Figure 1.

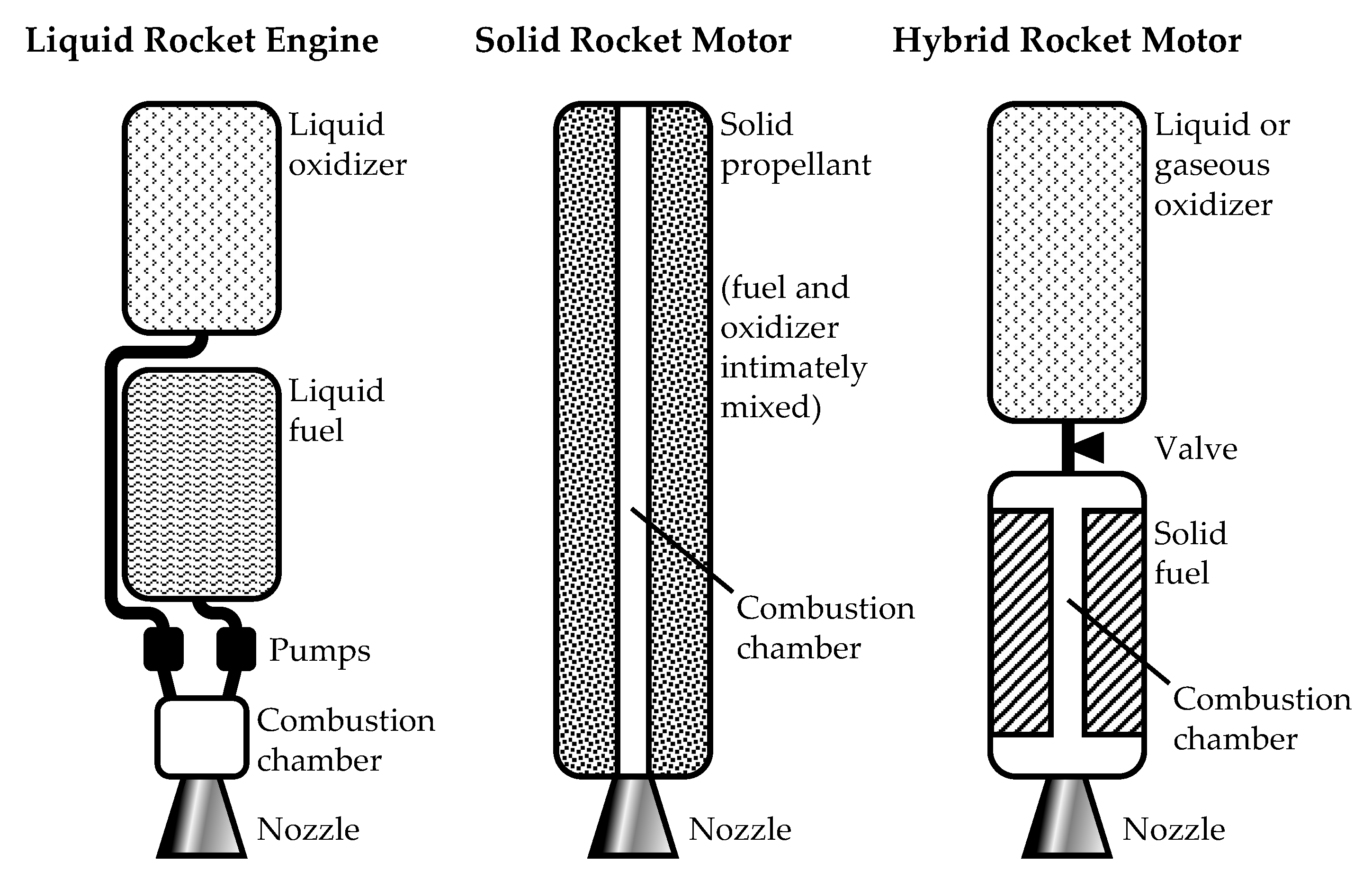

Schematic example of each of the 3 types of chemical rocket propulsion systems.

Figure 1.

Schematic example of each of the 3 types of chemical rocket propulsion systems.

Figure 2.

Schematic overview of the hybrid boundary layer combustion, based on the fundamental work of [

2].

Figure 2.

