Abstract

Influence of wastes generated during juice production: apple, carrot and red beet, added to barley straw, on density of pellet mass, pellet hardness, ash content and calorific value was assessed. Dry mass content of additives in the substrate to pellet production was: 0, 10, 20 and 30% of the mixture weight. The relative humidity of the raw material was: 17.0, 19.5 and 22%. Higher percentages of additives and higher moisture content in the raw materials increased the hardness and density of the pellet. The contents of natural polymers such as lignin, hemicellulose and cellulose were determined in primary materials used to prepare substrate and in pellet. Changes in the determination of these substances was observed as a result of the granulation process.

1. Introduction

In connection with the depletion of fossil fuel resources, people are looking for renewable and biodegradable energy carriers that will not result in environmental pollution during their combustion. To this end, power engineers have been investigating different biological raw materials that could be used to produce different forms of fuel [1,2,3]. Apart from the already widely used waste wood, these include agricultural waste and food industry residues, which are characterized by traits that following minor energy expenses for their refinement or processing would enable their use as fuels [1,4,5].

The popularity of the energy pellet as biofuel has encouraged the research on the processing of solid waste biomass into this type of energy carrier. An energy pellet must meet specific quality requirements [6]. This is particularly important during transport and storage. Atmospheric factors, including very low temperatures, can have a negative effect on fuel durability parameters [7].

Straw of cereals and other crops is a byproduct of plant production. After deducting the demand for litter and feed for livestock and maintaining the necessary amount for plowing, excess remains can be alternatively used as the source of energy in power production.

Straw is a bulk material, which affects its costs of transport and storage. Straw pelletization aiming at reducing its volume has been already applied in the production of feeds with the use of straw, and this method is currently used in the production of solid fuel based on this raw material. Bulk material compacting technologies enable the obtaining fuel with low moisture content and uniform density on the basis of straw. Granulated straw can be used in household furnaces and boilers, as well as power plants and heat and power plants. For the production of pellets, straw from rye [8,9], wheat [2,8,10,11,12], barley [13], rice [14,15,16], rapeseed [8,17,18,19], corn [20,21] and even tobacco [22] can be used. The method of obtaining straw pellets with high hardness and resistance to crushing is to mix it with a binder prior to granulation [11,12]. There have been attempts to use a binder in the form of organic waste substances, such as: rapeseed oilcake, soybean and spelt hulls, paper sludge and wastewater treatment sludge [8,10,23,24,25]. What is more, straw has been mixed with the following binder types: wheat seed, wheat flour, fodder beet pulp and even chicken manure [9,12,26].

Apart from natural additives to the substrate having a positive influence on pellet hardness, the same effect has been searched by using other additives and methods. Glycerol added to rapeseed straw and its effect on the quality of pellet has been tested [17]. Binders such as crude glycerol, bentonite, lignosulfonate and softwood residue (wood residue) added to rye straw resulted in increased resistance and calorific value of pellet [11]. Apart from the improved pellet hardness and resistance to damage, additives can have a positive effect on other traits of the granulated biofuel. It has been determined that the addition of paper sludge to straw results in an increased ash melting point [10,23,24]. Addition of the sludge may decrease the pellet hardness variability caused by the biomass heterogeneity [25].

The method of pelletization resulting from machine construction, substrate moisture content and pelletization temperature, particle size and plant species are important factors that can affect the quality of the pellet produced from biomass, including straw [20]. These factors affect the bulk density, density, stability and hardness of pellets [9,26,27]. Granulation temperature with humidity and size of raw material particles turned out to be the most important factors affecting the quality of pellet [13,21,28,29,30]. The moisture content from 13% to 20% at granule formation temperature between 60–80 °C was found to be the optimum for rice straw [15]. Factors such as biological composition of granulated biomass, its moisture content and mechanical phenomena occurring during pressure agglomeration should affect the changes in biochemical structure of materials [31].

Pomace is the waste that forms after fruit and vegetable juice production. The simplest technologies, particularly those used for natural unclarified juices, comprise of material disintegration and juice pressing, for instance in centrifugal separators. These technologies are used in households and in small fruit and vegetable enterprises. Pomace constitutes biodegradable waste, which may pose a problem for processing plants. At present, different attempts are made at managing this waste, in different ways. For the production of apple juice, 75% of apple weight is used to produce juice, while 25% is a byproduct that is apple pomace. As a rule, apple pomace is disposed of, which results in environmental pollution [32]. Attempts have been made to use apple pomace as substrates for enzyme, protein, organic acid and polysaccharide production [33]. Furthermore, apple pomace can be used as an ingredient of granulated feeds for livestock [34,35,36].

There is an ongoing research on the use of pomace from carrot root for the production of human and animal food [37,38,39]. For energy purposes, it can be used as the raw material for bioethanol production and a co-substrate for biogas production [40,41]. Carrot root pomace, similar to apple pomace, can be also applied in cellulose production [42].

Due to its nutritional value, red beet root pomace can be used as ingredient for the production of foods and feeds for animals [43,44]. It can also be used for energy purposes in anaerobic fermentation systems [45].

The unprocessed pomace from juice production in small enterprises and home processing constitutes an issue, but when dried and added to straw, it can become a co-substrate for pellet production, which could be used as energy pellet or feeding pellet for livestock. The content of lignin, cellulose, protein or starch in the substrate can affect the process of pressure agglomeration. The original material enriched with such components undergoes easier compaction, and the obtained pellet is characterized by high stability as compared with raw material with high fiber content [46,47].

The study objective was to assess the addition of apple, carrot and red beet juice production waste to barley straw on the physical and chemical parameters of the obtained pellet, such as: hardness, calorific value, density and ash content, as well as cellulose content. Furthermore, an attempt was made at assessing the effect of hemicellulose and lignin contained in the substrates on the parameters of the produced pellet.

2. Materials and Methods

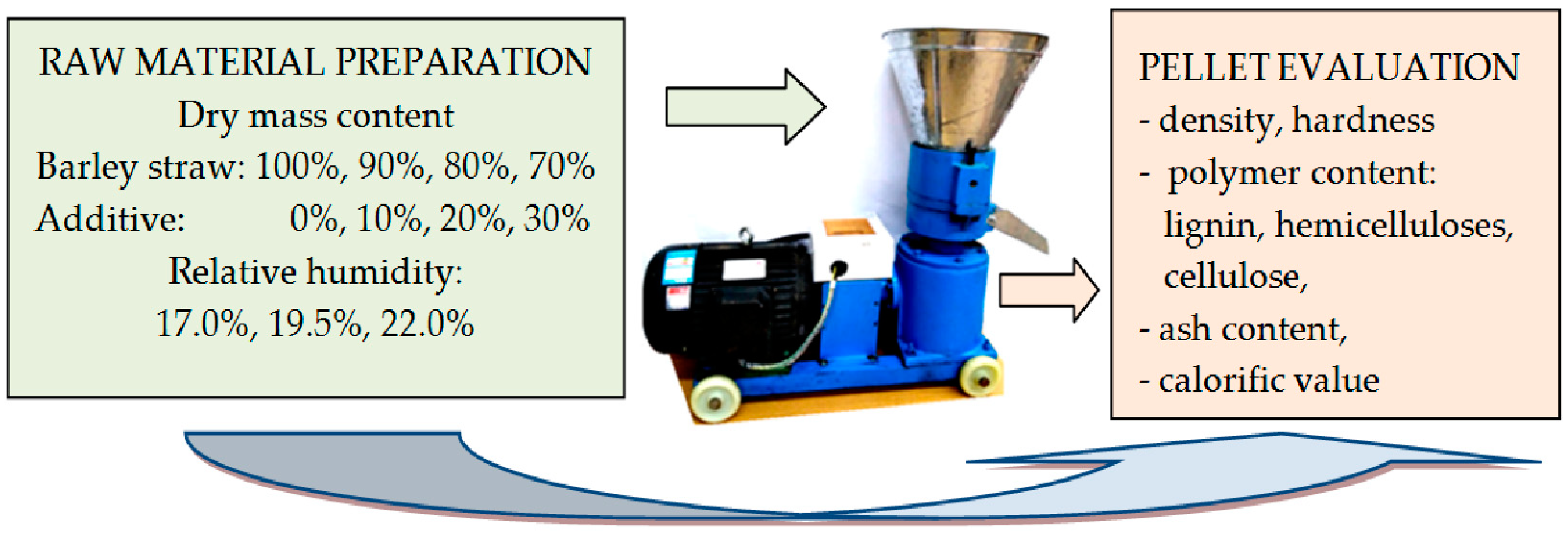

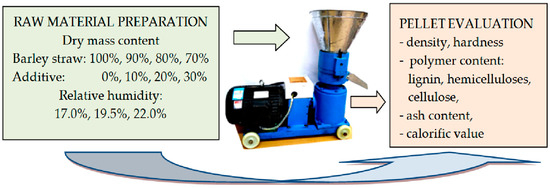

Post-harvest barley straw and pomace from apple fruit, carrot root and red beet root juice production were used to prepare material for the production of pellets. The pomace was the waste obtained in juice production in juice extractors. A general diagram of the entire process of preparing the raw materials for pellet production and the conducted research is shown in Figure 1.

