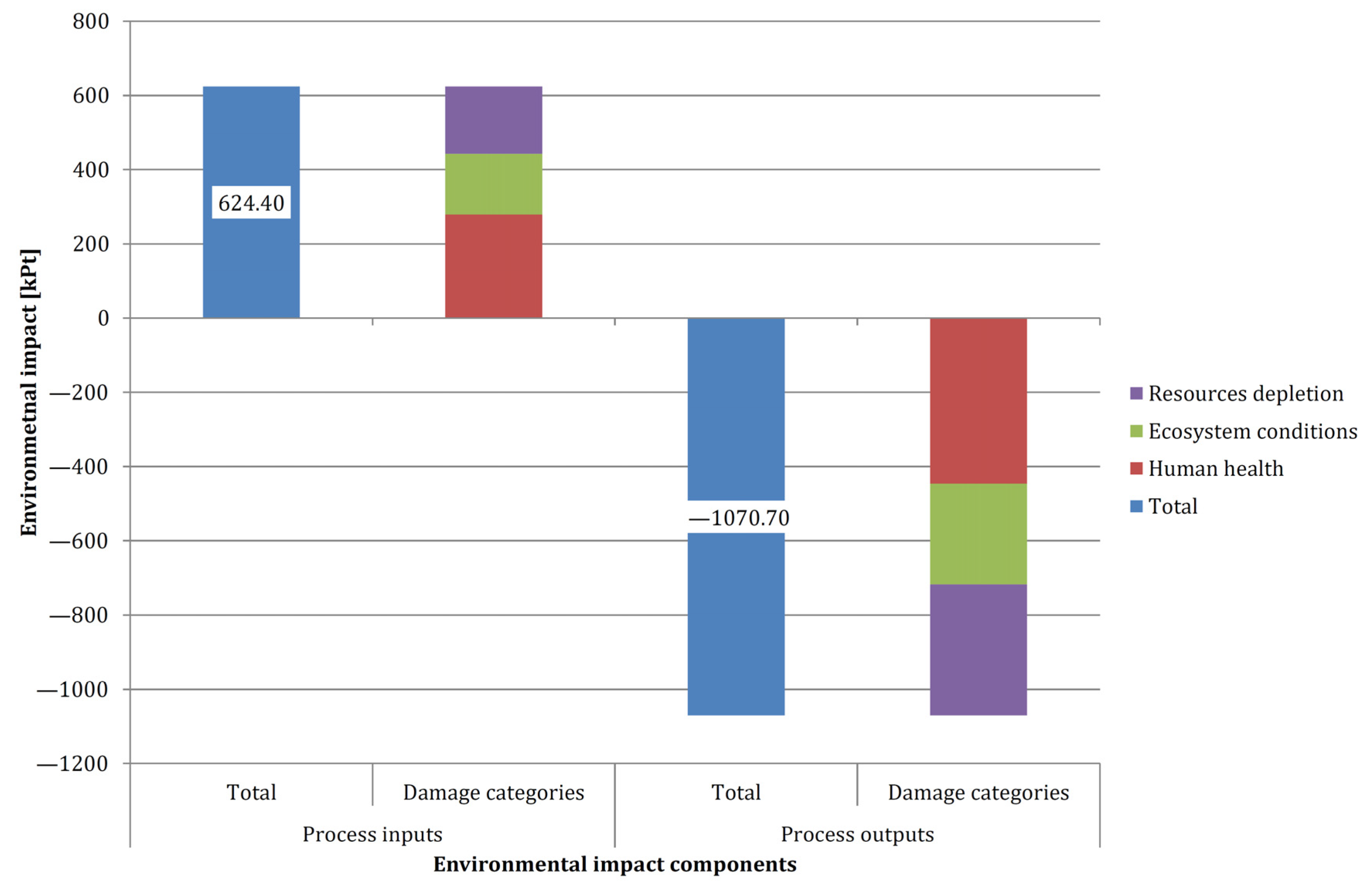

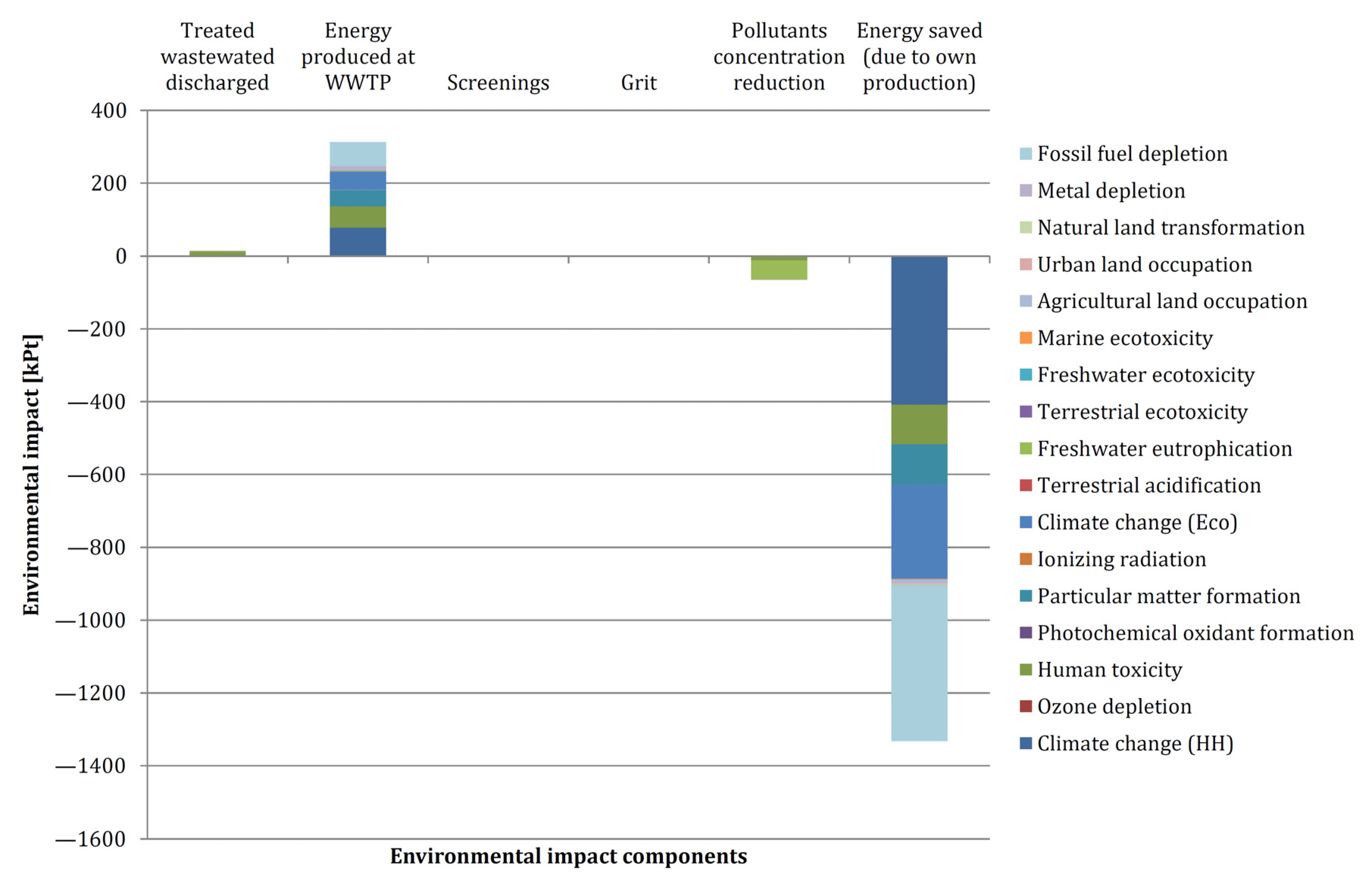

3.1. Overall Results—Comparison of Environmental Impacts for Process Inputs and Outputs

- (a)

- Aggregate values of total environmental impact indicators for the process under consideration in terms of (1) inputs (supplied resources) into the process and (2) outputs (received resources and environmental benefits) from the process;

- (b)