Schematic overview of the hybrid boundary layer combustion, based on the fundamental work of [

2].

Figure 3.

Schematic of the entrainment mechanism, as presented in [

4].

Figure 3.

Schematic of the entrainment mechanism, as presented in [

4].

Figure 4.

The ULB-HRM during operation [

7].

Figure 4.

The ULB-HRM during operation [

7].

Figure 5.

A 3D cut of the ULB-HRM (as presented in [

7], but reoriented horizontally).

Figure 5.

A 3D cut of the ULB-HRM (as presented in [

7], but reoriented horizontally).

Figure 6.

Computational domain (white area) and its dimensions.

Figure 6.

Computational domain (white area) and its dimensions.

Figure 7.

Complete mesh, with zoom on the motor region.

Figure 7.

Complete mesh, with zoom on the motor region.

Figure 8.

Review of the mesh convergence. Below the characteristic combustion chamber cell size of 1 mm, operating conditions remain quasi constant.

Figure 8.

Review of the mesh convergence. Below the characteristic combustion chamber cell size of 1 mm, operating conditions remain quasi constant.

Figure 9.

Computational domain with an overview of its boundaries.

Figure 9.

Computational domain with an overview of its boundaries.

Figure 10.

Plot as seen in [

38], showing instantaneous regression rates and corresponding mass fluxes evaluated from the midpoint of the port for four different pentane tests.

Figure 10.

Plot as seen in [

38], showing instantaneous regression rates and corresponding mass fluxes evaluated from the midpoint of the port for four different pentane tests.

Figure 11.

Static temperature field for cases SH1-04 and SH4-04.

Figure 11.

Static temperature field for cases SH1-04 and SH4-04.

Figure 12.

Streamlines for case SH4-04, colored by Mach number.

Figure 12.

Streamlines for case SH4-04, colored by Mach number.

Figure 13.

Comparison between experimental and numerical results.

Figure 13.

Comparison between experimental and numerical results.

Figure 14.

Static temperature field for case SH4-04, with shifting and frozen equilibrium.

Figure 14.

Static temperature field for case SH4-04, with shifting and frozen equilibrium.

Figure 15.

Impact of the frozen equilibrium model on and for the simulations of experiments SH1-04 and SH4-04.

Figure 15.

Impact of the frozen equilibrium model on and for the simulations of experiments SH1-04 and SH4-04.

Figure 16.

Impact of the vapor quality x on and for the simulations of experiments SH1-01 and SH2-01.

Figure 16.

Impact of the vapor quality x on and for the simulations of experiments SH1-01 and SH2-01.

Figure 17.

Influence of the oxidizer vapor quality x on the flowfield for case SH1-01.

Figure 17.

Influence of the oxidizer vapor quality x on the flowfield for case SH1-01.

Figure 18.

Impact of the oxidizer droplets diameter on for the simulations of experiments SH1-01 and SH2-01.

Figure 18.

Impact of the oxidizer droplets diameter on for the simulations of experiments SH1-01 and SH2-01.

Figure 19.

Influence of the oxidizer droplets diameter on the flowfield for case SH1-01.

Figure 19.

Influence of the oxidizer droplets diameter on the flowfield for case SH1-01.

Figure 20.

Impact of entrained fuel fraction on for the simulations of 8 experiments, while keeping the total fuel mass flow rate constant.

Figure 20.

Impact of entrained fuel fraction on for the simulations of 8 experiments, while keeping the total fuel mass flow rate constant.

Figure 21.

Impact of entrained fuel fraction on for the simulation of SH1-01, while keeping the gaseous fuel mass flow rate constant.

Figure 21.

Impact of entrained fuel fraction on for the simulation of SH1-01, while keeping the gaseous fuel mass flow rate constant.

Figure 22.

Influence of the entrained fuel fraction on the flowfield for case SH1-01, while keeping the total fuel mass flow rate constant and equal to the experimental value.

Figure 22.

Influence of the entrained fuel fraction on the flowfield for case SH1-01, while keeping the total fuel mass flow rate constant and equal to the experimental value.

Figure 23.

Influence of the entrained fuel droplets diameter on for cases SH1-01 and SH2-02. The diagram also includes the mass fraction of the total mass flow rate that exits the motor as liquid droplets, denoted by .