Figure 1.

The diagram of research.

Prior to the testing, relative moisture content of the raw materials was determined with the dry oven test. The moisture content determination was carried out in accordance with the PN-PN ISO 18134-1: 2015 2015-11 standard. Relative moisture content of the raw material was respectively: post-harvest barley straw—10.7%, apple pomace—73.9%, carrot pomace—67.3% and red beet pomace—65.5%. Sample drying was carried out at a temperature of 105 °C. Calculations were performed in accordance with the Formula (1):

where: Mad—relative moisture content (%), m1—empty vessel weight (g), m2—weight of vessel with sample before drying (g) and m3—weight of vessel with sample after drying (g).

After the determination of the preliminary moisture content, the pomace was dried for 48 h, in room temperature, in a drier with forced air circulation. After drying, the relative moisture content of apple pomace decreased to 11.9%, carrot pomace to 12.2% and red beet pomace to 15.8%. Subsequently, the materials were disintegrated: barley straw was disintegrated in a universal shredder, and pomace in a grinder mill. After the disintegration, the raw material particle size was, respectively: barley straw chaff 0.2–1.0 mm and pomace particles 0.1–0.3 mm. The size range of the raw materials particles resulted from the method of biomass preparation. Selection of the size of the straw particles was made on a shaker with sieves. The material was sieved through sieves with hole sizes of: 0.2, 0.315, 0.4, 0.5 and 1.0 mm. For the production of pellets this material was used, which passed through the sieve with the largest openings and remained on the sieve with the smallest holes. The size of the pomace particles resulted from the set degree of grinding them in the grinder mill.

The disintegrated raw materials were mixed by combining the disintegrated barley straw separately with: disintegrated apple, carrot and red beet root pomace. The prepared mixes contained: 10%, 20% and 30% contribution of pomace dry mass content, and, respectively, 90%, 80% and 70% barley straw dry mass. In addition, for comparative purposes, raw material with 100% content of barley straw was used as a control sample with 0% pomace addition. Subsequently, the prepared raw material groups: straw 100%, straw 90% + 10% pomace, straw 80% + 20% pomace and straw 70% + 30% pomace, were additionally divided into three equal groups so as to obtain three relative moisture contents by means of adding measured water volume: 17.0%, 19.5% and 22.0%. Water was introduced to the biomass by means of spraying and mixing with raw material. Thus, prepared groups of raw materials for pellet production were tightly packed into foil bags and placed for 24 h in a refrigerator, enabling the biomass to absorb the water in an equal manner.

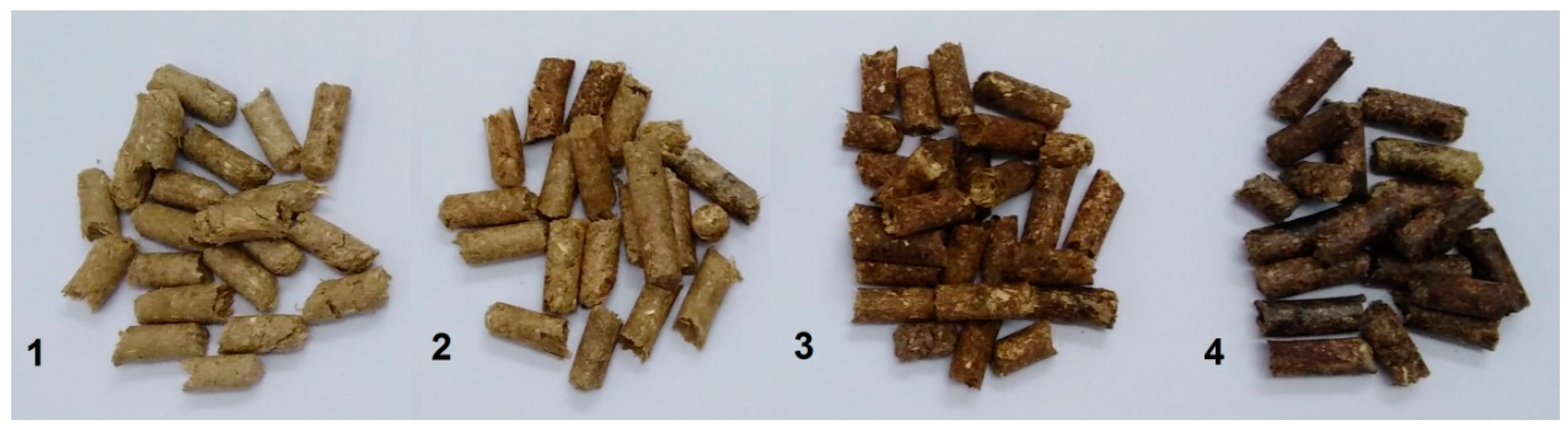

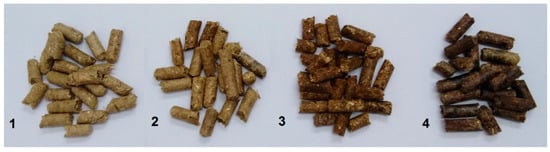

Pellets from the prepared raw material samples were produced in a disc granulator with rotating matrix, presented in Figure 1. The granulator had motor power rating of 4 kW, and it was equipped with a matrix with 22 mm thickness and 148 mm diameter, with 100 openings suitable for the production of pellet with the diameter of 6 mm. The matrix rotational speed was 870 rpm, the diameter of rolls pressing the biomass to the matrix was 78 mm. The perimeter of the rolls had 5 mm teeth, arranged every 2 mm. The distance set between the roll surface and the matrix surface was 0.4 mm. The granulation process temperature was taken with optical thermometer by means of measuring the external temperature of the container with pressure rolls and the rotating matrix. The temperature was 65 °C throughout the granulation process. The appearance of the pellet produced from individual materials is presented in Figure 2.

Figure 2.

View of pellets: 1—barley straw 100%, 2—barley straw with carrot pomace 30%, 3—barley straw with apple pomace 30%, and 4—barley straw with red beet pomace 30%.

After the production and before the measurements, the pellet samples were dried at the temperature of 105 °C in the ALPINA S-40 laboratory dryer to obtain zero water content. The granulate mass was checked every 30 min using a Radwag AS 160.X2 PLUS precision scales.

Pellet density was determined by means of calipers, measuring the length and diameter of 10 randomly selected pellets, the ends of which were first cut perpendicular to the side surface, so as to approximate the pellet shape to a cylinder. All prepared pellets were weighed in total, on the laboratory scales, with 0.0001 g accuracy. Each pellet volume was measured on the basis of the Formula (2). Pellet density was calculated as the ratio of the total weight to amount of pellet volumes, as seen in Formula (3).

where: Vi—volume of each pellet (cm3), Li—length of each pellet (cm) and Di—diameter of each pellet (cm).

where: ρ—pellet mean density (g∙cm−3), and M—total weight for 10 randomly selected pellets (g).

Hardness of the produced pellet was analyzed using the Kahl hardness tester (K31750011, Reinbek, Germany). The measurements were done in 25 replicates for each content of all substrate ingredients and for all substrate moisture content values. With the use of the Kahl hardness tester, the value of tangential force to the pellet cross section [N] was measured at which the pellet was crushed.

The filtration bag method and the Ankom A200 apparatus (Ankom A200; ANKOM Technology) were used to determine the content of lignin, cellulose and hemicellulose in the primary products used to prepare the substrate as well as in the produced pellet. Determination of the content of neutral detergent fiber (NDF) was carried out with the use of the Van Soest method [48]. Determination of acid detergent fiber (ADF) and acid detergent lignin (ADL) were carried out in accordance with the norm presented in the paper [48]. Cellulose content was determined on the basis of the difference between ADF and ADL fractions, whereas hemicellulose content was determined from the difference between NDF and ADF fractions [48].