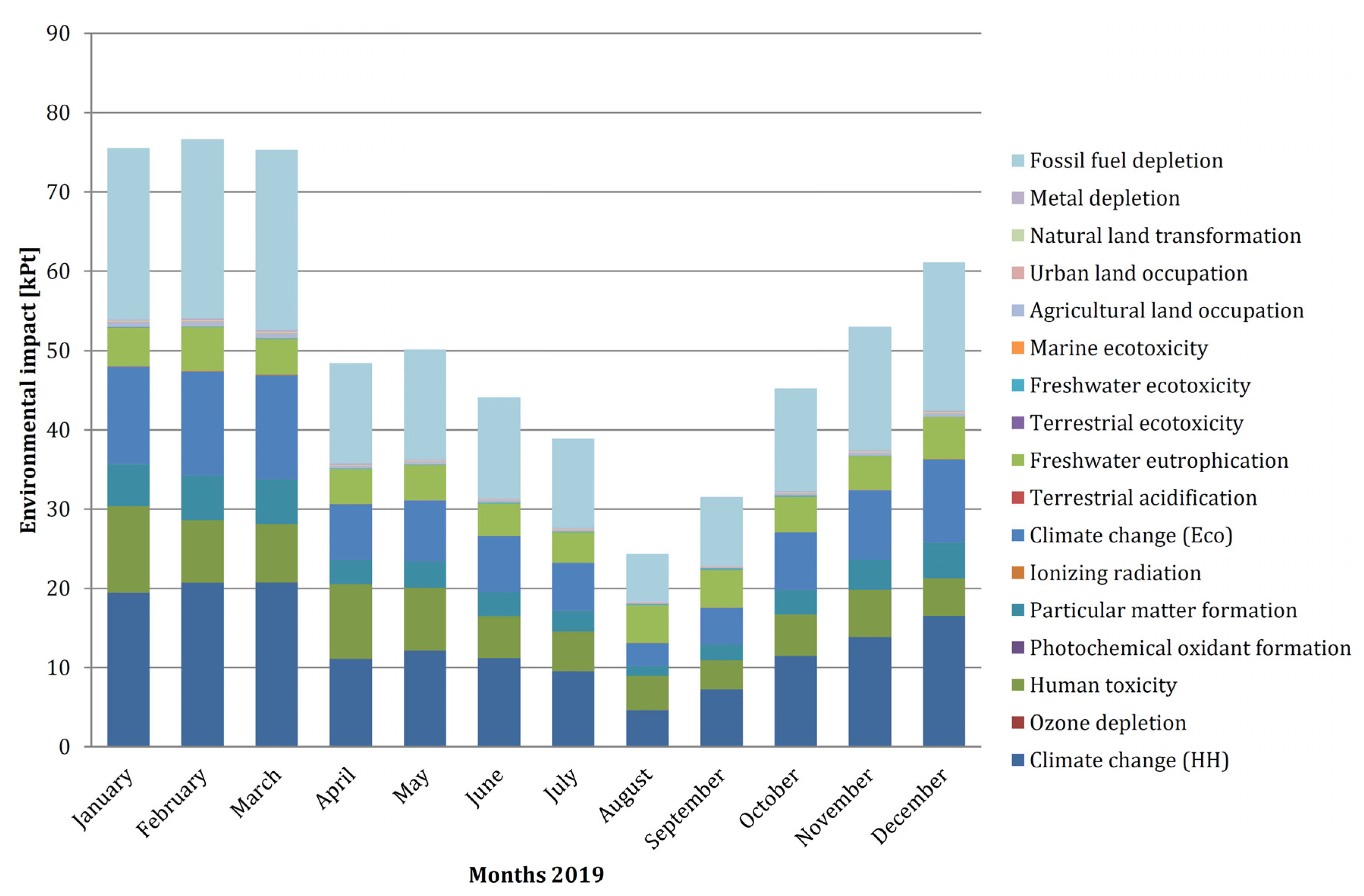

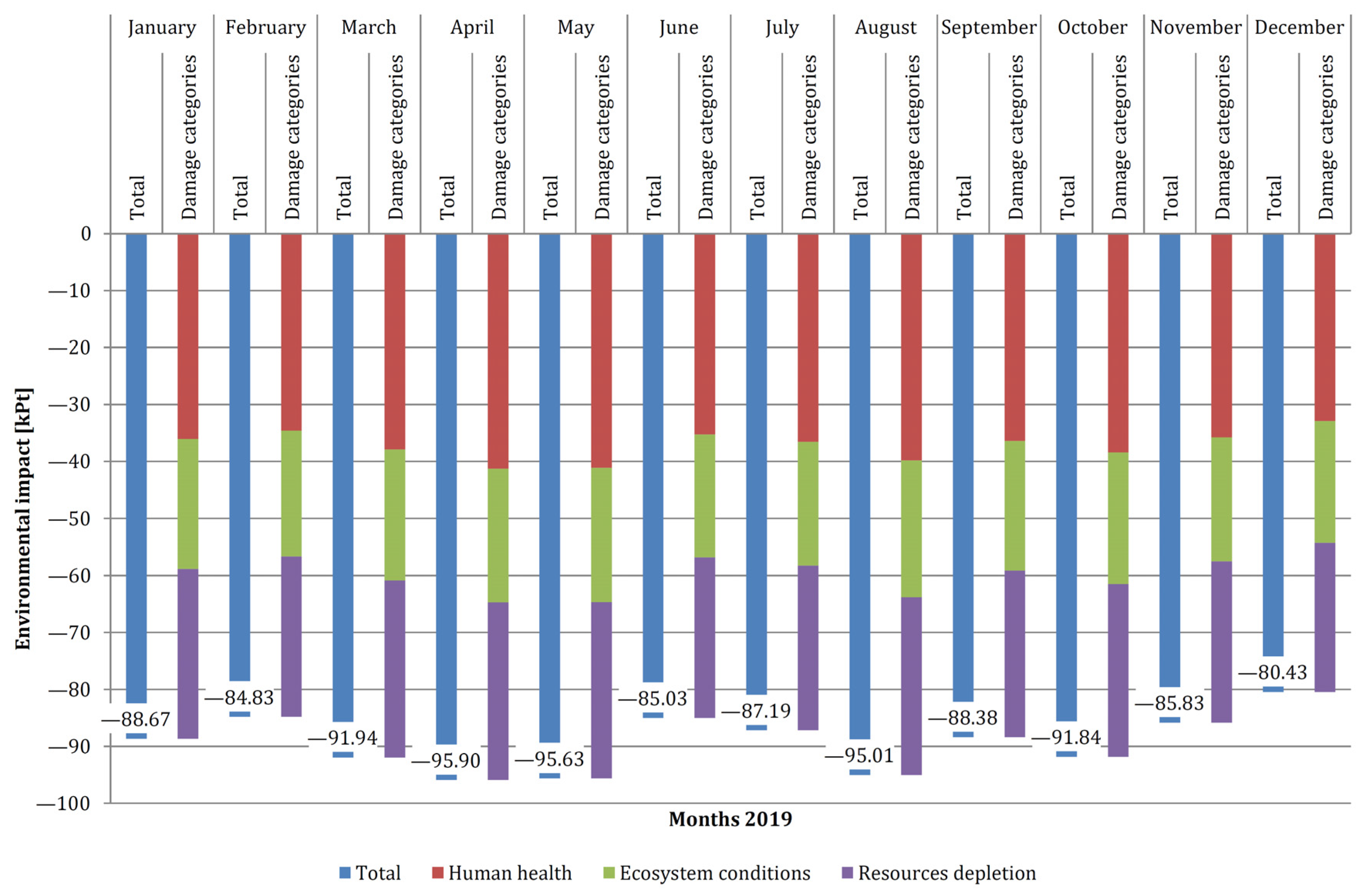

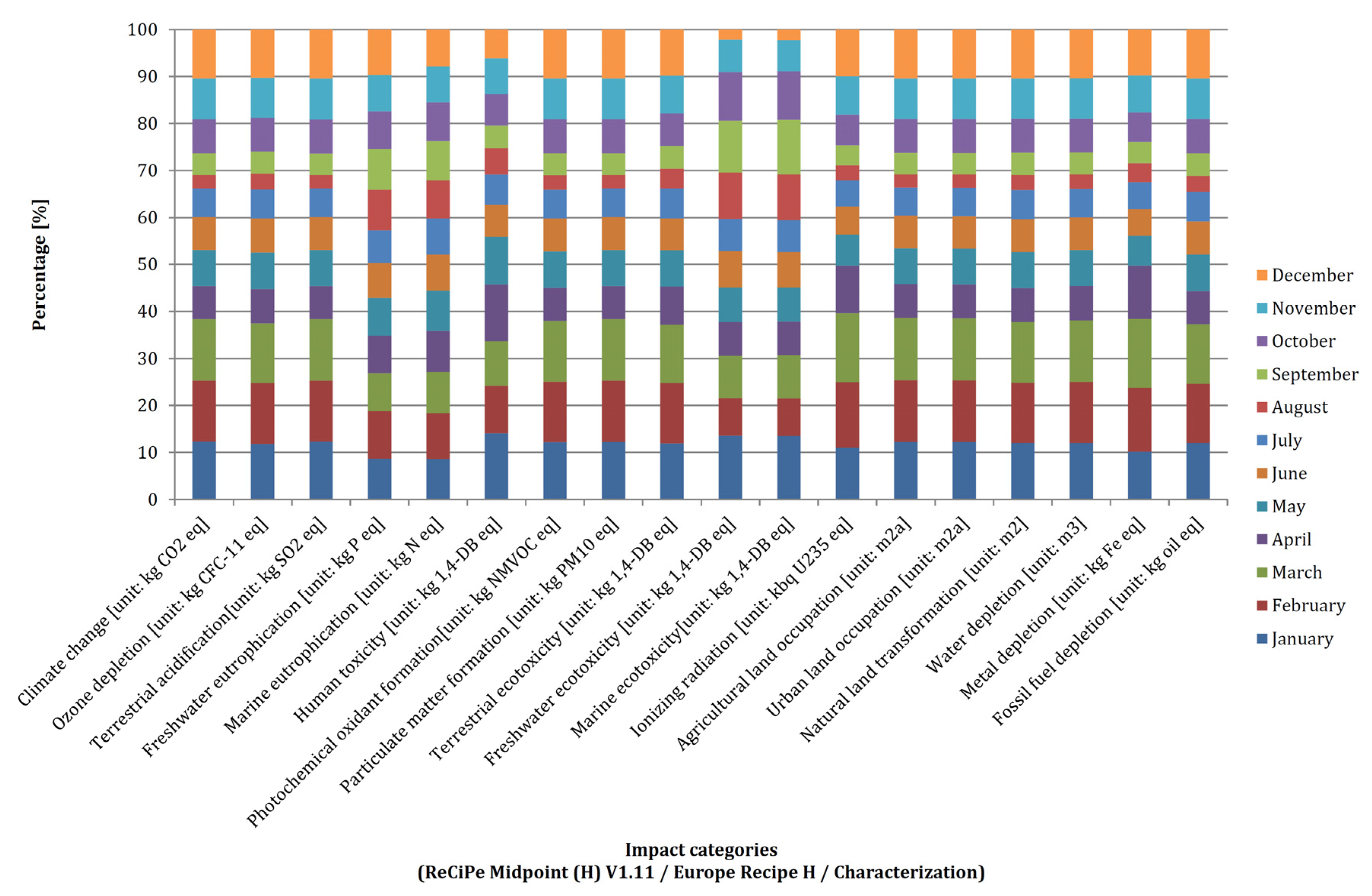

- Distribution of environmental impacts in individual months of the analyzed period (separately for inputs and outputs);

- (c)

- Detailed determinant(s) of environmental costs and benefits.