Figure 23.

Influence of the entrained fuel droplets diameter on for cases SH1-01 and SH2-02. The diagram also includes the mass fraction of the total mass flow rate that exits the motor as liquid droplets, denoted by .

Figure 24.

Influence of the entrained fuel droplets size on the flowfield for case SH1-01.

Figure 24.

Influence of the entrained fuel droplets size on the flowfield for case SH1-01.

Figure 25.

Combined influence of the entrained fuel fraction and fuel droplets size on the numerical chamber pressure for case SH1-01.

Figure 25.

Combined influence of the entrained fuel fraction and fuel droplets size on the numerical chamber pressure for case SH1-01.

Figure 26.

Combined influence of the entrained fuel fraction and fuel droplets size on the numerical chamber pressure for case SH1-01.

Figure 26.

Combined influence of the entrained fuel fraction and fuel droplets size on the numerical chamber pressure for case SH1-01.

Table 1.

Properties of the 4 types of SH injectors [

29] used during the 19 experiments.

Table 2.

Summary of oxidizer inlet boundary conditions for the baseline simulations.

Table 2.

Summary of oxidizer inlet boundary conditions for the baseline simulations.

| Parameter | Value or Setting | Remark |

|---|

| Species | | properties from [31,37] |

| Gas inlet type | mass flow inlet | |

| Liquid inlet type | droplets source | from inlet boundary |

| Total mass flow rate | | different for each simulation |

| Gas mass flow rate | | different for each simulation |

| Liquid mass flow rate | | different for each simulation |

| Droplets initial velocity | from Equation (13) | different for each simulation |

| Droplets diameter distribution | uniform | |

| Droplets diameter | 100 µm | |

| Droplets and gas orientation | normal to boundary | |

| Temperature | 280 K | test campaign conditions |

Table 3.

Chosen baseline values for the parameters in Equation (

17), and the resulting value for

.

Table 3.

Chosen baseline values for the parameters in Equation (

17), and the resulting value for

.

| | | | | | | | | |

|---|

| | N/m | m | kg/m | m/s | kg/m | m/s | Pa·s | m |

|---|

| Baseline values | | 0.07 | 4.0 | 4.0 | 700 | 0.010 | | 93 |

Table 4.

Ranges for

for varying values of the parameters in Equation (

17). At each line, the other parameters are kept at their baseline value.

Table 4.

Ranges for

for varying values of the parameters in Equation (

17). At each line, the other parameters are kept at their baseline value.

| Parameter | Unit | Lower Limit | Upper Limit | Resulting (m) |

|---|

| N/m | | | 66 − 118 |

| m | 0.06 | 0.08 | 86 − 100 |

| kg/m | 1.0 | 10.0 | 235 − 51 |

| m/s | 1.0 | 10.0 | 592 − 27 |

| kg/m | 600 | 800 | 96 − 91 |

| m/s | 0.001 | 0.100 | 137 − 64 |

| Pa·s | | | 106 − 84 |

Table 5.

Summary of fuel inlet boundary conditions for the baseline simulations.

Table 5.

Summary of fuel inlet boundary conditions for the baseline simulations.

| Parameter | Value or Setting | Remark |

|---|

| Evaporating species | | |

| Liquid species | paraffin | |

| Gas inlet type | mass source | in cells adjacent to grain wall |

| Liquid inlet type | droplets source | from grain wall |

| Total mass flow rate | | different for each simulation |

| Gas mass flow rate | | different for each simulation |

| Liquid mass flow rate | | different for each simulation |

| Droplets initial velocity | 0.28 m/s | |

| Droplets diameter distribution | uniform | |

| Droplets diameter | 100 µm | |

| Droplets orientation | normal to boundary | |

| Droplets temperature | 515 K | |

| Gas temperature | 700 K | |

| Grain wall temperature | 515 K | |

Table 6.

Summary of experimental results with 4 different showerhead (SH) injectors. The corresponding numerical results are listed as well.

Table 6.