Pellet higher heating value (HHV) was determined according to PN-ISO 1928:2002 standard, using a Kl-12Mn bomb calorimeter. The measurements were done in two replicates.

Ash content determination was carried out in accordance with PN-EN ISO 18122:2016-01 standard. Ash content in the pellets was carried out in muffle kiln by Nobertherm. Ash content was determined by maintaining samples at the temperature of 600 °C, in oxygen atmosphere in open crucibles. This temperature was maintained for two hours. Subsequently, before weighing, the ash samples were cooled down to room temperature in desiccators. Ash content Ad was expressed in percent, relative to dry mass, and was calculated from the following formula:

where: m1—weight of empty crucible with cover (g), m2—weight of crucible with cover and material before combustion (g) and m3—weight of crucible with cover and material after combustion (g). The measurements were done in four replicates.

3. Results and Discussion

3.1. Pellet Density

Density values of the produced pellet were determined on samples collected from all pellet types, using Formulas (2)–(4). The relative moisture content values of the raw materials: 17.0, 19.5 and 22%, were also taken into account.

Results presented in Table 1 suggest increased pellet density with the increase of percentage share of pomace added to straw. Increase in the density can also be observed at higher moisture content values of the substrate. The heightening of pellet density, resulting from the raised proportion of additives in barley straw and from the going up moisture content of the raw material, proves that the additives and humidity improve the barley straw ability of compaction under pressure.

Table 1.

Influence of substrate relative moisture content and substrate content on the density of obtained pellet.

