Topology Optimization to Reduce Electromagnetic Force Induced Vibration for the Specific Frequency of PMSM Motor Using Electromagnetic-Structural Coupled Analysis

Abstract

:1. Introduction

2. Electromagnetic Force Induced Vibration Analysis Using Electromagnetic-Structural Coupled Analysis

2.1. Electromagnetic-Structural Coupled Analysis

2.2. Electromagnetic Force Calculation

2.3. Frequency Response Analysis

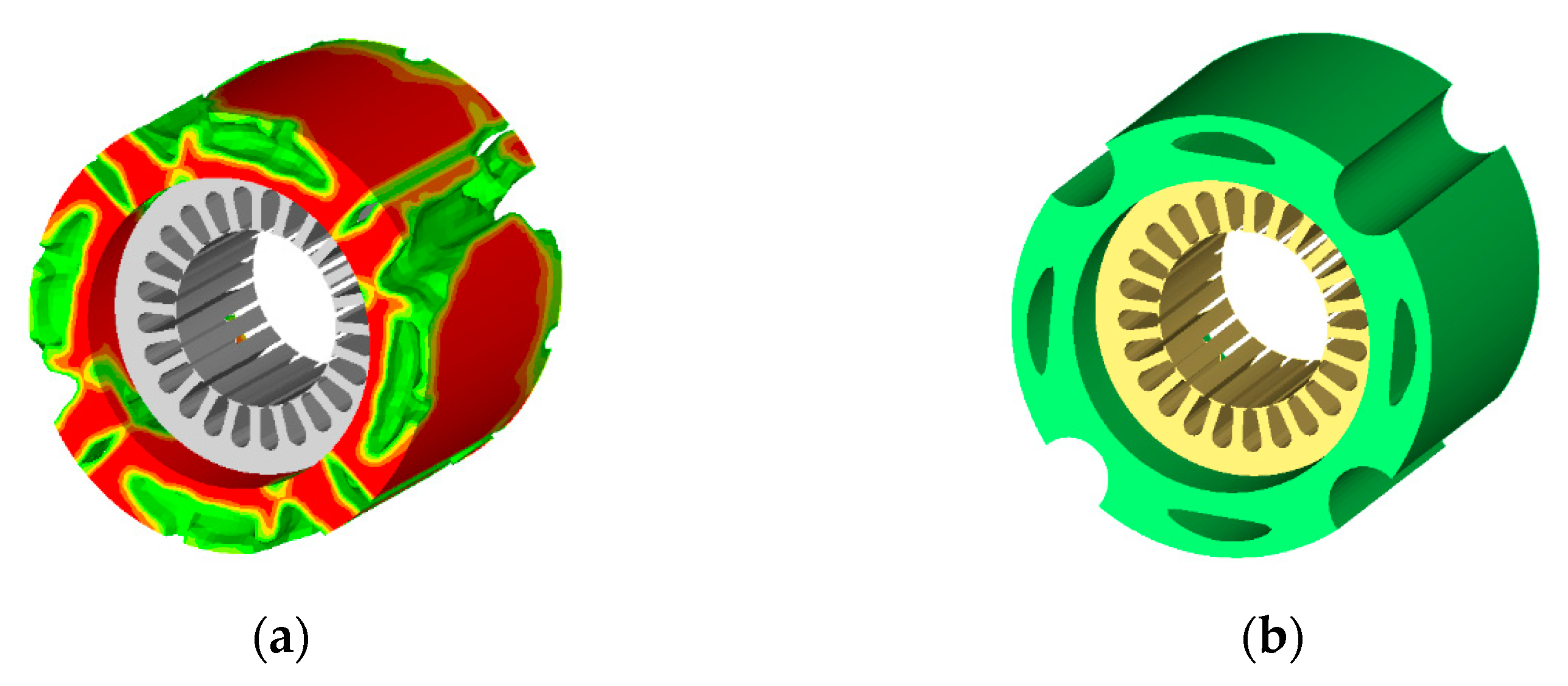

2.4. Topology Optimization Using Electromagnetic-Structural Coupled Analysis

3. Topology Optimization for Motor Housing Design

3.1. Topology Optimal Design Formualtion

3.2. Rectangular Shape Housing Initial Design

3.3. Circular Shape Housing Initial Design

3.4. Result and Discussion of Topology Optimization for Each Initial Design

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Li, Q.; Zhang, L.; Ma, Q. Development of permanent Magnet Synchronous Motor for Electric Vehicle. In Proceedings of the 1st International Conference on Sustainable Power Generation and Supply, Nanjing, China, 6–7 April 2009; Volume 3, pp. 1–5. [Google Scholar]