Summary of experimental results with 4 different showerhead (SH) injectors. The corresponding numerical results are listed as well.

| Exp. ID | | | | | | | | | | |

|---|

| (s) | (g/s) | (g/s) | (mm/s) | (bar) | (bar) | (N) | (N) | (s) |

|---|

| SH1-01 | 8.28 | 386.4 | 148.6 | 6.21 | 2.6 | 17.9 | 17.84 | 879 | 868 | 167.5 |

| SH1-02 | 8.29 | 380.3 | 152.1 | 6.20 | 2.5 | 17.0 | 17.67 | 768 | 856 | 147.1 |

| SH1-03 | 8.16 | 391.3 | 144.9 | 6.30 | 2.7 | 17.8 | 17.97 | 879 | 876 | 167.2 |

| SH1-04 | 8.10 | 384.0 | 142.2 | 6.35 | 2.7 | 17.7 | 17.65 | 873 | 856 | 169.1 |

| SH1-05 | 7.24 | 386.9 | 161.2 | 6.72 | 2.4 | 17.2 | 18.08 | 835 | 881 | 155.3 |

| SH1-06 | 7.07 | 387.1 | 143.4 | 6.64 | 2.7 | 17.7 | 17.78 | 873 | 865 | 167.8 |

| SH1-07 | 6.84 | 393.8 | 145.9 | 6.90 | 2.7 | 17.7 | 18.09 | 862 | 883 | 162.9 |

| SH1-08 | 6.48 | 393.3 | 157.3 | 7.01 | 2.5 | 18.2 | 18.27 | 912 | 893 | 168.9 |

| SH1-09 | 6.36 | 387.7 | 149.1 | 6.96 | 2.6 | 17.3 | 17.90 | 872 | 871 | 165.6 |

| SH1-10 | 6.28 | 384.1 | 153.6 | 9.65 | 2.5 | 17.1 | 17.83 | 864 | 867 | 163.9 |

| SH2-01 | 5.29 | 529.2 | 147.0 | 7.18 | 3.6 | 24.1 | 23.46 | 1142 | 1211 | 172.2 |

| SH2-02 | 5.23 | 542.5 | 150.7 | 7.28 | 3.6 | 24.4 | 24.10 | 1100 | 1249 | 161.8 |

| SH2-03 | 5.27 | 528.9 | 155.6 | 7.41 | 3.4 | 23.1 | 23.55 | 1082 | 1217 | 161.2 |

| SH3-01 | 5.29 | 538.3 | 153.8 | 7.33 | 3.5 | 22.8 | 23.77 | 1100 | 1235 | 162.0 |

| SH3-02 | 5.23 | 543.2 | 150.9 | 7.22 | 3.6 | 23.8 | 24.03 | 1168 | 1248 | 171.5 |

| SH3-03 | 5.27 | 537.6 | 153.6 | 7.38 | 3.5 | 24.4 | 23.76 | 1183 | 1234 | 174.5 |

| SH4-04 | 5.08 | 550.0 | 157.1 | 7.70 | 3.5 | 24.1 | 24.24 | 1172 | 1265 | 169.0 |

| SH4-05 | 5.15 | 537.5 | 153.6 | 7.69 | 3.5 | 23.3 | 23.63 | 1131 | 1231 | 166.8 |

| SH4-06 | 5.11 | 544.5 | 155.6 | 7.61 | 3.5 | 24.3 | 23.98 | 1137 | 1251 | 165.6 |

Table 7.

Average deviation of numerical values from experimental measurements.

Table 7.

Average deviation of numerical values from experimental measurements.

| Group | Chamber Pressure | Thrust |

|---|

| (%) | (%) |

|---|

| SH1 | | |

| SH2 | | |

| SH3 | | |

| SH4 | | |

| All | | |

Table 8.

Summary of the product stoichiometric coefficients for the 19 simulations.

Table 8.

Summary of the product stoichiometric coefficients for the 19 simulations.