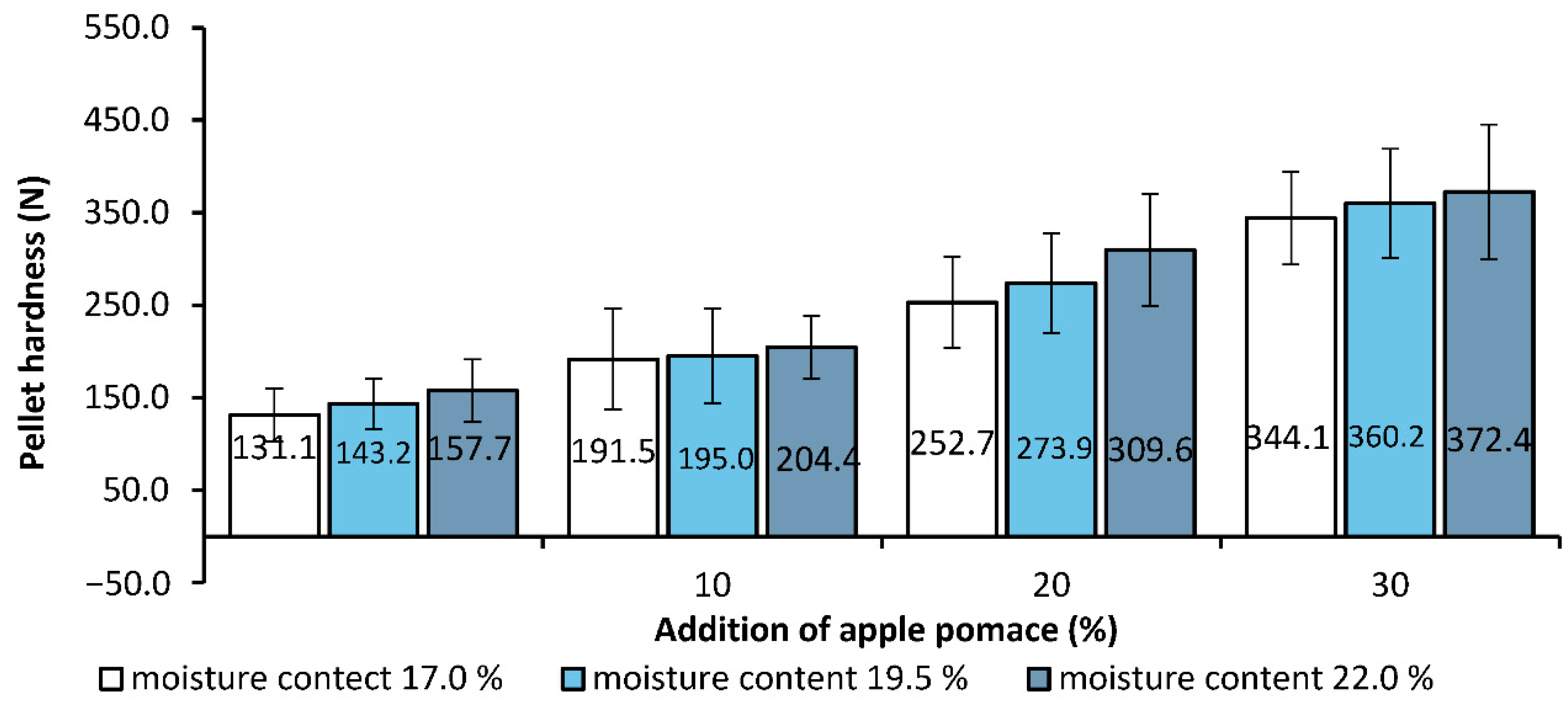

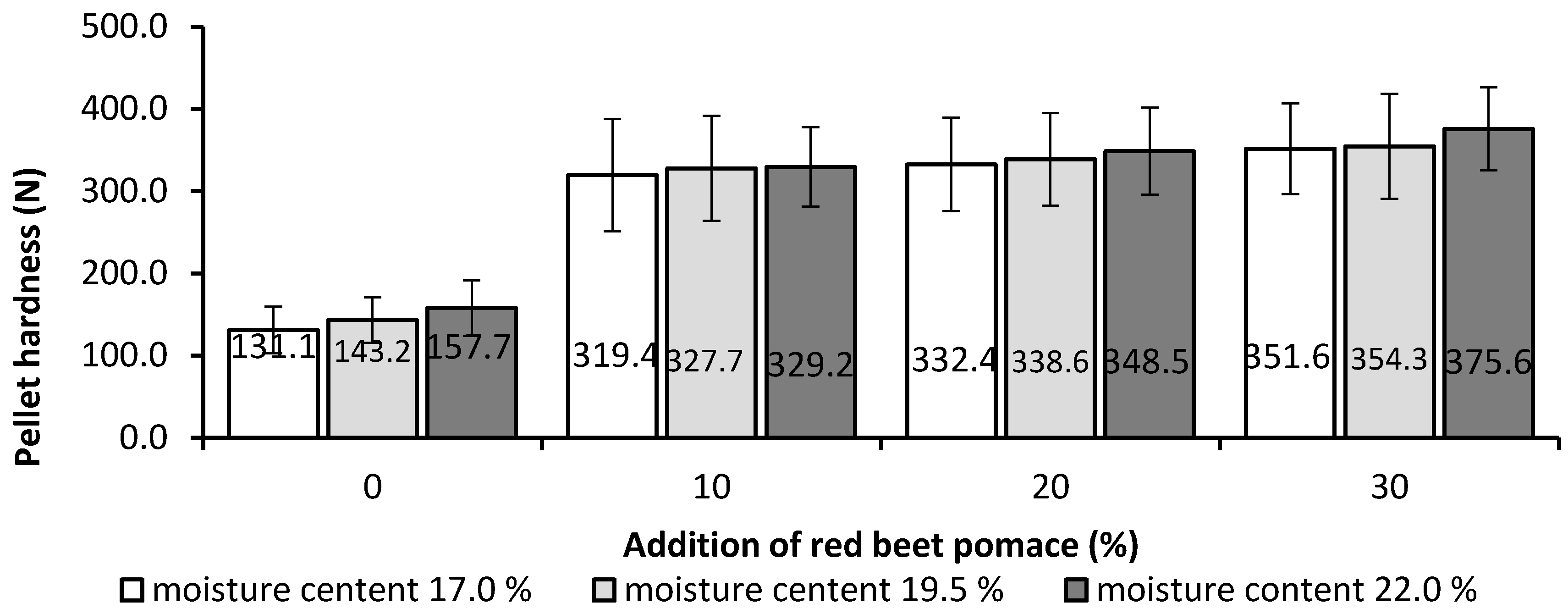

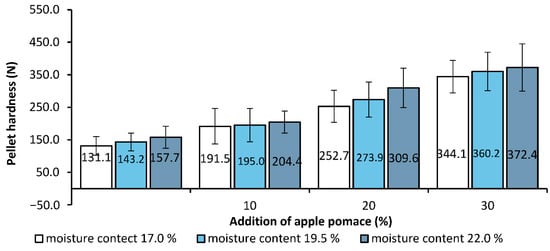

3.2. Pellet Hardness

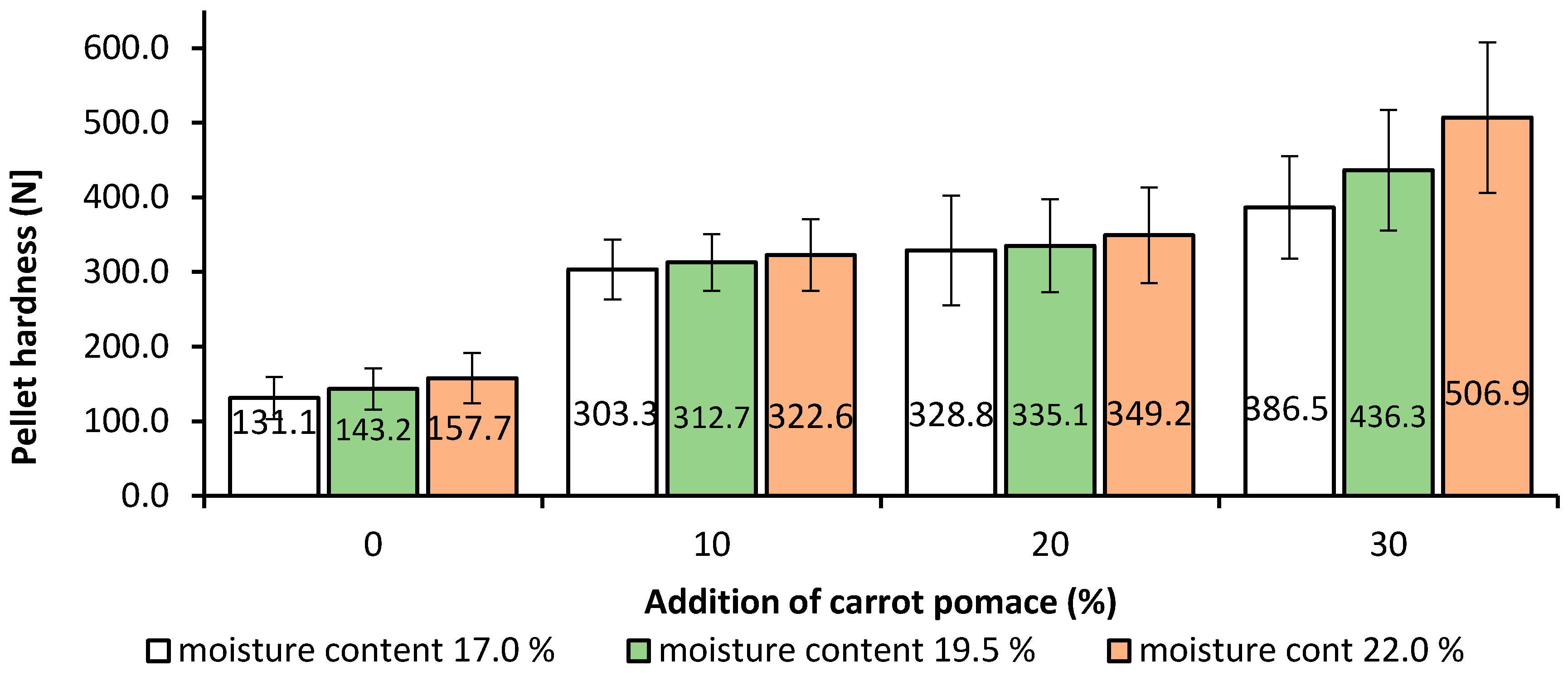

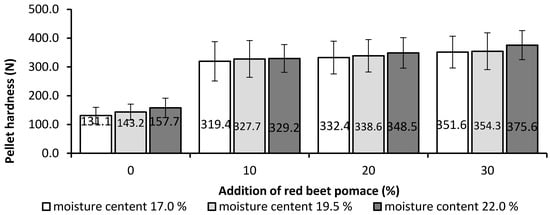

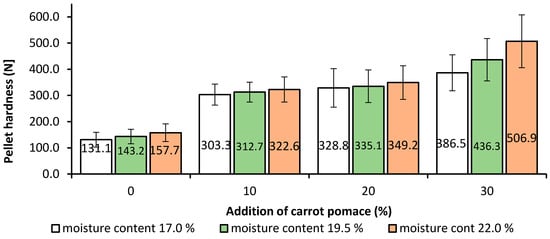

Values of pellet hardness obtained via the Kahl hardness tester, along with the error in the form of standard deviation, are presented graphically in Figure 3, Figure 4 and Figure 5. Figure 3 presents values of hardness of the pellet with the contribution of apple pomace in the substrate, Figure 4 with red beet pomace in the substrate and Figure 5 with carrot pomace in the substrate. Results of the study of the impact of percentage contribution of pomace in the substrate composition and relative moisture content on the pellet hardness were subject to variance analysis.

Figure 3.

Influence of the contribution of apple pomace in the mix with barley straw and mix moisture content on the hardness of the obtained pellet.

Figure 4.

Influence of the contribution of red beet pomace in the mix with barley straw and mix moisture content on the hardness of the obtained pellet.

Figure 5.

Influence of the contribution of carrot pomace in the mix with barley straw and mix moisture content on the hardness of the obtained pellet.