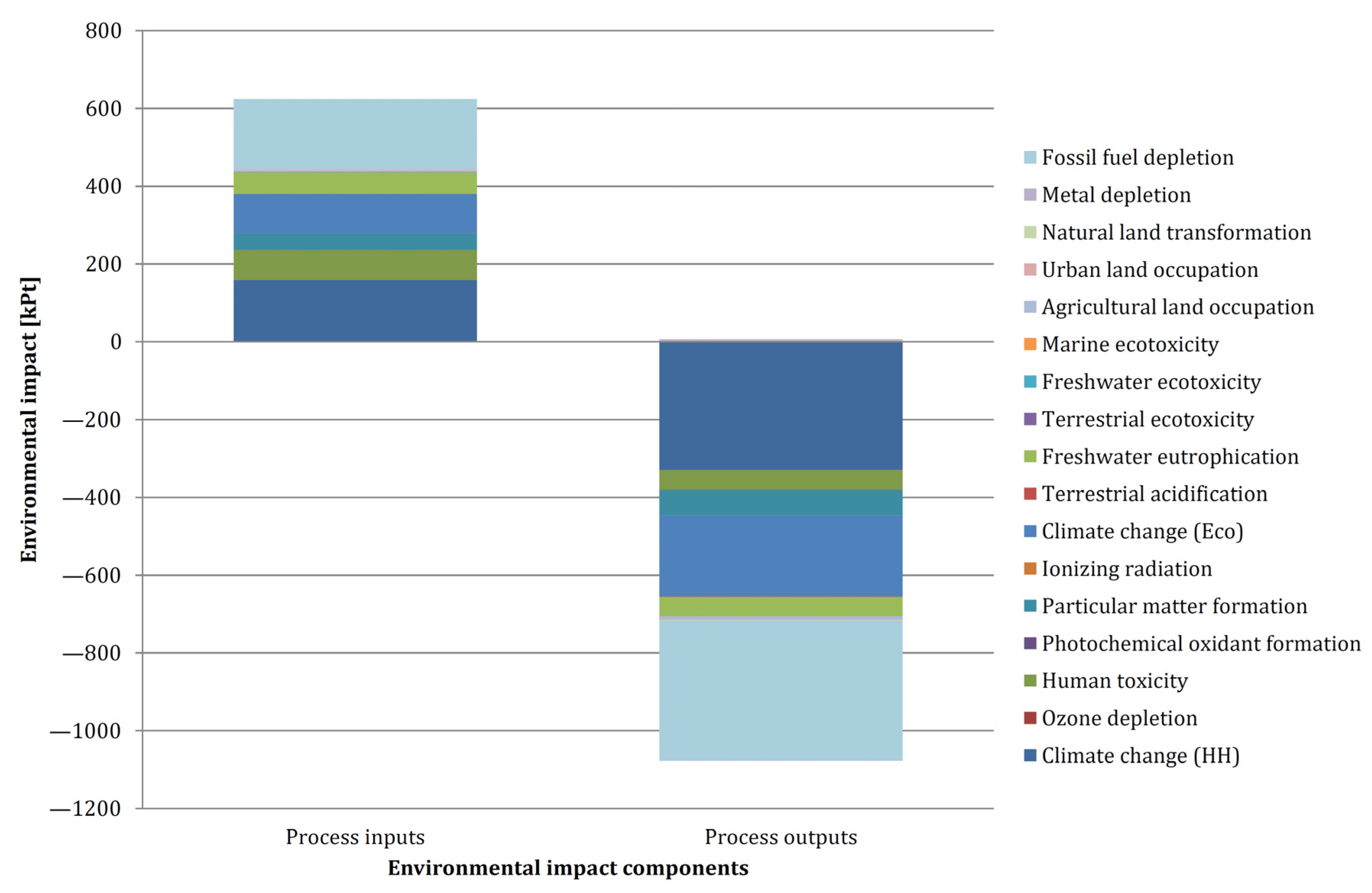

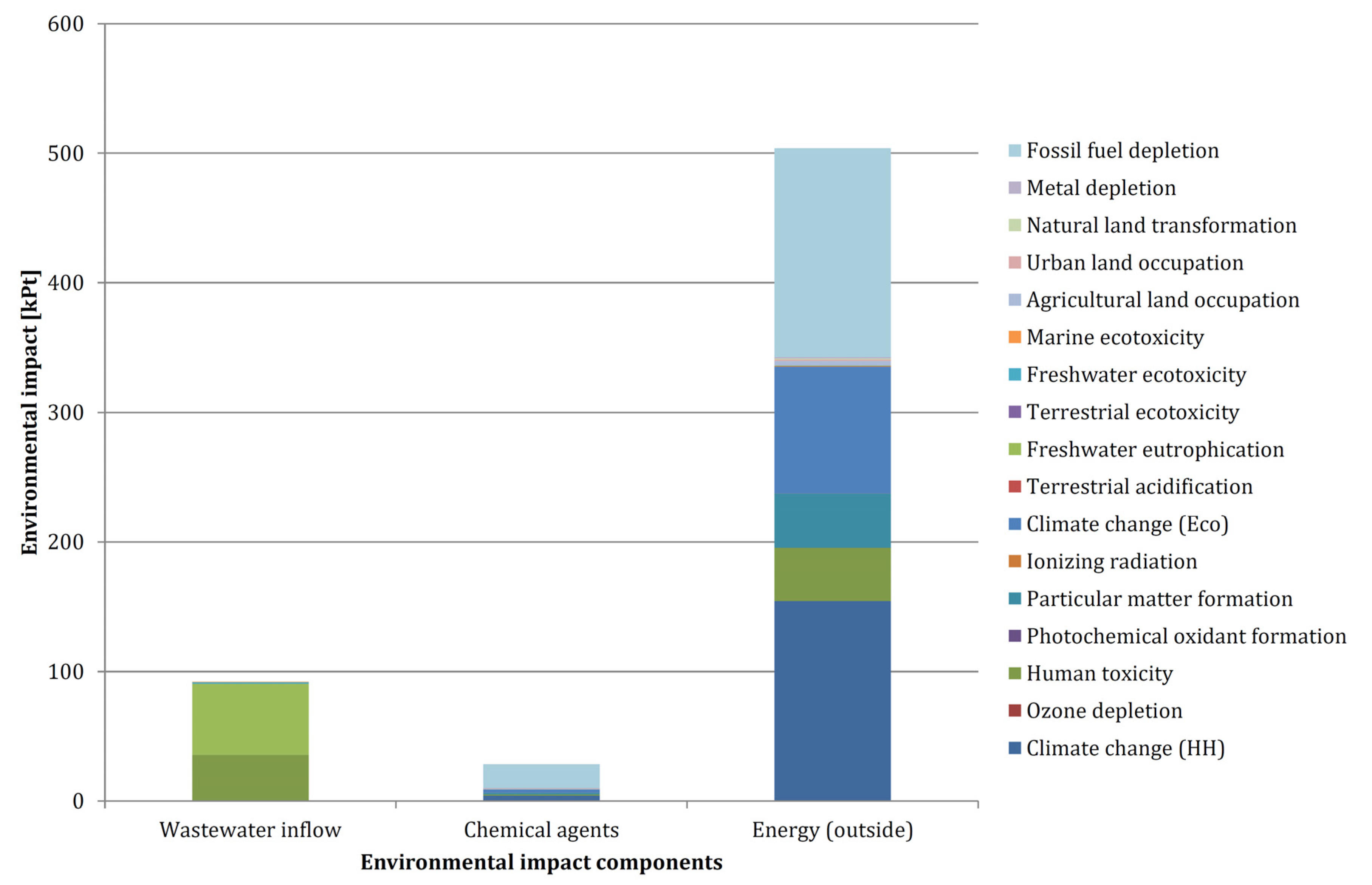

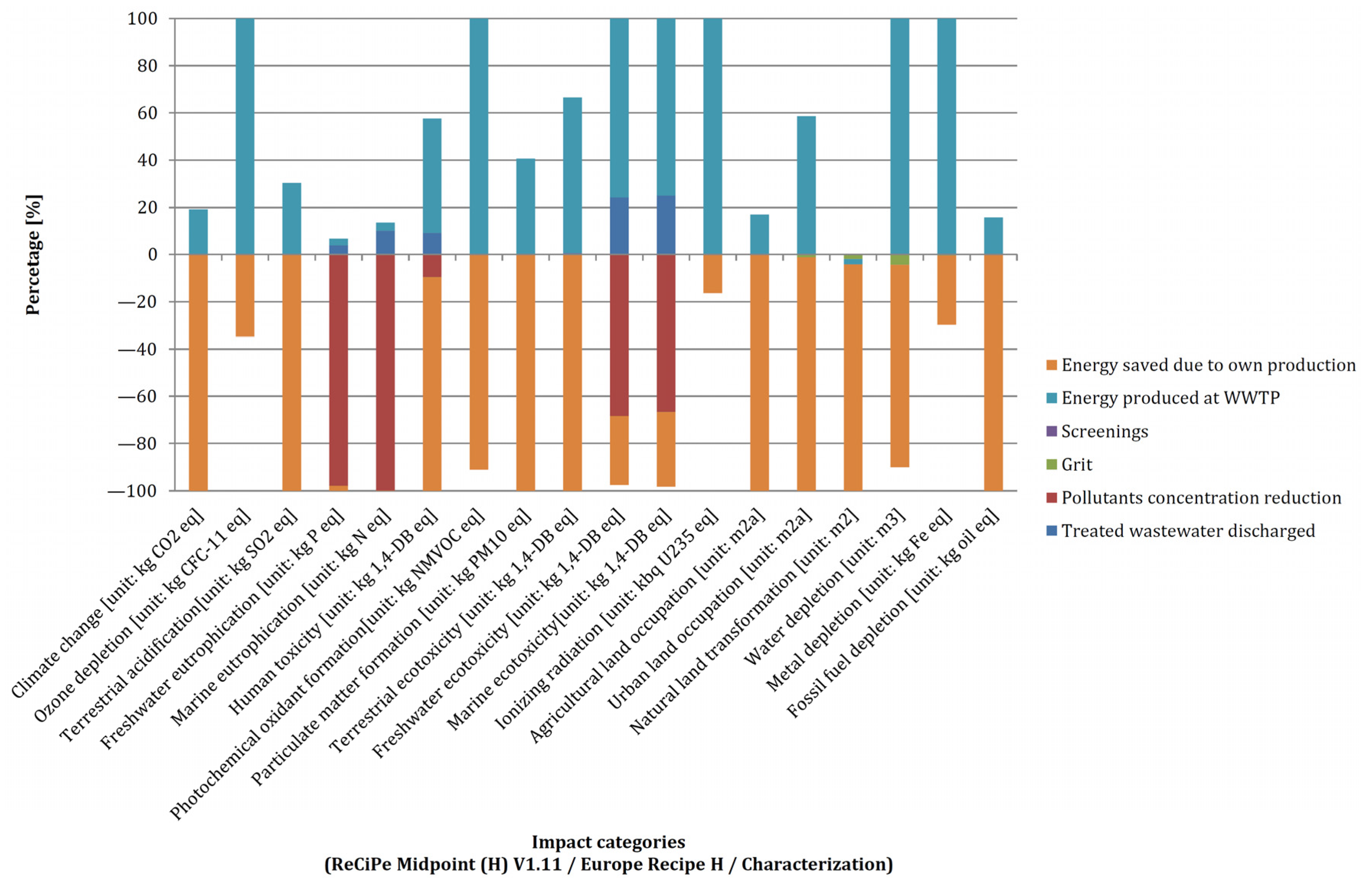

3.2. Components of Environmental Impacts for Inputs and Outputs of the Wastewater Treatment Process

3.2.1. Components of Environmental Impacts for Inputs to Treatment Processes

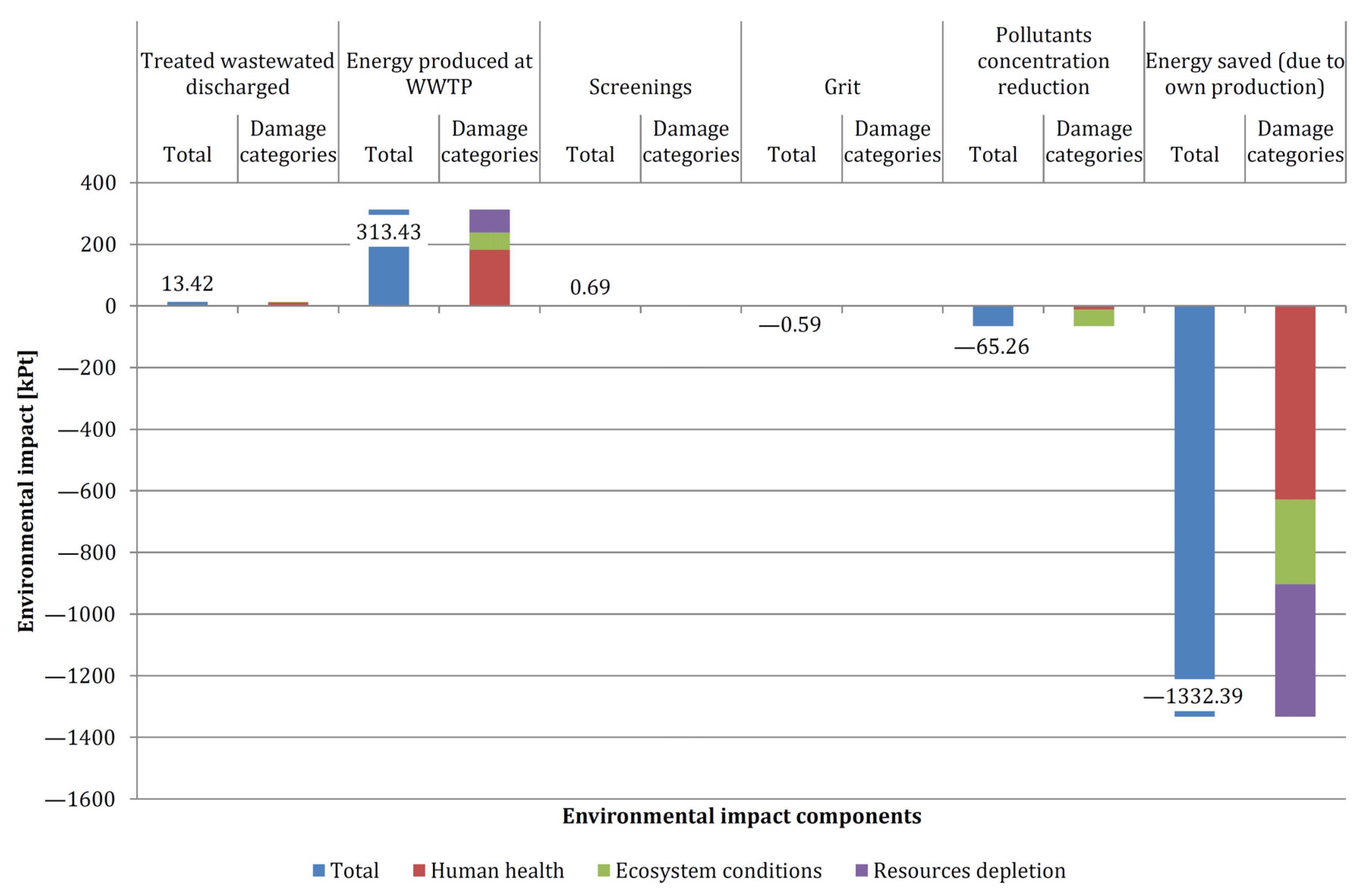

3.2.2. Components of Environmental Impacts for Outputs from Treatment Processes

3.3. Analysis Results—Detailed Environmental Impact Profiles

3.3.1. Components of the Environmental Impacts for Inputs to the Treatment Process

3.3.2. Components of Environmental Impacts for Outputs from the Treatment Process

- Environmental damage/burdens for the quantities characterizing the wastewater stream at the outlet to the receiver;

- Environmental benefits for quantities characterizing the reduction in the values of the characteristic parameters between the wastewater streams at the process inlet and outlet to the receiver.

