Surface Charge Properties of Epoxy Composites under DC Voltage Affected by Surface and Bulk Conductivity

Abstract

1. Introduction

2. Experimental Setup

2.1. Model Epoxy Resin Composites

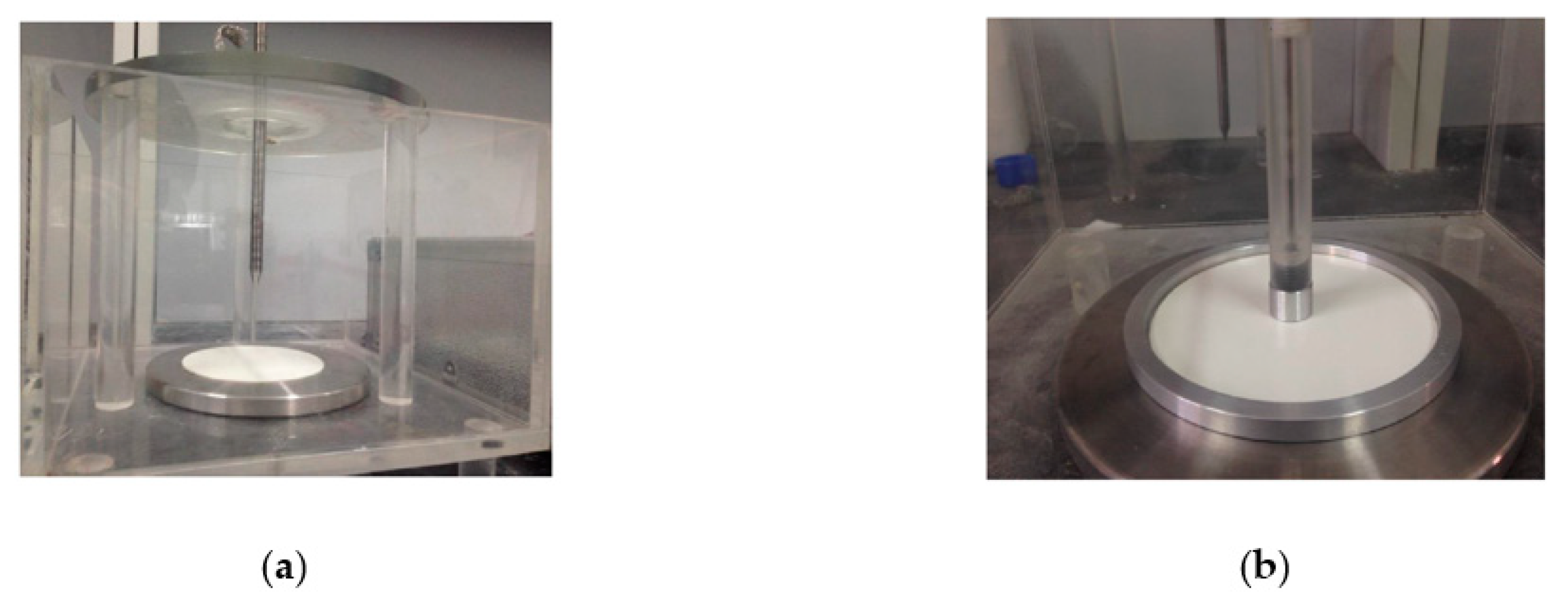