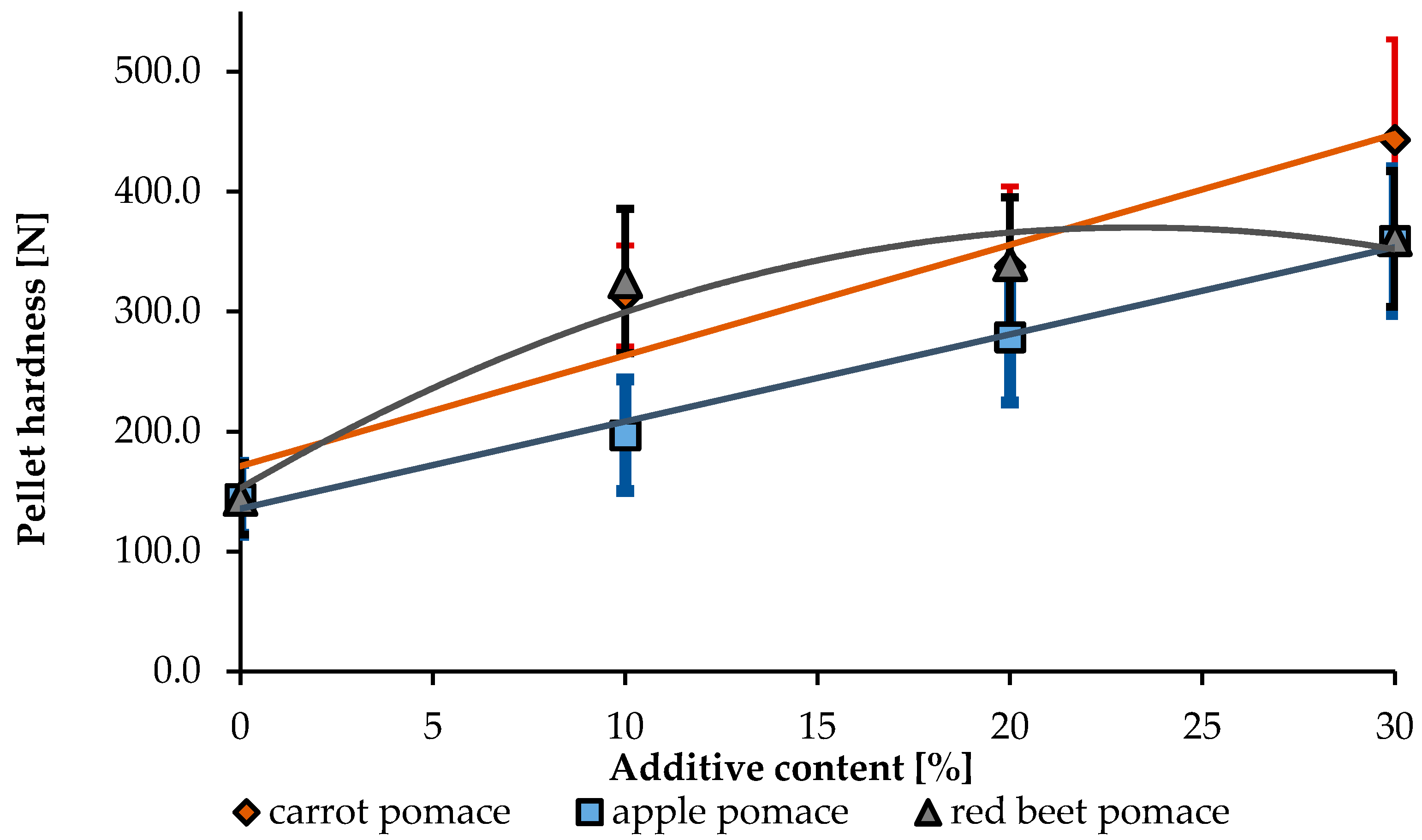

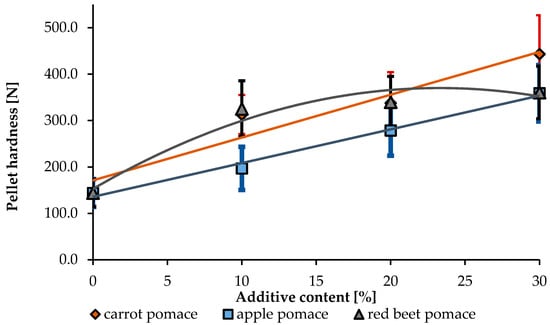

Significance of impact of individual factors on pellet hardness was determined using multi-factor analysis of variance, at significance level of p ≤ 0.05. In order to analyze the impact of percent content of pomace in the substrate on the hardness of the obtained pellet, all measurement results, including results of the effect of substrate moisture content, were taken into account. Final results are presented in Table 2 and in Figure 6.

Table 2.

Relationship between pellet hardness and the content of pomace addition to the substrate, Lowest Significant Difference (LSD) = 13.85 N, p < 0.05.

Figure 6.

Effect of the additive contribution in the mix with barley straw on the hardness of produced pellet.

Zero pomace content means that the pellet was made solely on the basis of barley straw. Analysis of variance was used to determine the value of the lowest significant difference—LSD, which was 13.85 N. Considering the value of the lowest significant difference, Table 2 shows that even at 10% content of pomace in the substrate, independent of their type, a significant increase in pellet hardness occurred. The addition of only 10% dry mass of pomace to barley straw resulted in the increase of pellet hardness by 37% for apple pomace, by 117% for carrot pomace and by 126% for red beet pomace. Further increase of the contribution of pomace in the substrate did not result in such a marked increase of hardness, but it still resulted in a significant hardness increase. For relationship regression, equations were determined to explain the effect of percentage content of dry mass of each additive type in dry mass of substrate with barley straw on the hardness of pellet made on the basis of the substrate, expressed in Newtons (Figure 6). The effect of the percentage contribution of carrot pomace dry mass—x1 on the pellet hardness—is explained by Equation (5), with correlation coefficient R2 = 0.9235:

The effect of the percentage contribution of red beet pomace dry mas—x2 on the pellet hardness—is explained by Equation (6), R2 = 0.9499:

The effect of the percentage contribution of apple pomace dry mass—x3 on the pellet—hardness is explained by Equation (7), R2 = 0.9913:

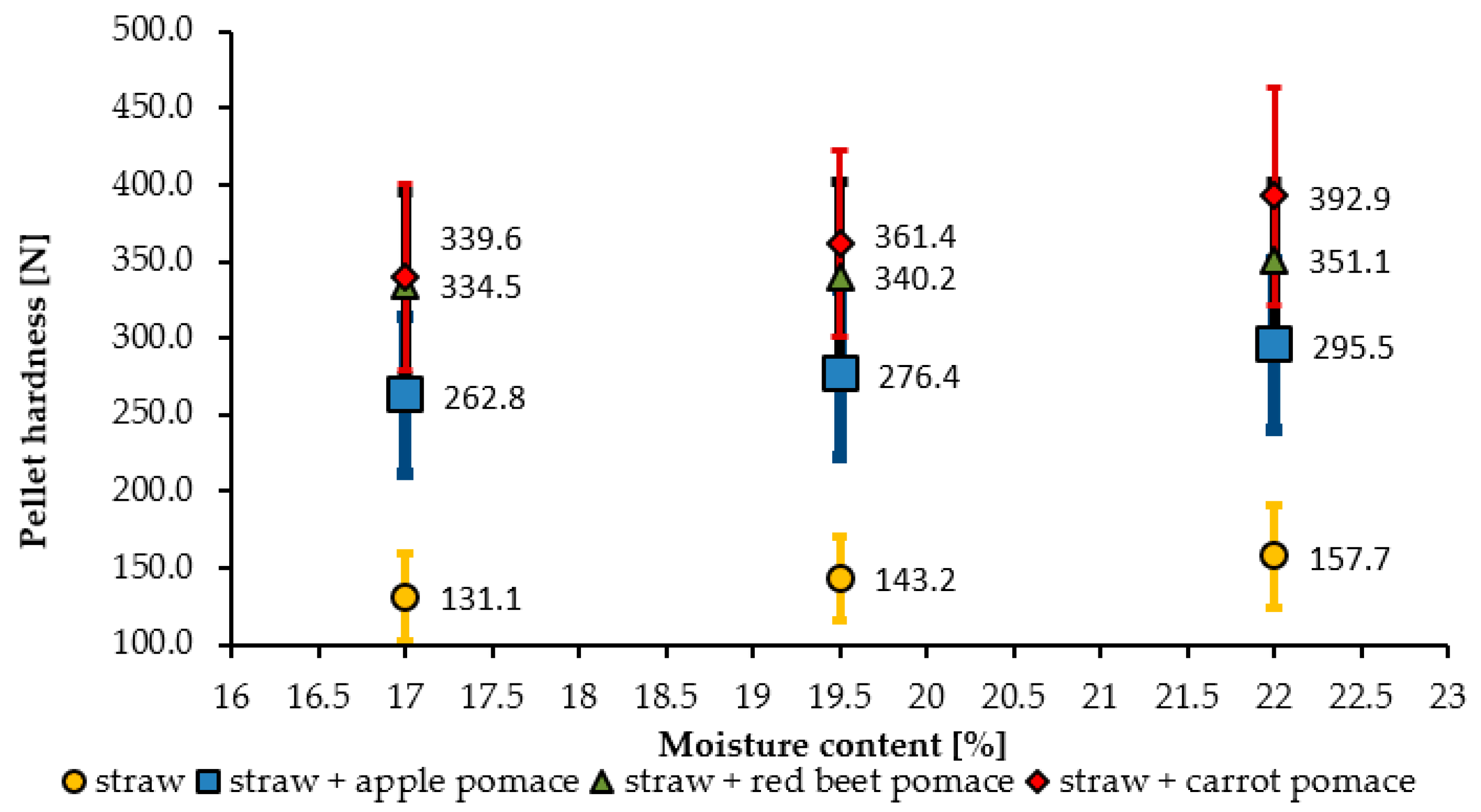

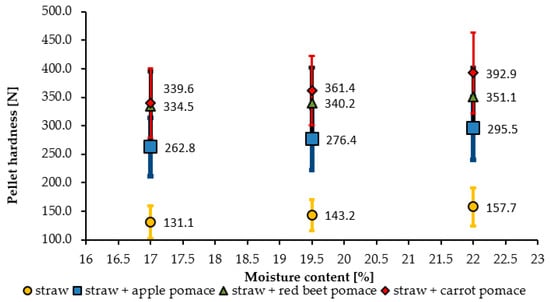

Additionally, analysis of the effect of substrate relative moisture content on the hardness of the obtained pellet was also conducted. All measurement results were used for the calculations along with the results of percentage contribution of additives in the substrate. Influence of substrate relative moisture content on the obtained pellet hardness is presented in Figure 7.

Figure 7.

Influence of raw material moisture content on the hardness of produced pellet.