- In terms of direct environmental nuisance, the energy produced from the plant’s own sources and the combustion of biogas generated during sewage sludge fermentation in bioreactors;

- In terms of potential environmental benefits, the avoided emissions associated with electrical power not consumed from external sources.

3.4. Uncertainty Analysis—Elements

4. Discussion and Major Conclusions

- Levels of relevant parameter values characteristic of the wastewater streams: raw and treated before release to the environment;

- The chemical additives (chemical agents and reagents) needed for the process;

- Electricity supplied to the wastewater treatment process from the outside, modelled on the Polish electrical power generation mix (according to the structure shown in Figure 4);

- By-products of a wastewater treatment process seen as waste (screenings) or as a regular replacement for a product directly sourced from the environment (grit as sand), which can then be used in construction;

- Energy generated from the plant’s own sources (combustion of biogas produced during sludge fermentation in bioreactors).

- Reduction of burdens from the wastewater as a result of the treatment process (the difference between the values of characteristic parameters at process input and output);

- The absence of environmental burdens as a result of preventing the need for supplying (based on the above-mentioned energy mix) electrical power in an amount equal to that produced from the plant’s own sources.

- Inputs to the wastewater treatment process;

- Outputs from the wastewater treatment process.

- Estimated environmental impacts for the inputs to the wastewater treatment process are environmental loads. They take positive values for all components of the process inputs: the raw wastewater stream that fed into the process, the chemical reagents used, and the electricity supplied from external sources.

- All direct outputs (except grit) are characterized by positive (and therefore harmful, environmentally) values of impact indicators. This is due to the following:

- o

- The wastewater stream at the process outlet leading to the receiving body (environment) contains certain quantities of characteristic, environmentally harmful, substances, and it is required by the relevant standards to determine their levels; these quantities have been significantly reduced (at least to the level required by law), but these substances are present in the treated wastewater, which, once directed to the environment, must be re-treated to be suitable for use;

- o

- Screenings (solid residues from mechanical separation processes) were modelled only as waste; the reason for adopting such a modelling approach was the impossibility of standardizing the composition of the screenings and the preliminary lack, at this stage of modelling, of options for unambiguous determination of the usefulness of these screenings, which would allow us to treat them as a fully-fledged by-product of the treatment process;

- o

- Energy from bioreactors is produced as a result of a physico-chemical process of sewage sludge fermentation in digesters, where a certain amount of biogas is released; this biogas is then incinerated and the energy obtained from this process is used in wastewater treatment processes. The share of energy from the plant’s own sources varied, depending on the month, between 62 and 89% of the total energy used.

- The estimated environmental impacts for the remaining wastewater treatment outputs and grit and intermediate outputs are environmental benefits (negative values assumed). For all the environmental benefits, this is due to the fact that there are so-called “avoided” impacts, i.e., indirect environmental benefits compared to obtaining an equivalent effect using primary environmental resources. This finding fully corresponds to the overall tendencies in the results obtained from other Polish studies [28,29,30]. For environmental benefits arising from the implementation of the wastewater management process in question, the “avoided” impacts concerned are:

- o

- Grit—All grit shown in Table 9 can be treated as a fully valuable product ready for use in the relevant industries (e.g., as a raw material in the construction industry), which in turn eliminates the need to obtain the same amount of sand from primary sources, i.e., from the environment;

- o

- Diminution of pollutant concentrations—The environmental benefit results from the fact that the measured values of parameters describing the content of harmful substances in wastewater are reduced from their top levels, characterizing the stream of raw wastewater at the process inflow to a lower level, and characterizing the stream of treated wastewater ready to be released to the receiver (environment); this parameter illustrates the amount of “avoided” environmental loads resulting from the wastewater with the original concentration of harmful substances not being released to the environment;

- o

- “Saved” energy—In this case, the environmental benefit results from the fact that the energy required for the wastewater treatment process, in an amount equal to the amount of energy that was produced in the plant from its own resources, was not taken from external sources.

- It was found, in the case of both process inputs and outputs, that the energy component, related to the energy intensity of the processes themselves, as well as the “avoided” environmental loads, is the main determinant of the magnitude of the generated impacts (the value of total environmental impact indicators). This finding supports the point of view of the case studies presented in [32]. Moreover, it can be noted that the amount of “avoided” emissions from electricity generated based on the modelled energy mix determines the negative value of the overall environmental impact indicator of the whole process (as the main factor, it determines the environmental friendliness of the process); the calculated overall environmental impact indicator of the process, including process inputs and outputs modelled according to the assumptions described in Section 2.2.2, is −446 kPt.

- Analysis of the structure of environmental impacts included in the detailed impact profiles, characterization, and weighting results allows us to conclude that, for the energy-intensive component and the chemical agent used, loads connected with the following phenomena account for the largest share:

- o

- Depletion of fossil fuels;

- o

- Climate change (in terms of harm to humans and ecosystems);

- o

- Human toxicity;

- o

- The formation of particulate matter in the atmosphere.

Furthermore, for the component related to the use of chemicals in wastewater treatment, depletion of metal resources also constitutes a significant burden. - With regard to the quantities of harmful substances tested (according to the set of parameters given in Table 4, Table 5, Table 6, Table 7 and Table 8) in raw and treated wastewater streams, a different distribution of environmental impact profiles was found. Only some impact categories are present there, of which the most significant ones are:

- o

- Eutrophication of freshwater: about 55% of the total impact for the raw wastewater stream and about 16% of the total impact for the treated wastewater stream;

- o

- Human toxicity: about 39% of the total impact for the raw wastewater stream and about 82% of the total impact for the treated wastewater stream,

- o

- Freshwater ecotoxicity: about 1–2% of the total impact.

Besides these, yet another, though much smaller, impact was discovered, associated with marine and soil ecotoxicity. - With regard to the variability of the environmental impacts across individual months, it should be noted that:

- o

- Environmental loads from wastewater treatment inputs are subject to considerable variability over individual months. The discrepancies reach 300%; the top load level was recorded in February (76.7 kPt) and the lowest in August (24.3 kPt);

- o

- Environmental impacts from wastewater treatment outputs are characterized by much lower variability (differences between individual months do not exceed 20%).

- Due to the fact that, in previous publications, available system boundaries and analysis assumptions, as well as the choice of functional units, were done arbitrarily, straightforward comparisons between the results are possible; nevertheless, tendency evaluation still can be done:

- o

- o

- Moreover, the statement made in this paper that the energy mix for the so-called conventional electricity source has the most significant contribution to the overall environmental impact indicator of the whole process is valid, and has been noticed, not only in the area of municipal WWTs, but also in industrial facilities [40],

- o

- Interestingly, it has been confirmed that the LCA results reveal concise areas of environmental optimization for large WWTPs (>50,000 PE), which was also noticed in the results of a case study done on 113 treatment facilities across Spain [9]; bigger facilities, although maintaining high treatment efficiency standards, present poorer environmental profiles than the plants that have a lack of careful continuous monitoring infrastructure. Therefore, LCA appears to be an even more crucial evaluation tool for scheduling future and holistic-approach optimization scenarios for WWTP significant stream volumes.

- For further analysis stages, we postulate that this study’s limitations must be considered. Thus, the following is necessary:

- o

- Clarifying the wastewater treatment model and modelling the flow of environmental impacts between individual process stages;

- o

- Taking into account inputs and outputs omitted at the described stage, output modelling of sewage sludge, and perhaps a separate environmental analysis of sludge use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ontiveros, G.A.; Campanella, E.A. Environmental performance of biological nutrient removal processes from a life cycle perspective. Bioresour. Technol. 2015, 150, 506–512. [Google Scholar] [CrossRef] [PubMed]

- Revollar, S.; Vilanova, R.; Vega, P.; Francisco, M.; Meneses, M. Wastewater treatment plant operation: Simple control schemes with a holistic perspective. Sustainability 2020, 12, 768. [Google Scholar] [CrossRef] [Green Version]

- De Feo, G.; Ferrara, C. Investigation of the environmental impacts of municipal wastewater treatment plants through a Life Cycle Assessment software tool. Environ. Technol. 2017, 38, 1943–1948. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.K.L.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Nghiem, L.D.; Nguyen, T.V. A Critical Review on Life Cycle Assessment and Plant-Wide Models towards Emission Control Strategies for Greenhouse Gas from Wastewater Treatment Plants. J. Environ. Manag. 2020, 264, 110440. [Google Scholar] [CrossRef]

- Alyaseri, I.; Zhou, J. Handling uncertainties inherited in life cycle inventory and life cycle impact assessment method for improved life cycle assessment of wastewater sludge treatment. Heliyon 2019, 5. [Google Scholar] [CrossRef]