- Deng, W.; Zuo, S. Electromagnetic vibration and noise of the permanent-magnet synchronous motors for electric vehicles: An overview. IEEE Trans. Transp. Electrif. 2019, 5, 59–70. [Google Scholar] [CrossRef]

- Islam, R.; Husain, I. Analytical model for predicting noise and vibration in permanent-magnet synchronous motors. IEEE Trans. Ind. Appl. 2010, 46, 2346–2354. [Google Scholar] [CrossRef]

- Yang, H.Y.; Lim, Y.C.; Kim, H.C. Acoustic noise/vibration reduction of a single-phase SRM using skewed stator and rotor. IEEE Trans. Ind. Electron. 2013, 60, 4292–4300. [Google Scholar] [CrossRef]

- Ishibashi, F.; Noda, S.; Mochizuki, M. Numerical simulation of electromagnetic vibration of small induction motors. IEEE Proc.-Electr. Power Appl. 1998, 145, 528–534. [Google Scholar] [CrossRef]

- Islam, M.S.; Islam, R.; Sebastian, T. Noise and vibration characteristics of permanent-magnet synchronous motors using electromagnetic and structural analyses. IEEE Trans. Ind. Appl. 2014, 50, 3214–3222. [Google Scholar] [CrossRef]

- Lin, F.; Zuo, S.; Wu, X. Electromagnetic vibration and noise analysis of permanent magnet synchronous motor with different slot-pole combinations. IET Electr. Power Appl. 2016, 10, 900–908. [Google Scholar] [CrossRef]

- Nam, J.; Kang, C.; Song, J.; Jang, G. Comparison of one-way and two-way coupled analyses of electromagnetic machines considering magnetic and structural interactions. AIP Adv. 2017, 056637, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Lin, F.; Zuo, S.; Deng, W.; Wu, S. Noise Prediction and Sound Quality Analysis of Variable-Speed Permanent Magnet Synchronous Motor. IEEE Trans. Energy Convers. 2017, 32, 698–706. [Google Scholar] [CrossRef]

- Deng, W.; Zuo, S. Analytical modeling of the electromagnetic vibration and noise for an external-rotor axial-flux in-wheel motor. IEEE Trans. Ind. Electron. 2018, 65, 1191–2000. [Google Scholar] [CrossRef]

- Cho, S.; Hwang, J.; Kim, C.W. A Study on Vibration Characteristics of Brushless DC Motor by Electromagnetic-Structural Coupled Analysis Using Entire Finite Element Model. IEEE Trans. Energy Convers. 2018, 33, 1712–1718. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, H.; Zeng, L.; Pei, R. Evaluation Method of Noise and Vibration used in Permanent Magnet Synchronous Motor in Electric Vehicle. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 6–9. [Google Scholar]

- Bao, M.; Chen, E.W.; Lu, Y.M.; Liu, Z.S.; Liu, S. Vibration and noise analysis for a motor of pure electric vehicle. Adv. Mater. Res. 2014, 915-916, 98–102. [Google Scholar] [CrossRef]

- Hur, J.; Reu, J.W.; Kim, B.W.; Kang, G.H. Vibration reduction of IPM-type BLDC motor using negative third harmonic elimination method of air-gap flux density. IEEE Trans. Ind. Appl. 2011, 47, 1300–1309. [Google Scholar]

- Gan, C.; Wu, J.; Shen, M.; Yang, S.; Hu, Y.; Cao, W. Investigation of skewing effects on the vibration reduction of three-phase switched reluctance motors. IEEE Trans. Magn. 2015, 51, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.P.; Ha, K.H.; Lee, J. Stator pole and yoke design for vibration reduction of switched reluctance motor. IEEE Trans. Magn. 2002, 38, 929–932. [Google Scholar] [CrossRef]

- Takiguchi, M.; Sugimoto, H.; Kurihara, N.; Chiba, A. Acoustic Noise and Vibration Reduction of SRM by Elimination of Third Harmonic Component in Sum of Radial Forces. IEEE Trans. Energy Convers. 2015, 30, 883–891. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Huang, Y.; Zou, J. Reduction of high-frequency vibration noise for dual-branch three-phase permanent magnet synchronous motors. Chin. J. Electr. Eng. 2020, 6, 42–51. [Google Scholar] [CrossRef]