| Exp. ID | | Coefficients Obtained via ICT, Based on | Resulting

|

|---|

| (bar) | | | | | | | | | (bar) |

|---|

| SH1-01 | 17.9 | 5.8670 | 1.5420 | 1.1070 | 0.8930 | 0.4300 | 0.4345 | 0.2660 | 0.2430 | 17.84 |

| SH1-02 | 17.0 | 5.8670 | 1.5390 | 1.1100 | 0.8900 | 0.4320 | 0.4365 | 0.2660 | 0.2450 | 17.67 |

| SH1-03 | 17.8 | 5.8670 | 1.5410 | 1.1070 | 0.8930 | 0.4310 | 0.4345 | 0.2660 | 0.2435 | 17.97 |

| SH1-04 | 17.7 | 5.8670 | 1.5410 | 1.1080 | 0.8920 | 0.4310 | 0.4350 | 0.2660 | 0.2435 | 17.65 |

| SH1-05 | 17.2 | 5.8670 | 1.5400 | 1.1090 | 0.8910 | 0.4320 | 0.4355 | 0.2660 | 0.2440 | 18.08 |

| SH1-06 | 17.7 | 5.8670 | 1.5410 | 1.1080 | 0.8920 | 0.4310 | 0.4350 | 0.2660 | 0.2435 | 17.78 |

| SH1-07 | 17.7 | 5.8670 | 1.5410 | 1.1080 | 0.8920 | 0.4310 | 0.4350 | 0.2660 | 0.2435 | 18.09 |

| SH1-08 | 18.2 | 5.8665 | 1.5420 | 1.1060 | 0.8940 | 0.4300 | 0.4335 | 0.2670 | 0.2430 | 18.27 |

| SH1-09 | 17.3 | 5.8670 | 1.5400 | 1.1090 | 0.8910 | 0.4310 | 0.4360 | 0.2660 | 0.2445 | 17.90 |

| SH1-10 | 17.1 | 5.8670 | 1.5390 | 1.1100 | 0.8900 | 0.4320 | 0.4365 | 0.2660 | 0.2450 | 17.83 |

| SH2-01 | 24.1 | 5.8645 | 1.5550 | 1.0880 | 0.9120 | 0.4210 | 0.4205 | 0.2710 | 0.2345 | 23.46 |

| SH2-02 | 24.4 | 5.8645 | 1.5560 | 1.0870 | 0.9130 | 0.4200 | 0.4200 | 0.2710 | 0.2340 | 24.10 |

| SH2-03 | 23.1 | 5.8650 | 1.5530 | 1.0900 | 0.9100 | 0.4220 | 0.4225 | 0.2700 | 0.2360 | 23.55 |

| SH3-01 | 22.8 | 5.8650 | 1.5530 | 1.0910 | 0.9090 | 0.4230 | 0.4225 | 0.2700 | 0.2355 | 23.77 |

| SH3-02 | 23.8 | 5.8645 | 1.5550 | 1.0880 | 0.9120 | 0.4210 | 0.4205 | 0.2710 | 0.2345 | 24.03 |

| SH3-03 | 24.4 | 5.8645 | 1.5560 | 1.0870 | 0.9130 | 0.4200 | 0.4200 | 0.2710 | 0.2340 | 23.76 |

| SH4-04 | 24.1 | 5.8645 | 1.5550 | 1.0880 | 0.9120 | 0.4210 | 0.4205 | 0.2710 | 0.2345 | 24.24 |

| SH4-05 | 23.3 | 5.8650 | 1.5540 | 1.0900 | 0.9100 | 0.4220 | 0.4220 | 0.2700 | 0.2350 | 23.63 |

| SH4-06 | 24.3 | 5.8645 | 1.5550 | 1.0870 | 0.9130 | 0.4200 | 0.4205 | 0.2710 | 0.2350 | 23.98 |

Table 9.

Effect on when applying incorrect product coefficients.

Table 9.

Effect on when applying incorrect product coefficients.

| Exp. ID | | Coefficients for | | Deviation |

|---|

| (bar) | (bar) | (bar) | (%) |

|---|

| SH1-02 | 17.0 | 17.0 | 17.667 | 0.22 |

| 24.4 | 17.706 |

| SH3-03 | 24.4 | 24.4 | 24.090 | 0.19 |

| 17.0 | 24.043 |

Table 10.

Effect on when varying the oxidizer inlet vapor quality x.

Table 10.

Effect on when varying the oxidizer inlet vapor quality x.

| Exp. ID | Vapor Quality | Resulting | Deviation from |

|---|

| x (%) | (bar) | Baseline (%) |

|---|

| SH1-01 | 0 | | 17.522 | | −1.79 |

| 20 | (*) | 17.841 | | 0.00 |

| 30 | | 17.844 | (=max) | +0.02 |

| 50 | | 17.508 | | −1.88 |

| 100 | |

14.804 |

(=min) | −17.04 |

| SH2-01 | 0 | | 22.804 | | −2.80 |

| 20 | (*) | 23.462 | (=max) | 0.00 |

| 50 | | 22.181 | | −5.46 |

| 100 | | 19.177 | (=min) | −18.26 |

Table 11.