- Rashid, S.S.; Liu, Y.-Q. Assessing environmental impacts of large centralized wastewater treatment plants with combined or separate sewer systems in dry/wet seasons by using LCA. Environ. Sci. Pollut. Res. 2020, 27, 15674–15690. [Google Scholar] [CrossRef] [Green Version]

- Vidal, N.; Poch, M.; Martí, E.; Rodríguez-Roda, I. Evaluation of the environmental implications to include structural changes in a wastewater treatment plant. J. Chem. Technol. Biotechnol. 2002, 77, 1206–1211. [Google Scholar] [CrossRef]

- Wu, J.G.; Meng, X.Y.; Liu, X.-M.; Liu, X.-W.; Zheng, Z.-X.; Xu, D.-Q.; Sheng, G.-P.; Yu, H.-Q. Life Cycle Assessment of a Wastewater Treatment Plant Focused on Material and Energy Flows. Environ. Manag. 2010, 46, 610–617. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Chenel, S.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Eco-efficiency analysis of Spanish WWTPs using the LCA + DEA method. Water Res. 2015, 68, 651–666. [Google Scholar] [CrossRef]

- Lijó, L.; Malamis, S.; González-García, S.; Moreira, M.T.; Fatone, F.; Katsou, E. Decentralised schemes for integrated management of wastewater and domestic organic waste: The case of a small community. J. Environ. Manag. 2017, 203, 732–740. [Google Scholar] [CrossRef] [Green Version]

- Lam, K.L.; Zlatanović, L.; van der Hoek, J.P. Life cycle assessment of nutrient recovery from wastewater—current methodological practices. In Proceedings of the 10th IWA Symposium on Modelling and Integrated Assessment, Copenhagen, Denmark, 1–4 September 2019; pp. 1–4. [Google Scholar]

- Tua, C.; Ficara, E.; Mezzanotte, V.; Rigamonti, L. Integration of a side-stream microalgae process into a municipal wastewater treatment plant: A life cycle analysis. J. Environ. Manag. 2020, 111605. [Google Scholar] [CrossRef] [PubMed]

- Houillon, G.; Jolliet, O. Life cycle assessment of processes for the treatment of wastewater urban sludge: Energy and global warming analysis. J. Clean. Prod. 2005, 13, 287–299. [Google Scholar] [CrossRef]

- Foley, J.; Yuan, Z.; Keller, J.; Senante, E.; Chandran, K.; Willis, J. N2O and CH4 Emission from Wastewater Collection and Treatment Systems; Technical Report; GlobalWater Research Coalition: London, UK, 2011. [Google Scholar]

- Arnell, M. Performance Assessment of Wastewater Treatment Plants: Multi-Objective Analysis Using Plant-Wide Models. Ph.D. Thesis, Lund University, Lund, Sweden, 16 December 2016. [Google Scholar]

- Wang, X.; Ratnaweera, H.; Holm, J.A.; Olsbu, V. Statistical monitoring and dynamic simulation of a wastewater treatment plant: A combined approach to achieve model predictive control. J. Environ. Manag. 2017, 193, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Santelmann, M.; Hulse, D.; Wright, M.; Enright, C.; Branscomb, A.; Tchintcharauli-Harrison, M.; Bolson, J. Designing and modeling innovation across scales for urban water systems. Urban Ecosyst. 2019, 22, 1149–1164. [Google Scholar] [CrossRef] [Green Version]

- Vicentin, R.; Fdz-Polanco, F.; Fdz-Polanco, M. Energy integration in wastewater treatment plants by anaerobic digestion of urban waste: A process design and simulation study. Int. J. Chem. Eng. 2019, 1–11. [Google Scholar] [CrossRef]

- Arias, A.; Behera, C.R.; Feijoo, G.; Sin, G.; Moreira, M.T. Unravelling the environmental and economic impacts of innovative technologies for the enhancement of biogas production and sludge management in wastewater systems. J. Environ. Manag. 2020, 270, 110965. [Google Scholar] [CrossRef]

- Hospido, A.; Moreira, T.; Martín, M.; Rigola, M.; Feijoo, G. Environmental evaluation of different treatment processes for sludge from urban wastewater treatments: Anaerobic digestion versus thermal processes. Int. J. Life Cycle Assess. 2005, 10, 336–345. [Google Scholar] [CrossRef]

- Hong, J.; Hong, J.; Otaki, M.; Jolliet, O. Environmental and economic life cycle assessment for sewage sludge treatment processes in Japan. Waste Manag. 2009, 29, 696–703. [Google Scholar] [CrossRef]

- Kalavrouziotis, I.; Filintas, A.; Koukoulakis, P.H.; Hatzopoulos, J. Application of multicriteria analysis in the management and planning of treated municipal wastewater and sludge reuse in agriculture and land development: The case of Sparti’s wastewater treatment plant, Greece. Fresenius Environ. Bull. 2011, 20, 287–295. [Google Scholar]

- Cao, Y.; Pawłowski, A. Life cycle assessment of two emerging sewage sludge-to-energy systems: Evaluating energy and greenhouse gas emissions implications. Bioresour. Technol. 2013, 127, 81–91. [Google Scholar] [CrossRef]

- Zaborowska, E.; Czerwionka, K.; Mąkinia, J. Integrated plant-wide modelling for evaluation of the energy balance and greenhouse gas footprint in large wastewater treatment plants. Appl. Energy 2021, 282, 116126. [Google Scholar] [CrossRef]

- Saraiva, A.; Presumido, P.; Silvestre, J.; Feliciano, M.; Rodrigues, G.; Silva, P.O.; Damásio, M.; Ribeiro, A.; Ramôa, S.; Ferreira, L.; et al. Water footprint sustainability as a tool to address climate change in the wine sector: A methodological approach applied to a portuguese case study. Atmosphere 2020, 11, 934. [Google Scholar] [CrossRef]

- Sweetapple, C.; Fu, G.; Butler, D. Identifying key sources of uncertainty in the modelling of greenhouse gas emissions from wastewater treatment. Water Res. 2013, 47, 4652–4665. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niero, M.; Pizzol, M.; Bruun, H.G.; Thomsen, M. Comparative life cycle assessment of wastewater treatment in Denmark including sensitivity and uncertainty analysis. J. Clean. Prod. 2014, 68, 25–35. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to conduct prospective life cycle assessment for emerging technologies? A systematic review and methodological guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- Burchart-Korol, D.; Zawartka, P. Determinants of environmental assessment of Polish individual wastewater treatment plants in a life cycle perspective. Arch. Environ. Prot. 2019, 45, 44–54. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Zawartka, P. Environmental life cycle assessment of septic tanks in urban wastewater system—A case study for Poland. Arch. Environ. Prot. 2019, 45, 68–77. [Google Scholar] [CrossRef]

- Zawartka, P.; Burchart-Korol, D.; Blaut, A. Model of carbon footprint assessment for the life cycle of the system of wastewater collection, transport and treatment. Sci. Rep. 2020, 10, 5799. [Google Scholar] [CrossRef]

- Corominas Ll Foley, J.; Guest, J.S.; Hospido, A.; Larsen, H.F.; Morera, S.; Shaw, A. Life cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar] [CrossRef]

- Fava, J. Society of Environmental Toxicology and Chemistry. A Technical Framework for Life-Cycle Assessment; SETAC and SETAC Foundation for Environmental Education: Washington, DC, USA, 1991. [Google Scholar]

- Klöpffer, W. Life cycle assessment. Environ. Sci. Pollut. Res. 1997, 4, 223–228. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. Report 2009, 1, 1–126. Available online: https://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 3 October 2020).

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- PSE Polskie Sieci Elektroenergetyczne. Available online: https://pse.pl/dane-sytemowe (accessed on 21 April 2020).