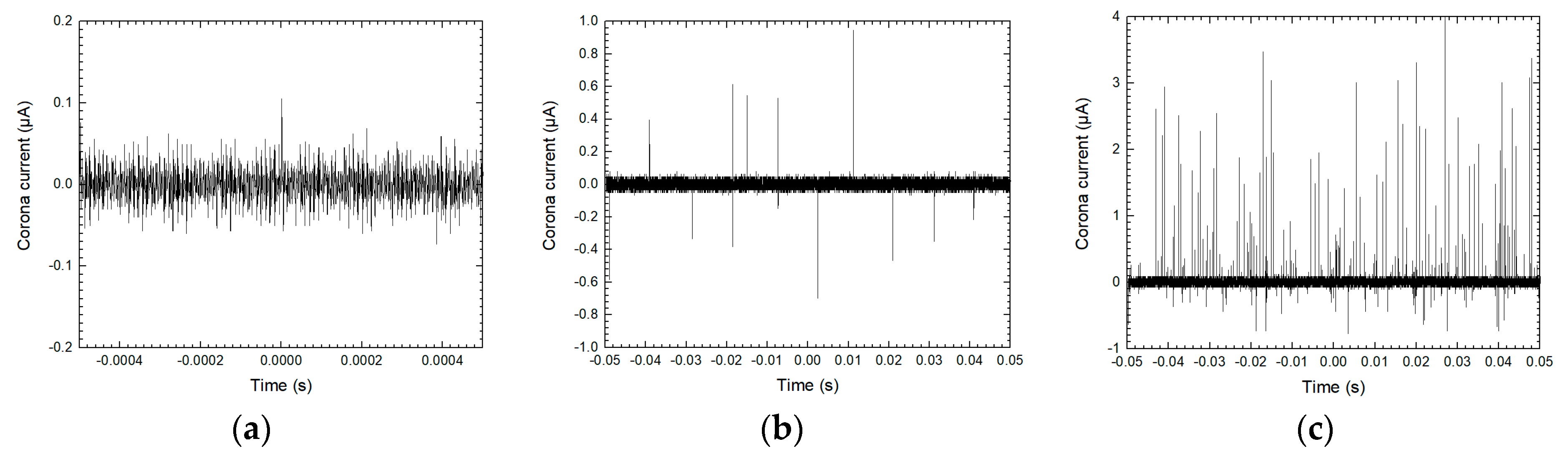

2.2. Measurement Setup

3. Results and Discussion

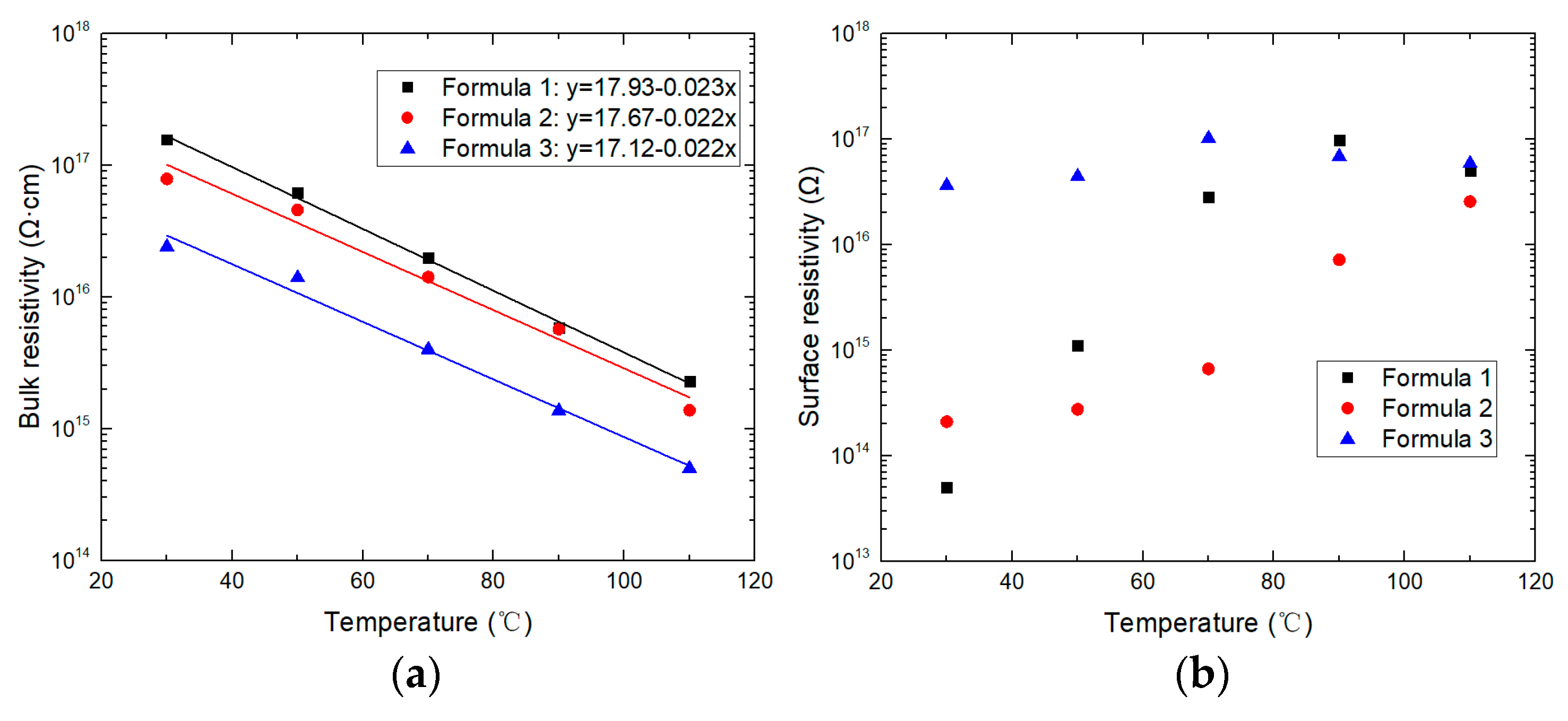

3.1. Bulk and Surface Resistivity

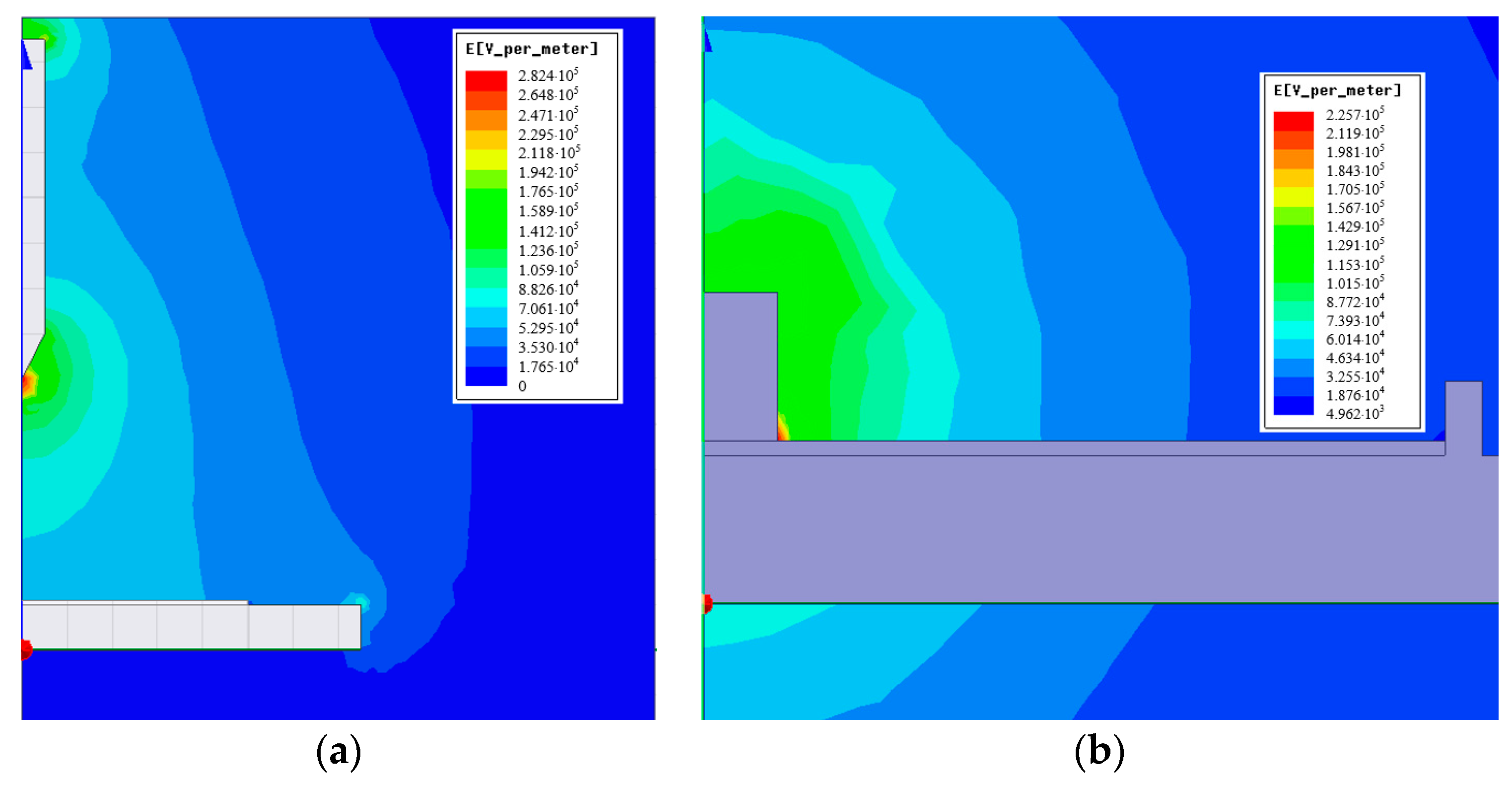

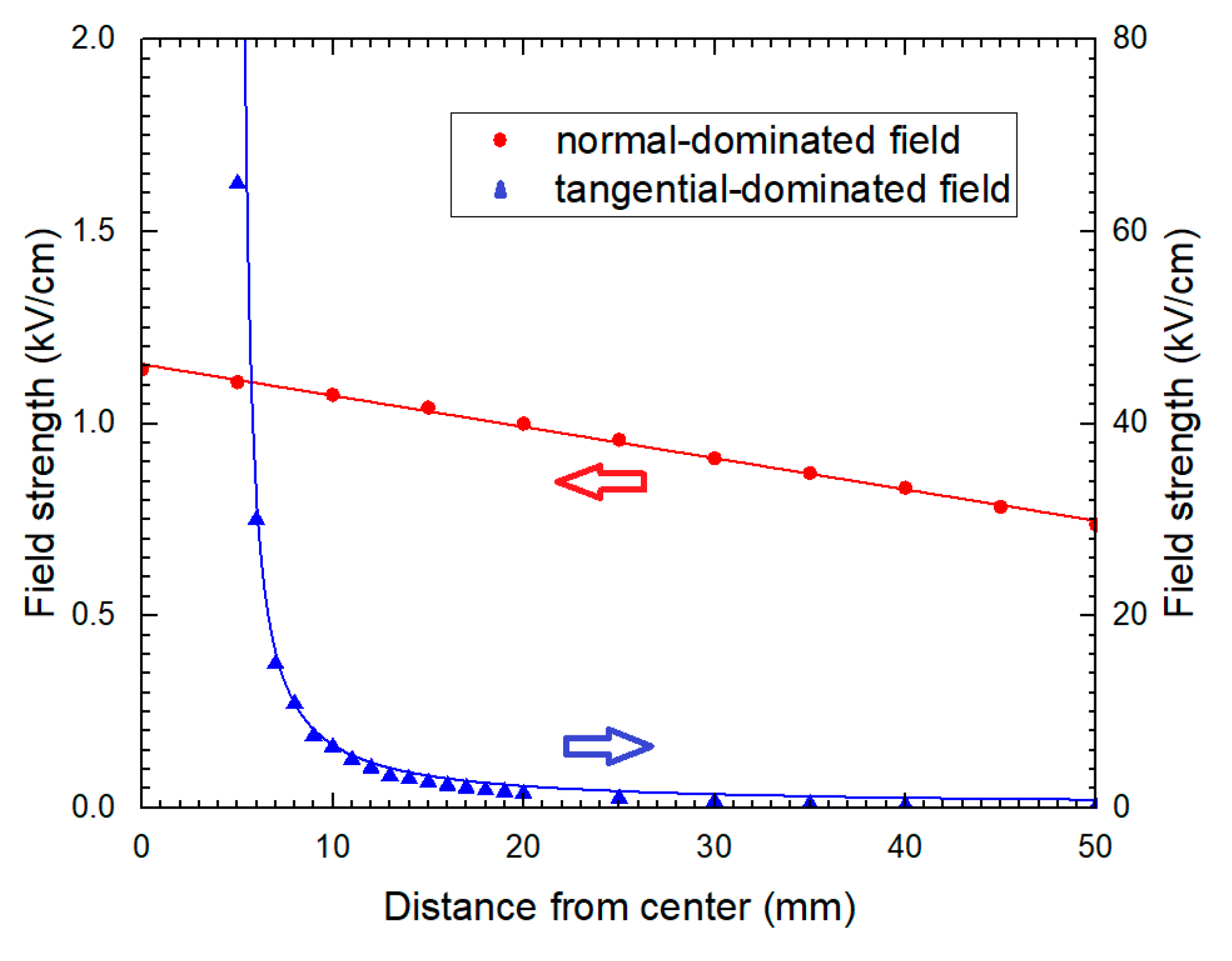