Significant increase of pellet hardness depending on the increase of relative moisture content was determined in the pellet made only of straw and in the pellet with the contribution of apple and carrot pomace. The hardness of the pellet made of a mix of straw and red beet was not found to be significantly affected by the substrate moisture content. Despite the fact that in the studied substrate moisture content range no optimum value could be determined, these results are similar to the results obtained earlier for similar studies. The optimum substrate moisture content value, upon which the pellet quality depends, may be a function of the type of added binder. In the case of addition of wheat flour to rapeseed straw, the maximum pellet hardness was obtained at the substrate relative moisture content of 30.7% [18], while the use of wheat straw and disintegrated wheat seed produced the highest pellet hardness at a substrate moisture content value of 26.6%. [12]. According to [15], the optimum moisture content for the obtaining of the maximum straw pelletization hardness is 13–20%, but the range of optimum substrate moisture content affecting the pellet quality should be viewed from the standpoint of the type of biomass granulated and the granulator design.

3.3. Polymer Content

The determined content of natural polymers: lignin, hemicellulose and cellulose, in the primary materials used to prepared the substrate intended for pellet production is presented in Table 3. Subsequently, the same method was used to determine lignin, hemicellulose and cellulose content in the pellet produced on the basis of the substrate.

Table 3.

Lignin, hemicellulose and cellulose content determined in primary materials used to prepare the substrate.

In order to determine the content of polymers, samples of pellet containing 70% dry mass of barley straw and 30% dry mass of additives and pellet made of 100% barley straw were used. Polymer content testing was performed on the pellet samples made solely of the substrate with relative moisture content of 22%. Table 4 presents the testing results.

Table 4.

Lignin, hemicellulose and cellulose content determined in pellets.

The cellulose and hemicellulose contained in the plant cell wall may undergo depolymerization during pellet production. In high temperatures, lignin is subject to melting and may penetrate to the outer layers of the pellet, resulting in its sticking and creating a slippery coat [31]. Testing of lignin content in the straw revealed 10.1% of the compound, whereas in the pellet made of this material, the content of lignin was higher at 15.0%. It is suspected that this may be linked to the easier extraction of lignin from the pellet during the determination of polymer content, which is the process of pellet formation that is conducted in high temperature, which results in lignin dissolution and penetration to the outer layers of the pellet. Polysaccharide (such as cellulose) content affects the increase of pellet hardness. The highest cellulose content—19.1%—was observed in the pellet with 30% addition of carrot, the hardness of which was also highest—443.2 N.

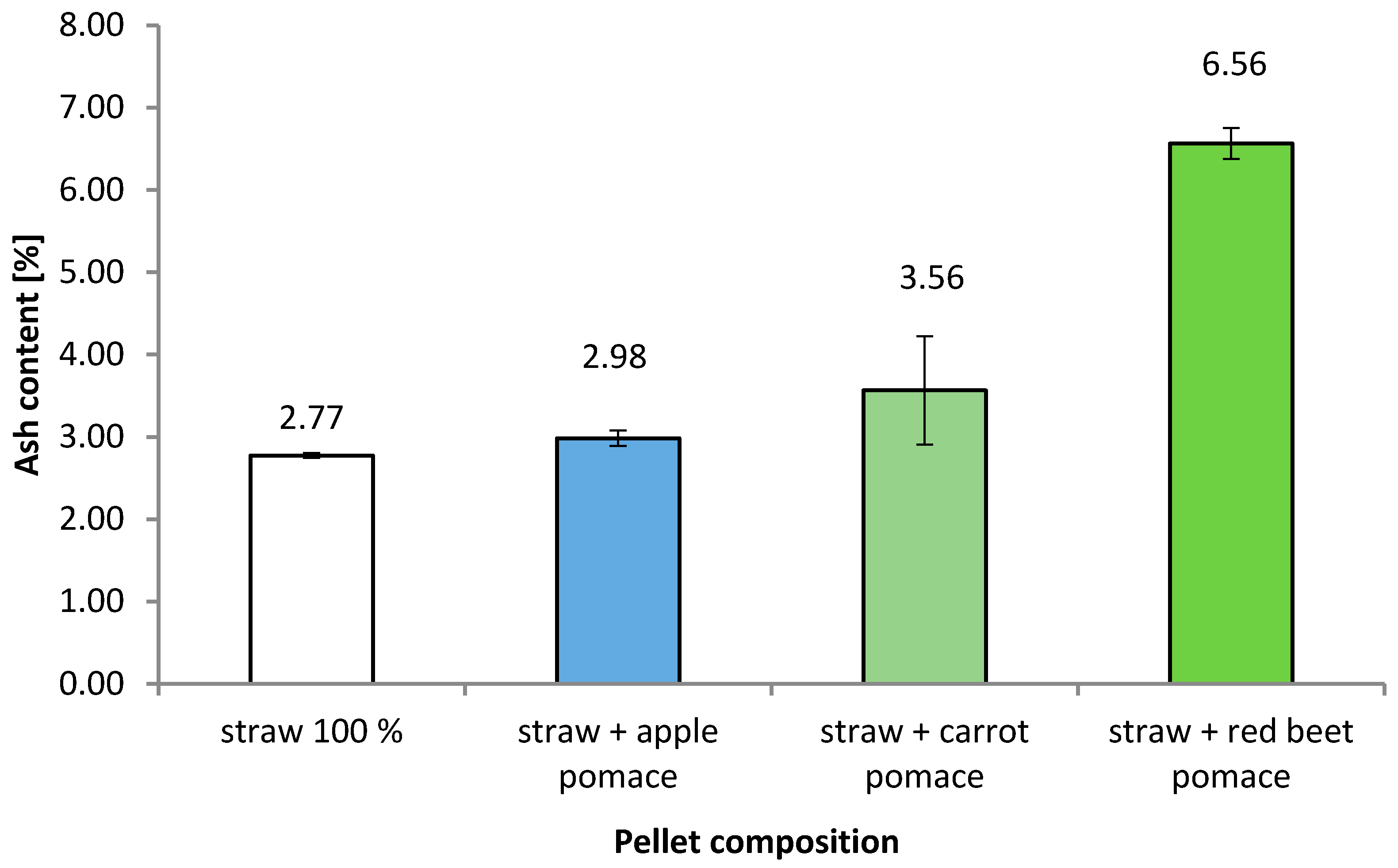

3.4. Ash Content and Calorific Value

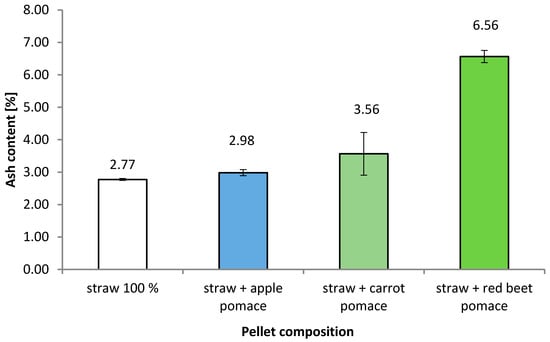

Ash content was determined on samples of pellet made of only barley straw and in pellet samples made of substrates with 30% content of the individual additives. The results are presented in Figure 8. In order to find out which of the barley straw additives influenced the ash content of the pellets, the least significant difference (LSD) value was counted, at level of significance p ≤ 0.05. The value of the least significant difference was 0.533. The significance increase was caused by the addition of carrot and red beet pomaces. There was no significant effect of the addition of apple pomace on the increase of ash content in the pellets.

Figure 8.

Ash content depending on the type of pomace addition mixed with barley straw in the substrate (at 0% and 30% contribution of additives).