- Takeshita, S.; Farzaneh, H.; Dashti, M. Life-cycle assessment of the wastewater treatment technologies in Indonesia’s fish-processing industry. Energies 2020, 13, 6591. [Google Scholar] [CrossRef]

| Parameter | Value | Units |

|---|---|---|

| Capacity | ||

| Population (served in 2019) | 920,471 | PE (1) |

| Population (maximum designed) | 958,000 | PE |

| wastewater treatment plant (WWTP) Inflow | ||

| Mean daily (2019, average) | 100,832 | m3 day−1 |

| WWTP flow (maximum designed) | 200,000 | m3 day−1 |

| Peak flow (2019) | 149,792 | m3 day−1 |

| Peak flow (maximum designed) | 260,000 | m3 day−1 |

| Organic Pollution Loading and Concentration (2019—average) | ||

| BOD5 (2)—influent | 594 | g m−3 |

| 60,000 | kg day−1 | |

| (designed) | 57,500 | kg day−1 |

| BOD5—effluent | 3.7 | g m−3 |

| BOD5—maximum required limit | 15.0 | g m−3 |

| COD (3) | 1239 | g m−3 |

| 138,000 | kg day−1 | |

| (designed) | 125,000 | kg day−1 |

| COD—effluent | 49.9 | g m−3 |

| COD—maximum required limit | 125.0 | g m−3 |

| Total Suspended Solids (TSS) | 571 | g m−3 |

| 57,670 | kg day−1 | |

| (designed) | 60,000 | kg day−1 |

| TSS—effluent | 6.4 | g m−3 |

| TSS—maximum required limit | 35.0 | g m−3 |

| Total Nitrogen (TN) | 103 | g m−3 |

| 10,400 | kg day−1 | |

| (designed) | 11,000 | kg day−1 |

| TN—effluent | 9.4 | g m−3 |

| TN—maximum required limit | 10 | g m−3 |

| Total Phosphorus (TP) | 7 | g m−3 |

| 1515 | kg day−1 | |

| (designed) | 1400 | kg day−1 |

| TP—effluent | 0.6 | g m−3 |

| TP—maximum required limit | 1.0 | g m−3 |

| Parameter | Value | Units |

|---|---|---|

| Thickened PS (2019—average) | ||

| Volume | 960 | m3 day−1 |

| Dry solids content | 5.2 | %DS |

| Organic matter as % of dry solids content | 76.6 | % |

| Thickened WAS (2019—average) | ||

| Volume | 480 | m3 day−1 |

| Dry solids content | 5.7 | %DS |

| Organic matter as % of dry solids content | 78.6 | % |

| Digestate (2019—average) | ||

| Volume | 1540 | m3 day−1 |

| Dry solids content | 3.0 | %DS |

| Organic matter as % of dry solids content | 63.3 | % |

| Dewatered Sludge (2019—average) | ||

| Volume (calculated) | 190 | m3 day−1 |

| Dry solids content | 22.8 | %DS |

| Organic matter as % of dry solids content | 69.2 | % |

| Month | Energy Consumption—TOTAL | Energy Consumption—from External Source | Energy Consumption—Produced from Biogas | Covered from Own Source |

|---|---|---|---|---|

| kWh | kWh | kWh | % | |

| January | 1,991,072 | 709,481 | 1,281,591 | 64 |

| February | 1,965,577 | 755,487 | 1,210,090 | 62 |

| March | 2,091,587 | 755,744 | 1,335,843 | 64 |

| April | 1,735,742 | 396,503 | 1,339,239 | 77 |

| May | 1,770,691 | 441,140 | 1,329,551 | 75 |

| June | 1,618,724 | 405,659 | 1,213,065 | 75 |

| July | 1,585,674 | 342,897 | 1,242,777 | 78 |

| August | 1,497,973 | 158,677 | 1,339,296 | 89 |

| September | 1,515,407 | 259,723 | 1,255,684 | 83 |

| October | 1,720,319 | 416,944 | 1,303,375 | 76 |

| November | 1,719,799 | 503,319 | 1,216,480 | 71 |

| December | 1,723,640 | 599,645 | 1,123,995 | 65 |

| Average | 1,744,684 | 478,768 | 1,265,916 | 73 |

| TOTAL | 20,936,205 | 5,745,219 | 15,190,986 |

| Month | Pollutant Concentration | ||||

|---|---|---|---|---|---|

| g m−3 | |||||

| COD | BOD5 | TSS | TN | TP | |

| January | 1326.9 | 468.7 | 688.7 | 98.2 | 14.6 |

| February | 1258.8 | 548.4 | 537.1 | 111.9 | 17.1 |

| March | 1288.6 | 567.5 | 682.7 | 98.9 | 13.5 |

| April | 1254.0 | 505.5 | 631.2 | 113.4 | 15.4 |

| May | 971.1 | 458.8 | 371.0 | 96.9 | 13.4 |

| June | 1144.0 | 477.2 | 581.7 | 99.3 | 14.3 |

| July | 1213.7 | 531.5 | 608.9 | 104.7 | 14.0 |

| August | 1428.1 | 681.5 | 667.5 | 109.8 | 17.4 |

| September | 1231.3 | 579.6 | 518.8 | 104.2 | 16.1 |

| October | 1245.9 | 557.5 | 443.7 | 99.2 | 14.2 |

| November | 1241.0 | 621.4 | 531.4 | 92.0 | 13.9 |

| December | 1263.5 | 595.0 | 588.3 | 104.3 | 19.0 |

| Average | 1238.9 | 549.4 | 570.9 | 102.7 | 15.2 |

| Parameter | Pollutant Concentration | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| g m−3 | ||||||||||||

| I | II | III | IV | V | VI | VII | VIII | IX | X | XI | XII | |

| Arsenic | 0.0068 | 0.0019 | 0.0017 | 0.0030 | 0.0016 | 0.0022 | 0.0021 | 0.0022 | 0.0016 | 0.0013 | 0.0020 | 0.0002 |

| Chrome | 0.0160 | 0.0120 | 0.0190 | 0.0210 | 0.0130 | 0.0120 | 0.0170 | 0.0330 | 0.0260 | 0.0490 | 0.0170 | 0.0060 |

| Zinc | 0.2800 | 0.1800 | 0.0350 | 0.2800 | 0.2000 | 0.2700 | 0.2300 | 0.3900 | 0.2000 | 0.3700 | 0.3700 | 0.0270 |

| Cadmium | 0.0005 | 0.0000 | 0.0059 | 0.0002 | 0.0002 | 0.0002 | 0.0001 | 0.0002 | 0.0000 | 0.0002 | 0.0002 | 0.0000 |

| Copper | 0.1700 | 0.0900 | 0.0960 | 0.0850 | 0.0830 | 0.1100 | 0.1100 | 0.1500 | 0.0690 | 0.1000 | 0.0840 | 0.0180 |

| Nickel | 0.0440 | 0.0250 | 0.0500 | 0.0330 | 0.0240 | 0.0170 | 0.0150 | 0.0370 | 0.1600 | 0.0580 | 0.0000 | 0.0043 |

| Lead | 0.0046 | 0.0030 | 0.0130 | 0.3700 | 0.2700 | 0.0390 | 0.0550 | 0.0600 | 0.0100 | 0.0410 | 0.0260 | 0.0011 |

| Mercury | 0.0005 | 0.0006 | 0.0003 | 0.0009 | 0.0004 | 0.0002 | 0.0005 | 0.0008 | 0.0003 | 0.0002 | 0.0001 | 0.0002 |

| Silver | 0.0016 | 0.0007 | 0.0007 | 0.0016 | 0.0013 | 0.0020 | 0.0006 | 0.0022 | 0.0004 | 0.0055 | 0.0029 | 0.0002 |

| Vanadium | 0.0013 | 0.0008 | 0.006 | 0.0016 | 0.0007 | 0.0020 | 0.0014 | 0.0027 | 0.0017 | 0.0013 | 0.0013 | 0.0001 |

| Total organic carbon—TOC * | 245.000 | x | x | 174.000 | x | x | 156.000 | x | x | 88.800 | x | x |

| Anionic surfactants * | 2.5600 | x | x | 1.6200 | x | x | 2.0500 | x | x | 0.0700 | x | x |

| Substances that extract with petroleum ether * | 76.0000 | x | x | 69.2000 | x | x | 58.0000 | x | x | 27.6000 | x | x |

| Phenol index | 0.1800 | 0.1900 | 0.1600 | 0.2600 | 0.1700 | 0.1600 | 0.4400 | 0.1000 | 0.1100 | 0.1200 | 0.1200 | 0.1200 |

| Mineral oil index (C10-C40) * | 0.3200 | x | x | 0.3100 | x | x | 0.2200 | x | x | 0.2300 | x | x |

| Chlorides | 245.00 | 216.00 | 225.00 | 263.00 | 321.00 | 227.00 | 413.00 | 173.00 | 235.00 | 215.00 | 211.00 | 232.00 |

| Sulphates | 126.00 | 109.00 | 121.00 | 126.00 | 121.00 | 144.00 | 93.00 | 88.00 | 122.00 | 129.00 | 139.00 | 120.00 |

| Silicon * | 8.5000 | x | x | 10.0000 | x | x | 8.1000 | x | x | 9.3000 | x | x |

| Month | Chemical Agents | |||||||

|---|---|---|---|---|---|---|---|---|

| Thickening Agent | Dewatering Agent I—CWWTP | Dewatering Agent I—LWWTP | Anti-Foam Agent | PIX113 (P-Percipitation) | PIX113 (Antiscalant) | Anti-Scalant I | Anti-Scalant II | |

| kg mth−1 | dm3 mth−1 | dm3 mth−1 | dm3 mth−1 | dm3 mth−1 | dm3 mth−1 | cm3 mth−1 | dm3 mth−1 | |

| January | 5937.6 | 7157.9 | 22,789.3 | 682.0 | 18,400.0 | 29.2 | 762.0 | 0.0 |

| February | 3653.8 | 5140.8 | 17,105.2 | 0.0 | 74,957.0 | 22.3 | 551.0 | 550.0 |