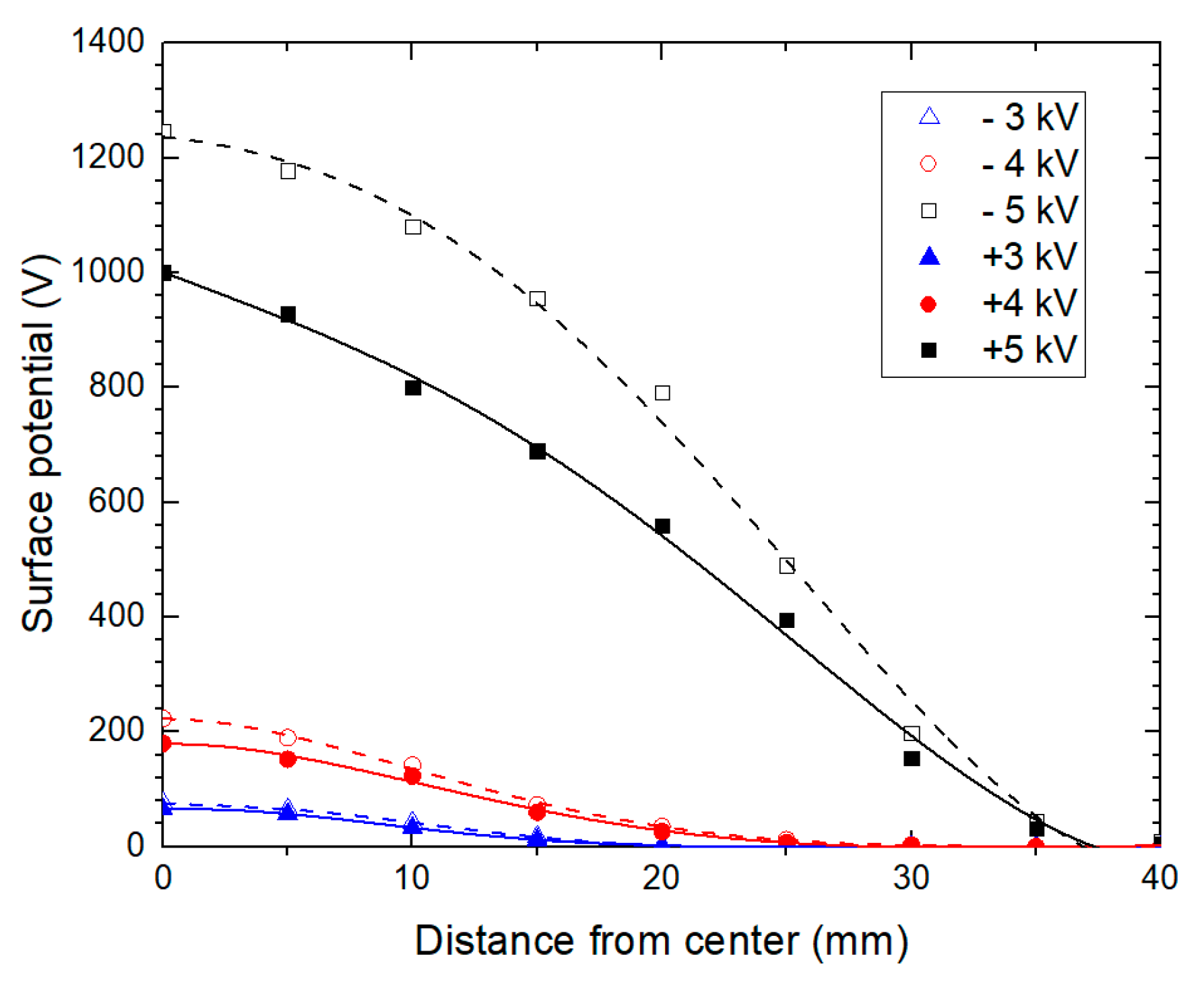

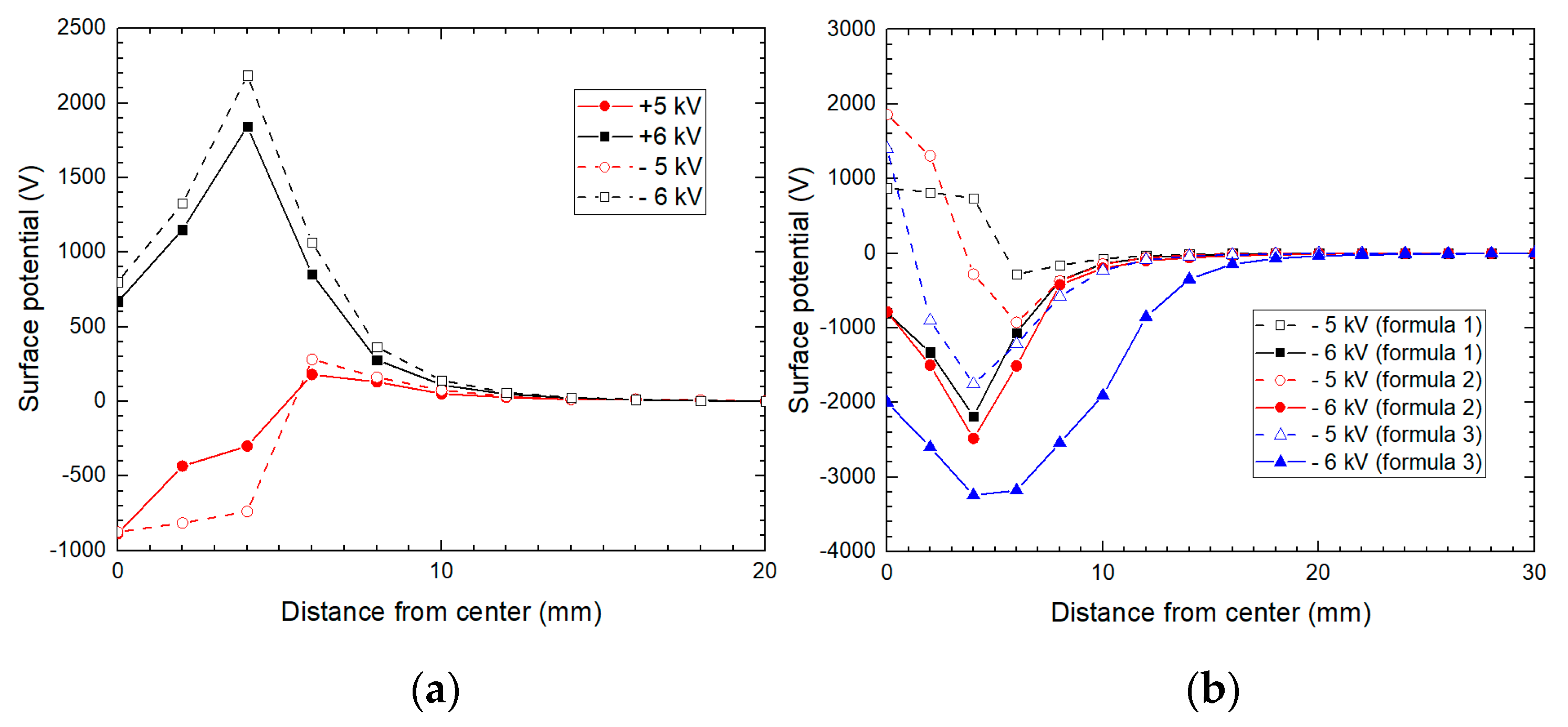

3.2. Surface Potential Distribution

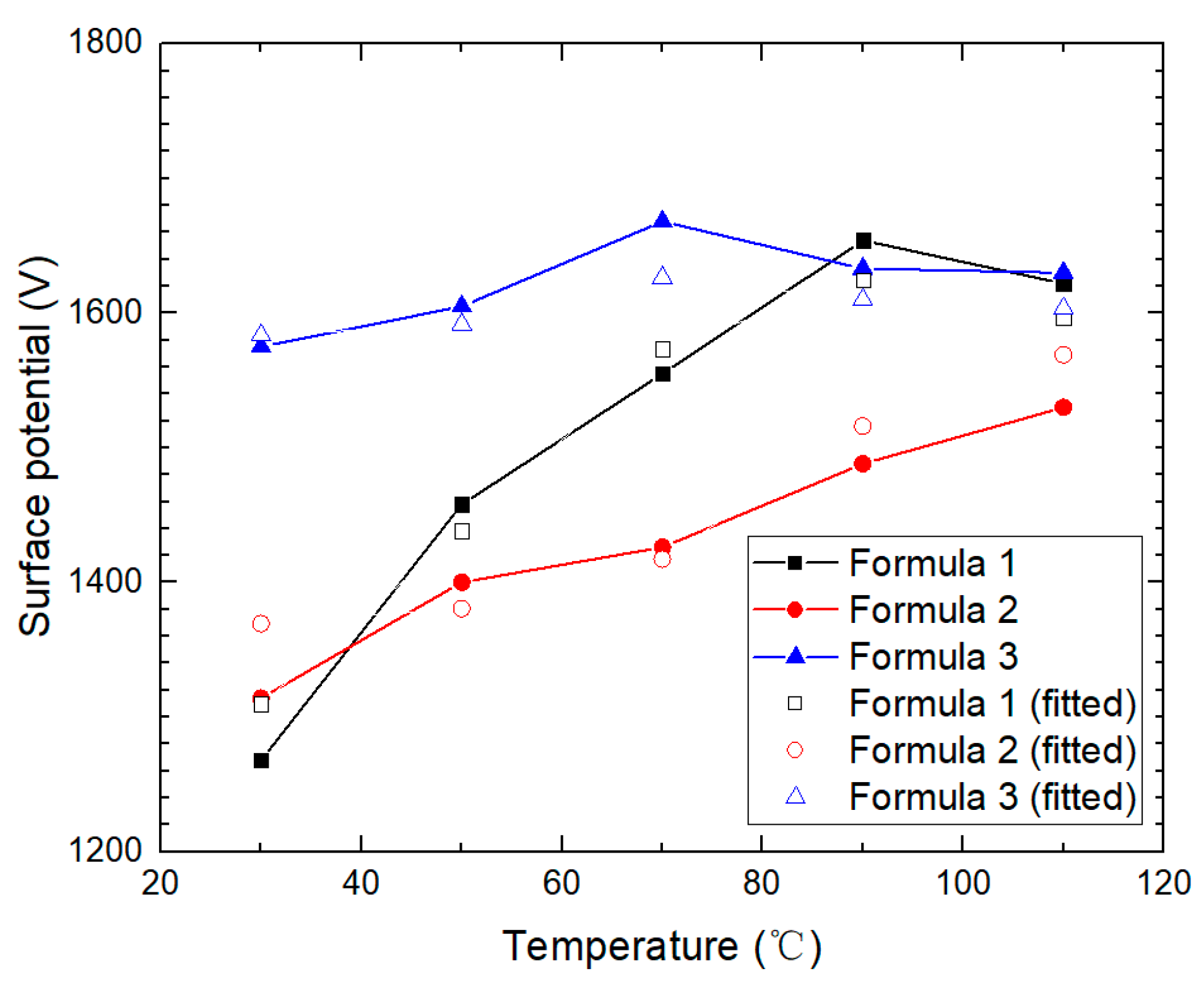

3.3. Temperature Dependence of Surface Charge Accumulation

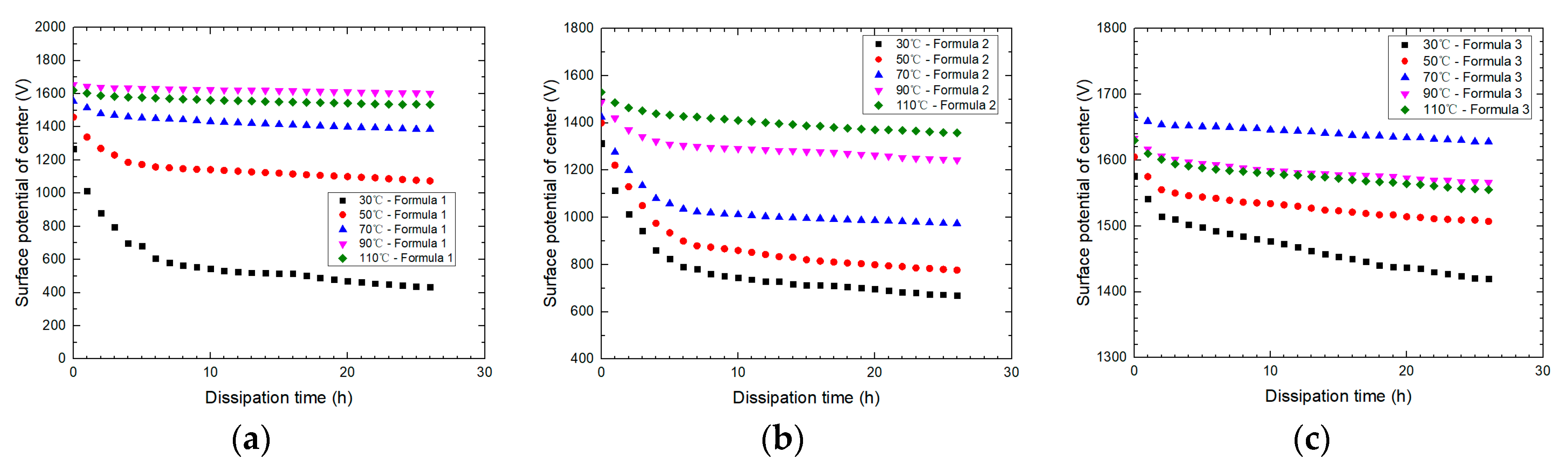

3.4. Temperature Dependence of Surface Charge Dissipation

4. Conclusions

- The logarithmic bulk resistivity decreased approximately linearly with the increase in temperature because of the molecular thermal motion. Overall, the surface resistivity increased, but the trend was complicated because it was affected by various factors.

- More charges accumulated on the sample surface under negative voltages. For a tangential-dominated electric field, both positive and negative charges accumulated after voltage was applied. More charge tends to accumulate under a normal-dominated electric field. The inner structure of DC bushing should be optimized accordingly to avoid normal electric fields applying on the dielectric surface.