Effect on when varying the oxidizer inlet vapor quality x.

Table 11.

Effect on when varying the oxidizer inlet vapor quality x.

| Exp. ID | Vapor Quality | Resulting | Deviation from |

|---|

| x (%) | (N) | Baseline (%) |

|---|

| SH1-01 | 0 | | 857 | | −1.27 |

| 20 | (*) | 868 | | 0.00 |

| 30 | | 869 | (=max) | +0.12 |

| 50 | | 863 | | −0.58 |

| 100 | | 796 | (=min) | −8.29 |

| SH2-01 | 0 | | 1193 | | −1.49 |

| 20 | (*) | 1211 | (=max) | 0.00 |

| 50 | | 1187 | | −1.98 |

| 100 | | 1116 | (=min) | −7.84 |

Table 12.

Effect on when varying the oxidizer inlet droplets diameter .

Table 12.

Effect on when varying the oxidizer inlet droplets diameter .

| Exp. ID | Droplets Diameter | Resulting | Deviation from |

|---|

| (µm) | (bar) | Baseline (%) |

|---|

| SH1-01 | 0 | | 14.85 | (extrapolation) (=min) | −16.76 |

| 20 | | 15.74 | | −11.78 |

| 100 | (*) | 17.84 | | 0.00 |

| 400 | | 18.80 | (=max) | +5.38 |

| 500 | | 18.73 | | +4.99 |

| SH2-01 | 0 | | 19.25 | (extrapolation) (=min) | −17.95 |

| 20 | | 19.65 | | −16.24 |

| 100 | (*) | 23.46 | | 0.00 |

| 200 | | 24.33 | (=max) | +3.71 |

| 500 | | 24.07 | | +2.60 |

Table 13.

Effect on when varying the entrained fuel fraction . For compactness, only the cases leading to the highest absolute deviations are summarized. Cases SH1-03, SH1-04, SH2-02 and SH3-01 are not shown.

Table 13.

Effect on when varying the entrained fuel fraction . For compactness, only the cases leading to the highest absolute deviations are summarized. Cases SH1-03, SH1-04, SH2-02 and SH3-01 are not shown.

| Exp. ID | Entrained Fuel | Resulting | Deviation from |

|---|

| Fraction (%) | (bar) | Baseline (%) |

|---|

| SH1-01 | 0 | | 18.25 | (=max) | +2.30 |

| 33 | | 17.99 | | +0.78 |

| 50 | (*) | 17.84 | | 0.00 |

| 67 | | 17.71 | | −0.73 |

| 100 | | 17.13 | (=min) | −4.04 |

| SH1-02 | 0 | | 18.08 | (=max) | +2.32 |

| 33 | | 17.79 | | +0.72 |

| 50 | (*) | 17.67 | | 0.00 |

| 67 | | 17.53 | | −0.79 |

| 100 | | 17.02 | (=min) | −3.64 |

| SH2-01 | 0 | | 23.80 | (=max) | +1.43 |

| 33 | | 23.60 | | +0.60 |

| 50 | (*) | 23.46 | | 0.00 |

| 67 | | 23.35 | | −0.47 |

| 100 | | 22.74 | (=min) | −3.08 |

| SH2-03 | 0 | | 23.96 | (=max) | +1.73 |

| 33 | | 23.66 | | +0.44 |

| 50 | (*) | 23.55 | | 0.00 |

| 67 | | 23.39 | | −0.67 |

| 100 | | 22.90 | (=min) | −2.78 |

Table 14.

Effect on when varying the entrained fuel droplets diameter .

Table 14.