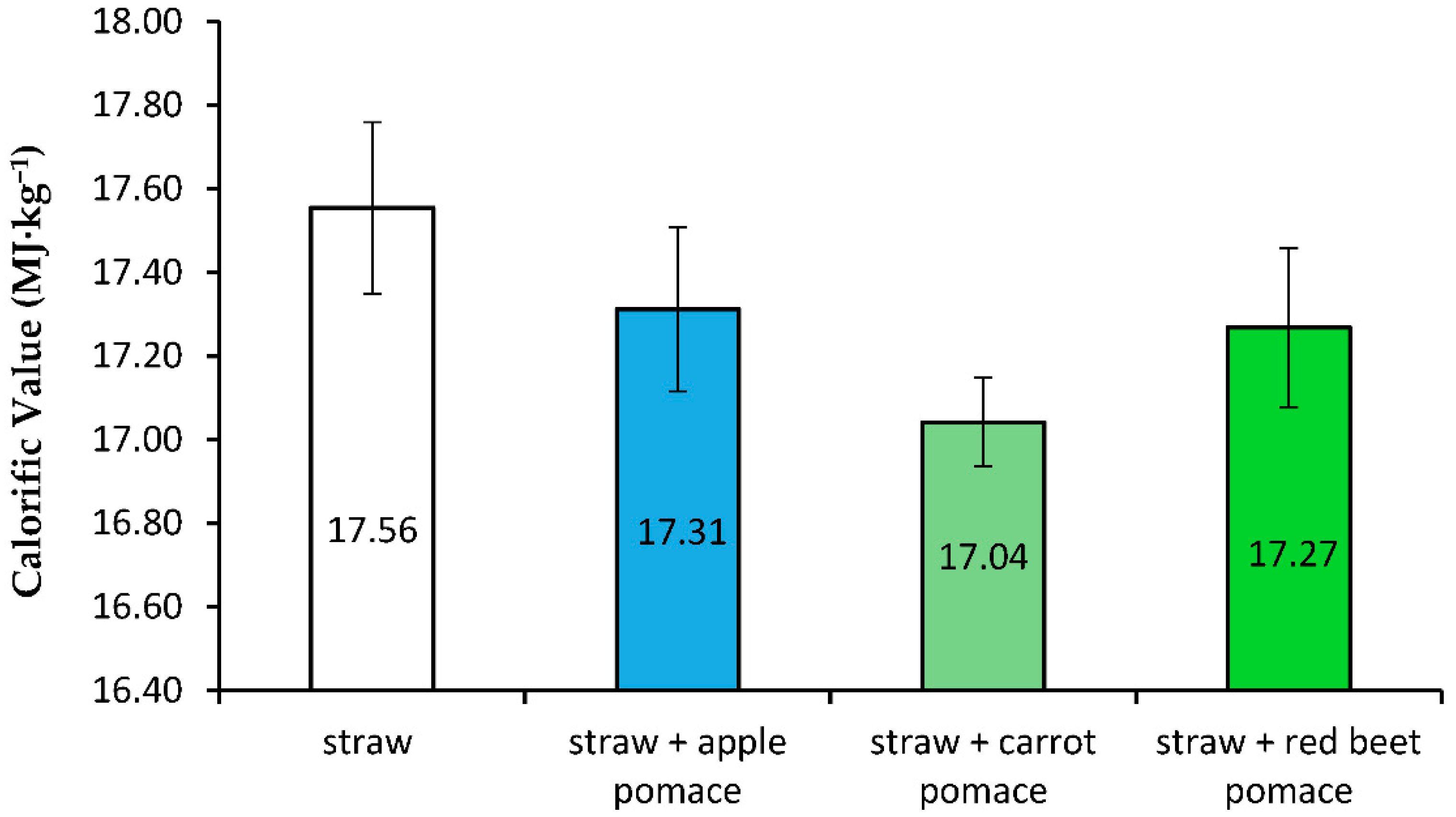

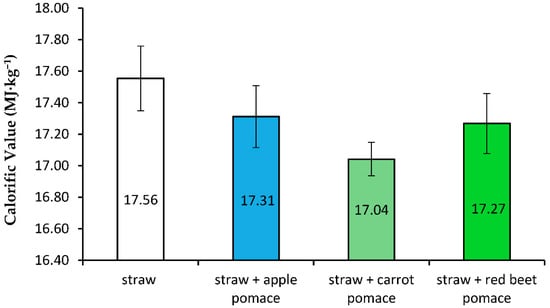

Calorific value of the pellets with 0% and 30% content of individual additives has been determined in a bomb calorimeter. Values for individual substrates, with standard deviation from measurements, are presented in Figure 9.

Figure 9.

Values of Calorific Value depending on the composition of pellet from barley straw and from straw with addition of pomace (30% contribution of additives).

The addition of pomace to straw resulted in a minor reduction of pellet calorific value in comparison to the value for the pellet made of straw only. The decrease in calorific value of pellets caused by a 30% addition of pomace did not exceed 7% in relation to the calorific value of pellets made from 100% barley straw. This can increase the fuel consumption in the boilers.

Increase of the ash content in fuel from barley straw can affect the operation of boilers, because of influences on the deposition of slag and ash in the furnace [49]. The addition of carrot pomace or red beet pomace to barley straw strongly increases the hardness of the pellet, but these additives also increase the mass of ash; therefore, they should be added to the straw in moderation. Moreover, the ash content in pellet from biomass not only depends on the type of additive, but also on its origin, type of contamination, harvest conditions and time of harvesting. In barley straw, the ash content may also depend on the size of the straw particles [50].

4. Conclusions

The addition of apple, carrot root and red beet root pomace in the range between 10–30% of dry mass to barley straw in the substrate used for pellet production resulted in increased density and hardness of the pellet. Increased hardness values were obtained already at 10% content of these substrates. The greatest increase of hardness, even in excess of 100%, was obtained from the mixture of straw with carrot and red beet pomace. Increase of pellet hardness and density was also obtained with the increase of relative moisture content of substrates to 22%, which is the upper humidity limit assumed for the study.

The pressure agglomeration process further affected the changes in the pellet material. Changes were observed when comparing values of the determined natural polymers, such as lignin, hemicellulose and cellulose, in the primary material used to produce the pellet, to the values of the same natural polymers in the produced pellet. Analysis of values of these polymers further allows a presumption that cellulose contained in the pellet affected the pellet hardness.

The addition of carrot root and red beet root pomace to barley straw resulted in increased mass of ash remaining after combustion of pellet made of such mixes. This is a disadvantage of using these types of pomace as a co-substrate for pellet production based on straw. Additions of pomace to barley straw further resulted in the reduced calorific value from the pellet made of these mixtures as compared with the calorific value obtained from pellet produced from straw only.

Author Contributions

Conceptualization, J.C., A.Z. and J.O.; Data curation, J.C.; Formal analysis, J.C., A.Z. and M.S.-K.; Investigation, J.C., A.Z. and M.S.-K.; Methodology, J.C., A.Z. and M.S.-K.; Resources, J.C., J.O. and Ľ.Š.; Software, J.C. and Ľ.Š.; Supervision, J.C. and Ľ.Š.; Validation, J.C., A.Z. and J.O.; Visualization, J.C. and A.Z.; Writing—original draft, J.C. and A.Z.; Writing—review & editing, J.C., J.O., Ľ.Š. and M.S.-K. All authors have read and agreed to the published version of the manuscript.

Funding

The fee for publishing this article was paid by Faculty of Mechanical Engineering, Slovak University of Technology in Bratislava.

Acknowledgments

The research presented in this paper is an outcome of the project No. APVV-0505-18 “Development of an original construction for a compacting machine with inverted kinematics” funded by the Slovak Research and Development Agency. The research was performed within the framework of a project of bilateral exchange of researchers between the Republic of Poland and the Slovak Republic titled Influence of thermal conditions of heating and moisture content on mechanical and energetic properties of biomass pellets (reference no: PPN/BIL/2018/1/00075) co-financed in Poland by the NAWA—National Agency of Academic Exchange. The authors would like to thank Waldemar Kuczyński and eng. Andrzej Janczak from Department of Energetics, Mechanical Faculty—Koszalin University of Technology for making the laboratory available for carrying out part of tests and providing assistance during their performance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lisy, M.; Lisa, H.; Jecha, D.; Balas, M.; Krizan, P. Characteristic Properties of Alternative Biomass Fuels. Energies 2020, 13, 1448. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Zukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Smuga-Kogut, M.; Bychto, L.; Walendzik, B.; Cielecka-Piontek, J.; Marecik, R.; Kobus-Cisowska, J.; Grajek, K.; Szymanowska-Powałowska, D. Use of Buckwheat Straw to Produce Ethyl Alcohol Using Ionic Liquids. Energies 2019, 12, 2014. [Google Scholar] [CrossRef]

- Ebeling, J.M.; Jenkins, B.M. Physical and Chemical Properties of Biomass Fuels. Trans. ASAE 1985, 28, 898–902. [Google Scholar] [CrossRef]

- Smuga-Kogut, M.; Wnuk, A.D.; Zgórska, K.; Kubiak, M.S.; Wojdalski, J.; Kupczyk, A.; Szlachta, J.; Luberański, A. Production of ethanol from wheat straw. Pol. J. Chem. Technol. 2015, 17, 89–94. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.B.; Kachel-Jakubowska, M.; Niedziołka, I.; Zaklika, B.; Zawislak, K.; Nadulski, R.; Sobczak, P.; Wojdalski, J.; Mruk, R. Impact of various kinds of straw and other raw materials on physical characteristics of pellets. Rocz. Ochr. Srodowiska 2017, 19, 270–287. [Google Scholar]