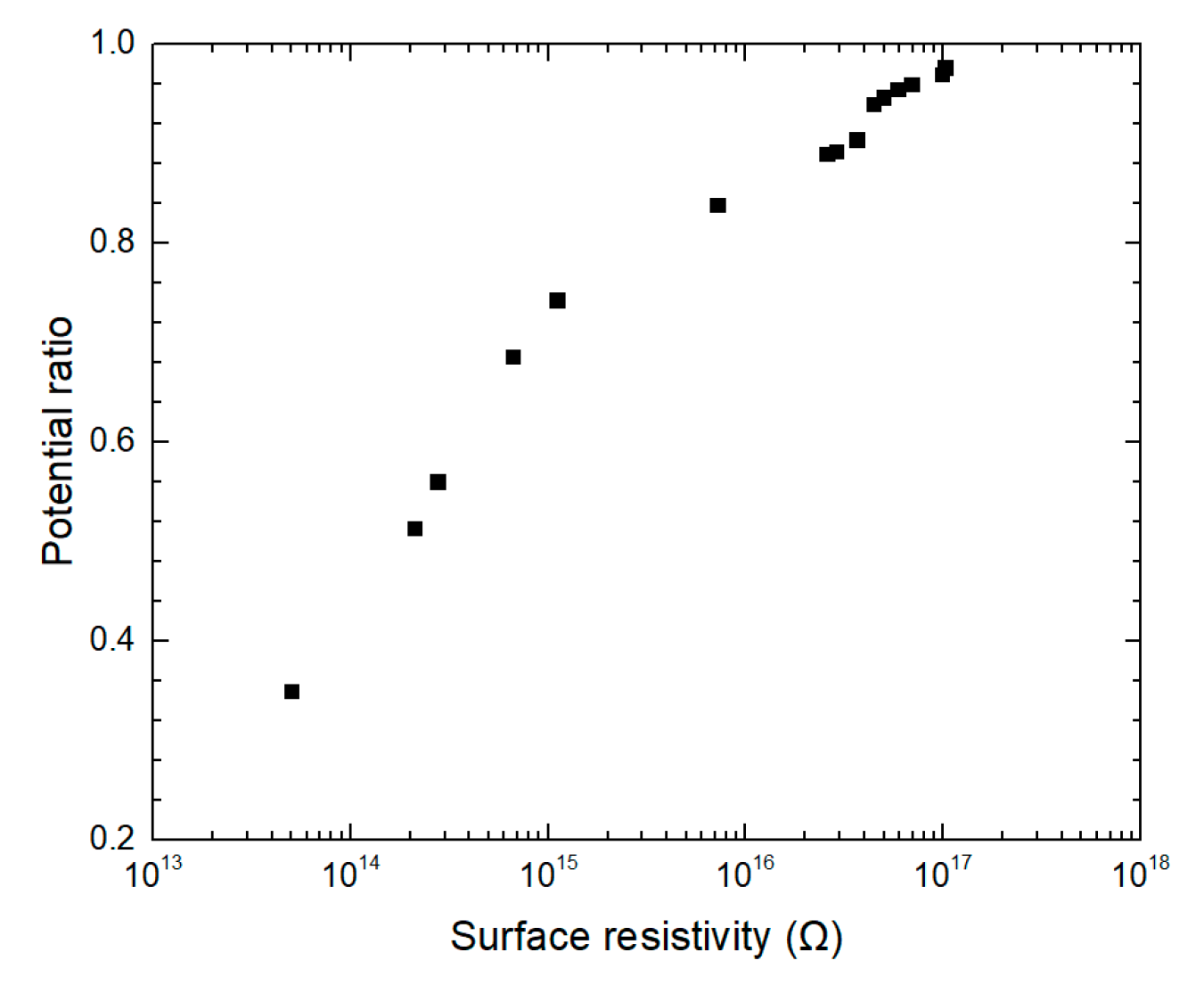

- For a normal-dominated electric field, the saturation potential of the sample surface was closely related to the surface resistivity, which indicated that the main source of the surface charge was discharge in the air. The saturation potential was basically proportional to the logarithmic surface resistivity. Among the three model samples investigated, the coefficient between surface potential and the logarithm of the surface resistivity was similar.

- For the samples under a normal-dominated electric field, the dissipation rate was dominated by the surface resistivity. It indicated that the surface charge mainly dissipated along the sample surface. Based on the results, formula modification could be conducted as well as surface modification in order to suppress the surface charge.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, X.; Zhou, Y.; Zeng, R. High. Voltage Engineering, 2nd ed.; Tsinghua University Press: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Chen, M.; Liu, X.; Liang, C.; Zhao, Y.; Tang, H. Study on surface charge accumulation characteristics of resin impregnated paper wall bushing core under positive AC voltage. Energies 2019, 12, 4420. [Google Scholar] [CrossRef]

- Liu, S. Study on Insulation Problems of ±1100kv DC Bushing Support Insulators. Ph.D. Thesis, Tsinghua University, Beijing, China, 2018. [Google Scholar]

- Li, C.; Hu, J.; Lin, C.; Zhang, B.; Zhang, G.; He, J. Surface charge migration and dc surface flashover of surface-modified epoxy-based insulators. J. Phys. D Appl. Phys. 2017, 50, 065301. [Google Scholar] [CrossRef]

- Zhang, B.; Qi, Z.; Zhang, G. Charge accumulation patterns on spacer surface in HVDC gas-insulated system: Dominant uniform charging and random charge speckles. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1229–1238. [Google Scholar] [CrossRef]

- Zhou, H.-Y.; Ma, G.-M.; Wang, Y.; Li, C.-R.; Tu, Y.-P.; Ye, S.-P.; Zhang, B.; Guo, X.-F.; Yan, X.-L. Surface charge accumulation on 500kV cone-type GIS spacer under residual DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1230–1237. [Google Scholar] [CrossRef]

- Li, H.; Kim, J. Volume and surface resistivity measurement of insulating materials using guard-ring terminal electrodes. Energies 2020, 13, 2811. [Google Scholar] [CrossRef]

- Chen, X.; Guan, H.; Jiang, T.; Du, H.; Paramane, A.; Zhou, H. Surface charge dissipation and DC flashover characteristic of DBD plasma treated epoxy resin/AlN nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 504–511. [Google Scholar] [CrossRef]

- Zhang, S.; Peng, Z.; Liu, P.; Li, N. Design and dielectric characteristics of the ±1100 kV UHV DC wall bushing in China. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 409–419 101109/TDEI2014004454. [Google Scholar] [CrossRef]

- Li, D.; Zhang, G.; Wang, T.; Hou, Y. Charge accumulation characteristic on polymer insulator surface under AC voltage in air and C 4 F 7 N/CO 2 mixtures. High. Volt. 2020, 5, 160–165. [Google Scholar] [CrossRef]

- Winter, A.; Kindersberger, J. Transient field distribution in gas-solid insulation systems under DC voltages. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 116–128. [Google Scholar] [CrossRef]

- Du, B.X.; Li, A.; Li, J. Effects of AC and pulse voltage combination on surface charge accumulation and decay of epoxy resin. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2368–2376. [Google Scholar] [CrossRef]

- Luo, Y.; Tang, J.; Pan, C.; Pan, Z.; Li, Y.; Cui, Z. Dynamics of surface charge and electric field distributions on basin-type insulator in GIS/GIL due to voltage polarity reversal. High. Volt. 2020, 5, 151–159. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, W.; Hou, Y.; Zhang, G. Surface charge accumulation and suppression on fullerene-filled epoxy-resin insulator under DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2011–2019. [Google Scholar] [CrossRef]

- Tu, Y.; Zhou, F.; Jiang, H.; Bai, F.; Wang, C.; Lin, J.; Cheng, Y. Effect of nano-TiO2/EP composite coating on dynamic characteristics of surface charge in epoxy resin. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1308–1317. [Google Scholar] [CrossRef]