Effect on when varying the entrained fuel droplets diameter .

| Exp. ID | Fuel Droplets Diameter | Resulting | Deviation from Baseline | Resulting | Resulting |

|---|

| (µm) | (bar) | (%) | (%) | (%) |

|---|

| SH1-01 | 10 | | 18.00 | (=max) | +0.90 | 0.00 | 0.00 |

| 100 | (*) | 17.84 | | 0.00 | 0.00 | 0.00 |

| 200 | | 17.70 | | −0.78 | 0.81 | 2.90 |

| 500 | | 17.15 | | −3.87 | 6.85 | 24.65 |

| 1000 | | 16.76 | | −6.05 | 12.72 | 45.79 |

| 2000 | | 16.70 | (=min) | −6.39 | 13.89 | 50.00 |

| 5000 | | 16.78 | | −5.94 | 13.89 | 50.00 |

| SH1-02 | 0 | | 23.53 | (=max) | +0.30 | 0.00 | 0.00 |

| 100 | (*) | 23.46 | | 0.00 | 0.00 | 0.00 |

| 1000 | | 22.42 | | −4.43 | 9.76 | 44.91 |

| 2000 | | 22.24 | (=min) | −5.20 | 10.87 | 50.00 |

| 5000 | | 22.31 | | −4.90 | 10.87 | 50.00 |

Table 15.

Example of how different combinations of and are affecting compared to its baseline value of 17.84 bar, for case SH1-01.

Table 15.

Example of how different combinations of and are affecting compared to its baseline value of 17.84 bar, for case SH1-01.

| Exp. ID | Fuel Droplets | Entrained Fuel | Resulting | Deviation from |

|---|

| Diameter | Fraction | | Baseline |

|---|

| (µm) | (%) | (bar) | (%) |

|---|

| SH1-01 | 100 | (*) | 50 | (*) | 17.84 | (=max) | 0.00 |

| 100 | (*) | 66 | | 17.71 | | −0.73 |

| 1000 | | 50 | (*) | 16.76 | | −6.05 |

| 1000 | | 66 | | 16.23 | (=min) | −9.02 |

Table 16.

Influence of the initial velocity magnitude of the injected fuel droplets on , for case SH1-01. The study was undertaken for µm and µm.

Table 16.

Influence of the initial velocity magnitude of the injected fuel droplets on , for case SH1-01. The study was undertaken for µm and µm.

| Exp. ID | Fuel Droplets | Fuel Droplets | Resulting | Deviation from |

|---|

| Diameter | Initial | | Baseline |

|---|

| (µm) | (m/s) | (bar) | (%) |

|---|

| SH1-01 | 100 | (*) | 0.10 | | 17.82 | (=min) | −0.11 |

| 100 | (*) | 0.28 | (*) | 17.84 | (=baseline) | 0.00 |

| 100 | (*) | 2.00 | | 17.90 | (=max) | +0.34 |

| SH1-01 | 500 | | 0.28 | (*) | 17.15 | | −3.87 |

| 500 | | 1.00 | | 17.23 | (=max) | −3.42 |

| 500 | | 2.00 | | 17.08 | (=min) | −4.26 |

Table 17.

Overview of investigated parameters and how they affect the predicted motor’s operating conditions with respect to the baseline CFD model.

Table 17.

Overview of investigated parameters and how they affect the predicted motor’s operating conditions with respect to the baseline CFD model.

| Sections | Investigated

Parameter | Studied

Range | Baseline

Value | Observed

Maximum

Impact |

|---|

| Section 3.1.1 | Chemical reaction | Coefficients for | | on |

| | equilibrium equation | 17 bar and 24.4 bar | (variable) | |

| Section 3.1.2 | Chemistry in | Frozen/Shifting | Shifting | on (frozen) |

| | nozzle | | | on (frozen) |

| Section 3.2.1 | Oxidizer inlet | 0–100% | | on @ |

| | vapor quality x | | | on @ |

| Section 3.2.2 | Oxidizer spray | 20–500 µm | 100 µm | on |

| | droplets diameter | | | @ µm |

| Section 3.3.1 | Entrained fuel | 0–100% | | on |

| | mass fraction | | | @ |

| Section 3.3.2 | Entrained fuel | 10–5000 µm | 100 µm | on |

| | droplets size | | | @ µm |

| Section 3.3.3 | Entrained fuel droplets | 0.10–2.00 m/s | 0.28 m/s | on |

| | initial velocity | | | @ m/s |

| Section 3.3.3 | Entrained fuel droplets | 10, 45, and 90 | 90 | Negligible (when |

| | initial angle | (downstream angle | (normal to | and are set |

| | | to grain surface) | grain surface) | to baseline values) |