| March | 4824.4 | 4318.3 | 18,600.0 | 0.0 | 88,650.0 | 24.4 | 621.0 | 0.0 |

| April | 5290.8 | 6360.0 | 18,348.0 | 0.0 | 90,425.0 | 24.2 | 617.0 | 100.0 |

| May | 6596.0 | 6398.4 | 20,280.2 | 0.0 | 2587.0 | 25.4 | 637.0 | 200.0 |

| June | 4219.0 | 6375.0 | 19,038.0 | 0.0 | 0.0 | 22.3 | 543.0 | 325.0 |

| July | 5281.3 | 5598.6 | 23,197.3 | 0.0 | 4995.0 | 25.2 | 726.0 | 0.0 |

| August | 6179.0 | 6014.0 | 21,669.0 | 0.0 | 8150.0 | 26.0 | 901.0 | 0.0 |

| September | 5012.6 | 9984.0 | 18,300.0 | 0.0 | 3449.0 | 26.4 | 1057.0 | 0.0 |

| October | 3869.7 | 7257.1 | 17,756.8 | 0.0 | 8306.0 | 22.4 | 931.0 | 0.0 |

| November | 5905.9 | 7431.0 | 18,924.0 | 600.0 | 18,685.0 | 41.7 | 993.0 | 0.0 |

| December | 6736.0 | 5908.6 | 25,482.0 | 620.0 | 25,322.0 | 24.6 | 1285.0 | 0.0 |

| Average | 5292.2 | 6495.3 | 20,124.2 | 158.5 | 28,660.5 | 26.2 | 802.0 | 97.9 |

| TOTAL | 63,506.1 | 77,943.7 | 241,489.8 | 1902.0 | 343,926.0 | 314.2 | 9624.0 | 1175.0 |

| Month | Pollutant Concentration | ||||

|---|---|---|---|---|---|

| g m−3 | |||||

| COD | BOD5 | TSS | TN | TP | |

| January | 51.0 | 4.1 | 5.6 | 8.0 | 0.9 |

| February | 70.7 | 5.4 | 13.2 | 9.6 | 1.5 |

| March | 72.5 | 6.6 | 14.2 | 9.9 | 1.3 |

| April | 69.4 | 4.7 | 13.8 | 10.4 | 0.6 |

| May | 43.3 | 3.3 | 4.3 | 10.4 | 0.2 |

| June | 52.0 | 3.0 | 4.2 | 8.9 | 0.3 |

| July | 40.4 | 2.7 | 3.8 | 9.0 | 0.3 |

| August | 40.5 | 3.3 | 3.9 | 10.4 | 0.4 |

| September | 42.0 | 3.1 | 3.6 | 10.4 | 0.3 |

| October | 41.1 | 3.1 | 4.7 | 9.3 | 0.4 |

| November | 36.4 | 2.2 | 2.6 | 8.7 | 0.3 |

| December | 39.3 | 2.7 | 3.1 | 7.7 | 0.3 |

| Average | 49.9 | 3.7 | 6.4 | 9.4 | 0.6 |

| Parameter | Pollutant Concentration | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg dm−3 | ||||||||||||

| I | II | III | IV | V | VI | VII | VIII | IX | X | XI | XII | |

| Arsenic | 0.0027 | 0.0011 | 0.0012 | 0.0022 | 0.0008 | 0.0010 | 0.0009 | 0.0006 | 0.0011 | 0.0009 | 0.0010 | 0.0001 |

| Chrome | 0.0018 | 0.0031 | 0.0022 | 0.0030 | 0.0012 | 0.0017 | 0.0017 | 0.0016 | 0.0016 | 0.0011 | 0.0003 | 0.0003 |

| Zinc | 0.0420 | 0.0350 | 0.0480 | 0.0310 | 0.0150 | 0.0760 | 0.0310 | 0.0540 | 0.0370 | 0.0300 | 0.0250 | 0.0093 |

| Cadmium | 0.0001 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| Copper | 0.0040 | 0.0047 | 0.0023 | 0.0170 | 0.0130 | 0.0130 | 0.0230 | 0.0120 | 0.0180 | 0.0062 | 0.0058 | 0.0008 |

| Nickel | 0.0450 | 0.0210 | 0.0200 | 0.0160 | 0.0120 | 0.0130 | 0.0120 | 0.0230 | 0.1200 | 0.0150 | 0.0000 | 0.0028 |

| Lead | 0.0007 | 0.0002 | 0.0010 | 0.0096 | 0.0120 | 0.0120 | 0.0033 | 0.0020 | 0.0000 | 0.0000 | 0.0000 | 0.0001 |

| Mercury | 0.0000 | 0.0003 | 0.0001 | 0.0001 | 0.0001 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| Silver | 0.0002 | 0.0001 | 0.0060 | 0.0000 | 0.0005 | 0.0013 | 0.0000 | 0.0002 | 0.0000 | 0.0055 | 0.0025 | 0.0002 |

| Vanadium | 0.0004 | 0.0005 | 0.0002 | 0.0002 | 0.0003 | 0.0005 | 0.0005 | 0.0002 | 0.0007 | 0.0006 | 0.0005 | 0.0000 |

| Total organic carbon—TOC * | 13.500 | x | x | 14.300 | x | x | x | x | x | x | ||

| Anionic surfactants * | 0.2100 | x | x | 0.3200 | x | x | 0.2100 | x | x | 0.0100 | x | x |

| Substances that extract with petroleum ether * | 1.0000 | x | x | 1.2000 | x | x | 1.4000 | x | x | 1.2000 | x | x |

| Phenol index | 0.0096 | 0.0152 | 0.0044 | 0.0088 | 0.0324 | 0.0324 | 0.1360 | 0.0072 | 0.0044 | 0.0100 | 0.0080 | 0.0084 |

| Mineral oil index (C10-C40) * | 0.1800 | x | x | 0.1000 | x | x | 0.1300 | x | x | 0.1500 | x | x |

| Chlorides | 165.00 | 199.00 | 212.00 | 208.00 | 192.00 | 179.00 | 214.00 | 228.00 | 222.00 | 208.00 | 207.00 | 193.00 |

| Sulphates | 120.00 | 139.00 | 126.00 | 168.00 | 146.00 | 148.00 | 133.00 | 152.00 | 147.00 | 144.00 | 138.00 | 122.00 |

| Silicon * | 7.1000 | x | x | 7.9000 | x | x | x | x | x | x | ||

| Month | Grit | Screenings |

|---|---|---|

| Mg mth−1 | Mg mth−1 | |

| January | 98.9 | 57.8 |

| February | 92.4 | 41.9 |

| March | 105.9 | 48.2 |

| April | 154.1 | 42.5 |

| May | 195.6 | 56.8 |

| June | 169.7 | 42.8 |

| July | 173.3 | 31.4 |

| August | 145.4 | 33.5 |

| September | 191.3 | 38.8 |

| October | 179.1 | 35.6 |

| November | 248.2 | 57.2 |

| December | 129.6 | 56.7 |

| Average | 156.9 | 45.3 |

| TOTAL | 1883.4 | 543.1 |

| Month | Digestate for Dewatering—CWWTP | Digestate for Dewatering—LWWTP | TOTAL |

|---|---|---|---|

| m3 mth−1 | m3 mth−1 | m3 mth−1 | |

| January | 46,291.0 | 9126.0 | 55,417 |

| February | 33,937.0 | 4998.0 | 38,935 |

| March | 39,868.0 | 7289.0 | 47,157 |

| April | 41,167.0 | 9697.0 | 50,864 |

| May | 40,948.0 | 8131.0 | 49,079 |

| June | 33,285.0 | 8787.0 | 42,072 |

| July | 37,963.0 | 7144.0 | 45,107 |

| August | 39,649.0 | 7245.0 | 46,894 |

| September | 40,673.0 | 8100.0 | 48,773 |

| October | 38,783.0 | 7570.0 | 46,353 |

| November | 34,969.0 | 7254.0 | 42,223 |

| December | 40,669.0 | 8767.0 | 49,436 |

| Average | 39,016.8 | 7842.3 | 46,859.2 |

| TOTAL | 468,202.0 | 94,108.0 | 562,310.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szulc, P.; Kasprzak, J.; Dymaczewski, Z.; Kurczewski, P. Life Cycle Assessment of Municipal Wastewater Treatment Processes Regarding Energy Production from the Sludge Line. Energies 2021, 14, 356. https://doi.org/10.3390/en14020356

Szulc P, Kasprzak J, Dymaczewski Z, Kurczewski P. Life Cycle Assessment of Municipal Wastewater Treatment Processes Regarding Energy Production from the Sludge Line. Energies. 2021; 14(2):356. https://doi.org/10.3390/en14020356

Chicago/Turabian StyleSzulc, Paulina, Jędrzej Kasprzak, Zbysław Dymaczewski, and Przemysław Kurczewski. 2021. "Life Cycle Assessment of Municipal Wastewater Treatment Processes Regarding Energy Production from the Sludge Line" Energies 14, no. 2: 356. https://doi.org/10.3390/en14020356