- Fujinami, H.; Yashima, M.; Takuma, T. Mechanism of the charge accumulation on gas insulated spacers under DC stress. In Proceedings of the 5th International Symposium on High Voltage Engineering, Braunschweig, Germany, 12–17 July 1987. [Google Scholar]

- Fujinami, H.; Takuma, T.; Yashima, M.; Kawamoto, T. Mechanism and effect of DC charge accumulation on SF/sub 6/ gas insulated spacers. IEEE Trans. Power Deliv. 1989, 4, 1765–1772. [Google Scholar] [CrossRef]

- Cooke, C.; Wootton, R.; Cookson, A. Influence of particles on AC and DC electrical performance of gas insulated systems at extra-high-voltage. IEEE Trans. Power Appar. Syst. 1977, 96, 768–777. [Google Scholar] [CrossRef]

- IEC Standard- International Electrotechnical Commission. Methods of Test for Volume Resistivity and Surface Resistivity of Solid Electrical Insulating Materials; International Electrotechnical Commission: Geneva, Switzerland, 1980. [Google Scholar]

- Chen, K. Experimental Study of Accumulation Characteristics of Surface Charges on Epoxy in Air. Master’s Thesis, Tsinghua University, Beijing, China, 2016. [Google Scholar]

- Kumada, A.; Okabe, S.; Hidaka, K. Resolution and signal processing technique of surface charge density measurement with electrostatic probe. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 122–129. [Google Scholar] [CrossRef]

- Li, C.; Hu, J.; Lin, C.; He, J. The control mechanism of surface traps on surface charge behavior in alumina-filled epoxy composites. J. Phys. D Appl. Phys. 2016, 49, 445304. [Google Scholar] [CrossRef]

- Babu, M.S.; Sarathi, R.; Vasa, N.J.; Imai, T. Investigation on space charge and charge trap characteristics of gamma-irradiated epoxy micro–nano composites. High. Volt. 2020, 5, 191–201. [Google Scholar] [CrossRef]

- Li, D.; Zhang, G.; Hou, Y.; Zhang, B. Charge distribution on polymer insulator surface under AC voltage. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1709–1715. [Google Scholar] [CrossRef]

- Wang, F.; Fang, Z.; Qiu, Y. Study of Charge Accumulation on Insulator Surface in HVDC Gas-Insulated Switchgear. Chin. Soc. Electr. Eng. 2005, 3, 107–111. (In Chinese) [Google Scholar]

- Zhang, G.; Zhang, B.; Wang, Q.; Li, J. Study of charge accumulation on insulator aurface in HVDC gas-insulated switchgear. High. Volt. Engir. 2015, 41, 1430–1436. (In Chinese) [Google Scholar] [CrossRef]

- Xing, Z.; Li, C.; Zhang, C.; Zhang, Z.; Li, W.; Ru, J.; Xiao, Y.; Zhou, Y.; Chen, X. Influence of epoxy insulating materials parameters on surface charge characteristics and surface flashover under DC. In Proceedings of the 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; pp. 184–187. [Google Scholar]

- Schueller, M.; Straumann, U.; Franck, C. Role of ion sources for spacer charging in SF6 gas insulated HVDC systems. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 352–359. [Google Scholar] [CrossRef]

- Iwabuchi, H.; Donen, T.; Matsuoka, S.; Kumada, A.; Hidaka, K.; Hoshina, Y.; Takei, M. Influence of surface-conductivity nonuniformity on charge accumulation of GIS downsized model spacer under DC field application. Electr. Eng. Jpn. 2012, 181, 29–36. [Google Scholar] [CrossRef]

- Hama, H.; Hikosaka, T.; Okabe, S.; Okubo, H. Cross-equipment study on charging phenomena of solid insulators in high voltage equipment. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 508–519. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) | Tensile Strength (MPa) | Bending Strength (MPa) | Relative Permittivity | Dielectric Loss (%) | Breakdown Strength (kV/mm) | Temperature of Glass Transition (°C) |

|---|---|---|---|---|---|---|---|

| Formula 1 | 2.28 | 80 | 137 | 5.2 | 0.25 | 33 | 144 |

| Formula 2 | 2.19 | 76 | 134 | 5.0 | 0.24 | 32 | 141 |

| Formula 3 | 2.25 | 70 | 132 | 5.0 | 0.25 | 30 | 118 |

| Temperature (°C) | Formula 1 | Formula 2 | Formula 3 |

|---|---|---|---|

| 30 | 92.56 | 91.75 | 95.10 |

| 50 | 96.91 | 96.96 | 96.41 |

| 70 | 94.50 | 96.21 | 98.07 |

| 90 | 97.33 | 93.84 | 96.99 |

| 110 | 97.14 | 93.24 | 97.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liang, X.; Chen, K.; Wu, C.; Liu, S. Surface Charge Properties of Epoxy Composites under DC Voltage Affected by Surface and Bulk Conductivity. Energies 2021, 14, 370. https://doi.org/10.3390/en14020370

Wang Q, Liang X, Chen K, Wu C, Liu S. Surface Charge Properties of Epoxy Composites under DC Voltage Affected by Surface and Bulk Conductivity. Energies. 2021; 14(2):370. https://doi.org/10.3390/en14020370

Chicago/Turabian StyleWang, Qian, Xidong Liang, Ke Chen, Chao Wu, and Shan Liu. 2021. "Surface Charge Properties of Epoxy Composites under DC Voltage Affected by Surface and Bulk Conductivity" Energies 14, no. 2: 370. https://doi.org/10.3390/en14020370

APA StyleWang, Q., Liang, X., Chen, K., Wu, C., & Liu, S. (2021). Surface Charge Properties of Epoxy Composites under DC Voltage Affected by Surface and Bulk Conductivity. Energies, 14(2), 370. https://doi.org/10.3390/en14020370