- Zdanowicz, A.; Chojnacki, J. Mechanical properties of pellet from chicken manure mixed with chopped rye straw. J. Res. Appl. Agric. Eng. 2017, 62, 216–218. [Google Scholar]

- Matúš, M.; Križan, P.; Šooš, Ľ.; Beniak, J. The effect of papermaking sludge as an additive to biomass pellets on the final quality of the fuel. Fuel 2018, 219, 196–204. [Google Scholar] [CrossRef]

- Lu, D.; Tabil, L.G.; Wang, D.; Wang, G.; Emami, S. Experimental trials to make wheat straw pellets with wood residue and binders. Biomass Bioenergy 2014, 69, 287–296. [Google Scholar] [CrossRef]

- Chojnacki, J.; Zdanowicz, A. Research into the hardness of pellet from wheat straw with an addition of ground wheat. J. Res. Appl. Agric. Eng. 2017, 62, 19–21. [Google Scholar]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Said, N.; Abdel daiem, M.M.; García-Maraver, A.; Zamorano, M. Influence of densification parameters on quality properties of rice straw pellets. Fuel Process. Technol. 2015, 138, 56–64. [Google Scholar] [CrossRef]

- Ishii, K.; Furuichi, T. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 2014, 34, 2621–2626. [Google Scholar] [CrossRef]

- Moliner, C.; Lagazzo, A.; Bosio, B.; Botter, R.; Arato, E. Production, Characterization, and Evaluation of Pellets from Rice Harvest Residues. Energies 2020, 13, 479. [Google Scholar] [CrossRef]

- Kachel, M.; Kraszkiewicz, A.; Subr, A.; Parafiniuk, S.; Przywara, A.; Koszel, M.; Zając, G. Impact of the Type of Fertilization and the Addition of Glycerol on the Quality of Spring Rape Straw Pellets. Energies 2020, 13, 819. [Google Scholar] [CrossRef]

- Zdanowicz, A.; Chojnacki, J. Impact of natural binder on pellet quality. In Proceedings of the 9th International Scientific Symposium on Farm Machinery and Process Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; pp. 456–460. [Google Scholar]

- Chojnacki, J.; Ondruska, J.; Kuczynski, W.; Soos, L.; Balasz, B. Emissions from the combustion of solid biofuels. In Proceedings of the 9th International Scientific Symposium on Farm Machinery and Process Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; pp. 70–75. [Google Scholar]

- Skonecki, S.; Potręć, M.; Laskowski, J. Właściwości fizyczne i chemiczne odpadów rolniczych. Acta Agrophysica 2011, 18, 443–455. [Google Scholar]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D.K. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw and big bluestem. Ind. Crop. Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Obidziński, S.; Puchlik, M.; Dołżyńska, M. Pelletization of Post-Harvest Tobacco Waste and Investigation of Flue Gas Emissions from Pellet Combustion. Energies 2020, 13, 6002. [Google Scholar] [CrossRef]

- Nosek, R.; Werle, S.; Borsukiewicz, A.; Żelazna, A.; Łagód, G. Investigation of Pellet Properties Produced from a Mix of Straw and Paper Sludge. Appl. Sci. 2020, 10, 5450. [Google Scholar] [CrossRef]

- Wang, L.; Skjevrak, G.; Hustad, J.E.; Grønli, M.G.; Skreiberg, O. Efects of additives on barley straw and husk ashes sintering characteristics. Energy Procedia 2012, 20, 30–39. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef] [PubMed]

- Zdanowicz, A.; Chojnacki, J. Usage of fodder beet tuber pulp as a binder in straw pressure agglomeration. In Proceedings of the 25th International PHD Students Conference (Mendelnet 2018), Brno, Czech Republic, 7–8 November 2018; pp. 472–477. [Google Scholar]

- Stelte, W.; Clemons, C.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B.; Sanadi, A.R. Fuel Pellets from Wheat Straw: The Effect of Lignin Glass Transition and Surface Waxes on Pelletizing Properties. Bioenergy Res. 2011, 5, 450–458. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Colley, Z.; Fasina, O.O.; Bransby, D.; Lee, Y.Y. Moisture Effect on the Physical Characteristics of Switchgrass Pellets. Trans. ASABE 2006, 49, 1845–1851. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Pelletizing Pure Biomass Substances to Investigate the Mechanical Properties and Bonding Mechanisms. BioResources 2017, 13, 1202–1222. [Google Scholar] [CrossRef]

- Shalini, R.; Gupta, D.K. Utilization of pomace from apple processing industries: A review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef]

- Vendruscolo, F.; Albuquerque, P.M.; Streit, F.; Esposito, E.; Ninow, J.L. Apple Pomace: A Versatile Substrate for Biotechnological Applications. Crit. Rev. Biotechnol. 2008, 1, 1–12. [Google Scholar]

- Maslovarić, M.D.; Vukmirović, D.M.; Čolović, R.R.; Spasevski, N.J.; Jovanović, R.D.; Tolimir, N.T. Pelleting properties and pellet quality of apple pomace. Food Feed Res. 2015, 42, 147–154. [Google Scholar] [CrossRef]

- Maslovarić, M.; Vukmirović, Đ.; Pezo, L.; Čolović, R.; Jovanović, R.; Spasevski, N.; Tolimir, N. Influence of apple pomace inclusion on the process of animal feed pelleting. Food Addit. Contam. Part A 2017, 34, 8. [Google Scholar] [CrossRef]

- Hejft, R.; Obidziński, S.; Jałbrzykowski, M.; Markowski, J. Production of heating pellets with apple pomace content. J. Res. Appl. Agric. Eng. 2016, 61, 29–34. [Google Scholar]

- Alam, M.S.; Pathania, S.; Sharma, A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. LWT 2016, 74, 135–144. [Google Scholar] [CrossRef]

- Lotfi Shirazi, S.; Koocheki, A.; Milani, E.; Mohebbi, M. Production of high fiber ready-to-eat expanded snack from barley flour and carrot pomace using extrusion cooking technology. J. Food Sci. Technol. 2020, 57, 2169–2181. [Google Scholar] [CrossRef]

- Bakshi, M.P.S.; Wadhwa, M.; Makkar, H.P.S. Waste to worth: Vegetable wastes as animal feed. CAB Rev. 2016, 11, 1–26. [Google Scholar] [CrossRef]

- Yu, C.-Y.; Jiang, B.-H.; Duan, K.-J. Production of Bioethanol from Carrot Pomace Using the Thermotolerant Yeast Kluyveromyces marxianus. Energies 2013, 6, 1794–1801. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Szymańska-Chargot, M.; Chylińska, M.; Gdula, K.; Kozioł, A.; Zdunek, A. Isolation and Characterization of Cellulose from Different Fruit and Vegetable Pomaces. Polymers 2017, 9, 495. [Google Scholar] [CrossRef]

- Dalla Costa, A.P.; Hermes, V.S.; de Oliveira Rios, A.; Flôres, S.H. Minimally processed beetroot waste as an alternative source to obtain functional ingredients. J. Food Sci. Technol. 2017, 54, 2050–2058. [Google Scholar] [CrossRef]

- Huaqin, W. CN103494021A—Green Chick Feed for Promoting Growth. Available online: https://worldwide.espacenet.com/patent/search/family/049859361/publication/CN103494021A?q=pn%3DCN103494021A (accessed on 19 November 2020).

- Bożym, M.; Florczak, I.; Zdanowska, P.; Wojdalski, J.; Klimkiewicz, M. An analysis of metal concentrations in food wastes for biogas production. Renew. Energy 2015, 77, 467–472. [Google Scholar] [CrossRef]

- Adamczyk, F. Wpływ wilgotności słomy zbożowej na stopień zagęszczenia uzyskiwanych brykietów. Inżynieria Rol. 2010, 1, 7–13. [Google Scholar]

- Kulig, R. Influence of grinding rate of chosen plant materials on physical properties of material. J. Res. Appl. Agric. Eng. 2010, 55, 59–62. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Emami, S.; Tabil, L.G.; Adapa, P.; Tilay, A.; George, E.; Ketabi, L.; Dalai, A. Effect of Fuel Additives on Agricultural Straw Pellet Quality. In Proceedings of the SBE/SCGAB 2013 Annual Conference University of Saskatchewan, Saskatoon, Saskatchewan, 7–10 July 2013; pp. 1–13. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).