- Jung, J.W.; Lee, S.H.; Lee, G.H.; Hong, J.P.; Lee, D.H.; Kim, K.N. Reduction design of vibration and noise in IPMSM type integrated starter and generator for HEV. IEEE Trans. Magn. 2010, 46, 2454–2457. [Google Scholar] [CrossRef]

- Cho, G.; Jang, W.; Jang, K.; Kim, G. The Optimal Design of Fractional-slot SPM to Reduce Cogging Torque and Vibration. J. Electr. Eng. Technol. 2012, 7, 753–758. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.Y.; Nam, J.K.; Jang, G.H. Reduction of magnetically induced vibration of a spoke-type iPM motor using magnetomechanical coupled analysis and optimization. IEEE Trans Magn. 2013, 49, 5097–5105. [Google Scholar] [CrossRef]

- Lin, F.; Zuo, S.G.; Deng, W.Z.; Wu, S.L. Reduction of vibration and acoustic noise in permanent magnet synchronous motor by optimizing magnetic forces. J. Sound. Vib. 2018, 429, 193–205. [Google Scholar] [CrossRef]

- Xie, Y.; Pi, C.; Li, Z. Study on design and vibration reduction optimization of high starting torque induction motor. Energies. 2019, 12, 1263. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Gao, H.; Wang, H.; Ma, W. NVH Optimization Analysis of Permanent Magnet Synchronous Motor by Rotor Slotting. Vehicles 2020, 2, 287–302. [Google Scholar] [CrossRef]

- Cho, S.; Lee, D.-C.; Hwang, J.; Kim, K.; Jang, G.U.; Bae, D.; Mok, H.S.; Kim, C.-W. Optimal design to reduce torque ripple of IPM motor with radial based function meta-model considering design sensitivity analysis. J. Mech. Sci. Technol. 2019, 33, 3955–3961. [Google Scholar] [CrossRef]

- Jang, G.U.; Kim, C.W.; Bae, D.; Cho, Y.; Lee, J.J.; Cho, S. Reliability-based robust design optimization for torque ripple reduction considering manufacturing uncertainty of interior permanent magnet synchronous motor. J. Mech. Sci. Technol. 2020, 34, 1249–1256. [Google Scholar] [CrossRef]

- Gieras, J.F.; Wang, C.; Lai, J.C. Noise of Polyphase Electric Motors; Taylor Francis: Abingdon, UK, 2005; pp. 1–368. [Google Scholar]

- Fang, Y.; Zhang, T. Vibroacoustic characterization of a permanent magnet synchronous motor powertrain for electric vehicles. IEEE Trans. Energy Convers. 2018, 33, 272–280. [Google Scholar] [CrossRef]

- Bourdin, B. Filters in topology optimization. Int. J. Numer. Methods Eng. 2001, 50, 2143–2158. [Google Scholar] [CrossRef]

- Suzuki, K.; Kikuchi, N. A homogenization method for shape and topology optimization. Comput. Methods Appl. Mech. Eng. 1990, 115, 15–30. [Google Scholar] [CrossRef] [Green Version]

| Specification | Quantity |

|---|---|

| Rated Power | 1500 W |

| Pole | 4 poles |

| Slots | 24 slots |

| Rated Current | 6.2 A |

| Rated Speed | 2000 rpm |

| Specific Frequency | Initial Model | Optimized Model | |

|---|---|---|---|

| Rectangular shape housing design | 3200 Hz | 28.09 | 1.99 |

| Circular shape housing design | 1866 Hz | 12.03 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, G.U.; Cho, S.; Moon, J.; Jeon, K.; Kim, C.-w. Topology Optimization to Reduce Electromagnetic Force Induced Vibration for the Specific Frequency of PMSM Motor Using Electromagnetic-Structural Coupled Analysis. Energies 2021, 14, 431. https://doi.org/10.3390/en14020431

Jang GU, Cho S, Moon J, Jeon K, Kim C-w. Topology Optimization to Reduce Electromagnetic Force Induced Vibration for the Specific Frequency of PMSM Motor Using Electromagnetic-Structural Coupled Analysis. Energies. 2021; 14(2):431. https://doi.org/10.3390/en14020431

Chicago/Turabian StyleJang, Gyeong Uk, Seunghyeon Cho, Jaemin Moon, Kyunghun Jeon, and Chang-wan Kim. 2021. "Topology Optimization to Reduce Electromagnetic Force Induced Vibration for the Specific Frequency of PMSM Motor Using Electromagnetic-Structural Coupled Analysis" Energies 14, no. 2: 431. https://doi.org/10.3390/en14020431